In the fast-paced world of global commerce, sourcing reliable tire inflation gauges presents a significant challenge for international B2B buyers. With the increasing emphasis on vehicle safety and performance, particularly in regions like Africa, South America, the Middle East, and Europe, ensuring accurate tire pressure is more crucial than ever. This guide will delve into the diverse range of tire inflation gauges available on the market, highlighting their various types, applications, and the importance of selecting the right tools for different vehicles and industries.

By equipping buyers with essential insights on supplier vetting, cost considerations, and key product features, this comprehensive resource aims to empower informed purchasing decisions. Buyers will learn how to assess quality and reliability, ensuring they select gauges that meet both safety standards and performance expectations. Furthermore, the guide addresses the nuances of regional market demands, allowing businesses to tailor their sourcing strategies effectively.

With a focus on delivering actionable knowledge, this guide serves as an invaluable tool for B2B buyers seeking to enhance their operational efficiency while navigating the complexities of the tire inflation gauge market. Whether you’re in Brazil, Saudi Arabia, or anywhere in between, understanding these elements will help you make confident, strategic choices that contribute to your bottom line.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Analog Tire Pressure Gauge | Mechanical dial, typically ranges from 0-100 PSI | Automotive repair shops, fleet management | Pro: Simple to use, no batteries required. Contro: Less precise than digital options. |

| Digital Tire Pressure Gauge | Electronic display, often with backlighting, precise readings | Automotive service centers, racing teams | Pro: High accuracy, easy to read. Contro: Requires batteries, potentially less durable. |

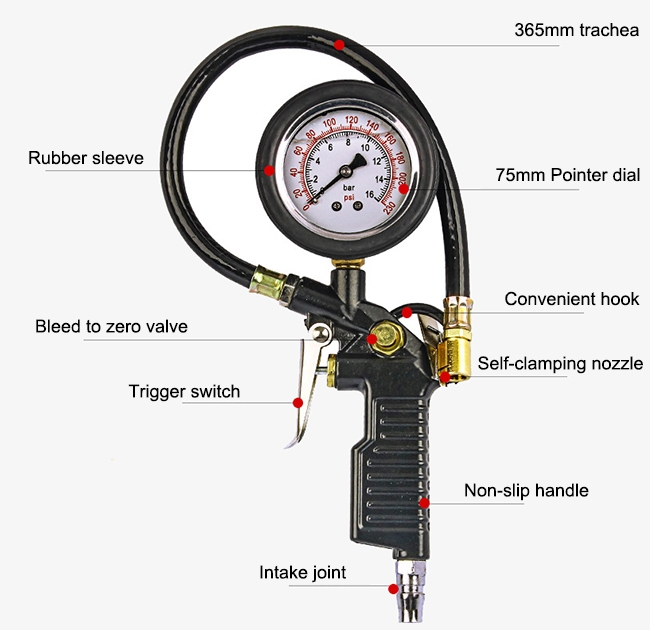

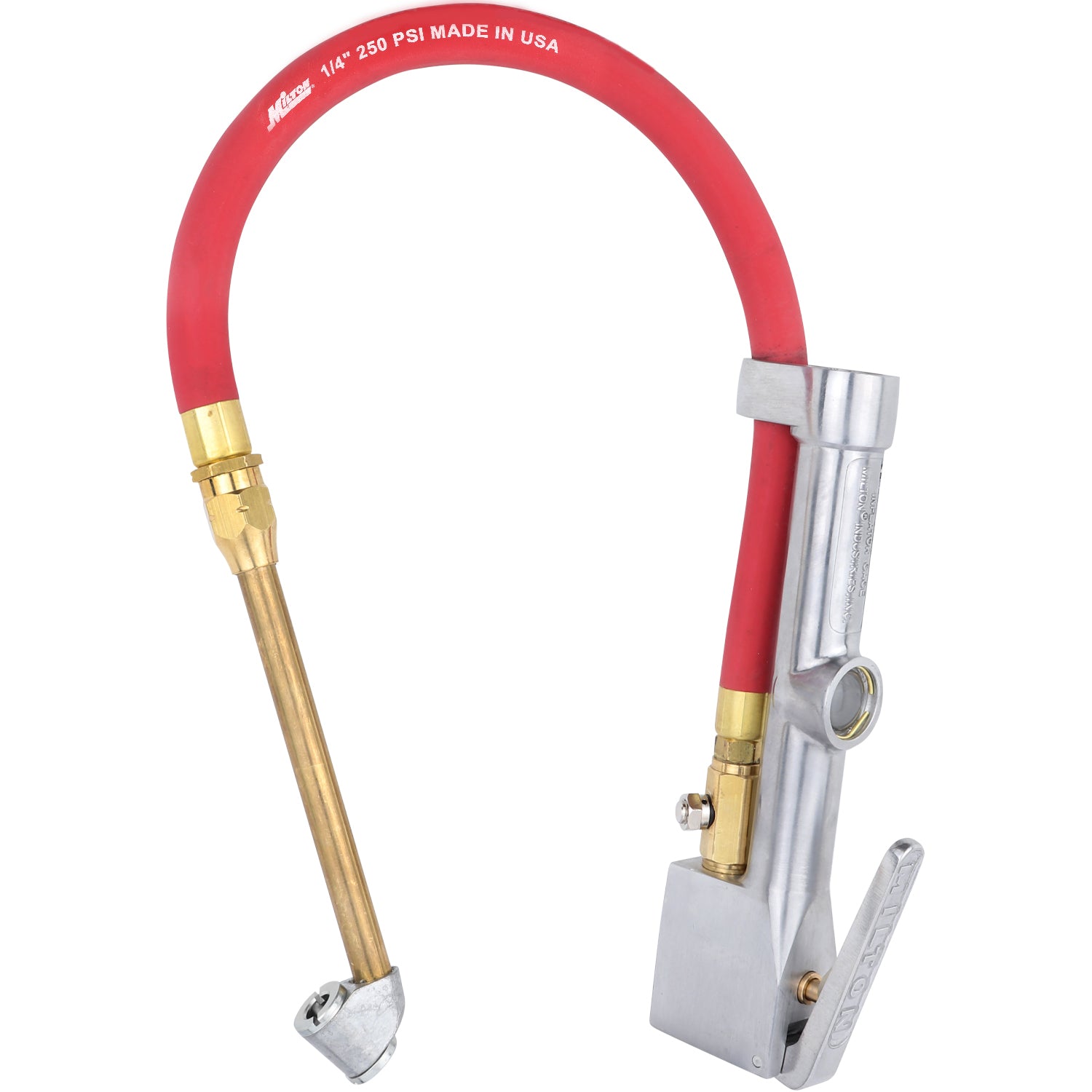

| Tire Inflator Gauge | Combines inflation and pressure measurement in one device | Tire shops, emergency service vehicles | Pro: Versatile, saves time. Contro: May require air compressor, can be bulkier. |

| Low-Pressure Tire Gauge | Specifically designed for low-pressure applications (e.g., ATVs) | Off-road vehicle maintenance, specialty shops | Pro: Accurate for low PSI measurements. Contro: Limited to specific applications. |

| Heavy-Duty Tire Pressure Gauge | Robust construction, often features a longer hose and durable design | Commercial fleets, heavy machinery operators | Pro: Built for durability, suitable for various tire types. Contro: Costo iniziale più elevato. |

Analog tire pressure gauges are mechanical devices that utilize a dial to indicate pressure levels, typically ranging from 0 to 100 PSI. They are favored in automotive repair shops and fleet management due to their simplicity and reliability. B2B buyers appreciate that these gauges do not require batteries, making them ideal for environments where power sources are limited. However, their accuracy may not match that of digital gauges, which can be a consideration for businesses focused on precision.

Illustrative image related to tire inflation gauge

Digital tire pressure gauges are known for their electronic displays, which often feature backlighting for easy reading in low-light conditions. These gauges provide precise measurements, making them suitable for automotive service centers and racing teams where accuracy is paramount. B2B buyers should consider the need for battery replacements and potential durability issues, but the benefits of high accuracy and ease of use often outweigh these drawbacks.

Tire inflator gauges combine the functions of inflating tires and measuring pressure, streamlining the process significantly. They are particularly useful in tire shops and for emergency service vehicles that require quick and efficient tire maintenance. While they offer versatility, buyers should be aware that many models require an air compressor, which can limit their portability and ease of use in certain situations.

Low-pressure tire gauges are specifically designed to measure lower PSI levels, making them ideal for off-road vehicles and specialty applications. Businesses involved in off-road vehicle maintenance or those operating in niche markets will find these gauges invaluable. While they provide accurate readings for specific needs, their limited range may not be suitable for general automotive applications.

Heavy-duty tire pressure gauges are built to withstand rigorous use, featuring robust construction and longer hoses for accessibility. They are often utilized by commercial fleets and heavy machinery operators who require reliable tools for various tire types. Although the initial investment may be higher, the durability and versatility of these gauges can lead to cost savings over time, making them a wise choice for businesses focused on long-term performance.

| Industria/Settore | Specific Application of Tire Inflation Gauge | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Riparazione di autoveicoli | Routine tire pressure checks for customer vehicles | Enhances customer safety and vehicle performance, reducing liability | Accuracy, durability, and ease of use are critical factors |

| Trasporto e logistica | Maintenance of commercial vehicle tire pressures | Increases fuel efficiency and extends tire lifespan, reducing costs | High PSI range and compatibility with various tire types |

| Produzione | Quality control in tire production | Ensures product quality and compliance with industry standards | Calibration accuracy and ability to handle high pressures |

| Agricoltura | Tire maintenance for farming equipment | Improves efficiency and reduces downtime in field operations | Rugged design and versatility for different equipment types |

| Sports & Recreation | Maintenance of sports equipment and recreational vehicles | Ensures safety and performance during usage | Lightweight design and portability for ease of transport |

In the automotive repair industry, tire inflation gauges are essential tools for performing routine checks on customer vehicles. Accurate tire pressure is crucial for safety and optimal vehicle performance, as under-inflated tires can lead to accidents and increased fuel consumption. Repair shops must ensure that the gauges they use are durable and provide precise readings, as customer trust hinges on the reliability of their services. For international buyers, sourcing gauges that meet regional regulations and standards is vital to maintain compliance and enhance service quality.

In the transportation and logistics sector, maintaining proper tire pressure in commercial vehicles is paramount. Tire inflation gauges help fleet managers ensure that all vehicles operate efficiently, which translates to lower fuel costs and reduced tire wear. This is especially important in regions where fuel prices are volatile. Companies should consider gauges that are versatile enough to accommodate various tire sizes and pressures while being robust enough to withstand daily use in diverse environments, particularly in regions like Africa and South America.

Manufacturers of tires rely on tire inflation gauges to uphold quality control standards during production. Ensuring that tires are inflated to the correct pressure is crucial for meeting safety and performance benchmarks. This not only impacts customer satisfaction but also compliance with industry regulations. For B2B buyers in this sector, sourcing gauges that offer high calibration accuracy and can handle the high pressures typical in tire manufacturing is essential to maintain product integrity.

In the agricultural industry, tire inflation gauges are vital for maintaining the performance of farming equipment. Proper tire pressure directly affects the efficiency of machinery, impacting productivity and minimizing downtime during critical planting and harvesting seasons. Buyers in this sector should prioritize rugged, high-performance gauges that can withstand the harsh conditions of agricultural environments while ensuring compatibility with various types of equipment. This is particularly relevant in regions with diverse agricultural practices, such as Brazil and Saudi Arabia.

In the sports and recreation sector, tire inflation gauges are used to maintain the safety and performance of various recreational vehicles and sports equipment. Ensuring that tires are inflated to the correct pressure can prevent accidents and enhance the overall experience for users. Buyers in this field should look for lightweight, portable gauges that are easy to transport and use, especially in outdoor settings. This is crucial for businesses catering to adventure tourism or sporting events, particularly in regions with active outdoor lifestyles.

Illustrative image related to tire inflation gauge

Il problema: For B2B buyers managing fleets or maintaining commercial vehicles, inaccurate tire pressure readings can lead to severe safety risks and increased operational costs. A faulty tire inflation gauge may report incorrect PSI, resulting in under-inflated or over-inflated tires. This not only impacts vehicle performance and fuel efficiency but also poses a significant safety hazard, potentially leading to tire blowouts and accidents. The challenge is particularly pronounced in regions with varying climates, where changes in temperature can further affect tire pressure.

La soluzione: To ensure accurate pressure readings, B2B buyers should invest in high-quality, certified tire inflation gauges that meet industry standards, such as ANSI B40.1. It’s advisable to perform regular calibration checks on gauges to verify their accuracy, especially before long-haul journeys. Additionally, consider incorporating digital tire inflation gauges, which often feature more precise readings and can reduce human error associated with manual gauges. Educating staff on the importance of checking tire pressure regularly, particularly before vehicle dispatch, can significantly mitigate risks. Implementing a routine maintenance schedule that includes tire pressure checks will enhance fleet safety and operational efficiency.

Il problema: Many B2B buyers face challenges when it comes to using tire inflation gauges under diverse working conditions, such as in remote areas or extreme weather. Manual gauges can be hard to read in low-light conditions or when the vehicle is positioned at awkward angles. Furthermore, the physical handling of gauges can become cumbersome, particularly when dealing with larger vehicles or equipment in tight spaces.

La soluzione: To address these usability issues, it is crucial to select tire inflation gauges designed for versatility and ease of use. Products with features like glow-in-the-dark dials or backlit displays can significantly enhance readability in low-light environments. Ergonomically designed gauges that provide a comfortable grip will facilitate easier handling, especially in awkward positions. Additionally, using gauges with flexible hoses or swivel chucks can help reach valves on vehicles with limited access. Providing comprehensive training for staff on the correct techniques for using tire inflation gauges in various conditions can further streamline operations and improve accuracy.

Il problema: B2B buyers managing fleets that include a variety of vehicles—such as cars, trucks, and specialized equipment—often encounter the issue of differing tire pressure requirements. Using a single type of tire inflation gauge may not meet the diverse needs of various vehicles, leading to inconsistent tire maintenance practices that can affect vehicle performance and safety.

Illustrative image related to tire inflation gauge

La soluzione: To effectively manage multiple tire types and their respective pressure requirements, it is essential to invest in a range of tire inflation gauges that cater to different PSI needs. For example, a digital tire inflator with adjustable pressure settings can accommodate various vehicle specifications, from standard passenger cars to high-pressure truck tires. Buyers should also consider gauges that display both PSI and kPa for flexibility in usage, especially in regions where different measurement systems are prevalent. Establishing a standardized protocol for tire pressure checks across all vehicle types, along with maintaining a well-organized inventory of gauges, will ensure consistent practices and enhance overall fleet management efficiency. Regular training sessions on the specific pressure requirements for different vehicles will further empower staff to uphold safety and performance standards.

When selecting materials for tire inflation gauges, several common options stand out due to their unique properties and performance characteristics. Understanding these materials can help international B2B buyers make informed decisions that align with their operational requirements and regional standards.

Proprietà chiave: Brass is known for its excellent corrosion resistance and good mechanical properties, making it suitable for various environmental conditions. It can withstand high pressures, typically rated up to 200 PSI, and performs well in a range of temperatures.

Illustrative image related to tire inflation gauge

Pro e contro: The durability of brass contributes to a long lifespan, which is a significant advantage for tire inflation gauges. However, brass can be more expensive than other materials, and its manufacturing process may involve complex machining, leading to higher production costs.

Impatto sull'applicazione: Brass is compatible with air and other non-corrosive gases, making it ideal for tire inflation applications. However, it may not be suitable for use with aggressive chemicals or environments with high humidity.

Considerazioni per gli acquirenti internazionali: Buyers in regions like Africa and South America should ensure compliance with local standards, such as ASTM or DIN, which may dictate material specifications. Brass is widely accepted, but pricing fluctuations can impact procurement strategies.

Proprietà chiave: Steel, particularly stainless steel, is renowned for its strength and durability. It offers high resistance to wear and tear and can handle pressures exceeding 300 PSI.

Illustrative image related to tire inflation gauge

Pro e contro: The key advantage of steel is its robustness, making it suitable for heavy-duty applications. However, it can be prone to rust if not properly treated, which could limit its lifespan in humid environments. Additionally, steel is generally heavier than other materials, which may affect the overall weight of the gauge.

Impatto sull'applicazione: Steel’s compatibility with air makes it a reliable choice for tire inflation. However, its susceptibility to corrosion necessitates protective coatings, which can add to manufacturing complexity.

Considerazioni per gli acquirenti internazionali: Buyers from the Middle East and Europe should consider the corrosion resistance of steel in their specific climates. Compliance with ISO standards is crucial, as is understanding the local market for steel products.

Proprietà chiave: Plastics, such as polycarbonate or ABS, are lightweight and can be molded into various shapes. They typically have lower temperature and pressure ratings than metals, generally around 100 PSI.

Illustrative image related to tire inflation gauge

Pro e contro: The primary advantage of plastic is its cost-effectiveness and ease of manufacturing, allowing for mass production. However, plastics may not offer the same durability or pressure resistance as metals, which could limit their application in high-performance scenarios.

Impatto sull'applicazione: While suitable for light-duty tire inflation, plastics may not perform well under extreme conditions or with high-pressure requirements. They are often used in consumer-grade gauges rather than professional tools.

Considerazioni per gli acquirenti internazionali: Buyers should evaluate the quality of plastic materials and ensure they meet safety standards relevant to their region. In Europe, for instance, compliance with REACH regulations is essential.

Proprietà chiave: Aluminum is lightweight and has good corrosion resistance, typically rated for pressures up to 150 PSI. It is also an excellent conductor of heat, which can be beneficial in certain applications.

Pro e contro: The lightweight nature of aluminum makes it easy to handle and transport. However, it is less durable than steel and can be more expensive to manufacture due to the need for specialized machining.

Impatto sull'applicazione: Aluminum is suitable for air applications and can be used in environments where weight is a consideration, such as in portable tire inflators. However, it may not be ideal for heavy-duty applications where high pressure and durability are critical.

Considerazioni per gli acquirenti internazionali: Buyers in regions with stringent material regulations, such as Europe, should ensure that aluminum products comply with relevant standards. Understanding the local market for aluminum can also help in negotiating better pricing.

Illustrative image related to tire inflation gauge

| Materiale | Typical Use Case for Tire Inflation Gauge | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Brass | Professional-grade gauges | Excellent corrosion resistance | Higher manufacturing costs | Medio |

| Acciaio | Applicazioni per impieghi gravosi | Elevata resistenza e durata | Prone to rust without treatment | Medio |

| Plastica | Consumer-grade gauges | Economico e leggero | Limited pressure and temperature rating | Basso |

| Alluminio | Portable tire inflators | Leggero e resistente alla corrosione | Less durable than steel | Medio |

This analysis provides a comprehensive overview of the materials commonly used in tire inflation gauges, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

The manufacturing process of tire inflation gauges involves several critical stages, each aimed at ensuring the final product meets performance and quality standards.

The first stage of manufacturing begins with the careful selection and preparation of raw materials. Common materials used include durable metals such as brass and aluminum for the gauge body, rubber for seals, and glass or plastic for the dial cover. Suppliers should ensure that these materials comply with international quality standards to ensure longevity and accuracy.

In the forming stage, manufacturers employ various techniques to create the components of the tire inflation gauge. Common methods include:

These techniques not only shape the materials but also influence the gauge’s durability and reliability.

Illustrative image related to tire inflation gauge

Assembly is a crucial phase where all the components come together. Skilled technicians or automated systems fit the gauge body, pressure mechanism, and display dial. Key assembly steps include:

Quality assurance is paramount in the manufacturing of tire inflation gauges, as precision is essential for safety and reliability. Manufacturers typically adhere to several international standards, such as ISO 9001, which outlines requirements for quality management systems.

International standards ensure that products meet global quality benchmarks. For tire inflation gauges, relevant certifications may include:

B2B buyers should verify that suppliers possess these certifications, as they indicate a commitment to quality and reliability.

To maintain high standards, manufacturers implement several quality control checkpoints throughout the production process:

Illustrative image related to tire inflation gauge

For international B2B buyers, especially those from regions like Africa, South America, and the Middle East, verifying a supplier’s quality control processes is essential. Here are actionable steps:

Manufacturers typically employ several testing methods to ensure that tire inflation gauges function correctly:

International B2B buyers must navigate unique challenges when sourcing tire inflation gauges from global suppliers. Key considerations include:

In conclusion, the manufacturing and quality assurance processes for tire inflation gauges are intricate and vital for ensuring product reliability. By understanding these processes, B2B buyers can make informed decisions, ensuring that they procure high-quality gauges that meet their operational needs. Adopting a thorough approach to supplier evaluation and quality assurance can lead to better partnerships and enhanced product performance in the field.

Illustrative image related to tire inflation gauge

This sourcing guide provides a systematic approach for B2B buyers looking to procure tire inflation gauges. Given the diverse applications across industries—from automotive to logistics—selecting the right gauge can enhance operational efficiency and safety. Follow these steps to ensure you make informed purchasing decisions.

Establishing clear technical specifications is the foundation of your procurement process. Determine the required pressure range (e.g., 0-100 PSI, 0-200 PSI) and gauge type (analog vs. digital) based on your specific use cases. Consider the materials and construction quality, as heavy-duty models may be necessary for rugged environments.

Understanding your budget is crucial for narrowing down your options. Evaluate the total cost of ownership, which includes the purchase price, maintenance, and potential replacement costs over time. Compare pricing across different suppliers to ensure you are getting the best value without compromising on quality.

Before making a commitment, it’s essential to research potential suppliers thoroughly. Look for reviews, testimonials, and case studies from other businesses in similar industries. Pay attention to their history of reliability and customer service, as this can significantly impact your purchasing experience.

Illustrative image related to tire inflation gauge

Ensure that the tire inflation gauges you are considering meet relevant industry standards and certifications. This may include ANSI or ISO certifications, which indicate adherence to quality and safety benchmarks. Compliance not only ensures product reliability but also protects your business from liability issues.

Whenever possible, request samples of the gauges you are considering. This allows you to assess their performance and usability firsthand. Evaluate the ease of reading the gauge, the quality of construction, and whether it meets your specific operational needs.

After-sales support can be a deciding factor in your purchasing decision. Check if the supplier offers a warranty on their products and what that entails. Reliable customer support can be invaluable for troubleshooting and ensuring longevity of the product, so prioritize suppliers who demonstrate a commitment to service.

Once you have selected a supplier, engage in negotiations to clarify pricing, delivery timelines, and payment terms. Establishing clear contractual terms is vital for safeguarding your interests. Confirm all details in writing before finalizing your order to prevent any misunderstandings later on.

By following these steps, B2B buyers can make informed decisions that enhance operational efficiency and ensure safety in tire maintenance practices.

When sourcing tire inflation gauges, understanding the cost structure is crucial for optimizing your procurement strategy. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

I materiali: The choice of materials significantly impacts the overall cost. High-quality brass, durable plastics, and precision gauges can increase the cost but contribute to better performance and longevity. Opting for lower-quality materials may reduce initial costs but could lead to higher replacement rates.

Lavoro: Labor costs vary by region and can influence the overall pricing. Regions with higher labor costs may result in higher prices for tire inflation gauges. In contrast, sourcing from countries with lower labor costs might provide short-term savings.

Illustrative image related to tire inflation gauge

Spese generali di produzione: This includes costs related to utilities, rent, and equipment maintenance. A manufacturer with efficient operations can offer more competitive pricing, making it essential to evaluate potential suppliers’ overhead management.

Utensili: Custom tooling for unique designs or specifications can be a significant upfront cost. If you require specialized gauges, factor in these costs when assessing supplier quotes.

Controllo qualità (CQ): Effective quality assurance processes ensure that products meet specifications and reduce the risk of defects. Suppliers who prioritize QC may charge a premium, but the investment often pays off in reduced warranty claims and enhanced customer satisfaction.

Logistica: Shipping costs, including freight and customs duties, can vary significantly based on the source country and destination. Consider these costs in your total procurement budget, especially for international shipments.

Margine: Suppliers typically include a profit margin in their pricing. Understanding the market rates for similar products can help you negotiate better terms.

Illustrative image related to tire inflation gauge

Several factors influence the pricing of tire inflation gauges, making it essential for buyers to consider these when sourcing.

Volume e quantità minima d'ordine (MOQ): Ordering in bulk often leads to significant discounts. Suppliers may offer better pricing for higher volumes, so it’s beneficial to assess your long-term needs and negotiate accordingly.

Specifiche e personalizzazione: Customized gauges with specific features or branding can increase costs. Clearly define your requirements and compare quotes from different suppliers to ensure you receive fair pricing for any modifications.

Qualità dei materiali e certificazioni: Products that comply with international standards or certifications may command higher prices. Ensure that the investment in quality and compliance aligns with your market demands.

Illustrative image related to tire inflation gauge

Fattori di fornitura: The reputation and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge a premium, but they often provide better customer service and product consistency.

Incoterms: The agreed terms of shipment (e.g., FOB, CIF) can affect the final price. Understanding Incoterms will help you calculate the total landed cost and avoid unexpected expenses.

To maximize cost-efficiency in your procurement process, consider the following tips:

Negoziare: Always negotiate pricing and terms with suppliers. Leverage your purchasing power, especially if you are a large buyer or can provide consistent orders over time.

Valutare il costo totale di proprietà (TCO): Look beyond the initial purchase price. Assess factors such as maintenance costs, lifespan, and warranty services to understand the total cost associated with a product.

Comprendere le sfumature dei prezzi per i mercati internazionali: Different regions may have varying pricing structures due to economic conditions, supply chain factors, and local competition. Familiarize yourself with the market dynamics in regions like Africa, South America, the Middle East, and Europe.

Consider Local Sourcing: If possible, sourcing from local suppliers can reduce shipping costs and lead times, improving overall efficiency.

Rimanete informati sulle tendenze del mercato: Keep abreast of market trends, including material costs and technological advancements, to make informed sourcing decisions.

By understanding the cost components, price influencers, and effective negotiation strategies, B2B buyers can make smarter decisions when sourcing tire inflation gauges, ensuring they achieve the best value for their investment.

When it comes to ensuring optimal tire pressure, various tools and methods exist beyond traditional tire inflation gauges. Understanding these alternatives can help B2B buyers select the most suitable solution for their operational needs, especially considering factors like performance, cost, and usability. Below, we compare tire inflation gauges with two viable alternatives: digital tire inflators and automatic tire inflation systems.

| Aspetto di confronto | Tire Inflation Gauge | Digital Tire Inflator | Automatic Tire Inflation System |

|---|---|---|---|

| Prestazioni | Accurate manual measurement | Quick and easy inflation with digital readout | Continuous monitoring and inflation |

| Costo | $19.95 – $39.99 | $35.95 – $89.99 | $1,000+ (installation costs) |

| Facilità di implementazione | Simple to use | Requires basic knowledge of operation | Requires professional installation |

| Manutenzione | Low (occasional calibration) | Moderate (battery replacement) | High (system checks and maintenance) |

| Il miglior caso d'uso | Personal and small fleet use | Small to medium fleets needing quick service | Large fleets requiring constant monitoring |

Digital tire inflators offer a significant upgrade over traditional gauges by providing quick inflation and precise digital readouts. They often come equipped with features like automatic shut-off and preset pressure settings, which enhance convenience during tire servicing. This makes them an excellent choice for businesses with small to medium fleets that require efficiency in tire maintenance. However, they tend to be more expensive than manual gauges and may require occasional battery replacements, adding to their long-term maintenance costs.

Automatic tire inflation systems represent the pinnacle of tire maintenance technology, continuously monitoring and adjusting tire pressure as needed. This system is particularly beneficial for large fleets, such as trucking companies, where maintaining optimal tire pressure is critical for safety and fuel efficiency. While these systems offer unparalleled convenience and safety, they come with a high upfront cost and require professional installation. Additionally, ongoing maintenance can be complex, demanding a dedicated team to ensure the system functions properly.

Choosing the right tire inflation solution depends on your specific business needs, operational scale, and budget constraints. For smaller businesses or those just starting, a tire inflation gauge or digital inflator might be sufficient, offering a balance of performance and cost-effectiveness. Conversely, larger organizations or those with significant fleet management responsibilities may find that investing in an automatic tire inflation system pays off in the long run through enhanced safety and reduced downtime. By carefully considering these factors, B2B buyers can make informed decisions that align with their operational requirements and financial goals.

When considering a tire inflation gauge for your business, understanding its technical properties is crucial for ensuring quality and performance. Here are some essential specifications that buyers should prioritize:

Pressure Range

Tire inflation gauges typically have a specified pressure range, often measured in PSI (pounds per square inch) or kPa (kilopascals). A common range is 0-100 PSI for standard vehicles, while specialized gauges may go up to 200 PSI or more for heavy-duty applications. Selecting a gauge with the appropriate range ensures it meets the needs of various tire types, from passenger cars to commercial trucks.

Accuracy Rating

Accuracy is critical in tire inflation to avoid under or over-inflation, which can lead to increased tire wear and reduced fuel efficiency. Gauges are often certified by standards such as ANSI B40.1, which defines the acceptable tolerance levels. An accuracy rating of ±1 PSI is generally considered sufficient for most applications, emphasizing the importance of precise readings in maintaining optimal tire performance.

Composizione del materiale

The durability and longevity of a tire inflation gauge are significantly influenced by its material composition. Common materials include high-grade brass, stainless steel, and reinforced plastics. Gauges made from these materials are less likely to corrode or break, providing a longer service life, especially in harsh environments typical of industrial or off-road settings.

Display Type

Tire inflation gauges come with various display types, including analog dials and digital screens. Digital gauges often provide easier readability and can include features like backlighting, while analog gauges are typically more rugged and require no batteries. The choice between these types can impact ease of use, especially in low-light conditions or for rapid readings.

Lunghezza e flessibilità del tubo flessibile

The hose length and its flexibility are essential for accessing hard-to-reach valve stems. A longer, more flexible hose can facilitate easier inflation in tight spaces, enhancing user convenience. This aspect is particularly important for businesses operating in diverse environments or with a fleet of vehicles requiring regular tire maintenance.

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some key terms to be familiar with:

Illustrative image related to tire inflation gauge

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand name. For tire inflation gauges, knowing whether a product is OEM can indicate its quality and compatibility with existing systems or equipment.

MOQ (quantità minima d'ordine)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This is crucial for B2B buyers, as it affects inventory management and cost calculations. Understanding the MOQ helps businesses plan their purchases effectively.

RFQ (Richiesta di offerta)

An RFQ is a standard business process where a buyer requests pricing and other information from suppliers for specific products. For tire inflation gauges, issuing an RFQ can help buyers compare offers and negotiate better terms, ensuring they get the best value for their investment.

Incoterms (Termini commerciali internazionali)

These are a set of international rules that define the responsibilities of buyers and sellers in global trade. Familiarity with Incoterms is essential when importing tire inflation gauges, as it clarifies issues such as shipping costs, risks, and the transfer of ownership.

Calibration

Calibration refers to the process of configuring an instrument to provide accurate measurements. Regular calibration of tire inflation gauges is necessary to maintain their accuracy and reliability, which is vital for safety and performance in vehicle operations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when purchasing tire inflation gauges, ensuring they select products that meet their operational needs and industry standards.

The tire inflation gauge market is experiencing significant growth driven by several global factors. Increasing vehicle ownership, particularly in emerging markets such as Brazil, Saudi Arabia, and other African nations, is leading to heightened demand for automotive maintenance tools. Furthermore, the growing emphasis on vehicle safety and efficiency is prompting both consumers and businesses to prioritize regular tire pressure checks, thus boosting the demand for reliable inflation gauges.

Current trends indicate a shift towards digital and smart tire inflation gauges, incorporating advanced technology such as Bluetooth connectivity and integrated sensors. These innovations offer real-time data transmission to mobile applications, allowing users to monitor tire pressure remotely. Additionally, the integration of Artificial Intelligence (AI) in tire maintenance tools is gaining traction, enabling predictive analytics for optimal performance and safety.

From a sourcing perspective, international B2B buyers are increasingly focused on establishing relationships with manufacturers who can provide high-quality, durable products at competitive prices. The rise of e-commerce platforms is facilitating easier access to global suppliers, making it simpler for businesses in Africa and South America to source tire inflation gauges that meet their specific needs. Furthermore, partnerships with local distributors are becoming vital for navigating regional regulations and ensuring timely delivery.

Sustainability is becoming a critical consideration in the tire inflation gauge sector. The environmental impact of manufacturing processes and the materials used in these products are under scrutiny. Buyers are increasingly seeking suppliers who utilize eco-friendly materials and processes to minimize their carbon footprint. This shift not only caters to consumer preferences but also aligns with global sustainability goals.

Illustrative image related to tire inflation gauge

Ethical sourcing practices are essential in establishing a responsible supply chain. Companies are encouraged to work with manufacturers who adhere to fair labor practices and have transparent supply chains. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the demand for “green” products is on the rise, with buyers showing interest in gauges made from recyclable materials or featuring biodegradable components. By prioritizing sustainability and ethical sourcing, businesses can enhance their brand reputation and appeal to a more environmentally conscious customer base.

The tire inflation gauge has evolved significantly since its inception. Initially, these tools were basic analog devices that provided limited functionality. Over the decades, technological advancements have led to the development of more sophisticated gauges that offer enhanced accuracy and usability.

The introduction of digital tire pressure gauges marked a turning point, providing users with precise readings and often additional features such as backlit displays and automatic shut-off functions to conserve battery life. More recently, the integration of smart technology has transformed how users interact with tire maintenance, enabling features like mobile app connectivity and real-time monitoring.

As the automotive landscape continues to evolve, tire inflation gauges are likely to see further innovations, enhancing their role in vehicle maintenance and contributing to overall road safety. For B2B buyers, understanding this evolution is crucial for making informed purchasing decisions that align with current and future market trends.

How do I ensure the accuracy of tire inflation gauges when sourcing suppliers?

To ensure accuracy, look for suppliers that provide detailed specifications and certification standards for their tire inflation gauges. Certifications such as ANSI B40.1 indicate that the product meets established accuracy standards. Request samples to conduct tests under your operational conditions, and consider customer reviews or third-party testing results as additional verification. Establish clear communication with potential suppliers to understand their quality assurance processes and policies regarding returns or replacements for inaccurate gauges.

What is the best tire inflation gauge for diverse applications?

The best tire inflation gauge for diverse applications is one that offers versatility in pressure range and compatibility with various tire types, including cars, motorcycles, and bicycles. Look for gauges with features like dual pressure measurement (PSI and kPa) and a robust design for durability. Digital gauges often provide precise readings and ease of use, while analog gauges can be more rugged. Brands with a reputation for reliability and strong customer support are recommended, especially for businesses that require consistent performance.

What are the common minimum order quantities (MOQs) for tire inflation gauges?

Minimum order quantities (MOQs) for tire inflation gauges can vary significantly depending on the supplier, the product type, and the materials used. Typically, MOQs range from 50 to 500 units for bulk purchases. It’s crucial to discuss your specific needs with potential suppliers, as some may offer flexibility in MOQs based on your business relationship or potential for future orders. Additionally, consider negotiating terms that allow for smaller trial orders before committing to larger quantities.

How can I vet suppliers of tire inflation gauges for international trade?

Vetting suppliers for international trade involves several steps. Start by verifying their business credentials, such as registration and compliance with local regulations. Look for suppliers with experience in exporting to your region, as they will be familiar with customs and logistics. Request references or case studies from previous clients, and utilize platforms like Alibaba or Global Sources to check ratings and reviews. Conduct video calls or site visits, if possible, to assess their manufacturing capabilities and quality control processes.

What payment terms should I expect when sourcing tire inflation gauges internationally?

Payment terms can vary widely among international suppliers, but common practices include upfront payments, partial payments, or payment upon delivery. Expect to negotiate terms that align with your cash flow and risk tolerance. Some suppliers may offer credit terms, especially if you establish a good relationship. It’s advisable to use secure payment methods, such as letters of credit or escrow services, to minimize risks. Always clarify the terms in your contract to avoid misunderstandings later.

What quality assurance measures should I look for in tire inflation gauges?

Quality assurance measures should include thorough testing protocols, adherence to international standards, and a clear warranty policy. Inquire whether the supplier conducts regular inspections and what certifications their products hold. Ask about their return and replacement policies for defective items. A reputable supplier will provide documentation of quality checks and be open to discussing their processes to ensure that their products meet your expectations and industry standards.

How can I ensure timely logistics and delivery when sourcing tire inflation gauges?

To ensure timely logistics and delivery, collaborate with suppliers who have a solid track record of meeting shipping deadlines. Discuss shipping methods that align with your urgency, such as air freight for faster delivery or sea freight for cost-effective options. Establish clear timelines and milestones in your contract. Consider working with freight forwarders experienced in international trade who can help navigate customs and logistics challenges, ensuring your products arrive as scheduled.

What should I consider regarding customization options for tire inflation gauges?

Customization options for tire inflation gauges can include branding, specific pressure ranges, and additional features like backlit displays or ergonomic designs. When discussing customization with suppliers, clarify your requirements, including design specifications and production timelines. Be aware that custom orders may have higher MOQs and longer lead times. Request samples of any customized products to ensure they meet your standards before placing a larger order.

Dominio: mactools.com

Registrato: 1997 (28 anni)

Introduzione: This company, MacTools – Analog Tire Inflator Gauge, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: Brands mentioned: Milton, Longacre, Astro, Matco. Features: Longacre offers analog and digital models, including temperature compensated ones. Astro inflators are priced around $80. Matco DT6 is a rebranded Astro 3018, priced at $90. Recommendations suggest that tire inflators should not be relied upon for accurate pressure measurement.

Dominio: jacosuperiorproducts.com

Registrato: 2014 (11 anni)

Introduzione: [{‘name’: ‘ElitePro™ Tire Pressure Gauge – 60 PSI’, ‘price’: ‘$22.95’, ‘original_price’: ‘$49.99’, ‘features’: “Rated the ‘Easiest To Read’ Tire Pressure Gauge by Road & Track Magazine. Accurate. Durable. Reliable.”}, {‘name’: ‘ElitePro™ Tire Pressure Gauge – 100 PSI’, ‘price’: ‘$22.95’, ‘original_price’: ‘$49.99’, ‘features’: “Rated the ‘Easiest To Read’ Tire Pressure Gauge by Road & Track Magazi…

In today’s competitive landscape, effective strategic sourcing of tire inflation gauges can significantly enhance operational efficiency and customer satisfaction. By prioritizing quality and accuracy in tire pressure measurement, businesses can ensure optimal vehicle performance, safety, and fuel efficiency. The versatility of products available—from analog gauges to advanced digital inflators—allows buyers to cater to diverse needs, whether for automotive, industrial, or recreational applications.

For international buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe, the importance of aligning with reliable suppliers cannot be overstated. Investing in high-quality tire inflation gauges not only supports compliance with safety standards but also fosters long-term partnerships that can lead to reduced costs and improved service offerings.

As we look towards the future, the demand for innovative tire inflation solutions will continue to grow. B2B buyers should seize the opportunity to engage with reputable manufacturers and distributors, ensuring they stay ahead in a rapidly evolving market. By making informed sourcing decisions today, businesses can position themselves for sustained success and operational excellence.

Illustrative image related to tire inflation gauge

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.

Illustrative image related to tire inflation gauge