In today’s competitive global market, sourcing the right tire inflator hose can pose significant challenges for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The need for reliable, high-quality inflator hoses is underscored by the increasing demand for efficient tire maintenance solutions in automotive, industrial, and recreational sectors. This comprehensive guide aims to demystify the complexities surrounding tire inflator hoses, providing essential insights into various types, applications, and supplier vetting processes.

Navigating the nuances of tire inflator hoses involves understanding the technical specifications, such as hose material, length, and compatibility with different tire inflators. Additionally, the guide will explore cost considerations, enabling buyers to identify budget-friendly options without compromising on quality. In an era where informed purchasing decisions are crucial, this resource empowers international B2B buyers with the knowledge necessary to select suppliers that meet their specific needs and standards.

By leveraging this guide, businesses can enhance their procurement strategies, ensuring they secure dependable tire inflator hoses that optimize operational efficiency. Whether you are in Germany seeking advanced technology or in Nigeria looking for cost-effective solutions, this guide is tailored to equip you with the tools to make confident, informed decisions in the global marketplace.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Standard Tire Inflator Hose | Typically features screw-on or clip-on connectors | Automotive repair shops, service stations | Pro: Efficiente dal punto di vista dei costi; Contro: Limited versatility. |

| Self-Locking Nozzle Hose | Patented design for quick-release and secure connection | Mobile tire service, automotive workshops | Pro: Fast inflation; Contro: Costo iniziale più elevato. |

| Multi-Tire Inflation Kits | Allows simultaneous inflation/deflation of multiple tires | Fleet management, off-road vehicle maintenance | Pro: Time-efficient; Contro: Bulkier setup. |

| Braided Hose Kits | Durable construction, often resistant to abrasion and wear | Heavy-duty applications, industrial settings | Pro: Long-lasting; Contro: Heavier and less flexible. |

| DIY Hose Kits | Customizable lengths and fittings based on specific needs | Custom installations, specialized services | Pro: Tailored solutions; Contro: Requires assembly expertise. |

Standard tire inflator hoses typically feature screw-on or clip-on connectors, making them a common choice for basic tire inflation needs. These hoses are often made from rubber or PVC, providing sufficient durability for everyday use. They are particularly suitable for automotive repair shops and service stations where cost-effectiveness is a priority. While they are budget-friendly, their limited versatility may not meet the requirements of businesses needing advanced inflation solutions.

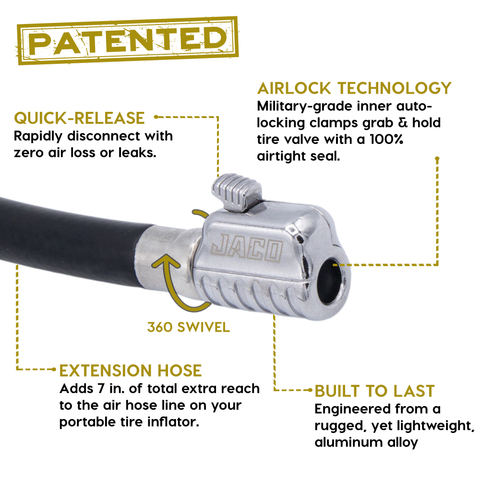

Self-locking nozzle hoses incorporate patented designs that enable quick-release and secure connections. This feature is particularly beneficial for mobile tire services and automotive workshops where speed and efficiency are crucial. These hoses reduce the risk of air leaks during inflation, ensuring a more reliable performance. Although they may come with a higher initial cost, the efficiency gains can justify the investment for businesses focused on rapid service delivery.

Illustrative image related to tire inflator hose

Multi-tire inflation kits allow for the simultaneous inflation and deflation of multiple tires, making them ideal for fleet management and off-road vehicle maintenance. These kits often include multiple hoses connected to a single manifold, which streamlines the inflation process. While they are time-efficient and suitable for larger operations, their bulkier setup may require additional storage space and can be less flexible in tight work environments.

Braided hose kits are constructed with durable materials that resist abrasion and wear, making them suitable for heavy-duty applications and industrial settings. Their robust design ensures longevity even under demanding conditions, which is a significant advantage for businesses that rely on consistent performance. However, these hoses tend to be heavier and less flexible than standard options, which may limit their usability in certain scenarios.

DIY hose kits provide the flexibility to customize lengths and fittings based on specific business needs. This adaptability makes them suitable for custom installations and specialized services, allowing businesses to tailor their tire inflation solutions. While they offer tailored solutions, they do require some assembly expertise, which may not be ideal for all buyers. For companies that prioritize customization and have the technical know-how, these kits can be a valuable investment.

| Industria/Settore | Specific Application of tire inflator hose | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Riparazione di autoveicoli | Tire inflation in workshops | Increases efficiency in service delivery and customer satisfaction | Durability, compatibility with various tire valves, and length options |

| Trasporto e logistica | Fleet maintenance for tire pressure management | Enhances vehicle safety and reduces downtime | Quick-connect features, length adaptability, and pressure ratings |

| Agricoltura | Inflation for agricultural vehicles and equipment | Ensures operational readiness and minimizes equipment failure | Resistance to environmental factors, hose flexibility, and fittings |

| Costruzione | Tire inflation for heavy machinery | Improves productivity and reduces the risk of on-site accidents | Robustness, temperature tolerance, and compatibility with air compressors |

| Retail & Consumer Services | Tire inflation stations at service centers | Attracts customers and provides added service value | Ease of use, self-locking features, and availability of replacement parts |

In automotive repair shops, tire inflator hoses are essential for efficiently inflating tires during service. The ability to quickly adjust tire pressure ensures vehicles are safe and ready for the road. These hoses often come with various connectors to fit different tire valves, and their durability is crucial for handling the repetitive use in busy environments. For international B2B buyers, sourcing hoses that withstand high pressure and are compatible with diverse tire models is vital, particularly in regions like Africa and South America, where tire specifications may vary significantly.

In the transportation and logistics sector, tire inflator hoses are crucial for maintaining fleet vehicles. Proper tire inflation is directly linked to vehicle safety, fuel efficiency, and overall operational performance. Companies benefit from investing in high-quality inflator hoses that allow for quick and efficient tire pressure management, reducing the risk of breakdowns. Buyers should consider hoses that offer quick-connect features and adaptability in length to accommodate different types of vehicles, particularly in regions like the Middle East and Europe, where fleets may vary widely.

Illustrative image related to tire inflator hose

Agricultural vehicles and equipment rely on tire inflator hoses for maintaining optimal tire pressure, which is vital for performance on uneven terrain. Ensuring that tires are properly inflated minimizes the risk of equipment failure, which can lead to costly delays in harvesting or planting. Buyers in the agricultural sector should prioritize hoses that resist environmental factors such as moisture and dirt, while also offering flexibility to maneuver around large machinery. This is especially important in regions like South America, where diverse agricultural practices are prevalent.

In construction, tire inflator hoses are used to inflate tires on heavy machinery, ensuring that equipment is safe and operational. Properly inflated tires improve productivity and reduce the likelihood of accidents on-site, which can have significant financial implications. Buyers in this sector should look for robust hoses that can withstand harsh conditions and high temperatures, as well as compatibility with various air compressors. This is particularly relevant in regions with extreme weather conditions, such as parts of Africa and the Middle East.

Retail service centers that offer tire inflation stations benefit from using high-quality tire inflator hoses. These hoses not only facilitate customer service but also enhance the overall customer experience by providing quick and easy access to tire maintenance. Businesses can attract more customers by showcasing efficient tire inflation solutions. When sourcing these hoses, it is important to consider features like ease of use and self-locking mechanisms to ensure customer satisfaction. This is especially relevant in European markets, where consumer expectations for service quality are high.

Il problema: In many B2B environments, particularly in regions with challenging climates like Africa and South America, buyers often struggle to find tire inflator hoses that can withstand extreme temperatures and rugged conditions. Standard hoses may deteriorate quickly, leading to frequent replacements, increased downtime, and ultimately higher operational costs. Buyers need hoses that not only perform well but also have a longer lifespan to ensure they are a sound investment.

La soluzione: When sourcing tire inflator hoses, prioritize options made from high-quality materials such as reinforced rubber or durable synthetic compounds. Look for products specifically designed for heavy-duty use, and ensure they are rated for the expected pressures and temperatures in your operating environment. Collaborate with suppliers who offer warranties or guarantees on their hoses, which can provide peace of mind regarding their longevity. Additionally, consider investing in hoses with protective features like abrasion-resistant covers and UV protection, which can significantly extend the life of the product in harsh conditions.

Il problema: Another common challenge faced by B2B buyers is the compatibility of tire inflator hoses with existing inflation equipment. Many businesses have a range of tire inflators, pumps, and other pneumatic tools, and not all hoses will fit seamlessly with their connectors or systems. This can lead to inefficiencies, increased costs due to the need for adapters, and potential safety hazards if incompatible hoses are used.

La soluzione: To avoid compatibility issues, thoroughly assess the specifications of your current tire inflation equipment before purchasing new hoses. Check the connector types, hose diameter, and pressure ratings of both the inflator and the hose. It is advisable to work with suppliers who can provide customized solutions or a variety of hose fittings that match your equipment. Additionally, consider investing in modular systems that allow for easy swapping of hoses and connectors, which can provide greater flexibility and reduce downtime during tire maintenance operations.

Il problema: In busy operations, such as fleet maintenance or automotive repair shops, inefficient inflation processes can lead to significant downtime. If the inflator hose is too short, it may require moving vehicles more often than necessary, or if the hose is not designed for quick connections, it can lead to wasted time during routine tire checks. This inefficiency can hamper productivity and affect overall service delivery.

Illustrative image related to tire inflator hose

La soluzione: To streamline the inflation process, invest in longer, flexible tire inflator hoses that provide better reach without the need to reposition vehicles frequently. Look for hoses with quick-connect fittings that facilitate faster attachment and detachment from tire valves. Additionally, consider multi-tire inflation kits that allow simultaneous inflation of multiple tires, significantly reducing the time spent on each vehicle. Training staff on the proper use of these hoses and employing best practices for tire maintenance can further enhance efficiency and minimize downtime, ultimately improving service delivery and operational productivity.

When selecting materials for tire inflator hoses, it is crucial to understand the properties, advantages, and limitations of each option. This knowledge aids international B2B buyers in making informed decisions that align with their operational needs and regional standards.

Rubber is a traditional choice for tire inflator hoses due to its flexibility and resilience. It typically offers a temperature rating of -40°F to 190°F and can withstand pressures up to 300 PSI. Rubber hoses are resistant to abrasion and can handle various environmental conditions, making them suitable for outdoor use.

Pro: Rubber hoses are durable, lightweight, and cost-effective. They provide excellent flexibility, allowing for easy maneuverability during use.

Contro: However, rubber can be susceptible to ozone and UV degradation over time, which may limit its lifespan in harsh conditions. Additionally, rubber hoses may not be suitable for high-temperature applications beyond their rated limits.

Illustrative image related to tire inflator hose

Impatto sull'applicazione: Rubber is compatible with air and other gases, making it ideal for tire inflation. However, its susceptibility to environmental factors should be considered, especially in regions with extreme weather.

PVC hoses are gaining popularity due to their lightweight nature and resistance to chemicals and corrosion. They typically operate effectively within a temperature range of -20°F to 150°F and can handle pressures up to 250 PSI.

Pro: The main advantages of PVC hoses are their affordability and resistance to abrasion, making them suitable for various applications. They are also less prone to kinking compared to rubber hoses.

Illustrative image related to tire inflator hose

Contro: The flexibility of PVC can be limited in colder temperatures, making it less suitable for extreme climates. Additionally, PVC hoses may not perform well under high-pressure applications.

Impatto sull'applicazione: PVC hoses are ideal for air and water applications but may not be suitable for high-temperature or high-pressure environments. Buyers in warmer climates may find PVC to be a cost-effective solution.

Reinforced nylon hoses are known for their high strength and durability. With a temperature rating of -40°F to 200°F and pressure ratings exceeding 300 PSI, these hoses are designed for heavy-duty applications.

Pro: The primary advantage of reinforced nylon is its high tensile strength and resistance to wear and tear. It is also lightweight, making it easy to handle.

Illustrative image related to tire inflator hose

Contro: The cost of reinforced nylon hoses is generally higher than rubber or PVC options. They can also be less flexible in colder temperatures, which might affect usability.

Impatto sull'applicazione: Reinforced nylon is suitable for high-pressure applications and can be used in various environments, including industrial settings. Buyers should consider the higher initial investment against the long-term durability benefits.

Braided steel hoses are designed for extreme durability and high-pressure applications. They can handle temperatures ranging from -40°F to 400°F and pressures up to 500 PSI or more.

Illustrative image related to tire inflator hose

Pro: The key advantage of braided steel is its exceptional strength and resistance to punctures and abrasions. It is ideal for heavy-duty industrial applications.

Contro: However, braided steel hoses are heavier and less flexible than other materials, making them more challenging to handle. They also tend to be more expensive.

Impatto sull'applicazione: These hoses are suitable for high-pressure air applications and can withstand harsh conditions. International buyers should ensure compliance with relevant safety standards, especially in industrial environments.

| Materiale | Typical Use Case for tire inflator hose | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Gomma | General tire inflation | Durable and flexible | Susceptible to ozone degradation | Basso |

| PVC | Light-duty air and water applications | Affordable and resistant to chemicals | Limited flexibility in cold temps | Basso |

| Reinforced Nylon | Heavy-duty industrial applications | Elevata resistenza alla trazione | Higher cost, less flexibility | Med |

| Braided Steel | Extreme high-pressure applications | Exceptional strength | Heavier, less flexible | Alto |

This guide provides a comprehensive overview of common materials used in tire inflator hoses, enabling B2B buyers from diverse regions to make informed decisions that align with their specific needs and compliance requirements.

The manufacturing of tire inflator hoses involves several key stages, each crucial for ensuring the final product meets the necessary performance and safety standards. The primary stages of production include material preparation, forming, assembly, and finishing.

Preparazione del materiale: The first step involves selecting high-quality materials, typically synthetic rubber or thermoplastic elastomers, known for their flexibility and durability. These materials are inspected for impurities and quality before they are cut into the required lengths. The preparation stage may also include the blending of materials with additives to enhance properties such as UV resistance, heat tolerance, and flexibility.

Formazione: During the forming stage, the prepared materials are shaped into the desired hose profile. This is often accomplished using extrusion techniques, where materials are heated and forced through a die to create a continuous length of hose. In some cases, braiding or weaving techniques may be applied to reinforce the hose, providing added strength and resistance to pressure.

Montaggio: The assembly stage involves attaching fittings and connectors to the hose. This may include crimping metal fittings onto the hose ends or incorporating specialized connectors designed for specific tire inflator applications. Precision is key in this stage to ensure that all connections are secure and capable of withstanding high pressures without leaking.

Finitura: The final stage includes various finishing processes, such as cutting the hoses to the required lengths, applying protective coatings, and conducting visual inspections for any defects. Quality checks are often performed at this stage to ensure that the hoses meet both aesthetic and functional standards before packaging.

Quality assurance in the manufacturing of tire inflator hoses is essential for ensuring safety, reliability, and customer satisfaction. Adhering to international and industry-specific standards helps manufacturers maintain quality throughout the production process.

Relevant International Standards: Many manufacturers seek ISO 9001 certification, which provides a framework for consistent quality management. This standard emphasizes a process-oriented approach, ensuring that manufacturers continuously improve their production processes and meet customer requirements. Additionally, compliance with CE marking ensures that the products conform to health, safety, and environmental protection standards within the European market.

Standard specifici del settore: Depending on the application, adherence to additional standards such as API (American Petroleum Institute) may be necessary, particularly for hoses used in environments involving petroleum products. These standards provide guidelines for testing and performance that can significantly impact the safety and functionality of the hoses.

Quality control (QC) checkpoints are critical throughout the manufacturing process, ensuring that any defects are identified and rectified before the final product reaches the market. Typical QC checkpoints include:

Illustrative image related to tire inflator hose

Controllo qualità in entrata (CQI): This initial checkpoint focuses on assessing the quality of raw materials upon arrival. Suppliers must provide documentation confirming compliance with relevant standards, and materials are often subject to sampling tests to verify their quality before use.

Controllo qualità in corso d'opera (IPQC): Continuous monitoring occurs during the manufacturing process. This includes checking dimensions, pressure ratings, and the integrity of fittings during the assembly stage. Regular inspections ensure that any deviations from quality standards are caught early, minimizing waste and rework.

Controllo qualità finale (CQC): Before the hoses are packaged and shipped, they undergo a final inspection. This includes visual checks for defects, functional tests to verify performance under pressure, and sometimes destructive testing to ensure the hoses can withstand their intended use.

Illustrative image related to tire inflator hose

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control measures is essential for ensuring product reliability. Here are several actionable strategies:

Audit dei fornitori: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control systems firsthand. This provides insight into the supplier’s adherence to international standards and their overall commitment to quality.

Richiesta di rapporti sulla qualità: Suppliers should be able to provide comprehensive quality assurance documentation, including results from IQC, IPQC, and FQC checkpoints. Detailed reports can help buyers understand the supplier’s quality control processes and any testing methods used.

Ispezioni di terzi: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control practices. These inspections typically occur at various stages of production and can provide buyers with assurance that the products meet specified standards.

Several testing methods are employed to ensure the quality and performance of tire inflator hoses. Common methods include:

Pressure Testing: This involves subjecting the hoses to high-pressure conditions to verify their ability to withstand operational stresses. Pressure testing is crucial for ensuring that hoses do not burst or leak during use.

Illustrative image related to tire inflator hose

Flexibility and Bend Testing: Hoses are tested for flexibility to ensure they can easily maneuver without kinking or damaging the material. This testing simulates real-world usage and is vital for maintaining the hose’s integrity over time.

Test ambientali: To assess durability, hoses may undergo environmental testing, which evaluates their performance under various conditions, such as extreme temperatures, exposure to UV light, or contact with chemicals.

International buyers should be aware of the nuances associated with quality control certifications when sourcing tire inflator hoses. Certifications may vary significantly by region, and understanding these differences is crucial for compliance and quality assurance.

Standard regionali: While ISO and CE certifications are widely recognized, other regions may have specific requirements. For instance, buyers in Africa may encounter different regulatory standards that must be met for local compliance. Understanding these regional differences can help buyers navigate the complexities of international sourcing.

Illustrative image related to tire inflator hose

Documentation and Traceability: Ensure that suppliers can provide clear documentation regarding their certifications and quality control processes. This includes certificates of compliance, test reports, and traceability documentation for raw materials.

Considerazioni culturali: Communication styles and business practices can vary greatly across regions. Establishing clear expectations regarding quality control and certifications upfront can help mitigate misunderstandings and foster a productive supplier relationship.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing tire inflator hoses, ensuring they select suppliers that prioritize quality and compliance.

When sourcing tire inflator hoses, it is essential to navigate the complexities of the market effectively. This guide serves as a step-by-step checklist to help B2B buyers make informed decisions that align with their operational needs and budget constraints.

Establishing clear technical specifications is crucial for ensuring that the tire inflator hose meets your operational requirements. Consider factors such as hose length, diameter, material (e.g., rubber vs. braided), and pressure rating. Understanding these specifications helps avoid compatibility issues with existing equipment and ensures optimal performance.

Illustrative image related to tire inflator hose

Conduct thorough research to identify reputable suppliers. Look for manufacturers with a solid track record in the industry and positive customer reviews. Utilize platforms like industry trade shows, online directories, and trade associations to compile a list of potential suppliers.

Before proceeding with any supplier, verify their certifications and compliance with international standards. This step is vital to ensure that the products meet quality and safety standards. Look for certifications such as ISO, CE, or any local regulatory compliance that applies to your target market.

Always request samples before placing a bulk order. Testing samples allows you to evaluate the hose’s quality, flexibility, and durability under your specific conditions. This can prevent costly mistakes and ensure that the product performs as expected in real-world scenarios.

Evaluate the pricing structures offered by different suppliers. Compare not only the unit prices but also consider shipping costs, bulk order discounts, and payment terms. Understanding the total cost of ownership can help you find the best value while maintaining quality.

Inquire about warranty terms and after-sales support offered by the supplier. A robust warranty can provide peace of mind regarding product reliability, while responsive customer support can aid in resolving any issues that may arise post-purchase. Ensure that the terms are clear and favorable to your business needs.

Illustrative image related to tire inflator hose

Lastly, assess the supplier’s delivery capabilities and lead times. Timely delivery is critical to maintaining your operational schedule, especially if you are dependent on these hoses for production or service. Confirm that the supplier can meet your timelines, especially during peak demand seasons.

By following this checklist, B2B buyers can navigate the procurement process for tire inflator hoses with greater confidence, ensuring they select the right products and suppliers for their specific needs.

When analyzing the cost structure for sourcing tire inflator hoses, several key components come into play. The primary cost factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

Illustrative image related to tire inflator hose

I materiali are a significant portion of the cost, as the choice of rubber, plastic, or metal can greatly influence pricing. For instance, hoses made from higher-grade materials designed for durability and heat resistance will typically command higher prices. Labor costs vary based on the manufacturing location; countries with lower labor costs can provide a competitive edge but may compromise quality.

Spese generali di produzione encompasses expenses related to facility operations, equipment maintenance, and administrative costs. These can vary widely depending on the scale of production and operational efficiency. Utensili costs are also crucial, especially for custom designs or unique specifications, as they can be substantial and are often amortized over production runs. Controllo qualità ensures that products meet safety and performance standards, which can add to the overall cost but is essential for maintaining buyer trust.

Logistica costs, including shipping and handling, are influenced by the distance from the supplier to the buyer, especially for international shipments. Finally, the margine del fornitore reflects the profit that manufacturers or distributors expect from the sale, which can vary based on market conditions and competition.

Several factors can influence the pricing of tire inflator hoses, making it crucial for buyers to understand these dynamics. Volume e quantità minima d'ordine (MOQ) play a pivotal role; larger orders typically attract volume discounts, which can significantly reduce per-unit costs.

Specifiche e personalizzazione also affect pricing. Custom hoses designed for specific applications or with unique features may incur additional costs due to the complexity of manufacturing. Buyers must weigh the need for customization against budget constraints.

Illustrative image related to tire inflator hose

Material quality and certifications are essential considerations. Hoses that meet international safety standards or are made from premium materials will generally be priced higher. Additionally, supplier factors, such as reputation and reliability, can influence pricing. Well-established suppliers with a track record of quality may command higher prices but offer better assurance of product performance.

Incoterms also play a critical role in pricing negotiations. Understanding the implications of shipping terms can help buyers manage costs effectively, especially regarding who bears responsibility for freight and customs duties.

To navigate the complexities of sourcing tire inflator hoses effectively, international B2B buyers should consider several strategic approaches. Negoziazione is a vital tool; buyers should engage suppliers in discussions about pricing, especially when placing large orders or establishing long-term partnerships. Building relationships can also lead to better terms and pricing adjustments.

Focus on cost-efficiency by evaluating the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, maintenance, and any potential downtime associated with product failure. This holistic view can lead to better long-term purchasing decisions.

Buyers must also be aware of sfumature di prezzo specific to their regions. For instance, buyers from Africa or South America may encounter additional tariffs or import restrictions that can affect overall costs. Similarly, European buyers should consider compliance with EU regulations, which may necessitate higher-quality products and certifications.

Illustrative image related to tire inflator hose

In summary, while indicative prices for tire inflator hoses can vary widely—ranging from around $50 for basic models to upwards of $300 for specialized kits—buyers should approach sourcing strategically. Understanding the underlying cost components and price influencers can empower B2B buyers to make informed decisions that align with their business objectives.

In the competitive landscape of tire inflation solutions, various methods exist alongside the traditional tire inflator hose. Understanding these alternatives is crucial for B2B buyers who aim to optimize their operations, reduce costs, and enhance efficiency. This analysis will compare the tire inflator hose with two notable alternatives: multi-tire inflation kits and electric tire inflators. Each solution offers unique advantages and limitations that can significantly impact decision-making.

| Aspetto di confronto | Tire Inflator Hose | Multi-Tire Inflation Kits | Electric Tire Inflators |

|---|---|---|---|

| Prestazioni | High efficiency for single tires; manual operation | Excellent for inflating multiple tires simultaneously | Quick inflation for single tires; varies by power source |

| Costo | Moderate ($20 – $30) | Higher ($150 – $300) | Varies ($30 – $200) |

| Facilità di implementazione | Simple setup; requires manual use | More complex; may require training | User-friendly; plug-and-play design |

| Manutenzione | Low maintenance; replaceable hoses | Moderate maintenance; check for leaks | Regular checks on electrical components |

| Il miglior caso d'uso | Individual tire inflation; portable use | Fleet operations; off-road vehicles | Quick inflation at home or on-the-go |

Multi-Tire Inflation Kits

Multi-tire inflation kits, such as those offered by MORRFlate, allow for simultaneous inflation or deflation of multiple tires. This is particularly beneficial for businesses that manage fleets or off-road vehicles where time efficiency is paramount. While the initial investment is higher compared to a standard tire inflator hose, the ability to service multiple tires at once can lead to significant time savings during routine maintenance. However, these kits may require some training for effective use and maintenance, which could pose a challenge for smaller operations.

Electric Tire Inflators

Electric tire inflators are increasingly popular due to their ease of use and speed. Designed for quick inflation, they are often portable and can be powered via a vehicle’s power outlet or a wall socket. This makes them ideal for both personal and professional use, particularly in emergency situations. However, they can vary significantly in price and performance, with some models being underpowered for larger tires. Additionally, reliance on electrical power may limit their effectiveness in remote areas, making them less versatile compared to traditional hoses or multi-tire kits.

Selecting the appropriate tire inflation solution hinges on understanding the specific needs of your operation. For businesses requiring efficient, simultaneous tire servicing, multi-tire inflation kits may provide the best return on investment despite their higher upfront costs. Conversely, if the focus is on individual tire maintenance with a more modest budget, a tire inflator hose remains a reliable choice. Electric tire inflators offer a quick and easy solution but should be evaluated based on the operational environment and power accessibility. Ultimately, aligning the choice with operational requirements, budget constraints, and maintenance capabilities will guide B2B buyers in making an informed decision that enhances productivity and efficiency.

Illustrative image related to tire inflator hose

When considering tire inflator hoses, several technical properties are critical for ensuring optimal performance and reliability. Understanding these specifications can guide B2B buyers in making informed purchasing decisions.

The material grade of a tire inflator hose is essential for durability and flexibility. Common materials include rubber, PVC, and thermoplastic elastomers. Rubber hoses typically offer better resistance to wear and tear, making them suitable for heavy-duty applications. PVC hoses are lighter and more flexible, ideal for portable use. Understanding the material helps buyers match the hose to their specific environmental conditions and usage requirements.

The internal diameter of the hose affects airflow and inflation speed. Standard sizes range from 1/4 inch to 1/2 inch. A larger diameter allows for a higher volume of air to flow through, which can be crucial for faster inflation times, especially in commercial settings. Buyers should consider the diameter in relation to the inflator’s output capacity to ensure efficiency.

Each tire inflator hose comes with a specified pressure rating, often measured in pounds per square inch (PSI). This rating indicates the maximum pressure the hose can safely handle. For example, hoses rated for 300 PSI are suitable for high-pressure applications, while those rated at 150 PSI may suffice for standard consumer use. Selecting a hose with an appropriate pressure rating is crucial to prevent blowouts and ensure safety during operation.

Illustrative image related to tire inflator hose

The operational temperature range of a tire inflator hose defines its usability under different climatic conditions. Hoses that can withstand extreme temperatures—both hot and cold—are essential for markets in regions with diverse weather patterns. For example, hoses designed to function effectively in temperatures ranging from -40°F to 150°F provide versatility for various applications, from automotive to industrial.

The length of the hose impacts its usability in different scenarios. Longer hoses allow for more flexibility in positioning the inflator, especially in crowded workspaces or when inflating multiple tires simultaneously. Buyers should consider the length that best suits their operational needs, balancing between mobility and storage convenience.

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some essential terms related to tire inflator hoses.

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications can help buyers ensure compatibility and quality when sourcing tire inflator hoses, especially for replacement parts in existing equipment.

Illustrative image related to tire inflator hose

MOQ is the minimum number of units a supplier is willing to sell in a single order. This term is crucial for B2B buyers as it impacts inventory management and cost efficiency. Knowing the MOQ helps in planning purchases to meet business needs without incurring excessive costs.

An RFQ is a document sent to suppliers to request pricing and terms for specific products. In the context of tire inflator hoses, submitting an RFQ can help buyers compare offers from different manufacturers, ensuring they receive the best value for their investment.

Incoterms are international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for understanding shipping costs and liabilities associated with tire inflator hose purchases.

Certification standards, such as ISO or ASTM, indicate that products meet specific quality and safety requirements. Buyers should look for hoses that comply with these standards to ensure reliability and performance in their applications.

By grasping these technical properties and industry terms, B2B buyers can navigate the market for tire inflator hoses more effectively, ensuring they make informed decisions that align with their operational needs.

The tire inflator hose market is experiencing robust growth, driven by several global trends. One significant factor is the increasing demand for portable and efficient tire inflation solutions, especially in regions with a high number of vehicles, such as Africa and South America. The rise in e-commerce and online retailing has also facilitated easy access to a variety of tire inflator products, enabling international buyers to source efficiently. Furthermore, technological advancements, such as self-locking nozzles and multi-tire inflation kits, are enhancing the functionality and appeal of tire inflator hoses, catering to the needs of both individual consumers and businesses.

Emerging B2B tech trends are transforming sourcing strategies. Digital platforms that offer comprehensive product catalogs and customer reviews are gaining traction, enabling buyers to make informed purchasing decisions. Additionally, the integration of automation and AI in inventory management is optimizing supply chains, reducing lead times, and improving overall efficiency. International buyers, particularly from Europe and the Middle East, are increasingly focused on sourcing from manufacturers that offer customization options, allowing them to meet specific market demands and customer preferences.

Sustainability is becoming a pivotal consideration in the tire inflator hose sector. As environmental awareness grows, international buyers are seeking products that minimize ecological impact. The production of tire inflator hoses often involves materials that can harm the environment if not sourced responsibly. Therefore, manufacturers are encouraged to adopt sustainable practices, such as using recycled materials or biodegradable alternatives in their products.

Ethical sourcing is equally crucial. B2B buyers are prioritizing suppliers who maintain transparent supply chains, ensuring that labor practices are fair and materials are sourced responsibly. Certifications such as ISO 14001 for environmental management systems and other ‘green’ certifications can serve as indicators of a company’s commitment to sustainability. By choosing suppliers with these credentials, buyers not only enhance their corporate social responsibility profile but also cater to a growing consumer base that values ethical considerations in product sourcing.

The tire inflator hose industry has evolved significantly over the decades. Initially, inflator hoses were simple, rubber-based products primarily used for manual inflation of tires. With advancements in technology, the introduction of automatic and portable tire inflators revolutionized the market. The development of specialized hoses, such as self-locking and quick-release variants, has further enhanced user experience and efficiency.

In recent years, the focus on customization and multi-tire inflation systems has emerged, catering to both individual consumers and commercial applications. This evolution reflects a broader trend toward convenience and efficiency, aligning with the demands of modern consumers and businesses alike. As the market continues to innovate, international buyers can expect a growing array of options designed to meet diverse needs and preferences.

How do I select the right tire inflator hose for my business needs?

Choosing the right tire inflator hose involves considering several factors such as the hose material, length, diameter, and pressure rating. Look for hoses made from durable materials like rubber or reinforced PVC that can withstand high pressure and temperature fluctuations. Additionally, consider the specific applications—whether for commercial tire service or personal use—and select a length that accommodates your workspace. Researching supplier specifications and customer reviews can also guide your decision to ensure reliability and performance.

What are the key features to look for in a tire inflator hose?

When sourcing a tire inflator hose, prioritize features like flexibility, durability, and ease of attachment. Self-locking or quick-release connectors enhance convenience during use, while braided or reinforced construction offers superior strength. Ensure the hose is compatible with various tire valves and inflators. A clear pressure gauge can also be beneficial for accurate inflation. Lastly, check for warranties or guarantees, which can indicate the manufacturer’s confidence in the product’s quality.

What customization options are available for tire inflator hoses?

Many suppliers offer customization options for tire inflator hoses, allowing you to tailor specifications to your needs. This may include custom lengths, diameters, colors, or specific connector types. Some manufacturers also provide the option to integrate branding elements, such as logos, onto the hose. Discussing your requirements with potential suppliers can reveal available customization options, ensuring that the product aligns with your brand and operational needs.

What is the typical minimum order quantity (MOQ) for tire inflator hoses?

The minimum order quantity (MOQ) for tire inflator hoses varies by supplier and can range from a few units to several hundred. Larger manufacturers may have higher MOQs due to production costs, while smaller suppliers might accommodate lower quantities. It’s essential to communicate your needs upfront, as some suppliers may be flexible with MOQs, especially for repeat customers or bulk purchases. Understanding MOQs helps in budgeting and inventory planning.

What payment terms should I expect when sourcing tire inflator hoses internationally?

Payment terms for international orders can vary significantly based on the supplier’s policies and your negotiation. Common terms include upfront payment, a deposit with the balance due upon shipment, or net payment terms such as net 30 or net 60 days. It’s advisable to discuss payment options early in the negotiation process. Utilizing secure payment methods, such as letters of credit or escrow services, can mitigate risks associated with international transactions.

How do I ensure quality assurance when sourcing tire inflator hoses?

To ensure quality assurance when sourcing tire inflator hoses, start by vetting suppliers thoroughly. Request samples before placing bulk orders to evaluate the product’s performance. Look for manufacturers with recognized quality certifications, such as ISO 9001. Additionally, inquire about their quality control processes, including testing methods and inspection protocols. Establishing clear quality expectations in your purchase agreement can also protect your interests.

What logistics considerations should I keep in mind when importing tire inflator hoses?

When importing tire inflator hoses, logistics considerations include shipping methods, customs regulations, and lead times. Determine whether air freight or sea freight is more suitable based on urgency and cost. Familiarize yourself with import duties and taxes applicable to your region. Engaging a freight forwarder can simplify the process, ensuring compliance with international shipping regulations and efficient delivery. Always plan for potential delays and communicate with your supplier to manage expectations.

How can I build a long-term relationship with my tire inflator hose supplier?

Building a long-term relationship with your tire inflator hose supplier involves consistent communication, transparency, and mutual respect. Regularly engage in discussions about product performance and market trends to foster collaboration. Provide feedback on products and services, and express appreciation for their efforts. Establishing a partnership mentality—where both parties work towards shared goals—can lead to better pricing, priority service, and potential exclusive offerings in the future.

Dominio: jacosuperiorproducts.com

Registrato: 2014 (11 anni)

Introduzione: Product Name: Lightning S2X Tire Inflator Hose Extension Self-Locking Nozzle

Price: $27.99 (originally $39.99)

Description: Patented air hose adapter for tire pumps (open flow) designed to replace standard screw-on, clip-on, or thumb-lock tire valve connectors on the air hose.

Shipping: 100% free shipping on all orders in the USA.

Availability: In stock and ready to ship.

Dominio: morrflate.com

Registrazione: 2019 (6 anni)

Introduzione: Multi Tire Inflation Deflation™ Kits from MORRFlate allow users to inflate and deflate multiple tires simultaneously. The product range includes both 4-way and 2-way tire hose kits, with options for pre-built kits or DIY kit builders where customers can select their manifold, gauge options, hose lengths, and various accessories. Key products include:

1. MORRFlate Braided Mega Quad (4-6 Tires, Up …

In the evolving landscape of tire inflator hoses, strategic sourcing remains a critical approach for international buyers. By prioritizing quality and innovation, companies can enhance their product offerings while ensuring reliability and efficiency in tire maintenance. The market is increasingly favoring advanced features such as self-locking nozzles and multi-tire inflation kits, which cater to diverse customer needs and improve operational efficiency.

Buyers from regions like Africa, South America, the Middle East, and Europe should leverage local suppliers and manufacturers to capitalize on regional advantages, such as reduced shipping costs and faster delivery times. Additionally, understanding the specific demands of local markets can guide procurement strategies, ensuring that businesses meet customer expectations effectively.

As we look ahead, the tire inflator hose market is poised for growth driven by technological advancements and increased consumer awareness. By embracing strategic sourcing practices and staying attuned to market trends, B2B buyers can secure a competitive edge. Now is the time to explore partnerships that align with your business objectives, fostering innovation and sustainability in your supply chain. Engage with suppliers who are committed to quality and innovation to ensure your business is well-positioned for future success.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.