In today’s fast-paced global market, sourcing the best electric air pump can be a daunting challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With a myriad of options available, businesses must navigate varying quality standards, pricing structures, and technological advancements to find a solution that meets their specific needs. This comprehensive guide aims to simplify that process by providing an in-depth analysis of different types of electric air pumps, their applications across various industries, and key factors to consider when making a purchase.

Our guide will cover essential topics, including supplier vetting processes, cost considerations, and the latest innovations in electric air pump technology. By equipping international buyers with actionable insights and best practices, we empower them to make informed purchasing decisions that can enhance operational efficiency and improve product offerings. Whether you are in the automotive sector, outdoor recreation, or manufacturing, this resource will help you identify the most suitable electric air pump for your business needs.

As you delve into this guide, you will uncover valuable information that not only streamlines your sourcing process but also ensures you are investing in high-quality products that deliver long-term performance and reliability.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Portable Electric Pumps | Compact, lightweight, battery-operated, often with digital gauges | Bicycle shops, outdoor sports retailers | Pro: Easy to transport, quick inflation. Contro: Limited capacity for larger tires. |

| High-Volume Inflators | Designed for larger inflatables, higher PSI capabilities, often bulkier | Water sports, event organizers, rental companies | Pro: Fast inflation for large items. Contro: Less portable, higher cost. |

| Multi-Purpose Pumps | Versatile, suitable for various applications (bikes, cars, sports equipment) | Automotive service centers, outdoor gear shops | Pro: One tool for multiple uses. Contro: May lack specialized features for specific applications. |

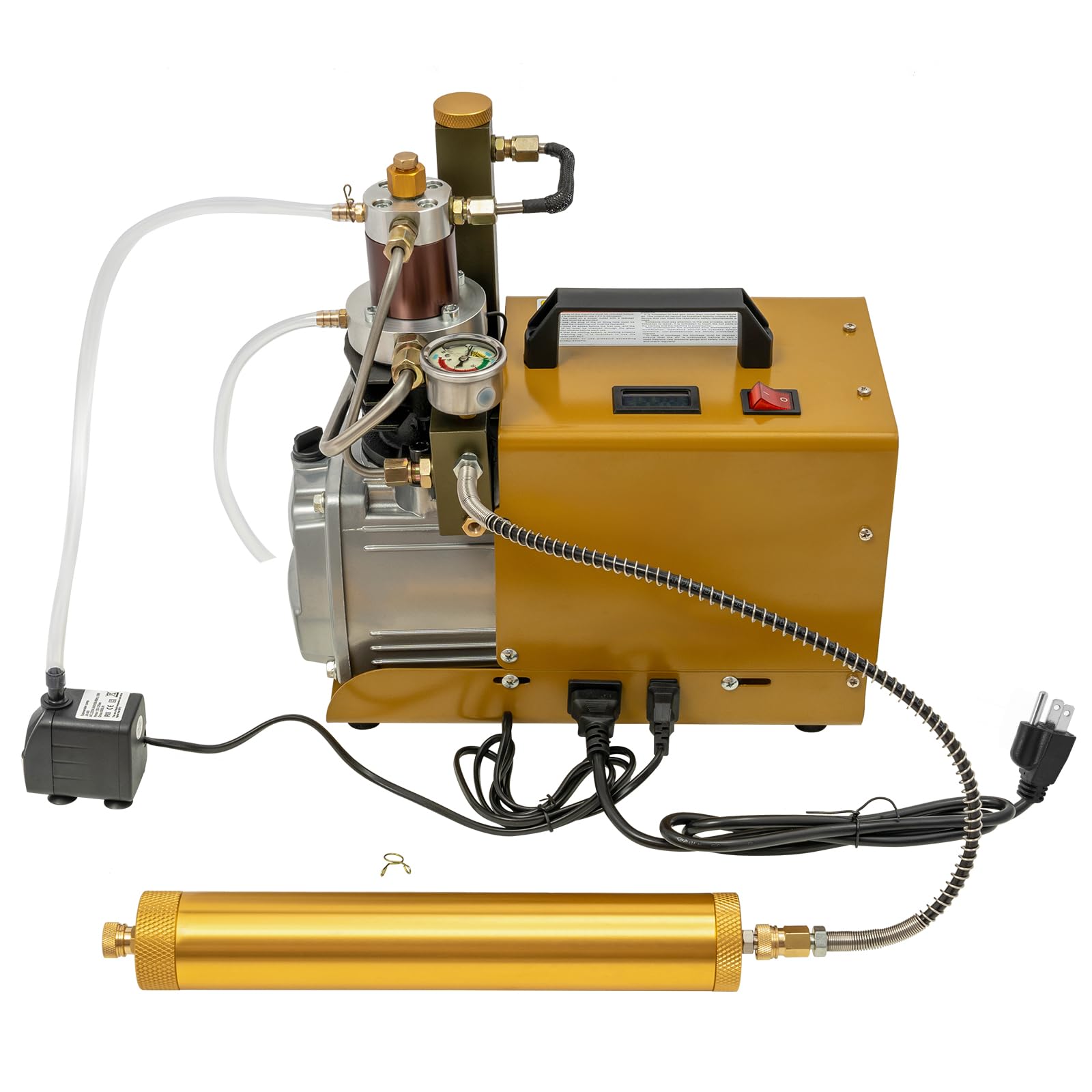

| Heavy-Duty Compressors | Industrial-grade, high power, suitable for continuous use | Construction, manufacturing, automotive industries | Pro: High durability, powerful performance. Contro: Expensive, requires more space. |

| Smart Electric Pumps | Integrated technology, app connectivity, programmable settings | Tech-focused retailers, bicycle manufacturers | Pro: Advanced features, user-friendly. Contro: Higher price point, potential tech issues. |

Portable electric pumps are compact and lightweight, making them ideal for businesses in the bicycle and outdoor sports sectors. They typically feature battery operation and digital gauges for precise inflation. Their primary application lies in retail environments where quick and efficient tire inflation is required. When considering procurement, businesses should assess battery life, inflation speed, and ease of use, as these factors will directly impact customer satisfaction and operational efficiency.

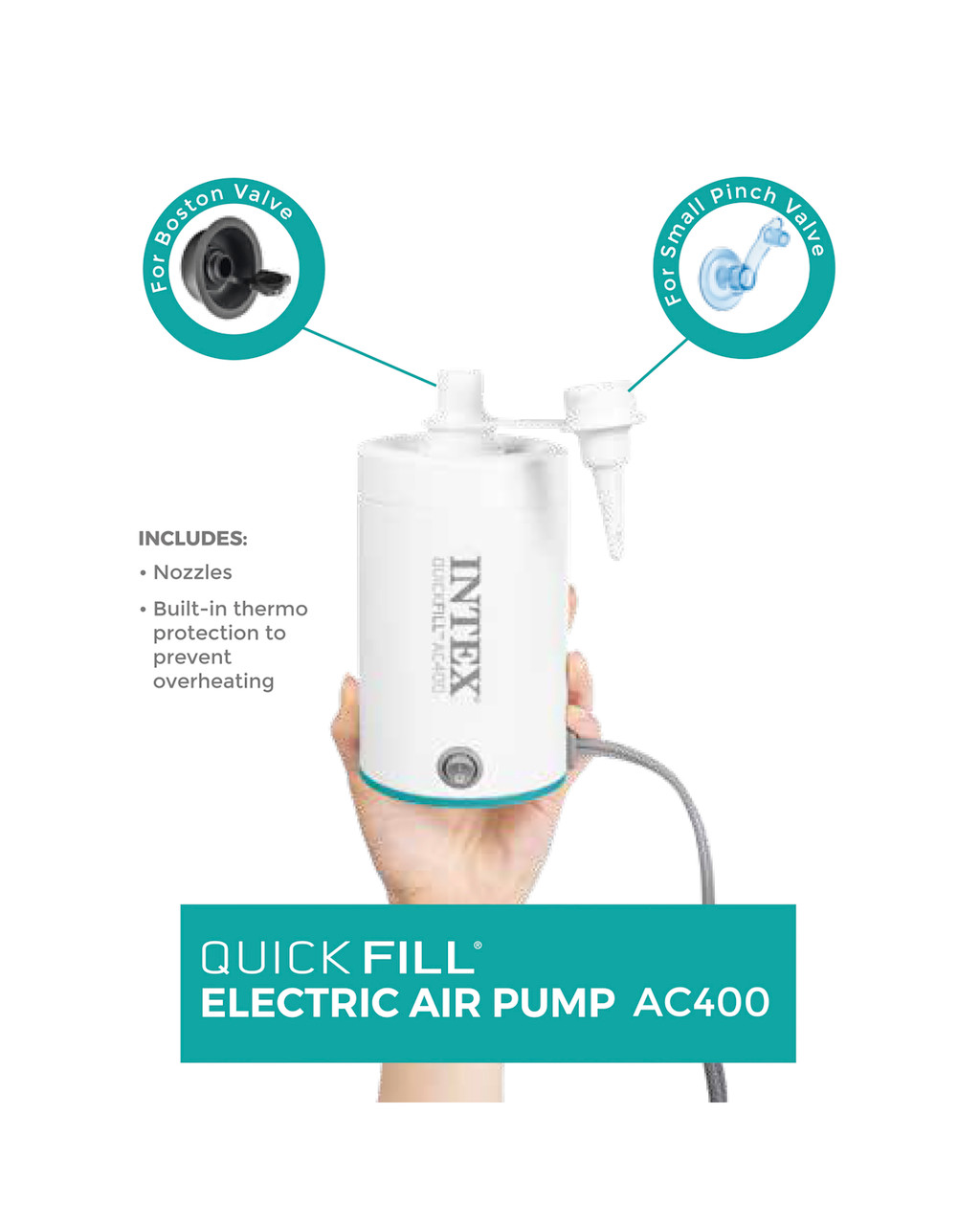

High-volume inflators are designed for larger inflatables, such as boats and event equipment. They can achieve higher PSI levels and inflate larger items quickly, making them suitable for rental companies and event organizers. While they provide fast inflation, buyers should weigh their bulkiness and higher costs against the need for high-capacity inflation in their operations. Considerations for purchase include the inflator’s power, ease of transport, and compatibility with various valve types.

Multi-purpose pumps offer versatility, catering to a range of applications from automotive to sports equipment. Businesses in automotive service centers or outdoor gear shops can benefit from having a single tool that meets multiple needs. While these pumps provide convenience, buyers should evaluate their performance in specific tasks, as they may not match the efficiency of specialized equipment. Key purchasing considerations include the pump’s adaptability, ease of use, and overall build quality.

Illustrative image related to best electric air pump

Heavy-duty compressors are tailored for industrial environments, providing high power and durability for continuous use in construction and manufacturing. Their robust design allows them to handle demanding tasks, making them essential for businesses that require reliable performance. However, the higher cost and space requirements can be drawbacks. Buyers should assess their operational needs, including power requirements and maintenance capabilities, to ensure they select the right compressor for their application.

Smart electric pumps integrate advanced technology, allowing for app connectivity and programmable settings that enhance user experience. These pumps are particularly appealing to tech-focused retailers and bicycle manufacturers looking to offer innovative products. While they come with a higher price tag, their advanced features, such as real-time pressure monitoring and automated inflation, can justify the investment. Businesses should consider their target market and the value of tech integration when evaluating these products.

| Industria/Settore | Specific Application of best electric air pump | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Riparazione di autoveicoli | Tire inflation for vehicles | Quick and efficient tire servicing improves customer satisfaction and reduces downtime. | Reliability, PSI range, compatibility with various valve types. |

| Sports Equipment Retail | Inflating sports balls and inflatable gear | Enhances customer experience by providing fast service and ensuring proper inflation for optimal performance. | Portability, ease of use, battery life, and pressure accuracy. |

| Produzione | Inflation for pneumatic tools and machinery | Increases productivity by ensuring tools are always ready for use without manual effort. | Durability, power source, maintenance requirements, and volume capacity. |

| Ricreazione all'aperto | Inflating camping gear and recreational inflatables | Offers convenience for customers, facilitating outdoor activities and enhancing their experience. | Compact size, inflation speed, and compatibility with various inflatables. |

| Logistics and Transport | Inflating tires for delivery vehicles | Ensures timely deliveries by maintaining proper tire pressure, improving fuel efficiency and safety. | Robustness, ease of transport, and ability to handle high volume usage. |

In the automotive repair sector, electric air pumps are indispensable for tire inflation. They enable mechanics to quickly inflate tires, enhancing service efficiency and reducing customer wait times. The ability to accurately adjust tire pressure is crucial for vehicle safety and performance. Buyers in this industry should prioritize pumps that offer reliability, a wide PSI range, and compatibility with various valve types to accommodate different vehicles.

Sports equipment retailers utilize electric air pumps for inflating balls and various inflatable gear. By providing this service, retailers enhance customer satisfaction, ensuring that products are ready for immediate use. The convenience of quick inflation helps in maintaining customer loyalty. When sourcing, retailers should consider factors such as portability, ease of use, battery life, and precision in pressure measurement to meet diverse customer needs.

In manufacturing, electric air pumps serve to inflate pneumatic tools and machinery. This application is vital for maintaining operational efficiency, as it eliminates the manual labor associated with traditional inflation methods. Businesses benefit from increased productivity and reduced downtime. Buyers should focus on the durability of pumps, their power source, maintenance requirements, and the volume capacity to ensure they can support continuous use in a demanding environment.

Electric air pumps are essential for outdoor recreation, providing quick inflation for camping gear, inflatable boats, and other recreational inflatables. This convenience allows users to spend more time enjoying their activities rather than preparing equipment. When sourcing these pumps, businesses should look for compact designs that offer fast inflation speeds and compatibility with various inflatables, ensuring a hassle-free experience for customers.

In logistics and transport, electric air pumps are crucial for maintaining proper tire pressure on delivery vehicles. Properly inflated tires improve fuel efficiency and ensure safer driving conditions, which is critical for timely deliveries. Buyers in this sector should seek robust pumps that are easy to transport and capable of handling high-volume usage to meet the demands of their operations effectively.

Il problema: B2B buyers often encounter electric air pumps that struggle to maintain consistent performance when inflating various types of tires, such as those found on bicycles, cars, or inflatable products. This inconsistency can lead to frustration, as users may find that some pumps fail to achieve the desired pressure levels, especially for high-performance or specialized tires. Additionally, the lack of clarity regarding compatibility with different valve types can complicate procurement decisions for businesses needing reliable equipment for diverse applications.

Illustrative image related to best electric air pump

La soluzione: To ensure optimal performance across different tire types, buyers should look for electric air pumps that feature adjustable pressure settings and come with multiple nozzle attachments for compatibility with various valves (e.g., Presta, Schrader, and Dunlop). When sourcing pumps, consider conducting thorough research on brands known for versatility and reliability. Reading detailed specifications and user reviews can reveal how well a pump performs under different conditions. Furthermore, consider investing in models with digital pressure gauges that allow for precise inflation, which can help mitigate the risk of over-inflation or under-inflation. Testing the pump with each tire type before committing to bulk purchases can also provide valuable insights into its performance.

Il problema: Many B2B buyers experience difficulties with the battery life of electric air pumps, particularly in settings where frequent and rapid inflation is required. Pumps that run out of power quickly can disrupt operations, leading to delays and inefficiencies, especially for businesses in sectors like logistics or outdoor recreation where timely service is critical. Additionally, slow charging times can exacerbate these challenges, leaving teams unable to rely on the equipment when needed most.

La soluzione: When evaluating electric air pumps, buyers should prioritize models with long-lasting batteries and fast-charging capabilities. Look for products that provide a clear indication of battery life and offer the option to charge via various methods (e.g., USB, car charger, or standard outlet). In practical terms, consider establishing a charging schedule to ensure that all equipment is fully powered before peak operational times. For businesses that require multiple pumps, investing in a few high-capacity pumps may be more efficient than relying on several lower-capacity models. Additionally, incorporating spare batteries or portable charging stations can help maintain productivity, allowing teams to quickly swap out or recharge pumps as needed.

Illustrative image related to best electric air pump

Il problema: Portability and ease of use are critical factors for B2B buyers who need electric air pumps for mobile applications, such as roadside assistance or outdoor events. Many pumps on the market can be bulky or cumbersome, making transportation challenging. Furthermore, complicated operation processes can hinder effective use, especially for staff who may not be technically inclined. This can lead to inefficiencies and wasted time during critical moments.

La soluzione: To address portability and usability, buyers should seek compact electric air pumps designed with user-friendly interfaces. Key features to look for include lightweight construction, ergonomic design, and intuitive controls. When selecting a pump, consider conducting hands-on demonstrations or requesting samples to assess ease of operation. Additionally, providing training sessions for staff on how to efficiently use the equipment can significantly enhance performance and user confidence. Opting for pumps with built-in storage for hoses and attachments can also streamline the process, ensuring that everything needed is readily accessible and organized.

Electric air pumps are increasingly popular for their efficiency and ease of use. Selecting the right materials for their construction is crucial for performance, durability, and cost-effectiveness. Below, we analyze four common materials used in electric air pumps, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is frequently used in the housing of electric air pumps. These materials offer excellent resistance to impact and corrosion, making them suitable for various environments. The temperature and pressure ratings are generally adequate for most applications, typically handling pressures up to 100 psi without deformation.

Pro: Plastic is lightweight and cost-effective, which helps reduce overall manufacturing costs. It is also easier to mold into complex shapes, allowing for innovative designs.

Contro: While durable, plastic can become brittle over time, especially under extreme temperature fluctuations. It may not be suitable for high-pressure applications beyond its rating.

Impatto sull'applicazione: Plastic is compatible with air and can be used in various environments, but it may not be ideal for applications involving high temperatures or aggressive chemicals.

Illustrative image related to best electric air pump

Considerazioni per gli acquirenti internazionali: Compliance with standards such as ASTM D638 (tensile properties) and ASTM D256 (impact resistance) is essential. Buyers from regions like Africa and South America should also consider the availability of replacement parts and serviceability.

Aluminum is another popular material used in electric air pumps, particularly for components like the pump body and internal mechanisms. Known for its strength-to-weight ratio, aluminum can handle higher pressures, often exceeding 150 psi.

Pro: Aluminum is highly durable and resistant to corrosion, making it suitable for long-term use. It also dissipates heat effectively, which can enhance performance during prolonged operation.

Illustrative image related to best electric air pump

Contro: The cost of aluminum is generally higher than plastic, which could impact the overall pricing of the product. Additionally, aluminum components may require more complex manufacturing processes.

Impatto sull'applicazione: Aluminum is compatible with air and can withstand various environmental conditions, making it suitable for both indoor and outdoor applications.

Considerazioni per gli acquirenti internazionali: Buyers should ensure compliance with international standards like ISO 9001 for quality management systems. In regions like Europe and the Middle East, the demand for high-quality aluminum products is increasing, making it a preferred choice.

Steel, particularly stainless steel, is sometimes used in electric air pumps for critical components like valves and fittings. Its high tensile strength allows it to handle extreme pressures, often exceeding 200 psi.

Pro: Steel is incredibly durable and offers excellent resistance to wear and tear. Stainless steel, in particular, is resistant to corrosion, making it suitable for various applications.

Contro: The weight of steel can be a disadvantage, especially in portable electric air pumps. Additionally, the cost of high-quality steel can be prohibitive, affecting the overall product pricing.

Impatto sull'applicazione: Steel is compatible with air and can be used in high-pressure applications, making it ideal for industrial settings.

Considerazioni per gli acquirenti internazionali: Compliance with standards such as ASTM A240 for stainless steel is crucial. Buyers in regions like Nigeria and Vietnam may also need to consider local sourcing options to reduce costs.

Rubber is primarily used for seals and gaskets in electric air pumps. Its excellent elasticity and ability to create airtight seals make it essential for maintaining pressure.

Pro: Rubber is cost-effective and provides excellent sealing capabilities, which are critical for performance. It is also resistant to wear and can handle a range of temperatures.

Illustrative image related to best electric air pump

Contro: Rubber can degrade over time, especially when exposed to UV light or extreme temperatures. This can lead to leaks and reduced performance.

Impatto sull'applicazione: Rubber is suitable for air applications but may not be ideal for environments with extreme temperatures or chemicals.

Considerazioni per gli acquirenti internazionali: Compliance with standards like ASTM D2000 for rubber materials is important. Buyers should consider the availability of replacement seals and gaskets in their regions.

| Materiale | Typical Use Case for best electric air pump | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Plastica | Housing and body components | Leggero e conveniente | Può diventare fragile nel tempo | Basso |

| Alluminio | Pump body and internal mechanisms | Durevole e resistente alla corrosione | Costi più elevati e produzione complessa | Med |

| Acciaio | Valves and fittings | High tensile strength and durability | Più pesante e più costoso | Alto |

| Gomma | Guarnizioni | Excellent sealing capabilities | Degrades over time under UV exposure | Basso |

This analysis provides B2B buyers with actionable insights into material selection for electric air pumps, facilitating informed purchasing decisions tailored to specific regional needs and compliance standards.

Illustrative image related to best electric air pump

Manufacturing electric air pumps involves several critical stages that ensure the final product is efficient, durable, and meets quality standards. The main stages include material preparation, forming, assembly, and finishing.

The first stage of manufacturing electric air pumps begins with material preparation. High-quality materials such as plastics, metals, and electronic components are sourced from reliable suppliers. The selection of materials is crucial, as they need to withstand high pressures and frequent use. For instance, the plastic housing should be both lightweight and durable to provide a robust exterior, while internal components like motors and valves must be made from corrosion-resistant materials.

Once the materials are procured, they undergo inspection to ensure they meet the specified standards. This includes checking for defects, dimensions, and compliance with international standards, such as ISO specifications.

After material preparation, the next stage is forming. This typically involves processes like injection molding for plastic components and metal stamping or machining for parts such as the pump body and valves.

Injection molding is particularly popular for creating complex shapes and designs in the pump casing. This method allows for precision and consistency, which are essential for the performance of the air pump. For metal components, CNC machining may be employed to achieve tight tolerances, ensuring that parts fit together seamlessly.

Once the individual components are formed, assembly begins. This stage involves integrating the mechanical and electronic parts, such as the motor, battery, and control circuitry. Assembly techniques may vary, but common practices include automated assembly lines and manual labor, depending on the complexity of the product and the volume of production.

Quality control measures are critical during assembly. Each unit may undergo initial inspections to ensure that all components are correctly installed and that there are no visible defects. This step is crucial, as any flaws in assembly can lead to performance issues later on.

The final manufacturing stage is finishing, which enhances both the aesthetics and functionality of the electric air pumps. This can include processes such as surface treatment, painting, and packaging.

Illustrative image related to best electric air pump

Surface treatments like anodizing for aluminum components or applying protective coatings can improve durability and resistance to environmental factors. Finally, each pump is carefully packaged to prevent damage during shipping, ensuring that it reaches the B2B buyer in perfect condition.

Quality assurance (QA) is integral to the manufacturing of electric air pumps, ensuring that products meet safety and performance standards. Key international standards include ISO 9001, which focuses on effective quality management systems, and CE marking, which indicates compliance with European health, safety, and environmental protection standards.

Il controllo di qualità prevede diversi punti di controllo durante il processo di produzione:

Controllo qualità in entrata (CQI): At this stage, raw materials are inspected upon arrival to ensure they meet specified standards.

Controllo qualità in corso d'opera (IPQC): This ongoing assessment occurs during various manufacturing stages, allowing for real-time adjustments and corrections.

Controllo qualità finale (CQC): Before packaging, each finished electric air pump undergoes a comprehensive inspection. This includes functional testing to ensure performance metrics, such as inflation speed and pressure accuracy, are met.

Testing methods for electric air pumps include:

B2B buyers should adopt several strategies to ensure that their suppliers maintain rigorous quality control:

Illustrative image related to best electric air pump

Audit dei fornitori: Conducting on-site audits of manufacturing facilities can provide insights into the production process, including QA practices.

Quality Assurance Reports: Requesting detailed QA reports that outline compliance with international standards and internal QA processes can help buyers assess supplier reliability.

Ispezioni di terzi: Engaging third-party inspection services can offer an unbiased evaluation of product quality before shipment. This is particularly important for buyers in regions like Africa and South America, where local standards may differ from international benchmarks.

When sourcing electric air pumps internationally, especially from regions such as Asia or Europe, buyers should be aware of specific nuances:

Cultural Differences in Quality Standards: Different regions may have varying approaches to quality assurance. Understanding these cultural nuances can help in establishing effective communication and expectations with suppliers.

Compliance with Local Regulations: Buyers must ensure that products meet the regulatory standards of their specific markets, which may require additional certifications beyond international standards.

Supply Chain Integrity: Given the complexity of global supply chains, buyers should consider the reliability of their suppliers in maintaining consistent quality through all stages of production and delivery.

By understanding the manufacturing processes and quality assurance practices of electric air pumps, B2B buyers can make informed decisions, ensuring they partner with suppliers who prioritize quality and reliability.

To assist B2B buyers in sourcing the best electric air pump, this guide provides a systematic approach that highlights essential steps to ensure a successful procurement process. Given the diversity of markets across Africa, South America, the Middle East, and Europe, this checklist is tailored to address the unique needs of international buyers.

Before initiating the sourcing process, it’s essential to clarify your technical requirements. Determine the intended use of the electric air pump, such as inflating bike tires, sports equipment, or automotive needs. Consider specifications like pressure capacity, power source (battery or AC), and portability, as these factors will influence performance and usability in different environments.

Stay informed about the latest trends and innovations in electric air pumps. Understanding current market offerings can help you identify products that meet modern efficiency and sustainability standards. Look for advancements such as built-in digital gauges, faster inflation times, and eco-friendly materials, which can enhance the value of your procurement.

Illustrative image related to best electric air pump

Thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, product catalogs, and case studies from other clients in similar industries or regions. Assess their manufacturing capabilities, quality control processes, and customer service reputation, as these factors are crucial for long-term partnerships.

Obtain quotes from multiple suppliers and compare pricing structures. While the initial cost is important, consider the total cost of ownership, which includes maintenance, warranty, and operational costs. A higher upfront investment in a more durable product may yield better long-term savings.

After-sales support is critical in ensuring that your procurement remains hassle-free. Inquire about warranty terms, repair services, and replacement parts availability. A responsive support system can significantly minimize downtime and enhance operational efficiency.

Given the international nature of your procurement, familiarize yourself with import regulations specific to your country. Understand duties, taxes, and compliance requirements related to electric appliances. Additionally, plan logistics for shipping and delivery to ensure timely receipt of your products.

Illustrative image related to best electric air pump

Before finalizing a bulk order, consider conducting a pilot test with a smaller quantity of electric air pumps. This allows you to evaluate performance in real-world conditions and gather feedback from users. Use this information to make any necessary adjustments before scaling up your order.

By following this checklist, B2B buyers can navigate the complexities of sourcing electric air pumps effectively, ensuring that they select products that meet their operational needs while fostering strong supplier relationships.

To effectively analyze the cost structure and pricing for sourcing the best electric air pumps, it’s essential to break down the various components that contribute to the overall cost and understand the factors influencing pricing in the international B2B marketplace.

I materiali: The primary materials for electric air pumps include durable plastics, metals for the internal components, and electronic parts such as batteries and microcontrollers. The choice of materials significantly impacts the pump’s durability and performance, affecting overall production costs.

Lavoro: Labor costs vary widely depending on the country of manufacturing. Regions with lower labor costs, such as parts of Southeast Asia, can offer significant savings. However, higher labor costs might correlate with better craftsmanship and quality assurance.

Spese generali di produzione: This includes expenses related to factory operations, utilities, and maintenance. Efficient production processes can reduce overhead costs, allowing for more competitive pricing.

Utensili: Initial setup costs for molds and production tools can be substantial, especially for custom designs. These costs are often amortized over large production runs, making them less impactful on per-unit pricing for higher volumes.

Controllo qualità (CQ): Implementing stringent QC measures ensures that each pump meets safety and performance standards. This can add to costs, but it is essential for maintaining brand reputation and customer satisfaction.

Logistica: Shipping costs can vary based on the destination and chosen Incoterms. For international buyers, understanding these logistics costs is crucial for accurate total pricing.

Margine: Manufacturers typically build in a profit margin, which can range from 10% to 30% depending on the market competition and brand positioning.

Volume e quantità minima d'ordine (MOQ): Pricing models often favor bulk orders. Larger volumes can reduce per-unit costs due to economies of scale. Negotiating MOQs can lead to significant savings.

Specifiche e personalizzazione: Custom features, such as unique designs or additional functionalities, can increase costs. Standard models are typically more affordable than customized versions.

Qualità dei materiali e certificazioni: Higher-quality materials and certifications (e.g., ISO, CE) can drive up costs but are essential for compliance with safety regulations, especially in markets like Europe.

Fattori di fornitura: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their products due to proven quality and service.

Incoterms: Understanding the terms of shipping and delivery is vital. Terms such as FOB (Free On Board) or CIF (Cost Insurance and Freight) can impact total landed costs and affect negotiations.

Negotiation Strategies: Leverage volume orders and long-term partnerships to negotiate better pricing. Suppliers may be willing to offer discounts for larger commitments or repeated orders.

Cost-Efficiency Considerations: Evaluate the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and operational efficiency over the product’s life. Sometimes a higher upfront cost can lead to lower long-term expenses.

Pricing Nuances for Different Markets: Buyers from regions like Africa, South America, and the Middle East should consider local market conditions, tariffs, and import duties that could affect the overall cost. Understanding regional preferences can also aid in negotiations.

Disclaimer for Indicative Prices: Always remember that prices can fluctuate based on market conditions, currency exchange rates, and supplier pricing strategies. It’s advisable to request updated quotes to ensure accurate budgeting.

By understanding these cost components and pricing influencers, B2B buyers can make informed decisions when sourcing electric air pumps, ultimately leading to more effective procurement strategies and enhanced profitability.

Illustrative image related to best electric air pump

In today’s market, businesses are constantly seeking efficient solutions for tire inflation, whether for bicycles, vehicles, or other applications. While the best electric air pump offers numerous advantages, it’s essential to consider alternative methods that might better suit specific needs, particularly for international buyers in diverse regions like Africa, South America, the Middle East, and Europe. This analysis will compare electric air pumps against traditional manual pumps and CO2 inflators, providing insights to help B2B buyers make informed decisions.

| Aspetto di confronto | Best Electric Air Pump | Manual Hand Pump | Gonfiatore di CO2 |

|---|---|---|---|

| Prestazioni | High PSI, quick inflation | Moderate PSI, slower inflation | High PSI, quick inflation |

| Costo | $50 – $75 | $20 – $60 | $30+ (cartridges additional) |

| Facilità di implementazione | User-friendly, portable | Requires physical effort | Easy to use, requires cartridges |

| Manutenzione | Low (battery care) | Moderate (mechanical wear) | Low (disposable cartridges) |

| Il miglior caso d'uso | Frequent use, long rides | Occasional inflation needs | Emergency repairs, light use |

Manual hand pumps are a traditional and widely used alternative for tire inflation. They are generally less expensive than electric pumps and do not require batteries or electricity, making them suitable for remote areas. However, they require physical effort, which can be a disadvantage during prolonged use or for users with limited strength. Additionally, the inflation speed is slower, and achieving precise pressure levels can be challenging without a gauge. These pumps are best suited for occasional use or for users who prefer a low-tech solution.

CO2 inflators provide a quick and efficient way to inflate tires, especially in emergency situations. They are lightweight and portable, making them ideal for cyclists on the go. However, the recurring cost of cartridges can add up, and they can be ineffective if multiple inflations are needed. Additionally, users must be cautious when handling the cold cartridges, which can be uncomfortable. CO2 inflators are best for riders who prioritize speed and portability but may not be ideal for regular or high-volume use.

When selecting an inflation solution, B2B buyers should consider their specific requirements, including frequency of use, budget constraints, and the operational environment. The best electric air pump offers quick, high-pressure inflation with minimal maintenance, making it suitable for frequent users or businesses with higher demands. On the other hand, manual hand pumps are cost-effective for occasional use, while CO2 inflators excel in emergency scenarios. By weighing these factors, businesses can make informed decisions that align with their operational needs and budgetary constraints, ensuring they choose the most effective tire inflation method for their applications.

Illustrative image related to best electric air pump

When selecting the best electric air pump for B2B applications, understanding the technical specifications is crucial. Here are some critical properties that should be evaluated:

The pressure rating indicates the maximum air pressure the pump can generate, typically measured in pounds per square inch (PSI) or bar. This specification is vital for ensuring compatibility with various applications, such as inflating tires, sports equipment, or inflatables. Pumps with higher PSI ratings are essential for heavy-duty tasks, while lower ratings may suffice for lighter applications.

Flow rate measures the volume of air the pump can deliver, usually expressed in liters per minute (L/min). A higher flow rate means faster inflation times, which is crucial for businesses that prioritize efficiency. This property is particularly important for high-volume operations, where quick turnaround times are necessary to meet customer demands.

Battery capacity, measured in milliamp hours (mAh), reflects how long the pump can operate on a single charge. For businesses, a higher battery capacity translates to longer usage without the need for frequent recharges, making it ideal for extensive applications or remote locations.

Illustrative image related to best electric air pump

The materials used in the pump’s construction significantly impact durability and performance. Common materials include high-grade plastics, aluminum, and rubber. Selecting pumps made from robust materials ensures longevity and reduces the risk of breakdowns, which can be costly for businesses.

The dimensions and weight of the electric air pump are essential for ease of storage and transportation. Compact and lightweight models are preferable, especially for businesses that require mobility, such as those in automotive services or outdoor equipment rentals.

The operational noise level of the pump, measured in decibels (dB), can affect the working environment, particularly in retail or residential areas. Lower noise levels are desirable in settings where customer comfort and experience are priorities.

Familiarity with industry-specific jargon is essential for navigating B2B transactions effectively. Here are some commonly used terms:

Illustrative image related to best electric air pump

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for sourcing high-quality pumps that meet specific operational standards.

MOQ indicates the minimum number of units a supplier requires for an order. This term is crucial for budgeting and inventory management, especially for businesses looking to maintain optimal stock levels without overcommitting financially.

An RFQ is a document that a buyer sends to potential suppliers to request pricing and terms for specific products. This process is essential for comparing offers and negotiating favorable terms for electric air pumps.

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms helps businesses manage logistics and avoid misunderstandings in cross-border transactions.

Lead time refers to the duration from placing an order to receiving the product. Knowing the lead time is essential for planning inventory and ensuring timely delivery to customers.

A warranty is a guarantee provided by the manufacturer regarding the condition and lifespan of the pump. Understanding warranty terms is critical for assessing product reliability and for making informed purchasing decisions.

By grasping these essential technical properties and trade terminology, B2B buyers can make more informed decisions, ensuring they select the right electric air pump for their specific needs.

The electric air pump sector is witnessing robust growth driven by the increasing demand for convenient and efficient tire inflation solutions across various industries, including automotive, cycling, and outdoor activities. As global consumer preferences shift towards portable and user-friendly products, electric air pumps have emerged as a preferred choice over traditional pumps. Key trends include technological advancements, such as the integration of smart features like digital pressure gauges and automatic shut-off systems, enhancing user experience and safety.

Additionally, the growing focus on e-mobility, particularly in regions like Europe and Asia, is propelling the demand for electric bike pumps. This trend is supported by government initiatives promoting sustainable transportation options. In emerging markets like Africa and South America, rising disposable incomes and increased participation in recreational cycling are further stimulating the market. International B2B buyers should also be aware of the competitive landscape, with numerous brands entering the market, often leveraging shared manufacturing capabilities. This trend may lead to price fluctuations and varying product quality, necessitating careful supplier evaluation.

Sustainability has become a pivotal factor in the sourcing of electric air pumps, reflecting broader environmental concerns and the demand for ethical supply chains. Buyers are increasingly prioritizing products that minimize environmental impact, such as those manufactured using recyclable materials or featuring energy-efficient technologies. Certifications like ISO 14001 for environmental management systems and eco-labels can serve as indicators of a supplier’s commitment to sustainability.

Illustrative image related to best electric air pump

Moreover, ethical sourcing practices are gaining traction, with businesses seeking partners who uphold fair labor practices and transparency throughout the supply chain. This demand not only reflects corporate responsibility but also resonates with consumers who are more inclined to support brands that demonstrate environmental stewardship. For international buyers, particularly those operating in regions like the Middle East and Africa, understanding and vetting suppliers for their sustainability credentials will be critical in maintaining brand reputation and meeting regulatory requirements.

The evolution of electric air pumps has been marked by significant technological advancements and shifts in consumer behavior. Initially, traditional hand pumps dominated the market due to their simplicity and lower cost. However, as consumer preferences evolved towards convenience and efficiency, electric air pumps began to gain traction. The introduction of compact and battery-operated models has made them increasingly accessible, especially for recreational users and professionals alike.

In recent years, the integration of smart technology has transformed the landscape, with features such as digital displays and automatic pressure settings enhancing functionality. This evolution is particularly relevant for B2B buyers who are looking for reliable, efficient, and user-friendly products that can cater to a wide range of applications, from automotive maintenance to outdoor sports. As the market continues to innovate, businesses must stay informed about emerging technologies and adapt their sourcing strategies to meet evolving consumer demands.

Illustrative image related to best electric air pump

1. How do I choose the best electric air pump for my business needs?

When selecting an electric air pump, consider factors such as inflation speed, capacity, size, and ease of use. Evaluate the specific applications your business requires, whether for bicycles, vehicles, or inflatables. It’s also essential to assess the durability and reliability of the pump, as these will impact long-term operational costs. Additionally, prioritize suppliers that offer quality assurance and have a reputation for excellent customer service, particularly in your region.

2. What specifications should I look for in an electric air pump?

Key specifications to evaluate include maximum pressure (PSI), inflation rate (how quickly it can inflate a tire), battery life, and portability. Look for pumps with digital gauges for accuracy and ease of use. Ensure compatibility with the types of valves you will be inflating, whether Presta or Schrader. Furthermore, consider the pump’s weight and dimensions to ensure it meets your logistical requirements, especially for transportation and storage.

3. What is the typical minimum order quantity (MOQ) for electric air pumps?

The MOQ for electric air pumps can vary significantly based on the manufacturer and your specific needs. Generally, it ranges from 50 to 500 units. For custom orders, higher MOQs may apply. When negotiating with suppliers, clarify your requirements and explore if they can accommodate smaller orders, especially if you are testing the market or entering a new region.

4. How can I ensure the quality of electric air pumps from suppliers?

To ensure quality, request samples before placing a large order. Conduct thorough supplier vetting by checking their certifications, production processes, and previous client testimonials. It’s beneficial to visit the manufacturing facility if possible or engage third-party inspection services. Additionally, establish clear quality assurance protocols and performance standards in your contract to hold suppliers accountable.

5. What are the common payment terms for international purchases of electric air pumps?

Payment terms can vary widely among suppliers. Common options include a deposit upfront (often 30-50%) with the balance due before shipment or upon delivery. Some suppliers may offer letters of credit or escrow services for larger transactions. It’s crucial to negotiate terms that protect your investment while ensuring the supplier has the incentive to deliver quality products on time.

6. What logistics considerations should I be aware of when importing electric air pumps?

When importing, consider shipping methods, customs duties, and lead times. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Ensure all documentation is in order for customs clearance, including invoices and packing lists. Additionally, working with a reputable freight forwarder can streamline the logistics process and help navigate regulatory requirements in your target markets.

7. Can electric air pumps be customized for branding purposes?

Yes, many manufacturers offer customization options, including branding with your logo and specific color schemes. Customization can enhance brand visibility and differentiate your products in the market. Discuss your requirements with suppliers early in the negotiation process and inquire about any additional costs or minimum order quantities associated with custom designs.

8. What warranties or after-sales support should I expect with electric air pumps?

Reputable suppliers typically provide a warranty period that covers defects in material and workmanship, ranging from one to three years. Ensure to clarify warranty terms, including what is covered and the process for making claims. After-sales support is equally important; inquire about availability for spare parts and repair services. A solid after-sales support system can significantly enhance customer satisfaction and retention.

Dominio: intheknowcycling.com

Registrato: 2013 (12 anni)

Introduzione: Electric bike pumps tested are compact, easy to use, and accurate, weighing around 150 grams (5½ ounces) and costing between $50 and $75. They can fully inflate a flat 28mm road tire to 70 psi or a 40mm gravel tire to 45 psi in about a minute, with the ability to do this 3 to 4 times on a full charge. They are designed for Presta and Schrader valves, and brands include Airbank, Anoutway, Cycplus, …

Dominio: forums.electricbikereview.com

Registrato: 2010 (15 anni)

Introduzione: 1. Fanttik X8 Ace Tire Pump: 150 psi, Presta/Schrader valve, USB-C recharge. 2. Bosch pump: USB rechargeable, suitable for car tires, noted for being handy. 3. CycPlus A8: XL-sized battery, reliable for routine airing-up duties, can use ebike’s battery. 4. CycPlus A7: Replacement for A7, similar functionality. 5. Fumpa pump: High build quality, not made in China, considered a pioneer in electric p…

Dominio: trainerroad.com

Registrato: 2010 (15 anni)

Introduzione: 1. Fumpa Pumps Australia: USB Type-C rechargeable electric bike pumps, made in Melbourne. 2. Craft Cadence Electric Minipump: Digital PSI Gauge, weighs 108 grams, priced at GBP 74.99, offers worldwide free delivery, 2-year warranty, and 30-day returns. 3. Fanttik X9 Ace Mini Bike Pump: Suitable for road, mountain, e-bike, and city bikes, priced at USD 49.97. 4. Cycplus AS2 Pro: Comes with an exten…

As the demand for efficient and reliable inflation solutions continues to rise across various sectors, strategic sourcing of electric air pumps becomes increasingly crucial for international B2B buyers. The evolution of electric air pumps has transformed the landscape, offering enhanced efficiency, portability, and accuracy compared to traditional methods. Buyers should prioritize models that boast digital gauges, quick inflation times, and compatibility with multiple valve types to ensure versatility in their operations.

Investing in high-quality electric air pumps can streamline processes, reduce downtime, and ultimately enhance customer satisfaction. As businesses in regions such as Africa, South America, the Middle East, and Europe seek to optimize their operations, aligning with reputable suppliers who offer innovative solutions will be paramount.

Looking ahead, the market for electric air pumps is poised for further growth, driven by advancements in battery technology and increased awareness of sustainable practices. B2B buyers are encouraged to leverage these trends by establishing partnerships with manufacturers that prioritize quality and sustainability. By doing so, they can not only meet current demands but also position themselves for future success in an evolving marketplace.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.