In today’s fast-paced global market, sourcing reliable equipment like the RYOBI tire inflator with battery and charger can be a significant challenge for B2B buyers. Companies need tools that not only perform efficiently but also meet diverse operational demands across various industries. This guide aims to address these challenges by providing a comprehensive overview of the RYOBI tire inflator, including its various types, applications, and specifications tailored to specific market needs.

The guide delves into the essential features of RYOBI tire inflators, such as their power capabilities, versatility in inflating different types of tires and sports equipment, and their user-friendly designs. It also offers insights into supplier vetting processes, ensuring that international buyers from regions like Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Nigeria—can confidently make informed purchasing decisions.

Furthermore, this resource highlights cost considerations, potential return on investment, and maintenance requirements, empowering businesses to optimize their procurement strategies. By navigating the complexities of the global market for RYOBI tire inflators, buyers can streamline their operations and enhance productivity, securing a competitive edge in their respective industries. This guide serves as a vital tool for any organization seeking to invest in high-quality, reliable inflators that meet their specific needs.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| ONE+ 18V High Pressure Inflator Kit | Inflates up to 160 PSI, digital pressure gauge | Automotive service, tire shops | Pro: High PSI capability; Contro: Limited battery life for heavy use. |

| ONE+ 18V Dual Function Inflator Kit | Dual function (inflation and deflation), compact size | Construction, landscaping | Pro: Versatile; Contro: May lack power for larger tires. |

| ONE+ 18V Cordless High Pressure Inflator Kit | Comes with 2.0 Ah battery, auto shut-off feature | Emergency services, fleet management | Pro: Convenient for quick inflation; Contro: Battery may require frequent recharges. |

| ONE+ 18V Digital Inflator Kit | LCD screen for pressure display, on-board storage | Sports facilities, recreational use | Pro: Accurate readings; Contro: Costo iniziale più elevato. |

| ONE+ 18V Compact Inflator Kit | Lightweight design, portable, lower PSI capability | Personal use, small vehicle maintenance | Pro: Easy to carry; Contro: Not suitable for heavy-duty applications. |

The ONE+ 18V High Pressure Inflator Kit is designed for high-performance tire inflation, reaching up to 160 PSI. Its digital pressure gauge ensures precise filling, making it ideal for automotive service and tire shops. B2B buyers should consider its high PSI capability for various vehicles but note that battery life may be limited during extensive use.

This model offers dual functionality, allowing for both inflation and deflation, which is particularly beneficial in construction and landscaping applications. Its compact size makes it portable, but B2B buyers should be aware that while versatile, it may not provide the power needed for larger tires, limiting its use in some scenarios.

The ONE+ 18V Cordless High Pressure Inflator Kit includes a 2.0 Ah battery and features an auto shut-off function, making it a convenient choice for emergency services and fleet management. Its quick inflation capabilities are a significant advantage, although the battery may require frequent recharges, which could affect productivity in high-demand environments.

Equipped with an LCD screen for pressure display and on-board accessory storage, the ONE+ 18V Digital Inflator Kit is perfect for sports facilities and recreational use. Its accurate pressure readings enhance user experience; however, the higher initial cost may be a consideration for budget-conscious buyers.

The ONE+ 18V Compact Inflator Kit is lightweight and portable, making it suitable for personal use and small vehicle maintenance. While its easy-to-carry design is a plus, it is not recommended for heavy-duty applications, making it less suitable for businesses that require robust inflation solutions. B2B buyers should evaluate their specific needs when considering this model.

| Industria/Settore | Specific Application of ryobi tire inflator with battery and charger | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Negozi di riparazione di autoveicoli | Quick tire inflation for vehicles undergoing maintenance or repair | Reduces downtime and enhances service efficiency | Battery longevity, compatibility with various tire sizes, ease of transport |

| Logistics and Transport | On-site tire inflation for delivery and transport vehicles | Minimizes delays and ensures fleet reliability | Durability in rugged conditions, battery charge time, and pressure accuracy |

| Sports Facilities | Inflating sports equipment such as balls and bikes | Saves time and ensures readiness for events | Portability, ease of use, and battery capacity for extended use |

| Construction Sites | Inflation of machinery tires and equipment | Enhances operational efficiency and safety | High PSI capabilities, robust design for harsh environments, and battery life |

| Servizi di emergenza | Rapid tire inflation for emergency vehicles and equipment | Critical for timely response in emergencies | Reliability, quick recharge, and compact design for storage |

In automotive repair shops, the Ryobi tire inflator is essential for quickly inflating tires during maintenance or repair. This tool allows technicians to efficiently manage tire pressures, ensuring optimal vehicle performance and safety. The inflator’s portability and battery operation eliminate the need for cumbersome cords, allowing for easy maneuverability around the shop. For international buyers, especially in regions with varying electrical infrastructure, battery-powered tools offer a reliable solution without dependency on local power sources.

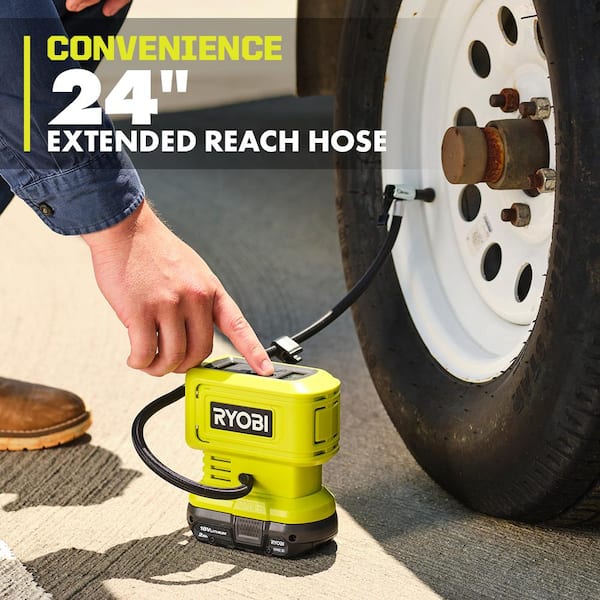

Illustrative image related to ryobi tire inflator with battery and charger

In the logistics and transport industry, the Ryobi tire inflator serves as a vital tool for maintaining the tire pressure of delivery vehicles. Timely tire inflation helps prevent delays caused by flat tires, thereby improving fleet reliability and reducing operational costs. The inflator’s ability to achieve high PSI levels ensures that tires are adequately inflated for long hauls. Buyers in regions like Africa or South America should consider the inflator’s durability and battery life, as these factors are crucial for on-the-road applications.

Sports facilities frequently use the Ryobi tire inflator to prepare sports equipment such as soccer balls, basketballs, and bicycles. The inflator enables quick and efficient inflation, allowing staff to ensure equipment is ready for use at all times. Its compact design and battery operation make it easy to store and transport across the facility. For international buyers, especially in regions where events may be held outdoors, the inflator’s reliability and ease of use are significant advantages.

On construction sites, the Ryobi tire inflator is crucial for maintaining the tire pressure of heavy machinery and equipment. Proper inflation is vital for the safety and efficiency of operations, as under-inflated tires can lead to accidents and equipment failures. The inflator’s ability to deliver high PSI levels and its rugged design make it ideal for the demanding conditions of construction environments. Buyers from the Middle East or Europe should prioritize features like durability and battery capacity to ensure the tool meets the rigorous demands of their work.

Emergency services rely on the Ryobi tire inflator for rapid tire inflation of emergency vehicles. In critical situations, having properly inflated tires is essential for ensuring timely responses. The inflator’s compact size allows for easy storage in vehicles, while its battery-powered operation ensures that it is always ready for use, regardless of the location. For buyers in regions with challenging terrains, the reliability and quick recharge capabilities of the inflator are crucial for maintaining operational readiness.

Il problema: B2B buyers often face challenges when sourcing inflators that can handle diverse tasks, such as inflating vehicle tires, sports equipment, and other applications that require different pressure settings. For instance, a logistics company might need to inflate truck tires to a specific PSI while also managing lower pressures for bicycle tires or sports balls. The Ryobi tire inflator, while versatile, may not always provide the expected performance consistency across these varied requirements, leading to inefficiencies and delays in operations.

La soluzione: To ensure that the Ryobi tire inflator meets various inflation needs effectively, buyers should consider investing in models with adjustable pressure settings and auto shut-off features. When sourcing, look for inflators like the 18V ONE+ Digital Inflator, which allows precise inflation up to 160 PSI, along with a digital pressure gauge for accuracy. Training staff on how to set the desired pressure for different applications can further enhance efficiency. Additionally, maintaining a well-stocked inventory of compatible accessories for different inflation needs can streamline operations and minimize downtime.

Il problema: In industries where tire inflation is a frequent requirement, such as transportation and construction, the battery life of the Ryobi inflator can become a significant pain point. Buyers may find that the standard battery included with the inflator does not last long enough during peak operational periods, leading to interruptions and a need for frequent recharging, which can cause delays in workflow.

La soluzione: To address battery life concerns, B2B buyers should consider purchasing additional high-capacity batteries, such as the Ryobi 6Ah Lithium High-Performance Battery. This investment ensures that there is always a backup ready for use, minimizing downtime. Additionally, implementing a battery management system within the operational workflow can help schedule recharging during non-peak hours, ensuring that inflators are always ready when needed. Buyers should also educate their teams on proper battery maintenance and care to extend the life of each unit.

Il problema: A common issue faced by companies that rely on the Ryobi tire inflator is the varying levels of familiarity and expertise among users. New employees or those less experienced with power tools may struggle to operate the inflator effectively, leading to improper use, inefficiencies, and potential safety hazards. This can be especially problematic in high-paced environments where time is critical.

La soluzione: To mitigate this issue, B2B buyers should implement a comprehensive training program that focuses on the proper use of the Ryobi tire inflator. This program should include hands-on demonstrations, instructional videos, and safety protocols tailored to the specific applications relevant to their operations. Additionally, creating easy-to-follow user guides or quick-reference cards can empower employees to operate the inflator confidently. Regular refresher courses can also be beneficial in ensuring all staff members are up to date with best practices, ultimately leading to increased efficiency and safety in the workplace.

When selecting materials for the Ryobi tire inflator with battery and charger, several factors must be considered, including performance, durability, cost, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of this product.

Proprietà chiave: High-impact ABS plastic is known for its excellent toughness and impact resistance. It can withstand a wide range of temperatures, making it suitable for various environmental conditions.

Pro e contro: The durability of ABS plastic is a significant advantage, as it can resist cracking and breaking under stress. It is also lightweight, which contributes to the overall portability of the inflator. However, it may not be as resistant to UV radiation and chemicals compared to other materials, potentially limiting its lifespan in harsh outdoor conditions.

Impatto sull'applicazione: Given its lightweight nature, ABS plastic is ideal for housing components of the inflator, ensuring ease of use. However, it may not be suitable for parts that come into direct contact with high temperatures or corrosive materials.

Considerazioni per gli acquirenti internazionali: Compliance with standards such as ASTM D648 for heat resistance is crucial. Buyers in regions like Africa and South America should also consider the material’s performance in high UV exposure environments.

Proprietà chiave: Aluminum alloys offer a high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity.

Illustrative image related to ryobi tire inflator with battery and charger

Pro e contro: The primary advantage of aluminum is its durability and resistance to rust, which is essential for outdoor tools. However, aluminum can be more expensive than plastic and may require specialized manufacturing processes, increasing production complexity.

Impatto sull'applicazione: Aluminum is suitable for components that require strength and durability, such as the inflator’s housing or internal mechanisms. Its thermal properties also help in dissipating heat generated during operation.

Considerazioni per gli acquirenti internazionali: Buyers should ensure compliance with international standards like ISO 9001 for quality management. In regions with high humidity, such as parts of the Middle East, the corrosion resistance of aluminum becomes a critical factor.

Proprietà chiave: Rubber is flexible, resilient, and has excellent elasticity, making it ideal for seals and gaskets.

Pro e contro: The flexibility of rubber allows it to create tight seals, preventing air leakage during inflation. However, it can degrade over time when exposed to UV light and extreme temperatures, limiting its lifespan.

Illustrative image related to ryobi tire inflator with battery and charger

Impatto sull'applicazione: Rubber is essential for components such as hoses and seals, ensuring efficient operation. Its compatibility with various gases makes it suitable for tire inflation.

Considerazioni per gli acquirenti internazionali: Compliance with standards like ASTM D2000 for rubber materials is essential. Buyers from regions with extreme weather conditions, such as Africa, should consider the rubber’s performance in both high heat and cold.

Proprietà chiave: Steel is known for its high tensile strength and durability, making it suitable for structural components.

Pro e contro: The strength of steel provides excellent durability, ensuring that the inflator can withstand heavy use. However, it is heavier than other materials and can be susceptible to rust if not properly treated.

Impatto sull'applicazione: Steel is ideal for internal structural components that require strength, such as the frame of the inflator. Its weight can be a disadvantage in terms of portability.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that the steel used complies with standards like ASTM A36 for structural steel. Additionally, regions with high moisture levels, such as parts of Europe, may require corrosion-resistant coatings.

| Materiale | Typical Use Case for ryobi tire inflator with battery and charger | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| High-Impact ABS Plastic | Housing components | Leggero e resistente | Limited UV and chemical resistance | Basso |

| Aluminum Alloy | Componenti strutturali | Elevato rapporto resistenza/peso | Costi più elevati e complessità di produzione | Med |

| Gomma | Hoses and seals | Excellent elasticity and sealing | Degrades under UV and extreme temperatures | Basso |

| Acciaio | Internal structural components | Durata eccezionale | Heavier and rust-prone without treatment | Med |

This guide provides a comprehensive overview of the materials used in the Ryobi tire inflator with battery and charger, allowing international B2B buyers to make informed decisions based on performance, cost, and compliance with regional standards.

The manufacturing process for the Ryobi tire inflator with battery and charger involves several key stages, ensuring that each unit meets high-quality standards while maintaining efficiency and cost-effectiveness.

The first step in the manufacturing process is material preparation. This includes sourcing high-quality materials such as durable plastics for the casing, metal components for the internal mechanisms, and lithium-ion cells for the battery. Suppliers are typically vetted to ensure they comply with international standards, which is crucial for B2B buyers looking for reliability and safety.

Once materials are prepared, the next stage is forming. This involves shaping the components using various techniques such as injection molding for plastic parts and stamping for metal components. The use of advanced technology in forming processes allows for precise and consistent dimensions, which are vital for the inflator’s performance and durability.

After forming, the components are assembled. This stage is critical as it combines all individual parts into a functional unit. Automated assembly lines are often employed to enhance efficiency, but skilled labor remains essential for quality checks during assembly. The assembly process includes integrating the battery and charger, ensuring that all electronic components are correctly installed and functional.

Illustrative image related to ryobi tire inflator with battery and charger

The final stage of manufacturing is finishing, which includes quality checks, painting, and packaging. The finishing process ensures that the inflators are not only functional but also visually appealing. This stage is where the product may undergo additional tests to verify that it meets performance specifications before it is packaged for distribution.

Quality assurance (QA) is a critical aspect of the manufacturing process for Ryobi tire inflators. It ensures that each product not only meets internal standards but also complies with international regulations and customer expectations.

For B2B buyers, understanding the quality assurance framework is essential. Ryobi adheres to several international standards, including ISO 9001, which focuses on quality management systems, ensuring that products consistently meet customer and regulatory requirements. Additionally, products may also comply with CE marking, indicating conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

Quality control checkpoints are integrated at various stages of the manufacturing process:

Controllo qualità in entrata (CQI): At this stage, raw materials are inspected for quality and compliance with specifications before being used in production.

Controllo di qualità in corso d'opera (IPQC): During the assembly process, periodic checks ensure that components are being assembled correctly and that any defects are identified early.

Controllo finale della qualità (CQC): After assembly, each inflator undergoes rigorous testing to confirm it meets performance standards, such as pressure output and battery life.

Common testing methods for the Ryobi tire inflator include:

Test funzionali: Ensures that the inflator operates correctly under various conditions.

Pressure Testing: Verifies that the inflator can reach and maintain specified pressure levels.

Test di durata della batteria: Assesses the longevity and performance of the battery under normal usage conditions.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial for minimizing risk.

Buyers should consider conducting audits of potential suppliers. This may include:

On-Site Audits: Visiting the manufacturing facility to evaluate processes, equipment, and quality control measures firsthand.

Document Review: Analyzing quality assurance documentation, including reports on past quality issues, corrective actions taken, and compliance certifications.

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can cover:

Pre-Shipment Inspections: To verify that products meet specifications before leaving the factory.

Random Sampling: To ensure a representative sample of products is tested for quality assurance.

B2B buyers operating in different regions may face unique challenges related to quality control. Understanding these nuances can help mitigate risks associated with international sourcing.

Different regions may have varying standards and regulations. For instance, products sold in Europe must comply with CE standards, while those in the Middle East may require adherence to local regulations. It is essential for buyers to be aware of these differences to ensure compliance and avoid costly delays.

Effective communication between buyers and suppliers is critical in maintaining quality standards. Establishing clear expectations regarding quality requirements, testing protocols, and timelines can help prevent misunderstandings and ensure that both parties are aligned.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for the Ryobi tire inflator with battery and charger is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions that align with their quality expectations and market requirements.

In today’s competitive market, sourcing the right tools, such as the RYOBI tire inflator with battery and charger, is essential for businesses aiming to provide high-quality service. This guide outlines a practical checklist to ensure that B2B buyers make informed decisions while procuring this essential tool.

Before initiating the sourcing process, clarify the technical requirements for the RYOBI tire inflator. Consider factors such as inflation pressure capacity (up to 160 PSI), battery compatibility, and the intended use (e.g., automotive, sports equipment). Establishing these specifications ensures that you select a model that meets your operational needs.

Verify the credentials of potential suppliers to ensure they meet industry standards. Look for certifications such as ISO 9001 or any relevant quality assurance marks that indicate adherence to manufacturing standards. This step is crucial to mitigate risks associated with subpar products and to ensure compliance with local regulations.

Assess the reliability of suppliers by checking their market reputation and customer feedback. Request case studies or testimonials from other businesses, especially those in your region or industry. Reliable suppliers are often transparent about their product quality and service, providing peace of mind during the purchasing process.

Gather quotations from multiple suppliers and compare prices alongside the offered features. Look beyond the initial cost; consider payment terms, warranties, and after-sales service. A comprehensive understanding of total costs will help you make a financially sound decision.

Illustrative image related to ryobi tire inflator with battery and charger

Whenever possible, request samples or demonstration units of the RYOBI tire inflator. Testing the product allows you to evaluate its performance, durability, and ease of use firsthand. This step is critical in ensuring that the product aligns with your expectations and operational needs.

Discuss delivery timelines and logistics with your chosen supplier to ensure timely availability of the inflators. Additionally, inquire about the support services they offer, such as technical assistance and spare parts availability. Reliable support can significantly enhance your operational efficiency and reduce downtime.

Once you have selected a supplier, finalize the purchase agreement by including all discussed terms, including pricing, delivery, warranties, and support. Ensure that both parties sign the agreement to avoid any misunderstandings in the future. A well-documented agreement protects your investment and establishes clear expectations.

By following this checklist, B2B buyers can confidently navigate the procurement process for the RYOBI tire inflator with battery and charger, ensuring that they acquire a tool that meets their business needs while minimizing risks.

When sourcing the Ryobi tire inflator with battery and charger, understanding the cost structure is crucial for B2B buyers. The primary components of cost include:

I materiali: The cost of raw materials such as plastics, metals, and electronic components significantly influences the overall price. High-quality materials may increase initial costs but can lead to enhanced durability and performance.

Lavoro: Labor costs vary by region and can impact the final pricing. In regions with higher labor costs, such as Europe, the price may reflect this, while sourcing from countries with lower labor rates, such as Vietnam or Nigeria, may offer cost advantages.

Spese generali di produzione: This includes expenses related to factory operations, utilities, and administrative costs. Efficient manufacturing processes can help reduce overheads, allowing for more competitive pricing.

Utensili: Investment in specialized tools for production can be significant. Buyers should be aware that initial tooling costs may be amortized over larger production volumes, potentially lowering the price per unit.

Controllo qualità (CQ): Ensuring product quality through rigorous testing and inspections adds to costs. However, effective QC can minimize returns and warranty claims, ultimately impacting the Total Cost of Ownership (TCO).

Logistica: Transportation and warehousing costs can vary widely based on the shipping distance and methods. Incoterms play a critical role in determining who bears these costs, influencing the final pricing.

Margine: Suppliers typically add a markup to cover costs and generate profit. Understanding the margin expectations of suppliers can aid in negotiations.

Several factors influence pricing that B2B buyers should consider:

Volume e quantità minima d'ordine (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs that align with their purchasing power while ensuring they do not overstock.

Specifiche e personalizzazione: Custom features or specific technical requirements can increase costs. Buyers should balance the need for customization with budget constraints.

Qualità dei materiali e certificazioni: Higher quality materials and compliance with international certifications can justify higher prices. Buyers in regions with stringent regulations should prioritize suppliers who meet these standards.

Fattori di fornitura: The reliability and reputation of suppliers can influence costs. Established suppliers may charge a premium but offer better service and quality assurance.

Incoterms: Understanding the implications of Incoterms (such as FOB, CIF, DDP) is essential for accurate cost calculations and risk management in logistics.

Effective Negotiation: Engage suppliers in discussions to understand their cost structure and explore possibilities for discounts based on volume or long-term contracts. Establishing strong relationships can lead to better terms.

Focus sull'efficienza dei costi: Evaluate not just the purchase price but the TCO, which includes maintenance, operational efficiency, and potential resale value. A slightly higher upfront cost may lead to lower overall expenses.

Be Mindful of Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and taxes that can affect overall pricing. Consider locking in prices or using hedging strategies to manage exchange rate risks.

Ricerca sulle tendenze del mercato locale: Understanding regional demand and competition can provide leverage in negotiations. Buyers in Africa, South America, the Middle East, and Europe should stay informed about local market conditions.

Consider Logistics and Delivery Times: Factor in logistics costs and delivery timelines in your sourcing strategy. Delays can lead to increased operational costs, so ensure that suppliers can meet your deadlines.

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and regional factors. Always conduct thorough market research and engage directly with suppliers for the most accurate pricing information.

When considering tire inflation tools, it is essential to evaluate various options to determine the best fit for specific operational needs. The Ryobi tire inflator with battery and charger stands out in the market due to its convenience and efficiency. However, other solutions may offer competitive advantages depending on the context of use, budget constraints, and specific requirements of businesses, particularly in international markets such as Africa, South America, the Middle East, and Europe.

| Aspetto di confronto | Ryobi Tire Inflator With Battery And Charger | Compressore d'aria portatile | Manual Foot Pump |

|---|---|---|---|

| Prestazioni | Inflates up to 160 PSI, digital gauge | High PSI output, quick inflation | Limited PSI, slower inflation |

| Costo | Moderate, around $89.97 | Varies, typically $50-$200 | Low, around $20-$40 |

| Facilità di implementazione | Cordless, easy to use | Requires power source | Manual operation, labor-intensive |

| Manutenzione | Low, occasional battery care | Moderate, oil changes needed | Very low, just clean periodically |

| Il miglior caso d'uso | Ideal for personal and light commercial use | Heavy-duty and frequent use | Emergency and low-frequency use |

Portable air compressors are versatile tools that can inflate tires rapidly and are suitable for various applications, including automotive and industrial uses. They typically deliver higher PSI outputs, allowing for faster inflation compared to the Ryobi inflator. However, they usually require an external power source, which may limit their use in remote locations. Additionally, their price range can vary significantly, which may be a consideration for budget-conscious buyers.

Pro:

– High inflation speed and pressure.

– Suitable for heavy-duty applications.

Contro:

– Dependence on a power source.

– Higher initial cost and maintenance needs.

A manual foot pump is a cost-effective and straightforward solution for tire inflation. It operates without electricity or batteries, making it an excellent choice for emergency situations or locations with limited access to power. While it is the most affordable option, it requires physical effort and may not be suitable for frequent use, especially in a commercial setting.

Pro:

– Very affordable and portable.

– No power source needed.

Contro:

– Slower and labor-intensive inflation process.

– Limited to lower PSI outputs, which may not be adequate for all vehicles.

When selecting the right tire inflation solution, B2B buyers should consider their specific operational needs, budget constraints, and the frequency of use. The Ryobi tire inflator with battery and charger offers a balance of performance, ease of use, and low maintenance, making it suitable for light commercial use. Conversely, if rapid inflation and high PSI output are essential, a portable air compressor may be more appropriate. For occasional use in emergencies, a manual foot pump can suffice at a lower cost. Ultimately, understanding the operational context and evaluating the unique features of each solution will enable buyers to make informed decisions that align with their business objectives.

When considering the Ryobi tire inflator with battery and charger for B2B procurement, understanding its technical specifications is essential for making informed purchasing decisions. Here are several critical properties to evaluate:

Pressure Range (PSI)

The inflator typically supports a pressure range of up to 160 PSI. This specification is crucial for various applications, including inflating vehicle tires, sports equipment, and more. A higher PSI capacity allows for versatility across different types of tires and inflatables, making it a valuable tool for businesses that deal with automotive services or recreational equipment.

Battery Capacity (Ah)

The battery capacity is often rated at either 1.3 Ah or 2.0 Ah, depending on the model. This measurement indicates how long the inflator can operate on a single charge. For B2B buyers, higher capacity means increased productivity, as the tool can be used for longer periods without needing to recharge, which is particularly beneficial in high-demand situations.

Inflation Speed (CFM)

The inflator’s speed is measured in Cubic Feet per Minute (CFM) and indicates how quickly it can fill a tire. A higher CFM rating means faster inflation times, which is advantageous for businesses needing to service multiple vehicles or equipment quickly, enhancing operational efficiency.

Manometro digitale

This feature provides accurate pressure readings, often displayed on an LCD screen. The ability to monitor pressure in real-time helps prevent over-inflation and ensures that tires are inflated to the manufacturer’s specifications. For B2B buyers, this contributes to safety and compliance with industry standards.

Auto Shut-off Feature

This functionality automatically stops inflation once the desired PSI is reached. It not only enhances convenience but also reduces the risk of damage to the inflator and the item being inflated. Businesses can benefit from this feature by minimizing the potential for human error and ensuring consistent performance.

Portability and Design

The inflator is designed for easy transport and storage, often including on-board accessory storage. A lightweight, compact design is crucial for businesses that may need to move equipment frequently or store it in limited spaces.

Understanding trade terminology is essential for B2B buyers to navigate purchasing processes effectively. Here are several key terms:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For buyers, sourcing from OEMs ensures quality and compatibility, particularly important for replacement parts or accessories.

MOQ (quantità minima d'ordine)

MOQ indicates the smallest number of units that a supplier is willing to sell. It is a crucial consideration for B2B buyers as it impacts inventory management and cash flow. Understanding MOQ helps businesses plan their purchases to meet demand without overstocking.

RFQ (Richiesta di offerta)

An RFQ is a document sent by a buyer to suppliers requesting price quotes for specific products or services. This process is essential for comparing costs and negotiating terms, ensuring that buyers receive the best value.

Incoterms (Termini commerciali internazionali)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding these terms helps businesses navigate logistics and manage risks effectively.

Tempi di consegna

This term refers to the amount of time it takes from placing an order until the goods are delivered. For B2B buyers, knowing the lead time is critical for planning and ensuring that they have the necessary equipment available when needed.

Garanzia

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and its lifespan. For B2B buyers, understanding warranty terms can influence purchasing decisions, as it reflects the manufacturer’s confidence in their product and provides assurance of support in case of defects.

By grasping these technical specifications and trade terms, B2B buyers can make well-informed decisions regarding the acquisition of the Ryobi tire inflator, aligning with their operational needs and strategic goals.

The global market for tire inflators, particularly those with integrated battery and charger systems, is experiencing notable growth driven by several factors. The increasing demand for portable and efficient tools among consumers and businesses alike is a primary driver. With the rise in outdoor activities and automotive usage across regions like Africa, South America, the Middle East, and Europe, the need for reliable tire maintenance solutions has intensified. Furthermore, advancements in battery technology, particularly lithium-ion batteries, have enhanced the performance and convenience of these inflators, making them more appealing to B2B buyers.

Emerging trends in e-commerce and digital marketing are reshaping how international buyers source these products. Online platforms provide a streamlined purchasing process, enabling businesses in various regions to access Ryobi inflators easily. Additionally, the rise of smart technology is influencing product design, with features such as digital pressure gauges and auto shut-off capabilities becoming standard. These advancements not only improve user experience but also reduce the risk of over-inflation, appealing to both DIY enthusiasts and professional users.

Sustainability is becoming a critical focus in the manufacturing and sourcing of products, including tire inflators. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their environmental impact. For Ryobi tire inflators, this translates to using eco-friendly materials in production and ensuring that manufacturing processes adhere to sustainability standards.

Ethical sourcing practices are also gaining importance. Buyers are seeking suppliers who can provide transparency in their supply chains, ensuring that materials are sourced responsibly. Certifications such as ISO 14001 for environmental management and adherence to the Global Reporting Initiative (GRI) guidelines are becoming essential for suppliers aiming to attract conscientious buyers. As consumers demand more sustainable products, Ryobi’s commitment to using recyclable materials and reducing waste will be a significant factor in its market competitiveness.

Illustrative image related to ryobi tire inflator with battery and charger

The evolution of the Ryobi tire inflator market reflects broader trends in consumer technology and tool innovation. Initially, inflators were simple, manually operated devices that required significant user effort and time. However, with the introduction of battery-powered options, particularly in the ONE+ series, users now enjoy enhanced portability and convenience. These advancements have shifted the perception of tire inflators from a basic tool to an essential component of vehicle maintenance.

As battery technology continues to improve, the efficiency and usability of inflators have also increased, allowing users to achieve desired pressure levels quickly and accurately. The integration of digital features, such as pressure monitoring and automatic shut-off, showcases the market’s responsiveness to user needs and technological advancements. This evolution not only reflects consumer expectations for performance and convenience but also highlights the competitive landscape in which Ryobi operates, pushing the brand to continually innovate and adapt to market demands.

By understanding these dynamics, international B2B buyers can make informed decisions about sourcing Ryobi tire inflators, ensuring they align with market trends, sustainability goals, and the evolving needs of their customers.

How do I solve issues with the Ryobi tire inflator not turning on?

If your Ryobi tire inflator does not turn on, first check the battery charge level. Ensure the battery is properly seated and fully charged. Inspect the battery contacts for any debris or corrosion, which can impede the connection. If the inflator still does not operate, consult the user manual for troubleshooting tips or contact the manufacturer for warranty support. It’s essential to maintain regular checks and proper storage of the inflator to ensure optimal performance.

What is the best Ryobi tire inflator model for commercial use?

For commercial applications, the Ryobi ONE+ 18V High-Pressure Inflator Kit is highly recommended. This model features a digital pressure gauge, auto shut-off, and the ability to inflate up to 160 PSI, making it ideal for various tire types, including cars and bikes. Its cordless design enhances mobility, while the included battery and charger ensure you have everything you need for continuous operation. Additionally, consider the availability of compatible accessories for versatility in different inflation tasks.

What are the minimum order quantities (MOQ) for purchasing Ryobi tire inflators?

Minimum order quantities can vary by supplier and region. Typically, B2B buyers can expect MOQs ranging from 10 to 50 units for Ryobi tire inflators. It’s advisable to negotiate with suppliers to find a quantity that meets your business needs while ensuring you benefit from competitive pricing. Always inquire about bulk discounts, as purchasing larger quantities may lower the unit cost significantly.

How can I vet suppliers for Ryobi tire inflators?

To effectively vet suppliers, start by researching their business history and reputation. Check for certifications, such as ISO standards, that indicate quality assurance practices. Request references from previous clients and seek feedback on their experiences. Additionally, assess the supplier’s responsiveness and willingness to provide product information and support. A reliable supplier should also offer a clear return policy and warranty for the products.

What payment terms should I expect when sourcing Ryobi tire inflators?

Payment terms for B2B purchases can vary widely. Common arrangements include a 30% deposit with the balance due before shipment or upon delivery. Some suppliers may offer net 30 or net 60 payment terms, allowing you additional time to pay after receipt of goods. Always clarify payment methods accepted, such as bank transfers or letters of credit, and ensure that terms are documented in the purchase agreement to avoid misunderstandings.

What quality assurance measures should I look for when purchasing?

When sourcing Ryobi tire inflators, inquire about the supplier’s quality assurance processes. Look for suppliers that conduct regular product inspections and testing to ensure compliance with industry standards. Request documentation of quality control certifications and any test reports for the inflators. A reputable supplier should be willing to share their QA procedures and demonstrate their commitment to delivering reliable products.

What logistics considerations should I keep in mind for international shipping?

International shipping of Ryobi tire inflators requires careful consideration of logistics. Evaluate shipping costs, delivery times, and customs regulations in your region. Confirm that the supplier has experience with international shipping and can provide necessary documentation for customs clearance. It’s also beneficial to select a reliable logistics partner to minimize delays and ensure safe delivery of your products.

Are there options for customization of Ryobi tire inflators for branding?

Many suppliers offer customization options for B2B buyers, including branding and packaging modifications. You can inquire about the possibility of adding your company logo or custom colors to the inflators. Customization may require a higher MOQ, so it’s important to discuss these details upfront. Ensure that any alterations do not compromise the product’s functionality or warranty.

Dominio: ryobitools.com

Registrato: 1999 (26 anni)

Introduzione: 18V ONE+ Power Inflator Kit with 1.3 Ah Battery and 18V Charger, Model: P737KNC, Status: Discontinued

In summary, the RYOBI tire inflator with battery and charger stands out as a valuable tool for various markets, particularly for international B2B buyers in Africa, South America, the Middle East, and Europe. Its versatility, ease of use, and powerful performance—capable of inflating up to 160 PSI—make it an ideal solution for automotive, sports, and recreational applications. Buyers should prioritize strategic sourcing to ensure they obtain high-quality products that meet their operational needs while also considering logistics and regional market dynamics.

Illustrative image related to ryobi tire inflator with battery and charger

Establishing partnerships with reliable suppliers will not only enhance product availability but also provide avenues for cost savings and improved service delivery. As the demand for portable and efficient tools continues to rise globally, investing in RYOBI’s innovative inflator technology positions businesses to capitalize on emerging opportunities.

Looking ahead, international buyers are encouraged to leverage the benefits of the RYOBI 18V ONE+ system, which offers compatibility across a wide range of tools and accessories. By making informed sourcing decisions today, businesses can secure a competitive edge in the evolving marketplace. Explore your options with RYOBI to elevate your operations and meet the growing demands of your customers.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Illustrative image related to ryobi tire inflator with battery and charger

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.