In the rapidly evolving automotive landscape, mastering the art of tire inflation is crucial for B2B buyers looking to optimize vehicle performance and safety. Proper tire inflation not only extends tire life but also enhances fuel efficiency and driving comfort, critical factors for fleets operating in diverse environments across Africa, South America, the Middle East, and Europe, including markets like Germany and Nigeria. This comprehensive guide serves as an essential resource, addressing the complexities of tire inflation from sourcing reliable suppliers to understanding the nuances of different tire types and their applications.

The guide meticulously outlines the steps for inflating tires correctly, the significance of maintaining appropriate pressure, and the potential risks associated with neglecting this vital aspect of vehicle maintenance. By providing insights into cost considerations, supplier vetting processes, and innovative inflation solutions such as portable compressors, this guide equips international B2B buyers with the knowledge needed to make informed purchasing decisions. Whether you are managing a fleet of vehicles or sourcing tires for a commercial operation, understanding how to inflate tires effectively is integral to ensuring operational efficiency and safety on the road. Embrace this opportunity to enhance your procurement strategy and elevate your business’s performance in the global market.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Manual Inflation | Requires physical interaction with a tire pump or compressor | Automotive service stations, fleet management | Pro: Efficiente dal punto di vista dei costi; Contro: Labor-intensive and time-consuming. |

| Automated Inflation Stations | Self-service kiosks with built-in gauges | Gas stations, automotive repair shops | Pro: Quick and easy to use; Contro: Gauge accuracy can vary. |

| Portable Air Compressors | Compact, battery-operated or plug-in devices | Fleet operators, emergency services | Pro: Convenient for on-the-go inflation; Contro: Limited power and capacity. |

| Nitrogen Inflation | Uses nitrogen instead of regular air | Performance vehicles, commercial fleets | Pro: Reduces pressure loss; Contro: Higher initial cost and availability issues. |

| Digital Tire Pressure Monitors | Real-time monitoring systems | Vehicle manufacturers, fleet services | Pro: Enhances safety and fuel efficiency; Contro: Higher installation costs. |

Manual inflation involves using a hand pump or a compressor to fill tires with air. This traditional method is commonly employed in automotive service stations and by fleet management teams. It is cost-effective but requires skilled personnel to ensure accurate inflation. B2B buyers should consider the labor intensity and time commitment associated with this method, as it may not be the most efficient choice for large fleets requiring frequent tire maintenance.

Automated inflation stations provide a self-service option where users can inflate tires without assistance. These kiosks often feature built-in gauges for accuracy, making them popular in gas stations and automotive repair shops. While they offer convenience and speed, B2B buyers should be aware that the accuracy of the gauges can vary, which may lead to over- or under-inflation if not monitored closely. Investing in these stations can streamline operations and improve customer satisfaction.

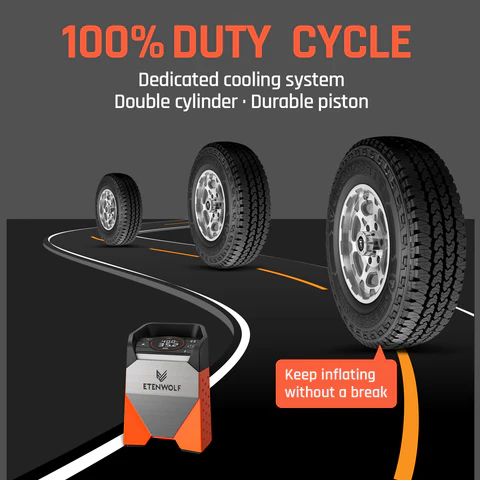

Portable air compressors are compact devices that can be used for tire inflation in various settings, including emergency services and fleet operations. These compressors are typically battery-operated or plug into a vehicle’s power source, providing flexibility for on-the-go inflation. The convenience of portable compressors makes them ideal for businesses that require quick tire maintenance. However, buyers should consider their limited capacity and power compared to larger, stationary models.

Nitrogen inflation involves filling tires with nitrogen instead of regular air, which can help maintain tire pressure longer due to the larger size of nitrogen molecules. This method is especially popular among performance vehicles and commercial fleets, as it can enhance fuel efficiency and tire lifespan. While the initial cost may be higher and availability can be an issue, B2B buyers should weigh the long-term benefits of reduced maintenance and improved performance against these factors.

Illustrative image related to how to inflate a tire

Digital tire pressure monitoring systems provide real-time data on tire pressure, which is crucial for ensuring safety and optimizing fuel efficiency. These systems are increasingly being integrated into vehicles by manufacturers and are essential for fleet services that require constant monitoring. Although the installation costs can be higher, the potential savings in fuel and maintenance, along with enhanced safety, make them an attractive option for B2B buyers focused on operational efficiency.

| Industria/Settore | Specific Application of how to inflate a tire | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Trasporto e logistica | Regular tire maintenance for fleet vehicles | Reduces operational costs through improved fuel efficiency and tire longevity | Reliable tire inflation equipment; service contracts for maintenance |

| Agricoltura | Tire inflation for agricultural machinery | Ensures optimal performance and reduces downtime during critical farming periods | Heavy-duty inflators; compatibility with various machinery types |

| Costruzione | Tire management for construction vehicles | Enhances safety on-site and minimizes tire-related accidents | Durable inflation tools; training for operators on proper usage |

| Mining | Tire inflation for heavy mining equipment | Increases equipment efficiency and lifespan, reducing operational costs | Specialized inflators for extreme conditions; regular monitoring systems |

| Riparazione di autoveicoli | Tire inflation services in repair shops | Attracts customers seeking reliable tire maintenance services | Calibration tools; partnerships with tire manufacturers for quality assurance |

In the transportation and logistics industry, maintaining proper tire pressure for fleet vehicles is critical. Fleet operators must regularly check and inflate tires to prevent underinflation, which can lead to increased fuel consumption and premature tire wear. By investing in reliable tire inflation equipment and establishing service contracts for regular maintenance, logistics companies can significantly reduce operational costs and enhance safety on the road. For international buyers, sourcing durable and precise tire inflation tools that comply with local regulations is essential.

In agriculture, properly inflated tires on machinery such as tractors and harvesters are vital for optimal performance and efficiency. Underinflated tires can lead to increased fuel consumption and reduced traction, impacting productivity during critical planting and harvesting seasons. Agricultural businesses should seek heavy-duty tire inflators that can withstand rugged environments and ensure compatibility with various equipment types. For buyers in developing regions, considering the availability of service and support for these tools is crucial to minimize downtime.

Construction sites rely heavily on various vehicles and machinery, making tire maintenance a key safety concern. Proper tire inflation ensures that construction vehicles operate efficiently, reducing the risk of accidents caused by tire blowouts or handling issues. Construction firms should prioritize sourcing durable inflation tools and consider training their operators on best practices for tire maintenance. This approach not only enhances safety but also minimizes project delays, which is particularly important for international buyers working in diverse environments.

In the mining sector, maintaining the correct tire pressure in heavy equipment is essential due to the challenging conditions and high operational demands. Properly inflated tires enhance equipment efficiency, reduce the likelihood of tire failure, and extend the lifespan of costly machinery. Mining companies should invest in specialized tire inflators designed for harsh environments and implement regular monitoring systems to ensure consistent pressure. For international buyers, understanding the specific needs of mining operations in their region can guide effective sourcing decisions.

Illustrative image related to how to inflate a tire

Automotive repair shops can attract more customers by offering comprehensive tire inflation services. Ensuring that tires are inflated to the correct pressure not only improves vehicle performance but also enhances safety for drivers. Repair shops should invest in calibrated inflation tools and consider partnerships with tire manufacturers to ensure quality service. For B2B buyers in the automotive sector, focusing on reliable equipment and effective training for staff can differentiate their services in competitive markets.

Il problema: For businesses operating fleets, inconsistent tire pressure can lead to operational inefficiencies and increased costs. Many fleet managers struggle to keep track of tire pressure across various vehicles, particularly when dealing with multiple tire types and sizes. Over time, this neglect can result in underinflation or overinflation, leading to hazardous driving conditions, increased fuel consumption, and accelerated tire wear. Moreover, the lack of a systematic approach to monitoring tire pressure can complicate maintenance schedules and leave managers feeling overwhelmed.

La soluzione: To tackle this issue, fleet managers should implement a standardized tire pressure monitoring system (TPMS) across their vehicles. Investing in a digital TPMS can automate pressure monitoring, providing real-time data directly to fleet managers via a centralized dashboard. This allows for immediate corrective actions and regular reporting on tire conditions. Additionally, establishing a monthly tire maintenance schedule, where tire pressures are checked and adjusted, ensures that all vehicles remain within manufacturer-recommended ranges. Training staff on the importance of tire pressure management will further enhance compliance and awareness, ultimately leading to a safer and more cost-effective fleet.

Il problema: In many regions, particularly in remote areas of Africa and South America, access to reliable tire inflation equipment can be a major hurdle for businesses. Lack of nearby service stations or the unavailability of proper inflation tools can leave fleets stranded or lead to delayed operations. This situation can cause frustration and financial loss, especially when downtime translates to lost productivity and revenue.

La soluzione: Businesses should consider investing in portable tire inflation equipment. A high-quality, battery-operated tire inflator can serve as a crucial asset for any fleet. These devices are compact, easy to use, and can be stored in vehicles or at maintenance depots for quick access. Additionally, training personnel on how to use these inflators effectively will ensure that tire pressures are maintained regularly, regardless of location. Establishing partnerships with local tire service providers can also facilitate quick repairs or tire checks, creating a comprehensive tire maintenance strategy that supports operational continuity.

Il problema: Many employees lack the knowledge and skills required to properly inflate tires, which can lead to improper inflation practices. This ignorance not only compromises vehicle safety but also results in increased tire wear and reduced fuel efficiency. For businesses that rely on their vehicles for service delivery, this gap in knowledge can create significant operational challenges and financial burdens.

La soluzione: Businesses can address this knowledge gap by implementing a comprehensive training program focused on tire maintenance. This program should cover the importance of correct tire inflation, how to read tire pressure gauges, and the steps for inflating tires properly. Workshops can be supplemented with instructional materials, such as video tutorials and quick-reference guides that employees can consult when needed. Encouraging a culture of safety and maintenance within the organization will empower employees to take responsibility for tire care, ultimately leading to better vehicle performance and safety on the road. Regular refresher courses can also be scheduled to keep tire maintenance knowledge current and top of mind.

When considering the materials used in tire inflation systems, it is essential to evaluate their properties, advantages, and limitations. This analysis focuses on four common materials: rubber, metal, plastic, and composite materials. Each material has distinct characteristics that influence its performance in tire inflation applications.

Rubber is a primary material used in tire valves and seals due to its excellent elasticity and flexibility. It can withstand a wide range of temperatures, typically from -40°F to 200°F (-40°C to 93°C), making it suitable for various climates. Additionally, rubber exhibits good pressure resistance, ensuring that it maintains the integrity of the tire’s air chamber.

Pros and Cons of Rubber:

Rubber is durable and cost-effective, making it a popular choice for many manufacturers. However, it can degrade over time due to exposure to UV light and ozone, leading to potential leaks. Furthermore, rubber components may require more complex manufacturing processes, which can increase production costs.

Impatto sull'applicazione:

Rubber is compatible with air and nitrogen, which are commonly used for tire inflation. However, its susceptibility to environmental factors means that buyers in regions with high UV exposure, such as parts of Africa and South America, should prioritize UV-resistant formulations.

Metal, particularly aluminum and brass, is often used in tire inflation valves and connectors. Metals provide high strength and durability, withstanding significant pressure and temperature variations. For instance, aluminum can handle temperatures up to 400°F (204°C) and pressures exceeding 100 psi.

Pros and Cons of Metal:

The key advantage of metal components is their longevity and resistance to wear and tear. However, they can be heavier than other materials, potentially affecting the overall weight of the tire assembly. Additionally, metal parts can be more expensive to produce, especially when precision engineering is required.

Impatto sull'applicazione:

Metal components are highly resistant to corrosion, especially when treated with protective coatings. This is crucial for buyers in humid or coastal regions, such as the Middle East, where corrosion can significantly impact performance. Compliance with standards like ASTM for metals is essential for international buyers.

Illustrative image related to how to inflate a tire

Plastics, particularly high-density polyethylene (HDPE) and polyvinyl chloride (PVC), are increasingly used in tire inflation systems, especially for connectors and hoses. These materials are lightweight and can be engineered to withstand pressures up to 50 psi.

Pros and Cons of Plastic:

Plastics are generally less expensive than metals and rubber, making them attractive for cost-sensitive applications. However, they may not offer the same level of durability and temperature resistance as metals or rubber, limiting their use in high-performance scenarios.

Impatto sull'applicazione:

Plastics can be susceptible to degradation from UV exposure and extreme temperatures, which may be a concern in regions with harsh climates. International buyers should ensure that the plastics used meet relevant standards, such as DIN in Europe, to guarantee performance.

Composite materials, which combine plastics and metals, are gaining traction in tire inflation applications. These materials can be engineered to provide the best of both worlds—strength from metals and lightweight properties from plastics.

Pros and Cons of Composites:

The primary advantage of composites is their tailored properties, which can be designed to meet specific performance criteria. However, they can be more expensive to manufacture and may require specialized production techniques.

Illustrative image related to how to inflate a tire

Impatto sull'applicazione:

For international buyers, composites can offer enhanced performance in extreme conditions, making them suitable for diverse markets. Compliance with international standards is crucial, as composites must be tested for their specific applications.

| Materiale | Typical Use Case for how to inflate a tire | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Gomma | Tire valves and seals | Excellent elasticity and flexibility | Si degrada nel tempo | Basso |

| Metallo | Valves and connectors | Elevata resistenza e durata | Più pesante e più costoso | Alto |

| Plastica | Hoses and connectors | Leggero e conveniente | Meno durevole dei metalli | Med |

| Composito | Advanced connectors and hoses | Tailored properties for performance | Higher manufacturing costs | Alto |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in tire inflation systems, helping them make informed decisions that align with their specific market needs and compliance requirements.

The manufacturing processes for tire inflation equipment involve several critical stages that ensure the final product is reliable, efficient, and safe for consumer use.

The first step in the manufacturing process is material preparation. This includes sourcing high-quality raw materials such as rubber, metal, and plastic. Suppliers often conduct extensive due diligence to ensure that materials meet specific standards, such as ISO 9001, which governs quality management systems. For tire inflation hoses and nozzles, materials must also be resistant to wear and environmental factors, including temperature fluctuations and exposure to various chemicals.

Once materials are prepared, they undergo various forming techniques. For rubber components, processes such as extrusion and molding are common. In the case of metal parts, techniques like stamping or machining are utilized. These processes require precision to ensure that the dimensions and tolerances of each part meet design specifications. Advanced technologies such as computer numerical control (CNC) machines are frequently used to enhance accuracy and efficiency.

The assembly stage integrates all manufactured components into a final product. This step is crucial as it ensures that all parts fit correctly and function as intended. Assembly lines often employ a combination of automated systems and skilled labor to maintain quality while maximizing production speed. During this stage, manufacturers may also incorporate features such as built-in pressure gauges or digital displays that improve user experience.

Finishing processes, including painting, coating, and packaging, are essential for enhancing the durability and aesthetics of tire inflation equipment. Coatings may protect against corrosion or UV degradation, which is particularly important for products intended for outdoor use. Quality assurance checks often occur at this stage to ensure that the product meets all visual and functional specifications before it is packaged for distribution.

Quality assurance (QA) is a vital aspect of the manufacturing process, especially for tire inflation devices that are critical for vehicle safety. International standards, such as ISO 9001, provide a framework for consistent quality management.

Manufacturers must comply with various international standards to ensure that their tire inflation products are safe and reliable. ISO 9001, for instance, focuses on continuous improvement and customer satisfaction. Additionally, industry-specific standards like CE marking for European markets or API standards for certain mechanical components may apply, depending on the market. Compliance with these standards not only enhances product credibility but also assures B2B buyers of the manufacturer’s commitment to quality.

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch any defects early on. These checkpoints typically include:

Testing methods vary based on the component but commonly include pressure testing, durability testing, and performance testing. For instance, tire inflation gauges may undergo accuracy testing to ensure they provide precise readings, while hoses might be tested for flexibility and resistance to punctures. Manufacturers may also conduct environmental testing to evaluate how products perform under extreme conditions, which is particularly relevant for international markets with varying climates.

For B2B buyers, ensuring the quality of tire inflation equipment involves several steps:

Buyers should conduct thorough audits of potential suppliers. This may include reviewing their quality management systems, inspecting manufacturing facilities, and evaluating their compliance with international standards. A well-structured audit will help buyers ascertain whether a supplier can consistently deliver high-quality products.

Requesting quality assurance reports is another effective way for buyers to verify a supplier’s commitment to quality. These reports should detail the results of various quality checks, including any non-conformities and corrective actions taken. A transparent report indicates a supplier’s accountability and can provide buyers with confidence in their purchasing decisions.

Engaging third-party inspection services can add an extra layer of assurance. These independent inspectors can evaluate the manufacturing processes and quality control systems of suppliers, offering unbiased assessments. For international buyers, especially those from regions like Africa, South America, and the Middle East, third-party inspections can help navigate local quality standards and ensure compliance with international expectations.

International buyers must be aware of specific nuances when dealing with suppliers across different regions.

Each region may have its own set of standards and regulations governing product quality. For example, European buyers may require CE certification, while buyers in the Middle East may have different regulatory requirements. Understanding these nuances can help buyers avoid compliance issues and ensure that the products they procure are suitable for their markets.

Buyers should also consider the reliability of local supply chains. In regions where infrastructure may be less developed, potential delays or quality issues could arise. Establishing strong relationships with suppliers and maintaining open lines of communication can help mitigate these risks.

In conclusion, the manufacturing processes and quality assurance measures for tire inflation equipment are critical for ensuring product reliability and safety. B2B buyers must conduct due diligence, including audits, quality assurance reports, and potential third-party inspections, to verify the quality of their suppliers. By understanding these processes and standards, buyers can make informed decisions that enhance their operational efficiency and product safety.

The following practical guide serves as a checklist for B2B buyers looking to procure resources or services related to tire inflation. Proper tire maintenance is critical for ensuring vehicle safety, optimizing performance, and minimizing operational costs. This guide outlines essential steps to help you make informed purchasing decisions.

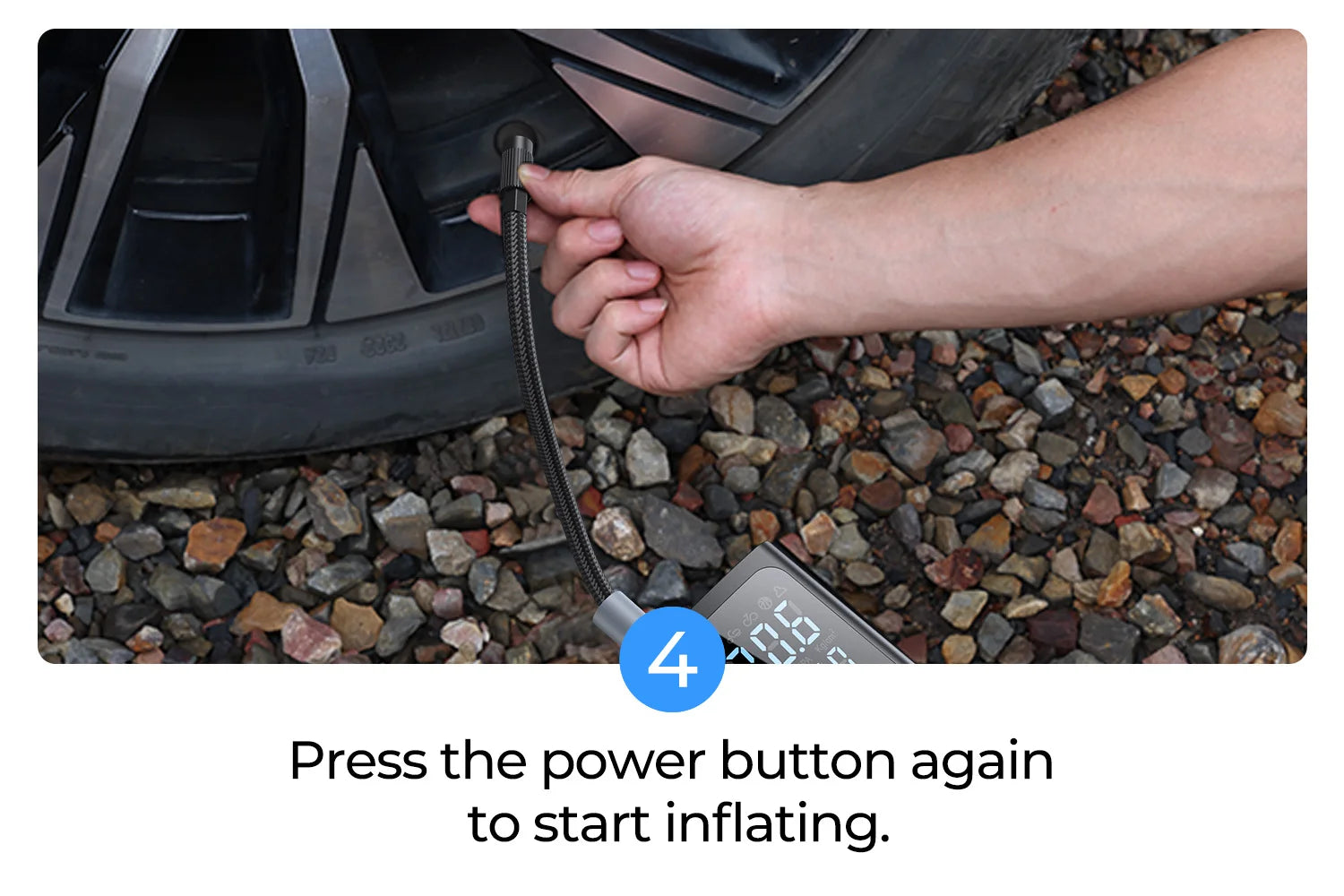

Before exploring suppliers, clearly define what equipment or services you require for tire inflation. This may include air compressors, tire gauges, or nitrogen inflation systems. Understanding your specific needs helps in selecting suppliers who specialize in the necessary products.

Investigate potential suppliers to ensure they meet industry standards and regulations. Look for certifications such as ISO 9001, which indicates a commitment to quality management.

When selecting tire inflation equipment, closely examine the technical specifications of the products. This includes pressure ranges, compatibility with different tire types, and ease of use.

Obtain quotes from multiple suppliers to compare pricing structures. This will help you understand the market rates and identify any hidden costs, such as shipping fees or warranty charges.

After confirming product specifications and pricing, evaluate the level of after-sales support offered by the supplier. This includes warranty terms, maintenance services, and customer service availability.

Ensure that the supplier offers access to spare parts for the equipment you intend to purchase. This is crucial for maintaining the longevity of your tire inflation solutions.

Illustrative image related to how to inflate a tire

If possible, conduct a trial run of the equipment before making a final purchase. This allows you to assess usability and performance in your specific operational environment.

By following this checklist, B2B buyers can make informed decisions when procuring tire inflation equipment and services, ultimately leading to enhanced safety, efficiency, and cost savings in their operations.

When considering the comprehensive cost and pricing analysis for tire inflation sourcing, it is essential to break down the various cost components, pricing influencers, and practical buyer tips. This analysis will provide international B2B buyers with the insights necessary to make informed purchasing decisions, particularly in regions like Africa, South America, the Middle East, and Europe.

I materiali: The primary materials involved in tire inflation include air compressors, inflation hoses, gauges, and accessories like tire valves and caps. The quality of these materials can significantly influence costs. For example, a high-quality inflation gauge may cost more but can provide accurate readings, reducing the risk of over- or under-inflation.

Lavoro: Labor costs encompass the wages paid to workers involved in manufacturing and assembling tire inflation products. In regions with higher labor costs, such as Germany, these expenses can be a significant portion of the overall price.

Spese generali di produzione: This includes costs associated with the operation of manufacturing facilities, such as utilities, rent, and equipment maintenance. Efficient operations can help minimize these costs, making it crucial for suppliers to optimize their manufacturing processes.

Utensili: The initial investment in specialized equipment and tooling for producing tire inflation products can be substantial. These costs are typically amortized over the production volume, which means larger orders can benefit from lower per-unit tooling costs.

Controllo qualità (CQ): Implementing rigorous quality control processes ensures that products meet safety and performance standards. Although this adds to the initial cost, it can prevent costly recalls and enhance brand reputation.

Logistica: Transportation and warehousing costs also play a significant role in the total cost structure. International shipping, tariffs, and handling fees can vary widely based on the shipping terms agreed upon.

Margine: Finally, suppliers will build in a margin that reflects their profitability goals. This can vary based on market competition and perceived value of the product.

Volume/MOQ: Bulk purchasing often leads to significant discounts. Buyers should negotiate minimum order quantities (MOQs) that align with their business needs to achieve cost savings.

Specifiche/Personalizzazione: Customization requests can increase costs. Buyers must balance the need for specific features against the potential for higher prices.

Material Quality/Certifications: Higher-quality materials and certifications (such as ISO standards) often come with increased costs but can provide long-term savings through durability and performance.

Fattori di fornitura: The supplier’s location, reputation, and production capacity can impact pricing. Suppliers with a robust distribution network may offer more competitive shipping rates.

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect overall pricing.

Negoziazione: Engage in negotiations to secure favorable pricing and terms. Building strong relationships with suppliers can lead to better deals and improved service.

Efficienza dei costi: Assess the total cost of ownership (TCO), which includes purchase price, maintenance, and operational costs. Focusing solely on initial costs can lead to higher long-term expenses.

International Pricing Nuances: Be aware of regional market dynamics. For instance, prices in Africa may reflect different economic conditions compared to Europe. Understanding local market conditions can help buyers negotiate better deals.

Quality vs. Price: While lower prices are attractive, they may come with hidden costs related to quality and durability. Always evaluate the long-term benefits of investing in higher-quality products.

Ricerca di mercato: Conduct thorough market research to identify competitive pricing and trends. This knowledge can empower buyers during negotiations and help them make more informed decisions.

Understanding the cost structure and pricing influencers associated with tire inflation sourcing is crucial for international B2B buyers. By focusing on key cost components and implementing effective negotiation strategies, buyers can optimize their purchasing decisions, ensuring both immediate and long-term value. As always, it is advisable to remain vigilant about market trends and supplier reliability to navigate the complexities of international sourcing effectively.

In the realm of tire maintenance, understanding various inflation methods is crucial for optimizing performance and safety. While traditional tire inflation remains a standard practice, several alternative solutions have emerged, each with its unique advantages and drawbacks. This analysis aims to provide B2B buyers with a comprehensive understanding of these alternatives, facilitating informed decisions based on specific operational needs.

| Aspetto di confronto | How To Inflate A Tire | Compressore d'aria portatile | Nitrogen Inflation |

|---|---|---|---|

| Prestazioni | Reliable for standard use | Offers consistent results | Reduces pressure loss |

| Costo | Low (typically free at stations) | Moderate (varies by model) | Higher (specialized service) |

| Facilità di implementazione | Simple and widely accessible | Requires familiarity with device | Requires specialized equipment |

| Manutenzione | Minimal (monthly checks needed) | Moderate (occasional upkeep) | Low (only at service intervals) |

| Il miglior caso d'uso | General consumer use | Emergency roadside assistance | Long-term fleet management |

A portable air compressor is an increasingly popular alternative for tire inflation, particularly for those who frequently travel or operate in remote areas. These devices are compact and can plug into a vehicle’s power outlet, providing convenience at any location. The primary advantage is the ability to inflate tires on demand without needing to visit a gas station. However, users must ensure they understand how to operate the device correctly, as improper use can lead to overinflation or inconsistent pressure levels. Additionally, the upfront cost of purchasing a quality compressor can vary, and ongoing maintenance is required to ensure optimal performance.

Nitrogen inflation involves filling tires with nitrogen gas rather than regular air. The primary benefit of this method is that nitrogen molecules are larger, resulting in slower pressure loss over time. This can lead to improved fuel efficiency and extended tire life, making it a favored option for fleets and high-performance vehicles. However, nitrogen inflation typically requires access to specialized equipment and services, which can be more expensive than traditional inflation methods. Moreover, while nitrogen can enhance tire performance, users must still monitor tire pressure regularly, as leaks can occur.

Selecting the appropriate tire inflation method depends on various factors, including operational requirements, budget constraints, and performance expectations. For businesses prioritizing cost-effectiveness and ease of access, traditional tire inflation remains a viable choice. In contrast, companies seeking enhanced tire longevity and performance may find nitrogen inflation or portable air compressors to be advantageous. Ultimately, evaluating the specific needs of your fleet or operations will guide you toward the most suitable tire inflation solution, ensuring safety, efficiency, and cost savings.

When inflating tires, several critical specifications play a pivotal role in ensuring optimal performance, safety, and longevity. Understanding these properties is essential for B2B buyers involved in the automotive or tire service sectors.

Recommended Tire Pressure (PSI)

This specification indicates the optimal air pressure for a tire, typically measured in pounds per square inch (PSI). Maintaining the correct PSI is crucial as it affects vehicle handling, fuel efficiency, and tire wear. For B2B buyers, adhering to manufacturer-recommended pressures can lead to reduced operational costs and enhanced safety.

Temperature Sensitivity

Tire pressure can fluctuate with temperature changes, losing approximately 1 PSI for every 10°F increase. This property is vital for businesses operating in regions with extreme weather conditions. Understanding temperature sensitivity helps in implementing regular pressure checks, ensuring tire performance is not compromised.

Valve Quality and Type

The tire valve is critical for maintaining air pressure and preventing moisture ingress. The quality of the valve impacts the tire’s ability to retain air and resist leaks. For B2B buyers, sourcing high-quality valves can reduce maintenance costs and improve safety across fleets.

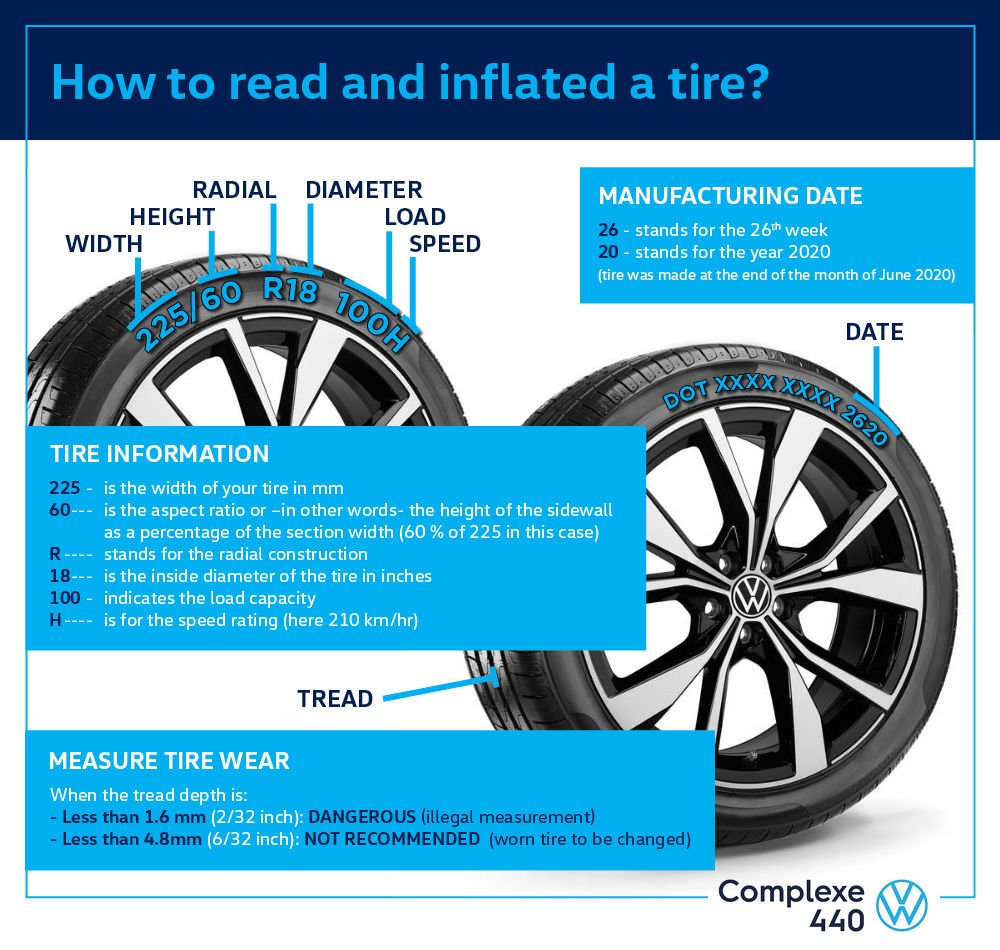

Tread Depth and Wear Indicators

While not directly related to inflation, the tread depth of a tire impacts its overall performance. Tires with insufficient tread depth can lead to hazardous driving conditions, especially in wet weather. B2B buyers should prioritize tires with clear wear indicators to ensure optimal safety and performance.

Composizione del materiale

The materials used in tire construction, such as rubber compounds and fabric layers, influence air retention and durability. Understanding the material grades can assist B2B buyers in selecting tires that offer longevity and performance suited to specific applications, such as commercial vehicles or passenger cars.

Familiarity with industry terminology is essential for effective communication and decision-making in the tire inflation market. Here are some common terms that B2B buyers should understand:

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of tires, it is crucial for buyers to know whether they are purchasing OEM tires or aftermarket options, as this affects compatibility and warranty considerations.

MOQ (quantità minima d'ordine)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory effectively and ensure they meet their operational needs without overcommitting resources.

RFQ (Richiesta di offerta)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. For tire inflation equipment and services, issuing an RFQ can facilitate competitive pricing and help buyers make informed purchasing decisions.

Incoterms (Termini commerciali internazionali)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Knowing Incoterms is essential for B2B buyers to understand shipping responsibilities, risk management, and cost implications associated with tire procurement.

Tire Pressure Monitoring System (TPMS)

This system uses sensors to monitor tire pressure and alert drivers when it falls below the recommended level. For businesses managing fleets, implementing TPMS can enhance safety and reduce tire-related incidents.

Calibration

Calibration refers to the process of verifying and adjusting the accuracy of tire pressure gauges or inflation systems. For B2B buyers, ensuring that equipment is properly calibrated is crucial to prevent errors in tire pressure readings, which can lead to safety issues and increased operational costs.

Understanding these properties and terms can empower B2B buyers to make informed decisions regarding tire inflation, ultimately enhancing the safety and efficiency of their operations.

The tire inflation sector is experiencing transformative shifts driven by technological advancements and increasing consumer awareness regarding vehicle safety and fuel efficiency. Globally, the demand for proper tire maintenance has surged, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Key drivers include rising fuel prices, growing vehicle ownership, and the increasing importance of sustainability in transportation.

Illustrative image related to how to inflate a tire

In terms of technology, innovations such as smart tire pressure monitoring systems (TPMS) and automated inflation systems are gaining traction. These technologies allow for real-time monitoring of tire pressure, alerting drivers to any deviations from the recommended levels. Moreover, mobile applications that facilitate tire maintenance and provide reminders for pressure checks are becoming common. In regions like Nigeria and Germany, where road conditions can be challenging, the adoption of portable tire inflation compressors is also on the rise, allowing users to inflate tires conveniently at home or on the go.

Another emerging trend is the focus on nitrogen inflation, which is gaining popularity due to its benefits, including reduced pressure loss and enhanced tire longevity. B2B buyers are increasingly sourcing equipment that supports these innovations, ensuring that their offerings align with modern consumer expectations and regulatory requirements.

Sustainability is becoming a critical factor in the tire inflation market, as businesses and consumers alike prioritize environmental responsibility. The tire industry has a significant environmental impact, from the extraction of raw materials to the end-of-life disposal of tires. As such, B2B buyers are increasingly looking for partners who demonstrate a commitment to ethical sourcing and sustainability.

One key area of focus is the use of environmentally friendly materials in tire production and inflation systems. Manufacturers are exploring the use of biodegradable materials and recycled components to minimize their carbon footprint. Additionally, green certifications, such as ISO 14001, are becoming essential for suppliers aiming to prove their environmental stewardship.

Illustrative image related to how to inflate a tire

Ethical supply chains are also gaining importance, with buyers seeking transparency in sourcing practices. This includes ensuring that raw materials are obtained without exploiting labor or harming local ecosystems. By choosing suppliers that prioritize sustainable practices, businesses can enhance their brand reputation and appeal to eco-conscious consumers, thereby creating a competitive advantage in the marketplace.

The evolution of tire inflation techniques has mirrored advancements in automotive technology and consumer expectations. Historically, tire inflation was a manual process, often relying on hand pumps and basic gauges. The introduction of compressed air systems marked a significant shift, making it easier and quicker to inflate tires.

In the late 20th century, the development of automatic tire inflation systems began to change the landscape. These systems, which could maintain optimal pressure without driver intervention, became particularly popular in commercial fleets due to their efficiency and safety benefits.

Today, the focus is on integrating digital technologies, such as TPMS and mobile applications, into tire maintenance. These innovations not only facilitate better tire management but also contribute to fuel efficiency and enhanced safety, reflecting the ongoing evolution towards smarter, more sustainable automotive solutions. As the market continues to develop, B2B buyers are encouraged to stay abreast of these trends to ensure their offerings remain relevant and competitive.

How do I solve the problem of underinflated tires?

To address underinflated tires, regularly check the tire pressure using a calibrated gauge. If you find the pressure is below the manufacturer’s recommended level, inflate the tires using an air compressor or at a service station. It’s crucial to monitor tire pressure monthly, especially in regions with extreme temperature variations that can cause air loss. Additionally, educate your team on the risks of underinflation, such as reduced fuel efficiency and increased tire wear, to ensure consistent maintenance practices.

What is the best method for inflating tires in different climates?

In warmer climates, check tire pressure in the morning when temperatures are cooler. For cold regions, adjust tire pressure to accommodate for temperature fluctuations, adding approximately 0.3 bar (4.35 PSI) if checking when warm. Ensure your staff is trained to recognize how temperature affects tire pressure, as this knowledge is vital for maintaining optimal tire performance and safety across diverse environments.

How can I ensure the quality of tire inflation equipment when sourcing suppliers?

When vetting suppliers for tire inflation equipment, prioritize those who provide detailed specifications and compliance certifications for their products. Request samples and conduct quality checks to verify the durability and accuracy of the equipment. Additionally, consider suppliers with a proven track record in your region to ensure they understand local standards and requirements, which can help mitigate risks associated with equipment failure.

What are the minimum order quantities (MOQ) for tire inflation products?

MOQs can vary significantly by supplier, often depending on the type of equipment and the supplier’s production capabilities. For bulk purchases, negotiate terms that align with your business needs, considering both immediate requirements and future demand. It’s advisable to discuss flexibility in order sizes to accommodate fluctuations in your inventory needs, especially in international markets.

What payment terms are standard for international tire inflation equipment purchases?

Standard payment terms can range from upfront payments to net 30 or net 60 days after delivery. When engaging with international suppliers, confirm their preferred payment methods, which may include letters of credit, wire transfers, or escrow services. Understanding these terms upfront can help manage cash flow effectively and build trust with your suppliers.

How can I customize tire inflation solutions for my specific business needs?

Customization options often depend on the supplier’s capabilities. Engage in discussions about your specific requirements, such as portable tire inflation systems or specialized gauges for different vehicle types. Request prototypes or mock-ups if possible, and establish clear communication channels for feedback throughout the development process to ensure the final product meets your expectations.

What logistics considerations should I be aware of when importing tire inflation equipment?

When importing tire inflation equipment, consider shipping costs, customs duties, and the reliability of logistics partners. Ensure that your supplier is experienced in handling international shipping and can provide documentation needed for customs clearance. It’s also beneficial to discuss lead times and potential delays to effectively plan inventory management and avoid stock shortages.

How can I maintain tire inflation equipment to ensure longevity and performance?

Regular maintenance of tire inflation equipment is essential for optimal performance. Schedule routine inspections to check for wear and tear, and ensure all components, such as hoses and gauges, are functioning correctly. Train your staff on proper usage and storage procedures to prevent damage. Keeping a maintenance log can also help identify recurring issues, enabling proactive solutions before they escalate.

Dominio: michelinman.com

Registrato: 2001 (24 anni)

Introduzione: Michelin offers a complete range of tires for various mobility needs, including passenger cars, SUVs, light commercial vehicles, and electric/hybrid vehicles. Their tire selection includes categories such as durability, confidence, sport, winter, and efficiency. Michelin’s product families include CrossClimate, Defender, Pilot Sport, Primacy, LTX, X Ice, Energy™, Latitude Sport, Pilot Alpin, and P…

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: This company, Reddit – Tire Pressure Compressor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: facebook.com

Registrato: 1997 (28 anni)

Introduzione: This company, Facebook – Social Media Platform, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In the realm of tire maintenance, strategic sourcing plays a pivotal role in ensuring operational efficiency and safety for businesses across diverse sectors. By prioritizing the procurement of high-quality inflation equipment and reliable tire service providers, B2B buyers can significantly enhance their fleet management practices. This not only extends the lifespan of tires but also contributes to improved fuel efficiency and safety on the roads, reducing the total cost of ownership.

Moreover, understanding the nuances of tire pressure management—such as the importance of checking pressure regularly and utilizing calibrated gauges—empowers businesses to minimize risks associated with under- or over-inflated tires. With variations in climate and terrain across regions like Africa, South America, the Middle East, and Europe, tailored strategies for tire inflation become critical for optimizing vehicle performance in diverse conditions.

As we look ahead, international B2B buyers are encouraged to invest in innovative tire maintenance solutions, including portable compressors and nitrogen inflation services. By doing so, businesses can not only improve operational reliability but also position themselves as leaders in sustainable practices. Embrace these insights to foster a culture of safety and efficiency, ultimately driving your business forward.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.