In today’s fast-paced global market, sourcing reliable tools like the Merlin tire pressure gauge can present significant challenges for B2B buyers. With fluctuating prices, varying quality standards, and diverse supplier capabilities, making informed purchasing decisions is crucial for businesses operating across Africa, South America, the Middle East, and Europe, including countries like Germany and Nigeria. This guide serves as a comprehensive resource, designed to demystify the complexities of procuring the Merlin tire pressure gauge, a professional-grade tool essential for maintaining vehicle safety and efficiency.

Our detailed exploration covers the range of available models, their specific applications in various industries, and the critical factors to consider when vetting suppliers. We delve into the cost structures associated with the Merlin tire pressure gauge, offering insights into how to maximize value while ensuring quality. Furthermore, the guide highlights best practices for maintenance and usage, empowering buyers to make choices that align with their operational needs.

By equipping international B2B buyers with actionable insights and expert advice, this guide aims to facilitate informed decision-making, ultimately enhancing operational efficiency and safety. As you navigate the global landscape of tire pressure gauges, let this resource be your trusted companion in achieving optimal procurement outcomes.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Digital Tire Pressure Gauge | Backlit LCD display, 0.1 PSI increments, auto on/off feature | Automotive repair shops, fleet maintenance | Pro: High accuracy, easy to read; Contro: Dependent on batteries. |

| Mechanical Tire Pressure Gauge | Analog dial, no batteries required, robust construction | Heavy machinery, construction equipment | Pro: Durable, no battery issues; Contro: Less precise than digital. |

| Smart Tire Pressure Monitoring | Bluetooth connectivity, real-time data on mobile devices | Logistics companies, tire manufacturing | Pro: Continuous monitoring, alerts; Contro: Higher cost, tech dependency. |

| Pistol Grip Tire Inflator | Integrated digital gauge, ergonomic grip, quick inflation | Tire service centers, automotive workshops | Pro: User-friendly, efficient; Contro: Bulkier than traditional gauges. |

| Multi-Unit Pressure Gauge | Displays pressure in multiple units (PSI, kPa, Bar, etc.) | International trade, diverse vehicle fleets | Pro: Versatile for global markets; Contro: Complexity may confuse some users. |

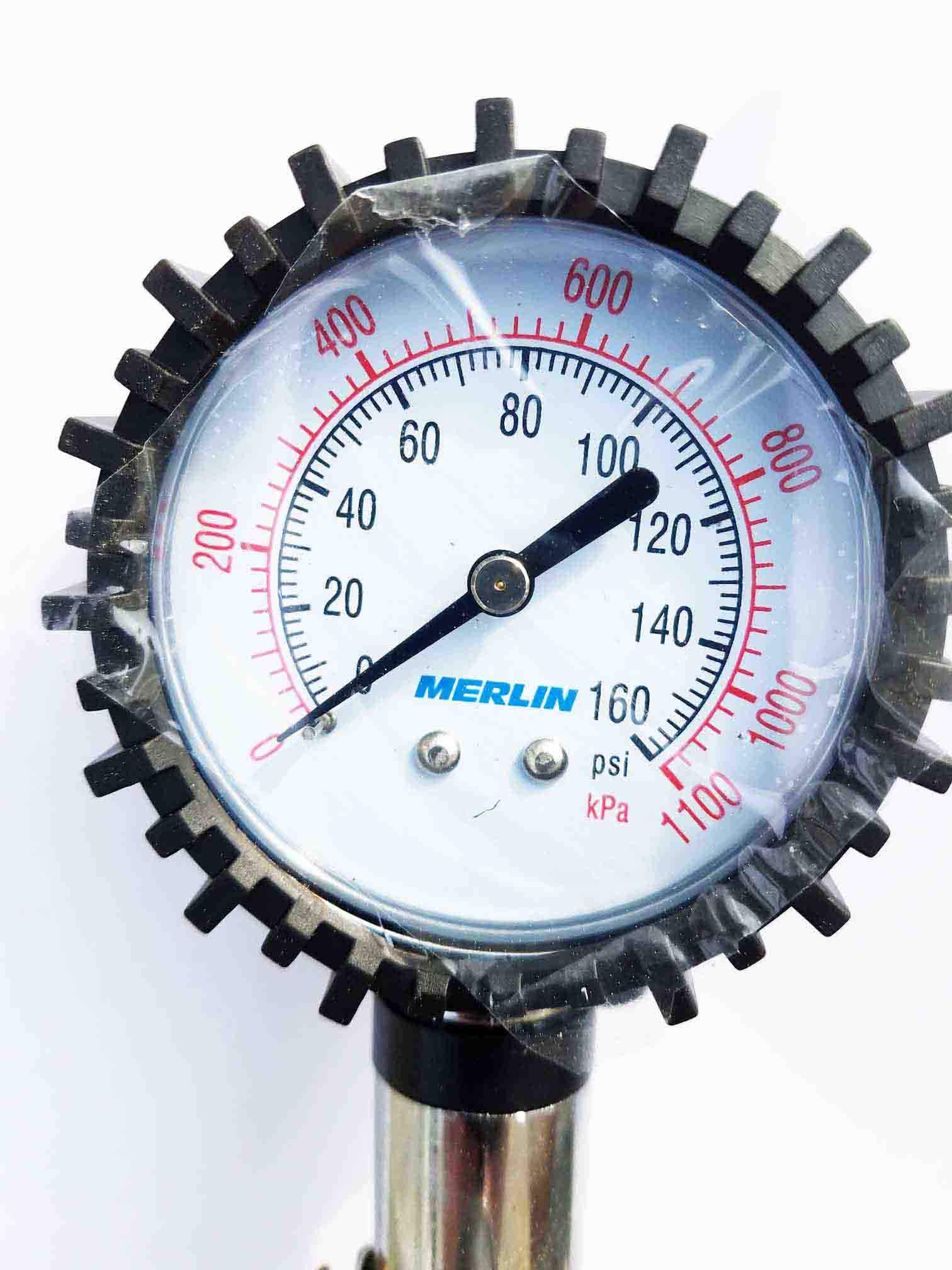

Digital tire pressure gauges, such as the MERLIN model, are equipped with a backlit LCD display that enhances visibility in various lighting conditions. They offer precise readings up to 150 PSI with increments of 0.1 PSI, making them ideal for automotive repair shops and fleet maintenance operations. When considering a purchase, B2B buyers should focus on accuracy, ease of use, and battery life, as these factors directly affect operational efficiency.

Illustrative image related to merlin tire pressure gauge

Mechanical tire pressure gauges are known for their robust construction and reliability. They utilize an analog dial for pressure readings, eliminating the need for batteries. This type is particularly suitable for heavy machinery and construction equipment, where durability is paramount. Buyers should evaluate the gauge’s construction quality and ease of calibration, as these elements are crucial for maintaining operational integrity in demanding environments.

Smart tire pressure monitoring systems leverage Bluetooth technology to provide real-time data to mobile devices. These systems are particularly beneficial for logistics companies and tire manufacturers, allowing for continuous monitoring and immediate alerts about pressure changes. When considering such a system, B2B buyers should assess the integration capabilities with existing fleet management software and the overall return on investment.

Pistol grip tire inflators combine the functionalities of a tire pressure gauge and inflator, featuring an ergonomic design for user comfort. They are particularly effective in tire service centers and automotive workshops, where quick and efficient service is essential. Buyers should look for models that offer both accuracy and ease of use, as these factors can enhance customer satisfaction and operational speed.

Multi-unit pressure gauges are designed to display pressure in various units, such as PSI, kPa, and Bar, catering to diverse international markets. This versatility is essential for businesses engaged in international trade or those with a varied fleet of vehicles. Buyers should consider the gauge’s adaptability and ease of use in different regions, as these attributes can significantly impact operational efficiency and compliance with local standards.

Illustrative image related to merlin tire pressure gauge

| Industria/Settore | Specific Application of merlin tire pressure gauge | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Riparazione di autoveicoli | Tire pressure checks during vehicle maintenance | Enhances safety and performance of vehicles, reduces wear on tires | Look for accuracy, durability, and ease of use in workshops |

| Trasporto e logistica | Regular tire pressure monitoring for fleet vehicles | Reduces fuel consumption and extends tire lifespan | Ensure compatibility with various tire types and sizes |

| Agricoltura | Tire pressure measurement for agricultural machinery | Improves operational efficiency and reduces equipment downtime | Consider ruggedness and resistance to environmental factors |

| Costruzione | Checking tire pressure on heavy machinery | Increases safety and productivity on construction sites | Focus on easy readability and portability for job sites |

| Produzione | Monitoring tire pressure on conveyor systems | Minimizes downtime and maximizes production efficiency | Look for features that allow for quick and precise readings |

In the automotive repair sector, the merlin tire pressure gauge is an essential tool for mechanics during routine vehicle maintenance. By providing accurate tire pressure readings, it helps ensure that vehicles operate safely and efficiently. Proper tire inflation reduces the risk of blowouts and enhances fuel efficiency, leading to significant cost savings for vehicle owners. Buyers in this sector should prioritize gauges that offer high durability and user-friendly features, ensuring they can withstand the demands of a busy workshop environment.

For transportation and logistics companies, regular tire pressure monitoring is crucial for maintaining fleet vehicles. The merlin tire pressure gauge allows fleet managers to keep tire pressure within optimal ranges, which can lead to lower fuel consumption and extended tire life. This is particularly vital for businesses operating in regions with variable climates, such as Africa and South America, where tire performance can fluctuate. Buyers should consider the gauge’s compatibility with various tire types and its ease of use to streamline operations.

In agriculture, the merlin tire pressure gauge is used to monitor the tire pressure of tractors and other machinery. Proper tire inflation is critical for maximizing traction and reducing soil compaction, which can affect crop yields. The gauge’s accuracy and ruggedness make it suitable for the often harsh and variable conditions found on farms. Buyers should look for features that enhance usability in outdoor environments, such as weather resistance and portability, to ensure reliable performance in the field.

Construction sites often rely on heavy machinery that requires precise tire pressure for optimal performance. The merlin tire pressure gauge is used to check the tire pressure of equipment like excavators and bulldozers, helping to prevent accidents and enhance productivity. Ensuring that machinery operates at the correct tire pressure minimizes the risk of tire failure and downtime. When sourcing for construction applications, businesses should prioritize gauges that are easy to read and transport, facilitating quick checks on job sites.

In manufacturing, the merlin tire pressure gauge can be applied to monitor tire pressure on conveyor systems. Maintaining the correct tire pressure is essential for ensuring smooth operations and reducing the likelihood of system failures. By using this gauge, manufacturers can minimize downtime and enhance overall productivity. Buyers in this sector should focus on features that allow for quick and precise readings, as well as durability to withstand the rigors of a manufacturing environment.

Il problema: B2B buyers in the automotive and transportation sectors often encounter the challenge of inconsistent tire pressure readings when using gauges like the MERLIN Digital Tire Pressure Gauge. This inconsistency can stem from factors such as poor calibration, battery issues, or simply the gauge’s inability to provide precise measurements under varying conditions. As a result, companies may face increased tire wear, reduced fuel efficiency, and safety concerns, ultimately affecting their bottom line and operational efficiency.

La soluzione: To ensure accurate and consistent readings, B2B buyers should regularly calibrate their MERLIN tire pressure gauges. Implement a routine maintenance schedule that includes testing the gauge against a known standard. Additionally, educate staff on proper usage techniques, such as ensuring the gauge is at room temperature and securely attached to the valve stem before taking a reading. Moreover, consider investing in multiple gauges to mitigate the risk of relying on a single device. Regularly replacing the AAA batteries will also help maintain the gauge’s performance, as low battery power can lead to inaccurate readings.

Illustrative image related to merlin tire pressure gauge

Il problema: Many international buyers, especially those from regions with diverse metric systems, may struggle with the various pressure units displayed on the MERLIN tire pressure gauge (PSI, Kg/cm², kPa, and Bar). This lack of understanding can lead to confusion when inflating tires to the correct pressure, resulting in either over-inflation or under-inflation, both of which can compromise vehicle safety and performance.

La soluzione: B2B buyers should prioritize training for their staff on the different pressure units and their implications for tire maintenance. Providing clear, visual reference charts that correlate each unit to specific tire pressure recommendations can be beneficial. Additionally, consider sourcing gauges that allow for easy switching between units, allowing operators to select their preferred measurement system. Engaging with manufacturers for training resources or workshops can further enhance understanding and ensure that all personnel are well-informed about tire pressure management.

Il problema: Users often face challenges when trying to access tire valves, particularly in commercial vehicles where space can be tight. The design of the MERLIN tire pressure gauge, although effective, may not be conducive to reaching all tire valves easily, especially in larger fleets or vehicles with unique configurations. This can lead to user frustration and time inefficiencies during routine maintenance checks.

La soluzione: To enhance accessibility, B2B buyers should consider purchasing the MERLIN tire pressure gauge with an extended hose and specialized chucks that accommodate hard-to-reach valves. Training staff on proper techniques for positioning the gauge can also help mitigate accessibility issues. Additionally, implementing a systematic approach to tire pressure checks—such as using a checklist to ensure all tires are serviced—can streamline the process. Lastly, investing in adjustable or flexible tire inflators can provide an alternative solution for accessing difficult valves while ensuring accurate pressure readings.

The selection of materials for the Merlin tire pressure gauge is critical to its performance, durability, and overall user experience. Understanding the properties, advantages, and limitations of these materials can help international B2B buyers make informed purchasing decisions.

Illustrative image related to merlin tire pressure gauge

Plastic is often utilized in the housing and components of the Merlin tire pressure gauge due to its lightweight nature and resistance to corrosion. Key properties include a temperature rating that can typically withstand moderate heat and pressure, making it suitable for automotive applications.

Pro: Plastic is generally cost-effective, lightweight, and can be molded into complex shapes, allowing for versatile designs. It is also resistant to rust and corrosion, which is crucial for products exposed to moisture and varying environmental conditions.

Contro: However, plastic may not offer the same level of durability as metals, particularly under extreme temperature variations or mechanical stress. It can also be less environmentally friendly, which may concern buyers in regions with stringent environmental regulations.

Impatto sull'applicazione: Plastic components are suitable for general automotive use, but may not be ideal for high-performance applications where precision and durability are paramount.

Considerazioni per gli acquirenti internazionali: Buyers from regions like Europe may prioritize compliance with environmental standards such as REACH, while those in Africa or South America might focus more on cost-effectiveness and availability.

Illustrative image related to merlin tire pressure gauge

Aluminum is another common material used in the construction of the Merlin tire pressure gauge, particularly for the body and internal components. It offers excellent strength-to-weight ratio and resistance to corrosion, making it ideal for outdoor and automotive applications.

Pro: Aluminum is lightweight, durable, and can withstand higher temperatures and pressures than plastic. Its corrosion resistance makes it suitable for various climates, including humid and coastal areas.

Contro: The primary drawback is that aluminum can be more expensive than plastic and may require more complex manufacturing processes, which could affect overall production costs.

Impatto sull'applicazione: Aluminum components contribute to the gauge’s accuracy and longevity, which is essential for maintaining tire pressure in diverse conditions.

Considerazioni per gli acquirenti internazionali: Buyers from Germany may expect compliance with DIN standards, while those in the Middle East might look for materials that can withstand extreme temperatures.

Illustrative image related to merlin tire pressure gauge

Stainless steel is often used for critical components such as the valve and connectors due to its exceptional strength and corrosion resistance. This material can handle high pressures and is less likely to degrade over time.

Pro: Stainless steel is highly durable and resistant to rust, making it ideal for long-term use in various environments. Its strength ensures that the gauge can withstand mechanical stress without failure.

Contro: The main limitation is the higher cost compared to plastic and aluminum. Additionally, stainless steel components can be heavier, which may affect the overall weight of the gauge.

Impatto sull'applicazione: Stainless steel is essential for applications requiring high precision and reliability, especially in commercial and industrial settings.

Considerazioni per gli acquirenti internazionali: Buyers should ensure compliance with ASTM standards for stainless steel grades, particularly in regions where quality assurance is critical.

Rubber is commonly used in seals and gaskets within the Merlin tire pressure gauge, providing flexibility and an airtight seal. Its properties include excellent temperature resistance and the ability to absorb shock.

Pro: Rubber is highly effective at preventing leaks and protecting sensitive components from dust and moisture. It is also relatively inexpensive and easy to manufacture.

Contro: However, rubber can degrade over time, especially when exposed to extreme temperatures or certain chemicals. This can lead to reduced performance and the need for replacement.

Impatto sull'applicazione: Rubber seals are crucial for maintaining the accuracy of pressure readings by ensuring that the internal mechanisms are protected from external elements.

Considerazioni per gli acquirenti internazionali: Buyers should be aware of the specific rubber compounds used, as some may not be suitable for certain climates or chemical exposures.

| Materiale | Typical Use Case for merlin tire pressure gauge | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Plastica | Housing and non-critical components | Leggero e resistente alla corrosione | Less durable under extreme conditions | Basso |

| Alluminio | Body and internal components | Strong and lightweight | Costi più elevati e complessità di produzione | Medio |

| Acciaio inox | Valves and connectors | Altamente durevole e resistente alla corrosione | Higher cost and weight | Alto |

| Gomma | Guarnizioni | Effective sealing and shock absorption | Può degradarsi nel tempo | Basso |

This strategic material selection guide aims to equip B2B buyers with insights into the materials used in the Merlin tire pressure gauge, enabling them to make informed decisions that align with their operational needs and regional standards.

The manufacturing of the Merlin Digital Tire Pressure Gauge involves several critical stages, ensuring a high-quality product that meets international standards. The primary stages include material preparation, forming, assembly, and finishing.

Preparazione del materiale:

The initial phase involves sourcing high-quality materials, including durable plastics for the casing and precision-engineered metal components for the internal mechanisms. Suppliers are often vetted for their ability to provide materials that comply with relevant standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals).

Formazione:

In this stage, the prepared materials are shaped into their respective components using techniques such as injection molding for the plastic casing and CNC machining for metal parts. This stage is crucial for ensuring that all components fit together precisely, which is essential for the gauge’s accuracy.

Montaggio:

The assembly process typically occurs in a cleanroom environment to minimize contamination. Here, components such as the LCD display, battery compartment, and pressure sensors are meticulously assembled. Automated assembly lines may be utilized to enhance efficiency, but skilled technicians also play a role in ensuring that each unit meets quality standards.

Finitura:

The final stage involves testing and quality checks, as well as the application of branding elements. The gauges undergo a rigorous finishing process, which may include polishing, sealing, and the addition of user manuals. This stage ensures that the product is not only functional but also visually appealing to end-users.

Quality assurance (QA) is a fundamental aspect of the manufacturing process for the Merlin Tire Pressure Gauge, with several checkpoints established to maintain product integrity.

Standard internazionali:

Compliance with international quality standards such as ISO 9001 is essential. This standard outlines the requirements for a quality management system (QMS) that ensures consistent quality in production and service. Additionally, certifications like CE mark and API (American Petroleum Institute) standards may apply, depending on the specific use cases of the tire pressure gauge.

Punti di controllo della qualità:

Several quality control (QC) checkpoints are established throughout the manufacturing process:

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is paramount. Here are some actionable strategies:

Audit dei fornitori:

Conducting on-site audits of the manufacturing facilities provides firsthand insight into the supplier’s processes and quality control measures. This includes evaluating their adherence to international standards and their internal QA protocols.

Rapporti sulla qualità:

Requesting detailed quality reports from suppliers can help buyers assess the consistency of product quality over time. This should include data on defect rates, testing outcomes, and compliance with international standards.

Ispezioni di terzi:

Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control processes. These inspections can verify that products meet specified standards before shipment, minimizing risks for buyers.

Certifications and Compliance Documentation:

Buyers should always request copies of relevant certifications and compliance documentation. This includes ISO certifications, CE markings, and any other industry-specific qualifications that validate the supplier’s commitment to quality.

B2B buyers from different regions face unique challenges and opportunities regarding quality control. Here are some key nuances to consider:

Differenze normative:

Different countries have varying regulatory requirements for product safety and quality. Buyers should familiarize themselves with local regulations to ensure compliance, especially when importing products.

Cultural Factors:

Cultural differences can affect communication and expectations regarding quality. Establishing clear guidelines and maintaining open lines of communication with suppliers can mitigate misunderstandings.

Local Support and Service:

Consider suppliers who offer local support and service. This can enhance the ability to address quality issues quickly and effectively, which is particularly crucial in regions where logistics may pose challenges.

Pratiche di sostenibilità:

Increasingly, buyers are prioritizing sustainability in their procurement processes. Verifying that suppliers adhere to environmentally friendly practices in their manufacturing and quality assurance processes can align with global sustainability trends.

Understanding the manufacturing processes and quality assurance measures for the Merlin Tire Pressure Gauge is essential for B2B buyers. By focusing on the stages of production, implementing robust quality control measures, and verifying supplier practices, buyers can ensure they source reliable, high-quality products that meet international standards. This not only enhances operational efficiency but also builds long-term partnerships with trusted suppliers across diverse markets.

To effectively source the MERLIN Digital Tire Pressure Gauge, B2B buyers must follow a systematic approach that ensures they secure high-quality products at competitive prices. This guide provides a checklist to streamline your procurement process, ensuring you make informed decisions that align with your business needs.

Before reaching out to suppliers, establish clear technical specifications for the MERLIN tire pressure gauge. Consider the gauge’s pressure range, accuracy, display type, and included accessories. Defining these parameters helps avoid confusion later and ensures you purchase a product that meets your operational requirements.

Conduct thorough research to identify suppliers that specialize in tire pressure gauges. Focus on suppliers with a solid reputation in the market and positive reviews from previous buyers. This will help you filter out unreliable suppliers.

It’s crucial to verify that your potential suppliers hold necessary certifications and comply with relevant industry standards. This step ensures that the products meet safety and quality requirements, reducing the risk of defective items.

Illustrative image related to merlin tire pressure gauge

Before placing a bulk order, request samples of the MERLIN tire pressure gauge. This allows you to evaluate the product’s performance and quality firsthand, ensuring it meets your specifications.

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and shipping conditions. Understanding the total cost of ownership will help you make a more informed decision.

Effective communication with your supplier is vital for a smooth procurement process. Clearly outline your expectations regarding response times, order updates, and issue resolution.

Finally, consider the level of post-purchase support offered by the supplier. This includes warranty coverage, availability of replacement parts, and customer service responsiveness.

By following this checklist, B2B buyers can confidently source the MERLIN Digital Tire Pressure Gauge, ensuring they secure a product that meets their needs while establishing a reliable supplier relationship.

When analyzing the cost structure of the Merlin Tire Pressure Gauge, several key components must be considered:

I materiali: The primary materials include high-grade plastic for the housing, electronic components for the LCD display and internal circuitry, and metals for the tire chucks. The quality of these materials can significantly impact the overall cost, especially if sourced from high-quality suppliers.

Lavoro: Labor costs vary based on the region of manufacturing. In countries with lower labor costs, such as China, expenses may be reduced. However, skilled labor may be required for quality assurance and assembly, which can increase costs.

Spese generali di produzione: This includes utilities, facility maintenance, and other indirect costs associated with the production process. Efficient manufacturing processes can help minimize these overhead costs.

Utensili: Initial tooling costs can be significant, especially for customized gauges. This includes the cost of molds and dies used in production, which can be amortized over larger production runs.

Controllo qualità (CQ): Implementing stringent QC measures ensures that each gauge meets the required specifications. This process involves testing accuracy and durability, which can add to the cost but is essential for maintaining product quality.

Logistica: Shipping costs can vary widely based on the destination, mode of transport, and Incoterms used. International shipping can incur additional tariffs and duties, impacting the overall cost.

Margine: Suppliers will typically add a margin to cover their operational costs and profit. Understanding the standard markup in your region can aid in negotiating better prices.

Several factors influence the pricing of the Merlin Tire Pressure Gauge:

Volume/MOQ: Larger orders often come with discounts, allowing buyers to achieve a lower per-unit cost. Understanding the minimum order quantities (MOQ) can help buyers negotiate better deals.

Specifiche e personalizzazione: Customized gauges or those with specific features (like enhanced durability or additional certifications) may incur higher costs. Buyers should weigh the benefits of customization against budget constraints.

Materiali e certificazioni di qualità: Higher quality materials and certifications (e.g., ISO standards) can increase costs but may also improve reliability and performance, making them worth the investment for long-term use.

Fattori di fornitura: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but often provide better quality assurance and customer service.

Incoterms: The chosen Incoterms (e.g., FOB, CIF) dictate shipping responsibilities and costs. Understanding these terms can help buyers optimize shipping expenses and avoid unexpected fees.

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

Leverage Volume Discounts: Consider consolidating orders or collaborating with other businesses to meet higher MOQs for better pricing.

Richiesta di preventivi dettagliati: Obtain comprehensive quotes that break down costs, including materials, labor, and logistics. This transparency can provide leverage during negotiations.

Valutare il costo totale di proprietà (TCO): Look beyond the initial purchase price. Consider factors like shipping, potential tariffs, and long-term maintenance costs when evaluating suppliers.

Understand Local Market Dynamics: Familiarize yourself with local market conditions, currency fluctuations, and supplier practices in your region. This knowledge can enhance your negotiation position.

Costruire relazioni: Cultivating long-term relationships with suppliers can lead to better terms and trust, resulting in favorable pricing and terms over time.

Buyers should be aware of several nuances in pricing when sourcing the Merlin Tire Pressure Gauge:

Regional Pricing Variations: Prices can vary significantly based on geographic location due to local market conditions, competition, and supply chain logistics.

Currency Fluctuations: Be mindful of currency exchange rates, as these can affect pricing, especially in international transactions.

Conformità normativa: Ensure that the products meet local regulations and standards, as non-compliance can lead to additional costs or penalties.

Import Duties and Taxes: Factor in any applicable import duties and taxes, which can significantly increase the total cost of acquisition.

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and current pricing.

When considering the best tools for measuring tire pressure, it is essential to explore various alternatives to the Merlin Tire Pressure Gauge. This analysis will evaluate different solutions, helping B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Aspetto di confronto | Merlin Tire Pressure Gauge | Digital Tire Pressure Gauge with Bluetooth | Mechanical Tire Pressure Gauge |

|---|---|---|---|

| Prestazioni | Accurate to 1% at 150 PSI | High accuracy, real-time data transmission | Accurate but limited to manual reading |

| Costo | $16.99 | $35.00 | $10.00 |

| Facilità di implementazione | User-friendly, portable | Requires app installation and Bluetooth pairing | Simple, no technology required |

| Manutenzione | Low, battery replacement needed | Low, app updates required occasionally | Very low, minimal parts to wear out |

| Il miglior caso d'uso | General automotive use | Fleet management and monitoring | Quick checks and basic use |

The Digital Tire Pressure Gauge with Bluetooth offers advanced features, including the ability to sync data with mobile applications for monitoring tire pressure over time. This is particularly beneficial for fleet management, where maintaining optimal tire pressure can enhance fuel efficiency and safety. However, the initial setup requires a compatible smartphone and the installation of an app, which may not be practical for all users. Additionally, the cost is higher than that of the Merlin gauge, making it a more significant investment.

The Mechanical Tire Pressure Gauge is a straightforward and cost-effective alternative. Priced around $10, it offers ease of use with no need for batteries or digital interfaces. This makes it an excellent choice for those who prefer simplicity and reliability. However, it lacks the precision and features of digital gauges, such as backlit displays and multiple measurement units. Mechanical gauges may also require more physical effort to read, which can be a disadvantage in low-light conditions or for users with limited dexterity.

In selecting the right tire pressure measurement tool, B2B buyers should assess their specific needs, including budget constraints, the scale of operations, and the required precision. The Merlin Tire Pressure Gauge offers a balance of affordability and functionality suitable for general automotive needs. In contrast, if real-time data tracking and analysis are vital, the Bluetooth-enabled digital gauge may justify its higher cost. Conversely, for those seeking a no-frills option, the mechanical gauge can serve as an effective, economical solution. Ultimately, understanding these alternatives allows buyers to select the best option aligned with their operational requirements and financial considerations.

When considering the purchase of the Merlin tire pressure gauge, understanding its essential technical properties is crucial for ensuring that it meets the specific needs of your business. Here are some key specifications:

Pressure Range (5-150 PSI)

The Merlin tire pressure gauge measures a pressure range from 5 to 150 PSI. This wide range accommodates various applications, from passenger vehicles to heavier machinery. For B2B buyers, this versatility is essential, as it allows for a single tool to serve multiple functions, reducing the need for multiple gauges.

Accuracy (1% at 150 PSI)

The gauge boasts an accuracy of 1% at 150 PSI, which translates to a margin of error of just 1.5 PSI. High accuracy is vital in industrial settings where precise tire pressure is crucial for safety and performance. This specification assures buyers that the gauge will provide reliable readings, leading to better maintenance of vehicles and equipment.

Display Type (Backlit LCD)

The easy-to-read backlit LCD display enhances usability in low-light conditions, making it suitable for workshops and outdoor settings. For international buyers, particularly in regions with varying light conditions, this feature ensures that the gauge can be used effectively at all times, enhancing operational efficiency.

Measurement Units (PSI, Kg/cm², kPa, Bar)

The gauge displays pressure in multiple units, including PSI, Kg/cm², kPa, and Bar. This flexibility is particularly beneficial for international B2B transactions, where different regions may prefer specific measurement units. It allows for smoother communication and understanding between buyers and sellers across various markets.

Hose Length (18 inches)

With an 18-inch hose, the gauge is designed for easy access to tire valves, even in tight spaces. This practical feature is particularly relevant for businesses in the automotive sector, where convenience and efficiency are paramount. A longer hose reduces the need for repositioning the vehicle, saving time and labor costs.

Battery Life (Two AAA Batteries)

The auto on/off feature preserves battery life, ensuring that the gauge remains operational when needed without frequent battery replacements. For B2B buyers, this translates to lower maintenance costs and increased reliability, making it a more attractive option for regular use.

Understanding industry jargon is essential for making informed purchasing decisions. Here are some common trade terms relevant to the Merlin tire pressure gauge:

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of tire pressure gauges, knowing whether a product is OEM can help buyers assess quality and compatibility with existing equipment.

MOQ (quantità minima d'ordine)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Buyers should be aware of MOQs when negotiating purchases, as this can affect inventory levels and overall costs, especially for smaller businesses.

RFQ (Richiesta di offerta)

An RFQ is a document sent to suppliers requesting pricing and availability for specific products. For B2B buyers, using an RFQ can streamline the procurement process, ensuring that they receive competitive pricing and detailed information from multiple suppliers.

Incoterms (Termini commerciali internazionali)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers, as they determine shipping costs, risk, and delivery responsibilities, helping to avoid misunderstandings during cross-border transactions.

Periodo di garanzia

The warranty period indicates the length of time a product is covered for defects or malfunctions. Knowing the warranty terms can provide peace of mind to buyers, ensuring that they are protected against potential issues after purchase.

Tempi di consegna

Lead time refers to the time it takes for an order to be processed and delivered. For B2B buyers, understanding lead times is essential for effective inventory management and planning, especially in industries where timely access to equipment is critical.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make more informed decisions regarding the acquisition of the Merlin tire pressure gauge, ensuring it aligns with their operational needs and market requirements.

The global market for tire pressure gauges, particularly the MERLIN brand, is experiencing significant growth driven by several key factors. Increasing awareness of vehicle maintenance and safety standards, alongside the rising number of vehicles in emerging markets like Africa and South America, is propelling demand for accurate and reliable tire pressure monitoring tools. Additionally, the shift towards digital technology is influencing sourcing trends; buyers now prefer gauges with advanced features such as backlit LCD displays and automatic shut-off functions, which enhance usability and battery life.

Emerging B2B technologies are also reshaping the sector. For instance, the integration of IoT (Internet of Things) capabilities into tire pressure gauges is gaining traction, allowing for real-time monitoring and data analytics. This trend is particularly relevant for fleet operators in regions like the Middle East and Europe, where efficiency and cost-effectiveness are paramount. Furthermore, international buyers are increasingly looking for products that offer multi-functional capabilities, such as pressure readings in various units (PSI, Kg/cm², kPa, and Bar), which cater to diverse market requirements.

In terms of market dynamics, international B2B buyers should be aware of regional variations in sourcing practices. For instance, while European markets may prioritize advanced technology and precision, African buyers may focus more on cost-effectiveness and durability. Understanding these nuances will enable buyers to make informed decisions that align with their specific market needs.

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the tire pressure gauge sector. The environmental impact of manufacturing processes and the materials used in products like the MERLIN tire pressure gauge cannot be overlooked. Buyers are increasingly seeking products that minimize waste and reduce carbon footprints, which can be achieved through the use of recyclable materials and eco-friendly packaging.

Moreover, the importance of ethical supply chains is gaining prominence. B2B buyers should ensure that their suppliers adhere to fair labor practices and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability. Additionally, engaging with suppliers who prioritize transparency in their supply chains can help mitigate risks associated with unethical practices.

Illustrative image related to merlin tire pressure gauge

Incorporating ‘green’ certifications into purchasing decisions not only supports sustainability goals but can also enhance brand reputation. For example, showcasing a commitment to environmentally friendly products can attract a growing demographic of eco-conscious consumers and businesses alike. As the demand for sustainable products continues to rise, aligning sourcing strategies with these principles will be essential for long-term success in the tire pressure gauge market.

The tire pressure gauge has evolved significantly since its inception. Initially, mechanical gauges were the standard, relying on analog technology to measure tire pressure. These early devices, while functional, often lacked precision and required manual calibration. As the automotive industry advanced, so too did the need for more accurate tools, leading to the development of digital tire pressure gauges.

Today, products like the MERLIN Digital Tire Pressure Gauge exemplify this evolution. They incorporate advanced features such as backlit displays and precise measurement increments, catering to a more tech-savvy consumer base. The transition from mechanical to digital has not only improved accuracy but has also made tire pressure monitoring more accessible and user-friendly. As technology continues to advance, the tire pressure gauge sector is poised for further innovation, making it an exciting area for international B2B buyers to explore.

Illustrative image related to merlin tire pressure gauge

How do I ensure the accuracy of the MERLIN tire pressure gauge?

To ensure the accuracy of the MERLIN tire pressure gauge, it is essential to calibrate it regularly according to the manufacturer’s guidelines. The gauge has an accuracy of 1% at 150 PSI, equating to 1.5 PSI at any point on the scale. For optimal performance, check the calibration against a known standard before use. Additionally, consider the environment where the gauge is stored, as extreme temperatures can affect its accuracy. Regular maintenance and battery checks will also help maintain precise readings.

What features make the MERLIN tire pressure gauge suitable for professional use?

The MERLIN tire pressure gauge is designed for professional use with features such as a backlit LCD display for easy reading in low light, an auto on/off function to save battery life, and the ability to measure in multiple units (PSI, Kg/cm², kPa, and Bar). Its accuracy of 1% at 150 PSI and the inclusion of two versatile tire chucks (angled and ball-type) enhance usability, making it ideal for automotive professionals and workshops.

What is the minimum order quantity (MOQ) for purchasing MERLIN tire pressure gauges?

The minimum order quantity (MOQ) for MERLIN tire pressure gauges may vary depending on the supplier. Typically, B2B suppliers may set an MOQ ranging from 50 to 100 units to ensure cost-effectiveness in shipping and handling. It is advisable to negotiate with suppliers for favorable terms, especially if you are looking to place a bulk order or establish a long-term partnership.

What payment terms should I expect when sourcing the MERLIN tire pressure gauge internationally?

Payment terms for international purchases can vary widely among suppliers. Common terms include upfront payment, 30% deposit with the balance due before shipment, or net 30/60 days after delivery. It is important to discuss payment methods accepted (e.g., bank transfer, credit card, or letters of credit) and ensure clarity on currency exchange rates, especially when dealing with international transactions.

How can I verify the credibility of a supplier for MERLIN tire pressure gauges?

To verify the credibility of a supplier, consider checking their business registration, customer reviews, and industry certifications. Request references from other B2B buyers and assess their responsiveness and communication. Utilize platforms like Alibaba or Global Sources to view supplier ratings and feedback. Additionally, conduct a background check or site visit if feasible, especially for large orders.

What shipping options are available for importing MERLIN tire pressure gauges?

Shipping options for importing MERLIN tire pressure gauges typically include air freight for quicker delivery or sea freight for cost efficiency. The choice of shipping method will depend on your urgency and budget. Discuss logistics with your supplier to determine the best option, taking into account customs clearance procedures, insurance, and tracking capabilities. Always factor in potential delays due to international shipping regulations.

Can I customize the MERLIN tire pressure gauge for my brand?

Many suppliers offer customization options for the MERLIN tire pressure gauge, including branding, color variations, and packaging. Customization often requires a minimum order quantity and may involve additional costs. When discussing customization, ensure you provide clear specifications and timelines to avoid misunderstandings. Confirm the supplier’s capability to meet your branding requirements while maintaining product quality.

What quality assurance measures should I expect for the MERLIN tire pressure gauge?

Quality assurance measures for the MERLIN tire pressure gauge should include rigorous testing for accuracy, durability, and compliance with international standards. Reputable suppliers should provide documentation of quality tests, such as ISO certifications or product-specific compliance reports. Additionally, inquire about the warranty policy, which typically covers defects in materials and workmanship for a specified period, ensuring you receive a reliable product.

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: MERLIN Pistol Grip Inflator with Analog Gauge

Dominio: ebay.com

Registrato: 1995 (30 anni)

Introduzione: {“title”: “Merlin Dual Chuck Lever Style Tire Inflator Gauge”, “max_pressure”: “160 Psi”, “condition”: “New”, “brand”: “Merlin”, “type”: “Gauge”, “description”: “The Merlin Dual Chuck Lever Style Tire Inflator Gauge is a versatile tool designed for inflating and measuring tire pressure quickly and accurately. Suitable for a wide range of applications in the HVAC and refrigeration industry.”, “ship…

Dominio: facebook.com

Registrato: 1997 (28 anni)

Introduzione: This company, Harbor Freight – Merlin Digital Gauge, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Dominio: surplusgy.com

Registered: 2023 (2 years)

Introduzione: This company, MERLIN – Digital Tire Pressure Gauge, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In summary, the MERLIN Digital Tire Pressure Gauge stands out as a robust option for businesses seeking reliable, accurate tire maintenance tools. With features such as an easy-to-read backlit LCD display, multiple pressure unit options, and an impressive accuracy rate of 1% at 150 PSI, this gauge offers exceptional value. Its auto on/off feature enhances battery life, making it a practical choice for long-term use in varied environments.

Strategic sourcing is crucial for B2B buyers aiming to streamline procurement while ensuring quality and cost-effectiveness. By sourcing the MERLIN tire pressure gauge from reputable suppliers, businesses can leverage competitive pricing and reliable product availability. This not only supports operational efficiency but also enhances customer satisfaction by ensuring that tools are consistently available and functional.

For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, investing in high-quality tire pressure gauges like the MERLIN model can significantly improve fleet maintenance and operational safety. As markets evolve, now is the time to strengthen your sourcing strategies. Embrace opportunities to collaborate with trusted suppliers and ensure your procurement process aligns with your business goals. Take the next step in enhancing your operational capabilities by considering the MERLIN tire pressure gauge for your tire maintenance needs.

Illustrative image related to merlin tire pressure gauge

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.