In the competitive landscape of motorcycle accessories, sourcing high-quality saddle bag crash bars presents a unique challenge for B2B buyers. These essential components not only enhance the aesthetic appeal of motorcycles but also provide crucial protection for saddlebags during rides. As international markets expand, particularly in regions like Africa, South America, the Middle East, and Europe—including key players such as Nigeria and Saudi Arabia—understanding the nuances of this product category becomes imperative for informed purchasing decisions.

This comprehensive guide delves into the various types of saddle bag crash bars available, ranging from sleek, stylish designs to robust, performance-oriented options. We will explore their applications across different motorcycle models, ensuring that buyers can select products that meet both functional and aesthetic requirements. Additionally, the guide will address supplier vetting processes, enabling buyers to identify reliable manufacturers that adhere to quality standards.

Cost considerations are also a focal point, providing insights into pricing structures and value propositions to help buyers maximize their budgets. By leveraging the information within this guide, B2B buyers will be equipped with the knowledge necessary to navigate the global market effectively, ensuring they make purchases that align with their business objectives and customer expectations. This empowers companies to enhance their offerings with durable, stylish saddle bag crash bars that resonate with motorcycle enthusiasts worldwide.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Standard Saddlebag Guards | Basic protection, often made of mild steel, simple bolt-on design | General motorcycle shops, aftermarket retailers | Pro: Cost-effective, easy installation. Contro: Limited aesthetic appeal, basic protection. |

| Performance Crash Bars | Enhanced structural integrity, two-step design for dual protection | High-performance motorcycle shops | Pro: Superior protection, stylish design. Contro: Higher cost, may require complex installation. |

| Customizable Saddlebag Guards | Options for finishes (chrome, black), and slider colors | Custom motorcycle builders, specialty shops | Pro: Tailored aesthetics, unique branding opportunities. Contro: Longer lead times, potential for higher prices. |

| Heavy-Duty Crash Bars | Made from thicker steel, often with additional reinforcement | Heavy-duty motorcycle retailers | Pro: Maximum protection, durable for rugged use. Contro: Heavier, may affect bike handling. |

| Integrated Saddlebag Support | Combines crash protection with additional saddlebag support | Touring motorcycle dealers, long-distance riding retailers | Pro: Offers added stability, reduces saddlebag wear. Contro: May be more expensive, installation complexity. |

Standard saddlebag guards provide essential protection for saddlebags against impacts and falls. Typically constructed from mild steel, they feature a straightforward bolt-on design that allows for quick installation. These guards are ideal for general motorcycle shops and aftermarket retailers due to their affordability and ease of use. However, they may lack aesthetic appeal and offer basic protection, making them less suitable for high-performance applications.

Performance crash bars are designed with enhanced structural integrity, often featuring a two-step design that provides dual-level protection for both the engine and saddlebags. These bars cater to high-performance motorcycle shops and are favored by riders who prioritize both style and functionality. While they offer superior protection and a more aggressive look, they come at a higher price point and may require more complex installation processes.

Customizable saddlebag guards allow buyers to choose from various finishes and slider colors, enabling them to match the aesthetic of their motorcycles. This feature appeals to custom motorcycle builders and specialty shops looking to offer unique products. While they provide tailored aesthetics and branding opportunities, buyers should consider the longer lead times and potentially higher costs associated with customization.

Heavy-duty crash bars are built from thicker steel and often include additional reinforcement to withstand rugged use. They are typically marketed through heavy-duty motorcycle retailers and are ideal for riders who require maximum protection during off-road or demanding conditions. Despite their durability, these bars can be heavier, which may impact bike handling and maneuverability.

Integrated saddlebag support bars combine crash protection with additional support for saddlebags, making them particularly beneficial for touring motorcycles. They are commonly found in touring motorcycle dealers and long-distance riding retailers. While they enhance stability and reduce saddlebag wear, buyers should be aware of the potential for increased costs and installation complexity associated with these comprehensive solutions.

| Industria/Settore | Specific Application of saddle bag crash bars | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Produzione di motocicli | Integration into touring motorcycle models to enhance safety and aesthetics | Increases product appeal and customer satisfaction through added protection | Ensure compatibility with various motorcycle models and styles |

| Automotive Accessories | Retailing as aftermarket accessories for custom motorcycle builds | Expands product range and attracts enthusiasts seeking customization | Assess market trends for design preferences and material quality |

| Gestione della flotta | Use in rental or delivery motorcycle fleets for added protection | Reduces repair costs and downtime by minimizing damage in accidents | Consider bulk purchasing options and durability under heavy use |

| Turismo e avventura | Supplying to tour operators for guided motorcycle tours | Enhances safety for riders, improving overall tour experience | Evaluate the ease of installation and maintenance for tour operators |

| Export and Trade | Sourcing for international markets, particularly in Africa and the Middle East | Opens new revenue streams through export opportunities | Understand regional regulations and import requirements |

In the motorcycle manufacturing industry, saddle bag crash bars are integrated into touring models to provide both aesthetic appeal and crucial protection for saddlebags. These bars safeguard against potential damage during low-speed incidents or tip-overs, thus enhancing the overall safety profile of the motorcycle. For international buyers, especially from regions like Africa and Europe, ensuring compatibility with diverse motorcycle models is essential. Manufacturers must focus on quality materials and innovative designs to meet the expectations of discerning customers.

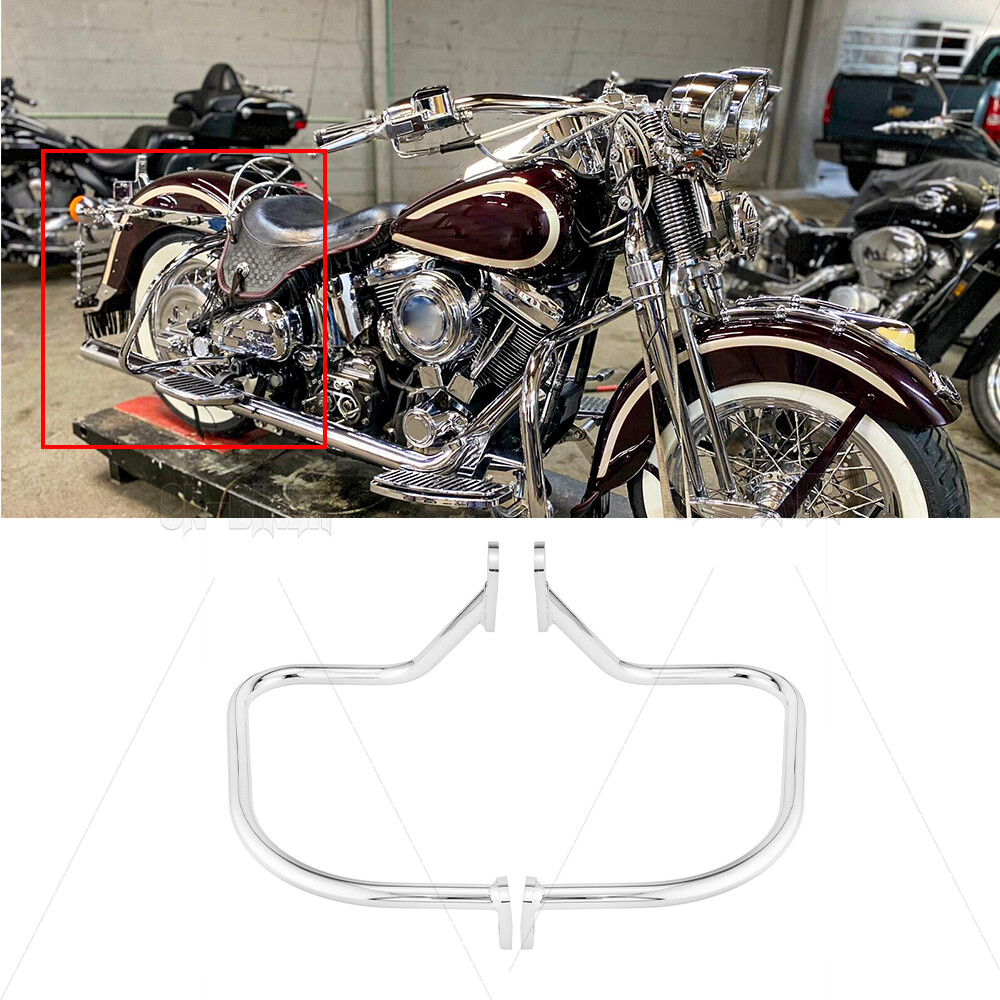

Illustrative image related to saddle bag crash bars

In the automotive accessories market, saddle bag crash bars are marketed as aftermarket enhancements for custom motorcycle builds. They allow enthusiasts to personalize their bikes while also improving safety. This sector thrives on trends, so suppliers should stay updated on the latest styles and materials preferred by consumers. Understanding customer preferences in various regions, such as South America and the Middle East, can help businesses tailor their offerings effectively.

Fleet management companies, particularly those operating motorcycle rental services, utilize saddle bag crash bars to protect their assets. These bars help minimize damage during accidents, ultimately reducing repair costs and downtime. For B2B buyers in this sector, it’s crucial to consider bulk purchasing options to maximize cost efficiency. Additionally, the durability of the bars under frequent use should be a primary concern to ensure long-term value.

Tour operators that offer guided motorcycle tours can benefit significantly from saddle bag crash bars. These components enhance rider safety, which is paramount for a positive tour experience. When sourcing these bars, tour operators should evaluate the installation process and maintenance needs, ensuring that they can easily manage their fleet. Understanding the specific requirements of different markets, such as those in Nigeria or Saudi Arabia, is also essential for providing adequate support.

Saddle bag crash bars present lucrative opportunities for export and trade, particularly in emerging markets across Africa and the Middle East. Businesses looking to expand their reach can tap into these regions by understanding local regulations and import requirements. Sourcing high-quality crash bars that meet international standards can set a company apart in competitive markets, ultimately leading to increased sales and brand recognition.

Il problema: B2B buyers often struggle to find saddle bag crash bars made from high-quality materials that meet both durability and aesthetic standards. Many suppliers may offer low-cost options, but these often compromise on strength and longevity. This can lead to frequent replacements, increased costs, and dissatisfied customers who demand both protection and style for their motorcycles. In regions where the market is growing, like Africa and South America, the pressure to deliver reliable products is amplified due to the rugged terrains and varied weather conditions that can affect the performance of motorcycle accessories.

La soluzione: To address this challenge, buyers should prioritize suppliers who specialize in crash bars made from premium materials such as mild steel or stainless steel with high tensile strength. When evaluating suppliers, request product samples to assess the quality firsthand. Look for crash bars that have undergone rigorous testing for durability and have quality certifications. Additionally, suppliers should offer a variety of finishes—such as powder coating or chrome plating—that not only enhance aesthetics but also provide protection against rust and corrosion. Engaging in detailed discussions about material specifications with potential suppliers can help buyers make informed decisions that align with their customers’ expectations.

Il problema: Installation complexity is a significant pain point for B2B buyers, especially those serving markets with varying levels of technical expertise among end-users. Many saddle bag crash bars come with complicated installation instructions that can deter customers, leading to dissatisfaction and potential returns. In regions like the Middle East and Europe, where motorcycle customizations are popular, the expectation for ease of installation is high. Buyers need to ensure that the products they source can be easily installed without requiring extensive mechanical skills.

La soluzione: Buyers should seek out suppliers that provide clear, step-by-step installation guides along with their products. Look for crash bars that feature a straightforward bolt-on design, which simplifies the installation process. Suppliers that offer video tutorials or customer support for installation can significantly enhance the purchasing experience. Additionally, consider products that come with all necessary hardware, reducing the need for customers to purchase extra components. Providing your customers with detailed installation resources can enhance their satisfaction and reduce the likelihood of returns due to installation issues.

Il problema: Compatibility is another critical concern for B2B buyers dealing with saddle bag crash bars. With a wide range of motorcycle models and variations, including different years and styles, finding crash bars that fit multiple models can be challenging. Buyers often face the frustration of sourcing products that may not be compatible with specific motorcycles, leading to inventory issues and customer dissatisfaction. This problem is particularly pronounced in diverse markets like Nigeria and Saudi Arabia, where specific motorcycle brands and models may dominate.

La soluzione: To mitigate compatibility issues, buyers should collaborate with manufacturers who provide comprehensive fitment guides and specifications for each product. Look for suppliers that offer a range of crash bars designed specifically for various motorcycle models, including detailed information on which models each crash bar fits. Additionally, consider sourcing products that come with adjustable features or universal designs that can accommodate a broader range of motorcycles. Establishing a strong relationship with manufacturers can also facilitate custom orders for specific models, thereby enhancing your product offering and meeting customer demands effectively.

Illustrative image related to saddle bag crash bars

Steel is a prevalent choice for saddle bag crash bars due to its high tensile strength and durability. Typically, mild steel is used, which offers a good balance between strength and weight. The temperature and pressure ratings of steel are generally high, making it suitable for various climates and riding conditions. Corrosion resistance can be enhanced through galvanization or powder coating, which is essential for regions with high humidity or salt exposure, such as coastal areas in Africa and South America.

Pro: Steel crash bars are robust and can withstand significant impacts, providing excellent protection for saddlebags. They are also relatively cost-effective, making them a popular choice among manufacturers.

Contro: Mild steel is susceptible to rust if not properly coated, and the weight can be a drawback for performance-focused riders. Additionally, manufacturing processes may require specialized equipment for welding and finishing.

Impatto sull'applicazione: Steel crash bars can handle a variety of media, including moisture and dirt, making them suitable for off-road applications. However, buyers should ensure that the protective coatings are appropriate for their specific environmental conditions.

Aluminum is another material gaining traction in the production of saddle bag crash bars. Known for its lightweight properties, aluminum offers good strength-to-weight ratios and excellent corrosion resistance, making it ideal for various weather conditions.

Illustrative image related to saddle bag crash bars

Pro: The lightweight nature of aluminum can enhance motorcycle performance and fuel efficiency. Additionally, aluminum’s resistance to corrosion means that it requires less maintenance over time, appealing to international buyers in regions with challenging climates.

Contro: While aluminum is strong, it is generally less durable than steel, which may not withstand as much impact. The cost of aluminum can also be higher than mild steel, impacting overall pricing strategies for manufacturers.

Impatto sull'applicazione: Aluminum is compatible with a range of media and is less likely to corrode in humid environments. However, buyers should consider the potential for denting or deformation upon impact, which could compromise the protective function of the crash bars.

Stainless steel is often chosen for its superior corrosion resistance and aesthetic appeal. This material is particularly advantageous for buyers in coastal regions or areas with high humidity, as it can withstand rust and degradation over time.

Pro: Stainless steel offers high durability and a polished finish that can enhance the overall look of the motorcycle. Its resilience against corrosion means that it maintains its integrity longer than other materials.

Illustrative image related to saddle bag crash bars

Contro: The primary drawback is the cost, as stainless steel is typically more expensive than both mild steel and aluminum. Additionally, it can be heavier, which may affect the motorcycle’s handling.

Impatto sull'applicazione: Stainless steel crash bars are ideal for environments where exposure to moisture and salt is prevalent. However, buyers should be aware of the need for proper installation to avoid issues related to weight distribution.

Composite materials, such as reinforced plastics or carbon fiber, are emerging as alternatives to traditional metals. These materials offer unique properties, including lightweight construction and high strength.

Illustrative image related to saddle bag crash bars

Pro: Composites can be incredibly lightweight, which can significantly improve motorcycle performance. They also offer excellent resistance to corrosion and environmental factors, making them suitable for various applications.

Contro: The primary limitation is the cost, as composites can be significantly more expensive than metals. Additionally, their impact resistance may not match that of steel or aluminum, making them less suitable for high-impact scenarios.

Impatto sull'applicazione: Composites are compatible with a range of environmental conditions but may not be suitable for all riders, particularly those who prioritize impact protection over weight savings.

| Materiale | Typical Use Case for saddle bag crash bars | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Acciaio | General use in various motorcycle models | Elevata resistenza e durata | Susceptible to rust | Medio |

| Alluminio | Lightweight applications, performance bikes | Lightweight, corrosion-resistant | Less durable than steel | Alto |

| Acciaio inox | Premium models, coastal regions | Excellent corrosion resistance | Higher cost, heavier | Alto |

| Composito | High-performance, specialized applications | Lightweight, resistant to corrosion | Higher cost, lower impact resistance | Alto |

This comprehensive analysis of materials provides B2B buyers with actionable insights to make informed decisions regarding the selection of saddle bag crash bars, tailored to their specific needs and regional considerations.

The manufacturing process of saddle bag crash bars involves several critical stages, each designed to ensure the final product meets the required standards for durability and safety. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to saddle bag crash bars

Preparazione del materiale

The process begins with the selection of high-quality materials, typically mild steel or stainless steel, known for their strength and flexibility. Raw materials are sourced from certified suppliers, ensuring compliance with international standards. The selected materials undergo cutting and machining to prepare them for the subsequent forming process. This step often includes quality checks to ensure the materials meet specified dimensions and tolerances.

Tecniche di formatura

The forming stage employs techniques such as bending, welding, and stamping to shape the crash bars. Advanced CNC (Computer Numerical Control) machines are frequently utilized for precision cutting and bending, allowing for intricate designs that enhance both aesthetics and functionality. TIG (Tungsten Inert Gas) welding is commonly used to join components, providing strong and reliable seams that can withstand impact. This stage is crucial, as the structural integrity of the crash bars is paramount for effective protection.

Montaggio

After forming, the individual components are assembled into the final product. This stage may involve additional welding or fastening, depending on the design. For example, some models feature sliders or protective caps that are attached during this phase. Each assembly is performed in a controlled environment to minimize contamination and ensure that all parts fit correctly.

Finishing Processes

The finishing stage is where the crash bars receive their protective coatings, often involving powder coating or chrome plating. This not only enhances the aesthetic appeal but also provides resistance against rust and corrosion. The finishing process is critical for durability, especially for products intended for use in diverse environments, such as those found in Africa, South America, the Middle East, and Europe.

Quality assurance (QA) is a vital component of the manufacturing process for saddle bag crash bars. It ensures that each product meets stringent standards before reaching the market. Manufacturers typically adhere to international quality standards, such as ISO 9001, which outlines requirements for a quality management system.

Standard e certificazioni internazionali

Compliance with international standards such as ISO 9001 is essential for manufacturers targeting global markets. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) can enhance credibility and marketability. These certifications indicate that the products have been tested and meet specific safety and performance criteria, which is particularly important for B2B buyers in regions with strict regulatory environments.

Punti di controllo della qualità

Various checkpoints throughout the manufacturing process help maintain quality. These include:

– Controllo qualità in entrata (CQI): Raw materials are inspected upon arrival to ensure they meet specifications.

– Controllo di qualità in corso d'opera (IPQC): Ongoing checks during manufacturing monitor critical processes to catch defects early.

– Controllo finale della qualità (CQC): The completed crash bars undergo a thorough inspection, including dimensional checks and visual inspections for defects.

Common Testing Methods

Manufacturers utilize a range of testing methods to verify the strength and durability of crash bars. Common tests include:

– Tensile Testing: Measures the material’s strength and flexibility.

– Impact Testing: Assesses how the crash bars withstand sudden forces.

– Corrosion Resistance Testing: Evaluates the longevity of finishes under various environmental conditions.

For international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are several strategies:

Audit dei fornitori

Conducting supplier audits can provide insights into the manufacturer’s quality management systems and practices. Buyers should inquire about the frequency of these audits and whether they are performed by internal teams or third-party organizations. Audits should cover all aspects of the manufacturing process, from material sourcing to final assembly and testing.

Quality Assurance Reports

Requesting quality assurance reports can help buyers understand the manufacturer’s compliance with industry standards. These reports should include data on past performance, defect rates, and any corrective actions taken in response to quality issues. Transparent reporting fosters trust and confidence in the supplier’s capabilities.

Ispezioni di terzi

Engaging third-party inspection services can offer an unbiased assessment of the manufacturing process. These inspections can be scheduled at various stages of production and should focus on key quality metrics. Buyers can specify the criteria for inspection, ensuring alignment with their requirements.

Understanding Regional Nuances

Buyers must be aware of the specific regulatory and quality standards that apply in their regions. For instance, products sold in the European market must meet CE certification requirements, while certain Middle Eastern countries may have unique compliance regulations. Understanding these nuances ensures that buyers select suppliers who can navigate the complexities of international trade.

While manufacturers strive for high-quality outputs, various challenges can arise in quality control processes:

Material Variability

Sourcing consistent quality materials can be challenging, especially in regions with fluctuating supply chains. Manufacturers must establish strong relationships with reliable suppliers and implement rigorous incoming quality checks.

Technological Advances

As manufacturing technology evolves, keeping pace with new techniques and equipment can be a hurdle. Continuous training for staff and investment in modern machinery are essential to maintain competitive advantage and product quality.

Conformità normativa

Navigating the myriad of international regulations can be complex. Manufacturers must stay informed about changes in standards and ensure their products comply with all necessary certifications, which can vary significantly across regions.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing saddle bag crash bars, ensuring they partner with reliable suppliers who deliver high-quality products.

Illustrative image related to saddle bag crash bars

When sourcing saddle bag crash bars, it’s essential to follow a structured approach to ensure that you select the right product for your needs. This checklist will guide you through the critical steps necessary to make informed decisions and establish successful supplier relationships.

Before you begin sourcing, clearly define the specifications your saddle bag crash bars must meet. Consider factors such as the model compatibility (e.g., Harley Davidson Touring models), materials (such as mild steel or stainless steel), and finish (powder-coated or chrome). This clarity will help you communicate your needs effectively to suppliers and ensure that the products align with your quality standards.

Understanding current market trends and pricing for saddle bag crash bars is crucial for making informed purchasing decisions. Analyze competitors’ offerings and pricing structures to determine a reasonable budget. Factors such as demand fluctuations, material costs, and regional price variations can significantly affect your purchasing strategy.

Illustrative image related to saddle bag crash bars

Vet potential suppliers thoroughly before making commitments. Request detailed company profiles, product catalogs, and case studies that demonstrate their experience in manufacturing saddle bag crash bars. Look for testimonials or references from other B2B buyers in your region, as this will provide insight into the supplier’s reliability and product quality.

Quality is paramount when sourcing crash bars, as they serve a protective function for valuable motorcycle components. Request samples or detailed product specifications to evaluate the materials and construction methods used. Pay attention to features like TIG welding for enhanced strength, powder-coated finishes for rust resistance, and the overall design, which should provide effective protection without compromising aesthetics.

Before finalizing your order, verify the supplier’s inventory levels and lead times for production and shipping. Timely delivery is critical to maintaining your business operations and meeting customer demands. Inquire about minimum order quantities and stock replenishment schedules to avoid potential delays.

Once you’ve selected a supplier, engage in negotiations regarding pricing, payment terms, and warranty conditions. Establish clear terms for returns, exchanges, and defect resolutions to protect your investment. Consider incorporating performance clauses that specify product quality and delivery timelines.

Effective communication is vital for successful supplier relationships. Set up a regular communication schedule to discuss order updates, product improvements, and market feedback. This proactive approach will foster a collaborative relationship and enable you to address any potential issues promptly.

By following this checklist, B2B buyers can streamline their sourcing process for saddle bag crash bars, ensuring they find high-quality products that meet their technical requirements and business needs.

When evaluating the cost structure for saddle bag crash bars, several components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the profit margin.

I materiali: The choice of materials significantly affects the overall cost. High-quality mild steel, stainless steel, or aluminum can vary in price, impacting durability and performance. For instance, powder-coated finishes add to material costs but enhance corrosion resistance.

Lavoro: Labor costs encompass the workforce involved in design, manufacturing, assembly, and quality control. Skilled labor, particularly for welding and finishing, may command higher wages, thus influencing the final price.

Spese generali di produzione: This includes costs associated with utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce these overheads.

Utensili: Initial tooling costs can be substantial, especially for custom designs. Buyers should consider whether the supplier has the necessary tooling capabilities to minimize setup costs.

Controllo qualità: Implementing rigorous QC processes ensures product reliability, which can increase costs but ultimately leads to customer satisfaction and reduced returns.

Logistica: Shipping and handling costs can vary widely based on destination, weight, and packaging. International buyers must factor in import duties and taxes, which can significantly affect total costs.

Margine: Suppliers typically include a margin to cover risks and ensure profitability. Understanding the typical margins in the industry can assist buyers in negotiations.

Several factors can influence the pricing of saddle bag crash bars in the international market:

Volume e quantità minima d'ordine (MOQ): Bulk orders can lead to reduced per-unit costs. Buyers should negotiate MOQs to secure better pricing while ensuring they meet inventory requirements.

Specifiche e personalizzazione: Custom specifications can increase costs due to the need for specialized tooling and processes. However, customized products can also command higher prices in the market.

Materiali e certificazioni di qualità: Higher-quality materials and certifications (like ISO) can justify a premium price, as they often correlate with better performance and longevity.

Fattori di fornitura: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more but offer better service, consistency, and support.

Incoterms: Understanding Incoterms is crucial for international buyers as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This knowledge can help avoid unexpected costs.

To enhance cost-efficiency and ensure value in sourcing saddle bag crash bars, buyers should consider the following strategies:

Negoziare i prezzi: Engage in negotiations with suppliers, particularly when ordering in bulk. Discuss potential discounts for larger orders or long-term contracts to secure better pricing.

Attenzione al costo totale di proprietà (TCO): Evaluate the total cost of ownership rather than just the purchase price. Consider factors like installation costs, durability, maintenance, and the potential for damage during use, which can influence long-term expenses.

Explore Local Suppliers: For international buyers, sourcing from local suppliers can reduce logistics costs and lead times. Establish relationships with local manufacturers to facilitate smoother transactions.

Comprendere le sfumature dei prezzi per gli acquirenti internazionali: Be aware of currency fluctuations, tariffs, and import duties that can affect pricing. Conduct market research to ensure competitive pricing and identify trends in the regions of interest.

While this analysis provides a framework for understanding costs and pricing, actual prices may vary based on market conditions, supplier negotiations, and specific product configurations. Buyers should conduct thorough research and obtain multiple quotes to ensure they are making informed purchasing decisions.

In the motorcycle accessories market, saddle bag crash bars are a popular choice for protecting saddlebags during low-speed drops or accidents. However, B2B buyers should consider various alternatives that can offer similar protection or additional benefits. This analysis compares saddle bag crash bars with two viable alternatives: saddlebag guards and integrated crash protection systems.

| Aspetto di confronto | Saddle Bag Crash Bars | Saddlebag Guards | Integrated Crash Protection Systems |

|---|---|---|---|

| Prestazioni | Excellent protection against impacts; suitable for low-speed drops. | Good protection; less robust than crash bars but effective for minor impacts. | Comprehensive protection; designed to absorb and distribute impact forces. |

| Costo | Moderate to high, typically between $200 – $450 depending on the model. | Lower cost, generally between $130 – $370. | Higher initial investment, often exceeding $500, but may reduce repair costs over time. |

| Facilità di implementazione | Requires some mechanical skills for installation; may need modifications. | Easier installation; often bolt-on without modifications. | Installation can be complex; may require professional fitting. |

| Manutenzione | Minimal; regular checks for wear and tear recommended. | Low maintenance; usually no wear components. | Requires more frequent checks due to integrated electronics and mechanisms. |

| Il miglior caso d'uso | Ideal for riders who frequently travel with saddlebags and prioritize robust protection. | Suitable for casual riders or those seeking aesthetic improvements with moderate protection. | Best for high-performance riders or those in accident-prone environments needing maximum protection. |

Saddlebag guards serve as a simpler alternative to crash bars, designed to protect saddlebags from minor impacts. Their lower cost makes them appealing for budget-conscious buyers. However, while they offer decent protection, they are not as robust as crash bars, making them less suitable for serious accidents. Installation is typically straightforward, requiring no modifications to the bike, which is a significant advantage for less experienced riders.

Integrated crash protection systems are comprehensive solutions that provide extensive protection for various motorcycle components, including the engine and saddlebags. These systems are engineered to absorb and distribute impact forces, making them ideal for high-performance riders or those who frequently navigate challenging environments. However, they come at a higher cost and may require professional installation, making them less accessible for some buyers. Maintenance can also be more demanding due to the complexity of the systems.

When selecting the best protection solution for saddlebags, B2B buyers should carefully evaluate their specific needs, riding habits, and budget constraints. Saddle bag crash bars offer robust protection ideal for frequent travelers, while saddlebag guards provide a cost-effective option for casual riders. For those seeking maximum protection and are willing to invest more upfront, integrated crash protection systems may be the best choice. Ultimately, understanding the unique benefits and limitations of each option will empower buyers to make informed decisions that enhance their motorcycle’s safety and performance.

Illustrative image related to saddle bag crash bars

When considering saddle bag crash bars, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some critical properties that define the quality and performance of these components:

Grado del materiale

Saddle bag crash bars are typically constructed from high-grade steel, such as mild steel or stainless steel. Mild steel is favored for its balance between strength and flexibility, providing adequate protection while absorbing impact without cracking. Stainless steel, on the other hand, offers superior corrosion resistance, making it suitable for diverse environmental conditions, particularly in regions with high humidity or salt exposure.

Tube Diameter

The diameter of the tubing used in crash bars is a significant factor affecting strength and weight. Common diameters include 1.25 inches, which strikes a balance between durability and weight. A larger diameter generally means increased strength, but it may also add weight, which can influence motorcycle handling. For B2B buyers, understanding the implications of tube diameter can assist in selecting products that meet specific performance requirements.

Welding Type

The welding method used in the construction of crash bars—often fully TIG (Tungsten Inert Gas) welded—ensures robust joint strength and enhances overall durability. This type of welding produces cleaner and stronger seams compared to other methods, which can be critical for maintaining the structural integrity of crash bars during impact.

Finish

The finish on crash bars, often a powder coat, is essential for aesthetic appeal and longevity. Powder coating provides a durable, weather-resistant surface that helps prevent rust and chipping. For international buyers, understanding the finish options can aid in selecting products that align with both functional and aesthetic preferences.

Capacità di peso

Some crash bars are designed with specific weight capacities, which is vital for ensuring they can withstand the load during rides, especially when saddlebags are fully loaded. This specification is particularly important for B2B buyers focused on safety and performance, as it directly impacts the reliability of the crash bars.

In the B2B marketplace for motorcycle accessories, familiarizing yourself with industry jargon can enhance communication and negotiation. Here are several key terms:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in the manufacturing of motorcycles. Understanding OEM specifications can help buyers ensure compatibility and quality when sourcing replacement parts or accessories like crash bars.

MOQ (quantità minima d'ordine)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers manage their budgets and inventory effectively, especially when considering bulk purchases of saddle bag crash bars for resale or fleet use.

RFQ (Richiesta di offerta)

An RFQ is a document sent to suppliers to request pricing for specific products. It allows buyers to compare costs and terms from different manufacturers, facilitating informed purchasing decisions.

Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps B2B buyers understand their obligations regarding shipping, insurance, and delivery, which is crucial when importing products like crash bars from overseas suppliers.

Tempi di consegna

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for planning inventory and ensuring that products are available when needed, especially in regions with fluctuating demand.

Compatibility

This term indicates whether a product will fit or work with a specific motorcycle model. For B2B buyers, ensuring compatibility with various models can significantly impact customer satisfaction and reduce return rates.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their business objectives and customer needs in the competitive market for saddle bag crash bars.

Illustrative image related to saddle bag crash bars

The global market for saddle bag crash bars is witnessing significant growth, driven by the increasing popularity of motorcycle touring and the rising demand for protective accessories among motorcycle enthusiasts. As riders seek to enhance both the functionality and aesthetic appeal of their bikes, saddle bag crash bars have become essential components. Key trends include the adoption of advanced materials such as high-quality steel and aluminum, which provide enhanced durability and lightweight properties. Furthermore, the integration of custom design elements, including powder coating options and compatibility with various motorcycle models, is becoming a standard expectation among B2B buyers.

Emerging technologies are also shaping sourcing strategies in this sector. For instance, manufacturers are increasingly utilizing 3D printing for prototyping and creating bespoke solutions tailored to specific motorcycle models. This trend not only reduces lead times but also allows for greater customization, appealing to international markets that value personalization. B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of these advancements, as they can leverage them to meet the unique demands of their local markets.

In addition, the growing emphasis on online sales platforms is transforming how businesses approach sourcing. Buyers can now access a wider range of products and suppliers globally, facilitating competitive pricing and diverse options. However, navigating these platforms requires an understanding of logistics and shipping nuances specific to different regions, particularly for buyers in emerging markets.

Sustainability is becoming a pivotal concern within the saddle bag crash bars sector as environmental awareness continues to rise globally. B2B buyers are increasingly prioritizing suppliers who adopt eco-friendly practices in their manufacturing processes. This includes the use of recycled materials, sustainable sourcing, and minimal waste production techniques. Buyers should look for manufacturers that provide transparency in their supply chains and adhere to recognized environmental standards.

Illustrative image related to saddle bag crash bars

Moreover, ethical sourcing is critical in ensuring that all materials used in the production of saddle bag crash bars are obtained responsibly. This encompasses not only environmental considerations but also labor practices within the supply chain. Companies that achieve certifications such as ISO 14001 for environmental management or Fair Trade certifications demonstrate a commitment to sustainable and ethical practices, which can be a deciding factor for buyers in their purchasing decisions.

The demand for ‘green’ certifications and materials is expected to grow, and B2B buyers should actively seek partnerships with manufacturers who prioritize sustainability. By aligning with suppliers who share these values, businesses can enhance their brand reputation and appeal to a growing segment of eco-conscious consumers.

The evolution of saddle bag crash bars can be traced back to the early days of motorcycle touring when riders sought ways to protect their bikes during long journeys. Initially, these components were rudimentary and often made from heavy materials that provided basic protection. Over the years, advancements in materials science and engineering have led to the development of lightweight, high-strength alternatives that enhance performance without compromising safety.

The introduction of customizable options and aesthetic enhancements has further transformed the market. Today, saddle bag crash bars are not only functional but also serve as an extension of a rider’s personal style, with various finishes and designs available to match the unique look of each motorcycle. This evolution reflects a broader trend within the motorcycle accessories market, where functionality meets personalization, catering to a diverse and discerning customer base.

Understanding this historical context allows B2B buyers to appreciate the technological advancements and market dynamics that influence current sourcing decisions, positioning them to make informed choices that align with both their business objectives and customer preferences.

How do I ensure the quality of saddle bag crash bars from international suppliers?

To ensure quality, start by researching potential suppliers through online directories and trade platforms. Request samples to assess material quality and craftsmanship. Verify certifications and compliance with international standards relevant to your region. Additionally, consider conducting factory audits or using third-party inspection services to evaluate production processes. Engage in communication with suppliers to clarify quality assurance protocols and warranty terms, ensuring they meet your expectations before placing larger orders.

What is the best material for saddle bag crash bars?

The best material for saddle bag crash bars is typically high-quality steel, as it provides the necessary strength and durability to withstand impacts. Look for options that are fully TIG welded, as this enhances structural integrity. Mild steel with a powder coat finish is also recommended, as it offers resistance to rust and corrosion. Some manufacturers may offer stainless steel options for added longevity. Always inquire about the specific grades of steel used and any protective finishes applied to ensure optimal performance.

What customization options are available for saddle bag crash bars?

Many manufacturers offer customization options such as different finishes (e.g., chrome, black powder coat) and design features tailored to specific motorcycle models. You can also request modifications in dimensions or additional features like integrated sliders or unique design patterns. When discussing customization, ensure to communicate your requirements clearly and inquire about minimum order quantities (MOQs) for customized products, as these can vary significantly among suppliers.

What are the common payment terms for international purchases of saddle bag crash bars?

Payment terms can vary by supplier but commonly include options such as wire transfers, letters of credit, or PayPal for smaller transactions. It’s advisable to negotiate payment terms upfront, considering factors like deposit percentages and payment upon shipment. Some suppliers may offer favorable terms for bulk orders, while others may require full payment in advance. Ensure that the payment method is secure and provides adequate protection against potential disputes.

How do I handle logistics and shipping for international orders of saddle bag crash bars?

When managing logistics for international orders, coordinate with your supplier to determine the best shipping method, whether air freight for speed or sea freight for cost-effectiveness. Make sure to discuss shipping costs and delivery timelines upfront. Familiarize yourself with import regulations and tariffs in your country to avoid unexpected fees. Additionally, consider using a freight forwarder to streamline the process and ensure compliance with customs requirements.

What are the minimum order quantities (MOQs) for saddle bag crash bars?

Minimum order quantities can vary significantly depending on the manufacturer and the complexity of the product. Some suppliers may require a minimum order of 50 units for standard designs, while customized products may have higher MOQs. When sourcing, ask potential suppliers about their MOQs early in the negotiation process to ensure they align with your purchasing needs and market demand.

How can I vet suppliers for saddle bag crash bars effectively?

To vet suppliers, start by checking their reputation through reviews and testimonials from other B2B buyers. Request references and follow up to gauge their reliability and product quality. Examine their production capabilities and certifications, such as ISO standards. Engaging in direct communication can provide insights into their responsiveness and professionalism. Additionally, consider visiting their facilities if feasible or utilizing third-party verification services to assess their operations.

What should I consider for warranty and after-sales support for saddle bag crash bars?

When sourcing saddle bag crash bars, inquire about warranty terms and after-sales support. A robust warranty indicates the manufacturer’s confidence in their product quality. Understand what the warranty covers—such as defects in materials and workmanship—and the duration of coverage. Additionally, clarify the process for addressing warranty claims and the availability of replacement parts. Good after-sales support can enhance your customer satisfaction and help resolve any issues that arise post-purchase.

Dominio: hogworkz.com

Registrato: 2014 (11 anni)

Introduzione: HOGWORKZ® Saddlebag Guards and Skid Plates for Harley-Davidson® Motorcycles

Dominio: factory47.com

Registrato: 2016 (9 anni)

Introduzione: {“product_name”: “Anarchy Saddlebag Guard Highway Bar for Harley Baggers”, “brand”: “Factory 47”, “price”: “$450.00”, “availability”: “Backordered”, “material”: “High-quality steel”, “diameter”: “1.25 inches”, “finish_options”: [“Gloss Black”, “Chrome”], “fitting_years”: “1997-2023”, “installation”: “Bolt-on design using stock bagger bolts, requires cutting of saddlebag bracket”, “installation_tim…

Dominio: advanblack.com

Registrato: 2016 (9 anni)

Introduzione: ProTek Rear Performance Crash Bar Saddlebags Guards for ’14-’25 Harley Touring. Two-Steps design, made from mild steel, fully TIG welded for enhanced strength. Gloss black powder coat finish. 37″ overall width, 1.25″ diameter tube. Comes with 4 sliders. Options available for black Delrin, anodized CNC, or anodized CNC with carbon inlay sliders in different colors. All sliders come with 3/8-16 scre…

Dominio: harley-davidson.com

Registrato: 1994 (31 anni)

Introduzione: Harley-Davidson saddlebag guards are designed to securely hold saddlebags while protecting the motorcycle from scuffs and scrapes during rides. Various kits are available for a wide range of models, including saddlebag supports, guards for both sides, and necessary mounting hardware. Kits are model-specific, with some compatible with multiple motorcycles and others for specific models. Options inc…

Dominio: speed-kingscycle.com

Registrato: 2015 (10 anni)

Introduzione: FL Saddle Bag Crash Bars 1999-2013

– SKU: 0506-0513

– Price: $275.95 (Gloss Black), $288.95 (Chrome)

– Finish Options: Gloss Black, Chrome

– Availability: In Stock

– Made in the U.S.A.

– Free Shipping on USA orders over $250

– Compatibility: Fits various Harley-Davidson models from 1997 to 2013, including:

– Electra Glide Classic EFI FLHTCI (1997-2013)

– Electra Glide Classic FLHTC (1997-2005)…

Dominio: fxrdivision.com

Registrato: 2013 (12 anni)

Introduzione: {“product_name”: “FXR Division FXRT / FXRD Bag FRONT Saddlebag Crash Guard”, “price”: “$324.99”, “description”: “The extremely RARE Saddlebag Guards for the FXRT and FXRD are now being reproduced by FXR Division. These are Clamshell Saddlebag Crash Guards that mount to your FXR Frame in FRONT of your Clamshell Saddlebags, using OEM HD specifications for an exact fit from almost 40 years ago. Made …

In conclusion, the strategic sourcing of saddle bag crash bars presents a significant opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By prioritizing quality, durability, and design, buyers can enhance their product offerings while meeting the increasing demand for motorcycle accessories that combine functionality with aesthetic appeal.

The market is characterized by a diverse range of options, from premium brands like HOGWORKZ® and Factory 47 to innovative solutions like ProTek. Each product brings unique features that cater to different customer needs, emphasizing the importance of understanding local market preferences and trends.

Engaging in strategic sourcing not only ensures competitive pricing but also fosters relationships with suppliers who can offer insights into evolving consumer behaviors. As the motorcycle culture continues to thrive globally, now is the time for buyers to act. Investing in high-quality saddle bag crash bars will not only protect assets but also position businesses for success in a growing market.

We encourage international buyers to explore partnerships with reputable manufacturers to secure premium products that resonate with their clientele. Embrace this opportunity to elevate your product line and drive sales in the burgeoning motorcycle accessories market.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.