Navigating the complexities of sourcing nitrogen inflated tires can be daunting for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As businesses strive to enhance vehicle performance and safety, understanding the nuanced benefits of nitrogen inflation becomes critical. This guide is designed to empower decision-makers by providing a comprehensive overview of nitrogen inflated tires, covering essential aspects such as types, applications, supplier vetting, and cost considerations.

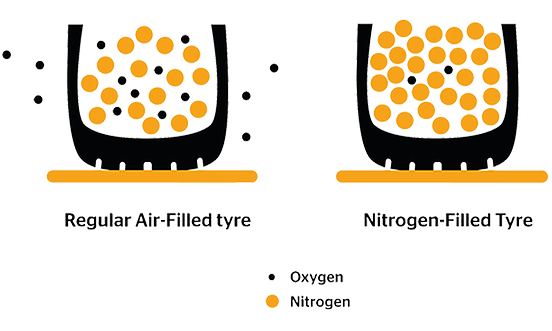

In an era where efficiency and performance are paramount, nitrogen inflated tires present a compelling option for various applications, from passenger vehicles to heavy-duty trucks. Buyers will learn how to assess the unique advantages of nitrogen, including improved tire pressure retention and reduced oxidation, while also weighing practical factors like cost and maintenance requirements. The guide will offer actionable insights into selecting reputable suppliers, ensuring that your procurement process is both efficient and effective.

By equipping B2B buyers with the knowledge to make informed purchasing decisions, this guide aims to facilitate a smoother entry into the global market for nitrogen inflated tires. Whether you’re a fleet manager in Germany or a logistics coordinator in Saudi Arabia, understanding these dynamics will not only enhance operational efficiency but also contribute to long-term cost savings and safety.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Passenger Vehicle Tires | Standard tires filled with nitrogen; suitable for everyday use | Automotive dealerships, fleet services | Pro: Improved pressure retention, reduced oxidation. Contro: Minimal performance difference compared to air. |

| Heavy-Duty Truck Tires | Designed for high loads; maintain pressure under heavy conditions | Logistics, transportation companies | Pro: Enhanced safety, reduced downtime. Contro: Higher initial cost, requires specialized filling equipment. |

| Aviation Tires | Specialized for aircraft; withstand extreme pressure changes | Airlines, cargo transport | Pro: Superior performance at high altitudes, enhanced safety. Contro: Significant cost, requires expert maintenance. |

| Motorsport Tires | High-performance tires; designed for competitive racing | Racing teams, motorsport events | Pro: Improved handling, reduced tire degradation. Contro: Expensive, limited availability. |

| Agricultural Tires | Built for rugged terrain; support heavy agricultural machinery | Farming equipment manufacturers | Pro: Improved durability, better traction. Contro: Requires specialized nitrogen filling services. |

Passenger vehicle tires filled with nitrogen are commonly used in everyday automotive applications. They are designed for regular vehicles, providing a reliable option for maintaining tire pressure. The key benefit lies in their ability to retain pressure longer than standard air-filled tires, which can lead to improved fuel efficiency and safety. However, for B2B buyers, the performance difference may not justify the additional costs, especially when routine maintenance practices can achieve similar results with regular air.

Heavy-duty truck tires are specifically engineered to handle substantial loads and severe driving conditions. The use of nitrogen in these tires helps maintain optimal pressure under heavy loads, reducing the risk of blowouts and enhancing vehicle safety. For logistics and transportation companies, investing in nitrogen-filled tires can lead to fewer breakdowns and lower maintenance costs over time. However, buyers must consider the initial investment and the need for specialized filling equipment.

Aviation tires are designed to endure extreme conditions, including significant pressure changes during flight. The use of nitrogen is critical in these applications to prevent tire degradation and ensure safety at high altitudes. Airlines and cargo transport companies benefit from the enhanced reliability and performance of nitrogen-filled tires. Despite their advantages, the high costs and the necessity for expert maintenance make these tires a specialized purchase for aviation professionals.

Illustrative image related to nitrogen inflated tires

Motorsport tires filled with nitrogen are tailored for high-performance racing environments. These tires provide improved handling and reduced degradation during intense driving conditions. For racing teams and event organizers, the benefits of nitrogen inflation can translate into competitive advantages on the track. However, the high cost and limited availability may pose challenges for teams with budget constraints.

Agricultural tires are built to withstand rugged terrains and heavy machinery. When filled with nitrogen, these tires exhibit enhanced durability and better traction, which are crucial for farming operations. For manufacturers of farming equipment, offering nitrogen-filled tires can be a selling point, as they promise to reduce wear and tear. Nonetheless, buyers should evaluate the need for specialized nitrogen filling services, which may increase operational costs.

| Industria/Settore | Specific Application of nitrogen inflated tires | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Aviation | Tire inflation for commercial aircraft | Enhanced safety and performance in high-pressure environments | Compliance with aviation safety standards and regulations |

| Trasporto e logistica | Fleet management for heavy-duty trucks | Improved fuel efficiency and reduced tire wear | Availability of nitrogen filling stations in operational regions |

| Mining | Tires for heavy machinery and equipment | Increased durability and reduced maintenance costs | Sourcing nitrogen with high purity levels for optimal performance |

| Agricoltura | Tires for agricultural vehicles | Enhanced traction and reduced soil compaction | Consideration for tire size and compatibility with various machinery |

| Costruzione | Tires for construction vehicles | Enhanced stability and safety on uneven terrain | Need for robust supplier relationships for consistent supply |

In the aviation industry, nitrogen inflated tires are critical for commercial aircraft. The high-pressure environment of takeoff and landing requires tires that can withstand extreme conditions without failure. Nitrogen helps maintain consistent tire pressure, reducing the risk of blowouts and enhancing safety. For international buyers, compliance with stringent aviation safety standards is essential, necessitating a focus on suppliers who can guarantee high purity nitrogen and adherence to regulatory requirements.

Illustrative image related to nitrogen inflated tires

Within the transportation and logistics sector, nitrogen inflated tires are increasingly utilized in fleet management for heavy-duty trucks. These tires help improve fuel efficiency by maintaining optimal pressure, which in turn reduces rolling resistance and enhances mileage. Additionally, they experience less wear over time, leading to lower replacement costs. Buyers in Africa, South America, and the Middle East should consider the availability of nitrogen filling stations in their operational regions to ensure ongoing maintenance and support.

In mining, heavy machinery and equipment often operate under extreme conditions, making nitrogen inflated tires a valuable asset. These tires provide increased durability, minimizing the frequency of replacements and reducing overall maintenance costs. Furthermore, the reduced oxidation of rubber due to nitrogen inflation helps extend the tire’s lifespan. B2B buyers in this sector must focus on sourcing nitrogen with high purity levels to optimize performance and ensure reliability in demanding environments.

Agricultural vehicles benefit significantly from nitrogen inflated tires, which enhance traction and reduce soil compaction. This is crucial for maintaining soil health and optimizing crop yields. The stability provided by these tires also improves the safety of operations on uneven terrain. Buyers need to consider the specific tire sizes and compatibility with various agricultural machinery to ensure effective performance in their operations.

In the construction industry, nitrogen inflated tires are vital for construction vehicles that operate on uneven and challenging terrains. These tires provide enhanced stability and safety, reducing the risk of accidents and improving productivity. For construction firms, establishing robust supplier relationships for consistent nitrogen supply is essential to avoid downtime and maintain project timelines. Buyers should also assess the durability and performance specifications of tires suitable for their specific machinery needs.

Illustrative image related to nitrogen inflated tires

Il problema: For B2B buyers managing fleets, maintaining optimal tire pressure is critical for safety, fuel efficiency, and tire longevity. However, nitrogen inflated tires can complicate routine checks. Fleet managers may find that drivers are less likely to regularly check tire pressures if they believe that nitrogen-filled tires require less maintenance. This can lead to under-inflation, which not only increases fuel consumption but also poses safety risks.

La soluzione: To effectively manage nitrogen inflated tires in a fleet, it is essential to establish a comprehensive tire maintenance program. This includes training drivers on the importance of regular tire pressure checks, even for nitrogen-filled tires. Implement a scheduled maintenance routine that includes pressure checks every month. Utilize digital tire pressure monitoring systems (TPMS) that alert fleet managers and drivers to any significant pressure drop. This proactive approach ensures that nitrogen benefits, such as reduced pressure loss, are maximized while maintaining safety and efficiency.

Il problema: Many B2B buyers are confronted with the challenge of justifying the cost of nitrogen inflation for their tires. With the added expense of nitrogen filling services, decision-makers may hesitate to implement this technology, especially if they are not fully convinced of its benefits. This can lead to indecision or a reliance on traditional air inflation methods, which may not provide the same level of performance.

La soluzione: To justify the investment in nitrogen inflation, buyers should focus on total cost of ownership (TCO) analysis. Highlight potential savings from improved fuel efficiency, reduced tire wear, and extended tire life. Conduct case studies or pilot programs to gather data on performance metrics, such as fuel economy improvements and maintenance costs. Additionally, negotiate with suppliers for bulk pricing on nitrogen filling services to reduce upfront costs. By presenting clear data and potential long-term savings, B2B buyers can effectively make a case for the adoption of nitrogen inflation.

Il problema: A common pain point for buyers of nitrogen inflated tires is ensuring the nitrogen purity level during the filling process. If the nitrogen isn’t sufficiently pure, the benefits associated with using nitrogen—such as reduced oxidation and lower pressure loss—may be compromised. This inconsistency can lead to frustration and dissatisfaction among users who expect reliable performance from their nitrogen-filled tires.

Illustrative image related to nitrogen inflated tires

La soluzione: To ensure consistent nitrogen purity, buyers should establish partnerships with reputable suppliers who utilize advanced nitrogen generation systems. Verify that the supplier adheres to industry standards for nitrogen purity, ideally above 95%. It may also be beneficial to invest in nitrogen inflation equipment that can be used in-house to maintain control over the filling process. Regular audits and performance assessments of the nitrogen filling equipment will also help ensure that purity levels are maintained. By taking these steps, B2B buyers can enhance the reliability and effectiveness of nitrogen inflated tires, ensuring they receive the full range of benefits.

When considering the strategic material selection for nitrogen inflated tires, several key materials come into play. Each material has distinct properties, advantages, and limitations that can significantly impact performance and suitability for specific applications. Below, we analyze four common materials used in the construction of nitrogen inflated tires.

Rubber is the primary material used in tire manufacturing due to its elasticity and durability. The key properties of rubber relevant to nitrogen inflated tires include excellent temperature resistance, typically ranging from -40°C to 70°C, and high pressure ratings that can withstand the demands of heavy loads. Additionally, rubber exhibits good corrosion resistance against various environmental factors.

Illustrative image related to nitrogen inflated tires

Pro: Rubber tires provide superior grip and handling, essential for safety and performance. They are relatively low-cost and widely available, making them a preferred choice for manufacturers.

Contro: Rubber can degrade over time due to exposure to UV light and ozone, which may affect the longevity of the tire. Manufacturing complexities can arise from the need for specific formulations to enhance performance characteristics.

Impatto sull'applicazione: The compatibility of rubber with nitrogen is favorable, as it does not react adversely with nitrogen gas. However, regular maintenance is crucial to ensure optimal performance.

Considerazioni per gli acquirenti internazionali: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Europe and the Middle East may prefer tires that meet stringent environmental regulations.

Illustrative image related to nitrogen inflated tires

Steel belts are often used in tire construction to provide structural integrity and enhance performance. The key properties of steel include high tensile strength and excellent resistance to deformation under pressure, which is vital for maintaining tire shape and performance under load.

Pro: Steel reinforcement contributes to improved durability and puncture resistance, making tires safer for heavy-duty applications. It also helps maintain tire pressure over time.

Contro: The cost of steel reinforcement can be higher than other materials, and the manufacturing process is more complex due to the need for precise engineering.

Impatto sull'applicazione: Steel belts are compatible with nitrogen inflated tires, providing enhanced performance in high-pressure environments. They also help mitigate the risk of tire blowouts.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that steel used in tire construction adheres to local standards, particularly in regions like Africa and South America, where infrastructure may vary.

Nylon is utilized in tire manufacturing primarily for its lightweight and strong properties. It offers excellent temperature stability and resistance to abrasion, making it suitable for various driving conditions.

Pro: Nylon enhances the overall performance of tires by reducing rolling resistance, which can improve fuel efficiency. Its lightweight nature contributes to better handling and maneuverability.

Contro: Nylon can be more expensive than traditional rubber, and its performance can be affected by exposure to moisture, which may lead to degradation over time.

Impatto sull'applicazione: Nylon’s compatibility with nitrogen makes it a viable option for tires designed for high-performance vehicles. Its properties can enhance the tire’s ability to maintain pressure.

Illustrative image related to nitrogen inflated tires

Considerazioni per gli acquirenti internazionali: Buyers should consider the availability of nylon in their region and ensure compliance with standards that govern material safety and performance.

Carbon black is a reinforcing filler used in tire rubber to enhance durability and performance. It improves the tire’s resistance to wear and aging, making it a critical component in tire longevity.

Pro: The addition of carbon black can significantly enhance the strength and durability of tires, leading to longer service life. It also improves traction and handling characteristics.

Contro: The manufacturing process can be more complex due to the need for precise formulations, and the cost can be higher compared to tires without carbon black.

Illustrative image related to nitrogen inflated tires

Impatto sull'applicazione: Carbon black is compatible with nitrogen and contributes to maintaining tire pressure over time, which is essential for performance.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that carbon black used in tires meets local environmental regulations, especially in Europe, where there are strict guidelines regarding material safety.

| Materiale | Typical Use Case for nitrogen inflated tires | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Gomma | Standard passenger and commercial tires | Excellent grip and handling | Si degrada nel tempo | Basso |

| Acciaio | Heavy-duty and performance tires | High durability and puncture resistance | Costi più elevati e produzione complessa | Alto |

| Nylon | High-performance and lightweight tires | Reduces rolling resistance | Sensitive to moisture | Med |

| Carbon Black | All types of tires | Increases strength and durability | Complex manufacturing | Med |

This detailed analysis provides B2B buyers with a comprehensive understanding of the materials used in nitrogen inflated tires, enabling informed decisions that align with regional standards and performance requirements.

The manufacturing of nitrogen inflated tires involves several critical stages, each designed to ensure the final product meets stringent performance and safety standards. The primary stages include material preparation, forming, assembly, and finishing.

Preparazione del materiale:

The tire manufacturing process begins with the selection of high-quality raw materials. Natural and synthetic rubber, carbon black, and reinforcing materials such as steel belts and fabric layers are sourced. These materials are then compounded with various additives to enhance durability, flexibility, and resistance to wear and oxidation. Special attention is given to the formulation of compounds that will maintain tire integrity under the unique pressures and conditions associated with nitrogen inflation.

Formazione:

After preparation, the rubber compounds are processed into specific shapes using techniques such as extrusion and calendering. During extrusion, rubber is forced through a die to create tire components like treads and sidewalls. Calendering involves rolling rubber sheets into specific thicknesses. These components are then assembled into a green tire, which is an uncured tire that still requires vulcanization.

Montaggio:

The assembly process involves layering the various components of the tire. The inner liner, which is crucial for maintaining nitrogen gas, is added first to ensure airtightness. Next, the body plies, belts, and tread are added in a specific order, with precise alignment to enhance performance. Once assembled, the green tire is placed in a mold for curing.

Finitura:

Curing, or vulcanization, is a heat process that bonds the components together and gives the tire its final shape. After curing, tires undergo finishing processes such as trimming and inspection for any defects. Finally, they are marked with relevant specifications, including the nitrogen inflation indicator, which is often represented by a distinctive green cap on the valve stem.

Quality assurance is paramount in the production of nitrogen inflated tires, ensuring that they meet international standards and perform reliably in diverse conditions. The quality control process encompasses several stages and techniques.

Illustrative image related to nitrogen inflated tires

Relevant International Standards:

Compliance with international standards such as ISO 9001 is essential for manufacturers. This standard outlines criteria for a quality management system, emphasizing continual improvement and customer satisfaction. Additionally, CE marking is crucial for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards. For specific applications, adherence to industry-specific standards like API for petroleum products is necessary.

Punti di controllo della qualità:

Quality control checkpoints are integrated throughout the manufacturing process:

– Controllo qualità in entrata (CQI): Raw materials are inspected upon arrival to ensure they meet specified standards for quality and safety.

– Controllo qualità in corso d'opera (IPQC): During production, ongoing inspections are conducted to monitor processes and detect any deviations from quality standards.

– Controllo qualità finale (CQC): After curing, each tire is subjected to rigorous testing, including visual inspections and performance evaluations to ensure compliance with safety standards.

Common Testing Methods:

Various testing methods are employed to evaluate tire performance, including:

– Pressure Testing: Ensures that tires can maintain the required nitrogen pressure over time.

– Tread Wear Testing: Assesses how the tire performs under different driving conditions.

– Impact and Durability Testing: Evaluates the tire’s resistance to impacts and its overall longevity.

– Uniformity Testing: Checks for balance and alignment to prevent vibration during use.

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure reliable product performance.

Audit dei fornitori:

Conducting thorough audits of potential suppliers is crucial. This includes reviewing their manufacturing processes, quality control measures, and compliance with international standards. Audits can be performed by the buyers themselves or through third-party inspection agencies that specialize in tire manufacturing.

Richiesta di rapporti sulla qualità:

Buyers should ask for detailed quality control reports, including information on the materials used, production processes, and results from testing procedures. These documents should outline compliance with relevant standards and any certifications obtained.

Ispezioni di terzi:

Engaging third-party inspectors can provide an unbiased assessment of a supplier’s quality control processes. These inspections can be critical for ensuring that suppliers adhere to the required manufacturing and safety standards.

Navigating the complexities of quality control in the tire manufacturing sector requires an understanding of regional standards and practices, especially for buyers from diverse markets.

Regional Standards Compliance:

Different regions may have varying standards for tire manufacturing. Buyers must ensure that suppliers comply with local regulations, which may differ from international standards. For example, European Union regulations may require specific certifications that are not mandated in other regions.

Considerazioni culturali:

Cultural differences can impact communication and expectations regarding quality. Buyers should be aware of these nuances when negotiating terms and establishing quality expectations with suppliers from different regions.

Logistics and Supply Chain Factors:

The supply chain’s complexity can affect quality assurance. Buyers should consider the entire logistics process, including transportation, storage, and handling, as these factors can impact tire performance. Ensuring that suppliers have robust systems for managing these aspects is crucial for maintaining quality.

In conclusion, understanding the manufacturing processes and quality assurance measures for nitrogen inflated tires is essential for B2B buyers seeking reliable products. By focusing on the manufacturing stages, quality control measures, and verification methods, buyers can make informed decisions that align with their operational needs and market expectations.

Illustrative image related to nitrogen inflated tires

This practical sourcing guide is designed to assist B2B buyers in effectively procuring nitrogen inflated tires. By following this checklist, organizations can make informed decisions that enhance tire performance, safety, and cost efficiency. This guide addresses key considerations in the procurement process, ensuring that buyers are equipped with the necessary insights to select the right suppliers and products.

Clearly outline the technical requirements for the nitrogen inflated tires you intend to procure. Consider factors such as tire size, load capacity, and intended vehicle use (e.g., passenger vehicles, commercial trucks, or specialty applications).

Conduct thorough research to identify potential suppliers specializing in nitrogen inflated tires. Look for suppliers with a proven track record and positive reviews from other B2B clients.

Before making a commitment, it’s essential to verify that potential suppliers hold relevant certifications and have robust quality control processes in place.

Illustrative image related to nitrogen inflated tires

Once you have shortlisted suppliers, request detailed quotations that include pricing, delivery timelines, and payment terms. This will help you compare offers effectively.

Evaluate the after-sales support and warranty options offered by suppliers. Strong support can enhance long-term satisfaction with your purchase.

If feasible, conduct a trial or pilot program with a limited quantity of tires before making a larger purchase. This allows you to assess performance in real-world conditions.

Once you have completed the evaluation and testing phases, finalize the supplier relationship by negotiating terms and conditions that reflect both parties’ expectations.

By following this structured checklist, B2B buyers can confidently navigate the procurement process for nitrogen inflated tires, ensuring optimal performance and value for their investments.

Understanding the cost structure of nitrogen inflated tires is crucial for B2B buyers. The primary components of cost include:

I materiali: The production of nitrogen inflated tires involves high-quality rubber compounds, internal structures, and nitrogen gas. The quality of these materials directly influences the final product’s performance and durability.

Lavoro: Skilled labor is essential in manufacturing, particularly for quality control and assembly. Labor costs can vary significantly based on the region and skill level required.

Spese generali di produzione: This includes costs associated with factory operations, utilities, equipment maintenance, and administrative expenses. Overhead can vary widely depending on the geographical location of the manufacturer.

Utensili: Specialized molds and machinery are necessary for tire production. Tooling costs can be substantial, especially for custom tire specifications.

Controllo qualità (CQ): Rigorous testing and quality assurance processes are mandatory to ensure tire safety and performance. These costs are essential for maintaining industry certifications and customer trust.

Logistica: Transportation and warehousing costs play a significant role in the overall pricing structure. International shipping logistics can introduce additional complexities and costs, particularly for buyers in remote regions.

Margine: Manufacturers and suppliers typically apply a margin to cover risks and generate profit. This margin can fluctuate based on market competition and demand.

Pricing for nitrogen inflated tires is influenced by various factors:

Volume/MOQ (quantità minima d'ordine): Larger orders often lead to better pricing due to economies of scale. Buyers should negotiate for volume discounts to enhance cost efficiency.

Specifiche e personalizzazione: Custom tire designs and specifications can increase costs. Buyers should clearly outline their requirements to avoid unexpected expenses.

I materiali: The choice of materials can significantly affect pricing. Premium materials may enhance performance but will also increase the overall cost.

Qualità e certificazioni: Tires that meet international safety and quality standards often carry a premium price. Buyers should verify certifications to ensure compliance with regional regulations.

Fattori di fornitura: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more for their assurance of quality and service.

Incoterms: Understanding shipping terms can aid in calculating total costs. Incoterms dictate responsibilities for shipping, insurance, and tariffs, which can affect pricing.

B2B buyers should consider the following strategies for effective sourcing:

Negoziazione: Leverage your purchasing power by negotiating terms and pricing. Discuss potential discounts for bulk purchases or long-term contracts.

Efficienza dei costi: Assess the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, performance longevity, and safety. This comprehensive view can lead to more informed purchasing decisions.

International Pricing Nuances: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and import tariffs, which can significantly influence final costs.

Supplier Assessment: Conduct thorough research on potential suppliers, including reviews, past performance, and financial stability. A reliable supplier can reduce risks and ensure consistent quality.

Prices for nitrogen inflated tires can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough market research and obtain multiple quotes to understand the current pricing landscape accurately.

In the quest for optimal tire performance, B2B buyers must consider various tire inflation options to meet their operational needs. While nitrogen inflated tires have gained attention for their purported benefits, alternative solutions also merit examination. This analysis will compare nitrogen inflation against two viable alternatives: traditional air inflation and tire sealant technology. Each option offers distinct advantages and drawbacks that can influence a buyer’s decision based on specific applications and requirements.

| Aspetto di confronto | Nitrogen Inflated Tires | Traditional Air Inflation | Tire Sealant Technology |

|---|---|---|---|

| Prestazioni | Reduced pressure loss; better for high-pressure applications | Sufficient for most vehicles; pressure loss over time | Prevents slow leaks; enhances tire lifespan |

| Costo | Higher initial cost (approx. $5+ per tire) | Generally free; minimal ongoing costs | Moderate cost; one-time application for most products |

| Facilità di implementazione | Requires specialized equipment for filling | Readily available at most service stations | Requires initial installation; some expertise may be needed |

| Manutenzione | Regular checks needed; must top off with nitrogen | Regular checks needed; easy to top off with air | Minimal ongoing maintenance; self-sealing capabilities |

| Il miglior caso d'uso | High-performance vehicles; racing; heavy-duty applications | Everyday vehicles; general consumer use | Commercial fleets; off-road vehicles; puncture-prone environments |

Traditional air inflation is the most common method for filling tires, primarily due to its accessibility and cost-effectiveness. Air is free and available at almost all service stations, making it convenient for most consumers. However, air contains moisture and oxygen, which can lead to faster pressure loss and tire degradation over time. Regular maintenance is crucial, as air-filled tires can lose pressure more quickly than nitrogen-filled counterparts, especially in varying temperature conditions.

Tire sealant technology offers a proactive solution to tire maintenance by applying a sealant that can automatically fill small punctures. This technology minimizes air loss, enhancing tire lifespan and reducing the frequency of tire changes. However, it comes with a moderate upfront cost and may require some expertise for installation. Sealants may not be suitable for all tire types, and their effectiveness diminishes with larger punctures or significant damage, which could lead to more complicated repairs.

When choosing the right tire inflation solution, B2B buyers must consider their specific operational needs and contexts. Nitrogen inflated tires are ideal for high-performance scenarios where tire pressure maintenance is critical, while traditional air inflation remains a practical and cost-effective option for general use. Tire sealant technology can be advantageous for commercial fleets or vehicles prone to punctures, offering a blend of convenience and enhanced durability. Ultimately, the decision should align with the buyer’s budget, maintenance capabilities, and performance expectations to ensure optimal tire performance and longevity.

Understanding the technical properties of nitrogen inflated tires is essential for B2B buyers seeking to make informed purchasing decisions. Here are some critical specifications to consider:

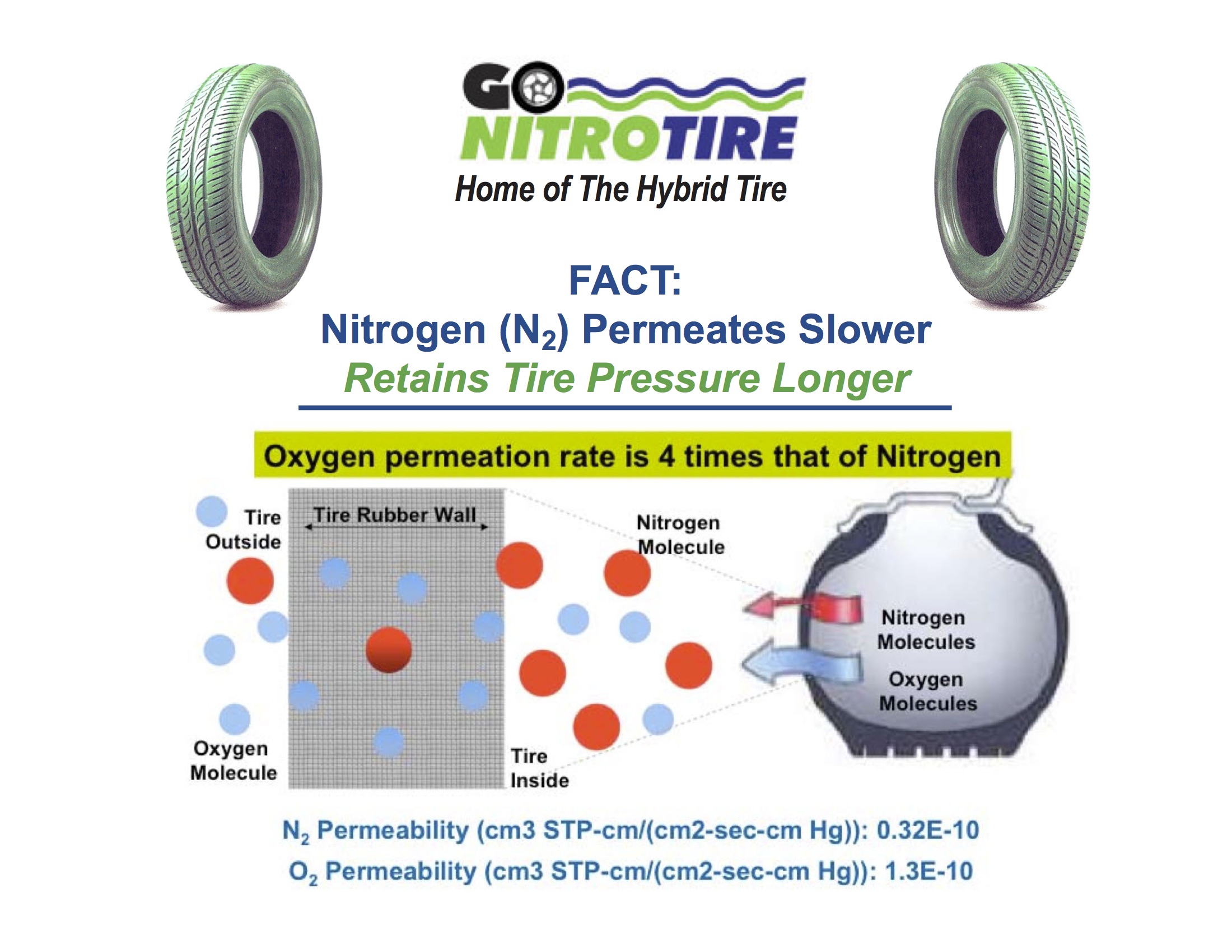

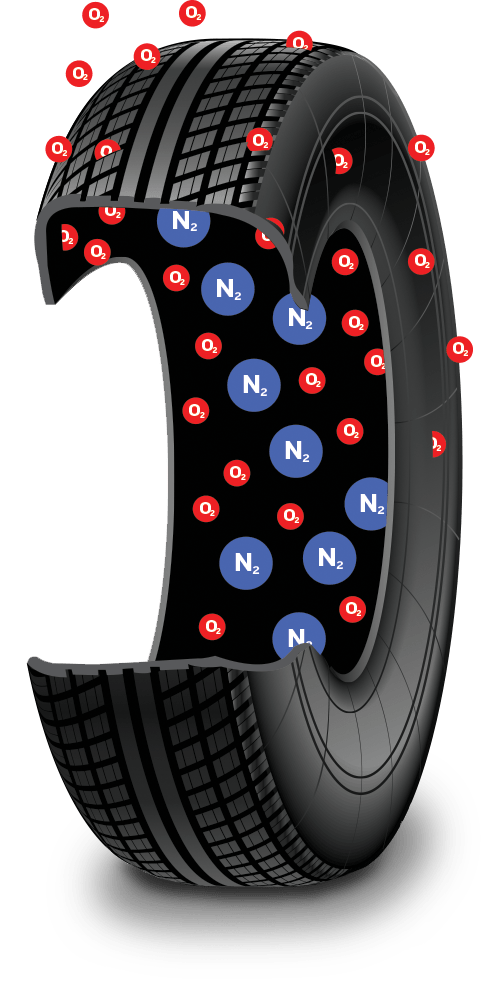

Nitrogen used in tire inflation typically has a purity level of 95% or higher. This means that the nitrogen gas is mostly free of moisture and other gases that can contribute to tire degradation. For buyers, high purity levels are crucial because they ensure better pressure retention and reduced oxidation of tire materials, leading to longer tire life.

The pressure retention rate is a measure of how well tires maintain their inflation over time. Studies indicate that nitrogen inflated tires lose pressure at a slower rate than those filled with air—approximately 2.2 psi loss for nitrogen compared to 3.5 psi for air over a year. For B2B buyers, this property is vital as it translates to lower maintenance costs and improved safety, especially in commercial applications where tire reliability is paramount.

Nitrogen reduces the amount of oxygen inside the tire, which helps to minimize oxidation. Oxidation can make rubber brittle and reduce the tire’s lifespan. For businesses that rely on heavy-duty applications, such as transportation and logistics, this property can lead to significant cost savings over time by delaying the need for tire replacements.

Nitrogen inflation provides better temperature stability compared to regular air. Nitrogen is less affected by temperature changes, which helps in maintaining consistent tire pressure. For companies operating in varying climates, this property is important for ensuring optimal performance and safety across different conditions.

While nitrogen does not directly affect the rolling resistance of tires, maintaining proper tire pressure helps to optimize fuel efficiency and tire wear. For B2B buyers in industries where fuel costs are a significant concern, understanding how nitrogen can indirectly contribute to lower rolling resistance is beneficial.

Familiarity with industry terminology is critical for effective communication and negotiation. Here are several essential terms that B2B buyers should know:

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of nitrogen inflated tires, knowing the OEM can help buyers ensure compatibility and quality assurance.

Illustrative image related to nitrogen inflated tires

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps B2B buyers plan their inventory and purchasing strategies effectively, ensuring they meet supplier requirements while optimizing stock levels.

An RFQ is a document sent to suppliers to solicit price quotes for specific goods or services. For businesses looking to procure nitrogen inflated tires, submitting an RFQ can help compare prices and terms from different suppliers, enabling informed purchasing decisions.

These are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risks, and logistics involved in the procurement of nitrogen inflated tires.

This rating measures the durability of a tire’s tread and is often indicated on tire specifications. For B2B buyers, understanding treadwear ratings can help in selecting tires that will provide the best longevity and performance based on their operational needs.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions regarding nitrogen inflated tires, ultimately leading to better performance and cost savings in their operations.

Illustrative image related to nitrogen inflated tires

The nitrogen inflated tires market is gaining traction globally due to several key drivers. One of the primary factors is the growing awareness of safety and fuel efficiency among vehicle operators, particularly in regions like Africa, South America, the Middle East, and Europe. Nitrogen-filled tires are known to retain pressure longer than conventional air, which can lead to improved vehicle performance and reduced fuel consumption—an attractive proposition for fleet operators and businesses managing logistics.

Emerging technologies are also influencing the market. The rise of tire pressure monitoring systems (TPMS) and smart tire technologies allows real-time tracking of tire conditions, further enhancing the benefits of nitrogen inflation. These advancements are crucial for international B2B buyers looking to integrate innovative solutions into their operations.

Moreover, regulatory changes aimed at reducing carbon footprints are pushing industries to adopt more sustainable practices. This trend is particularly evident in Europe and the Middle East, where compliance with environmental regulations is critical for business operations. As a result, suppliers are increasingly focusing on offering nitrogen inflation solutions that align with sustainability goals.

Sustainability has become a cornerstone of the nitrogen inflated tires market, influencing both sourcing strategies and product offerings. The environmental impact of tire production and disposal is significant, prompting B2B buyers to seek suppliers who prioritize eco-friendly practices. The use of nitrogen in tires can contribute to longer tire life and reduced rolling resistance, which translates to lower emissions over time.

Ethical sourcing is equally important. Buyers are increasingly demanding transparency in supply chains, seeking out suppliers who adhere to ethical practices. This includes sourcing raw materials responsibly and ensuring fair labor practices throughout the production process. Certifications such as ISO 14001 (Environmental Management) and ISO 26000 (Social Responsibility) are becoming essential for suppliers aiming to build trust with international buyers.

Illustrative image related to nitrogen inflated tires

In addition, the adoption of “green” materials in tire production, such as bio-based rubbers and recycled materials, is gaining momentum. These innovations not only reduce the carbon footprint of tire manufacturing but also appeal to environmentally-conscious businesses looking to enhance their sustainability profiles.

The evolution of nitrogen inflated tires can be traced back to the aerospace industry, where the need for safety and performance in high-pressure environments first highlighted the benefits of nitrogen inflation. Over the past two decades, the automotive sector has gradually embraced this technology, initially targeting high-performance vehicles and commercial fleets.

As awareness of tire maintenance and safety has increased, nitrogen inflation has expanded into passenger vehicles and everyday use. Recent studies have underscored its potential benefits, such as reduced pressure loss and improved tire longevity. This evolution has been fueled by advancements in tire technology, regulatory pressures for enhanced safety measures, and a broader shift towards sustainability in the automotive industry.

Illustrative image related to nitrogen inflated tires

For international B2B buyers, understanding this historical context is crucial for making informed sourcing decisions. As the market continues to mature, the focus will likely shift towards integrating innovative technologies and sustainable practices, setting the stage for the next phase of growth in the nitrogen inflated tires sector.

How do I ensure the quality of nitrogen inflated tires before purchasing?

To guarantee the quality of nitrogen inflated tires, conduct thorough due diligence on potential suppliers. Request certifications such as ISO 9001, which demonstrates adherence to quality management standards. It’s also beneficial to ask for product samples and customer testimonials. Conducting a factory visit can provide insights into the manufacturing processes, including how nitrogen purity is maintained during inflation. Additionally, ensure that the supplier has robust quality assurance protocols in place to monitor tire performance and longevity.

What are the key benefits of using nitrogen inflated tires over regular air?

Nitrogen inflated tires offer several advantages, particularly in commercial and heavy-duty applications. They maintain tire pressure more consistently, reducing the frequency of inflation checks and minimizing the risk of under-inflation. Nitrogen’s reduced permeability compared to regular air helps to lower tire degradation, which can enhance safety and performance. This is particularly beneficial for fleets operating in extreme conditions, as it can lead to improved fuel efficiency and longer tire lifespan, ultimately reducing operational costs.

What customization options are available for nitrogen inflated tires?

Customization options for nitrogen inflated tires can vary by supplier. Common options include different tread patterns, sizes, and rubber compounds tailored to specific vehicle types and operational environments. Some manufacturers may also offer branding opportunities, allowing you to label tires with your company’s logo or specific product markings. Discuss your requirements with potential suppliers to explore available customization options that can align with your business needs and enhance your brand presence in the market.

What is the minimum order quantity (MOQ) for nitrogen inflated tires?

Minimum order quantities (MOQ) for nitrogen inflated tires depend on the supplier and your specific requirements. Generally, larger orders can lead to better pricing and terms, while smaller orders may incur higher costs. It’s advisable to communicate your projected needs to suppliers upfront, as they may offer flexibility on MOQs for long-term partnerships or bulk purchases. Additionally, clarify whether the MOQ affects customization options, as some suppliers may have different thresholds based on the complexity of custom orders.

What payment terms should I expect when sourcing nitrogen inflated tires?

Payment terms for nitrogen inflated tires can vary widely among suppliers. Common arrangements include upfront deposits, typically ranging from 30% to 50%, with the balance due upon delivery or after a set period. Some suppliers may offer credit terms for established relationships, allowing for payment after a specified number of days post-delivery. Always negotiate payment terms that align with your cash flow and operational needs, and ensure that they are documented in the purchase agreement to avoid any misunderstandings.

How do I vet suppliers for nitrogen inflated tires effectively?

Vetting suppliers for nitrogen inflated tires involves several key steps. Start by researching their market reputation and industry experience, focusing on customer reviews and case studies. Verify their certifications and compliance with international standards. Additionally, request references from other clients, especially those in similar industries or regions. Establishing clear communication and asking detailed questions about their production processes, quality control measures, and logistics capabilities will also help ensure you select a reliable partner.

What logistics considerations should I keep in mind when importing nitrogen inflated tires?

When importing nitrogen inflated tires, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose between air freight for faster delivery or sea freight for cost-effectiveness, depending on your urgency and budget. Familiarize yourself with import duties and taxes applicable in your country, as these can affect overall costs. Collaborate closely with your supplier and freight forwarder to ensure proper documentation and compliance with regulations to facilitate a smooth import process.

Are there specific regulations for nitrogen inflated tires in international markets?

Yes, regulations regarding nitrogen inflated tires can vary by region. In Europe, for example, tires must meet specific safety and environmental standards outlined by the EU. In contrast, countries in Africa and South America may have different compliance requirements. It’s crucial to research the regulations in your target markets to ensure that the tires you source meet local standards. Engaging with legal experts or local partners can provide valuable insights into compliance, ensuring that your products can be marketed and sold without legal complications.

Dominio: cars.usnews.com

Registrato: 1995 (30 anni)

Introduzione: Nitrogen in tires offers several pros and cons. Pros include: 1) Nitrogen escapes from a tire more slowly than air due to the larger atomic radius of nitrogen, which may lead to less frequent inflation. 2) Nitrogen can keep tire pressure more consistent, especially in fluctuating temperatures, as it is less affected by temperature changes compared to air. 3) Nitrogen can prolong tire life because …

Dominio: continental-tires.com

Registrato: 2000 (25 anni)

Introduzione: Nitrogen can be used to inflate tires instead of air, offering benefits such as improved tire pressure retention and reduced temperature fluctuations. This practice is gaining popularity among driving enthusiasts and is not limited to race car driving. Continental emphasizes the importance of maintaining proper tire pressure for long-term tire care.

Dominio: principlevolvocarssanantonio.com

Registrato: 2017 (8 anni)

Introduzione: Nitrogen-filled tires can hold their pressure longer, potentially improving comfort and fuel economy. Filling tires with air is less expensive and more commonly available at gas stations. Both nitrogen and air can effectively fill tires, each with unique advantages and disadvantages. Nitrogen is preferred in heavy-duty applications like race cars and aircraft due to its larger molecular size, whic…

Dominio: robertson-tire.com

Registrato: 1999 (26 anni)

Introduzione: Nitrogen-filled tires lose pressure about 40% slower than regular air. They can contain up to 98% pure nitrogen, which helps maintain air pressure longer. Benefits include increased tread life, better tire pressure retention, cooler-running tire temperatures, improved handling and performance, extended tire lifespan, and maximized tire pressure.

In summary, the strategic sourcing of nitrogen inflated tires presents a compelling opportunity for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. While the advantages of nitrogen-filled tires—such as reduced pressure loss and potential improvements in fuel efficiency—are backed by some research, it is crucial to weigh these benefits against the costs and maintenance requirements.

Investing in nitrogen inflation systems may be more justified for heavy-duty applications, such as commercial transportation and aviation, where the operational demands are higher. For passenger vehicles, however, consistent maintenance and regular air checks can yield similar benefits at a lower cost.

As the market evolves, buyers are encouraged to engage with suppliers who can provide tailored solutions that meet their specific needs. Embracing strategic sourcing practices will not only enhance operational efficiency but also drive long-term cost savings. Looking ahead, the demand for nitrogen inflated tires is expected to grow as more businesses recognize the potential for improved performance and safety. Now is the time to explore partnerships and leverage innovative tire management solutions for a sustainable competitive advantage.

Illustrative image related to nitrogen inflated tires

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.