In an increasingly competitive global market, sourcing a reliable gas station air compressor can be a daunting task for B2B buyers, especially when looking for options “near me.” The challenge lies not only in identifying suitable suppliers but also in ensuring that these compressors meet the specific needs of your operations, whether for a busy gas station in Brazil or a service center in Saudi Arabia. This comprehensive guide delves into the various types of gas station air compressors, their applications, and the intricacies of supplier vetting.

International buyers will gain insights into the key factors influencing pricing, installation, and maintenance costs, enabling informed purchasing decisions that align with their business goals. Additionally, the guide will explore innovative features, such as digital inflation systems and payment options that can enhance customer experience and operational efficiency. With actionable strategies for identifying reputable suppliers and understanding market dynamics, this resource is tailored to empower businesses in Africa, South America, the Middle East, and Europe. Ultimately, navigating the global market for gas station air compressors becomes a streamlined process, allowing you to focus on what matters most—growing your business and satisfying your customers.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Standalone Air Machines | Coin-operated, digital inflation system, robust design | Gas stations, convenience stores | Pro: Easy to install, minimal maintenance required. Contro: Initial cost may be high. |

| Portable Air Compressors | Lightweight, compact, rechargeable, versatile | Automotive service, on-the-go repairs | Pro: Convenient for emergency situations. Contro: Limited capacity and power. |

| Wall-Mounted Air Units | Space-saving design, direct power connection, often with payment systems | Urban gas stations, bike shops | Pro: Saves space, can serve multiple vehicles. Contro: L'installazione può richiedere l'intervento di un professionista. |

| High-Performance Compressors | Heavy-duty, high PSI output, often with multiple attachments | Fleet services, heavy machinery repair | Pro: Fast inflation, suitable for larger vehicles. Contro: Higher energy consumption. |

| Integrated Air/Vacuum Stations | Combines air and vacuum services in one unit | Full-service gas stations | Pro: Increases customer convenience. Contro: Higher upfront investment and maintenance. |

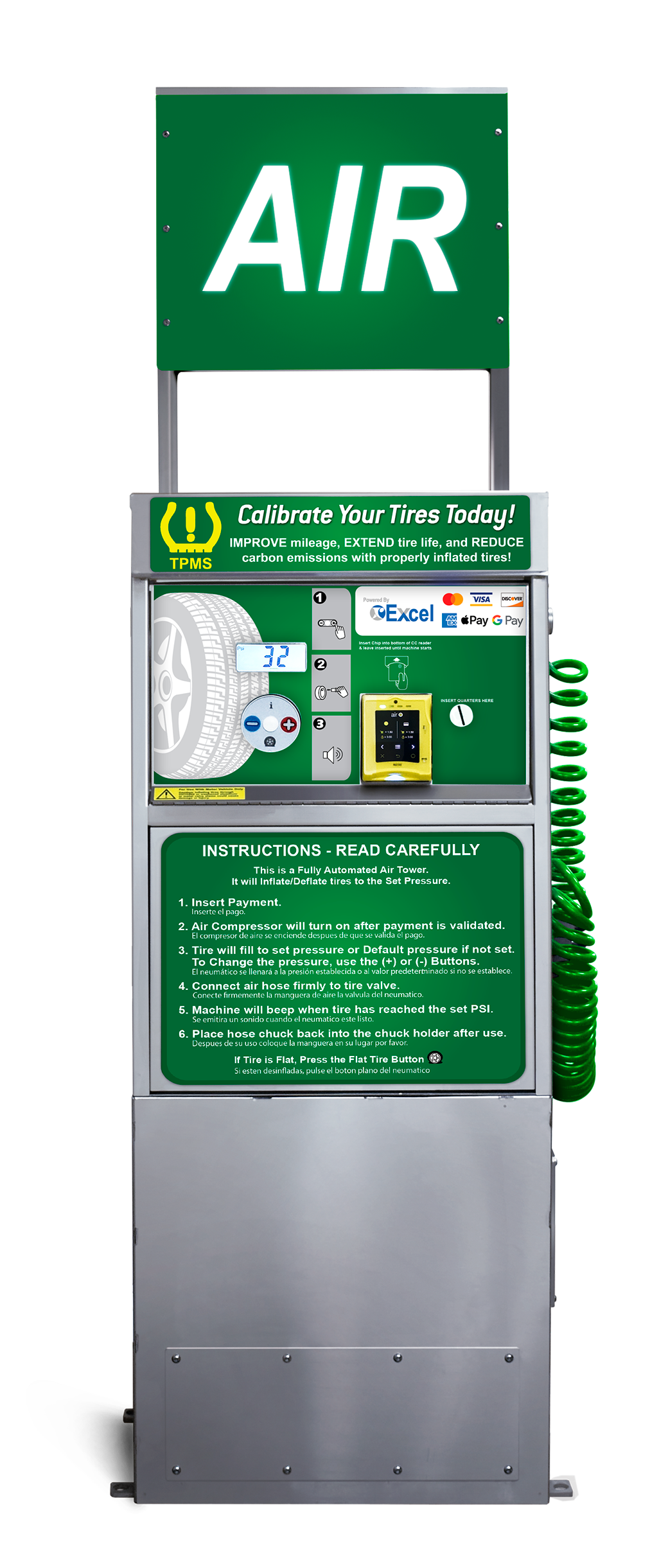

Standalone air machines are typically found at gas stations and convenience stores, featuring coin-operated mechanisms and digital inflation systems. They are robustly designed to withstand outdoor conditions and are ideal for businesses looking to offer self-service tire inflation. When purchasing, B2B buyers should consider factors such as durability, ease of use, and payment options, as these can influence customer satisfaction and revenue generation.

Portable air compressors are lightweight and designed for versatility, making them ideal for automotive service providers and individuals requiring on-the-go solutions. They can be easily stored in a vehicle’s trunk, allowing for quick tire inflation during emergencies. However, B2B buyers must consider their limited capacity and power, which may not meet the demands of larger vehicles or frequent use.

Wall-mounted air units are designed to save space while providing efficient tire inflation services. They are particularly suitable for urban gas stations and bike shops, where space is at a premium. These units often come with digital displays and payment systems. Buyers should evaluate installation requirements and the potential for high foot traffic to maximize ROI from these units.

Illustrative image related to gas station air compressor near me

High-performance compressors are designed for heavy-duty use, offering high PSI outputs and capabilities for inflating larger vehicles and machinery. They are commonly used in fleet services and heavy machinery repair environments. While they provide fast inflation times and robust performance, B2B buyers should be aware of their higher energy consumption and operational costs.

Integrated air/vacuum stations combine air inflation and vacuum services, providing a comprehensive solution for full-service gas stations. This convenience can significantly enhance customer experience, leading to increased customer retention and satisfaction. However, B2B buyers should factor in the higher initial investment and ongoing maintenance costs when considering these systems for their operations.

| Industria/Settore | Specific Application of gas station air compressor near me | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Automotive Services | Tire inflation at gas stations | Provides convenience to customers, increases foot traffic | Reliability of equipment, ease of maintenance, payment options |

| Transportation and Logistics | Fleet vehicle maintenance | Ensures optimal tire pressure, enhances fuel efficiency | Compliance with local regulations, robust design for heavy usage |

| Costruzione | Equipment inflation | Supports pneumatic tools and machinery on job sites | Durability in harsh conditions, power requirements, portability |

| Agricoltura | Agricultural machinery maintenance | Optimizes tire performance for tractors and other vehicles | Compatibility with various machinery, service support availability |

| Recreational Vehicles and Biking | Inflation for bicycles and RVs | Enhances customer satisfaction and service offerings | Space-saving designs, multiple inflation options, user-friendly interface |

In the automotive services sector, gas station air compressors are primarily used for tire inflation. This service not only provides convenience for customers who require quick tire checks but also encourages additional purchases and services at the station. An effective air compressor can enhance customer satisfaction by reducing wait times and ensuring accurate inflation, which is critical for vehicle safety. For international buyers, sourcing equipment that meets local standards for reliability and maintenance is essential to maintain service quality.

For the transportation and logistics industry, gas station air compressors are vital for maintaining fleet vehicles. Regular tire inflation is essential for optimizing fuel efficiency and ensuring vehicle safety on the road. Businesses in this sector must consider compressors that can handle high usage and offer features such as digital monitoring and payment systems to streamline operations. Additionally, compliance with local regulations regarding emissions and equipment standards is a key consideration for international buyers.

In construction, gas station air compressors are utilized for inflating tires on heavy machinery and pneumatic tools. This application is crucial for ensuring that equipment operates efficiently and safely on job sites. Buyers in this sector should prioritize robust and durable compressor designs that can withstand harsh environmental conditions, along with sufficient power capacity to meet the demands of various tools. Service support and the ability to source replacement parts are also important considerations.

Agricultural businesses use gas station air compressors to maintain the tire pressure of tractors and other vehicles essential for farming operations. Proper inflation is vital for maximizing fuel efficiency and minimizing wear and tear on equipment. International buyers should focus on compressors that are compatible with diverse agricultural machinery and can provide reliable service in remote locations. Additionally, sourcing from suppliers with a strong service network can ensure timely maintenance and support.

For the recreational vehicle (RV) and biking sectors, gas station air compressors provide essential tire inflation services. Offering this service can significantly enhance customer satisfaction and attract more visitors to gas stations. Compressors should be user-friendly and capable of accommodating various tire types, including those of bicycles and RVs. Buyers need to consider space-saving designs and multiple inflation options to cater to a diverse clientele, ensuring that they meet the needs of both casual cyclists and RV enthusiasts.

Illustrative image related to gas station air compressor near me

Il problema: B2B buyers, such as gas station operators or fleet managers, often face challenges in accessing reliable air compressors at their locations. Many gas stations are equipped with outdated or malfunctioning air machines, leading to customer dissatisfaction and potential loss of business. In regions where air compressors are not consistently available, companies may find it difficult to maintain customer loyalty, as drivers increasingly expect easy access to tire inflation services.

La soluzione: To overcome this problem, B2B buyers should prioritize investing in modern, robust air compressor systems that offer features like digital inflation, contactless payment options, and real-time monitoring. When sourcing air compressors, consider suppliers that provide comprehensive support services, including installation and maintenance. Establishing partnerships with manufacturers who specialize in commercial-grade air machines ensures that your compressors remain operational and up to date. Additionally, consider implementing a customer feedback system to monitor user experiences and identify areas for improvement in service delivery.

Il problema: Many gas stations and convenience stores struggle with the operational costs associated with running air compressor services, particularly if they offer free air. The expenses can arise from electricity, maintenance, and the costs of managing payment systems, leading to a reluctance to offer this service. This situation can deter potential customers who might otherwise rely on your station for tire maintenance.

La soluzione: To mitigate these costs, consider adopting a mixed revenue model that includes both free and paid services. For example, you could offer free air for customers who purchase fuel or other products, while charging a nominal fee for standalone tire inflation. This strategy not only encourages fuel sales but also helps cover operational costs. Investing in energy-efficient air compressors can further reduce electricity expenses. Look for models that have low power consumption while still providing reliable service. Lastly, exploring partnerships with tire retailers or automotive service providers can create additional revenue streams and enhance the value proposition for your customers.

Il problema: B2B buyers often encounter issues with the inconsistent availability of air services at gas stations. This inconsistency can stem from poorly maintained equipment, lack of staff training, or even variations in local regulations regarding air services. For fleet operators or transport companies, this unreliability can lead to delays, increased operational costs, and frustrated drivers who cannot access necessary tire inflation services during their routes.

La soluzione: To ensure consistent air service availability, gas stations should implement a regular maintenance schedule for their air compressors, including routine checks and timely repairs. Additionally, training staff on the importance of maintaining operational air services can empower them to address minor issues before they escalate. B2B buyers should also consider installing smart air machines equipped with monitoring technology that can alert managers to maintenance needs in real-time. Collaborating with local regulatory bodies can help ensure compliance with any regional air service requirements, further enhancing reliability. Building a reputation for dependable service will not only retain existing customers but also attract new ones who prioritize convenience during their travels.

When selecting materials for gas station air compressors, several factors such as performance, durability, and cost must be considered. This section analyzes four common materials used in the construction of air compressors, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Proprietà chiave: Steel is known for its high tensile strength and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 400°F and can handle pressures exceeding 200 psi, making it suitable for most air compressor applications.

Illustrative image related to gas station air compressor near me

Pro e contro: Steel is highly durable and resistant to deformation, which is essential for maintaining performance over time. However, it is prone to corrosion, especially in humid environments, which can lead to maintenance issues. Additionally, the manufacturing process can be complex and costly, particularly if high-grade stainless steel is used.

Impatto sull'applicazione: Steel is compatible with various media, including air and some gases, but its susceptibility to rust necessitates protective coatings or treatments, especially in regions with high humidity.

Considerazioni per gli acquirenti internazionali: Buyers from regions like Africa and the Middle East should consider local environmental conditions that may affect steel’s longevity. Compliance with standards such as ASTM or DIN is crucial for ensuring quality.

Illustrative image related to gas station air compressor near me

Proprietà chiave: Aluminum is lightweight and has excellent corrosion resistance, making it suitable for portable air compressors. It can handle pressures up to 150 psi and temperatures up to 300°F.

Pro e contro: The primary advantage of aluminum is its weight, which facilitates easier transport and installation. However, it is less durable than steel and may deform under high stress. Its manufacturing process is generally simpler and less expensive than that of steel.

Impatto sull'applicazione: Aluminum is ideal for applications where weight is a critical factor, such as in mobile air compressors. However, its lower strength limits its use in heavy-duty applications.

Considerazioni per gli acquirenti internazionali: In regions like South America, where transportation infrastructure may be less developed, the lightweight nature of aluminum can be advantageous. Buyers should also verify compliance with local standards for pressure vessels.

Proprietà chiave: Composite materials, often made from a combination of polymers and fibers, provide excellent corrosion resistance and can withstand moderate pressures and temperatures.

Pro e contro: Composites are lightweight and resistant to corrosion, making them ideal for use in harsh environments. However, they may not withstand as high pressures as metal options and can be more expensive due to complex manufacturing processes.

Impatto sull'applicazione: Composites are suitable for applications where weight and corrosion resistance are prioritized over pressure handling capabilities.

Considerazioni per gli acquirenti internazionali: Buyers from Europe and the Middle East should consider the specific performance requirements of their applications, as well as compliance with relevant standards for composite materials.

Proprietà chiave: Cast iron is known for its high durability and ability to withstand high temperatures and pressures, typically rated up to 500°F and 250 psi.

Pro e contro: The primary advantage of cast iron is its robustness and longevity, making it suitable for heavy-duty applications. However, it is heavy and can be prone to rust if not properly maintained, which can increase operational costs.

Impatto sull'applicazione: Cast iron is ideal for stationary air compressors used in gas stations, where high durability is required.

Considerazioni per gli acquirenti internazionali: Buyers in regions with strict regulations should ensure that the cast iron components meet local compliance standards. Additionally, the weight of cast iron may affect shipping costs.

| Materiale | Typical Use Case for gas station air compressor near me | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Acciaio | Heavy-duty stationary compressors | Elevata resistenza e durata | Prone to corrosion | Alto |

| Alluminio | Portable air compressors | Leggero e resistente alla corrosione | Less durable than steel | Medio |

| Composito | Harsh environment applications | Excellent corrosion resistance | Limited pressure handling | Alto |

| Cast Iron | Stationary heavy-duty compressors | Robust and long-lasting | Heavy and prone to rust | Medio |

The manufacturing process of gas station air compressors is multifaceted, involving several critical stages to ensure that the final product meets the required performance and durability standards. The primary stages include:

The first step in the manufacturing process involves selecting high-quality materials that can withstand the rigors of continuous use in diverse environments. Common materials include stainless steel for the outer casing, high-grade aluminum for internal components, and durable rubber for hoses. Suppliers often conduct material inspections to confirm compliance with international standards and specifications.

Once the materials are prepared, they undergo various forming techniques. This may include processes such as stamping, bending, and machining to create the individual components of the air compressor. Advanced techniques like CNC machining are frequently employed to achieve precise dimensions, which are crucial for the overall performance and efficiency of the compressor.

The assembly stage is where the components come together. Skilled technicians or automated systems align and connect the various parts, including the motor, pump, control systems, and casing. During assembly, quality checks are often implemented to ensure that each part is fitted correctly and functions as intended. This stage may also involve the installation of electronic components, such as digital inflation systems and payment interfaces, which are increasingly popular in modern gas station air compressors.

Finishing processes enhance both the aesthetic and functional properties of the compressor. This may include painting, powder coating, or applying anti-corrosive treatments to protect against environmental factors. Additionally, a final inspection occurs at this stage to ensure that the compressor meets all specifications and is free of defects before it is packaged for distribution.

Quality control (QC) is a crucial aspect of the manufacturing process, particularly for gas station air compressors, which are expected to operate reliably in various conditions. B2B buyers should look for adherence to several international and industry-specific standards.

One of the most recognized quality management standards, ISO 9001, ensures that manufacturers maintain a consistent quality level across their products and processes. Companies that are ISO 9001 certified have demonstrated a commitment to quality management principles, including customer focus, process approach, and continuous improvement.

For buyers in Europe, ensuring that products have the CE marking is essential. This mark indicates compliance with European health, safety, and environmental protection standards. It signifies that the air compressors have been tested and meet the necessary directives, ensuring safety and reliability for end-users.

Illustrative image related to gas station air compressor near me

For manufacturers targeting the oil and gas sector, adherence to American Petroleum Institute (API) standards can provide an additional layer of assurance regarding the performance and safety of the compressors. API standards are particularly relevant for compressors designed for high-pressure applications.

To maintain high-quality standards, manufacturers implement several quality control checkpoints throughout the production process:

IQC involves inspecting materials and components as they arrive at the manufacturing facility. This step ensures that all incoming materials meet the specified requirements before they are used in the production process.

During the manufacturing process, IPQC checks are performed at various stages to monitor compliance with specifications. This can include checking dimensions, pressure tests, and operational tests of components to identify any issues early in the production cycle.

FQC is the last line of defense before products are shipped to customers. This stage includes comprehensive testing of the finished air compressors, including performance tests, safety checks, and durability assessments. Any units that fail to meet quality standards are either reworked or discarded.

Illustrative image related to gas station air compressor near me

For international buyers, especially those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is vital to ensuring product reliability. Here are several strategies:

Regular audits of suppliers can provide insights into their manufacturing processes and quality control practices. Buyers should consider scheduling on-site visits to assess the manufacturing environment, equipment, and personnel practices.

Manufacturers should be able to provide detailed quality reports that outline their QC processes, including results from IQC, IPQC, and FQC stages. These reports can help buyers understand the effectiveness of the supplier’s quality management system.

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. These services can perform inspections at various stages of production and offer detailed reports on compliance with international standards.

B2B buyers from different regions may encounter specific nuances in quality control that are important to consider:

Each region may have different quality standards and regulations. Buyers should familiarize themselves with local requirements in their target markets, such as compliance with regional certifications or standards.

Communication can be a challenge when dealing with international suppliers. It’s crucial for buyers to ensure that quality documentation is available in a language they understand to avoid misinterpretations.

Cultural attitudes towards quality and business practices can vary significantly. Buyers should be aware of these differences and establish clear communication channels to discuss quality expectations and resolve any issues that may arise.

By understanding the manufacturing processes and quality assurance measures in place for gas station air compressors, B2B buyers can make informed purchasing decisions that align with their operational needs and standards.

This guide serves as a comprehensive checklist for B2B buyers seeking to procure gas station air compressors. It outlines essential steps that will help you navigate the sourcing process effectively, ensuring you choose a solution that meets your operational needs while maximizing value.

Establishing clear technical specifications is crucial before initiating your procurement process. Determine the required air pressure, flow rate, and compressor type that aligns with your gas station’s needs. This helps in narrowing down options and ensuring that the equipment you choose can handle the volume and type of service you plan to offer.

Conduct thorough research on potential suppliers who specialize in gas station air compressors. Look for companies with a proven track record and strong market presence. This step is essential to ensure you are dealing with reputable manufacturers who can provide reliable products.

Before making a commitment, it’s important to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. This due diligence will help you assess the reliability and quality of the supplier’s products.

Once you’ve shortlisted potential suppliers, request detailed quotes that include product specifications, delivery timelines, and pricing. Comparing these quotes allows you to evaluate which supplier offers the best value without compromising on quality.

After-sales support is a critical factor in your purchasing decision. Ensure that the supplier offers comprehensive support services, including installation, maintenance, and troubleshooting assistance. This can significantly affect the long-term performance of your air compressor.

Familiarize yourself with local regulations regarding gas station equipment and safety standards. Compliance with these regulations is not only essential for legal operation but also for maintaining customer trust and safety.

Once you’ve chosen a supplier, it’s time to finalize the purchase agreement. Ensure that the contract includes all agreed-upon terms, delivery timelines, and warranty details. This protects both parties and clarifies expectations.

By following these steps, B2B buyers can ensure a strategic and informed procurement process for gas station air compressors, leading to enhanced operational efficiency and customer satisfaction.

When analyzing the cost structure for sourcing gas station air compressors, several components play a crucial role. The primary cost components include:

Illustrative image related to gas station air compressor near me

I materiali: The choice of materials impacts the durability and performance of air compressors. Stainless steel, for instance, is often preferred for its resistance to corrosion, but it also raises costs. The use of high-quality components in the compressor, such as advanced digital inflation systems, can further increase material costs.

Lavoro: Labor costs encompass the workforce involved in manufacturing, assembling, and testing the compressors. Regions with higher labor costs, such as parts of Europe, may see higher overall pricing compared to areas where labor is more affordable, such as parts of Africa or South America.

Spese generali di produzione: This includes costs related to the facility, utilities, equipment depreciation, and indirect labor. Manufacturers with advanced automation may have lower overhead, allowing for competitive pricing.

Utensili: Specific tooling for compressor production can represent a significant initial investment. Custom designs or specialized features can require bespoke tooling, which adds to the upfront costs.

Controllo qualità (CQ): Implementing rigorous QC processes ensures that air compressors meet safety and performance standards. This is especially important for international buyers who must comply with specific regulatory requirements.

Logistica: Shipping and handling costs can vary significantly based on distance, shipping method, and volume. Import duties and tariffs also play a role in the overall logistics costs for international buyers.

Margine: The profit margin set by manufacturers affects the final price. Factors such as brand reputation and market demand can influence the margin applied.

Several factors influence the pricing of gas station air compressors:

Volume/MOQ: Larger purchase volumes often lead to discounted pricing. Manufacturers may offer lower per-unit costs for bulk orders, making it financially advantageous for businesses to buy in larger quantities.

Specifiche e personalizzazione: Custom features or specifications can significantly increase costs. Buyers should assess whether standard models meet their needs before opting for custom designs, which can inflate budgets.

Materiali e certificazioni di qualità: Higher quality and certified materials often come at a premium. Certifications may be necessary for compliance with safety and environmental regulations, particularly for international markets.

Fattori di fornitura: The reputation and reliability of suppliers can affect pricing. Established suppliers may command higher prices due to their experience and quality assurance processes.

Incoterms: Understanding Incoterms is essential for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) can impact the total cost, as they define who bears shipping costs and responsibilities.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Negoziazione: Engage suppliers in negotiations to find mutually beneficial pricing. Highlighting potential for bulk purchases or long-term partnerships may yield better rates.

Costo totale di proprietà (TCO): Consider the TCO, which includes not just the purchase price but also installation, maintenance, and operational costs over the compressor’s lifespan. This holistic view can lead to better investment decisions.

Le sfumature dei prezzi per gli acquirenti internazionali: Be aware of currency fluctuations and how they may affect pricing. Establishing contracts in stable currencies can mitigate risks.

Supplier Diversity: Explore multiple suppliers to compare pricing and quality. This not only provides options but also strengthens negotiating power.

Understanding the comprehensive cost structure and pricing dynamics of gas station air compressors is vital for making informed sourcing decisions. By considering the various cost components, price influencers, and strategic negotiation tips, international buyers can achieve greater value in their procurement efforts. Always remember that indicative prices may vary based on market conditions, and it’s advisable to conduct thorough market research to establish a competitive and fair pricing framework.

In the realm of tire maintenance and inflation, the availability of gas station air compressors has long been a go-to solution for both consumers and businesses. However, as the landscape of air inflation technology evolves, various alternatives have emerged that may offer distinct advantages depending on specific operational needs. This section will explore viable alternatives to gas station air compressors, providing insights into their performance, cost-effectiveness, ease of implementation, maintenance requirements, and ideal use cases.

| Aspetto di confronto | Gas Station Air Compressor Near Me | Compressore d'aria portatile | On-Site Air Compressor System |

|---|---|---|---|

| Prestazioni | Moderate to High | Moderate | Alto |

| Costo | Often free or low cost | $30 – $200 | $1,000 – $10,000 |

| Facilità di implementazione | Generally available and accessible | Easy to use, portable | Requires installation |

| Manutenzione | Minimal (occasional servicing) | Low (regular checks) | High (requires regular upkeep) |

| Il miglior caso d'uso | Quick stops for tire inflation | Emergency or remote use | High-volume tire shops or fleets |

Portable air compressors serve as a convenient alternative to gas station compressors, especially for individuals or businesses that require on-the-go inflation capabilities. These compact devices can easily fit in a trunk, making them ideal for emergencies or remote locations where access to gas stations is limited. While they are relatively affordable, ranging from $30 to $200, their performance can be limited in terms of pressure output compared to stationary systems. Additionally, users must ensure they have a power source, which can be a drawback in certain situations.

Illustrative image related to gas station air compressor near me

For businesses that regularly service vehicles, such as tire shops or fleet operators, investing in an on-site air compressor system may be the most efficient solution. These systems are designed for high-volume usage, providing consistent and powerful air output. Although the initial investment can range from $1,000 to $10,000, the long-term benefits often outweigh the costs. However, on-site systems require regular maintenance and monitoring to ensure optimal performance, which can increase operational overhead. This option is best suited for enterprises that prioritize efficiency and volume in their tire inflation needs.

When determining the best air compression solution for your business, it is crucial to assess your specific needs and operational context. Gas station air compressors offer a convenient and often cost-effective option for occasional use, while portable air compressors provide flexibility for emergency situations. On the other hand, on-site air compressor systems deliver high performance and efficiency for businesses that demand consistent tire inflation services. By evaluating the performance, cost, ease of implementation, and maintenance requirements of each alternative, B2B buyers can make informed decisions that align with their operational goals and customer service standards.

When selecting a gas station air compressor, understanding its technical specifications is vital for ensuring efficiency and reliability. Here are some key properties to consider:

The construction material of an air compressor directly impacts its durability and resistance to environmental factors. Stainless steel is commonly used for its corrosion resistance and longevity, which is essential for outdoor installations. High-grade materials can withstand harsh weather conditions, reducing maintenance costs and prolonging the compressor’s life.

Air compressors come in various types, including reciprocating, rotary screw, and scroll compressors. Each type has its own advantages depending on the application. For instance, rotary screw compressors are often favored in gas stations for their continuous operation capability and efficiency in high-demand scenarios. Understanding the type helps buyers select a model that meets their operational needs.

The pressure rating, measured in PSI (pounds per square inch), indicates the maximum pressure the compressor can deliver. For gas stations, a pressure rating between 100-150 PSI is typically sufficient for inflating automotive tires. Selecting a compressor with the appropriate pressure rating ensures efficient service for customers and prevents potential damage to tires from over-inflation.

Flow rate, expressed in CFM (cubic feet per minute), measures the volume of air the compressor can deliver. A higher flow rate means quicker inflation times, which is critical for maintaining customer satisfaction during peak hours. B2B buyers should assess their expected customer traffic to choose a compressor that can handle the demand without lagging.

Gas station air compressors can be powered by electricity or gas. Electric models are generally more efficient and have lower operational costs, while gas-powered compressors might be necessary in areas where electricity supply is unreliable. Evaluating the power source is essential for operational continuity and cost management.

Familiarizing oneself with industry jargon can enhance communication and negotiation with suppliers. Here are some common terms:

An OEM refers to a company that produces components or equipment that may be marketed by another manufacturer. In the context of air compressors, understanding OEM relationships can help buyers ensure they are sourcing high-quality parts that meet specific industry standards.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory planning. Some suppliers may have a high MOQ, which could necessitate bulk purchasing and storage considerations.

Illustrative image related to gas station air compressor near me

An RFQ is a standard business process where buyers invite suppliers to submit price quotes for specific products. This process helps buyers compare costs and terms across different vendors, enabling informed decision-making based on budget and specifications.

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms is essential for B2B transactions, as they clarify who is responsible for shipping, insurance, and tariffs, thus preventing disputes.

These terms relate to the guarantees provided by manufacturers regarding the performance and service of the air compressors. A solid warranty can protect buyers from potential defects or failures, while service agreements ensure ongoing support and maintenance, which are critical for operational efficiency.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing gas station air compressors, ensuring that they select the right equipment to meet their operational needs and customer expectations.

The global market for gas station air compressors is shaped by several pivotal trends driven by technological advancements and evolving consumer preferences. One major driver is the increasing demand for convenience and efficiency among consumers, particularly in urban areas. As busy lifestyles push customers to seek quick service, gas stations equipped with modern air compressors that offer automated, user-friendly interfaces are gaining popularity.

Moreover, the rise of digital payment solutions is transforming how air services are accessed. Many gas stations are adopting cashless payment options for air services, catering to the tech-savvy consumer. This trend is particularly pronounced in regions like Europe and North America, but it is gradually making inroads into markets in Africa and South America, where mobile payment systems are becoming prevalent.

Emerging technologies, such as IoT-enabled air compressors, are also reshaping market dynamics. These smart systems can monitor performance and usage patterns, allowing gas stations to optimize operations and reduce maintenance costs. For international B2B buyers, especially from regions like Saudi Arabia and Brazil, investing in advanced air compressor technology can lead to enhanced service offerings and operational efficiencies.

Sustainability is becoming a cornerstone of sourcing strategies in the gas station air compressor sector. With growing awareness of environmental issues, buyers are increasingly prioritizing energy-efficient models that minimize carbon footprints. This shift is especially significant in regions facing stringent environmental regulations, such as Europe and parts of the Middle East.

Illustrative image related to gas station air compressor near me

Ethical sourcing is another critical component of this trend. B2B buyers are encouraged to seek suppliers who demonstrate commitment to sustainable practices, such as using recyclable materials and reducing waste in manufacturing processes. Certifications like ISO 14001 for environmental management systems are becoming essential criteria for evaluating potential partners.

Investing in green technologies not only aligns with corporate social responsibility goals but can also lead to cost savings in the long run. Energy-efficient compressors reduce operational costs, while sustainable practices can enhance brand reputation among environmentally-conscious consumers. For buyers in emerging markets, aligning with suppliers that prioritize sustainability can provide a competitive edge in an increasingly eco-aware marketplace.

The evolution of the gas station air compressor market has been marked by significant technological advancements and changing consumer expectations. Initially, air compressors at gas stations were basic, manual machines that required coins for operation. However, as consumer demand for convenience grew, manufacturers began developing digital air inflation systems that offer features like credit card payments and real-time monitoring.

The introduction of portable air compressors also revolutionized the market, providing consumers with the ability to inflate tires at their convenience, regardless of location. This shift not only increased accessibility but also created new opportunities for B2B buyers to offer innovative solutions to their customers.

Today, the focus is on integrating smart technologies that enhance user experience and operational efficiency. As the market continues to evolve, it is essential for international B2B buyers to stay informed about emerging trends and technologies that can help them meet the demands of a modern consumer base. Understanding these dynamics is key to making informed sourcing decisions in the gas station air compressor sector.

Illustrative image related to gas station air compressor near me

1. How do I select the right gas station air compressor for my business needs?

Choosing the right gas station air compressor involves evaluating several factors. First, consider the compressor’s capacity and PSI rating, which should match your intended usage, whether for inflating vehicle tires or powering pneumatic tools. Additionally, assess the machine’s durability and maintenance requirements, particularly if you expect high-volume usage. Look for features like digital inflation systems, payment options, and customization capabilities that align with your business model. Finally, research suppliers for their reliability and customer service to ensure ongoing support.

2. What are the best air compressors for gas stations based on performance and reliability?

The best air compressors for gas stations typically include robust models such as the SC09-SS and SC05-SS, known for their stainless steel construction and innovative digital air inflation systems. These machines often feature customizable designs, internal compressors, and optional credit card payment systems, making them user-friendly. Look for models that also offer vacuum attachments for added service options. Reliability is key, so consider brands with proven track records and positive customer feedback.

3. What are the common payment options available for gas station air compressors?

Most modern gas station air compressors offer a range of payment options to enhance customer convenience. Common methods include coin-operated systems, credit card readers, and cashless payment solutions such as mobile wallets. When selecting a compressor, ensure it supports multiple payment methods to cater to diverse customer preferences. Additionally, some suppliers provide customizable payment systems, allowing you to integrate the compressor with your existing point-of-sale systems.

4. What are the typical minimum order quantities (MOQs) for gas station air compressors?

Minimum order quantities for gas station air compressors can vary significantly based on the supplier and the specific model. Generally, MOQs may range from a single unit for specialty suppliers to several units for bulk orders from manufacturers. When negotiating, consider your business needs and potential growth; placing a larger initial order might yield discounts and better terms. Always clarify MOQs during discussions with suppliers to avoid misunderstandings.

5. How do I vet suppliers for gas station air compressors internationally?

Vetting international suppliers requires a thorough approach. Start by checking their industry reputation through online reviews and references from previous clients. Verify their compliance with international quality standards and certifications relevant to your market. Assess their financial stability and production capacity to ensure they can meet your demands. Engaging in direct communication helps clarify their support services, warranty policies, and responsiveness, which are crucial for long-term partnerships.

6. What quality assurance (QA) measures should I look for when sourcing air compressors?

Quality assurance measures are critical when sourcing air compressors. Look for suppliers that adhere to recognized international standards such as ISO 9001, which ensures consistent quality management. Request documentation related to testing and certification of their products, including performance tests and safety assessments. Additionally, inquire about their warranty policies and after-sales support, as these can indicate a commitment to product quality and customer satisfaction.

7. What logistics considerations should I keep in mind when importing air compressors?

When importing air compressors, logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder experienced in handling machinery to navigate import regulations in your country. Ensure you understand the duties and taxes applicable to your shipment, as these can impact total costs. Additionally, plan for potential delays by establishing clear communication with your supplier regarding production and shipping schedules.

8. How can I customize air compressors to better serve my target market?

Customization options for air compressors can significantly enhance their appeal to your target market. Discuss with your supplier the possibility of adding features such as customized branding, specific PSI settings, or integrated payment systems tailored to local customer preferences. Additionally, consider the design and functionality that align with your business model, such as multi-use capabilities for tire inflation and vacuum services. Collaborating closely with suppliers can lead to innovative solutions that differentiate your offerings in the market.

Dominio: freeairpump.com

Registrato: 2012 (13 anni)

Introduzione: Map of places that provide free air for tires, with over 12k locations in the U.S. User-generated content, updated weekly. Users can submit new locations and report inaccuracies. Free air is typically offered at tire shops, car repair stations, bike shops, and certain gas station chains. Notable gas station chains include Co-op, Family Express, Getgo, Hy-vee, Kroger, Kum&Go, KwikTrip, Pilot truck …

Dominio: yelp.com

Registrato: 2003 (22 anni)

Introduzione: This company, Yelp – Free Air Pump Finder, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: jmesales.com

Registrato: 1998 (27 anni)

Introduzione: Commercial vacuums and air machines built of sturdy stainless steel for durability. Suitable for gas stations, car washes, auto repair shops, trucking firms, and car dealerships. Available in coin-operated and simple on/off models. Accessories available.

Dominio: facebook.com

Registrato: 1997 (28 anni)

Introduzione: WORKING air pressure machine for tires

As international markets continue to expand, the demand for effective and efficient gas station air compressor solutions is more critical than ever. Key takeaways from our guide highlight the importance of strategic sourcing, emphasizing that B2B buyers should prioritize reliable suppliers that offer durable, technologically advanced air compressors. The integration of digital inflation systems and payment options will not only enhance customer satisfaction but also streamline operations for gas station owners.

Furthermore, with the growing trend towards sustainability, sourcing compressors that align with eco-friendly practices can create a competitive advantage in regions such as Africa, South America, the Middle East, and Europe. Buyers should also consider the unique regulatory environments and consumer expectations in their respective markets, as these factors can influence purchasing decisions.

Looking ahead, it is essential for B2B buyers to leverage the insights gained from this guide to make informed sourcing decisions. Engaging with reputable manufacturers and distributors will ensure access to high-quality air compressors that meet the evolving needs of gas stations. Now is the time to act—explore your options and forge partnerships that will drive growth and innovation in your business.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.