In the dynamic landscape of international trade, sourcing the right manual air pump can pose a significant challenge for B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. This guide aims to illuminate the complexities surrounding the procurement of manual air pumps, offering insights into various types, applications, and supplier vetting processes that are essential for making informed purchasing decisions.

Manual air pumps are indispensable tools across multiple industries, from advertising to recreational activities, making it crucial for businesses to understand their specific needs and the advantages each type offers. With a focus on practical applications, this guide delves into the nuances of selecting the right pump based on intended use, whether for inflating promotional items like inflatable tents or for personal use in outdoor adventures.

Moreover, this comprehensive resource equips buyers with critical knowledge about cost considerations, supplier reliability, and market trends, enabling them to navigate the global marketplace with confidence. By addressing common pain points and providing actionable strategies, this guide empowers international B2B buyers, particularly those from Nigeria and Brazil, to optimize their sourcing processes and enhance operational efficiency.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Pompa a mano | Simple design, manual operation, portable | Sports equipment, inflatable products, camping gear | Pro: Cost-effective, lightweight. Contro: Ad alta intensità di lavoro, inflazione più lenta. |

| Foot Pump | Operated by foot, larger volume of air per stroke | Kayaking, water sports, air mattresses | Pro: Faster inflation, hands-free operation. Contro: Requires physical effort, bulkier. |

| Dual Action Pump | Inflates on both up and down strokes | Inflatable decorations, event setups | Pro: Efficient air transfer, quicker inflation. Contro: Slightly more complex design, higher cost. |

| Electric-Manual Hybrid | Combines manual pumping with electric assist | Large inflatables, commercial-grade applications | Pro: Reduces effort, faster inflation. Contro: Higher cost, requires power source. |

| Specialty Pumps | Designed for specific applications (e.g., balloons) | Event planning, party supplies | Pro: Tailored functionality, precise inflation. Contro: Limited versatility, can be expensive. |

Hand pumps are the most basic type of manual air pump, characterized by their straightforward design that requires manual operation. They are lightweight and portable, making them ideal for various applications, including sports equipment and camping gear. For B2B buyers, the primary consideration is cost-effectiveness; however, the labor-intensive nature of hand pumps may not be suitable for larger or more frequent inflation tasks. Businesses with limited budgets or those requiring occasional use may find hand pumps advantageous.

Foot pumps operate via foot action, enabling users to inflate items more quickly and with less manual effort than hand pumps. They are particularly useful in industries related to water sports and camping, where larger volumes of air are needed for kayaks or air mattresses. Buyers should note that while foot pumps are more efficient, they can be bulkier and may require physical exertion. Companies focusing on efficiency may prefer foot pumps for their faster inflation capabilities.

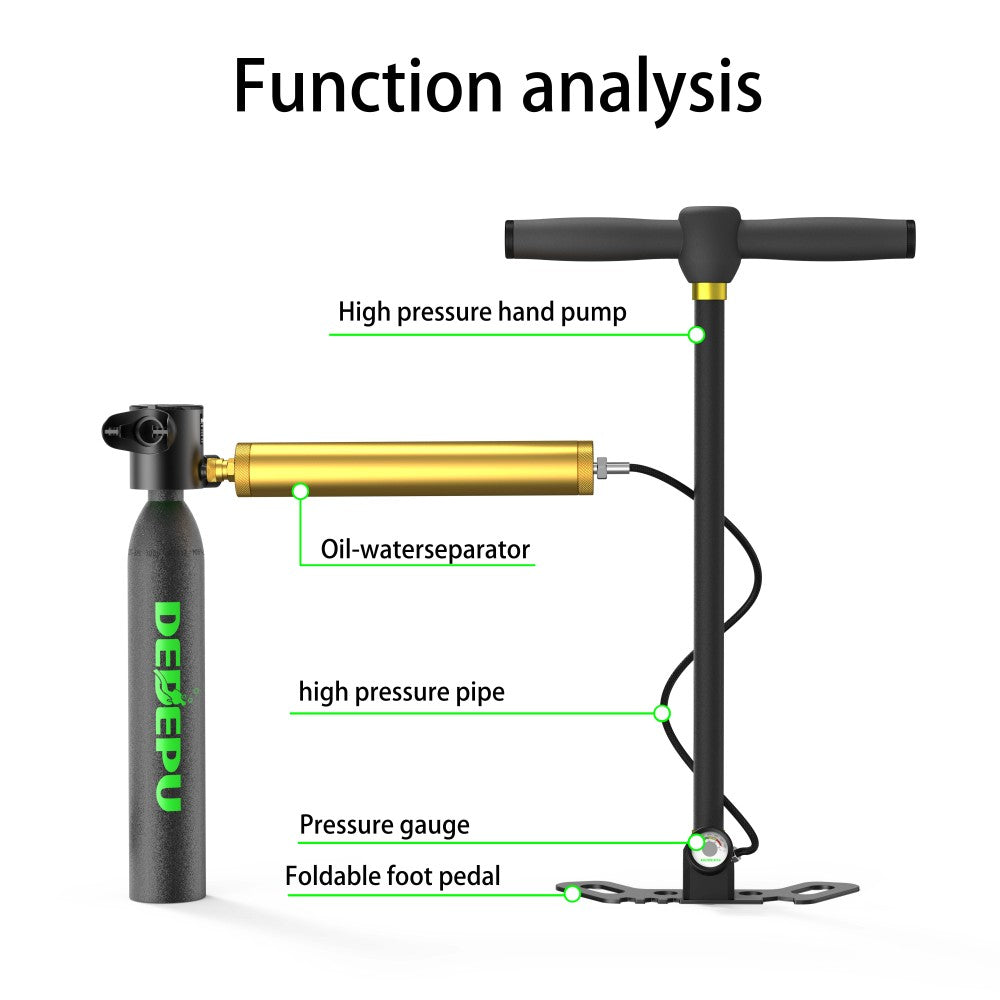

Illustrative image related to manual air pump

Dual action pumps are designed to inflate on both the upward and downward strokes, maximizing air transfer efficiency. This feature makes them suitable for inflating decorations and setups for events, where time is often of the essence. B2B buyers looking for quick inflation solutions will appreciate the speed and efficiency of dual action pumps. However, they come with a slightly higher price tag and more complex design, which should be considered when making purchasing decisions.

Electric-manual hybrid pumps combine the benefits of manual pumping with electric assistance, catering to larger inflatables and commercial-grade applications. They significantly reduce the physical effort required for inflation, making them an attractive option for businesses that frequently deal with large items. While they offer faster inflation times, buyers should be aware of the higher costs and the necessity for a power source, which can limit their use in certain environments.

Specialty pumps are tailored for specific applications, such as inflating balloons or unique event decorations. They provide precise control over the inflation process, making them ideal for businesses in event planning and party supply sectors. While they offer specialized functionality, their limited versatility and potentially higher costs compared to general-purpose pumps should be factored into purchasing decisions. B2B buyers should evaluate their specific needs to determine if the investment in specialty pumps aligns with their operational goals.

| Industria/Settore | Specific Application of Manual Air Pump | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Gestione degli eventi | Inflating promotional inflatables and tents | Quick setup and flexibility for outdoor events | Durability, portability, and compatibility with various inflatables. |

| Automotive | Tire inflation for vehicles and machinery | Ensures safety and operational efficiency | Pressure accuracy, ease of use, and ruggedness for field use. |

| Sports & Recreation | Inflating sports equipment like balls and boats | Enhances user experience and equipment readiness | Size compatibility, inflation speed, and ease of transport. |

| Produzione | Inflating packaging and protective materials | Protects products during transit and storage | Material quality, inflation speed, and reliability under various conditions. |

| Agricoltura | Inflating farm machinery tires and equipment | Reduces downtime and maintenance costs | Adaptability to various tire sizes and manual operation ease. |

In the event management sector, manual air pumps are essential for inflating promotional inflatables, such as archways and tents, quickly and efficiently. These pumps allow event planners to set up engaging environments for exhibitions and outdoor festivals without relying on electrical power sources. The ability to inflate large structures manually ensures flexibility in remote locations, which is particularly advantageous in regions like Africa and South America where power supply may be inconsistent. Buyers should consider the pump’s durability and portability, ensuring it can withstand repeated use in various conditions.

In the automotive industry, manual air pumps are invaluable for tire inflation, particularly in regions where automated solutions may not be readily available. These pumps enable users to maintain proper tire pressure, which is crucial for vehicle safety and efficiency. For international buyers, especially in the Middle East and Africa, the ability to manually inflate tires can significantly reduce downtime during long-distance travel. Key considerations include the pump’s pressure accuracy and its ruggedness, which is vital for use in challenging terrains.

Manual air pumps find significant applications in the sports and recreation sector, where they are used to inflate balls, inflatable boats, and other sporting equipment. Ensuring that equipment is ready for use enhances the overall user experience and promotes safety during activities. For businesses in Europe and South America, sourcing pumps that are compact and easy to transport can facilitate quick setups for events and recreational activities. Buyers should look for pumps that offer compatibility with various sizes of equipment and efficient inflation speeds.

In manufacturing, manual air pumps are utilized for inflating packaging materials and protective structures that safeguard products during transportation. This application is crucial for maintaining product integrity and reducing damage costs. Businesses in diverse regions, including Africa and South America, benefit from manual pumps as they offer a cost-effective solution without the need for electrical power. When sourcing, companies should prioritize the quality of materials used in the pump, inflation speed, and reliability under different environmental conditions.

In agriculture, manual air pumps are essential for inflating tires on farm machinery and equipment. This capability is crucial for reducing downtime, ensuring that farmers can maintain their operations efficiently. In regions with limited access to electricity, such as rural areas in Africa and South America, manual pumps provide a reliable solution for tire maintenance. Buyers should focus on the pump’s adaptability to various tire sizes and its ease of operation, which can significantly impact productivity in agricultural settings.

Il problema: B2B buyers often encounter manual air pumps that are not ergonomically designed, leading to inefficient inflation processes. This inefficiency can result in excessive physical strain on workers, reduced productivity, and delays in setup times for events or installations. For instance, companies that rely on inflatable advertising, such as large promotional tents or displays, may find that a poorly designed pump leads to frustration and wasted labor hours, ultimately affecting their bottom line.

La soluzione: To mitigate this issue, buyers should prioritize sourcing manual air pumps that feature ergonomic designs, such as those with comfortable grips and optimal pumping mechanisms. When evaluating options, look for pumps with features like dual-action functionality, which allows air to be pushed into the inflatable on both the up and down strokes. This design significantly decreases the time and effort required for inflation. Additionally, investing in high-quality pumps from reputable manufacturers can ensure longevity and reliability, reducing the frequency of replacements and maintenance.

Illustrative image related to manual air pump

Il problema: Another common pain point for B2B buyers is the challenge of achieving the correct air pressure for inflatables. Insufficient or excessive inflation can compromise the integrity of the product, leading to safety hazards or unappealing presentations. For businesses that depend on inflatable structures for events, such as trade shows or festivals, improper inflation can result in damage, lost revenue, and a tarnished reputation.

La soluzione: To address this concern, B2B buyers should consider manual air pumps that include built-in pressure gauges. These gauges allow users to monitor inflation levels accurately, ensuring that inflatables are neither under-inflated nor over-inflated. Furthermore, it is advisable to train staff on the recommended inflation levels for each specific inflatable product. Establishing clear guidelines and using pumps equipped with pressure indicators will help maintain product quality and safety standards.

Il problema: Many manual air pumps are bulky and not designed with portability in mind, creating logistical challenges for B2B buyers. Companies that transport equipment for events or installations often struggle to find a convenient and compact solution for storing and carrying their pumps. This issue can lead to additional shipping costs or the risk of damage during transport, which can be particularly detrimental for businesses operating across regions in Africa, South America, or the Middle East.

La soluzione: To solve this problem, buyers should seek out compact, lightweight manual air pumps that can easily fit into transport cases or vehicle trunks. Look for pumps that can be disassembled or collapsed for storage without compromising performance. Additionally, consider investing in transport bags specifically designed for air pumps, which can offer protection during transit. By prioritizing portability and protective storage solutions, companies can streamline their logistics and ensure their equipment remains in excellent condition, ready for use whenever needed.

When selecting materials for manual air pumps, it’s essential to consider the properties and performance characteristics of each option. The choice of material can significantly impact the pump’s durability, efficiency, and suitability for specific applications. Here, we analyze four common materials used in the construction of manual air pumps: plastic, aluminum, steel, and rubber.

Illustrative image related to manual air pump

Plastic, particularly high-density polyethylene (HDPE) and polypropylene, is frequently used in manual air pumps due to its lightweight nature and resistance to corrosion. These materials typically have a temperature rating of -40°C to 80°C and can withstand moderate pressure levels.

Pro: Plastic is cost-effective and easy to mold into complex shapes, which simplifies manufacturing processes. Additionally, it is resistant to a variety of chemicals, making it suitable for various applications.

Contro: While plastic is durable, it may not withstand extreme temperatures or pressures as effectively as metals. Over time, UV exposure can lead to degradation, especially in outdoor applications.

Impatto sull'applicazione: Plastic is compatible with air and non-corrosive gases, making it ideal for inflating lightweight items like inflatable toys or air mattresses.

Considerazioni per gli acquirenti internazionali: Compliance with international standards such as ASTM and ISO is crucial. Buyers should ensure that the plastic used meets safety and environmental regulations in their respective regions, especially in countries with strict import policies.

Aluminum is another popular choice for manual air pumps due to its excellent strength-to-weight ratio and resistance to corrosion. It can handle higher pressures, typically up to 150 psi, and operates effectively in a temperature range of -40°C to 120°C.

Pro: Aluminum is lightweight yet robust, making it suitable for portable applications. It also has good thermal conductivity, which can be beneficial in certain applications.

Illustrative image related to manual air pump

Contro: While aluminum is more durable than plastic, it is generally more expensive. It may also require additional surface treatment to enhance corrosion resistance, particularly in humid environments.

Impatto sull'applicazione: Aluminum pumps are ideal for applications requiring higher pressure and durability, such as inflating sports equipment or commercial-grade inflatable structures.

Considerazioni per gli acquirenti internazionali: Buyers should verify that aluminum components comply with local standards, such as EN or ASTM, to ensure product reliability and safety.

Steel, particularly stainless steel, is known for its exceptional strength and durability. It can handle high pressures, often exceeding 200 psi, and operates effectively in extreme temperatures ranging from -50°C to 150°C.

Pro: Steel is highly durable and resistant to wear and tear, making it suitable for heavy-duty applications. It also has excellent resistance to corrosion when treated or alloyed properly.

Contro: The primary drawback of steel is its weight, which can make pumps less portable. Additionally, steel is generally more expensive than plastic and aluminum.

Impatto sull'applicazione: Steel pumps are ideal for industrial applications where high pressure and durability are essential, such as in automotive or construction settings.

Considerazioni per gli acquirenti internazionali: Compliance with international standards such as JIS and ASTM is critical. Buyers should also consider the implications of shipping heavier steel products, which may increase logistics costs.

Rubber is often used in seals and gaskets within manual air pumps to ensure airtight performance. It can withstand a temperature range of -30°C to 90°C and provides excellent flexibility and resilience.

Pro: Rubber seals enhance the longevity of the pump by preventing air leaks. It is also relatively inexpensive and easy to manufacture.

Illustrative image related to manual air pump

Contro: Rubber can degrade over time, especially when exposed to UV light or extreme temperatures. It may also not be suitable for high-pressure applications.

Impatto sull'applicazione: Rubber is critical for ensuring efficient operation in applications where maintaining air pressure is essential, such as in inflatable products.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that rubber components meet relevant safety and environmental regulations, particularly in regions with stringent compliance requirements.

| Materiale | Typical Use Case for Manual Air Pump | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Plastica | Inflating lightweight items like toys | Leggero e conveniente | Limited pressure tolerance | Basso |

| Alluminio | Sports equipment and commercial inflatables | Elevato rapporto resistenza/peso | Higher cost, requires treatment | Medio |

| Acciaio | Industrial applications requiring high pressure | Durata eccezionale | Heavy and expensive | Alto |

| Gomma | Seals and gaskets for airtight performance | Excellent flexibility and resilience | Si degrada nel tempo | Basso |

This material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance requirements and regional compliance standards.

Illustrative image related to manual air pump

The manufacturing of manual air pumps involves several critical stages, each contributing to the final product’s quality and performance. Understanding these stages helps B2B buyers appreciate the complexities involved and make informed purchasing decisions.

The first step in the manufacturing process is material preparation. Manual air pumps are typically constructed from durable plastics, rubber, and metals like aluminum or steel. Each material is selected for its specific properties:

These materials undergo rigorous quality checks to ensure they meet industry specifications. Sourcing materials from reputable suppliers with certifications can significantly reduce risks related to performance and safety.

The forming stage involves shaping the prepared materials into the required components of the manual air pump. This can include processes such as:

Each method is chosen based on the material and the specific component’s design, balancing efficiency and quality.

Once the components are formed, they move to the assembly line. This stage is crucial as it combines various parts into a functioning product. Key assembly techniques include:

During assembly, it’s essential to ensure that all components fit correctly and function as intended. Any misalignment can lead to performance issues in the final product.

The finishing stage enhances the pump’s appearance and protects it from environmental factors. Common finishing processes include:

A well-finished product not only performs better but also attracts buyers who value quality and durability.

Quality assurance (QA) is vital throughout the manufacturing process to ensure that the final product meets international standards and customer expectations.

For B2B buyers, understanding the relevant quality standards is crucial. Key standards include:

These certifications provide assurance that the products have undergone rigorous testing and meet specific safety and performance criteria.

Illustrative image related to manual air pump

Quality control checkpoints are essential to maintaining high standards throughout the manufacturing process. Common checkpoints include:

These checkpoints allow manufacturers to catch defects early, ensuring that only high-quality products reach the market.

Testing is a critical component of quality assurance. Common methods include:

These testing methods provide valuable insights into the product’s quality and longevity.

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure they receive reliable products. Here are some strategies:

Regular audits of suppliers can help buyers assess their quality control practices. These audits should include:

Suppliers should provide comprehensive quality reports that detail their QC processes, inspection results, and testing methods. These reports should include:

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These organizations can conduct:

By implementing these strategies, B2B buyers can mitigate risks associated with purchasing manual air pumps from international suppliers, ensuring they receive high-quality products that meet their operational needs.

Understanding the manufacturing processes and quality assurance measures for manual air pumps is critical for B2B buyers. By familiarizing themselves with the key stages of production and the relevant quality control standards, buyers can make informed decisions that lead to successful procurement and long-term satisfaction with their purchases. This knowledge is particularly valuable for buyers in diverse regions such as Africa, South America, the Middle East, and Europe, where varying standards and practices may apply.

In the competitive landscape of B2B procurement, having a clear and structured approach to sourcing manual air pumps is essential for ensuring quality and reliability. This guide provides a step-by-step checklist designed specifically for international buyers looking to navigate the complexities of procurement.

Establishing clear technical specifications is crucial to ensure that the manual air pumps meet your operational needs. Consider factors such as size, pressure capacity, material durability, and intended use. For instance, if the pumps are to be used for inflating large outdoor equipment, ensure they can deliver the necessary airflow and pressure efficiently.

Conduct thorough research to identify suppliers that specialize in manual air pumps. Utilize online platforms, industry directories, and trade shows to compile a list of potential vendors. Focus on suppliers with experience in your region, as they may better understand local market demands and logistics.

Before proceeding with any supplier, it is imperative to verify their certifications and compliance with international standards. Look for ISO certifications or other relevant quality assurance endorsements. This step helps mitigate risks associated with product quality and ensures that the pumps meet safety and performance regulations.

Once you have shortlisted potential suppliers, request product samples to evaluate their quality firsthand. Testing the samples allows you to assess the functionality and durability of the pumps. Pay attention to aspects such as ease of use, build quality, and the effectiveness of inflation.

Pricing can vary significantly between suppliers, so it’s important to conduct a comparative analysis. Ensure that the quoted prices reflect the quality of the product and include all associated costs, such as shipping and customs duties. Additionally, clarify payment terms to avoid any potential disputes later.

Before making a final decision, seek customer reviews and testimonials regarding the suppliers you are considering. Contact previous clients to gain insights into their experiences and the reliability of the supplier. Positive feedback from similar businesses can indicate a trustworthy partner.

Once you have selected a supplier, ensure that all terms are clearly documented in a formal contract. This should include delivery timelines, warranties, and return policies. Having a well-defined agreement protects both parties and establishes expectations for the procurement process.

By following these steps, B2B buyers can effectively navigate the sourcing process for manual air pumps, ensuring they select a supplier that meets their needs while minimizing risks associated with procurement.

When sourcing manual air pumps, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

I materiali: The choice of materials, such as high-quality plastics, metals, or rubber, significantly impacts the overall cost. For instance, pumps made from durable materials tend to have higher upfront costs but can offer better longevity and performance, making them more cost-effective over time.

Lavoro: Labor costs can vary based on the manufacturing location. Regions with lower wage rates may offer more competitive pricing, but this can also affect quality. It is essential to balance cost with the expertise of the workforce in producing high-quality air pumps.

Spese generali di produzione: This encompasses all indirect costs related to production, including utilities, rent, and equipment maintenance. Suppliers often factor these expenses into the unit price, so it’s wise to inquire about the specifics when negotiating.

Utensili: If custom molds or equipment are required for specific designs, these costs can add substantially to the initial investment. Understanding the tooling costs associated with your order is vital, especially for customized products.

Controllo qualità (CQ): Rigorous QC processes ensure that products meet specified standards. Suppliers may charge extra for enhanced QC measures, which is particularly important for international shipments where compliance with local regulations is necessary.

Logistica: Shipping costs can vary greatly depending on the supplier’s location, delivery method, and the final destination. International buyers should consider customs duties, tariffs, and insurance, which can significantly influence the total cost.

Margine: Suppliers will typically include their profit margin in the pricing. Understanding the expected margins in your industry can help you gauge whether you’re receiving a fair price.

Several factors can influence the pricing of manual air pumps:

Volume/MOQ: Higher order volumes often lead to reduced per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can also impact negotiation strategies.

Specifiche e personalizzazione: Custom features or specific technical requirements can increase costs. Buyers should clearly communicate their specifications to avoid unexpected expenses.

Materiali e certificazioni di qualità: Products that meet international quality certifications (e.g., ISO) may carry higher costs but provide assurance of reliability and safety, which is particularly important in regulated markets.

Fattori di fornitura: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge a premium but could save buyers from potential issues down the line.

Incoterms: Understanding the Incoterms (International Commercial Terms) involved in the transaction can clarify who is responsible for shipping, insurance, and tariffs, which directly affects the total landed cost.

To maximize cost-efficiency when sourcing manual air pumps, consider the following tips:

Negotiate Wisely: Build relationships with suppliers and engage in negotiations that explore bulk discounts, long-term contracts, or favorable payment terms.

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational costs, and potential savings from high-quality pumps. This holistic view can lead to better decision-making.

Understand Pricing Nuances for International Purchases: Be aware of potential hidden costs such as currency fluctuations, import duties, and shipping delays, which can affect the overall budget.

Research Local Regulations: Different regions may have varying compliance requirements. Understanding these can prevent costly mistakes and ensure smooth import processes.

It’s essential to note that prices can fluctuate based on market conditions, supplier negotiations, and other external factors. Always request updated quotes and conduct thorough market research to ensure you receive competitive pricing tailored to your specific needs.

Illustrative image related to manual air pump

When considering air inflation solutions for business operations, it’s essential to evaluate various options available in the market. While manual air pumps are a popular choice due to their simplicity and reliability, alternative solutions may offer enhanced efficiency or adaptability for specific use cases. This section compares manual air pumps with electric air pumps and CO2 inflators, providing insights into their respective advantages and disadvantages.

| Aspetto di confronto | Manual Air Pump | Pompa dell'aria elettrica | Gonfiatore di CO2 |

|---|---|---|---|

| Prestazioni | Moderate inflation speed; requires physical effort | High inflation speed; automated operation | Instant inflation; limited to small items |

| Costo | Low initial investment | Moderate to high cost | Variable cost based on CO2 cartridge use |

| Facilità di implementazione | Simple setup; no power source needed | Requires power source; easy to operate | Requires CO2 cartridges; portable |

| Manutenzione | Minimal; occasional cleaning | Moderate; check for wear and tear | Basso; sostituire le cartucce quando necessario |

| Il miglior caso d'uso | Ideal for occasional, low-volume tasks | Suitable for frequent, high-volume inflation | Best for quick, portable needs, like sports equipment |

Electric air pumps provide a significant advantage in terms of performance, as they can inflate items rapidly with minimal physical effort. This makes them an excellent choice for businesses that require frequent and quick inflation, such as event organizers or rental companies. However, their dependency on a power source can be a limitation in remote locations or outdoor events where electricity might not be readily available. Additionally, the initial investment cost for electric pumps is generally higher than that of manual pumps, which can be a deterrent for smaller businesses or those with limited budgets.

CO2 inflators excel in scenarios where quick inflation is necessary, such as for sports balls or small inflatable items. They offer a level of portability that electric and manual pumps cannot match, making them ideal for on-the-go applications. The immediate inflation capability is a significant advantage; however, the recurring cost of CO2 cartridges can add up over time, particularly for businesses that require extensive use. Furthermore, CO2 inflators are not suitable for larger items, limiting their application scope.

Illustrative image related to manual air pump

Choosing the right air inflation solution depends heavily on the specific needs and circumstances of your business. Manual air pumps are cost-effective and reliable for infrequent, low-volume tasks. Electric air pumps are ideal for businesses that need speed and efficiency but require a power source. CO2 inflators serve niche markets where portability and quick inflation are essential. By carefully assessing your operational requirements, budget constraints, and use cases, you can select the most suitable option that aligns with your business goals.

When considering a manual air pump for B2B applications, understanding its technical specifications is crucial for ensuring reliability and performance. Here are some essential properties to evaluate:

The material used in the construction of a manual air pump significantly affects its durability and performance. Common materials include high-density polyethylene (HDPE) and aluminum. HDPE is lightweight and resistant to corrosion, making it suitable for outdoor use, while aluminum offers strength and a longer lifespan. For B2B buyers, selecting the right material ensures the pump can withstand frequent use and varying environmental conditions.

This specification indicates the volume of air the pump can deliver per stroke, usually measured in liters or cubic centimeters. A higher capacity means quicker inflation times, which is essential for businesses that need to inflate multiple items efficiently, such as inflatable advertising or sports equipment. Understanding pump capacity helps B2B buyers match the pump to their specific operational needs.

The weight of the manual air pump affects its portability. Lightweight models are easier to transport and store, which is particularly important for companies that operate in multiple locations or require mobility for events. B2B buyers should consider the balance between weight and durability, ensuring that they select a model that is both easy to handle and robust enough for their applications.

The maximum pressure a manual air pump can achieve, typically measured in PSI (pounds per square inch), is a critical specification. Pumps with higher pressure ratings can inflate larger and more robust items, making them suitable for a wider range of applications. For B2B buyers, knowing the pressure rating helps in selecting pumps that meet the specific requirements of their products.

The design of the pump handle and overall structure plays a vital role in user comfort and efficiency. Ergonomic designs reduce strain during operation, which is particularly beneficial for frequent use. B2B buyers should prioritize pumps that offer comfort features, as they can lead to increased productivity and reduced employee fatigue.

Familiarity with industry terminology is essential for effective communication in B2B transactions. Here are several key terms relevant to manual air pumps:

Illustrative image related to manual air pump

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of manual air pumps, buyers may work directly with OEMs for customized products or bulk orders, ensuring the specifications meet their operational needs.

This term refers to the smallest amount of product a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it impacts inventory levels and initial investment. Buyers should negotiate MOQs based on their usage rates and storage capabilities.

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. For manual air pumps, submitting an RFQ allows businesses to compare multiple suppliers and make informed purchasing decisions based on price, quality, and delivery timelines.

These are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers as they determine who is responsible for shipping, insurance, and tariffs, which can significantly affect overall costs.

Lead time refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times is critical for B2B buyers, especially when planning for seasonal demand or special events where manual air pumps are needed.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

The manual air pump sector is currently experiencing significant transformation driven by various global trends. One of the primary factors is the increasing demand for portable and environmentally friendly inflation solutions. As consumers and businesses alike seek more sustainable options, manual air pumps—often made with fewer materials and requiring no electricity—are gaining traction. This trend is especially pronounced in developing regions such as Africa and South America, where access to reliable electricity can be inconsistent.

Emerging technologies are also shaping the market dynamics. Innovations in design and materials are leading to lighter, more durable pumps that cater to diverse applications—from camping and outdoor activities to industrial uses. The rise of e-commerce platforms has expanded market access for B2B buyers, allowing them to source products from international manufacturers more efficiently. Additionally, the increasing focus on supply chain transparency is prompting buyers to seek suppliers who can demonstrate quality assurance and ethical practices.

As international B2B buyers from regions like Nigeria and Brazil navigate these dynamics, understanding local market needs and preferences becomes crucial. Tailoring offerings to meet regional requirements, such as adapting pump designs for different climates and usage scenarios, can significantly enhance market penetration.

Sustainability is becoming a critical factor in the procurement of manual air pumps. The environmental impact of manufacturing processes and materials used in production is under scrutiny, with buyers increasingly favoring suppliers who prioritize eco-friendly practices. This shift is particularly relevant in markets like Europe, where regulatory frameworks encourage sustainable business operations.

Ethical sourcing practices are also gaining importance. Buyers are now more inclined to partner with manufacturers who can provide transparency regarding their supply chains, ensuring that labor practices meet international standards. Certifications such as Fair Trade and ISO 14001 for environmental management can enhance a supplier’s credibility and appeal to conscientious buyers.

Moreover, the use of recycled or biodegradable materials in the production of manual air pumps is gaining momentum. These innovations not only reduce the carbon footprint but also align with the values of environmentally conscious consumers. For B2B buyers, sourcing from manufacturers that demonstrate a commitment to sustainability can lead to enhanced brand reputation and customer loyalty.

The manual air pump has evolved significantly since its inception, transitioning from basic hand-operated devices to more sophisticated products that cater to a variety of applications. Originally designed for simple tasks, such as inflating sports equipment, these pumps have adapted over time to meet the needs of diverse industries, including automotive, recreational, and construction sectors.

Historically, manual air pumps were predominantly made from metal, which was durable but heavy. The introduction of lightweight plastics in the late 20th century revolutionized the market, making pumps more portable and user-friendly. Today, innovations continue to emerge, with manufacturers focusing on ergonomic designs, increased efficiency, and improved inflation speeds. This evolution reflects a broader trend in the B2B space toward products that enhance usability and efficiency while addressing sustainability concerns.

In conclusion, as manual air pumps continue to evolve, B2B buyers must stay informed about market trends, sustainability practices, and the historical context that shapes the sector. This knowledge will enable them to make informed sourcing decisions that align with both operational needs and ethical standards.

How do I select the right manual air pump for my business needs?

When choosing a manual air pump, consider the specific applications you require it for, such as inflating advertising displays, tents, or other equipment. Evaluate factors such as pump size, capacity, and ease of use. Additionally, assess the durability of materials used and whether the pump can handle the specific pressure needs of your products. Request samples from suppliers to ensure the pump meets your quality standards.

What are the typical minimum order quantities (MOQ) for manual air pumps?

MOQs for manual air pumps can vary significantly based on the supplier and the customization options you choose. Generally, MOQs can range from 50 to 500 units. It’s advisable to inquire directly with suppliers to understand their specific requirements and whether they offer flexible options for smaller orders, especially for new businesses or those testing the market.

What customization options are available for manual air pumps?

Many suppliers offer customization options such as branding, color choices, and design modifications. You can typically request your logo printed on the pump or select specific colors that align with your brand identity. Be sure to discuss these options with the supplier, and ask for a sample or proof before finalizing the order to ensure the customization meets your expectations.

What payment terms are commonly accepted for international orders of manual air pumps?

Payment terms for international orders can include options like advance payment, letters of credit, and payment upon delivery. It’s essential to negotiate favorable terms that suit your cash flow situation. Many suppliers require a deposit upfront, with the balance due before shipment. Always clarify payment methods and conditions to avoid any misunderstandings.

How can I vet suppliers of manual air pumps effectively?

To vet suppliers, start by checking their business credentials, including registration and compliance with international trade regulations. Look for reviews or testimonials from previous customers to gauge their reliability and product quality. Additionally, consider requesting references and visiting their manufacturing facilities if possible. Engaging in direct communication can also help assess their responsiveness and professionalism.

What quality assurance measures should I look for when sourcing manual air pumps?

Quality assurance is crucial to ensure that the manual air pumps meet industry standards. Look for suppliers that conduct regular quality checks and possess relevant certifications, such as ISO standards. You can also request third-party inspection services before shipment to verify that the pumps meet your specifications and quality requirements.

What are the logistics considerations for importing manual air pumps?

When importing manual air pumps, consider shipping methods, customs clearance processes, and potential tariffs. Air freight is faster but more expensive than sea freight. Ensure that your supplier is experienced in international shipping and can provide necessary documentation for customs. Additionally, factor in lead times for production and shipping to plan your inventory effectively.

How can I ensure timely delivery of manual air pumps from international suppliers?

To ensure timely delivery, establish clear communication with your supplier regarding production timelines and shipping schedules. Request regular updates during the manufacturing process, and consider using freight forwarders who specialize in international shipping. Building a good relationship with your supplier can also help in prioritizing your orders, especially during peak seasons.

Dominio: vispronet.com

Registered: 2007 (18 years)

Introduzione: Manual Air Pump

Price: $39.99

Free shipping

Used to manually inflate air tents, columns, and tables

No power is needed to work this manual air pump

Lightweight and compact pump is easy to transport and carry

Includes: hand pump, three adapters, and an air hose

Dominio: target.com

Registrato: 1997 (28 anni)

Introduzione: Manual air pumps available for various uses including inflating exercise balls, air mattresses, and pool toys. Options include handheld, electric, battery-operated, and manual aerator pumps made from metal or durable plastic. Some pumps feature 12-volt charger sockets for car or boat use. Multiple power or speed settings are available. Brands include Spaldin, Intex Quick-Fill, EcoPlus, Swimline, a…

Dominio: intexcorp.com

Registrato: 1995 (30 anni)

Introduzione: [{‘SKU’: ‘69613E’, ‘name’: ‘Double Quick Mini Hand Pump’, ‘price’: ‘$4.99’}, {‘SKU’: ‘69611E’, ‘name’: ‘Bellows Foot Pump – 11 Inch’, ‘price’: ‘$7.99’}, {‘SKU’: ‘68612E’, ‘name’: ‘Double Quick I Hand Pump’, ‘price’: ‘$4.99’}, {‘SKU’: ‘68605E’, ‘name’: ‘Double Quick III S Hand Pump’, ‘price’: ‘$8.99’}, {‘SKU’: ‘68614E’, ‘name’: ‘Double Quick II Hand Pump’, ‘price’: ‘$5.99’}, {‘SKU’: ‘68615E’, ‘name…

In the competitive landscape of manual air pumps, strategic sourcing remains a vital approach for international B2B buyers. Understanding the diverse applications—from inflatable advertising to recreational uses—can help buyers identify the right product tailored to their specific needs. By focusing on quality, supplier reliability, and cost-effectiveness, businesses can enhance operational efficiency and ensure customer satisfaction.

Leveraging strategic sourcing allows companies to build long-term relationships with suppliers, fostering collaboration and innovation. Buyers should prioritize suppliers that offer comprehensive services, such as customization options and fast turnaround times, which can significantly enhance the overall value proposition. Additionally, evaluating suppliers based on their geographical location can mitigate shipping costs and improve delivery timelines, especially for buyers in emerging markets like Nigeria and Brazil.

As global demand for sustainable and efficient solutions rises, the manual air pump market is poised for growth. International buyers are encouraged to stay ahead of industry trends by engaging with suppliers who prioritize innovation and sustainability. By embracing strategic sourcing now, businesses can position themselves to capitalize on future opportunities, ensuring they remain competitive in a rapidly evolving marketplace. Take the next step—explore your sourcing options today and harness the potential of manual air pumps to drive your business forward.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.