In the fast-paced world of logistics and transportation, the efficiency of a fleet hinges significantly on maintaining optimal tire pressure. For international B2B buyers seeking to source a reliable 4 tire inflation system, the challenge often lies in navigating a diverse market filled with varying technologies, pricing structures, and supplier reputations. This guide serves as an essential resource for those looking to streamline their tire management processes, ensuring that vehicles operate safely and efficiently across diverse terrains and conditions.

Throughout this comprehensive guide, we will explore the different types of 4 tire inflation systems available, including manual and automated options, as well as their various applications in sectors such as transportation, agriculture, and construction. We will also delve into the critical aspects of supplier vetting, providing insights on how to assess potential partners based on quality, service, and reliability. Additionally, we will outline cost considerations, helping you to make budget-conscious decisions without compromising on performance.

By equipping B2B buyers from regions such as Africa, South America, the Middle East, and Europe—particularly Germany and Saudi Arabia—with the knowledge to make informed purchasing decisions, this guide empowers you to enhance your fleet’s operational efficiency. Whether you are expanding your supplier network or optimizing your existing tire inflation solutions, this resource will help you navigate the complexities of the global market with confidence.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Multi Tire Inflation Kits | Allows simultaneous inflation and deflation of multiple tires; offers customizable options for hose lengths and configurations. | Off-road vehicles, fleet management, construction vehicles. | Pro: Efficient, customizable, saves time. Contro: May require additional setup for DIY kits. |

| Air Delivery Systems | Integrated with onboard compressors; includes pressure regulators and blow-off valves for precise control. | Heavy-duty vehicles, off-road adventures, emergency services. | Pro: Reliable, quick setup, dual air source compatibility. Contro: Costo iniziale più elevato. |

| Modular Inflation Systems | Comprises interchangeable components for scalability; suitable for different vehicle types. | Commercial fleets, automotive service providers, logistics. | Pro: Flexible, easy to upgrade; can adapt to various applications. Contro: Complexity in assembly may deter some users. |

| Digital Inflation Controllers | Features digital gauges and automatic pressure adjustments; often includes remote operation capabilities. | Automotive repair shops, racing teams, and commercial transport. | Pro: Enhanced accuracy, user-friendly, reduces manual errors. Contro: Requires power source and may be more expensive. |

| Manual Inflation Kits | Basic systems using manual pumps; often portable and easy to store. | Small businesses, personal use, emergency kits. | Pro: Cost-effective, simple to use, portable. Contro: Labor-intensive, slower compared to automated systems. |

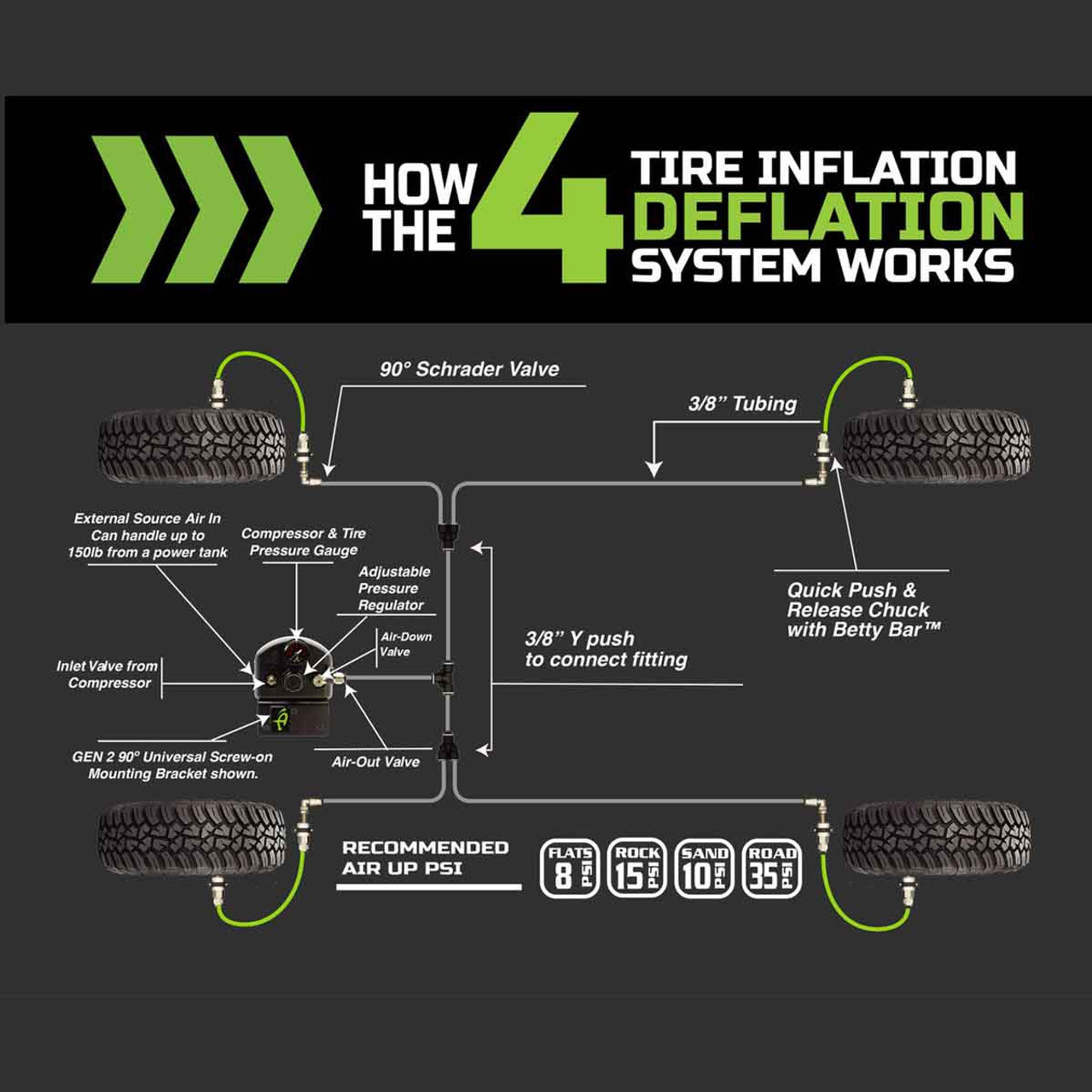

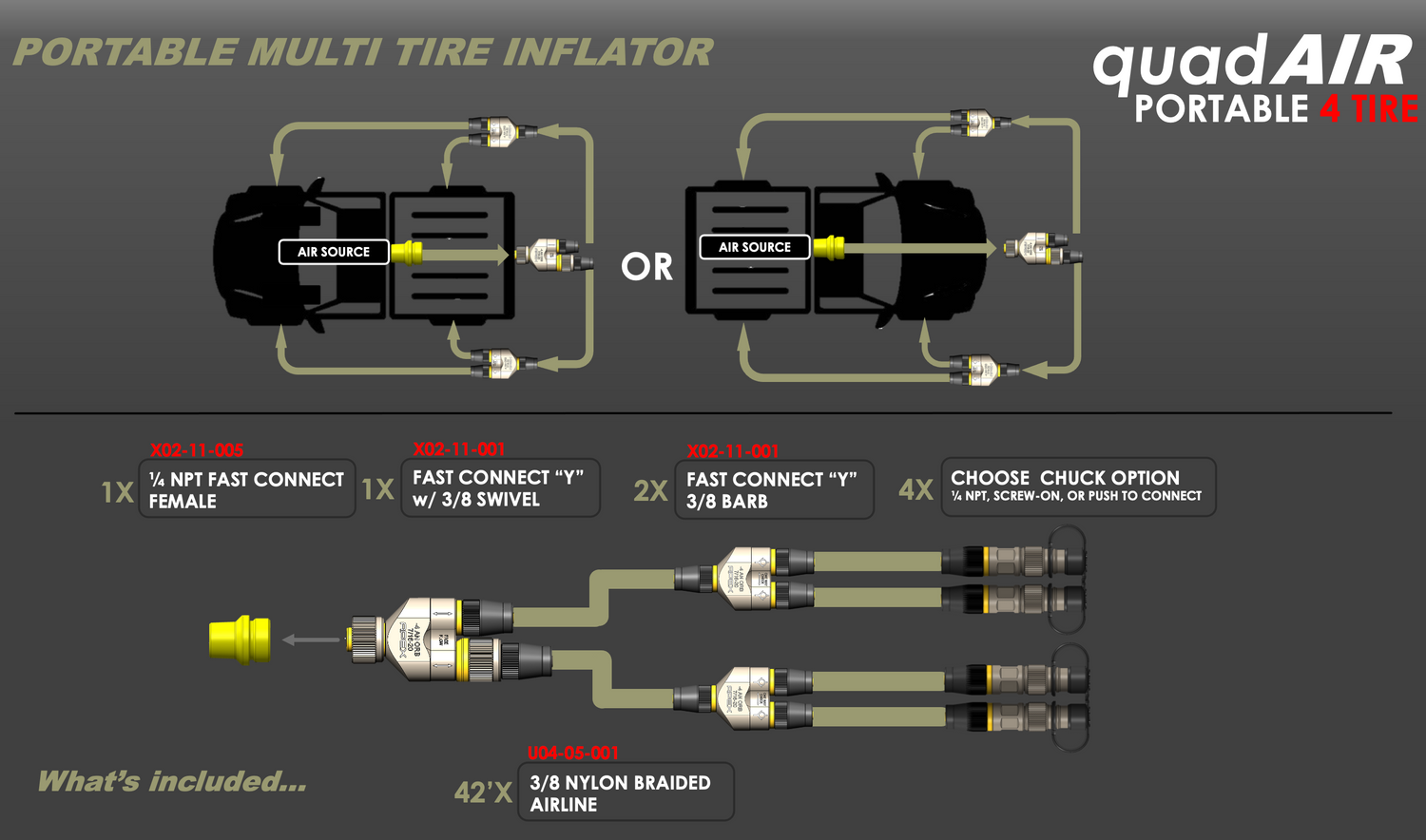

Multi Tire Inflation Kits are designed to inflate or deflate several tires simultaneously, making them ideal for off-road and fleet vehicles. These kits often come in various configurations, allowing businesses to customize hose lengths and fittings according to their needs. Key purchasing considerations include the kit’s compatibility with existing air compressors and the ease of use, particularly for operators who may not have extensive mechanical experience.

Air Delivery Systems integrate with onboard compressors, enabling users to manage tire pressure with precision. These systems feature advanced components like pressure regulators and blow-off valves, ensuring safe air delivery. They are particularly suitable for heavy-duty applications, such as emergency services and off-road adventures. B2B buyers should consider the system’s installation requirements and compatibility with different vehicle types to ensure optimal performance.

Modular Inflation Systems are characterized by interchangeable components that allow for scalability and adaptability. This makes them perfect for commercial fleets or automotive service providers that may need to adjust their setup based on varying vehicle types. When purchasing, businesses should evaluate the ease of assembly and the potential for future upgrades, which can provide long-term value and efficiency.

Illustrative image related to 4 tire inflation system

Digital Inflation Controllers provide enhanced accuracy in tire pressure management, often featuring automatic adjustments and remote operation capabilities. These systems are particularly beneficial for automotive repair shops and racing teams, where precision is crucial. Buyers should assess the power requirements and initial investment costs, as these systems can be more expensive but may offer significant time savings and reduced manual errors.

Manual Inflation Kits are straightforward systems that utilize manual pumps, making them a cost-effective solution for small businesses or personal use. While they are portable and easy to store, they require more labor and time compared to automated systems. Businesses should consider their operational needs and the frequency of use when deciding whether to invest in a manual kit or opt for a more advanced solution.

| Industria/Settore | Specific Application of 4 Tire Inflation System | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Riparazione di autoveicoli | Quick tire inflation for vehicle servicing | Reduces downtime, enhances customer satisfaction | Compatibility with various tire sizes and types |

| Agricoltura | Inflation control for agricultural vehicles | Optimizes fuel efficiency and improves traction | Durability in harsh environments and ease of use |

| Costruzione | Managing tire pressure for heavy machinery | Enhances safety and extends equipment lifespan | Ability to handle high-pressure requirements |

| Trasporto e logistica | Efficient tire management for fleets | Lowers maintenance costs and improves operational efficiency | Rapid inflation/deflation features and portability |

| Off-Road & Adventure | Tire pressure adjustment for off-road vehicles | Increases performance and safety on rugged terrains | Compatibility with portable compressors and rugged design |

In automotive repair, a 4 tire inflation system streamlines the process of inflating tires during routine services or repairs. By allowing technicians to inflate all four tires simultaneously, it minimizes the time spent on each vehicle, leading to increased throughput and enhanced customer satisfaction. For B2B buyers in this sector, compatibility with various tire sizes and types is crucial, as well as the reliability of the system to ensure consistent performance in a busy workshop environment.

In the agricultural sector, the 4 tire inflation system is essential for managing the tire pressure of tractors and other farming equipment. Proper tire inflation is vital for optimizing fuel efficiency, improving traction, and reducing soil compaction. Buyers from agricultural businesses in regions like Africa and South America should consider systems that are durable and easy to operate in harsh field conditions, as well as those that can withstand frequent use.

Illustrative image related to 4 tire inflation system

Construction companies utilize 4 tire inflation systems to maintain the tire pressure of heavy machinery such as excavators and bulldozers. Proper tire inflation enhances safety by improving vehicle handling and extending the lifespan of tires, which can be costly to replace. For international buyers, particularly in the Middle East where construction activities are booming, sourcing systems that can handle high-pressure requirements and are designed for rough terrains is vital for operational success.

In the transportation and logistics sector, a 4 tire inflation system is crucial for fleet management. By efficiently managing tire pressure, companies can lower maintenance costs, improve fuel efficiency, and enhance operational efficiency. B2B buyers in this sector should focus on sourcing systems that offer rapid inflation and deflation features, ensuring that vehicles can be serviced quickly and remain on the road longer, particularly in regions with diverse road conditions.

For off-road and adventure vehicles, the 4 tire inflation system allows users to quickly adjust tire pressure based on terrain. This flexibility enhances vehicle performance and safety while navigating rugged landscapes. Buyers from adventure tourism businesses and off-road enthusiasts in Europe and the Middle East should prioritize systems that are compatible with portable compressors and rugged enough to withstand extreme conditions, ensuring reliability during their outdoor activities.

Il problema: B2B buyers managing fleets or off-road vehicles often face significant downtime caused by the manual inflation of multiple tires. This process can be tedious, especially in remote locations or during urgent operations, leading to lost productivity and increased operational costs. For example, a logistics company may find itself delayed in deliveries simply because drivers must stop to inflate tires individually, which can take up valuable time that could otherwise be spent on the road.

Illustrative image related to 4 tire inflation system

La soluzione: To combat this issue, investing in a 4 tire inflation system that allows for simultaneous inflation and deflation is essential. Look for systems that integrate with onboard compressors for seamless operation. For instance, systems like the Overland Vehicle Systems Gen2 Air Delivery System can inflate or deflate all four tires at once, significantly cutting down on the time spent managing tire pressure. When sourcing these systems, consider factors such as compatibility with existing equipment, ease of installation, and the ability to withstand varying environmental conditions. Properly training staff on the use of this system can further enhance efficiency, ensuring that they can quickly set up and manage the process during operations.

Il problema: Another common challenge for B2B buyers is the inconsistent tire pressure across vehicles in a fleet. This inconsistency can lead to uneven wear, reduced fuel efficiency, and increased risk of tire blowouts, posing safety risks for drivers. For example, a construction company may not regularly monitor tire pressure, resulting in vehicles that are unsafe to operate and potentially leading to accidents or costly downtime.

La soluzione: Implementing a 4 tire inflation system with built-in pressure monitoring features can provide a proactive solution to this problem. Systems equipped with pressure regulators and blow-off valves, like those from manufacturers such as MORRFlate, help maintain consistent tire pressure automatically. When selecting a system, prioritize those with digital gauges or integrated monitoring capabilities to alert users to any discrepancies. Additionally, establishing a routine maintenance schedule that includes checks of the inflation system can ensure that it remains functional and effective, thereby enhancing overall safety and performance.

Illustrative image related to 4 tire inflation system

Il problema: B2B buyers may encounter compatibility issues when integrating a new 4 tire inflation system with their existing vehicles or equipment. This is particularly problematic for companies operating a diverse fleet, where different vehicles may have varying air intake configurations. A failure to properly match systems can lead to additional costs and operational inefficiencies, which can be frustrating for fleet managers trying to streamline processes.

La soluzione: To address compatibility concerns, buyers should conduct thorough research before making a purchase. Look for versatile 4 tire inflation systems that offer dual air source compatibility, allowing them to connect to both onboard compressors and portable pumps. Additionally, consider systems with adjustable fittings and hoses, which can be tailored to different vehicle specifications. Engaging with suppliers who offer comprehensive technical support and installation guidance can also ease the integration process. Finally, consider conducting pilot tests with a small number of vehicles to ensure that the selected system meets the operational needs before rolling it out across the entire fleet. This careful approach can save time and reduce the risk of costly mistakes.

When selecting materials for a 4 tire inflation system, it is crucial to consider their properties, performance characteristics, and suitability for various applications. Below, we analyze four common materials used in these systems: rubber, polyurethane, stainless steel, and aluminum.

Rubber is a widely used material in tire inflation systems due to its flexibility and excellent sealing properties. It typically has a temperature rating of -40°F to 212°F (-40°C to 100°C) and can withstand moderate pressure levels.

Pro: Rubber is durable and resistant to wear, making it suitable for various environmental conditions. It is also cost-effective, which is a significant advantage for bulk purchases.

Contro: However, rubber can degrade over time when exposed to UV light and ozone, leading to potential failures. Additionally, its performance may be compromised in extreme temperatures.

Impatto sull'applicazione: Rubber hoses are compatible with air and nitrogen, making them ideal for standard tire inflation. However, they may not be suitable for high-pressure applications.

Considerazioni per gli acquirenti internazionali: Buyers from regions like Africa and South America should ensure that the rubber used complies with local standards, such as ASTM or DIN, to avoid issues with durability and performance.

Illustrative image related to 4 tire inflation system

Polyurethane is another popular material, particularly for hoses and fittings. It offers a higher temperature rating than rubber, typically ranging from -40°F to 158°F (-40°C to 70°C), and can handle higher pressures.

Pro: Polyurethane is known for its excellent abrasion resistance and flexibility, making it ideal for rugged environments. It also exhibits good chemical resistance, which is beneficial for various applications.

Contro: However, polyurethane can be more expensive than rubber, which may impact overall project costs. Additionally, it may not be as durable under extreme UV exposure.

Illustrative image related to 4 tire inflation system

Impatto sull'applicazione: Polyurethane hoses are suitable for both air and water applications, providing versatility in tire inflation systems.

Considerazioni per gli acquirenti internazionali: Compliance with international standards is crucial, especially in Europe, where regulations may dictate material specifications.

Stainless steel is often used for fittings and connectors in tire inflation systems due to its strength and corrosion resistance. It can withstand high temperatures and pressures, making it suitable for demanding applications.

Illustrative image related to 4 tire inflation system

Pro: The durability of stainless steel ensures long-term performance and reliability, reducing maintenance costs. It is also resistant to rust and corrosion, which is particularly beneficial in humid or saline environments.

Contro: The primary drawback is its higher cost compared to other materials, which may not be justifiable for all applications. Additionally, stainless steel components can be heavier, which may affect overall system weight.

Impatto sull'applicazione: Stainless steel is ideal for high-pressure applications and is compatible with various media, including air and nitrogen.

Considerazioni per gli acquirenti internazionali: Buyers in regions like the Middle East should ensure that stainless steel components meet local standards for corrosion resistance, especially in coastal areas.

Aluminum is increasingly used in tire inflation systems, particularly for lightweight components. It offers a temperature rating similar to stainless steel and can handle moderate pressures.

Illustrative image related to 4 tire inflation system

Pro: Aluminum is lightweight and resistant to corrosion, making it easy to handle and install. Its cost is generally lower than stainless steel, providing a balance between performance and affordability.

Contro: However, aluminum may not be as strong as stainless steel, which could limit its use in high-pressure applications. It can also be prone to scratches and dents.

Impatto sull'applicazione: Aluminum is suitable for air applications but may require additional protective coatings for enhanced durability.

Considerazioni per gli acquirenti internazionali: Buyers should verify that aluminum components comply with relevant standards, such as JIS in Japan or DIN in Germany, to ensure quality and performance.

Illustrative image related to 4 tire inflation system

| Materiale | Typical Use Case for 4 Tire Inflation System | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Gomma | Hoses and seals for air inflation | Economico e durevole | Degrades with UV exposure | Basso |

| Polyurethane | Hoses and fittings for air and water | Excellent abrasion resistance | Higher cost than rubber | Med |

| Acciaio inox | Fittings and connectors for high-pressure use | Long-lasting and corrosion-resistant | Costo più elevato e peso maggiore | Alto |

| Alluminio | Lightweight components for air applications | Leggero e resistente alla corrosione | Less strength under high pressure | Med |

This strategic material selection guide provides actionable insights for B2B buyers, enabling informed decisions that align with performance requirements and regional compliance standards.

The manufacturing and quality assurance processes for a 4 tire inflation system are critical to ensuring reliability, safety, and performance, especially for international B2B buyers. This section provides an in-depth analysis of typical manufacturing processes and quality control measures relevant to suppliers of these systems.

The manufacturing process of a 4 tire inflation system typically consists of four main stages: material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring the final product meets the high standards expected by B2B buyers.

Illustrative image related to 4 tire inflation system

The first step in the manufacturing process involves selecting high-quality materials that can withstand the pressures and environmental conditions they will face. Common materials include:

Before fabrication, these materials undergo rigorous testing to ensure they meet required specifications.

Once materials are prepared, they are formed into their respective components. This involves various techniques such as:

These techniques are performed using advanced machinery to maintain consistency and precision throughout the production process.

Illustrative image related to 4 tire inflation system

The assembly stage involves the integration of various components into a complete system. This typically includes:

Quality checks are often performed during assembly to catch any defects early in the process.

After assembly, the finishing stage enhances the product’s durability and aesthetics. This may include:

Quality assurance (QA) is integral to the manufacturing process, ensuring that each 4 tire inflation system meets international standards and client expectations.

Several international standards guide the quality assurance processes in manufacturing:

Manufacturers must ensure compliance with these standards to facilitate international trade, particularly in regions like Europe and the Middle East.

Quality control (QC) is typically implemented through several checkpoints throughout the manufacturing process:

Various testing methods are employed to validate the quality and functionality of the 4 tire inflation systems:

These tests are essential for ensuring that the product performs reliably in diverse conditions faced by users in different regions.

B2B buyers must adopt a proactive approach to verify the quality control measures of their suppliers:

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is vital:

In conclusion, understanding the manufacturing processes and quality assurance measures for 4 tire inflation systems is essential for B2B buyers. By focusing on the stages of manufacturing, relevant standards, quality checkpoints, and verification methods, buyers can ensure they partner with reliable suppliers, ultimately leading to successful procurement and operation in their respective markets.

Illustrative image related to 4 tire inflation system

In the competitive landscape of tire inflation systems, making an informed procurement decision is essential for B2B buyers. This practical guide outlines a step-by-step checklist to help you source a reliable and efficient 4 tire inflation system that meets your operational needs.

Begin by identifying the specific technical requirements for your 4 tire inflation system. Consider factors such as the type of vehicles you will be servicing, the desired inflation speed, and the compatibility with existing air compressors. Defining these parameters early on will streamline your search and ensure that potential suppliers can meet your operational demands.

Investigate the credentials of potential suppliers to ensure they have a solid reputation in the market. Look for certifications, industry awards, and compliance with international quality standards such as ISO. A supplier’s track record can provide insight into their reliability and the quality of their products.

Illustrative image related to 4 tire inflation system

Assess the specific features of the tire inflation systems offered by different suppliers. Key features to consider include the ability to inflate and deflate multiple tires simultaneously, compatibility with various air sources, and the durability of hoses and fittings. Understanding these features will help you select a system that enhances efficiency and reduces downtime.

Once you have shortlisted potential suppliers, request detailed quotes that outline pricing, shipping costs, and delivery timelines. A comprehensive quote should also include warranty information and any additional costs for installation or accessories. This transparency will aid in comparing options and making an informed decision.

After-sales support is crucial for the long-term satisfaction with your tire inflation system. Inquire about the supplier’s customer service policies, warranty terms, and return procedures. A supplier that offers strong after-sales support can significantly reduce the risks associated with equipment failure.

Ensure that the products you are considering comply with local regulations in your target markets, particularly if you are sourcing from international suppliers. Compliance with regional safety and environmental standards is vital for operational legality and sustainability.

Illustrative image related to 4 tire inflation system

Once you have completed your evaluations and selected a supplier, it’s time to finalize the contract. Ensure that all agreed-upon terms, including pricing, delivery schedules, and warranties, are clearly outlined in the contract. This will protect your interests and ensure that both parties have a clear understanding of the expectations.

Following this checklist will equip you with the knowledge and tools necessary to make a strategic procurement decision for a 4 tire inflation system that meets your business needs.

When evaluating the cost structure and pricing for a 4 tire inflation system, it’s essential to understand the various cost components that contribute to the final price. This analysis will help B2B buyers make informed sourcing decisions and optimize their purchasing strategies.

I materiali: The primary materials in a 4 tire inflation system include high-quality hoses, fittings, valves, and regulators. The choice of materials significantly impacts durability and performance, with DOT-approved components often commanding higher prices due to their safety and compliance standards.

Lavoro: Labor costs encompass the workforce involved in manufacturing, assembly, and quality control. Skilled labor is particularly crucial for ensuring that systems are assembled correctly and meet rigorous safety standards.

Spese generali di produzione: This includes costs associated with factory operations, such as utilities, equipment maintenance, and indirect labor. Efficient manufacturing processes can lower overhead, impacting the overall pricing of the products.

Utensili: The cost of tooling is a significant consideration, especially for manufacturers producing custom or specialized systems. Initial investments in tooling can be substantial, but they are amortized over the production run, affecting pricing strategies.

Controllo qualità (CQ): Rigorous testing and quality assurance processes are essential to ensure product reliability. Quality control can add to the overall cost, but it is a necessary investment to maintain brand reputation and customer satisfaction.

Logistica: Shipping and handling costs can vary widely depending on the destination and shipping method. International shipping may incur additional fees, including customs duties and taxes, which can significantly influence the final price.

Margine: Manufacturers typically apply a markup on their costs to achieve a profit margin. This margin can vary based on market competition, brand positioning, and perceived value.

Several factors influence the pricing of 4 tire inflation systems, particularly for international buyers:

Volume/MOQ: Bulk orders often lead to reduced per-unit costs. Buyers looking to purchase larger quantities should negotiate minimum order quantities (MOQ) to achieve better pricing.

Specifiche e personalizzazione: Custom features or specifications can increase costs. Buyers should assess whether standard models meet their needs or if customizations are necessary.

Qualità e certificazioni: Products that meet international safety and quality certifications typically command higher prices. Buyers should weigh the benefits of these certifications against their budget constraints.

Fattori di fornitura: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their products due to perceived reliability and service quality.

Incoterms: Understanding the terms of sale (Incoterms) is crucial for international transactions. Different terms can shift responsibility for shipping and logistics, influencing the total cost of ownership.

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, strategic negotiation and cost management are vital:

Negoziare i prezzi: Engaging suppliers in discussions about pricing can lead to more favorable terms, especially for bulk purchases. Building long-term relationships with suppliers can also yield better pricing over time.

Valutare il costo totale di proprietà (TCO): Look beyond the initial purchase price. Consider factors such as maintenance, warranty, and potential downtime. A lower upfront cost may result in higher long-term expenses if the product is less reliable.

Comprendere le sfumature dei prezzi: Be aware of regional pricing differences and the impact of currency fluctuations on international purchases. Conduct thorough market research to ensure competitive pricing.

In conclusion, a comprehensive understanding of the cost components and pricing influencers for 4 tire inflation systems enables buyers to make informed decisions. By leveraging negotiation strategies and considering the total cost of ownership, B2B buyers can optimize their sourcing processes for maximum value.

When it comes to managing tire pressure, especially in industries reliant on heavy machinery or off-road vehicles, the 4 tire inflation system is a popular choice. However, several alternative solutions can also achieve similar objectives. This section provides a comparative analysis of the 4 tire inflation system against two other viable options: individual tire inflation systems and centralized tire inflation systems. Understanding the strengths and weaknesses of each can help B2B buyers make informed decisions tailored to their specific operational needs.

| Aspetto di confronto | 4 Tire Inflation System | Individual Tire Inflation System | Centralized Tire Inflation System |

|---|---|---|---|

| Prestazioni | Simultaneous inflation/deflation of all four tires | Inflates/deflates tires one at a time | Allows for simultaneous inflation/deflation of multiple tires, similar to the 4 tire system |

| Costo | Moderate ($200 – $350) | Low to Moderate ($50 – $150) | High ($500 – $1000+) |

| Facilità di implementazione | Requires installation but generally user-friendly | Very easy to implement, often portable | More complex installation, may require professional setup |

| Manutenzione | Low maintenance, durable components | Minimal maintenance required | Moderate maintenance, regular checks needed |

| Il miglior caso d'uso | Ideal for off-road vehicles and fleets needing quick tire adjustments | Best for personal vehicles or smaller operations | Suitable for large fleets and industrial applications requiring regular tire management |

Individual tire inflation systems are straightforward solutions that allow operators to inflate or deflate each tire separately. They are typically more affordable and easier to implement, making them ideal for personal vehicles or smaller operations. However, this method can be time-consuming, especially when managing multiple vehicles or tires, which could lead to inefficiencies in operations that require frequent tire adjustments.

Centralized tire inflation systems offer a more advanced solution, allowing for the simultaneous inflation or deflation of multiple tires, similar to the 4 tire inflation system. While they can be costly and may involve a complex installation, they are particularly beneficial for large fleets or industrial applications where tire pressure management is critical. The downside is that they require more maintenance and regular checks to ensure optimal performance, which could lead to increased operational costs over time.

Choosing the right tire inflation solution hinges on understanding your specific operational needs, budget constraints, and the scale of your operations. For businesses with a smaller fleet or less frequent tire adjustments, individual tire inflation systems may suffice. In contrast, for those requiring efficient, high-volume tire management, investing in a centralized system or a robust 4 tire inflation system could yield significant long-term benefits. Assessing these factors will enable B2B buyers to make informed decisions that enhance productivity and operational efficiency.

Illustrative image related to 4 tire inflation system

When evaluating a 4 tire inflation system, understanding the critical specifications is essential for making informed purchasing decisions. Here are some key properties to consider:

Grado del materiale

The quality of materials used in the construction of a tire inflation system significantly impacts its durability and performance. Common materials include high-grade rubber for hoses and aluminum or stainless steel for fittings. High-grade materials ensure resistance to wear and tear, particularly in harsh environments, which is crucial for industries such as transportation and logistics.

Operating Pressure Range

This specification defines the range of air pressure the system can handle, typically measured in PSI (pounds per square inch). A standard 4 tire inflation system may operate within a range of 0 to 150 PSI. Understanding the pressure range is vital for ensuring compatibility with various vehicle types and for maintaining safety during inflation and deflation processes.

Flow Rate

The flow rate, usually expressed in CFM (cubic feet per minute), indicates how quickly air can be transferred through the system. A higher flow rate allows for faster inflation or deflation of tires, which is essential for efficiency in time-sensitive operations such as fleet management or off-road adventures.

Connector Type

The type of connectors used in the system can affect its ease of use and compatibility with existing equipment. Common connector types include push-to-connect and quick-connect fittings, which facilitate a user-friendly experience. Knowing the connector type is critical for ensuring seamless integration with other air supply equipment.

Temperature Resistance

The materials and components of the system should be able to withstand varying temperatures, especially in regions with extreme climates. A system with high-temperature resistance is crucial for maintaining functionality and safety, particularly in hot environments prevalent in regions like Africa and the Middle East.

Garanzia e assistenza

A solid warranty and customer support are indicators of a manufacturer’s confidence in their product. Systems that come with a multi-year warranty and dedicated customer service provide peace of mind and reduce long-term operational risks.

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

OEM (Original Equipment Manufacturer)

This term refers to a company that produces components that are used in another company’s product. In the context of tire inflation systems, OEMs often provide parts that meet specific standards set by vehicle manufacturers, ensuring compatibility and reliability.

MOQ (quantità minima d'ordine)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget management and inventory planning, particularly for businesses that require bulk purchases for fleet operations.

RFQ (Richiesta di offerta)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. Crafting an effective RFQ can help businesses secure competitive pricing and establish clear expectations for product specifications and delivery timelines.

Incoterms (Termini commerciali internazionali)

These are a set of predefined international rules that clarify the responsibilities of buyers and sellers in global transactions. Familiarity with Incoterms, such as FOB (Free On Board) or CIF (Cost Insurance and Freight), is crucial for understanding shipping costs, risk transfer, and delivery responsibilities.

Tempi di consegna

This term refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time helps businesses plan their operations and avoid downtime due to equipment shortages.

Compatibility

In the context of tire inflation systems, compatibility refers to the ability of the system to work with various vehicles or existing equipment. Ensuring compatibility is vital to avoid additional costs related to modifications or replacements.

By understanding these key properties and trade terms, B2B buyers can make more informed decisions regarding their 4 tire inflation system needs, ultimately leading to better operational efficiency and cost management.

The 4 tire inflation system sector is experiencing significant growth, driven by several global factors. Increasing vehicle ownership in emerging markets, particularly in Africa and South America, has heightened the demand for efficient tire management solutions. The expansion of the automotive aftermarket, coupled with a growing emphasis on off-road and recreational vehicles, particularly in regions like the Middle East and Europe, is further propelling this market. Key trends include the integration of advanced technologies such as IoT-enabled tire pressure monitoring systems, which allow for real-time monitoring and management, thereby enhancing safety and performance.

B2B buyers are increasingly seeking suppliers that offer customizable solutions. For instance, companies like MORRFlate and Overland Vehicle Systems provide modular kits that can be tailored to specific vehicle needs, appealing to businesses operating in diverse terrains. Additionally, the trend towards digitalization is evident, with many suppliers offering online platforms for easier procurement and product configuration. As a result, international buyers must remain agile, adapting their sourcing strategies to leverage these emerging technologies and meet the evolving demands of their customers.

Illustrative image related to 4 tire inflation system

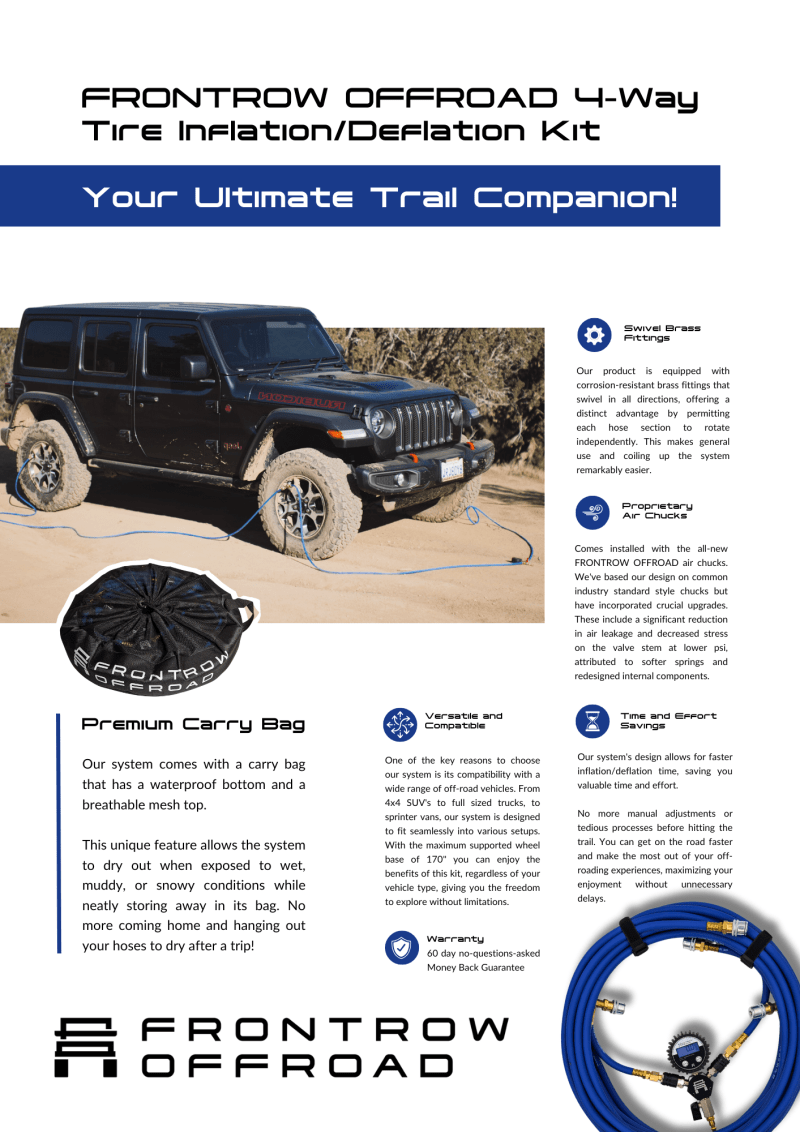

Sustainability is becoming a cornerstone for B2B buyers in the 4 tire inflation system market. Increasing regulatory pressures and consumer awareness regarding environmental impact are pushing companies to adopt greener practices. Buyers are now prioritizing suppliers who demonstrate a commitment to sustainability through the use of eco-friendly materials and manufacturing processes. For example, sourcing components made from recycled materials or those certified by recognized environmental standards can enhance a company’s reputation and appeal to a broader customer base.

Ethical sourcing is equally crucial. Buyers are encouraged to ensure that their suppliers adhere to fair labor practices and maintain transparency in their supply chains. This not only mitigates risks associated with supply chain disruptions but also aligns with corporate social responsibility goals. The focus on sustainability and ethical practices is prompting suppliers to innovate, leading to the development of products that are both environmentally friendly and high-performing. By prioritizing these values, international buyers can enhance their competitive advantage and contribute positively to the global market landscape.

The evolution of the 4 tire inflation system sector has been marked by significant technological advancements and shifts in consumer preferences. Initially, tire inflation was a manual process that relied heavily on portable air compressors and hand pumps. Over time, as automotive technology progressed, the introduction of pneumatic systems allowed for more efficient and simultaneous tire inflation.

In recent years, the sector has witnessed a shift towards more integrated solutions, such as onboard air delivery systems that facilitate the simultaneous inflation and deflation of multiple tires. This evolution has been further accelerated by the rise of off-roading and recreational vehicle markets, which demand reliable and efficient tire management solutions. Today’s systems are characterized by their ease of use, durability, and compatibility with various air sources, catering to a diverse range of applications and consumer needs. As the market continues to evolve, businesses must stay abreast of these changes to leverage new opportunities for growth and innovation.

Illustrative image related to 4 tire inflation system

1. How do I ensure the reliability of a 4 tire inflation system supplier?

To ensure supplier reliability, conduct thorough due diligence before placing an order. Start by checking the supplier’s credentials, including industry certifications and customer reviews. Request samples to evaluate product quality and performance firsthand. It’s also beneficial to ask for references from other B2B clients who have previously purchased similar products. Engaging in direct communication can help assess their responsiveness and customer service capabilities, which are critical in establishing a long-term business relationship.

2. What factors should I consider when choosing a 4 tire inflation system?

When choosing a 4 tire inflation system, consider compatibility with your vehicle’s specifications and the types of terrains you’ll encounter. Evaluate the system’s features, such as simultaneous tire inflation and deflation capabilities, air source compatibility, and ease of installation. Durability is essential, so look for products made from high-quality materials that can withstand harsh conditions. Lastly, consider after-sales support and warranty terms to ensure ongoing service and maintenance.

3. What are the typical minimum order quantities (MOQs) for 4 tire inflation systems?

Minimum order quantities (MOQs) for 4 tire inflation systems can vary widely based on the supplier and the complexity of the product. Generally, MOQs may range from 10 to 100 units. It’s essential to clarify this with your supplier during negotiations. Some manufacturers may offer lower MOQs for new clients or first-time orders to encourage business relationships. Be sure to inquire about pricing tiers, as larger orders often come with discounts.

Illustrative image related to 4 tire inflation system

4. How can I customize a 4 tire inflation system for my specific needs?

Customization options for a 4 tire inflation system typically depend on the supplier’s capabilities. Discuss your specific requirements, such as hose lengths, fitting types, and any additional features you need. Some suppliers may offer modular systems that allow for easy upgrades or changes. Always request a prototype or detailed specifications before finalizing your order to ensure that the product meets your operational needs.

5. What payment terms are generally offered for B2B purchases of 4 tire inflation systems?

Payment terms for B2B purchases can vary by supplier and region but typically include options such as net 30, net 60, or even net 90 days. Some suppliers may require a deposit upfront, with the balance payable upon delivery or after a set period. It’s advisable to discuss these terms upfront and negotiate them based on your company’s cash flow and creditworthiness. Be sure to confirm the accepted payment methods, which may include bank transfers, letters of credit, or trade financing options.

6. How do I handle logistics and shipping for international orders of 4 tire inflation systems?

When handling logistics for international orders, partner with reliable freight forwarders familiar with customs regulations in your country. Ensure that all necessary documentation, such as commercial invoices and packing lists, is prepared to facilitate smooth customs clearance. Discuss shipping options with your supplier to choose the most cost-effective and timely delivery methods. Be aware of potential tariffs and import duties that may apply, as these can affect your overall costs.

7. What quality assurance processes should I expect from suppliers of 4 tire inflation systems?

Reputable suppliers should have quality assurance processes in place to ensure product reliability and safety. Inquire about their testing protocols, which may include pressure tests and material durability assessments. Ask if they have certifications from recognized industry standards, such as ISO. Additionally, request information about their return policy and warranty coverage to protect against defects and ensure customer satisfaction.

Illustrative image related to 4 tire inflation system

8. How can I assess the long-term performance of a 4 tire inflation system?

To assess the long-term performance of a 4 tire inflation system, consider the manufacturer’s warranty and customer support. A comprehensive warranty indicates confidence in the product’s durability. After purchasing, maintain regular inspections and follow the manufacturer’s maintenance guidelines to ensure optimal performance. Gathering feedback from your team who uses the system can also provide insights into its reliability and effectiveness over time, helping you make informed decisions for future purchases.

Dominio: morrflate.com

Registrazione: 2019 (6 anni)

Introduzione: Multi Tire Inflation Deflation™ Kits from MORRFlate include both 4-way and 2-way tire hose kits. Customers can choose from pre-built kits or DIY options, selecting components like manifolds, gauges, hose lengths, and accessories. Key products include:

– MORRFlate Braided Mega Quad (4-6 Tires, Up To 200″ Wheelbase) priced between $245.00 and $285.00.

– MORRFlate Quad Compact (4-Tire Hose Kit, Up to…

Dominio: speedflate.com

Registrazione: 2020 (5 anni)

Introduzione: Speedflate 4x Basic Inflation/Deflation System

– Price: $159.99

– Available Colors: Red, Black, Green, Orange

– Pressure Rating: 300 PSI

– Functionality: Inflate/deflate all 4 tires simultaneously; equalizes pressure between all tires

– Compatibility: Works with Power Tank; new air chucks compatible with all valve stems including Apex rapid deflate stems

– Digital gauge included for easy pressure …

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: 4 wheel inflation systems, typically priced around $200, are debated among users regarding their value. Some users prefer two-tire systems to reduce strain on compressors, while others have created DIY solutions for less cost. A common concern is that many compressors may not be powerful enough to inflate all four tires simultaneously.

Dominio: lasfit.com

Registrato: 2016 (9 anni)

Introduzione: LASFIT H4 4-Tire Inflation/Deflation System, Rapid Air Up/Down for Off-Road Adventures. Model No: LAP-H4, Price: $199.99. Features: Efficient 4-Tire Deflation System (deflates from 35PSI to 15PSI in 3 minutes), Rapid 4-Tire Inflation System (inflates from 15PSI to 35PSI in 5 minutes with LASFIT X4 air compressor), Digital Tire Pressure Gauge (1PSI to 150PSI range, 1% accuracy, 0.1psi precision), B…

Dominio: trailtacoma.com

Registrazione: 2019 (6 anni)

Introduzione: DIY 4-Way Tire Inflation & Deflation Kit

**Key Components:**

– 2x WYNNsky 3/8″X 25ft Rubber Air Compressor Hose

– 4x Standard Bore Lock-On Air Chuck

– 2x Joywayus 3/8″ ID Hose Barb Tee 3 Way Union Fitting

– 2x 3/8″ barbed brass fitting to 1/4″ quick connect air hose

– 1x Hromee 3-Way Air Manifold with 3 Steel Couplers and 1/4″ Male NPT Plug

– 1x 1/4 Inch Shut Off Ball Valve NPT

– 1x Quick-Connect…

In the rapidly evolving landscape of tire inflation systems, strategic sourcing remains crucial for businesses aiming to optimize operations and enhance profitability. By investing in high-quality 4 tire inflation systems, organizations can ensure efficiency, reduce downtime, and maintain vehicle performance. Key takeaways include the importance of selecting systems that offer simultaneous inflation and deflation capabilities, compatibility with both onboard and portable compressors, and robust construction designed for various environments.

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, understanding the market dynamics and supplier capabilities is essential. Building strong partnerships with reliable manufacturers can lead to better pricing, improved service levels, and access to innovative technologies that meet specific regional needs.

Looking ahead, businesses should prioritize sourcing strategies that not only address immediate operational demands but also anticipate future trends in vehicle maintenance and off-road capabilities. By embracing these insights, companies can position themselves for success in a competitive global market. Explore your options today and invest in a tire inflation system that aligns with your business objectives for sustainable growth.

Illustrative image related to 4 tire inflation system

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.