In today’s competitive transportation landscape, one of the pressing challenges faced by fleet operators and logistics managers is sourcing efficient tire inflation systems, particularly the Hendrickson Tire Inflation System. Improperly inflated tires not only compromise safety but also lead to increased fuel consumption and premature tire wear, ultimately resulting in costly downtime. This comprehensive guide delves into the various types of Hendrickson Tire Inflation Systems, including the TIREMAAX CP, PRO, and PRO-LB models, highlighting their applications across diverse trailer configurations.

International B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe, will find valuable insights into supplier vetting processes, cost considerations, and potential return on investment. By understanding the intricacies of these systems and their compatibility with different trailer types, businesses can make informed purchasing decisions that enhance operational efficiency and reduce maintenance costs.

This guide not only empowers buyers with essential knowledge but also serves as a roadmap for navigating the global market for tire inflation solutions. With actionable insights and expert recommendations, it aims to facilitate strategic sourcing decisions that align with the unique needs of diverse industries, ultimately contributing to improved fleet performance and sustainability.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| TIREMAAX CP | Continuous tire pressure monitoring, compatible with various axle configurations. | General freight and logistics transportation. | Pro: Cost-effective, easy installation; Contro: Limited to lower PSI settings. |

| TIREMAAX PRO | Advanced inflate and deflate capabilities, suitable for a range of tire sizes. | Long-haul trucking, especially in varied terrain. | Pro: Maximizes tire life, enhances fuel efficiency; Contro: Investimento iniziale più elevato. |

| TIREMAAX PRO-LB | Designed for low-profile tires, supports dual and super single configurations. | Specialized trailers and low-profile applications. | Pro: Optimized for specific tire types; Contro: May require specialized installation expertise. |

| TIREMAAX Digital | Integrated digital monitoring system for real-time tire pressure data. | Fleets requiring precise monitoring for efficiency. | Pro: Real-time data access, proactive maintenance; Contro: Higher complexity and cost. |

| TIREMAAX ROI | ROI calculator for assessing financial benefits of system installation. | Fleet management and financial planning. | Pro: Helps justify investment, clear financial insights; Contro: Dependent on accurate data input for reliability. |

The TIREMAAX CP system is characterized by its continuous tire pressure monitoring capabilities, which ensure that tire inflation is maintained within optimal ranges. This system is compatible with various axle configurations, making it versatile for different trailer types. It is particularly suitable for general freight and logistics transportation, where cost-effectiveness and ease of installation are crucial for fleet operators. Buyers should consider the initial setup requirements and the system’s performance at lower PSI settings.

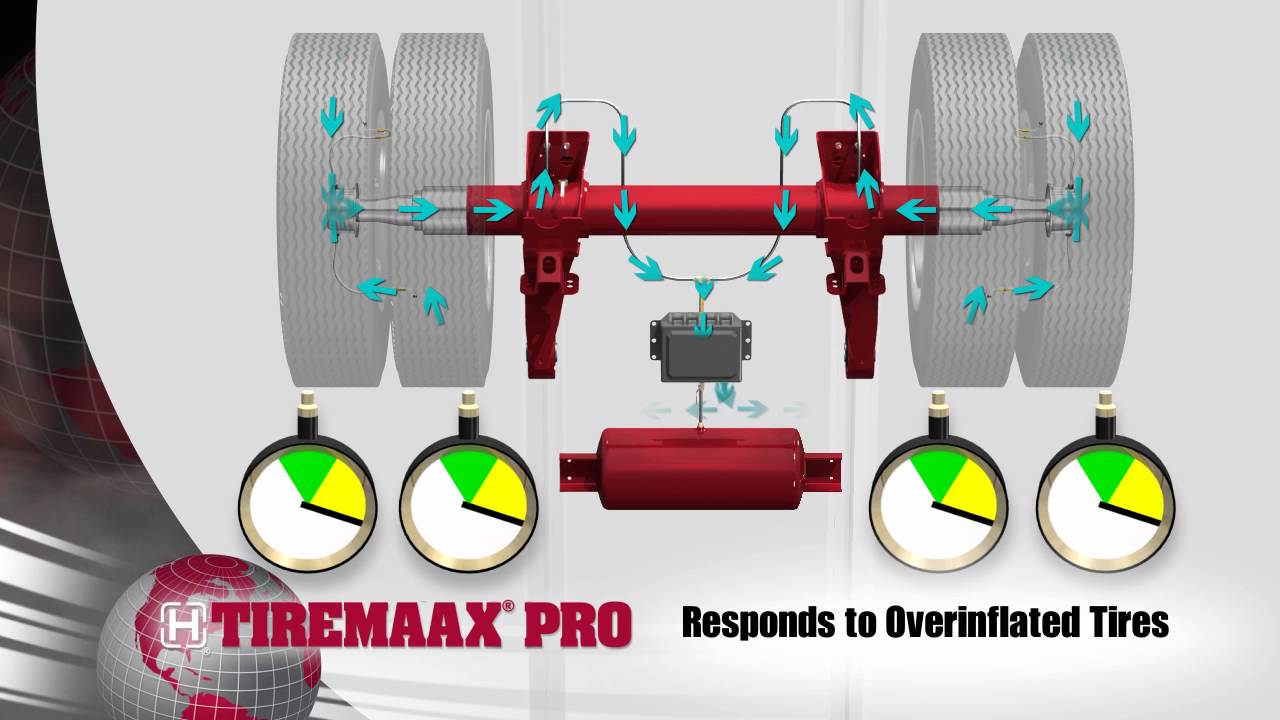

The TIREMAAX PRO system stands out for its advanced inflate and deflate capabilities, allowing for precise tire pressure management tailored to varying load conditions. This system is ideal for long-haul trucking, especially when traversing diverse terrains that can affect tire performance. The benefits include maximized tire life and improved fuel efficiency, which can significantly lower operational costs. However, prospective buyers should be prepared for a higher initial investment compared to simpler systems.

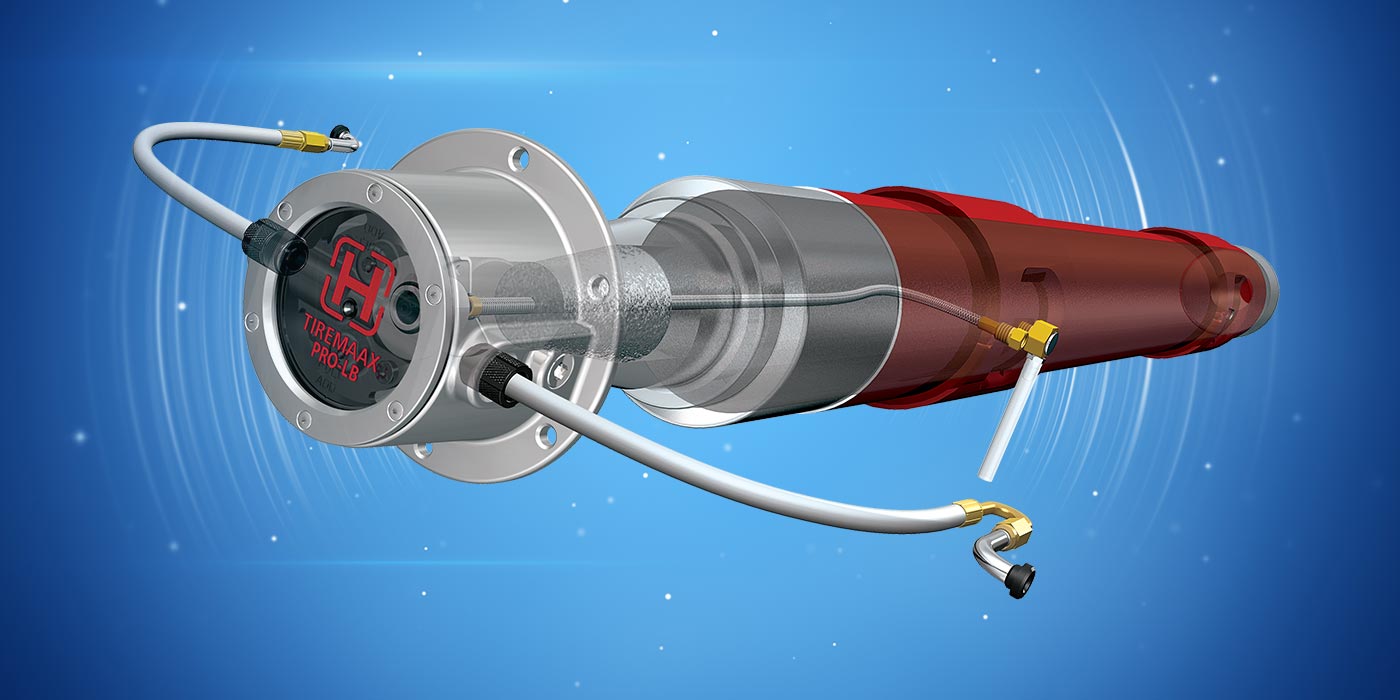

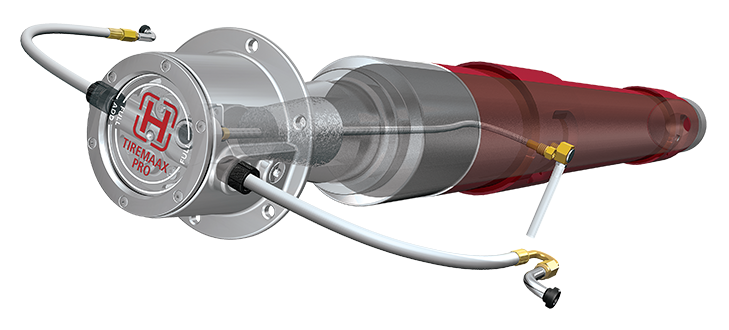

The TIREMAAX PRO-LB system is specifically designed for low-profile tires and supports both dual and super single configurations. This makes it particularly suitable for specialized trailers and applications where space and weight are critical factors. Buyers in niche markets should evaluate the system’s performance against their specific tire types and ensure they have access to installation expertise, as the system may require specialized knowledge.

TIREMAAX Digital systems integrate advanced technology for real-time tire pressure data monitoring, providing fleet operators with actionable insights for proactive maintenance. This system is particularly beneficial for fleets that prioritize efficiency and safety. While it offers the advantage of real-time data access, buyers should be aware of the increased complexity and potential costs associated with implementation and maintenance.

The TIREMAAX ROI calculator is a valuable tool for fleet managers looking to assess the financial benefits of installing tire inflation systems. By providing clear insights into potential savings and return on investment, it aids in justifying expenditures on tire management technologies. However, the reliability of the ROI calculation depends on the accuracy of the data inputted, making it essential for buyers to have solid operational metrics.

| Industria/Settore | Specific Application of hendrickson tire inflation system | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Trasporto e logistica | Fleet management for long-haul trucking | Reduces fuel consumption and tire wear, enhancing operational efficiency | Compatibility with various axle types and tire sizes |

| Costruzione e attrezzature pesanti | Tire maintenance for construction vehicles | Minimizes downtime due to tire failures, ensuring project timelines are met | Installation requirements and local support availability |

| Agricoltura | Tire inflation for agricultural machinery | Improves traction and reduces soil compaction, enhancing yield | Adaptability to different tire pressures based on crop type |

| Mining | Tire pressure management for mining trucks | Increases tire lifespan and reduces operational costs | Durability under extreme conditions and terrain compatibility |

| Public Transport | Maintenance for buses and transit vehicles | Enhances safety and reduces operational costs through improved fuel efficiency | Compliance with local regulations and safety standards |

In the transportation and logistics sector, the Hendrickson tire inflation system is crucial for fleet management, particularly for long-haul trucking. By maintaining optimal tire pressure, this system significantly reduces fuel consumption and tire wear, leading to enhanced operational efficiency. For international buyers, especially in regions like Africa and South America, considerations include ensuring compatibility with various axle types and tire sizes to accommodate diverse fleet configurations.

In the construction industry, the tire inflation system is employed for maintaining the tires of heavy machinery. This application is vital as it minimizes downtime caused by tire failures, which can delay project timelines. Buyers in this sector must consider installation requirements and the availability of local support to ensure seamless integration into their existing fleet of construction vehicles.

Agricultural machinery benefits from the Hendrickson tire inflation system by achieving optimal tire pressure, which enhances traction and reduces soil compaction. This is particularly important for maximizing crop yield. Buyers in agriculture should focus on the system’s adaptability to different tire pressures based on crop type, ensuring that the equipment is tailored to their specific operational needs.

In the mining sector, the tire pressure management capabilities of the Hendrickson system are critical for mining trucks operating in harsh conditions. By increasing tire lifespan and reducing operational costs, this system plays a pivotal role in maintaining productivity. Buyers must consider the durability of the system under extreme conditions and its compatibility with various terrain types to ensure reliable performance.

For public transport vehicles, such as buses, the Hendrickson tire inflation system contributes to enhanced safety by maintaining proper tire pressure. This not only improves fuel efficiency but also reduces operational costs. International buyers need to ensure that the system complies with local regulations and safety standards, thereby guaranteeing the safety of passengers and the reliability of public transport services.

Il problema: Many fleet operators struggle with maintaining consistent tire pressure across their vehicles, which can lead to increased fuel consumption and tire wear. In regions with extreme weather conditions, such as the Middle East or Southern Africa, fluctuating temperatures can exacerbate tire inflation issues. This inconsistency not only affects the operational efficiency of fleets but also results in unplanned maintenance costs and potential downtime due to tire failures. The challenge lies in effectively monitoring tire pressure in real-time, which can be labor-intensive and prone to human error.

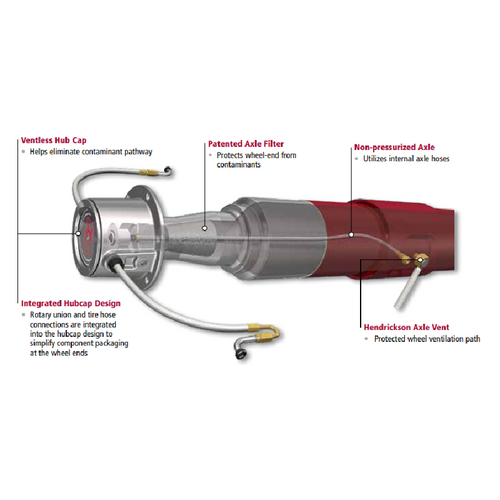

La soluzione: Implementing the Hendrickson TIREMAAX® PRO tire pressure control system can significantly alleviate this issue. This advanced system continuously monitors tire pressure and automatically adjusts it as needed, ensuring that tires remain at optimal inflation levels. To properly source and specify this system, buyers should assess their fleet’s specific needs, including tire size and axle configuration. They can consult the TIREMAAX digital catalog to identify the appropriate model for their trailers. Additionally, investing in training sessions provided by Hendrickson’s service education portal can empower fleet maintenance teams to effectively manage the system, thereby reducing reliance on manual checks and enhancing overall fleet productivity.

Il problema: B2B buyers often face challenges when it comes to the installation and ongoing maintenance of tire inflation systems, particularly for diverse fleets with varying axle types and configurations. Misalignment during installation can lead to system failures or inefficiencies, which can be frustrating and costly. This complexity is compounded in regions like Brazil or Germany, where local regulations may require adherence to specific safety standards and equipment compatibility.

La soluzione: To overcome these installation hurdles, it is essential for buyers to work closely with qualified suppliers like Hendrickson. The TIREMAAX® installation kits come with detailed instructions tailored to specific trailer types and axle configurations, ensuring a straightforward setup process. Buyers should consult with Hendrickson representatives to determine the right kit for their fleet and request any necessary technical support during installation. Additionally, establishing a regular maintenance schedule for the system can help identify potential issues early on, minimizing downtime. Utilizing Hendrickson’s support professionals for routine checks can also ensure that the system operates optimally, thus enhancing the longevity of both tires and the inflation system itself.

Il problema: One of the primary concerns for fleet managers and B2B buyers is understanding the return on investment (ROI) associated with the implementation of tire inflation systems. Given the initial costs involved, especially in regions with tight budgets, decision-makers may hesitate to invest without clear metrics demonstrating potential savings. This hesitation can lead to missed opportunities for cost savings through enhanced fuel efficiency and reduced tire maintenance.

La soluzione: To effectively calculate ROI, fleet managers should utilize the TIREMAAX® ROI calculator available on Hendrickson’s website. This tool allows buyers to input their fleet’s specific parameters, such as current fuel costs, average tire life, and maintenance expenses, to estimate potential savings. By analyzing these metrics, decision-makers can present a compelling case to stakeholders regarding the financial benefits of adopting the TIREMAAX system. Furthermore, documenting real-world performance post-installation can provide additional data to support future investment decisions, helping to create a culture of continuous improvement within the fleet management strategy. By framing the investment in terms of long-term savings and operational efficiency, B2B buyers can justify the upfront costs associated with the Hendrickson tire inflation system.

When selecting materials for the Hendrickson Tire Inflation System, it is crucial to consider their properties, advantages, and potential limitations. This analysis focuses on four common materials used in the system: aluminum, stainless steel, rubber, and thermoplastics. Each material has specific characteristics that can significantly impact the performance and reliability of the tire inflation system.

Aluminum is widely used in various components of the Hendrickson Tire Inflation System due to its excellent strength-to-weight ratio. It typically has a temperature rating of up to 150°C and offers good corrosion resistance, particularly when anodized.

Pro: Aluminum is lightweight, which contributes to overall vehicle efficiency. It is also relatively easy to manufacture and can be extruded into complex shapes, making it suitable for various applications within the system.

Contro: While aluminum is durable, it can be prone to fatigue over time, especially under constant pressure cycling. Additionally, it may require protective coatings to enhance its corrosion resistance in harsh environments.

Illustrative image related to hendrickson tire inflation system

Impatto sull'applicazione: Aluminum components are compatible with air and moisture, making them ideal for tire inflation systems. However, care must be taken to ensure that the aluminum does not come into contact with certain chemicals that could lead to degradation.

Stainless steel is another common material used in the Hendrickson Tire Inflation System, particularly for components that require high strength and corrosion resistance. With a temperature rating of up to 800°C, stainless steel can withstand extreme conditions.

Pro: Its durability and resistance to corrosion make stainless steel ideal for long-term applications. It is also highly resistant to wear and can handle high-pressure environments effectively.

Contro: The primary drawback of stainless steel is its cost, which is generally higher than aluminum or rubber. Additionally, it is heavier, which can affect the overall weight of the vehicle.

Illustrative image related to hendrickson tire inflation system

Impatto sull'applicazione: Stainless steel is compatible with a wide range of media, including air and various lubricants. Its robustness makes it suitable for critical components that require reliability under high stress.

Rubber is predominantly used in seals, hoses, and gaskets within the Hendrickson Tire Inflation System. It offers excellent flexibility and can operate effectively at temperatures ranging from -40°C to 120°C.

Pro: Rubber provides a tight seal, preventing air leaks and ensuring optimal tire pressure. Its flexibility allows for easy installation and adaptability to different configurations.

Illustrative image related to hendrickson tire inflation system

Contro: Over time, rubber can degrade due to exposure to UV light, ozone, and certain chemicals, potentially leading to failure. Additionally, it may not perform well in extremely high-temperature environments.

Impatto sull'applicazione: The compatibility of rubber with air and various fluids makes it suitable for tire inflation systems. However, international buyers should consider the specific rubber grades that meet local standards for durability and performance.

Thermoplastics, such as polyamide (nylon) and polyvinyl chloride (PVC), are used in various components of the Hendrickson Tire Inflation System. These materials offer good chemical resistance and can operate effectively at temperatures up to 80°C.

Pro: Thermoplastics are lightweight and can be molded into complex shapes, making them ideal for intricate designs. They are also generally more cost-effective than metals.

Contro: While thermoplastics are resistant to many chemicals, they may not withstand high temperatures as well as metals. Additionally, they can be less durable under mechanical stress compared to aluminum or stainless steel.

Impatto sull'applicazione: Thermoplastics are suitable for non-structural components that require flexibility and chemical resistance. Buyers should ensure that the selected thermoplastic meets relevant international standards for performance.

| Materiale | Typical Use Case for hendrickson tire inflation system | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Alluminio | Structural components and brackets | Lightweight and easy to manufacture | Prone to fatigue and corrosion | Medio |

| Acciaio inox | High-stress components and fittings | Elevata forza e resistenza alla corrosione | Higher cost and weight | Alto |

| Gomma | Seals, hoses, and gaskets | Excellent sealing and flexibility | Si degrada nel tempo | Basso |

| Thermoplastics | Non-structural components and connectors | Leggero e conveniente | Lower durability under stress | Medio |

This strategic material selection guide provides valuable insights for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding the properties and implications of each material helps buyers make informed decisions that align with local compliance and performance standards.

The manufacturing process of Hendrickson Tire Inflation Systems involves several critical stages that ensure the final product meets high-performance standards. These stages include material preparation, forming, assembly, and finishing.

Preparazione del materiale

The process begins with the careful selection of high-quality materials such as durable metals and advanced polymers. These materials are evaluated for their mechanical properties, corrosion resistance, and longevity. Suppliers must adhere to strict specifications, and materials undergo rigorous inspection before being approved for production.

Tecniche di formatura

Once the materials are prepared, they undergo various forming techniques. For metal components, processes such as stamping, machining, and bending are utilized to create precise parts that fit together seamlessly. Advanced CNC (Computer Numerical Control) machinery is commonly used to enhance accuracy and repeatability, ensuring that each component meets the specified tolerances.

Processo di assemblaggio

The assembly stage is where the components come together to form the complete tire inflation system. This is typically done in a cleanroom environment to minimize contamination. Automated assembly lines may be employed for efficiency, while skilled technicians oversee critical assembly operations, ensuring that each part is correctly installed. Each unit undergoes initial testing to confirm operational integrity before moving to the next stage.

Illustrative image related to hendrickson tire inflation system

Finitura

The finishing stage involves applying coatings, such as protective finishes or paints, to enhance durability and aesthetics. This stage may also include additional quality checks to ensure that all components are free from defects. Once finished, the systems are packaged for distribution, ensuring that they are protected during transport.

Quality assurance (QA) is integral to the manufacturing of Hendrickson Tire Inflation Systems, ensuring that products meet both international and industry-specific standards.

International Standards Compliance

Hendrickson adheres to ISO 9001, which outlines the requirements for a quality management system. Compliance with ISO 9001 ensures a consistent approach to quality in manufacturing, focusing on customer satisfaction and continuous improvement. Furthermore, CE marking indicates that products comply with European health, safety, and environmental protection standards.

Industry-Specific Certifications

In addition to ISO certifications, Hendrickson’s products may also meet industry-specific standards, such as those set by the American Petroleum Institute (API) for components used in heavy-duty applications. This compliance not only enhances the reliability of the tire inflation systems but also instills confidence in international B2B buyers regarding the product’s quality.

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that every product meets the required specifications.

Controllo qualità in entrata (CQI)

At the outset, IQC checks the materials received from suppliers. This involves verifying certificates of conformity and performing tests on samples to ensure compliance with specified standards. Any materials that do not meet quality requirements are rejected and returned to the supplier.

Controllo qualità in corso d'opera (IPQC)

During the manufacturing process, IPQC is implemented to monitor production activities. Technicians conduct regular inspections at various stages, such as during material forming and assembly, to catch any defects early. This proactive approach helps to minimize waste and rework.

Controllo qualità finale (CQC)

Before products are packaged and shipped, FQC ensures that each tire inflation system operates correctly. This involves functional testing, performance assessments, and visual inspections. Any discrepancies are addressed immediately, ensuring that only products that pass all tests reach the market.

B2B buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, should take proactive measures to verify the quality control practices of suppliers.

Audits and Inspections

Conducting regular audits of the supplier’s manufacturing facilities can provide valuable insights into their quality control processes. Buyers can assess compliance with international standards and evaluate the effectiveness of QC checkpoints. Engaging third-party inspection services can also offer an unbiased view of the supplier’s quality practices.

Richiesta di rapporti sulla qualità

Buyers should request detailed quality reports that outline the QC processes, test results, and any corrective actions taken. These reports should reflect compliance with relevant international and industry-specific standards. Transparency in reporting can foster trust and ensure alignment between buyer expectations and supplier capabilities.

Understanding Quality Certification Nuances

For international B2B buyers, it’s essential to understand the nuances of quality certifications in different regions. Certification standards may vary significantly, and what is acceptable in one region may not be in another. Buyers should familiarize themselves with local regulations and ensure that suppliers possess the necessary certifications for their target markets.

Illustrative image related to hendrickson tire inflation system

Testing methods play a pivotal role in the quality assurance of tire inflation systems, ensuring that they perform effectively under various conditions.

Test funzionali

Functional testing assesses the operational capabilities of the tire inflation systems. This includes checking the inflation and deflation mechanisms, pressure regulation, and overall performance under simulated real-world conditions. Functional tests help identify potential failures before products reach the market.

Test di durata

Durability tests evaluate how well the tire inflation systems withstand environmental factors such as temperature fluctuations, humidity, and exposure to contaminants. These tests help ensure that the systems maintain performance over their expected lifespan, which is crucial for B2B buyers concerned with long-term reliability.

Pressure Testing

Pressure testing is critical for verifying the integrity of the system. This method involves subjecting the tire inflation components to pressures exceeding their rated specifications to identify any weaknesses or potential failure points. This testing ensures that the systems can operate safely and effectively under various load conditions.

Understanding the manufacturing processes and quality assurance practices for Hendrickson Tire Inflation Systems is essential for B2B buyers. By focusing on the stages of manufacturing, quality control checkpoints, and testing methods, buyers can make informed decisions when sourcing these systems. Furthermore, verifying supplier practices through audits, quality reports, and an understanding of international certifications will help mitigate risks and ensure the procurement of high-quality products.

This practical sourcing guide provides B2B buyers with a comprehensive checklist for procuring Hendrickson’s tire inflation systems. With the rising costs associated with tire maintenance and the critical importance of maintaining optimal tire pressure for safety and efficiency, selecting the right system is essential. This checklist will help you navigate the procurement process effectively.

Understanding your specific requirements is the first step in sourcing a tire inflation system. Consider factors such as the type of vehicles in your fleet, tire sizes, and the intended application of the inflation system. This clarity will guide you in selecting the appropriate TIREMAAX model, whether it’s the CP, PRO, or PRO-LB, ensuring compatibility with your existing systems.

Begin by compiling a list of potential suppliers for the Hendrickson tire inflation systems. Look for manufacturers with a strong reputation and proven track record in your region, particularly those familiar with the specific needs of buyers in Africa, South America, the Middle East, and Europe. Supplier reviews, industry certifications, and case studies can provide valuable insights into their reliability and service quality.

Illustrative image related to hendrickson tire inflation system

Before finalizing your supplier, verify their certifications and compliance with international standards. This step is crucial for ensuring that the products meet safety and quality benchmarks, which can significantly affect performance and durability. Look for certifications such as ISO and specific compliance for your region to ensure the supplier adheres to best practices.

Whenever possible, request product demonstrations or samples from your shortlisted suppliers. Experiencing the product firsthand can provide insights into its functionality and ease of use. Additionally, it allows you to assess the support and training that suppliers may offer, which is essential for smooth installation and operation.

When evaluating offers, focus not just on the initial purchase price but also on the total cost of ownership (TCO). This includes potential savings from improved fuel efficiency, reduced tire wear, and lower maintenance costs over the system’s lifespan. Calculate the ROI using tools provided by suppliers, like the TIREMAAX ROI Calculator, to understand the long-term financial benefits.

After-sales support is a critical factor in ensuring the longevity and reliability of your investment. Inquire about the warranty terms, availability of spare parts, and technical support options. A supplier that offers comprehensive after-sales service can significantly reduce downtime and enhance the operational efficiency of your fleet.

Illustrative image related to hendrickson tire inflation system

Once you have selected a supplier, carefully review the contract terms before signing. Ensure all specifications, delivery timelines, payment terms, and service agreements are clearly outlined. This diligence will help prevent misunderstandings and ensure that your procurement process aligns with your operational needs and budget constraints.

By following this checklist, you can make informed decisions that will enhance the efficiency and safety of your fleet operations with Hendrickson’s tire inflation systems.

The cost structure for sourcing the Hendrickson Tire Inflation System, particularly the TIREMAAX® models, includes several critical components. These typically encompass materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

I materiali: The TIREMAAX systems are built from high-quality materials designed for durability and performance. This includes specialized alloys for the pressure control components and high-grade plastics for the housing. The choice of materials significantly influences the overall cost, with premium materials yielding higher performance and longevity.

Lavoro: Labor costs cover the workforce involved in assembly, quality checks, and installation. Skilled labor is essential for ensuring that the systems are manufactured to precise specifications, which may vary based on the model and application.

Spese generali di produzione: This encompasses indirect costs associated with production facilities, utilities, equipment depreciation, and administrative expenses. Efficient manufacturing processes can help mitigate these costs, making it critical for suppliers to maintain streamlined operations.

Utensili: The initial investment in tooling can be substantial, especially for customized systems. This cost is often amortized over the production run, and it can vary significantly depending on the complexity of the system being produced.

Controllo qualità (CQ): Given the safety and operational implications of tire inflation systems, rigorous QC processes are essential. This includes testing for leaks, pressure consistency, and overall system reliability, which can add to the cost but ultimately ensures product performance.

Logistica: Transporting the systems to various international markets incurs costs related to freight, customs duties, and warehousing. These logistics expenses can vary based on location, with international buyers from regions such as Africa, South America, and Europe needing to account for potentially higher shipping costs.

Margine: Finally, suppliers will include a profit margin in their pricing structure, which can vary based on market demand, competition, and the perceived value of the product.

Several factors influence the pricing of Hendrickson Tire Inflation Systems, especially in the B2B marketplace.

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly affect pricing. Larger orders often lead to volume discounts, making it advantageous for fleets to consolidate purchases.

Specifiche/Personalizzazione: Customization options—such as specific pressure settings, integration with existing systems, or unique configurations—can increase costs. Buyers should clearly define their requirements to receive accurate pricing.

I materiali: The choice of materials not only impacts durability but also the cost. Buyers should assess their long-term needs against the initial expenditure to ensure value.

Qualità/Certificazioni: Systems that meet international quality standards or certifications may come at a premium. Buyers in regulated markets, such as Europe, must prioritize compliance to avoid costly penalties.

Fattori di fornitura: Supplier reputation, experience, and service capabilities play a role in pricing. Established suppliers may charge more due to their proven track record and customer support.

Incoterms: Understanding Incoterms is crucial for international buyers. These terms dictate the responsibilities of buyers and sellers in shipping, insurance, and tariffs, significantly impacting overall costs.

For international B2B buyers, particularly those in regions like Africa and South America, strategic sourcing of Hendrickson Tire Inflation Systems can lead to significant cost savings.

Negoziazione: Engage in negotiations with suppliers to secure better pricing, especially for large orders. Highlighting long-term partnership potential can incentivize suppliers to offer favorable terms.

Efficienza dei costi: Evaluate the Total Cost of Ownership (TCO), which includes not only the purchase price but also installation, maintenance, and operational costs over the system’s lifespan. This holistic view can guide more informed purchasing decisions.

Sfumature di prezzo per i mercati internazionali: Be aware of the economic conditions and currency fluctuations in your region. These factors can affect pricing and should be considered when budgeting for purchases.

Leverage Supplier Relationships: Building strong relationships with suppliers can lead to better support, faster service, and potentially lower prices. Consider sourcing from suppliers with local representation to facilitate communication and logistics.

Rimanete informati: Keep abreast of market trends and technological advancements in tire inflation systems to ensure that you are sourcing the most efficient and cost-effective solutions available.

By understanding these cost components, price influencers, and strategic buyer tips, B2B buyers can make informed decisions when sourcing the Hendrickson Tire Inflation System, ultimately leading to enhanced operational efficiency and reduced long-term costs.

In the competitive landscape of fleet management, maintaining optimal tire pressure is crucial for safety, efficiency, and cost savings. The Hendrickson Tire Inflation System is a leading solution, but several alternatives exist, each with unique benefits and drawbacks. This analysis compares Hendrickson’s system with two viable alternatives: the PressurePro Tire Pressure Monitoring System (TPMS) and the TireMinder Tire Pressure Monitoring System.

| Aspetto di confronto | Hendrickson Tire Inflation System | PressurePro TPMS | TireMinder TPMS |

|---|---|---|---|

| Prestazioni | Continuous monitoring and automatic inflation; enhances tire life and fuel efficiency | Real-time monitoring; alerts for low pressure but manual inflation required | Real-time monitoring; alerts for low pressure; manual inflation required |

| Costo | Initial investment around $1,350-$1,500; ROI through fuel savings and reduced tire wear | Lower initial cost, typically $500-$800; potential higher long-term costs due to manual intervention | Similar to PressurePro; $500-$800; may require additional monitoring equipment |

| Facilità di implementazione | Designed for specific trailer systems; requires some installation expertise | Easy to install; can be retrofitted on existing tires without major modifications | User-friendly installation; can be set up quickly on most trailers |

| Manutenzione | Low maintenance; system checks itself; occasional filter replacement | Requires regular checks and manual inflation; maintenance can be labor-intensive | Requires regular checks and manual inflation; similar maintenance to PressurePro |

| Il miglior caso d'uso | Ideal for fleets with high mileage and long-haul operations; maximizes uptime | Suitable for fleets looking for cost-effective monitoring; best for shorter routes | Good for smaller fleets or those with varied route lengths; offers basic monitoring capabilities |

The PressurePro TPMS offers a cost-effective solution for tire monitoring, providing real-time alerts when tire pressure drops below set thresholds. While it does not automatically inflate tires, it is easy to install and can be retrofitted to most existing tire setups. The initial cost is lower than the Hendrickson system, making it attractive for fleets with budget constraints. However, the requirement for manual inflation can lead to increased labor and potential downtime, which may negate some of its cost benefits.

Similar to PressurePro, TireMinder provides real-time monitoring and alerts for tire pressure. Its installation is user-friendly, allowing for quick setup on various trailer types. The system is priced comparably to PressurePro, making it an accessible option for many fleet operators. However, like PressurePro, it lacks automatic inflation capabilities, necessitating manual intervention. This can be a drawback for fleets aiming to minimize maintenance efforts and maximize vehicle uptime.

Selecting the appropriate tire inflation solution involves assessing your fleet’s specific needs and operational demands. The Hendrickson Tire Inflation System is an excellent choice for fleets focused on maximizing tire life and minimizing downtime, particularly in high-mileage scenarios. In contrast, PressurePro and TireMinder offer more budget-friendly options for fleets that may not require automatic inflation but still seek effective monitoring. Ultimately, consider the performance, cost, ease of implementation, and maintenance needs when making your decision to ensure that your investment aligns with your fleet’s operational goals.

Illustrative image related to hendrickson tire inflation system

When considering the Hendrickson Tire Inflation System, several critical specifications stand out. Understanding these properties is essential for B2B buyers to make informed decisions regarding investment and implementation in their fleets.

Pressure Range: The TIREMAAX systems are designed to operate within specific pressure settings, typically ranging from 70 to 120 PSI, depending on the model (TIREMAAX CP, PRO, or PRO-LB). This range is crucial because maintaining optimal tire pressure directly affects fuel efficiency, tire longevity, and overall vehicle safety. For fleet operators, this translates to significant cost savings in fuel and maintenance.

Compatibility with Suspension Systems: The TIREMAAX systems are compatible with various Hendrickson integrated air suspension systems and non-integrated axles. This versatility is vital for B2B buyers, as it ensures that the system can be installed across multiple types of trailers, reducing the need for specialized equipment and facilitating easier upgrades.

Mechanical Controller: The TIREMAAX PRO model features a patented mechanical controller that maintains desired tire pressures and isolates tires when parked. This feature is significant for fleet management, as it prevents pressure loss and ensures that tires are always ready for operation, thereby maximizing uptime and reducing the risk of tire failure.

Durability Features: With components like a long-life rotary union designed to last up to one million miles and serviceable filters at the supply port, the TIREMAAX systems are built for longevity. For B2B buyers, investing in durable equipment minimizes the frequency of replacements and repairs, leading to long-term cost efficiency.

Installation Complexity: The installation kits are designed for ease of use, often requiring only general knowledge of trailer air system components. Some Hendrickson axles are pre-drilled for hose installation, while others may need additional modifications. Understanding this aspect can help buyers gauge the potential labor costs involved in deploying the system.

Return on Investment (ROI): Hendrickson provides tools like the TIREMAAX ROI Calculator, allowing potential buyers to assess the financial benefits of installing the tire inflation system. This feature is crucial for B2B decision-makers, as it provides a clear financial justification for the investment based on anticipated savings in fuel and maintenance costs.

Navigating the procurement of tire inflation systems involves familiarity with specific industry terminology. Here are several key terms that are essential for B2B buyers:

OEM (Original Equipment Manufacturer): This term refers to companies like Hendrickson that manufacture parts and systems that are used in the production of vehicles. Understanding OEM relationships is crucial for buyers looking to ensure compatibility and quality in their tire inflation systems.

MOQ (quantità minima d'ordine): This refers to the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for fleet operators to determine the financial commitment required for purchasing tire inflation systems.

RFQ (Richiesta di offerta): An RFQ is a standard business process where buyers request pricing information from suppliers. This term is vital for B2B buyers looking to compare costs and terms from multiple vendors before making a purchase decision.

Incoterms (Termini commerciali internazionali): These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC). They are crucial for defining the responsibilities of buyers and sellers in international transactions, such as shipping costs and risks associated with the transportation of tire inflation systems.

Tire Pressure Control System (TPC): This term refers to systems like TIREMAAX that automatically monitor and manage tire pressure. Understanding TPCs helps buyers recognize the technology’s role in enhancing fleet efficiency and safety.

Fleet Uptime: This refers to the amount of time a fleet is operational and not in maintenance. For B2B buyers, maximizing fleet uptime is a primary objective, as it directly correlates with revenue generation and operational efficiency.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding the Hendrickson Tire Inflation System, ensuring they choose the right solutions for their operational needs.

The Hendrickson tire inflation system market is shaped by several global drivers, particularly the rising costs of fuel and tire maintenance. As fleets seek to optimize operational efficiency, the demand for automatic tire pressure control systems has surged. This is especially pertinent in regions like Africa and South America, where infrastructure challenges can lead to significant downtime due to tire failures. Additionally, regulatory pressures around emissions and fuel efficiency are pushing businesses to adopt technologies that enhance fuel economy, making systems like TIREMAAX® vital for compliance and cost savings.

Emerging B2B technology trends also play a critical role in this sector. For instance, the integration of IoT (Internet of Things) capabilities in tire inflation systems allows for real-time monitoring and data analytics, enabling fleet managers to make informed decisions. This technology not only improves tire longevity but also enhances safety by preventing blowouts. As the market evolves, international buyers from Europe and the Middle East are increasingly looking for suppliers that offer these advanced features in their tire inflation systems.

Sustainability is becoming a cornerstone of procurement strategies for international B2B buyers, particularly in Europe and North America. The environmental impact of tire maintenance—specifically, the energy consumption and waste associated with improperly inflated tires—has prompted a shift towards more sustainable practices. Companies are now prioritizing tire inflation systems that not only improve fuel efficiency but also minimize carbon footprints through better resource management.

Ethical sourcing is equally important, as buyers are increasingly scrutinizing supply chains for sustainability certifications and the use of green materials. Hendrickson’s commitment to sustainable practices is reflected in its design and manufacturing processes, which aim to reduce waste and energy consumption. By choosing products that meet ‘green’ certifications, B2B buyers can demonstrate their commitment to sustainability, which is becoming a key differentiator in competitive markets.

The Hendrickson tire inflation system has evolved significantly since its inception, driven by advancements in technology and a growing awareness of the importance of tire maintenance. Initially, tire inflation systems were manual, requiring frequent checks and adjustments. However, the introduction of automated systems, such as TIREMAAX®, revolutionized the industry by providing continuous monitoring and automatic adjustments to tire pressure.

Over the years, the focus has shifted from merely maintaining tire pressure to integrating smart technologies that offer real-time data and analytics. This evolution not only enhances operational efficiency but also aligns with the global trend towards digital transformation in the transportation sector. As B2B buyers increasingly demand sophisticated solutions that ensure safety, reliability, and sustainability, Hendrickson’s tire inflation systems remain at the forefront of meeting these needs.

Illustrative image related to hendrickson tire inflation system

How can I ensure proper tire inflation with the Hendrickson TIREMAAX system?

To ensure optimal tire inflation using the Hendrickson TIREMAAX system, it is essential to regularly monitor the system’s performance and check for any leaks or malfunctions. The TIREMAAX system continuously checks tire pressure, allowing for real-time adjustments. Implementing a maintenance schedule and utilizing Hendrickson’s service support can significantly enhance tire longevity and fuel efficiency. Additionally, ensure that your tires are compatible with the system’s specifications to maximize effectiveness.

What are the key benefits of using the Hendrickson TIREMAAX tire inflation system?

The Hendrickson TIREMAAX tire inflation system provides several benefits, including extended tire life, improved fuel efficiency, and minimized downtime due to tire failures. By maintaining optimal tire pressure, the system helps reduce tire wear and enhances vehicle handling. Moreover, the automatic inflation and deflation features ensure that tires remain within the recommended pressure range, which is crucial for safety and performance. Overall, the investment in TIREMAAX can lead to substantial cost savings for fleets.

What is the typical lead time for ordering Hendrickson TIREMAAX systems?

Lead times for ordering Hendrickson TIREMAAX systems can vary based on several factors, including the specific model, customization requests, and your geographical location. Typically, standard orders may take 4-6 weeks for delivery, while customized solutions may require additional time for manufacturing and testing. It is advisable to contact your local distributor or Hendrickson directly to obtain precise timelines and ensure timely delivery for your fleet’s needs.

Are there minimum order quantities (MOQs) for the TIREMAAX systems?

Minimum order quantities for Hendrickson TIREMAAX systems may vary depending on the model and the distributor’s policies. Generally, larger fleets may benefit from bulk purchasing options, which can lead to discounts and better pricing. It’s recommended to discuss your specific needs with your supplier to understand any MOQs and potential savings associated with larger orders, particularly if you are operating in regions like Africa or South America where distribution may differ.

What payment terms are typically offered for international buyers?

Payment terms for international buyers of Hendrickson TIREMAAX systems can differ based on the supplier and the buyer’s creditworthiness. Common payment options include advance payment, letters of credit, or open account terms for established relationships. It’s essential to clarify payment terms before finalizing your order to avoid any misunderstandings. Consider discussing currency exchange rates and transaction fees, especially if sourcing from regions like Europe or the Middle East.

How do I vet suppliers for the Hendrickson TIREMAAX systems?

When vetting suppliers for Hendrickson TIREMAAX systems, consider their industry experience, reputation, and customer reviews. Request references from other businesses that have purchased similar systems. Evaluate their customer service capabilities, including technical support and warranty offerings. Additionally, confirm that they are authorized distributors of Hendrickson products to ensure quality and authenticity. Engaging with suppliers that have a strong presence in your region can also facilitate smoother logistics and service.

What customization options are available for the TIREMAAX systems?

Hendrickson offers various customization options for TIREMAAX systems to meet the specific needs of different fleets. Customizations may include adjustments to pressure settings, integration with existing vehicle systems, and tailored installation kits. It’s important to discuss your requirements with your supplier to explore available options. Custom solutions can enhance the effectiveness of the system and ensure compatibility with your fleet’s unique specifications.

What logistics considerations should I keep in mind when sourcing TIREMAAX systems?

When sourcing TIREMAAX systems, logistics considerations include shipping methods, customs regulations, and potential tariffs. Ensure you understand the import/export requirements specific to your region, especially when importing to areas like Africa or South America. Collaborate with your supplier to determine the best shipping options that balance cost and delivery time. Additionally, consider local distribution networks that can facilitate quicker access to replacement parts and service, ensuring your fleet remains operational.

Dominio: hendrickson-intl.com

Registrato: 1997 (28 anni)

Introduzione: Hendrickson TIREMAAX Tire Pressure Control Systems are designed to address improper tire inflation, which can significantly reduce fuel economy and tire life. The TIREMAAX lineup includes TIREMAAX CP, PRO, and PRO-LB systems, utilizing advanced patented technology to maintain proper tire pressure. Key features include:

– Compatibility with Hendrickson integrated air suspension systems and non-inte…

In summary, the Hendrickson TIREMAAX® tire inflation systems present a significant opportunity for B2B buyers seeking to enhance operational efficiency and reduce costs associated with tire maintenance. By implementing these advanced tire pressure control solutions, companies can achieve notable savings through improved fuel economy, extended tire life, and minimized downtime due to tire failures. The strategic sourcing of TIREMAAX systems not only addresses prevalent maintenance challenges but also aligns with global sustainability initiatives by promoting more efficient resource usage.

As international buyers from regions such as Africa, South America, the Middle East, and Europe consider their procurement strategies, it is essential to recognize the long-term value of investing in reliable tire inflation technology. The competitive advantages offered by Hendrickson’s innovative solutions are paramount for businesses looking to optimize their fleet operations and maintain a strong market presence.

Looking ahead, we encourage B2B buyers to explore the full range of TIREMAAX products and assess their potential return on investment. By prioritizing strategic sourcing of tire inflation systems, companies can position themselves for sustained growth and resilience in a rapidly evolving industry landscape.

Illustrative image related to hendrickson tire inflation system

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.