The global market for tire pressure machines presents both opportunities and challenges for B2B buyers seeking reliable and efficient solutions. With the increasing emphasis on vehicle safety, fuel efficiency, and operational cost reduction, sourcing the right tire pressure machine has become a critical decision for businesses across various sectors. From automotive service providers in Germany to fleet operators in Brazil, understanding the diverse types of tire pressure machines and their applications is essential for optimizing performance and customer satisfaction.

This comprehensive guide delves into the various types of tire pressure machines available, their specific applications across industries, and crucial factors to consider when vetting suppliers. Buyers will gain insights into cost structures, maintenance requirements, and technological advancements that can enhance operational efficiency. Furthermore, the guide addresses regional considerations, helping international buyers from Africa, South America, the Middle East, and Europe make informed decisions tailored to their unique market dynamics.

By equipping B2B buyers with the knowledge to evaluate options critically, this guide empowers organizations to select tire pressure machines that not only meet their immediate needs but also align with long-term strategic goals. In an increasingly competitive landscape, making informed purchasing decisions can lead to improved profitability and enhanced customer loyalty.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Gonfiatori digitali per pneumatici | Automated pressure calibration, user-friendly interfaces | Gas stations, tire shops, car washes | Pro: High accuracy, increased customer satisfaction. Contro: Investimento iniziale più elevato. |

| Analog Tire Gauges | Manual pressure readings, mechanical operation | Fleet maintenance, auto repair shops | Pro: Low cost, easy maintenance. Contro: Less accuracy, slower process. |

| Portable Tire Inflators | Compact, battery-operated, easy to transport | Mobile service providers, emergency kits | Pro: Convenience, versatility. Contro: Limited power, may require frequent recharging. |

| Commercial Air Machines | High-capacity, designed for heavy usage | Large tire shops, automotive service centers | Pro: Fast inflation, durable. Contro: Higher operational costs, requires space. |

| Coin-Operated Machines | Pay-per-use, often found in public spaces | Gas stations, convenience stores | Pro: Generates additional revenue, attracts customers. Contro: Maintenance and coin collection can be cumbersome. |

Digital tire inflators are advanced machines that automatically calibrate tire pressure, often featuring user-friendly interfaces and digital displays. These machines are particularly suitable for gas stations, tire shops, and car washes, where efficiency and customer satisfaction are paramount. B2B buyers should consider the initial investment cost against the potential for increased service speed and customer retention, as high accuracy can lead to fewer customer complaints and repeat business.

Analog tire gauges utilize mechanical mechanisms to provide pressure readings and are typically favored in settings like fleet maintenance and auto repair shops. Their simplicity and low cost make them attractive for businesses with budget constraints. However, buyers should weigh the benefits of ease of maintenance against the limitations of accuracy and speed, which can affect service quality in high-volume environments.

Portable tire inflators are compact and battery-operated, making them ideal for mobile service providers and emergency kits. Their versatility allows businesses to offer on-the-go tire inflation services, which can enhance customer satisfaction. However, B2B buyers should note that while these machines provide convenience, they may have limited power and require frequent recharging, which could affect service delivery in high-demand situations.

Illustrative image related to tire pressure machine

Commercial air machines are designed for heavy usage, making them suitable for large tire shops and automotive service centers. They offer high-capacity inflation capabilities and durability, allowing businesses to serve multiple customers efficiently. However, buyers should consider the higher operational costs and the need for adequate space to accommodate these machines, as they can be larger and more complex than other types.

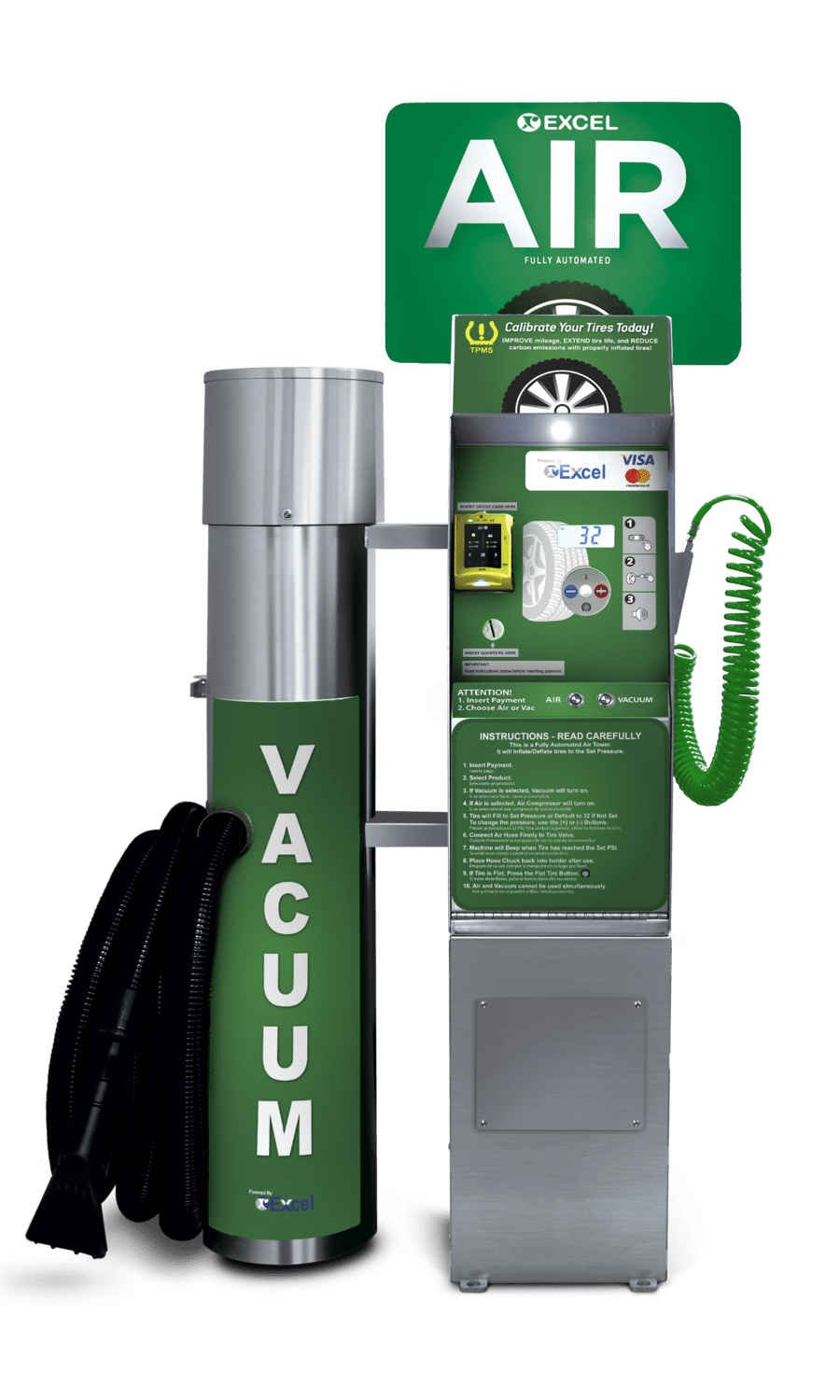

Coin-operated machines are prevalent in public spaces like gas stations and convenience stores, allowing businesses to generate additional revenue through pay-per-use services. These machines attract customers looking for quick tire inflation solutions, thereby increasing foot traffic. However, B2B buyers must be prepared for the challenges of machine maintenance and coin collection, which can add operational complexity.

| Industria/Settore | Specific Application of Tire Pressure Machine | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Gas Stations & Convenience Stores | Customer Self-Service Air Stations | Attracts more customers, increases sales through ancillary services | Reliability, ease of use, payment options (coin, card, cashless) |

| Negozi di riparazione di autoveicoli | Streamlined Tire Inflation Process | Enhances technician efficiency and improves customer satisfaction | Durability, precision, user-friendly interface |

| Gestione della flotta | Regular Tire Maintenance for Vehicles | Reduces fuel consumption and extends tire lifespan | Calibration accuracy, maintenance support, robust design |

| Car Wash Facilities | Integrated Air Inflation Stations | Boosts customer loyalty and drives additional service sales | Space efficiency, ease of integration, service support |

| Car Dealerships | Pre-Delivery Tire Checks | Ensures vehicle safety and enhances customer trust | Accuracy, speed of inflation, compatibility with various vehicle types |

Gas stations and convenience stores utilize tire pressure machines as self-service air stations to enhance customer experience. By providing easy access to tire inflation, these businesses attract more customers, leading to increased foot traffic and ancillary sales. For international buyers, particularly in regions like Africa and South America, sourcing reliable and user-friendly machines is critical. Payment options should cater to local preferences, including coin, credit card, and cashless systems, ensuring a seamless user experience.

In automotive repair shops, tire pressure machines streamline the tire inflation process, allowing technicians to focus on other critical tasks. These machines not only improve operational efficiency but also enhance customer satisfaction by ensuring accurate tire pressure calibration. Buyers from regions like Europe and the Middle East should prioritize machines that are durable and easy to use, as well as those that offer precise inflation capabilities to maintain safety standards.

Fleet management companies leverage tire pressure machines for regular maintenance of their vehicles, which is essential for reducing fuel consumption and extending tire lifespan. Consistent tire pressure management leads to better vehicle performance and lower operational costs. When sourcing machines, fleet managers should look for high calibration accuracy, ease of maintenance, and robust designs that can withstand frequent use in diverse environments.

Illustrative image related to tire pressure machine

Car wash facilities benefit from integrating tire pressure machines into their service offerings, as these stations can significantly boost customer loyalty and encourage repeat visits. By providing added convenience, car washes can drive additional service sales, such as detailing or oil changes. Buyers in this sector should consider machines that are space-efficient and easy to integrate into existing setups, along with reliable service support to minimize downtime.

Car dealerships use tire pressure machines for pre-delivery checks to ensure vehicle safety and reliability. This practice not only enhances customer trust but also contributes to a positive buying experience. International buyers should focus on machines that offer quick and accurate inflation, compatibility with various vehicle types, and support for diverse tire technologies, especially as the automotive landscape evolves with electric and hybrid vehicles.

Il problema: One of the significant challenges faced by B2B buyers, especially in tire shops and auto repair facilities, is ensuring the accuracy of tire pressure machines. Inaccurate tire readings can lead to poor vehicle performance, increased fuel consumption, and compromised safety for drivers. This is particularly concerning in regions with varied climates, such as Africa and Europe, where temperature fluctuations can affect tire pressure. For businesses, the repercussions can be significant—ranging from customer dissatisfaction to increased liability risks.

La soluzione: To mitigate this issue, B2B buyers should prioritize investing in high-quality, precision-engineered tire pressure machines that offer automatic calibration features. When sourcing these machines, it’s essential to look for models that are certified by recognized automotive standards organizations. Additionally, regular maintenance checks and recalibration should be scheduled to ensure ongoing accuracy. Businesses can also implement a routine training program for technicians, emphasizing the importance of proper usage and monitoring of the equipment. This approach not only enhances safety but also improves customer trust and satisfaction.

Illustrative image related to tire pressure machine

Il problema: Equipment malfunctions can lead to significant operational downtime, causing frustration for both employees and customers. For tire service centers, this issue is compounded during peak seasons, such as before major holidays or during adverse weather conditions when tire maintenance demands increase. An unreliable tire pressure machine can slow down service times, leading to lost revenue and a damaged reputation.

La soluzione: To prevent downtime, B2B buyers should opt for tire pressure machines that come with comprehensive warranties and excellent customer support. It’s advisable to choose equipment from manufacturers with a proven track record of reliability and service excellence. Additionally, creating a partnership with local service technicians for prompt repairs and maintenance is crucial. Implementing a predictive maintenance schedule based on usage analytics can also help identify potential issues before they lead to equipment failure. This proactive approach ensures that the machines remain operational and efficient, thus maintaining service levels during high-demand periods.

Il problema: In an increasingly competitive market, customer experience can make or break a business. Tire service providers often struggle with outdated or complicated tire pressure machines that deter customers from using their services. This is especially true in regions where consumers expect quick and efficient service, such as in urban centers in South America and Europe. A cumbersome user interface can lead to frustration, negatively impacting customer retention and overall business reputation.

La soluzione: To enhance customer experience, B2B buyers should invest in modern tire pressure machines that feature intuitive, user-friendly interfaces. Machines equipped with digital displays, clear instructions, and multi-language support can significantly improve usability for diverse customer bases. Additionally, offering payment options that include cashless transactions can streamline the process, making it more convenient for users. Training staff to assist customers in using these machines can further enhance service quality, ensuring that customers feel supported throughout their experience. By prioritizing user experience, businesses can foster customer loyalty and encourage repeat visits, ultimately driving revenue growth.

When selecting materials for tire pressure machines, it is essential to consider factors such as durability, cost, and compatibility with various media. Below, we analyze four common materials used in tire pressure machines, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to tire pressure machine

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. It typically has a temperature rating of up to 150°C and can handle pressures of around 300 psi, making it suitable for tire pressure applications.

Pro: Aluminum is durable and lightweight, which makes it easy to handle and install. It is also resistant to rust, ensuring longevity in various environments.

Contro: While aluminum is generally cost-effective, it can be more expensive than some alternatives like plastic. Manufacturing complexity can increase if intricate designs are required.

Impatto sull'applicazione: Aluminum is compatible with air and nitrogen, making it suitable for various tire inflation applications. Its lightweight nature can improve mobility in portable machines.

Considerazioni per gli acquirenti internazionali: Compliance with standards such as ASTM and DIN is critical. Buyers in regions like Europe and South America may prefer aluminum due to its lightweight properties, which can enhance operational efficiency.

Steel, particularly stainless steel, is another common material used in tire pressure machines. It boasts high strength and can withstand high pressures (up to 500 psi) and temperatures (up to 200°C).

Illustrative image related to tire pressure machine

Pro: Steel’s durability and strength make it ideal for heavy-duty applications. It is also relatively low-cost compared to other metals.

Contro: Steel is heavier than aluminum, which can be a disadvantage in portable applications. It is also prone to corrosion if not properly treated, which can affect longevity.

Impatto sull'applicazione: Steel is well-suited for high-pressure applications and can handle various gases, including air and nitrogen.

Considerazioni per gli acquirenti internazionali: Buyers should be aware of corrosion resistance requirements, especially in humid regions like parts of Africa and the Middle East. Compliance with local standards is essential for market acceptance.

Plastics, particularly high-density polyethylene (HDPE) and polycarbonate, are often used in the construction of tire pressure machines. These materials offer good chemical resistance and can handle temperatures up to 80°C and pressures around 150 psi.

Pro: Plastics are lightweight, cost-effective, and resistant to many chemicals, making them suitable for various environments.

Contro: Plastics may not be as durable as metals and can degrade over time, especially under UV exposure or extreme temperatures.

Impatto sull'applicazione: Plastic components are ideal for non-pressurized parts of tire pressure machines, such as housings and interfaces.

Illustrative image related to tire pressure machine

Considerazioni per gli acquirenti internazionali: Buyers should ensure that the selected plastic material complies with local regulations regarding durability and safety, particularly in regions with stringent environmental laws.

Rubber is primarily used in seals and hoses within tire pressure machines. It can withstand pressures of up to 200 psi and offers good flexibility and resilience.

Pro: Rubber is excellent for creating airtight seals, ensuring no air leakage occurs during inflation. It is also cost-effective and easy to replace.

Contro: Rubber can degrade over time due to exposure to ozone and UV light, requiring regular maintenance and replacement.

Impatto sull'applicazione: Rubber is essential for ensuring the reliability of tire inflation systems by maintaining airtight connections.

Considerazioni per gli acquirenti internazionali: Buyers should consider the climatic conditions of their regions, as rubber may require more frequent replacement in areas with extreme weather conditions.

| Materiale | Typical Use Case for tire pressure machine | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Alluminio | Structural components and housings | Leggero e resistente alla corrosione | Higher cost than some alternatives | Medio |

| Acciaio | High-pressure tanks and frames | Elevata resistenza e durata | Heavier and prone to corrosion | Basso |

| Plastica | Alloggiamenti e componenti non pressurizzati | Economico e leggero | Meno durevole dei metalli | Basso |

| Gomma | Seals and hoses | Excellent sealing properties | Si degrada nel tempo | Basso |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their tire pressure machine offerings, ensuring they choose materials that align with their operational needs and regional considerations.

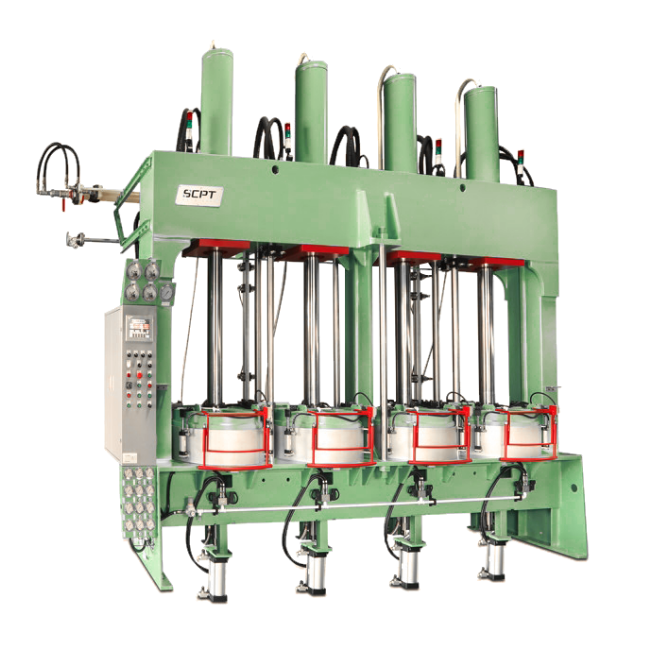

The manufacturing of tire pressure machines involves several critical stages that ensure both functionality and reliability. These stages typically include material preparation, forming, assembly, and finishing.

Illustrative image related to tire pressure machine

Preparazione del materiale

The process begins with sourcing high-quality materials that meet industry standards. Common materials include durable metals for structural components and advanced plastics for user interfaces. Suppliers often conduct initial quality checks to ensure the materials are free from defects and suitable for use in tire pressure machines. This stage is crucial as the integrity of the materials directly impacts the performance and longevity of the final product.

Tecniche di formatura

Once materials are prepared, they undergo various forming techniques. Metal components may be shaped through processes such as stamping, bending, and machining. For plastics, injection molding is commonly used to create parts like buttons and casing. These techniques are selected based on the design specifications and the intended application of the tire pressure machine, ensuring that each part can withstand operational stresses.

Processo di assemblaggio

After forming, the components are assembled. This stage often employs automated assembly lines alongside skilled labor to ensure precision. Key elements such as sensors, digital displays, and air valves are integrated into the machines. The assembly process is crucial as it requires meticulous attention to detail to ensure all components work seamlessly together.

Tocchi finali

The final stage of manufacturing involves finishing processes such as painting, coating, or applying protective films. These processes not only enhance the machine’s aesthetics but also provide additional protection against environmental factors such as moisture and dust. Quality checks during this stage ensure that the machines meet the expected durability and performance standards.

Quality assurance (QA) is integral to the manufacturing of tire pressure machines, ensuring that products meet international standards and customer expectations.

Illustrative image related to tire pressure machine

What International Standards Should B2B Buyers Look For?

B2B buyers should look for manufacturers that comply with international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with CE marking indicates that the product meets European safety and health standards, while adherence to API (American Petroleum Institute) standards is important for equipment used in petroleum-related environments. These certifications can be indicators of a manufacturer’s commitment to quality and safety.

Quali sono i principali punti di controllo della qualità nel processo di produzione?

Quality control (QC) checkpoints are established at various stages of the manufacturing process, including:

Testing methods are vital to ensuring that tire pressure machines operate effectively and safely. Common testing methods include:

B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control practices of potential suppliers:

Illustrative image related to tire pressure machine

International B2B buyers must navigate several nuances related to quality control:

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing tire pressure machines, ensuring they select reliable suppliers that meet their operational needs.

This guide is designed to assist B2B buyers in the effective sourcing of tire pressure machines. By following this step-by-step checklist, you will ensure that you select the right equipment that meets your operational needs while also enhancing customer satisfaction and safety.

Clearly outline the technical requirements for the tire pressure machine based on your business model. Consider factors such as the type of vehicles you service, the desired inflation speed, and the accuracy level required. Knowing these specifications helps narrow down options and ensures that the machine can handle your operational demands.

Establish a realistic budget that encompasses not just the purchase price, but also installation, maintenance, and potential operational costs. This step is critical as it sets the parameters for your search and ensures you don’t overspend or compromise on quality. Be prepared for variations in pricing based on features and technology.

Illustrative image related to tire pressure machine

Before making a decision, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from previous clients in similar industries or geographical locations. This due diligence can provide insights into the supplier’s reliability, product quality, and customer service, which are essential for long-term partnerships.

Investigate the features offered by different tire pressure machines. Look for advanced functionalities such as digital interfaces, automatic pressure calibration, and user-friendly designs. Such features can enhance efficiency, improve user experience, and ultimately lead to greater customer satisfaction.

Ensure that the tire pressure machine complies with local regulations and industry standards specific to your region. This is crucial for avoiding fines and ensuring safety. Familiarize yourself with the regulations in your target markets, especially if you are operating in multiple countries.

Whenever possible, request a trial or demonstration of the tire pressure machines you are considering. This allows you to evaluate the machine’s performance in real-world conditions and assess its usability for both your staff and customers. Observing the machine in action can highlight potential issues that may not be apparent from specifications alone.

Once you’ve selected a supplier, negotiate terms that include warranty coverage, maintenance support, and potential revenue-sharing options. Robust after-sales support is vital for minimizing downtime and ensuring consistent service quality. Establish clear communication channels for ongoing support to address any issues that may arise post-purchase.

By following these steps, B2B buyers can make informed decisions when sourcing tire pressure machines, ensuring that they invest in products that enhance operational efficiency and customer satisfaction.

When considering the sourcing of tire pressure machines, B2B buyers must navigate a complex cost structure and pricing model that influences their purchasing decisions. Understanding these components can help buyers make informed choices and negotiate effectively.

The cost structure of tire pressure machines typically consists of several key components:

I materiali: The primary materials used in tire pressure machines include metal alloys for the body, plastics for interfaces, and electronic components for digital displays. The quality of these materials significantly impacts durability and performance, thus affecting overall costs.

Lavoro: Labor costs vary by region and are influenced by the complexity of the assembly process. Skilled labor is often required for the assembly of electronic components, which can increase labor costs, especially in countries with higher wage standards.

Spese generali di produzione: This includes costs related to factory operations, utilities, and equipment maintenance. Overhead can fluctuate based on the scale of production and efficiency of operations.

Utensili: The initial investment in tooling can be substantial, particularly for customized machines. Tooling costs are amortized over production volume, making them a critical factor for buyers considering larger orders.

Controllo qualità (CQ): Ensuring the machines meet safety and performance standards involves additional costs. Rigorous QC processes are essential, particularly for machines that will be used in commercial settings.

Logistica: Shipping and handling can add significant costs, especially for international buyers. Import duties, taxes, and freight costs should all be factored into the total cost.

Margine: Suppliers typically include a profit margin that can vary based on market demand, competition, and the uniqueness of the product. Understanding the supplier’s margin can aid in negotiations.

Several factors can influence the pricing of tire pressure machines:

Volume e quantità minima d'ordine (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs to optimize cost efficiency.

Specifiche e personalizzazione: Custom features or specifications can significantly increase costs. Buyers should balance the need for customization with budget constraints.

Materiali e certificazioni di qualità: Machines made from high-quality materials or those that meet specific certifications (e.g., ISO standards) will typically be priced higher. Buyers should assess the importance of these factors based on their operational requirements.

Fattori di fornitura: The reputation and reliability of suppliers can affect pricing. Established suppliers with a history of quality and service may command higher prices but can offer better long-term value.

Incoterms: Understanding shipping terms is crucial for cost calculations. Incoterms dictate who bears the risk and costs during shipping, which can impact the final price paid by the buyer.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips for effective negotiation:

Illustrative image related to tire pressure machine

Ricerca sui prezzi di mercato: Understanding the market landscape and average prices can empower buyers during negotiations. This knowledge helps in identifying fair pricing and recognizing when a supplier’s quote is inflated.

Attenzione al costo totale di proprietà (TCO): Buyers should consider not just the purchase price but also the long-term costs associated with maintenance, operational efficiency, and potential downtime. This holistic view can justify a higher upfront investment if it leads to lower TCO.

Leverage Volume Discounts: If planning to purchase multiple units, negotiate for volume discounts. Suppliers are often willing to reduce prices for larger orders.

Explore Flexible Payment Terms: Discussing payment terms can lead to better cash flow management, which is essential for businesses operating in fluctuating economic environments.

Essere consapevoli delle sfumature dei prezzi: Each market has unique pricing dynamics. For instance, currency fluctuations, local economic conditions, and trade tariffs can all impact pricing. Buyers should stay informed about these factors to make better purchasing decisions.

While sourcing tire pressure machines involves navigating a multifaceted cost structure, understanding the key components and price influencers can empower B2B buyers. By applying strategic negotiation tactics and focusing on the total cost of ownership, buyers can optimize their purchasing decisions for maximum value. Note that prices can vary widely based on specifications and market conditions, so it’s advisable to obtain multiple quotes to ensure competitive pricing.

When considering tire inflation solutions, B2B buyers must evaluate various alternatives to the traditional tire pressure machine. This analysis focuses on two viable alternatives: manual tire inflators and digital tire pressure monitoring systems (TPMS). Each option presents unique advantages and challenges, making it essential to assess their suitability for different business needs.

| Aspetto di confronto | Tire Pressure Machine | Manual Tire Inflator | Digital Tire Pressure Monitoring System (TPMS) |

|---|---|---|---|

| Prestazioni | Provides consistent inflation with precise pressure settings. | Varies by operator skill and may lead to inaccuracies. | Continuously monitors tire pressure, alerting users to deviations. |

| Costo | Higher upfront investment, but potential for revenue generation. | Lower initial cost, but may require frequent replacement. | Moderate cost; can save on fuel and maintenance in the long run. |

| Facilità di implementazione | Requires installation and initial setup. | Simple to use and portable, no installation needed. | Can be integrated into existing vehicle systems, but may require professional installation. |

| Manutenzione | Regular maintenance needed to ensure accuracy and functionality. | Minimal maintenance; however, replacement is common. | Low maintenance, but requires occasional battery changes or system checks. |

| Il miglior caso d'uso | Ideal for commercial settings like gas stations and tire shops. | Suitable for personal use or small-scale operations. | Best for fleet management and vehicle owners seeking proactive maintenance. |

Manual tire inflators are a cost-effective solution for businesses that require basic tire inflation capabilities without the need for complex technology. These devices are portable and easy to operate, making them suitable for individual users or smaller businesses that do not require a high volume of tire service. However, the performance heavily depends on the operator’s skill, potentially leading to inaccuracies in tire pressure. Additionally, while the initial costs are low, the need for frequent replacements can add up over time, making them less economical in the long run.

Digital TPMS offers a modern approach to tire management by continuously monitoring tire pressure and alerting users to any changes. This real-time feedback can enhance safety and fuel efficiency, making it a smart investment for fleet operators and businesses that prioritize vehicle maintenance. However, the installation can be more complex, and costs can vary depending on the system’s sophistication. While the maintenance requirements are low, occasional battery changes may be necessary. The upfront investment may deter some businesses, but the long-term savings on fuel and tire wear can justify the cost.

Selecting the right tire inflation solution depends on your business model, customer base, and operational goals. For high-traffic environments such as gas stations or tire shops, a tire pressure machine may be the best choice due to its consistent performance and potential for revenue generation. Manual tire inflators are ideal for small businesses or personal use, where budget constraints are a primary concern. Meanwhile, digital TPMS is well-suited for fleet operators aiming for proactive maintenance and safety. By carefully assessing these factors, B2B buyers can make informed decisions that align with their specific needs and maximize operational efficiency.

When considering the procurement of tire pressure machines, several technical specifications stand out as critical for ensuring optimal performance and reliability. Here are the essential properties to evaluate:

The material used in the construction of tire pressure machines affects durability and longevity. Common materials include stainless steel and high-grade plastics. Stainless steel is resistant to corrosion and wear, making it suitable for outdoor and high-traffic environments, while high-grade plastics can offer lightweight and cost-effective solutions. Understanding material grade helps buyers select machines that can withstand local environmental conditions, particularly in regions with extreme weather.

The pressure range indicates the minimum and maximum tire pressure that the machine can inflate. Most machines operate between 0 to 100 psi (pounds per square inch), but specialized models may go higher. Selecting a machine with an appropriate pressure range is crucial for servicing a diverse fleet of vehicles, ensuring compatibility with various tire specifications.

Accuracy is vital for tire pressure machines, with tolerances typically ranging from ±1 psi to ±3 psi. This specification indicates how closely the machine can match the set pressure. High accuracy is essential for maintaining tire health, improving fuel efficiency, and ensuring driver safety. B2B buyers should prioritize machines with tighter tolerances for better service delivery.

Illustrative image related to tire pressure machine

Inflation speed is a measure of how quickly a tire can be filled to the desired pressure. It is usually expressed in liters per minute (L/min). Faster inflation speeds enhance customer satisfaction and reduce wait times, making it a key performance indicator for businesses that rely on quick service, such as gas stations and tire shops.

A user-friendly interface simplifies the process of tire inflation, making it accessible for customers with varying technical skills. Additionally, modern machines often come with multiple payment options, including coins, credit cards, or contactless payments. Offering a variety of payment methods can increase usage rates and improve the customer experience, leading to higher revenues for businesses.

Understanding industry jargon is essential for effective communication and negotiation in the B2B market. Here are some common terms associated with tire pressure machines:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing tire pressure machines, buyers may look for OEM products to ensure quality and compatibility with existing systems. Partnering with reputable OEMs can guarantee reliable support and service.

Illustrative image related to tire pressure machine

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and upfront costs. Understanding the MOQ helps businesses plan their purchases more effectively, especially when managing cash flow.

An RFQ is a document issued by potential buyers to suppliers to obtain price quotes for specific products. In the context of tire pressure machines, submitting an RFQ allows buyers to compare pricing, features, and terms from multiple suppliers, facilitating informed decision-making.

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify issues like shipping costs, insurance, and risk management. Familiarity with Incoterms helps B2B buyers navigate international logistics effectively, particularly when sourcing from suppliers across different regions.

Illustrative image related to tire pressure machine

These terms outline the conditions under which a manufacturer will repair or replace a defective product. Understanding warranty coverage is essential for B2B buyers to mitigate risks associated with equipment failures. Solid warranty and support terms can significantly influence a buyer’s choice, ensuring peace of mind in the procurement process.

By familiarizing themselves with these technical properties and industry terms, B2B buyers can make informed decisions when selecting tire pressure machines that align with their operational needs and business goals.

The tire pressure machine sector is experiencing notable growth, driven by increasing awareness of vehicle safety and fuel efficiency. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are witnessing a shift towards digital and automated tire inflators. These machines not only provide accurate tire pressure readings but also enhance user experience with features such as cashless payment options and user-friendly interfaces. The rising popularity of electric vehicles (EVs) further amplifies the demand for sophisticated tire pressure solutions, as maintaining optimal tire pressure is crucial for maximizing EV efficiency.

Emerging technologies like IoT (Internet of Things) are becoming increasingly integrated into tire pressure machines. These innovations allow for real-time monitoring of tire pressure data and performance analytics, offering businesses insights that can lead to improved service delivery and customer satisfaction. Additionally, B2B sourcing trends reflect a growing preference for suppliers who can provide comprehensive solutions, including maintenance and customer support. This trend is particularly pronounced in markets like Germany and Brazil, where service quality and reliability are paramount.

As the market evolves, buyers are also looking at partnerships that can enhance their service offerings, such as revenue-sharing models with suppliers. This not only minimizes upfront costs but also allows businesses to provide value-added services to their customers, thereby driving traffic and increasing sales in their establishments.

Illustrative image related to tire pressure machine

Sustainability is becoming a critical consideration for B2B buyers in the tire pressure machine sector. The environmental impact of manufacturing and operating these machines is under scrutiny, prompting a shift towards ethical sourcing practices. Companies are increasingly focusing on minimizing their carbon footprints by selecting suppliers who utilize sustainable materials and processes. Certifications such as ISO 14001, which emphasizes effective environmental management systems, are gaining traction among buyers seeking to enhance their sustainability credentials.

Moreover, there is a growing demand for products made from recyclable materials and those that comply with eco-friendly standards. Suppliers that can demonstrate a commitment to sustainable practices not only attract environmentally-conscious buyers but also position themselves favorably in competitive markets. In regions like Europe, where regulatory frameworks are stringent, businesses are more inclined to partner with manufacturers that prioritize sustainability in their operations.

As tire pressure machines evolve, incorporating energy-efficient technologies will also become essential. These advancements not only reduce operational costs for businesses but also align with the global shift towards greener practices, appealing to a broader customer base that values sustainability.

The evolution of tire pressure machines dates back to the early 20th century when manual inflation methods dominated. Over the decades, technological advancements have transformed these machines into sophisticated, automated systems. The introduction of digital tire inflators in the late 1990s marked a significant turning point, offering enhanced accuracy and user-friendliness.

Illustrative image related to tire pressure machine

As vehicle safety standards have evolved, the importance of maintaining proper tire pressure has become more pronounced. Modern tire pressure machines now incorporate features such as automatic shut-off, real-time pressure monitoring, and even integration with vehicle onboard systems. For B2B buyers, understanding this historical context is vital, as it highlights the ongoing innovation in the sector and the necessity of adopting state-of-the-art solutions that meet contemporary safety and efficiency standards.

In summary, the tire pressure machine sector is characterized by rapid technological advancements, a strong emphasis on sustainability, and an evolving historical landscape that shapes current market dynamics. B2B buyers must navigate these trends to make informed sourcing decisions that align with their operational goals and customer expectations.

How do I choose the right tire pressure machine for my business?

Selecting the appropriate tire pressure machine involves evaluating your specific business needs, such as the volume of vehicles serviced and the types of tires handled. Consider whether you need a manual or digital machine; digital models often provide greater accuracy and user-friendliness. Additionally, assess features like inflation speed, pressure calibration capabilities, and ease of maintenance. Request product demonstrations from suppliers and gather feedback from current users to ensure you make an informed decision that aligns with your operational goals.

What are the key features to look for in a tire pressure machine?

When sourcing a tire pressure machine, focus on essential features such as accuracy, speed, and ease of use. Look for machines that offer digital readouts, automatic shut-off when the desired pressure is reached, and compatibility with various tire types. Other beneficial features include integrated air compressors, user-friendly interfaces, and maintenance alerts. Additionally, consider the machine’s durability and warranty terms to ensure long-term reliability, especially in high-traffic environments like tire shops or gas stations.

What is the typical lead time for ordering tire pressure machines internationally?

Lead times for international orders of tire pressure machines can vary significantly based on the supplier’s location, production capacity, and shipping logistics. Generally, you can expect lead times to range from 4 to 12 weeks. Factors such as customizations, order quantities, and the shipping method selected (air or sea freight) will also impact delivery times. It’s advisable to communicate directly with suppliers to clarify timelines and ensure alignment with your business needs.

How can I vet suppliers of tire pressure machines for quality and reliability?

To vet suppliers effectively, start by researching their reputation within the industry through customer reviews and testimonials. Request references from existing clients to gain insights into their experiences. Additionally, check for certifications and compliance with international standards, which indicate a commitment to quality. Consider visiting manufacturing facilities if feasible, or request product samples to assess quality firsthand. A robust due diligence process will help you select a reliable supplier that meets your business requirements.

What are the common payment terms when purchasing tire pressure machines?

Payment terms can vary widely among suppliers and may include options such as advance payment, net 30/60/90 days, or payment upon delivery. In international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. Discuss and negotiate terms upfront to avoid any misunderstandings later. Additionally, inquire about any available financing options or discounts for bulk orders, which can help optimize your cash flow.

Can tire pressure machines be customized to fit specific business needs?

Yes, many manufacturers offer customization options for tire pressure machines to cater to specific business requirements. Customizations may include branding, unique color schemes, or additional features such as integrated payment systems or data tracking capabilities. When discussing customization, clearly outline your needs and expectations to the supplier. Keep in mind that custom features may influence lead times and costs, so factor these into your budgeting and planning.

What logistics considerations should I be aware of when importing tire pressure machines?

When importing tire pressure machines, consider logistics factors such as shipping methods, customs regulations, and import duties. Research the best transportation options (air vs. sea) based on cost and urgency. Additionally, ensure compliance with local regulations regarding machinery imports, which may include certifications or inspections. Collaborate with a reliable freight forwarder who can guide you through the logistics process, helping to streamline customs clearance and ensure timely delivery.

What quality assurance measures should I expect from suppliers of tire pressure machines?

Reputable suppliers should have established quality assurance measures in place, including regular product testing and adherence to international standards. Inquire about their manufacturing processes, including quality control protocols and certifications (e.g., ISO). A thorough quality assurance program should also include post-sale support, such as warranties and maintenance services. Establishing clear expectations regarding quality will help ensure that the machines you receive meet your operational standards and contribute to long-term performance.

Dominio: exceltiregauge.com

Registrato: 2004 (21 anni)

Introduzione: High-Quality Air Machines & Tire Inflators from Excel Tire Gauge include: SC09-SS Pay Air Machine, SC05-SS Free Air Machine, SC05-SS Kiosk Air Machine, SCWM-23 Wall Mount Air Machine, PNT PRO Automatic Tire Inflator, and PNT 4 Automatic Tire Inflator. The products are designed for various industries including gas stations, car washes, tire shops, auto repair, quick lube, fleets, rental cars, and c…

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: Automatic air station for vehicle tires, typically found at locations like Wawa or Sheetz. Features include: setting tire pressure using up and down arrows (default pressure is usually 32 PSI), nozzle attachment for tire valve, automatic air pumping with pressure checks, and an audible beep when finished.

Dominio: target.com

Registrato: 1997 (28 anni)

Introduzione: This company, Target – Tire Pressure Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

As the global market for tire pressure machines continues to evolve, strategic sourcing emerges as a critical factor for B2B buyers aiming to enhance their operational efficiency and customer satisfaction. The insights gained from diverse industries highlight the importance of investing in high-quality, user-friendly inflation solutions that not only improve tire performance but also increase foot traffic and revenue for businesses.

By selecting reliable suppliers, companies can ensure they are equipped with durable and innovative tire pressure machines that cater to the specific needs of their clientele, whether in gas stations, tire shops, or car washes. The integration of digital air machines offers a modern approach to tire inflation, enhancing the user experience while providing real-time data analytics for improved decision-making.

Looking ahead, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize partnerships that emphasize quality, customer service, and technological advancement. Embrace the opportunity to differentiate your business in a competitive landscape by leveraging cutting-edge tire pressure solutions. Make the strategic choice today to invest in superior tire inflation technology, and watch your customer satisfaction and operational efficiency soar.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.

Illustrative image related to tire pressure machine