The increasing demand for efficient tire inflation solutions poses a significant challenge for international B2B buyers seeking reliable suppliers. As businesses strive to maintain operational efficiency and customer satisfaction, understanding the nuances of the tire inflation station market becomes crucial. This guide delves into the various types of tire inflation stations, their applications across different sectors, and practical insights on supplier vetting.

From traditional air machines to advanced digital inflators, the options are vast, each with unique features tailored to specific business needs. This comprehensive resource equips buyers from Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—with the knowledge to make informed purchasing decisions. By exploring cost considerations, maintenance requirements, and the latest technological advancements, readers can navigate the complexities of sourcing tire inflation stations effectively.

Moreover, this guide offers actionable insights on maximizing return on investment and enhancing customer experience through strategic air solutions. Ultimately, it serves as a vital tool for B2B buyers looking to optimize their operations while ensuring safety and reliability in tire maintenance. With the right information at hand, businesses can confidently select the tire inflation stations that best meet their unique requirements, driving both efficiency and profitability.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Digital Air Machines | Automated, user-friendly interface; precise tire calibration; cashless payment options | Gas stations, convenience stores, car washes | Pro: Attracts customers, enhances satisfaction; Contro: Higher initial investment costs. |

| Garage Inflation Stations | Compact design; wall-mounted; versatile for various vehicles and inflatables | Automotive repair shops, residential garages | Pro: Space-efficient, quick inflation; Contro: Limited to home usage. |

| Self-Service Kiosks | Coin-operated or free; accessible 24/7; often includes tire pressure monitoring | Fleets, auto rental companies, public areas | Pro: Low operational cost, increases customer footfall; Contro: Maintenance can be challenging. |

| Mobile Tire Inflation Units | Portable, often truck-mounted; equipped for roadside assistance and emergency use | Fleet services, emergency services, roadside assistance | Pro: Flexibility and mobility; Contro: Limited air capacity and may require frequent refilling. |

| Commercial Tire Inflation Systems | High-capacity, durable machines; designed for continuous use in high-demand environments | Tire shops, fleet maintenance facilities | Pro: Efficient for high volume; Contro: Requires significant space and investment. |

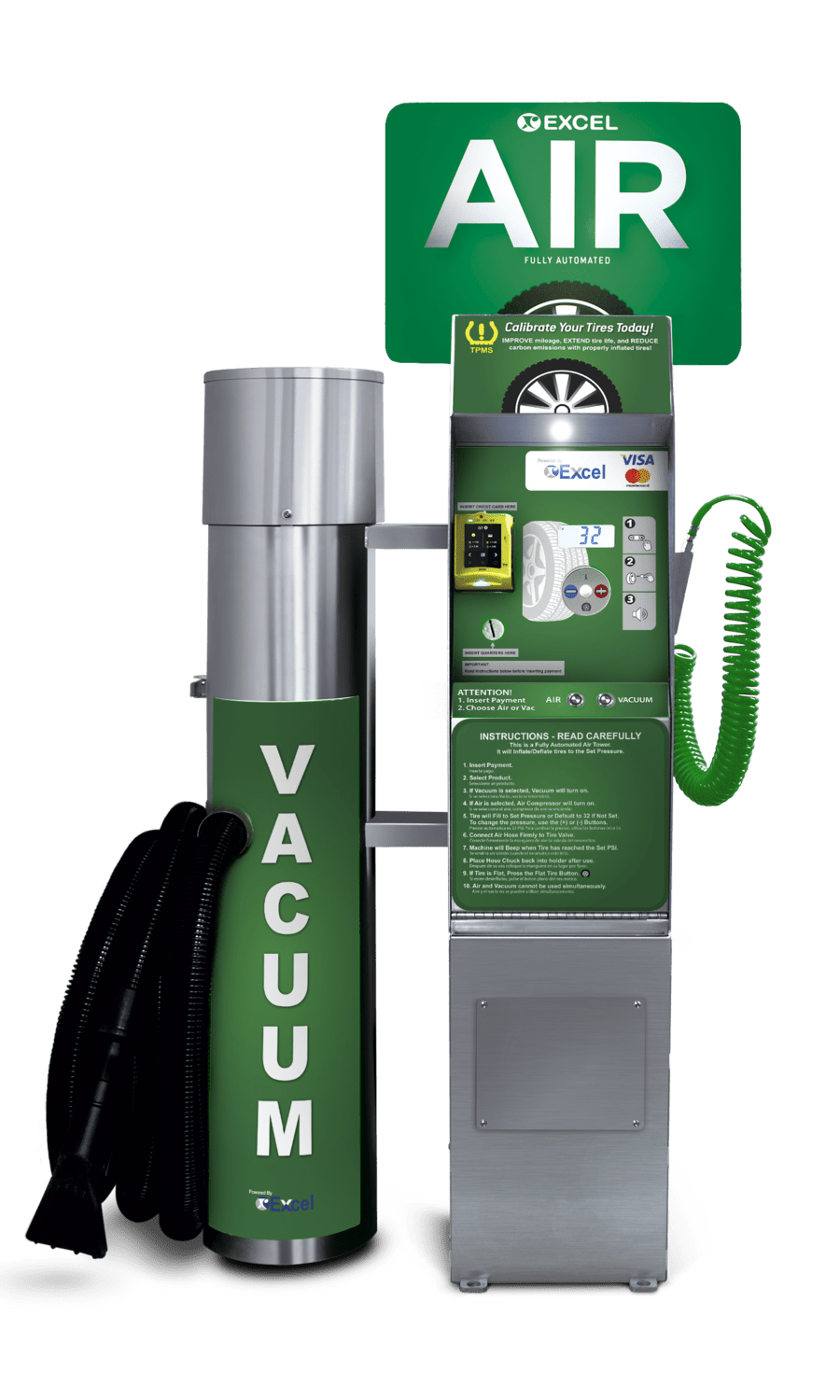

Digital air machines are characterized by their automated operation and user-friendly interfaces, allowing customers to easily inflate tires with precise calibration. These machines typically accept various payment methods, including cashless options, making them convenient for users. They are ideal for gas stations and convenience stores looking to enhance customer experience and increase foot traffic. When considering a purchase, B2B buyers should evaluate the machine’s durability, ease of use, and potential return on investment through increased sales.

Garage inflation stations are compact, wall-mounted units designed for home or small business use. They can quickly inflate a range of items, from car tires to sports equipment, making them versatile for automotive repair shops and residential garages. Their space-saving design is a significant advantage for buyers with limited space. However, B2B purchasers should consider the inflation speed and hose length to ensure they meet their specific needs.

Self-service kiosks are designed for 24/7 accessibility, allowing customers to inflate their tires at their convenience. Typically coin-operated or free, they are commonly found in fleet service areas and public spaces. The low operational cost and ability to attract new customers are strong selling points. However, buyers must be prepared for the challenges of maintenance and ensuring the machines are always functional to maintain customer satisfaction.

Mobile tire inflation units are portable solutions ideal for roadside assistance and emergency services. These truck-mounted systems can reach vehicles in various locations, providing convenience for fleet services and emergency responders. Their flexibility is a significant advantage, but buyers should be aware of the limitations in air capacity and the need for frequent refilling. Assessing the unit’s operational range and ease of transport is crucial for B2B buyers.

Commercial tire inflation systems are robust machines designed for high-demand environments such as tire shops and fleet maintenance facilities. They offer high-capacity inflation, making them suitable for businesses that require quick turnaround times. While these systems can significantly improve efficiency, potential buyers should consider the substantial investment and space requirements associated with these larger units. Evaluating the long-term benefits against initial costs is essential for informed purchasing decisions.

Illustrative image related to tire inflation station

| Industria/Settore | Specific Application of Tire Inflation Station | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Gas Stations & Convenience Stores | Providing free or paid air inflation services | Attracts customers, increases foot traffic, and boosts ancillary sales | Durability, ease of use, maintenance support, and revenue-sharing options |

| Negozi di riparazione di autoveicoli | Streamlining tire inflation during service appointments | Enhances technician efficiency and improves customer satisfaction | Accuracy, speed of inflation, and integration with existing equipment |

| Gestione della flotta | Regular maintenance of vehicle tire pressure | Increases fuel efficiency and extends tire lifespan | Scalability, reliability, and remote monitoring capabilities |

| Car Wash Facilities | Offering tire inflation as an additional service | Increases customer loyalty and encourages repeat visits | User-friendly interface, payment options, and space considerations |

| Rental Car Agencies | Ensuring optimal tire pressure before vehicle rentals | Reduces breakdowns and enhances customer safety | Precision, ease of use, and speed of service |

In gas stations and convenience stores, tire inflation stations serve as a crucial service point for drivers. By providing free or paid air inflation, these stations attract more customers who may also purchase fuel or snacks. The key for international buyers is to focus on machines that are durable and easy to maintain, especially in regions with extreme weather conditions. Additionally, revenue-sharing programs can offset initial costs and enhance profitability.

Automotive repair shops utilize tire inflation stations to streamline the tire servicing process. These stations allow technicians to quickly and accurately inflate tires, improving overall service efficiency and customer satisfaction. For buyers in this sector, it’s essential to consider machines that offer precise calibration and are user-friendly, as this will minimize training time and enhance productivity.

Fleet management companies rely on tire inflation stations to maintain optimal tire pressure across their vehicles. Regular inflation helps improve fuel efficiency and prolongs tire life, which is crucial for operational cost management. Buyers in this field should prioritize systems that offer scalability and remote monitoring capabilities to ensure comprehensive maintenance across diverse fleets.

Car wash facilities can enhance their service offerings by including tire inflation stations. This additional service not only improves customer experience but also encourages repeat visits as customers appreciate the convenience. When sourcing these stations, it’s vital to consider user-friendly interfaces and various payment options to cater to a wide range of customers, ensuring seamless operation.

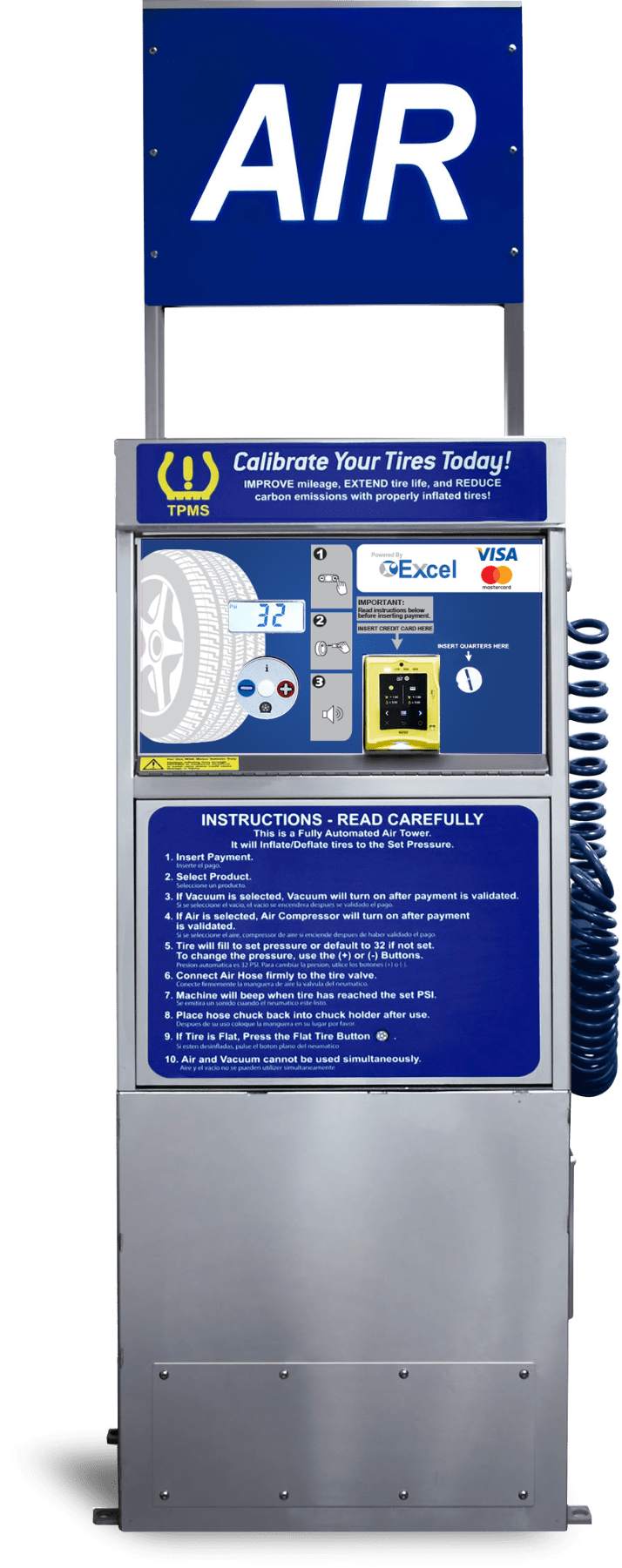

Illustrative image related to tire inflation station

Rental car agencies use tire inflation stations to ensure that vehicles are in optimal condition before being rented out. Proper tire pressure reduces the risk of breakdowns and enhances safety for renters. Buyers in this sector should seek inflation stations that are quick and easy to use, as well as those that provide accurate readings to ensure customer safety and satisfaction.

Il problema: Many B2B buyers, particularly those managing fleets or automotive services, face the issue of inconsistent tire pressure due to outdated or malfunctioning tire inflation stations. This inconsistency can lead to accelerated tire wear, reduced fuel efficiency, and increased maintenance costs. For fleet managers in regions with variable weather conditions, the challenge intensifies as fluctuations in temperature can significantly affect tire pressure. This not only impacts operational costs but also poses safety risks to drivers.

La soluzione: To mitigate this problem, B2B buyers should invest in modern digital tire inflation stations that provide precise air calibration. When sourcing these machines, look for models equipped with real-time pressure monitoring and automatic shut-off features to prevent over-inflation. Additionally, consider stations that can be integrated with mobile apps for remote monitoring. For example, providing employees with training on how to utilize these machines effectively can ensure that tire pressure is consistently maintained at optimal levels, thus enhancing tire longevity and safety.

Il problema: Automotive service providers and gas station owners often deal with the burden of high maintenance costs associated with outdated tire inflation equipment. Older models can break down frequently, require costly repairs, and lack the efficiency of newer machines. This not only drains financial resources but can also deter customers from using their services if they find the inflation process inconvenient or unreliable.

La soluzione: To address this, businesses should consider transitioning to newer, more reliable tire inflation stations that come with warranty support and lower maintenance needs. When evaluating options, prioritize machines with durable construction and user-friendly interfaces. It’s also beneficial to participate in a revenue share program with manufacturers who offer installation, maintenance, and support as part of the package. This not only minimizes upfront costs but also allows businesses to enhance customer satisfaction by providing a seamless tire inflation experience.

Illustrative image related to tire inflation station

Il problema: For gas stations and service centers, a lack of customer engagement can result in lost revenue opportunities. Customers may avoid using tire inflation stations if they perceive them as inconvenient, outdated, or difficult to operate. This is especially true in regions where competition is fierce, and businesses are vying for customer loyalty. If customers are not engaging with the tire inflation services, they are less likely to purchase other services or products offered at the location.

La soluzione: To enhance customer engagement, B2B buyers should invest in modern, aesthetically pleasing tire inflation stations that are easy to use and feature clear, multilingual instructions. Incorporating payment options such as contactless payments can also streamline the process. Additionally, consider placing signage that highlights the benefits of maintaining proper tire pressure, such as fuel savings and safety. By creating a positive user experience and educating customers on the importance of tire maintenance, businesses can drive traffic to their locations and encourage repeat visits. Implementing loyalty programs that reward customers for using the tire inflation station can further incentivize engagement.

When selecting materials for tire inflation stations, it is crucial to consider their properties, advantages, disadvantages, and how they align with international standards. The following analysis covers four common materials used in the construction of tire inflation stations: steel, aluminum, plastic, and rubber.

Steel is a widely used material in the construction of tire inflation stations due to its exceptional strength and durability. It typically has a high temperature and pressure rating, making it suitable for high-demand applications. Steel’s corrosion resistance can be enhanced through galvanization or powder coating, which helps protect against rust, especially in humid or corrosive environments.

Illustrative image related to tire inflation station

Pro: Steel is highly durable and can withstand harsh conditions, making it suitable for outdoor installations. It is also cost-effective for large-scale production due to its abundance and ease of manufacturing.

Contro: The weight of steel can complicate installation and maintenance. Additionally, if not properly treated, it can corrode over time, particularly in coastal or humid regions.

Impatto sull'applicazione: Steel’s strength makes it ideal for heavy-duty applications, but its weight may limit portability. International buyers should consider compliance with standards such as ASTM A36 for structural steel.

Aluminum is another popular choice for tire inflation stations, known for its lightweight and corrosion-resistant properties. It has a lower temperature and pressure rating compared to steel but is still sufficient for most tire inflation applications.

Pro: The lightweight nature of aluminum facilitates easier installation and maintenance. Its natural corrosion resistance makes it suitable for various climates, especially in coastal areas.

Illustrative image related to tire inflation station

Contro: Aluminum can be more expensive than steel, and while it is durable, it may not withstand extreme impacts as well as steel.

Impatto sull'applicazione: Aluminum is ideal for portable tire inflation stations. Buyers from regions with strict environmental regulations may prefer aluminum for its recyclability and lower carbon footprint. Compliance with standards like ASTM B221 for aluminum extrusions is essential.

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly used in tire inflation stations for components like housings and nozzles. These materials are lightweight and resistant to corrosion and chemicals.

Pro: Plastic is cost-effective and offers excellent resistance to various environmental factors. It is also easy to mold into complex shapes, allowing for innovative designs.

Contro: Plastics generally have lower strength and pressure ratings compared to metals. They may become brittle over time, especially under UV exposure.

Impatto sull'applicazione: Plastic components are suitable for less demanding applications, such as residential tire inflation stations. International buyers should consider compliance with standards such as ISO 9001 for quality management systems.

Rubber is primarily used for seals, hoses, and gaskets in tire inflation stations. Its excellent flexibility and resilience make it ideal for applications requiring airtight seals under varying pressure conditions.

Pro: Rubber provides excellent sealing capabilities and is resistant to wear and tear. It can also withstand a wide range of temperatures.

Contro: Rubber can degrade over time due to ozone exposure and UV radiation, necessitating regular inspections and replacements.

Impatto sull'applicazione: Rubber components are critical for ensuring the reliability of tire inflation stations. Buyers should be aware of compliance with standards such as ASTM D2000 for rubber materials.

| Materiale | Typical Use Case for tire inflation station | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Acciaio | Structural framework and housing | Elevata durata e resistenza | Can corrode if untreated | Medio |

| Alluminio | Portable inflation stations | Leggero e resistente alla corrosione | More expensive than steel | Alto |

| Plastica | Housings and nozzles | Cost-effective and easy to mold | Lower strength and pressure ratings | Basso |

| Gomma | Seals and hoses | Excellent sealing capabilities | Degrades over time without care | Medio |

This guide provides a comprehensive overview of the materials commonly used in tire inflation stations, equipping international B2B buyers with the insights needed for informed decision-making.

The manufacturing of tire inflation stations involves several critical stages that ensure both efficiency and quality. Understanding these processes can help B2B buyers make informed decisions when sourcing equipment.

Material preparation is the foundational step in manufacturing tire inflation stations. This phase typically involves sourcing high-quality materials such as steel for the frame, durable plastics for the casing, and specialized components like pressure gauges and inflation hoses. Suppliers often establish relationships with certified material vendors to ensure compliance with international standards, minimizing the risk of defects.

To further enhance durability, manufacturers may employ techniques such as galvanization or powder coating to protect metal parts from corrosion. This is especially important for markets in regions with high humidity or salt exposure, such as coastal areas in South America or the Middle East.

Forming is the next stage, where raw materials are shaped into parts. Common techniques include stamping, bending, and injection molding. For example, the frame of a tire inflation station is usually made from stamped steel, while plastic components, like the housing for electronic displays, are created through injection molding.

Advanced manufacturers may utilize computer numerical control (CNC) machining to achieve precise dimensions and tolerances. This level of accuracy is critical, as even minor discrepancies can affect the functionality and safety of the equipment.

Assembly is a complex process that combines various components into a finished product. Typically, this involves both manual labor and automated systems. For tire inflation stations, key components such as compressors, hoses, and electronic controls are assembled in a clean environment to minimize contamination.

Quality control checkpoints are integrated into the assembly line. As components are assembled, they undergo inspections to ensure they meet predefined specifications. This may include checking the fit of hoses, the accuracy of pressure gauges, and the functionality of electronic displays.

Illustrative image related to tire inflation station

Finishing processes add the final touches to tire inflation stations, enhancing both aesthetics and functionality. This includes painting, labeling, and applying protective coatings. A well-finished product not only looks professional but also offers better resistance to wear and environmental factors.

Manufacturers often conduct final inspections during the finishing stage to ensure that the product meets quality standards. This is critical for B2B buyers who seek reliable equipment that will perform under various conditions.

Quality assurance is a vital component of the manufacturing process. B2B buyers should be familiar with the various standards and checkpoints that ensure product reliability and performance.

International standards, such as ISO 9001, play a crucial role in maintaining quality across manufacturing processes. ISO 9001 focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) standards for equipment used in fuel-related industries are important. These certifications ensure that the product adheres to safety and environmental regulations, which is particularly relevant for markets in Europe and the Middle East.

Illustrative image related to tire inflation station

Quality control (QC) checkpoints are established at various stages of the manufacturing process. Key checkpoints include:

Controllo qualità in entrata (CQI): This stage involves inspecting raw materials and components before they enter the production line. Ensuring that materials meet specifications prevents defects in the final product.

Controllo di qualità in corso d'opera (IPQC): During assembly, ongoing checks are made to verify that each component is assembled correctly and functions as intended. This may include pressure testing and functionality checks.

Controllo finale della qualità (CQC): Once the tire inflation station is fully assembled, a comprehensive inspection is conducted. This includes testing for performance, durability, and safety compliance.

B2B buyers should take proactive steps to verify the quality control measures of their suppliers. Here are some effective methods:

Conduzione di audit: Regular audits of manufacturing facilities can provide insights into QC practices. Buyers should request access to audit reports and certification documents to ensure compliance with relevant standards.

Request Documentation: Suppliers should provide detailed documentation of their quality assurance processes, including inspection reports and compliance certifications. This transparency helps buyers assess reliability.

Coinvolgere ispettori terzi: Utilizing third-party inspection services can offer an unbiased evaluation of the manufacturing process. These inspectors can verify compliance with international standards and ensure that the product meets quality expectations.

When sourcing tire inflation stations from international suppliers, especially from regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific quality control nuances:

Differenze culturali: Understanding regional manufacturing practices and standards can be crucial. For instance, manufacturers in Germany may adhere to stricter regulations compared to those in other regions.

Trasparenza della catena di approvvigionamento: Buyers should ensure that suppliers have transparent supply chains. This includes understanding where materials are sourced and how they impact the final product’s quality.

Logistics and Compliance: B2B buyers must consider logistics, including shipping and customs regulations, which can affect product integrity. Ensuring that suppliers comply with local laws and international standards is essential for maintaining quality.

In conclusion, the manufacturing processes and quality assurance practices for tire inflation stations are integral to delivering reliable and efficient equipment. By understanding these processes, B2B buyers can make informed decisions, ensuring they partner with manufacturers that meet their quality standards and operational needs.

To assist B2B buyers in sourcing a tire inflation station, this practical guide outlines essential steps to ensure a successful procurement process. With varying needs across international markets, this checklist is designed to help you make informed decisions tailored to your specific requirements.

Illustrative image related to tire inflation station

Before initiating the procurement process, clearly outline the technical specifications you require for your tire inflation station. Consider factors such as inflation speed, pressure range, and the types of vehicles you will be servicing. This step is crucial as it ensures that the equipment you select will meet your operational needs and enhance service efficiency.

Verify that the tire inflation stations comply with local regulations and international safety standards. Different regions may have specific requirements regarding equipment safety and environmental impact. Ensuring compliance not only protects your business from legal liabilities but also enhances your reputation among customers who value safety and sustainability.

Conduct thorough evaluations of potential suppliers to gauge their reliability and product quality. Request company profiles, product catalogs, and case studies that highlight their experience in your industry. Look for reviews or testimonials from other B2B clients to understand their service levels and product performance, particularly in regions similar to your market.

Examine the features offered by various tire inflation stations, such as digital interfaces, ease of use, and connectivity options. Advanced features like real-time pressure monitoring and user-friendly controls can significantly enhance customer experience and operational efficiency. Choose technology that aligns with your business goals, whether it’s maximizing customer satisfaction or improving technician productivity.

Inquire about the maintenance requirements and support services provided by the supplier. A reliable supplier should offer comprehensive after-sales support, including installation, training, and ongoing maintenance services. Understanding these aspects is essential for minimizing downtime and ensuring that your tire inflation station operates efficiently over time.

Analyze the financial terms proposed by suppliers, including pricing, payment options, and potential revenue-sharing models. Some suppliers may offer flexible financing or leasing options, which can ease budget constraints. Make sure to understand the total cost of ownership, including installation and maintenance, to avoid unexpected expenses down the line.

Once you have selected a supplier, ensure that all contractual terms are clearly defined. This includes delivery timelines, warranty conditions, and service level agreements. A well-defined contract protects both parties and fosters a strong business relationship, allowing for smoother transactions and effective conflict resolution in the future.

By following these steps, B2B buyers can navigate the procurement process for tire inflation stations effectively, ensuring that their investments meet operational needs and enhance customer satisfaction.

When sourcing tire inflation stations, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Illustrative image related to tire inflation station

I materiali: The quality and type of materials used in tire inflation stations directly impact costs. High-quality components such as durable hoses, precision gauges, and robust compressors will typically result in higher prices but offer better longevity and performance.

Lavoro: Manufacturing labor costs can vary significantly based on the region. For instance, labor in Europe may be more expensive than in certain parts of Africa or South America. Buyers should consider the labor cost implications when sourcing from different geographic locations.

Spese generali di produzione: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturers may pass on savings to buyers, while those with higher overheads will reflect these costs in their pricing.

Utensili: Customization often requires specific tooling that can add to initial costs. Buyers who need tailored solutions should be prepared for higher upfront investments.

Controllo qualità (CQ): Implementing rigorous QC processes ensures that the products meet specified standards, but it also contributes to overall costs. Buyers should weigh the benefits of quality assurance against potential price increases.

Logistica: Transportation costs can vary based on distance, shipping methods, and the chosen Incoterms. International buyers should factor in these expenses to understand the total cost fully.

Margine: Suppliers will include a profit margin in their pricing, which can fluctuate based on market demand and competition. Understanding the typical margins in the industry can aid in negotiations.

Several factors can influence the pricing of tire inflation stations:

Volume/MOQ: Purchasing in bulk typically lowers the per-unit cost. Buyers should assess their needs to determine the optimal order quantity to maximize savings.

Specifiche e personalizzazione: Customized stations with specific features, such as digital interfaces or unique branding, will incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

Materiali e certificazioni di qualità: Premium materials and certifications (such as ISO or CE) can increase costs. Buyers should balance the need for quality with budget constraints.

Fattori di fornitura: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their proven products and services, while lesser-known brands might offer lower prices but at higher risks.

Incoterms: Understanding the implications of Incoterms is essential for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly alter the total cost of ownership.

Leverage Negotiation: Engage in open discussions with suppliers about pricing, especially for bulk orders. Highlight long-term relationships and potential future orders to negotiate better rates.

Focus sull'efficienza dei costi: Evaluate not just the initial price but the total cost of ownership, which includes maintenance, energy consumption, and potential downtime.

Comprendere le sfumature dei prezzi per i mercati internazionali: Buyers from Africa, South America, the Middle East, and Europe should be aware of local economic conditions and currency fluctuations that might affect pricing. Additionally, consider the logistics and import duties that can significantly impact final costs.

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing agreements, exclusive deals, and improved service.

Richiesta di preventivi dettagliati: Ask suppliers for itemized quotes that break down costs. This transparency helps identify areas for negotiation and ensures clarity in pricing.

While the cost of tire inflation stations can vary widely based on numerous factors, understanding the underlying components and influencers enables buyers to make informed decisions. It is essential to consider both immediate costs and long-term benefits, ensuring that any investment aligns with operational needs and financial strategies. Keep in mind that indicative prices may fluctuate, so always verify current market conditions before finalizing any agreements.

In the competitive landscape of tire maintenance solutions, businesses must evaluate various options to find the most effective and efficient methods for tire inflation. While tire inflation stations provide a dedicated approach to maintaining tire pressure, several alternative technologies and methods can also meet similar needs. Understanding the strengths and weaknesses of these alternatives is crucial for B2B buyers looking to optimize their operations.

| Aspetto di confronto | Tire Inflation Station | Gonfiatore portatile per pneumatici | Manual Hand Pump |

|---|---|---|---|

| Prestazioni | Fast inflation, precise pressure control | Varies by model, generally slower | Slow and labor-intensive |

| Costo | Moderate initial investment | Low to moderate cost | Very low cost |

| Facilità di implementazione | Requires installation and setup | Plug-and-play, highly portable | Simple to use, no setup required |

| Manutenzione | Low maintenance; occasional servicing needed | Minimal maintenance required | Requires manual effort; no upkeep |

| Il miglior caso d'uso | Ideal for service stations and workshops | Great for roadside assistance | Suitable for emergencies and low-frequency use |

Portable tire inflators are compact, user-friendly devices designed for quick tire inflation on the go. They are typically powered by a vehicle’s 12V outlet, making them easy to use in emergencies. The advantages of portable inflators include their affordability and convenience, especially for individual users or small businesses. However, their performance can vary significantly between models, often resulting in slower inflation times compared to dedicated tire inflation stations. Additionally, the reliance on vehicle power may limit their use in more remote locations.

Illustrative image related to tire inflation station

Manual hand pumps are a cost-effective solution for tire inflation, especially in low-budget scenarios. They require no power source, making them highly portable and easy to use. The simplicity of design means they are often very durable and long-lasting. However, manual pumps are labor-intensive and can be time-consuming, especially for larger tires. This makes them less suitable for high-volume environments like tire shops or service stations, where efficiency and speed are paramount.

When selecting the ideal tire inflation solution, B2B buyers should consider their specific operational needs, budget constraints, and the volume of tire maintenance required. Tire inflation stations are advantageous for businesses that prioritize speed and accuracy, particularly in high-traffic areas. Conversely, portable inflators offer flexibility and ease of use for roadside assistance, while manual pumps serve as a low-cost backup for less frequent use. Evaluating these factors will enable buyers to make informed decisions that align with their operational strategies and customer service goals.

When evaluating tire inflation stations, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some critical specifications that buyers should consider:

Pressure Range (PSI)

The pressure range indicates the maximum and minimum air pressure the inflation station can handle, typically measured in pounds per square inch (PSI). Most tire inflation stations have a range of 0-60 PSI, making them suitable for various vehicles, including cars, motorcycles, and bicycles. This specification is vital for ensuring compatibility with different tire types, enhancing customer satisfaction, and reducing the risk of equipment failure due to improper pressure.

Power Supply Requirements

Tire inflation stations usually require a specific voltage and wattage to operate efficiently. Common models may operate on a 120V or 220V power supply. Understanding these requirements helps businesses determine where to install the machines, ensuring they are accessible and functional without the need for extensive electrical modifications.

Hose Length and Type

The hose length affects the convenience and accessibility of the inflation station. A 20-foot hose allows users to reach tires that are not directly adjacent to the machine, making it versatile for various applications. Additionally, the hose material should be durable and resistant to wear and tear, ensuring longevity and reliability.

Gauge Accuracy

Accuracy in measuring tire pressure is critical for optimal tire performance and safety. Tire inflation stations should feature easy-to-read gauges with a tolerance level that ensures precise inflation. An accurate gauge minimizes the risk of under-inflation or over-inflation, which can lead to increased fuel consumption and tire wear.

Construction Material

The material used in the construction of tire inflation stations affects durability and maintenance. Common materials include steel and high-grade plastic, which offer resistance to corrosion and environmental conditions. Understanding material grades is essential for evaluating the longevity and reliability of the equipment in various climates.

User Interface

A user-friendly interface is critical for enhancing the customer experience. Digital displays, intuitive controls, and multilingual options can significantly improve usability, especially in diverse markets. A well-designed interface not only attracts more users but also minimizes the need for staff assistance, thereby increasing operational efficiency.

Understanding industry jargon is essential for navigating the procurement process effectively. Here are some common terms that B2B buyers should be familiar with:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of tire inflation stations, OEM parts ensure compatibility and reliability, which is crucial for maintaining service quality.

MOQ (quantità minima d'ordine)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory effectively and ensure they meet supplier requirements without overcommitting resources.

RFQ (Richiesta di offerta)

An RFQ is a formal request sent to suppliers asking for a quote on specific products or services. This process helps buyers compare pricing and terms, ensuring they receive the best value for their investment.

Incoterms (Termini commerciali internazionali)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms is essential for B2B transactions, as they clarify who is responsible for costs and risks during transportation.

Tempi di consegna

Lead time refers to the amount of time it takes from placing an order to the delivery of goods. Understanding lead times is crucial for businesses to plan their inventory and service offerings effectively, minimizing downtime and ensuring customer satisfaction.

Periodo di garanzia

This term indicates the duration during which a product is covered for defects and repairs. A robust warranty period can be a significant factor in purchasing decisions, as it reflects the manufacturer’s confidence in their product’s durability and reliability.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions regarding tire inflation stations, ultimately enhancing operational efficiency and customer satisfaction.

The tire inflation station sector is experiencing significant growth driven by several global factors. Increased vehicle ownership in emerging markets, particularly in Africa and South America, has amplified the demand for efficient tire maintenance solutions. Additionally, the rising awareness of the importance of tire pressure for fuel efficiency and safety is fostering a shift toward advanced inflation technologies. Digital air machines are becoming increasingly popular due to their user-friendly interfaces and precise calibration capabilities, attracting international buyers seeking to enhance customer satisfaction and loyalty.

Emerging technologies, such as smart tire inflation systems that monitor tire pressure in real-time, are gaining traction. These systems not only provide convenience but also improve vehicle performance by ensuring optimal tire pressure. The integration of cashless payment options in tire inflation stations is also a notable trend, appealing to tech-savvy consumers and facilitating a seamless user experience.

For B2B buyers from regions like Europe, particularly Germany, there is a growing emphasis on high-quality, durable products that can withstand varying climatic conditions. Similarly, buyers from the Middle East are increasingly looking for solutions that address the unique challenges posed by extreme temperatures. As the market expands, understanding local consumer preferences and regulatory requirements is essential for successful sourcing and market penetration.

Sustainability is becoming a critical consideration in the tire inflation station sector. As environmental regulations tighten and consumers demand greener options, businesses must prioritize sustainable practices in their sourcing strategies. The production of tire inflation stations can have a significant environmental impact, particularly through the materials used and energy consumed during manufacturing. Therefore, international B2B buyers are increasingly seeking suppliers who demonstrate a commitment to sustainability.

Ethical supply chains are essential for ensuring that products are sourced responsibly. Buyers should look for manufacturers that adhere to international labor standards and have transparent sourcing practices. Certifications such as ISO 14001 for environmental management systems and other green certifications can be indicators of a supplier’s commitment to sustainability.

Furthermore, the adoption of eco-friendly materials in the manufacturing of tire inflation stations is on the rise. Buyers can enhance their brand image and meet consumer demand by sourcing products that utilize recycled materials or are designed for energy efficiency. By prioritizing sustainability and ethical sourcing, businesses can not only comply with regulations but also appeal to a growing segment of environmentally conscious consumers.

The evolution of the tire inflation station sector reflects broader technological advancements and changing consumer behaviors. Initially, tire inflation was a manual and often inconvenient process, typically conducted at gas stations with limited functionality. As vehicle technology progressed and the importance of tire maintenance became more evident, the industry began to innovate.

The introduction of automated and digital air machines revolutionized the sector, offering precise pressure calibration and user-friendly interfaces. This shift not only improved efficiency for consumers but also enhanced the operational capabilities of service stations and tire shops. Today, the market is characterized by a focus on customer experience, with many businesses incorporating features such as cashless payment options and mobile app integration.

This evolution continues to shape the sector, as sustainability and smart technology increasingly dictate the future of tire inflation stations. As a result, businesses that adapt to these trends will be better positioned to meet the demands of the modern consumer and thrive in a competitive landscape.

1. How do I choose the right tire inflation station for my business needs?

Selecting the right tire inflation station involves assessing your specific operational requirements. Consider factors such as the volume of vehicles you service, the types of vehicles (cars, trucks, etc.), and the space available for installation. Look for features like automatic inflation, user-friendly interfaces, and compatibility with various tire sizes. Additionally, evaluate the machine’s durability and warranty options, especially if you operate in challenging environments, such as high temperatures or humidity levels common in regions like Africa and South America.

2. What is the best tire inflation station for commercial use?

For commercial use, digital tire inflation stations are often the best choice due to their accuracy and efficiency. Look for models that offer features like automatic shut-off, digital pressure gauges, and fast inflation times. Brands with strong reputations in your region, such as Excel Tire Gauge or Slime Products, may offer tailored solutions to suit fleet operations or gas stations. Assess customer reviews and case studies to understand how these machines perform in similar business contexts.

3. What are the typical payment terms when sourcing tire inflation stations internationally?

Payment terms can vary significantly based on the supplier and your negotiating power. Common arrangements include upfront payment, partial payment upon order confirmation, and the balance upon delivery. For larger orders, you may negotiate terms such as net 30 or net 60 days to facilitate cash flow. Always ensure that payment methods are secure and consider using letters of credit for additional protection in international transactions.

4. How do I vet suppliers for tire inflation stations?

When vetting suppliers, research their industry reputation, customer reviews, and years of experience. Request references from other businesses that have purchased similar products. Evaluate their manufacturing standards and certifications to ensure compliance with international quality norms. Additionally, consider visiting their facilities if feasible or using third-party inspection services to assess product quality before placing an order.

5. What is the minimum order quantity (MOQ) for tire inflation stations?

MOQs can vary widely depending on the manufacturer and product type. Some suppliers may have an MOQ of as low as one unit, while others may require orders of ten or more for bulk pricing. Discuss your needs with potential suppliers to find flexible options, especially if you are a smaller business or just starting. Additionally, inquire about the possibility of sample orders to evaluate the product before committing to a larger purchase.

6. Are customization options available for tire inflation stations?

Many manufacturers offer customization options to tailor tire inflation stations to your specific business needs. This can include branding with your company logo, adjusting the inflation speed, or adding features such as coin or card payment systems. Discuss your requirements during the initial conversations with suppliers to understand the scope of customization and any associated costs.

7. What quality assurance measures should I consider when purchasing tire inflation stations?

Quality assurance measures are crucial to ensure product reliability and performance. Look for suppliers that adhere to international quality standards, such as ISO certifications. Inquire about the testing processes for their products, including durability tests, accuracy checks, and safety evaluations. Additionally, consider requesting warranties that cover parts and labor, providing peace of mind regarding the longevity of your investment.

8. What logistics considerations should I keep in mind when importing tire inflation stations?

When importing tire inflation stations, logistics planning is essential. Consider the shipping methods available, including air freight for faster delivery or sea freight for cost savings. Be aware of customs regulations and tariffs in your country, as these can impact total costs. Collaborate with a reliable freight forwarder to streamline the import process and ensure compliance with all legal requirements, including necessary documentation for customs clearance.

Dominio: exceltiregauge.com

Registrato: 2004 (21 anni)

Introduzione: High-Quality Air Machines & Tire Inflators from Excel Tire Gauge include: SC09-SS Pay Air Machine, SC05-SS Free Air Machine, SC05-SS Kiosk Air Machine, SCWM-23 Wall Mount Air Machine, PNT PRO Automatic Tire Inflator, PNT 4 Automatic Tire Inflator. The products are designed for various industries including gas stations, car washes, tire shops, auto repair, fleets, rental cars, and car dealerships. …

Dominio: haltec.com

Registrato: 1998 (27 anni)

Introduzione: Automatic Tire Inflation Systems (ATIS) by Haltec are designed for trucks, trailers, fleets, and aircraft. Key features include:

– Customizable branded faceplates available upon request.

– Hardwired and mountable to mobile service trucks.

– Calibration confirmation every 6 minutes during use and at power-on.

– Accuracy of 0.5% FS.

– Die cast aluminum housing for durability and weather protect…

Dominio: enve.com

Registrato: 1999 (26 anni)

Introduzione: {‘product_name’: ‘ENVE Air Pressure Station’, ‘price’: ‘$750.00’, ‘description’: ‘Automatic digital inflation that accurately inflates any tire to within .5% of a psi or bar. Connects to existing air compressor or bottled air and mounts on any wall or surface.’, ‘features’: [‘Digital interface’, ‘Three tire pressure presets’, ‘Tubeless tire/flat tire override function’, ‘Mobile device scannable NF…

In today’s competitive landscape, strategic sourcing of tire inflation stations presents a significant opportunity for businesses across diverse sectors, including automotive, retail, and fleet management. By investing in advanced, user-friendly inflation solutions, companies can enhance customer satisfaction, streamline operations, and increase revenue. Digital air machines, with their revenue-sharing models and precise calibration, not only attract more customers but also promote safety and efficiency among technicians.

Illustrative image related to tire inflation station

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, the emphasis on quality and reliability in tire inflation stations is paramount. Businesses must prioritize partnerships with reputable manufacturers that demonstrate a commitment to innovation and customer service. This strategic approach will not only enhance operational efficiency but also position companies to meet the growing demand for reliable tire maintenance solutions.

As the market evolves, leveraging data-driven insights and sustainable practices will be crucial. The future of tire inflation stations is bright, and now is the time to act. Engage with trusted suppliers, explore new technologies, and invest in solutions that will propel your business forward. Embrace this opportunity to elevate your service offerings and ensure that your operations remain competitive in an ever-changing marketplace.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Illustrative image related to tire inflation station

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.