Navigating the global market for portable air compressors for cars presents a unique set of challenges for B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. With an ever-growing demand for reliable vehicle maintenance tools, sourcing the right portable air compressor can be daunting. Buyers must consider various factors, including types, applications, supplier vetting processes, and cost implications.

This comprehensive guide serves as an essential resource for international B2B buyers, offering insights into the diverse categories of portable air compressors tailored for various vehicle types. From compact models ideal for personal cars to robust options designed for heavy-duty trucks and SUVs, we cover the spectrum of available solutions. Additionally, we delve into supplier evaluation criteria to ensure quality and reliability, helping you navigate the complexities of international trade and import regulations.

By empowering B2B buyers with actionable insights and strategic recommendations, this guide facilitates informed purchasing decisions. It aims to enhance your understanding of the market landscape, ensuring you select the best portable air compressors that meet your operational needs while optimizing cost-efficiency. Whether you are a distributor seeking to expand your product line or a fleet manager looking to maintain vehicle performance, this guide is your key to making confident, informed choices in the competitive world of portable air compressors for cars.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Gonfiatori per pneumatici a batteria | Battery-operated, compact design, preset pressure | Automotive maintenance, roadside assistance | Pro: Portable, easy to use. Contro: Limited battery life, may not handle high-pressure tires. |

| 12V Powered Air Compressors | Plugs into vehicle’s 12V outlet, moderate size | Fleet management, emergency services | Pro: Continuous power while vehicle is running. Contro: Limited reach if vehicle is stationary. |

| Heavy-Duty Air Compressors | High PSI capacity, typically larger and heavier | Trucking, construction, off-road vehicles | Pro: Fast inflation, suitable for larger tires. Contro: Bulky, may require additional setup. |

| Multi-Functional Inflators | Includes attachments for various inflatables | Automotive, recreational, home use | Pro: Versatile for multiple applications. Contro: May lack power for heavy-duty tasks. |

| Gonfiatori digitali per pneumatici | Digital pressure gauge, automatic shut-off feature | Automotive service centers, retail | Pro: Accurate readings, user-friendly. Contro: May be pricier than analog options. |

Cordless tire inflators are compact, battery-operated devices designed for quick and convenient tire inflation. They typically feature preset pressure settings, allowing users to inflate tires to the desired PSI without manual monitoring. Ideal for automotive maintenance and roadside assistance, these inflators are particularly appealing to businesses that prioritize mobility and ease of use. However, B2B buyers should consider the battery life, as prolonged use may require recharging.

Illustrative image related to portable air compressors for cars

12V powered air compressors connect directly to a vehicle’s 12V outlet, providing a reliable source of power while the engine is running. These compressors are suitable for fleet management and emergency services where immediate tire inflation is necessary. They offer the advantage of continuous operation without the need for recharging; however, their range may be limited by the vehicle’s position, which can be a drawback in certain scenarios.

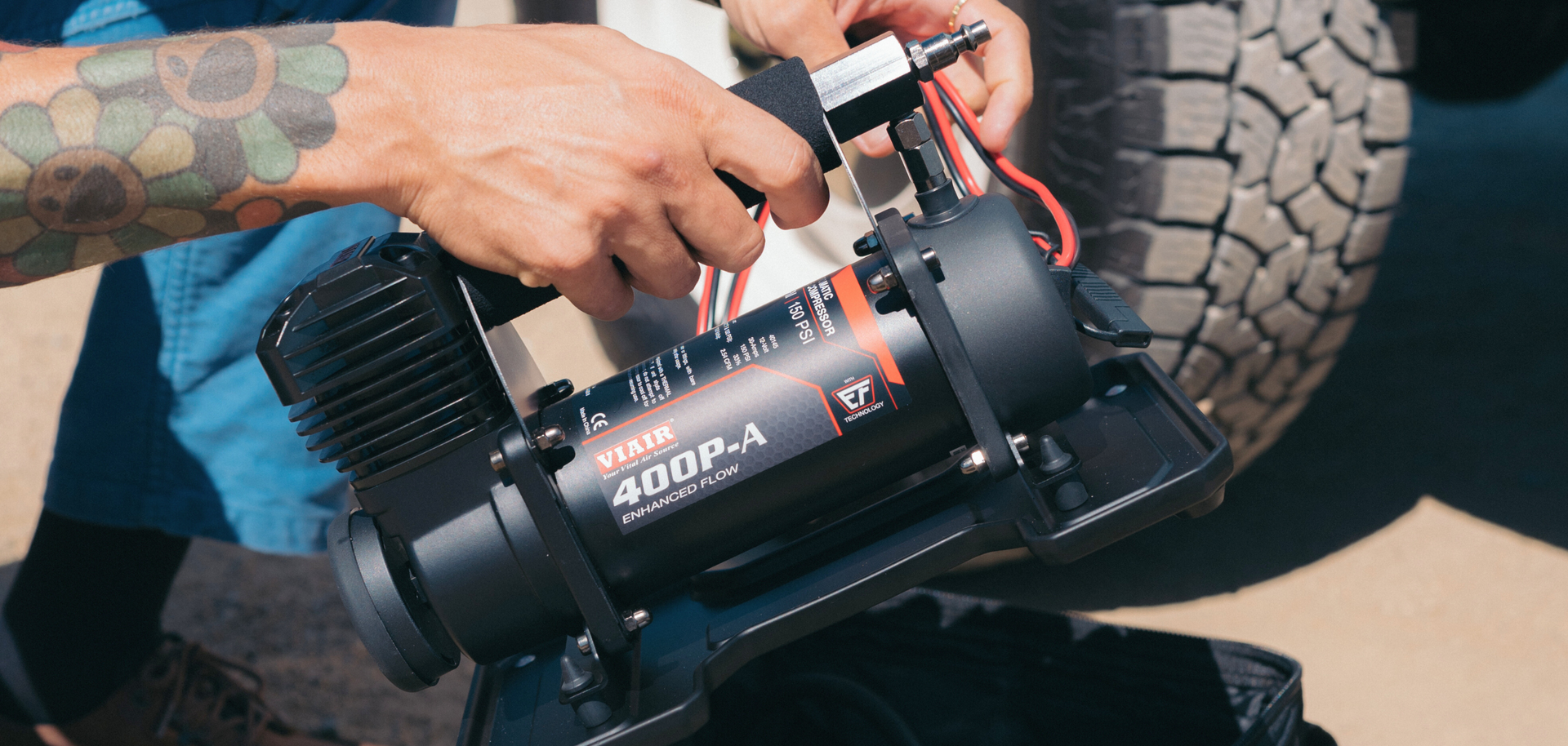

Heavy-duty air compressors are designed for high PSI applications, making them ideal for larger tires commonly found on trucks and off-road vehicles. Their robust construction allows for rapid inflation and prolonged use, catering to industries like trucking and construction. While they offer significant advantages in performance, their bulkiness and weight might pose challenges in terms of portability and ease of storage for B2B buyers.

Multi-functional inflators come with various attachments, enabling users to inflate not just tires but also recreational items like pool floats and sports equipment. This versatility makes them suitable for automotive, recreational, and home use, appealing to businesses that require a multi-purpose tool. However, buyers should be cautious as these inflators may lack the power necessary for heavy-duty tasks, making them less effective for commercial automotive applications.

Digital tire inflators feature advanced technology such as digital pressure gauges and automatic shut-off functions, which enhance accuracy and user experience. They are particularly beneficial for automotive service centers and retail environments, where precision is paramount. While these inflators tend to be more expensive than their analog counterparts, their ease of use and reliability can justify the investment for B2B buyers focused on efficiency and customer satisfaction.

| Industria/Settore | Specific Application of Portable Air Compressors for Cars | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Riparazione di autoveicoli | Tire inflation and maintenance for customer vehicles | Ensures customer safety and satisfaction, reducing vehicle downtime | Reliability, ease of use, and speed of inflation are crucial. |

| Gestione della flotta | Regular maintenance for commercial vehicle fleets | Minimizes operational disruptions, ensuring timely deliveries | Capacity for high PSI, portability, and durability are key factors. |

| Construction and Logistics | Inflating tires on construction vehicles and trailers | Enhances productivity by reducing downtime due to tire issues | Must handle rugged conditions and provide high performance. |

| Servizi di emergenza | Quick tire inflation for emergency response vehicles | Critical for rapid response times, ensuring operational readiness | Compact design and multiple power options for versatility. |

| Recreational Vehicle Rentals | Pre-rental tire checks and inflation for RVs | Increases customer satisfaction and safety, reducing liability risks | Must be lightweight, easy to operate, and portable for convenience. |

In automotive repair shops, portable air compressors are essential for maintaining customer vehicles, particularly for tire inflation and pressure checks. These compressors enable technicians to quickly address low tire pressures, which can enhance vehicle safety and performance. For B2B buyers, reliability and ease of use are paramount, as technicians need to efficiently service multiple vehicles daily. Additionally, compressors should be capable of achieving high PSI levels to accommodate various vehicle types, ensuring they meet diverse customer needs.

Illustrative image related to portable air compressors for cars

For businesses managing commercial vehicle fleets, portable air compressors are vital for regular tire maintenance. By ensuring that all vehicles are operating with optimal tire pressure, companies can minimize the risk of breakdowns and improve fuel efficiency. This leads to timely deliveries and reduced operational disruptions. When sourcing compressors for fleet use, buyers should prioritize models that offer portability and high-performance capabilities, as well as durability to withstand frequent use in various conditions.

In the construction and logistics sectors, portable air compressors are used to inflate tires on heavy-duty vehicles and trailers. Maintaining proper tire pressure is critical in these industries to ensure safety and productivity on job sites. A malfunctioning tire can lead to significant delays and increased costs. B2B buyers in these sectors should consider compressors that can withstand rugged environments and provide high inflation performance, ensuring they can handle the demands of construction and logistics operations.

Emergency services rely on portable air compressors for quick tire inflation of response vehicles. In critical situations, every second counts, and having a reliable compressor can mean the difference between timely assistance and delayed response. For B2B buyers in this sector, it is essential to choose compressors that are compact and easy to operate, with multiple power options to ensure readiness in various scenarios. The ability to quickly inflate tires can enhance the operational effectiveness of emergency response teams.

Recreational vehicle rental companies utilize portable air compressors to conduct pre-rental tire checks and inflation. Ensuring that RVs are in optimal condition before rentals not only enhances customer safety but also improves overall satisfaction, reducing liability risks. Buyers in this industry should look for lightweight and portable compressors that are easy to operate, allowing staff to efficiently prepare vehicles for rental. Features like built-in pressure gauges and adapters for various inflatables can further enhance usability and customer experience.

Il problema: B2B buyers responsible for fleet management often face the challenge of maintaining tire pressure across a wide range of vehicle types, from compact cars to heavy-duty trucks. Each vehicle requires different air pressure levels, and a single portable air compressor may not suffice. This inconsistency can lead to reduced fuel efficiency, uneven tire wear, and safety hazards, impacting operational costs and vehicle longevity. Additionally, the need for quick service during roadside emergencies compounds the pressure on fleet managers to make the right purchasing decisions.

Illustrative image related to portable air compressors for cars

La soluzione: To address this issue, buyers should invest in versatile portable air compressors that cater to various vehicle types. Look for models that feature adjustable pressure settings and can handle a wide psi range, ideally from 0 to 160 psi. Suppliers should provide detailed specifications that highlight the compressor’s compatibility with different vehicles. Furthermore, consider purchasing a compressor that includes multiple nozzle attachments for inflating diverse items such as truck tires, bicycle tires, and inflatable sports equipment. By choosing a compressor with these capabilities, fleet managers can ensure tire safety across their entire fleet while minimizing downtime and enhancing overall efficiency.

Il problema: For businesses operating in remote areas, having a reliable source of power for portable air compressors can be a significant concern. Many inflators are battery-operated, and their power can diminish quickly, especially when multiple tires need inflating. This issue is particularly problematic for companies that must ensure their vehicles are road-ready at all times, as inadequate battery life can lead to delays and increased operational costs.

La soluzione: B2B buyers should prioritize air compressors that offer dual power options: both battery and direct connection to a vehicle’s 12-volt outlet. This feature allows for continuous operation without the risk of running out of battery power. When sourcing these compressors, look for models that advertise the ability to inflate multiple tires on a single charge, which not only showcases their efficiency but also their reliability. Additionally, consider investing in compressors equipped with built-in battery management systems that prevent overheating and extend battery life. This approach ensures that the compressors remain functional during critical moments, thus safeguarding operational continuity.

Il problema: Many portable air compressors on the market come with complex interfaces or lack user-friendly features, making them difficult for employees to operate effectively. This complexity can lead to improper usage, resulting in over-inflation or damage to tires. For businesses, this means additional costs for repairs and potential liability issues if an employee misuses the equipment.

Illustrative image related to portable air compressors for cars

La soluzione: To mitigate this risk, B2B buyers should focus on sourcing portable air compressors with intuitive designs and user-friendly interfaces. Look for models that feature digital displays with preset pressure settings, automatic shut-off functions, and clear instructions to ensure ease of use. Providing training sessions for employees on how to operate the compressors correctly can also enhance safety and efficiency. Additionally, consider investing in compressors that offer built-in safety features, such as pressure gauges that accurately display current tire pressure. By prioritizing ease of use and safety in your purchasing decisions, you can minimize the risk of accidents and ensure that all staff members can operate the equipment with confidence.

When selecting portable air compressors for cars, the choice of materials plays a crucial role in determining the product’s performance, durability, and overall suitability for various applications. Below, we analyze four common materials used in the construction of these devices, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Proprietà chiave:

Aluminum is lightweight, has excellent corrosion resistance, and can withstand moderate temperature and pressure variations. Its thermal conductivity allows for efficient heat dissipation during operation, which is essential for maintaining performance.

Pro e contro:

The primary advantage of aluminum is its low weight, making it ideal for portable applications. It is also relatively easy to manufacture and can be extruded into various shapes. However, aluminum can be more expensive than other materials like steel and may not withstand high-impact conditions as well.

Impatto sull'applicazione:

Aluminum is suitable for components that require a balance of strength and weight, such as housing and casing. It is compatible with various media, including air and non-corrosive gases, but may not be ideal for applications involving aggressive chemicals.

Considerazioni per gli acquirenti internazionali:

B2B buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN regarding aluminum alloys. In markets like Africa and South America, the availability of aluminum may vary, affecting cost and supply chain considerations.

Proprietà chiave:

Steel is known for its high strength and durability, with excellent resistance to wear and impact. It can handle high pressures and temperatures, making it suitable for heavy-duty applications.

Illustrative image related to portable air compressors for cars

Pro e contro:

The key advantage of steel is its robustness, which contributes to a longer lifespan under demanding conditions. However, it is heavier than aluminum and may require additional protective coatings to prevent rust and corrosion, particularly in humid environments.

Impatto sull'applicazione:

Steel is often used for structural components, such as frames and pressure vessels, where strength is critical. It is compatible with air and various gases but may not be suitable for corrosive environments without proper treatment.

Considerazioni per gli acquirenti internazionali:

Buyers in regions with high humidity, like parts of South America and Africa, should consider corrosion-resistant steel grades. Compliance with international standards, such as JIS for Japanese buyers, is also essential.

Illustrative image related to portable air compressors for cars

Proprietà chiave:

Plastics, particularly high-density polyethylene (HDPE) and polycarbonate, are lightweight, resistant to corrosion, and can be molded into complex shapes. They can also handle moderate pressure and temperature ranges.

Pro e contro:

The main advantage of plastics is their low cost and versatility in design. They can be produced in various colors and forms, enhancing aesthetic appeal. However, plastics generally have lower strength compared to metals and may degrade under UV exposure or extreme temperatures.

Impatto sull'applicazione:

Plastics are often used for non-structural components like housing, knobs, and connectors. They are suitable for air and non-corrosive gases but may not perform well in high-pressure applications.

Considerazioni per gli acquirenti internazionali:

B2B buyers should ensure that the plastics used comply with relevant safety and environmental regulations, especially in Europe, where REACH compliance is critical. In markets like Brazil, understanding local material standards is essential for compliance.

Illustrative image related to portable air compressors for cars

Proprietà chiave:

Rubber is flexible, has excellent elasticity, and can withstand a range of temperatures. It is also resistant to many chemicals, making it suitable for seals and gaskets.

Pro e contro:

Rubber’s flexibility allows for effective sealing, which is crucial for maintaining pressure in air compressors. However, it can degrade over time, especially when exposed to UV light or extreme temperatures, leading to potential failures.

Impatto sull'applicazione:

Rubber is primarily used for seals, hoses, and vibration dampening components. It is compatible with air and various gases but may not be suitable for high-temperature applications without special formulations.

Illustrative image related to portable air compressors for cars

Considerazioni per gli acquirenti internazionali:

Buyers should consider the specific rubber grades that meet international standards for durability and chemical resistance. In regions like the Middle East, where temperatures can be extreme, selecting the right rubber formulation is critical.

| Materiale | Typical Use Case for Portable Air Compressors for Cars | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Alluminio | Alloggiamento e involucro | Leggero e resistente alla corrosione | Costo più elevato e minore resistenza agli urti | Medio |

| Acciaio | Structural components and pressure vessels | Elevata resistenza e durata | Heavier and requires corrosion protection | Medio |

| Plastica | Non-structural components like knobs and connectors | Low cost and versatile design | Lower strength and UV degradation | Basso |

| Gomma | Seals and hoses | Excellent sealing and flexibility | Degrades over time under UV exposure | Basso |

This analysis should assist international B2B buyers in making informed decisions regarding material selection for portable air compressors, ensuring optimal performance and compliance with regional standards.

The manufacturing of portable air compressors for cars involves several critical stages that ensure the final product meets both performance and safety standards. These stages typically include material preparation, forming, assembly, and finishing.

The first stage involves selecting high-quality materials, such as durable plastics, metals like aluminum and steel, and rubber for seals and hoses. Suppliers must ensure that the materials comply with international standards to guarantee safety and performance. Materials undergo testing for strength, flexibility, and resistance to environmental factors. For example, metal components may be treated for corrosion resistance, while plastics are often tested for UV stability.

Illustrative image related to portable air compressors for cars

Once materials are prepared, they undergo forming processes. Techniques such as injection molding for plastic parts and die-casting for metal components are commonly employed. These methods allow for precision shaping and consistency across production batches. Advanced technologies like CNC (Computer Numerical Control) machining may also be utilized to achieve high accuracy in critical components, such as pressure gauges and pumps.

The assembly stage is crucial for ensuring that all components fit together seamlessly. This often involves automated assembly lines where skilled technicians and robotic systems work in tandem. Key components, such as the motor, compressor unit, and controls, are integrated to create a fully functional unit. Quality checks are performed at various points to catch any defects early, ensuring that each unit meets specifications before moving to the next stage.

Finishing touches include painting, labeling, and final inspections. These steps not only enhance the aesthetic appeal of the product but also provide important information about usage, safety, and compliance. Surface treatments, such as powder coating, may also be applied to improve durability and resistance to wear and tear. After finishing, products undergo final quality assurance checks before packaging for distribution.

Quality assurance is vital in ensuring that portable air compressors meet both safety and performance expectations. Various international standards, such as ISO 9001, provide frameworks for quality management systems. Compliance with these standards indicates that a manufacturer has established effective processes for continual improvement.

Illustrative image related to portable air compressors for cars

Quality control (QC) checkpoints are essential for maintaining high standards throughout the manufacturing process. Common checkpoints include:

Testing methods vary based on the component and intended use of the air compressor. Common methods include:

For international B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are several methods:

B2B buyers from regions such as Africa, South America, the Middle East, and Europe must navigate various nuances in quality control. These include:

In conclusion, selecting the right manufacturer for portable air compressors involves a comprehensive understanding of the manufacturing processes and quality assurance measures. By focusing on reputable suppliers that adhere to international standards, conducting thorough audits, and ensuring transparent quality control practices, B2B buyers can mitigate risks and secure high-quality products that meet their operational needs.

This guide serves as a comprehensive checklist for B2B buyers looking to procure portable air compressors for cars. By following these steps, you can ensure that you make an informed decision, securing a reliable product that meets the specific needs of your business and clients.

Establishing clear technical specifications is essential for aligning your procurement needs with available products. Consider factors such as maximum pressure (PSI), power source (cordless vs. corded), and size. This will help you identify which features are non-negotiable for your target market, whether for everyday passenger vehicles or larger SUVs and trucks.

Understanding current market trends is crucial for identifying the most sought-after features and models. Analyze customer feedback and reviews from reliable sources to gauge which air compressors are performing well. Pay attention to emerging technologies or features such as built-in pressure gauges or USB charging ports that can give you a competitive edge.

Illustrative image related to portable air compressors for cars

Before committing to a supplier, it’s vital to conduct thorough evaluations. Request company profiles, product catalogs, and references from other buyers in similar industries or regions. Look for suppliers with a track record of reliability and quality assurance processes, as this can significantly impact the performance of your products.

Ensure that the products meet relevant safety and quality standards for your target market. Different regions may have specific regulations regarding electrical appliances and pressure equipment. Certifications such as CE, UL, or ISO can provide assurance of quality and safety, making it easier to gain trust from your customers.

Analyze the total cost of ownership, including initial purchase price, shipping, and potential maintenance costs. Compare the prices of similar products across different suppliers to ensure competitive pricing. Keep in mind that the cheapest option may not always provide the best value; consider performance, warranty, and after-sales support as part of your cost evaluation.

Illustrative image related to portable air compressors for cars

Before finalizing your order, request samples from shortlisted suppliers to evaluate product performance. Testing the air compressors in real-world scenarios will help you verify their capabilities, such as inflation speed and accuracy. This step is crucial to ensure that the product meets your defined specifications and customer expectations.

Once you have selected a supplier and tested the products, proceed to negotiate terms of purchase. Discuss payment terms, delivery schedules, and warranties. Ensure that you have a clear understanding of return policies and after-sales support, as these factors can significantly affect your relationship with the supplier and the satisfaction of your customers.

By following this checklist, you can streamline the sourcing process for portable air compressors, ensuring that your procurement aligns with both business goals and customer satisfaction.

The cost structure of portable air compressors for cars encompasses several critical components. I materiali represent a significant portion of the overall cost, with quality components such as motors, batteries, and casings impacting the final price. Labor costs vary by region but are crucial in determining the pricing, especially in regions with higher wage standards. Spese generali di produzione includes expenses related to factory operations, utilities, and equipment depreciation, which can fluctuate based on the production scale.

Tooling costs are also a factor, particularly when customized designs or specifications are required. Quality control (QC) processes are essential to ensure that each unit meets safety and performance standards, adding to the overall expenditure. Lastly, logistics costs related to transportation and storage can significantly influence pricing, especially for international shipments.

Several price influencers can affect the final cost of portable air compressors. Volume and minimum order quantities (MOQs) play a pivotal role; purchasing in bulk often leads to discounted prices. Additionally, the complexity of specifications or customization can drive up costs. For instance, features such as built-in pressure gauges, battery types, or additional accessories may increase material and assembly costs.

Il qualità e certificazioni of the components also matter. Products that meet international safety standards or have undergone rigorous testing may command higher prices but offer better reliability and performance. Supplier factors, such as reputation and reliability, can also affect pricing; established suppliers may charge a premium for their proven track record.

Finally, understanding Incoterms is vital for international buyers. These terms define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, which can significantly impact overall costs.

B2B buyers can employ several strategies to negotiate better pricing on portable air compressors. Understanding the total cost of ownership (TCO) is essential; this includes not just the purchase price but also maintenance, operational costs, and potential resale value. Buyers should consider the long-term implications of their investment, especially when evaluating cheaper options that may incur higher operational costs due to lower quality.

When negotiating, it is beneficial to leverage volume purchasing to secure discounts. Establishing a good relationship with suppliers can also lead to better terms over time. Be clear about your specifications and requirements upfront to avoid misunderstandings that could lead to unexpected costs later.

Illustrative image related to portable air compressors for cars

Gli acquirenti devono anche essere consapevoli di sfumature di prezzo specific to their regions. For example, in Africa and South America, tariffs and import duties can significantly affect pricing, while in Europe, stringent regulations may necessitate higher compliance costs. Understanding these local factors can provide leverage in negotiations.

While this analysis provides a comprehensive overview of costs and pricing for portable air compressors, it is crucial to remember that prices can vary widely based on market conditions, supplier negotiations, and specific buyer requirements. Prospective buyers should approach sourcing with a clear understanding of their needs and the associated costs to ensure that they achieve the best possible value for their investment. Always consider requesting multiple quotes and performing due diligence on suppliers to ensure competitive pricing and quality assurance.

In the automotive maintenance landscape, ensuring optimal tire pressure is crucial for performance, safety, and efficiency. While portable air compressors for cars are a popular solution, several alternative methods and technologies can also fulfill this need. This section evaluates the strengths and weaknesses of portable air compressors in comparison to other viable options, helping B2B buyers make informed decisions.

Illustrative image related to portable air compressors for cars

| Aspetto di confronto | Portable Air Compressors For Cars | CO2 Tire Inflators | Manual Hand Pumps |

|---|---|---|---|

| Prestazioni | High; can inflate multiple tires quickly and to high pressures | Moderate; good for quick fills but limited by CO2 cartridge size | Low; requires significant manual effort and time |

| Costo | Moderate ($40 – $100) | Low to Moderate ($15 – $60) | Very Low ($10 – $30) |

| Facilità di implementazione | Easy; plug-and-play, often battery-operated | Easy; requires minimal setup | Challenging; requires physical effort and technique |

| Manutenzione | Low; occasional cleaning and checks | Low; replace CO2 cartridges as needed | Low; infrequent maintenance, but may require repairs over time |

| Il miglior caso d'uso | Regular vehicle maintenance, emergencies | Quick fixes and emergencies in low-volume settings | Very low-budget scenarios or manual enthusiasts |

CO2 tire inflators utilize compressed carbon dioxide cartridges to quickly inflate tires. They are especially handy for cyclists and motorcyclists who require a portable and lightweight solution. Pros include their compact size and rapid inflation capabilities, making them ideal for emergency situations or quick tire top-ups. However, their performance is limited by the size of the CO2 cartridges, which can only inflate a limited number of tires before needing replacement. This makes them less suitable for regular vehicle maintenance or for inflating larger tires.

Manual hand pumps are the most basic option available for inflating tires. They are typically inexpensive and require no power source, making them a practical choice for those on a tight budget or in remote areas. While they are lightweight and portable, the drawbacks are significant: inflating a tire can be labor-intensive and time-consuming, often requiring considerable effort, particularly for larger tires. Their effectiveness is also limited in terms of the pressure they can achieve, making them less desirable for routine automotive maintenance where quick and efficient inflation is necessary.

When choosing the right solution for tire inflation, B2B buyers should assess their specific needs, considering factors such as frequency of use, tire types, and budget constraints. Portable air compressors offer a balanced combination of performance and convenience for regular vehicle maintenance, making them the go-to choice for businesses with a fleet or those involved in automotive services. On the other hand, CO2 tire inflators may be ideal for specialized applications, like cycling, while manual hand pumps can serve as a low-cost backup option. Ultimately, the decision should align with the operational demands and resource availability of the buyer’s business.

Illustrative image related to portable air compressors for cars

Understanding the technical specifications of portable air compressors is crucial for B2B buyers in making informed purchasing decisions. Here are some key specifications to consider:

The maximum pressure, measured in pounds per square inch (PSI), indicates how much air pressure the compressor can generate. Most portable air compressors for cars can reach between 100 to 160 PSI. This specification is vital for ensuring that the compressor can adequately inflate various tire sizes, particularly for larger vehicles like trucks and SUVs. A higher PSI capability means versatility in handling diverse inflation tasks.

The duty cycle reflects the percentage of time the compressor can operate within a given period, typically stated over a 10-minute interval. For example, a 50% duty cycle means the unit can run for 5 minutes and then requires 5 minutes to cool down. This property is essential for B2B buyers as it affects the compressor’s efficiency and longevity, particularly in high-demand situations.

Portable air compressors can be powered by various sources, including 12-volt car batteries, AC outlets, or rechargeable batteries. Understanding the power source is crucial for operational flexibility, especially in regions with limited access to electricity. Buyers should evaluate the convenience of power options based on their intended usage scenarios.

Illustrative image related to portable air compressors for cars

The weight of the compressor directly impacts its portability. Lightweight models are easier to carry and store, making them ideal for emergency kits. For businesses that require frequent transportation of equipment, choosing a model that balances weight with performance is key to maximizing efficiency.

Additional features such as built-in pressure gauges, LED lights, and automatic shut-off functions enhance usability. A digital pressure gauge provides accurate readings, while an automatic shut-off prevents over-inflation, ensuring user safety. These features can significantly improve the overall user experience, making them essential considerations for B2B buyers.

Familiarity with industry jargon is crucial for effective communication and negotiation. Here are some common terms relevant to portable air compressors:

Illustrative image related to portable air compressors for cars

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers assess product quality and compatibility, ensuring they source reliable equipment.

MOQ indicates the smallest order size that a supplier is willing to accept. Knowing the MOQ is essential for budgeting and inventory management, especially for businesses aiming to stock up on portable air compressors for resale or fleet use.

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products. Utilizing RFQs can help B2B buyers compare costs and terms from multiple vendors, facilitating better purchasing decisions.

Incoterms are international trade terms that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with these terms is crucial for B2B transactions, as they clarify delivery obligations, risk management, and cost responsibilities.

This term refers to the terms under which a manufacturer or seller provides repair or replacement services for defective products. Understanding warranty conditions is essential for evaluating long-term value and support for portable air compressors.

Illustrative image related to portable air compressors for cars

By mastering these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring they select the most suitable portable air compressors for their needs.

The global portable air compressor market for cars is experiencing substantial growth, driven by increasing vehicle ownership, a rise in recreational activities, and a growing focus on vehicle maintenance. In regions like Africa and South America, where road conditions can be unpredictable, the demand for reliable portable air compressors is surging. Moreover, the European market, particularly in countries like Germany, is witnessing a shift towards more compact and efficient models, catering to urban consumers who prioritize portability and ease of use.

Emerging technologies are also shaping the landscape. Battery-powered and cordless models are becoming increasingly popular, offering convenience and flexibility for users. Innovations such as integrated pressure gauges, automatic shut-off features, and multifunctional designs—capable of inflating various items beyond tires—are appealing to a broader audience. As international B2B buyers look to source these products, understanding the nuances of local preferences and technological advancements is crucial.

Sourcing trends indicate a preference for manufacturers who offer customizable solutions, allowing businesses to tailor products to their specific markets. Additionally, the rise of e-commerce platforms is facilitating easier access to a wider range of suppliers, enabling buyers to compare products and prices more effectively.

As global awareness around environmental issues intensifies, sustainability is becoming a key consideration for B2B buyers in the portable air compressor sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Businesses are increasingly favoring suppliers who adopt sustainable practices, such as using recycled materials or implementing energy-efficient production methods.

Ethical sourcing is also gaining traction, with buyers prioritizing suppliers who ensure fair labor practices and transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential for manufacturers aiming to demonstrate their commitment to sustainability and ethical practices. Additionally, companies that incorporate “green” materials and technologies into their products, such as eco-friendly lubricants or recyclable packaging, can differentiate themselves in a competitive market.

For international buyers, understanding these sustainability trends is not just about compliance; it can also enhance brand reputation and attract environmentally conscious consumers. As the market evolves, those who prioritize sustainability and ethical sourcing will likely gain a competitive edge.

The evolution of portable air compressors for cars can be traced back to the early 20th century, when manual pumps were the primary method for inflating tires. Over the decades, advancements in technology led to the development of electric and battery-powered models, significantly improving efficiency and convenience. By the late 20th century, the integration of digital pressure gauges and automatic shut-off features revolutionized the user experience, making tire maintenance more accessible.

Today, the market is characterized by a diverse range of products catering to various consumer needs, from compact models suitable for everyday use to heavy-duty compressors designed for larger vehicles. This evolution reflects broader trends in automotive care and consumer expectations, setting the stage for continued innovation and growth in the portable air compressor sector.

How do I choose the right portable air compressor for my business needs?

Choosing the right portable air compressor involves assessing your specific needs, such as the types of vehicles you’ll service, the required PSI, and the frequency of use. Consider compressors that can handle various tire sizes, from passenger vehicles to SUVs. Look for features like portability, battery life, and speed of inflation. Additionally, evaluate brands that offer reliable customer support and warranty options to ensure long-term satisfaction.

What is the best portable air compressor for inflating tires?

The best portable air compressor for inflating tires often depends on the specific application. For general use, models like the AstroAI Cordless Tire Inflator are highly recommended due to their efficiency and ease of use. If your business services larger vehicles, consider the Viair 88P, which is designed for high-pressure applications. Always check for features like built-in pressure gauges and automatic shut-off to enhance usability.

What are the key specifications to look for in portable air compressors?

When sourcing portable air compressors, key specifications include maximum PSI, duty cycle, power source (battery vs. corded), and weight. A higher maximum PSI is essential for larger tires, while a longer duty cycle ensures the compressor can operate efficiently without overheating. Additionally, consider the compressor’s dimensions for ease of transport and storage, especially if your business requires frequent mobility.

What are the common payment terms for international purchases of air compressors?

Payment terms for international purchases can vary widely depending on the supplier and the buyer’s relationship. Common options include Letters of Credit (LC), telegraphic transfers (TT), and payment upon delivery. It’s essential to clarify payment terms upfront to avoid misunderstandings. Ensure you understand any potential currency exchange fees and international transaction costs that may apply to your order.

How can I verify the reliability of a portable air compressor supplier?

To verify the reliability of a supplier, conduct thorough due diligence. Check for certifications and compliance with international quality standards, such as ISO 9001. Request references from other businesses that have sourced from them. Additionally, assess their customer service responsiveness, warranty policies, and after-sales support. Engaging in a small trial order can also help gauge their reliability before committing to larger orders.

What is the minimum order quantity (MOQ) for portable air compressors?

Minimum order quantities (MOQs) for portable air compressors can vary significantly between suppliers. Some manufacturers may have MOQs as low as 10 units, while others may require orders of 100 or more. When negotiating, discuss your specific needs and see if the supplier can accommodate lower quantities for initial orders. This flexibility can help you test market demand without overcommitting financially.

What logistics considerations should I keep in mind when importing air compressors?

Logistics considerations for importing air compressors include shipping methods, customs clearance, and delivery timelines. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency and budget. Ensure you have a reliable logistics partner familiar with customs regulations in your country. Proper documentation, including invoices and packing lists, is crucial to avoid delays at customs.

How can I ensure quality assurance for the air compressors I source?

To ensure quality assurance for sourced air compressors, request product samples for testing before bulk orders. Establish clear quality control standards in your purchase agreement, including specifications for performance and durability. Consider conducting factory audits or hiring third-party inspection services to verify product quality before shipment. Maintaining open communication with your supplier throughout the production process can also help mitigate quality issues.

Dominio: automoblog.com

Registrato: 2004 (21 anni)

Introduzione: Best Portable Tire Inflators for 2025: 1. Slime Cordless Tire Inflator – Easy to use and stow. 2. 20V Avid Power – Drill-style design and carrying case. 3. Fanttik X8 Apex – Overall good quality and functionality. 4. DeWalt 20V MAX – Built for lifetime usage, may require separate battery purchase. 5. Milwaukee M18 – Robust and powerful with four memory settings, may require separate battery purcha…

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: Looking for a good air compressor primarily to use for car tires. Recommendations include: 1. Viair 88p – noted for its value and utility. 2. Milwaukee M18 – praised for quality, especially if already using Milwaukee batteries. 3. California Air Tools – recommended for being oil-free and quiet, with a specific mention of an 8-gallon model that is easy to transport.

In summary, the strategic sourcing of portable air compressors for cars presents a compelling opportunity for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. Key considerations include product performance, portability, and features that cater to diverse regional needs, such as inflation speed and pressure capacity. The analysis of top-performing models, like the AstroAI Cordless Tire Inflator and Viair 88P, highlights the importance of selecting inflators that balance efficiency with user-friendly design.

As market dynamics shift, strategic sourcing will not only enhance supply chain resilience but also ensure access to innovative solutions that meet evolving customer expectations. Emphasizing quality and reliability in procurement will be essential for maintaining competitive advantage in various markets.

Looking ahead, international buyers are encouraged to leverage these insights to make informed purchasing decisions that align with their operational needs. By prioritizing strategic partnerships with reputable manufacturers and suppliers, businesses can secure products that drive customer satisfaction and foster long-term growth in their respective regions. Seize this opportunity to elevate your sourcing strategy and position your business for success in the portable air compressor market.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.