In today’s competitive landscape, sourcing reliable AutoZone air compressors can pose significant challenges for B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe. With varying standards, regulations, and technological requirements, understanding the nuances of air compressor options available through AutoZone is critical for ensuring operational efficiency and product reliability. This guide serves as an essential resource, delving into the different types of air compressors, their specific applications, and the essential components that accompany them.

Throughout this comprehensive guide, we will explore a wide range of topics including supplier vetting processes, cost considerations, and the latest advancements in air compressor technology. By addressing these key areas, we aim to equip international buyers with the knowledge necessary to make informed purchasing decisions. Whether you are looking to procure portable tire inflators for emergency roadside assistance or heavy-duty air compressors for industrial applications, this guide will provide actionable insights tailored to your needs.

As you navigate the global market for AutoZone air compressors, our goal is to empower you with the tools and understanding required to enhance your procurement strategies, ultimately leading to improved operational success and customer satisfaction.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Portable Tire Inflators | Compact, lightweight, often battery or 12V powered | Automotive service, roadside assistance | Pro: Easy to use, portable, cost-effective. Contro: Limited power for larger tires. |

| Stationary Air Compressors | Larger, typically belt-driven, high-capacity | Workshops, manufacturing, heavy-duty tasks | Pro: High efficiency, suitable for continuous use. Contro: Requires dedicated space and power supply. |

| Suspension Air Compressors | Designed for vehicle suspension systems | Automotive repair, fleet maintenance | Pro: Essential for proper vehicle function. Contro: Installation complexity, can be costly. |

| Electric Air Compressors | Powered by electricity, quieter operation | Indoor workshops, automotive detailing | Pro: Low noise, consistent power. Contro: Limited mobility, dependent on power source. |

| Gas-Powered Air Compressors | Powered by gasoline, high portability | Construction sites, remote locations | Pro: High power output, great for outdoor use. Contro: Maintenance required, potential emissions issues. |

Portable tire inflators are compact devices designed to inflate vehicle tires quickly and efficiently. They are often powered by a vehicle’s 12V outlet or come with a rechargeable battery, making them ideal for roadside assistance or emergency situations. B2B buyers in the automotive service industry find these inflators invaluable for their ease of use and cost-effectiveness. However, they may have limitations in terms of power, making them less suitable for larger vehicles or heavy-duty applications.

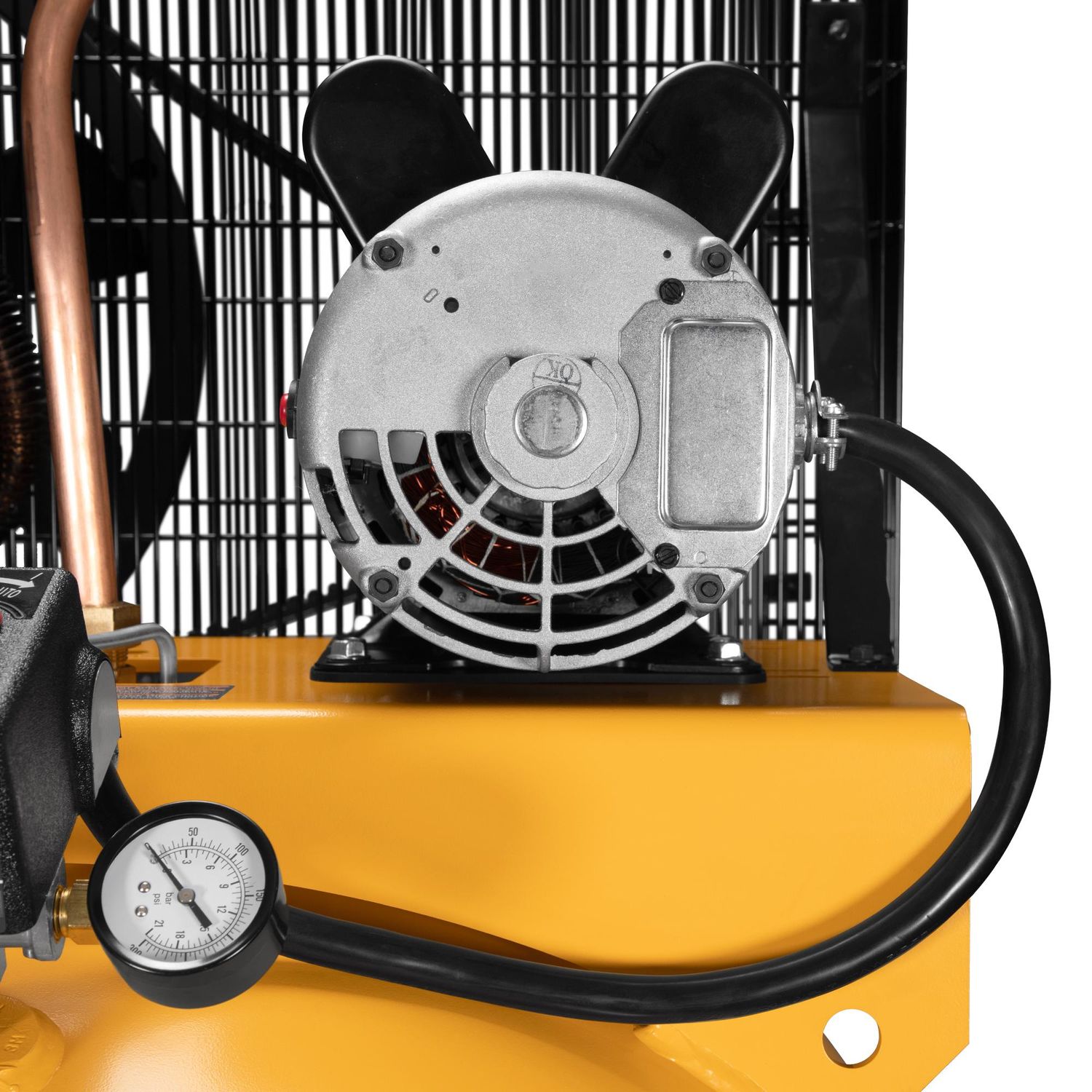

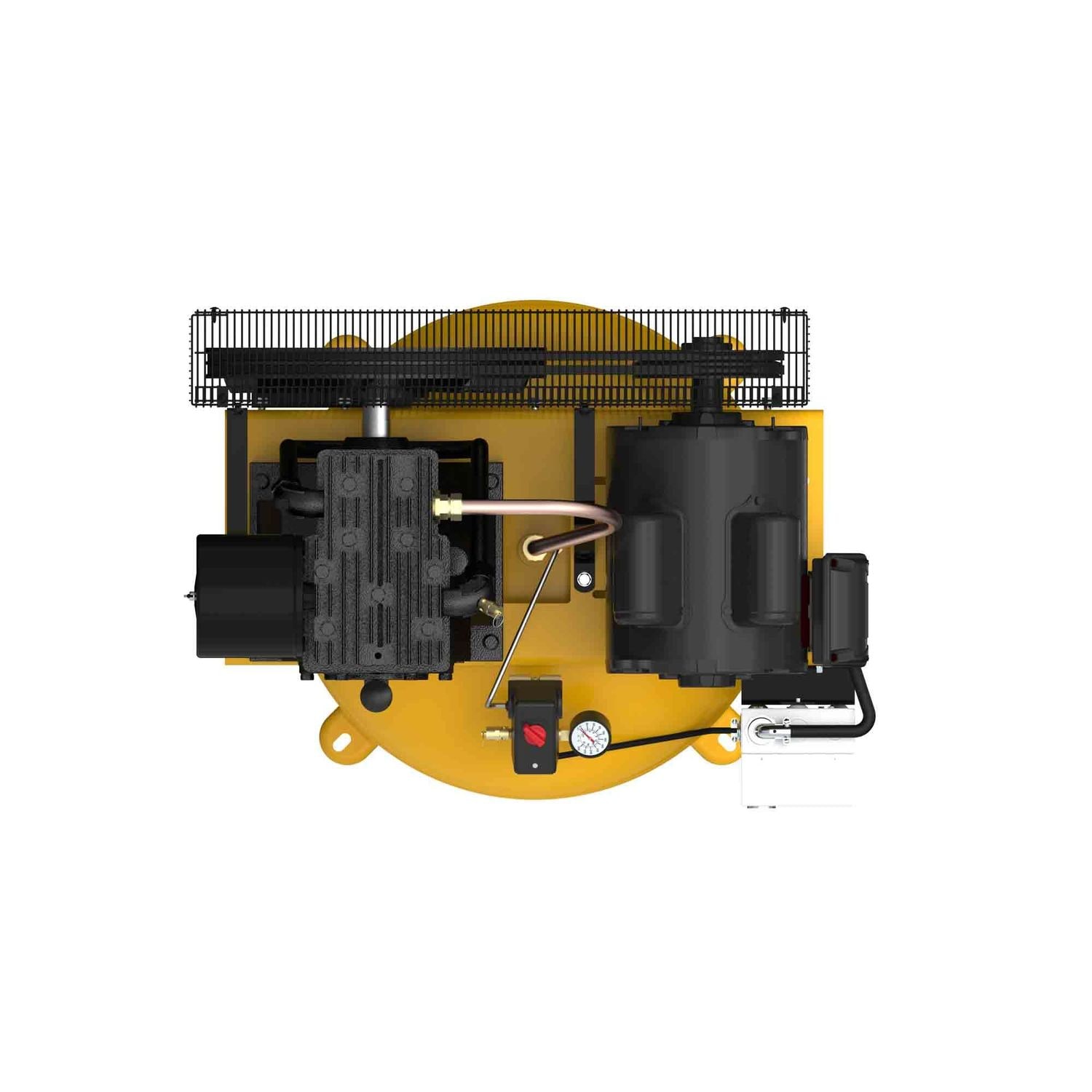

Stationary air compressors are larger, high-capacity machines typically found in workshops and manufacturing settings. They are designed for continuous use and can power a variety of pneumatic tools. Their efficiency makes them a preferred choice for businesses requiring consistent air supply for heavy-duty tasks. However, these compressors require dedicated space and a stable power supply, which may not be feasible for all B2B buyers.

Suspension air compressors are specialized devices used in vehicle suspension systems, essential for maintaining proper vehicle function. They are commonly used in automotive repair shops and fleet maintenance operations to ensure vehicles operate safely and efficiently. While they provide critical support, these compressors can be complex to install and may represent a higher upfront cost for buyers, necessitating careful consideration of long-term benefits.

Electric air compressors are popular in indoor workshops due to their quieter operation and consistent power supply. They are suitable for automotive detailing and other tasks requiring a stable air source. B2B buyers appreciate their low noise levels, which enhance the working environment. However, their reliance on a power source can limit mobility, making it crucial for businesses to assess their operational needs before purchase.

Gas-powered air compressors provide high portability and power output, making them ideal for construction sites and remote locations where electricity may not be available. These compressors are favored for their ability to operate in various conditions, supporting tasks like powering pneumatic tools and inflating tires. However, they require regular maintenance and may raise emissions concerns, making them a consideration for environmentally conscious buyers.

Illustrative image related to autozone air compressors

| Industria/Settore | Specific Application of autozone air compressors | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Riparazione di autoveicoli | Tire inflation and maintenance | Ensures vehicle safety and operational efficiency | Consider compressor power, portability, and compatibility with various tire types. |

| Produzione | Pneumatic tools for assembly lines | Enhances productivity and reduces manual labor | Evaluate air pressure capacity and reliability for continuous use. |

| Costruzione | Powering pneumatic tools for construction projects | Increases efficiency in heavy-duty applications | Look for durability, ease of transport, and noise levels. |

| Agricoltura | Inflating and maintaining tires on agricultural equipment | Ensures operational readiness in rural settings | Focus on the compressor’s portability and ability to handle various tire sizes. |

| Trasporto e logistica | Maintenance of fleet vehicles | Minimizes downtime and enhances fleet reliability | Assess ease of use, maintenance requirements, and service support. |

In the automotive repair sector, AutoZone air compressors are essential for tire inflation and maintenance. They provide quick and efficient inflation, ensuring that vehicles are roadworthy and safe. This is particularly important for businesses that rely on vehicle fleets, as proper tire maintenance can prevent accidents and improve fuel efficiency. International buyers should consider the compressor’s power and portability, as well as compatibility with various tire types, to ensure they meet their operational needs.

In manufacturing environments, AutoZone air compressors power pneumatic tools used on assembly lines. This application enhances productivity by enabling faster and more efficient operations compared to manual labor. A reliable compressor ensures that tools operate consistently, reducing downtime. Buyers in this sector should evaluate the air pressure capacity and reliability of compressors, as continuous use is often required in high-output manufacturing settings.

In construction, AutoZone air compressors are vital for powering pneumatic tools such as nail guns and drills. Their ability to provide high-pressure air allows workers to complete tasks more quickly and efficiently, which is crucial on tight schedules. Durability and ease of transport are key considerations for international buyers, as construction sites often require robust equipment that can withstand harsh conditions while being easy to move around.

Agricultural businesses utilize AutoZone air compressors for inflating and maintaining tires on various types of equipment, including tractors and harvesters. Ensuring that equipment is always operational is crucial for productivity in farming. Buyers from rural areas should focus on the compressor’s portability and its ability to handle different tire sizes, as these factors can significantly impact their operational efficiency in the field.

Illustrative image related to autozone air compressors

In the transportation and logistics sector, maintaining fleet vehicles is critical for minimizing downtime and ensuring reliability. AutoZone air compressors facilitate quick tire inflation and repairs, allowing vehicles to return to service faster. Buyers should assess the ease of use, maintenance requirements, and available service support when sourcing compressors, as these factors can influence overall fleet management efficiency.

Il problema: B2B buyers often struggle to identify the appropriate air compressor that meets their specific operational requirements. For instance, a company in the automotive repair sector may need a heavy-duty air compressor to power pneumatic tools efficiently. However, they might face challenges due to the overwhelming variety of models and specifications available, leading to confusion and potential misalignment with their needs. This can result in wasted time, financial resources, and operational inefficiencies.

La soluzione: To effectively source the right air compressor from AutoZone, buyers should begin by conducting a thorough needs assessment. This involves identifying the types of air tools that will be used and their power requirements, such as PSI (pounds per square inch) and CFM (cubic feet per minute). AutoZone offers a range of air compressors tailored for various applications, including portable models for light tasks and robust models for heavy-duty use. Utilizing the detailed product specifications available on AutoZone’s website can help buyers match the compressor’s capabilities with their operational demands. Furthermore, engaging with AutoZone’s customer support can provide insights and recommendations based on their extensive product knowledge.

Illustrative image related to autozone air compressors

Il problema: Regular maintenance is crucial for the longevity and efficiency of air compressors, but many B2B buyers lack the knowledge or resources to perform these tasks properly. Inadequate maintenance can lead to compressor failures, which can halt operations and incur costly downtime. For example, a manufacturing firm may experience reduced productivity if their air compressor malfunctions due to improper maintenance.

La soluzione: To combat maintenance challenges, it is essential for buyers to establish a scheduled maintenance plan that includes routine checks and servicing. AutoZone provides comprehensive guides and resources on maintaining air compressors, detailing tasks such as changing filters, checking for leaks, and monitoring oil levels. B2B buyers can also consider investing in AutoZone’s air compressor repair parts and accessories to ensure they have the necessary components on hand for timely repairs. Regular training sessions for staff on proper maintenance practices can further enhance operational efficiency and minimize the risk of compressor-related disruptions.

Il problema: International B2B buyers, particularly in regions with inconsistent power supply, face significant challenges when sourcing air compressors that require stable electricity to function efficiently. For instance, businesses in parts of Africa or South America may encounter frequent power outages, affecting their ability to use traditional electric air compressors effectively. This situation can result in delays in service delivery and increased operational costs.

Illustrative image related to autozone air compressors

La soluzione: To address power supply limitations, buyers should consider investing in portable or battery-powered air compressors available at AutoZone. These models do not rely solely on electrical outlets and can be used in various situations, providing flexibility and reliability. Additionally, buyers should evaluate the specifications of air compressors to ensure they can operate under variable power conditions. For organizations in areas with frequent power fluctuations, AutoZone also offers power management solutions, including surge protectors and voltage regulators, which can help safeguard equipment and maintain consistent performance. By proactively addressing power supply concerns, businesses can ensure uninterrupted operations and enhance overall productivity.

When selecting air compressors, understanding the materials used in their construction is crucial for ensuring optimal performance, longevity, and compliance with international standards. Here, we analyze four common materials utilized in AutoZone air compressors, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Aluminum is a popular choice for various components of air compressors due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of up to 150°C and can withstand moderate pressures.

Illustrative image related to autozone air compressors

Pro: Aluminum is highly resistant to corrosion, making it suitable for environments with high humidity or exposure to chemicals. Its lightweight nature facilitates easier handling and installation, reducing shipping costs.

Contro: While durable, aluminum can be less robust than steel under extreme conditions, leading to potential deformation under high stress. Additionally, it may be more expensive than some other materials, impacting overall cost-effectiveness.

Impatto sull'applicazione: Aluminum is compatible with a range of media, including air and non-corrosive gases, making it ideal for general-purpose air compressors.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that the aluminum components meet standards such as ASTM B221 for structural applications. In regions like Europe and the Middle East, compliance with EU regulations regarding material safety may also be necessary.

Steel is widely used in the construction of air compressor frames and tanks due to its high strength and durability. It can withstand high pressures, often rated above 200 psi, and performs well in various temperature ranges.

Pro: Steel’s robustness ensures long-lasting performance, making it suitable for heavy-duty applications. It is also generally more cost-effective than aluminum, particularly for large-scale production.

Contro: Steel is prone to corrosion if not properly treated, which can lead to failure in humid or corrosive environments. Its weight can also increase shipping costs and complicate installation.

Illustrative image related to autozone air compressors

Impatto sull'applicazione: Steel is ideal for applications requiring high-pressure capabilities, such as industrial air compressors. However, it may not be suitable for environments where corrosion is a concern unless adequately protected.

Considerazioni per gli acquirenti internazionali: Compliance with standards such as ASTM A36 for structural steel is essential. Buyers in regions like South America and Africa should consider local environmental conditions that may affect steel’s performance.

Plastic materials are increasingly used in non-structural components of air compressors, such as housings and fittings. They typically have a temperature rating of around 80°C and can handle moderate pressures.

Pro: Plastics are lightweight, resistant to corrosion, and can be manufactured in various colors and shapes, enhancing aesthetic appeal. They also tend to be less expensive than metals.

Contro: Plastic components may not withstand high pressures as effectively as metals, limiting their use in critical applications. They can also degrade under UV exposure or high temperatures over time.

Illustrative image related to autozone air compressors

Impatto sull'applicazione: Plastic is suitable for applications involving low-pressure air and non-corrosive gases, making it ideal for portable or consumer-grade compressors.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that plastic components meet relevant standards such as ISO 9001 for quality management. In Europe, compliance with REACH regulations regarding chemical safety is critical.

Rubber is commonly used for seals and gaskets in air compressors, providing essential airtight connections. It can withstand temperatures ranging from -30°C to 100°C and is effective in low-pressure applications.

Pro: Rubber offers excellent flexibility and resilience, making it ideal for sealing applications. It is also relatively inexpensive and easy to manufacture.

Illustrative image related to autozone air compressors

Contro: Rubber can degrade over time, especially when exposed to extreme temperatures or chemicals, leading to potential leaks. Its performance can vary significantly based on the specific rubber compound used.

Impatto sull'applicazione: Rubber seals are crucial for maintaining pressure in air compressors, ensuring efficient operation and preventing leaks.

Considerazioni per gli acquirenti internazionali: Buyers should verify that rubber components comply with ASTM D2000 for rubber materials. In regions with extreme temperatures, selecting the right rubber compound is vital for performance.

Illustrative image related to autozone air compressors

| Materiale | Typical Use Case for AutoZone Air Compressors | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Alluminio | Compressor housings and components | Leggero e resistente alla corrosione | Less robust under extreme conditions | Medio |

| Acciaio | Tanks and frames | Elevata resistenza e durata | Prone to corrosion without treatment | Basso |

| Plastica | Non-structural components | Leggero e conveniente | Limited pressure tolerance | Basso |

| Gomma | Guarnizioni | Excellent sealing capability | Degrades over time under harsh conditions | Basso |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in AutoZone air compressors, helping them make informed purchasing decisions tailored to their specific regional needs and applications.

The manufacturing process of AutoZone air compressors involves several critical stages, each designed to ensure that the final product meets rigorous quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

The first step in the manufacturing process is material preparation. High-quality materials such as aluminum, steel, and plastic are sourced from reputable suppliers. These materials undergo rigorous inspections to ensure they meet the required specifications. This is crucial for the durability and reliability of the air compressors. For example, aluminum is often chosen for its lightweight properties, while steel is used for its strength and longevity.

Once the materials are prepared, they are subjected to various forming techniques. This can include processes such as casting, machining, and stamping. For instance, the compressor housing may be cast from aluminum to create a lightweight yet robust structure. Machining processes ensure precise dimensions and tolerances, which are vital for optimal performance and efficiency. Advanced techniques such as CNC machining may also be employed to enhance precision and reduce waste.

The assembly stage involves the careful integration of various components, including the motor, pump, and control systems. Each unit is assembled in a controlled environment to minimize contamination and defects. This is often done using automated systems combined with skilled labor to ensure consistency and quality. During this phase, components are checked for compatibility and functionality, ensuring that each compressor operates efficiently.

Finishing techniques play a vital role in the final appearance and protection of the air compressors. Processes such as painting, powder coating, and anodizing are commonly used to enhance corrosion resistance and aesthetic appeal. These finishes not only protect the compressor from environmental factors but also contribute to the overall durability of the product. Additionally, quality checks are conducted post-finishing to ensure that the finish meets industry standards.

Quality assurance is critical in the manufacturing of air compressors, especially for B2B buyers who demand reliability and performance. The manufacturing process adheres to international standards such as ISO 9001, which outlines the requirements for a quality management system. This ensures that processes are consistently improved, leading to enhanced customer satisfaction.

In addition to ISO 9001, air compressors may also need to comply with industry-specific certifications, such as CE marking for products sold in the European Economic Area and API standards for certain industrial applications. These certifications indicate that the products meet essential health, safety, and environmental protection standards.

Illustrative image related to autozone air compressors

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that each compressor meets established standards. Key checkpoints include:

Various testing methods are employed to verify the performance and safety of air compressors. Common methods include:

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several strategies:

International buyers must be aware of the varying quality control and certification requirements across different regions. For example, while CE marking is essential for products sold in Europe, buyers in the Middle East may prioritize compliance with local standards. It is crucial for B2B buyers to communicate their specific requirements clearly and ensure that suppliers can meet these standards.

In summary, understanding the manufacturing processes and quality assurance measures for AutoZone air compressors is vital for B2B buyers. By ensuring that suppliers adhere to international standards and implementing robust quality control measures, buyers can confidently invest in products that meet their operational needs.

Illustrative image related to autozone air compressors

In the competitive landscape of air compressor procurement, especially for international B2B buyers, having a structured approach can significantly impact the success of your sourcing efforts. This checklist will guide you through critical steps to ensure you acquire quality AutoZone air compressors that meet your operational requirements.

Understanding your specific needs is the foundation of effective sourcing. Clearly outline the technical specifications required for your air compressors, including pressure ratings, tank sizes, and power source preferences (electric vs. gas).

– Consider your application: Different tasks may require different compressor capabilities, such as high pressure for industrial applications or portability for automotive servicing.

Once you have defined your specifications, research the available product options. AutoZone offers a variety of air compressors with differing features that may suit your needs.

– Key features to consider: Look for models with automatic shut-off capabilities, ease of maintenance, and compatibility with various air tools. Additionally, assess the noise level and energy efficiency of the units.

Illustrative image related to autozone air compressors

Before committing to a supplier, conduct a thorough evaluation. Request comprehensive information, including company profiles, product catalogs, and customer testimonials.

– Check for industry experience: Suppliers with a proven track record in your industry can offer valuable insights and support throughout the procurement process.

Ensuring that your supplier meets international standards is vital for quality assurance. Verify any relevant certifications that indicate compliance with safety and quality standards.

– Look for ISO certifications: These can provide assurance that the supplier adheres to recognized quality management practices, which is crucial for reliability in performance.

If possible, request samples or arrange for demonstrations of the air compressors. This step allows you to assess the product’s performance and suitability for your specific applications firsthand.

– Evaluate ease of use: Ensure that the compressor is user-friendly and meets your operational standards before making a bulk purchase.

Once you have identified suitable suppliers and products, enter into negotiations regarding pricing and terms of sale. Be clear about your budget constraints while discussing bulk purchase discounts or payment terms.

– Consider total cost of ownership: Factor in shipping, installation, and maintenance costs when evaluating the overall investment.

After finalizing your purchase, ensure that you have a plan for post-purchase support. This includes warranty coverage, maintenance services, and access to spare parts.

– Assess supplier support options: Suppliers that offer comprehensive after-sales support can help mitigate downtime and ensure long-term operational efficiency.

By following this checklist, B2B buyers can streamline the procurement process for AutoZone air compressors, ensuring they make informed decisions that align with their operational needs and budgetary constraints.

When sourcing AutoZone air compressors, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to autozone air compressors

I materiali: The quality and type of materials used significantly affect costs. For instance, compressors with higher-grade components or those designed for specific applications (e.g., industrial versus automotive) will typically have higher material costs.

Lavoro: Labor costs encompass both direct and indirect expenses associated with manufacturing. Regions with lower labor costs may offer more competitive pricing but can also lead to variations in quality.

Spese generali di produzione: This includes utilities, rent, and administrative expenses necessary for production. Efficient manufacturing processes can help reduce these overheads, translating into lower prices for buyers.

Utensili: Initial setup costs for specialized tools can be substantial, particularly for custom or high-specification compressors. These costs are often amortized over large production runs, influencing pricing strategies.

Controllo qualità (CQ): Ensuring that products meet international standards and certifications incurs additional costs. Buyers should consider whether the supplier has robust QC processes, as this can impact long-term reliability and total cost of ownership.

Logistica: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping method, and Incoterms can significantly influence the total cost.

Margine: Suppliers typically add a profit margin to cover risks and ensure sustainability. Understanding this aspect can help in negotiations.

Several factors can influence the final pricing of air compressors, particularly for B2B buyers looking to source internationally.

Volume e quantità minima d'ordine (MOQ): Bulk purchases often lead to discounts. Understanding the MOQ of suppliers can help in planning purchases to optimize costs.

Specifiche e personalizzazione: Custom specifications can lead to higher costs due to additional engineering and production requirements. Buyers should clearly define their needs to avoid unexpected expenses.

Qualità dei materiali e certificazioni: Higher-quality materials and compliance with international certifications can increase costs. However, investing in quality can reduce long-term maintenance and replacement costs.

Fattori di fornitura: A supplier’s reputation, reliability, and production capacity can affect pricing. Established suppliers may charge more due to their proven track record but can offer better support and warranty terms.

Incoterms: The choice of Incoterms (International Commercial Terms) can significantly impact logistics costs and responsibilities. Understanding these terms is essential for accurate cost forecasting.

For international buyers from regions such as Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings.

Research and Benchmarking: Familiarize yourself with market prices and competitor offerings. This knowledge can empower you during negotiations.

Attenzione al costo totale di proprietà (TCO): When discussing prices, emphasize the importance of TCO, which includes purchase price, maintenance, and operational costs. Suppliers may be willing to adjust prices if they see long-term value.

Leverage Volume Discounts: If your business can commit to larger orders or longer-term contracts, leverage this to negotiate better terms and pricing.

Richiesta di preventivi dettagliati: Ask for itemized quotes that break down costs. This transparency can reveal areas for negotiation and ensure you understand the pricing structure.

Essere consapevoli delle sfumature dei prezzi: Understand that pricing strategies may vary by region due to economic conditions, shipping costs, and local demand. Use this knowledge to your advantage in negotiations.

While indicative pricing can provide a baseline, it is essential to engage in thorough discussions with suppliers to obtain precise quotes tailored to your specific needs. The combination of understanding cost components, price influencers, and negotiation strategies will empower international B2B buyers to make informed purchasing decisions that align with their business objectives.

When selecting an air compressor for various applications, B2B buyers must consider multiple options available in the market. AutoZone air compressors are a popular choice, but alternative solutions may offer distinct advantages depending on specific needs. This analysis compares AutoZone air compressors with two viable alternatives: portable tire inflators and gas-powered air compressors.

| Aspetto di confronto | AutoZone Air Compressors | Portable Tire Inflators | Gas-Powered Air Compressors |

|---|---|---|---|

| Prestazioni | High PSI output; suitable for multiple tasks | Limited PSI; ideal for tire inflation | High PSI and CFM; versatile for heavy-duty tasks |

| Costo | Moderate ($100-$300) | Low ($30-$200) | High ($500-$2000) |

| Facilità di implementazione | Requires electrical outlet; straightforward setup | Extremely portable; plug-and-play | Requires fuel and maintenance; more complex setup |

| Manutenzione | Low; occasional filter change | Very low; minimal upkeep | High; regular oil and filter changes needed |

| Il miglior caso d'uso | General automotive repairs and applications | Emergency tire inflation; lightweight vehicles | Heavy-duty industrial applications; construction sites |

Portable tire inflators are compact devices specifically designed for tire inflation. Their main advantage is their affordability and ease of use, making them ideal for individual drivers and small businesses. They can be powered by a vehicle’s 12V outlet or a rechargeable battery, providing flexibility in usage. However, they typically offer lower PSI and are not suitable for heavy-duty tasks like powering pneumatic tools or inflating large equipment.

Gas-powered air compressors are designed for demanding applications that require high air pressure and volume (CFM). They are often used in construction and industrial settings where electric power is unavailable or impractical. These compressors deliver superior performance and versatility, making them suitable for various pneumatic tools. However, they come with a higher price point and require regular maintenance, including fuel management and oil changes. This complexity may deter some businesses from opting for this solution.

When deciding between AutoZone air compressors and their alternatives, B2B buyers should carefully assess their specific requirements. If you need a versatile compressor for automotive repairs and various applications, AutoZone air compressors may be the most suitable option. For businesses focused on emergency roadside assistance or light tire inflation, portable tire inflators offer convenience and cost-effectiveness. On the other hand, if your operations demand robust performance for heavy-duty tasks, gas-powered air compressors are worth the investment despite their higher cost and maintenance needs. Ultimately, aligning the choice of air compressor with your operational needs and budget will ensure optimal performance and value.

Understanding the critical specifications of AutoZone air compressors is essential for B2B buyers to ensure they select the right equipment for their needs. Here are some of the key properties to consider:

PSI Rating (Pounds per Square Inch)

The PSI rating indicates the maximum pressure that the air compressor can generate. It is crucial for determining the compressor’s capability in driving various pneumatic tools or inflating tires. A higher PSI rating often translates to better performance, especially in professional or industrial settings where heavy-duty tasks are common.

CFM (Cubic Feet per Minute)

CFM measures the air flow rate produced by the compressor. This specification is vital when assessing how quickly a compressor can refill air tools, such as impact wrenches or spray guns. Buyers should match the CFM rating of the compressor with the air consumption requirements of their tools to ensure efficiency and effectiveness.

Tank Size

The tank size, typically measured in gallons, determines the volume of compressed air the unit can store. A larger tank allows for longer operation without needing to restart the compressor, making it suitable for continuous use in workshops or service centers. Buyers should consider their operational needs when choosing tank size to minimize downtime.

Fonte di alimentazione

Air compressors can be powered by electricity, gasoline, or diesel. Understanding the power source is critical for B2B buyers as it influences mobility, operational costs, and suitability for different environments. For instance, electric models are ideal for indoor use, while gasoline or diesel units may be better suited for remote locations.

Noise Level (Decibels)

The noise level of an air compressor, measured in decibels (dB), can impact work environments, especially in customer-facing areas or residential neighborhoods. A lower dB rating is preferable in such settings, and buyers should consider models that offer quieter operation without sacrificing performance.

Durability and Material Grade

The materials used in the construction of air compressors, such as aluminum or steel, affect their durability and resistance to wear. Buyers should assess the material grade to ensure the compressor can withstand their specific operational demands, especially in rugged conditions.

Familiarity with industry jargon is crucial for making informed purchasing decisions. Here are some key terms that B2B buyers should understand:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that are sold under another company’s brand name. For air compressors, sourcing OEM parts ensures compatibility and quality. Buyers should look for OEM components to maintain equipment performance and reliability.

MOQ (quantità minima d'ordine)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget management, as it can affect inventory levels and overall purchasing costs. Buyers should negotiate MOQ terms to align with their operational needs without overcommitting resources.

RFQ (Richiesta di offerta)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. In the context of air compressors, submitting an RFQ helps buyers obtain competitive pricing and better understand the supplier’s offerings, enabling more informed decision-making.

Incoterms (Termini commerciali internazionali)

Incoterms are a series of international rules that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is critical for international B2B transactions involving air compressors, as they dictate who bears the costs and risks during transport.

Garanzia

A warranty is a guarantee provided by the manufacturer regarding the quality and lifespan of a product. B2B buyers should carefully review warranty terms for air compressors to ensure they are protected against defects and operational failures.

Tempi di consegna

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is crucial for inventory planning and ensuring that air compressors are available when needed, especially for businesses reliant on timely operations.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when sourcing AutoZone air compressors, ultimately enhancing operational efficiency and reducing costs.

The air compressor market is experiencing significant growth, driven by rising demand across various sectors, including automotive, construction, and industrial applications. In particular, the AutoZone air compressors segment is positioned well due to increasing consumer awareness about vehicle maintenance and the growing trend of DIY automotive repairs. This shift is particularly pronounced in regions like Africa and South America, where the DIY culture is gaining traction due to economic constraints and a lack of access to professional services.

Emerging technologies are also reshaping the sourcing landscape. Smart air compressors equipped with IoT capabilities are becoming popular, allowing users to monitor performance and maintenance needs via smartphone applications. This trend is particularly appealing to B2B buyers in Europe and the Middle East, where advanced technology adoption is high. Furthermore, there is a noticeable shift towards portable and battery-operated compressors, driven by the need for convenience and mobility.

International B2B buyers must also navigate fluctuating supply chain dynamics. Disruptions caused by geopolitical tensions and the pandemic have underscored the importance of diversifying supply sources. Establishing relationships with multiple suppliers can mitigate risks associated with dependency on single-source vendors, ensuring a more stable supply of air compressors and related accessories.

Sustainability is increasingly influencing purchasing decisions in the B2B landscape. Environmental impact considerations are pushing companies to seek air compressors that not only perform efficiently but also minimize energy consumption and emissions. Buyers are now prioritizing products that come from manufacturers with robust sustainability practices.

Ethical sourcing has gained momentum, as businesses recognize the importance of transparency in their supply chains. B2B buyers are encouraged to partner with suppliers who adhere to ethical labor practices and demonstrate a commitment to reducing their carbon footprint. Certifications such as ISO 14001 for environmental management and Energy Star ratings for energy efficiency are becoming critical benchmarks for evaluating potential suppliers.

In the AutoZone air compressors sector, the use of recycled materials and eco-friendly packaging is on the rise. Buyers should look for products that are certified ‘green’ or utilize sustainable materials in their construction. By prioritizing suppliers who align with these values, businesses not only enhance their brand reputation but also contribute to a more sustainable future.

The evolution of the air compressors market, particularly within the AutoZone sector, has been marked by technological advancements and changing consumer preferences. Initially dominated by traditional gas-powered models, the market has gradually shifted towards electric and portable solutions, reflecting the growing demand for convenience and efficiency.

Illustrative image related to autozone air compressors

Over the years, manufacturers have focused on enhancing the design and functionality of air compressors, leading to innovations such as quieter operation, improved portability, and increased energy efficiency. This evolution has been fueled by the need for more versatile tools that cater to a broader range of applications, from home use to professional automotive servicing.

As the market continues to evolve, B2B buyers must stay informed about the latest trends and advancements to make strategic sourcing decisions that align with their operational needs and sustainability goals.

1. How do I solve issues with my air compressor not starting?

If your air compressor fails to start, first check the power source; ensure that it’s plugged in and that the outlet is functioning. Inspect the circuit breaker or fuse box for any tripped breakers or blown fuses. If the power supply is adequate, examine the compressor’s pressure switch and ensure it’s set correctly. Additionally, check for any debris blocking the air intake or issues with the motor. If these steps do not resolve the issue, consider consulting with a professional technician for further troubleshooting or repairs.

2. What is the best type of air compressor for automotive applications?

The best type of air compressor for automotive applications typically depends on the specific tasks you intend to perform. For general tire inflation and small jobs, a portable electric compressor is highly convenient. For more demanding tasks, such as powering air tools, a larger, stationary compressor with higher PSI (pounds per square inch) ratings is advisable. Brands like Duralast and ACDelco offer reliable options in various capacities, ensuring you select one that aligns with your business needs and the types of vehicles you service.

3. What are the minimum order quantities (MOQs) for AutoZone air compressors?

Minimum order quantities for AutoZone air compressors can vary based on the specific model and supplier arrangements. Typically, wholesalers may set MOQs ranging from 10 to 50 units to ensure cost-effectiveness and efficient inventory management. It’s essential to communicate directly with suppliers to determine their specific MOQ policies and to negotiate terms that suit your purchasing needs, especially when sourcing for international markets.

4. How can I vet suppliers for AutoZone air compressors?

To effectively vet suppliers for AutoZone air compressors, begin by reviewing their credentials, including business licenses and industry certifications. Request references from existing clients to gauge reliability and service quality. Additionally, conduct a background check on their history in the industry and assess their financial stability. Consider visiting their facilities if possible, and inquire about their quality assurance processes to ensure they meet international standards, particularly in your target markets in Africa, South America, the Middle East, and Europe.

5. What payment terms are commonly offered for B2B purchases of air compressors?

Payment terms for B2B purchases of air compressors can vary widely among suppliers. Common terms include net 30, net 60, or cash on delivery (COD). Some suppliers may offer discounts for early payments or require a deposit upfront for larger orders. It’s crucial to discuss and negotiate these terms before finalizing the purchase to ensure they align with your cash flow and financial planning needs, especially for international transactions where currency exchange rates may also impact costs.

6. How can I ensure the quality of the air compressors I purchase?

To ensure the quality of air compressors, request detailed product specifications and certifications from your suppliers. Conduct thorough inspections upon delivery, checking for any visible damage or defects. It’s also beneficial to ask about the warranty and return policies, which can provide additional assurance of quality. Consider working with suppliers who have established quality control processes and who can provide documentation of compliance with international standards, especially if you plan to distribute these products in different countries.

7. What logistics considerations should I keep in mind when importing air compressors?

When importing air compressors, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Determine whether to use air freight or ocean freight based on your budget and urgency. Familiarize yourself with the import regulations of your destination country, including necessary documentation and compliance standards. Working with a reputable freight forwarder can streamline the process and help navigate any logistical challenges that may arise, ensuring timely delivery to your business.

8. Are there customization options available for air compressors?

Many suppliers offer customization options for air compressors, including branding, color schemes, and specific features tailored to your market needs. When negotiating with suppliers, inquire about the possibility of customizing the compressors to better suit your target audience or to differentiate your product offering in competitive markets. Be sure to discuss any additional costs or minimum order requirements associated with customization to ensure it aligns with your business strategy and budget.

Could not verify enough suppliers for autozone air compressors to create a list at this time.

In the competitive landscape of air compressor sourcing, particularly for AutoZone products, strategic sourcing emerges as a crucial component for B2B buyers. By aligning procurement strategies with the specific needs of your market, businesses can enhance operational efficiency and reduce costs. AutoZone’s diverse range of air compressors, including portable tire inflators and specialized suspension air compressors, cater to various applications, ensuring that international buyers find solutions tailored to their requirements.

Understanding the importance of quality and reliability in air tools is essential, especially in regions like Africa, South America, the Middle East, and Europe, where demand for durable equipment is paramount. Sourcing from reputable suppliers like AutoZone not only guarantees access to high-quality products but also supports businesses in maintaining customer satisfaction through reliable performance.

As you consider your sourcing strategies, prioritize partnerships that emphasize innovation and customer support. The future of air compressor technology is evolving rapidly, and aligning with forward-thinking suppliers can provide your business with a competitive edge. Take the next step in optimizing your procurement process—explore AutoZone’s offerings and position your business for success in the dynamic global market.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Illustrative image related to autozone air compressors

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.