In the ever-evolving automotive industry, sourcing the right tire pressure gauge from AutoZone can pose a significant challenge for international B2B buyers. With varying standards, fluctuating demands, and the need for reliable products that ensure vehicle safety and efficiency, navigating this market requires a strategic approach. This comprehensive guide delves into various types of tire pressure gauges, their applications, and essential considerations for supplier vetting, allowing businesses to make informed purchasing decisions.

Understanding the importance of accurate tire pressure management is crucial, as improper inflation can lead to increased fuel consumption, reduced tire lifespan, and compromised vehicle safety. This guide empowers B2B buyers from diverse regions—such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany—by providing actionable insights into product specifications, pricing structures, and supplier reliability.

With a focus on maximizing value and minimizing risks, this resource equips international buyers with the knowledge needed to select the right tire pressure gauges for their specific needs. By addressing key challenges and offering practical solutions, we aim to enhance your procurement process, ensuring you can confidently navigate the global market for tire pressure gauges while optimizing operational efficiency and safety standards.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Analog Tire Gauge | Mechanical dial display, no batteries required | Automotive repair shops, fleet services | Pro: Durable, no batteries needed; Contro: Less precise than digital models. |

| Digital Tire Gauge | Electronic display, often with backlight | Automotive manufacturing, logistics | Pro: High accuracy, easy to read; Contro: Requires batteries, may be less durable. |

| Stick Tire Gauge | Compact, simple design, often pocket-sized | Mobile tire service providers | Pro: Portable, straightforward; Contro: Limited features, may lack precision. |

| Bluetooth Tire Gauge | Connects to mobile devices for data tracking | Fleet management, automotive tech companies | Pro: Data analytics, remote monitoring; Contro: Higher cost, relies on technology. |

| Inflator Tire Gauge | Combines inflation and pressure measurement | Tire service centers, automotive workshops | Pro: Multifunctional, time-saving; Contro: Bulkier, may be more expensive. |

Analog tire gauges are characterized by their mechanical dial displays, which do not require batteries. They are typically robust and can withstand harsh workshop environments, making them ideal for automotive repair shops and fleet services. When considering B2B purchases, buyers should evaluate the gauge’s accuracy and ease of use, as well as its durability over time. While these gauges are reliable, they may not offer the precision that digital models provide, which could be a concern for businesses requiring exact measurements.

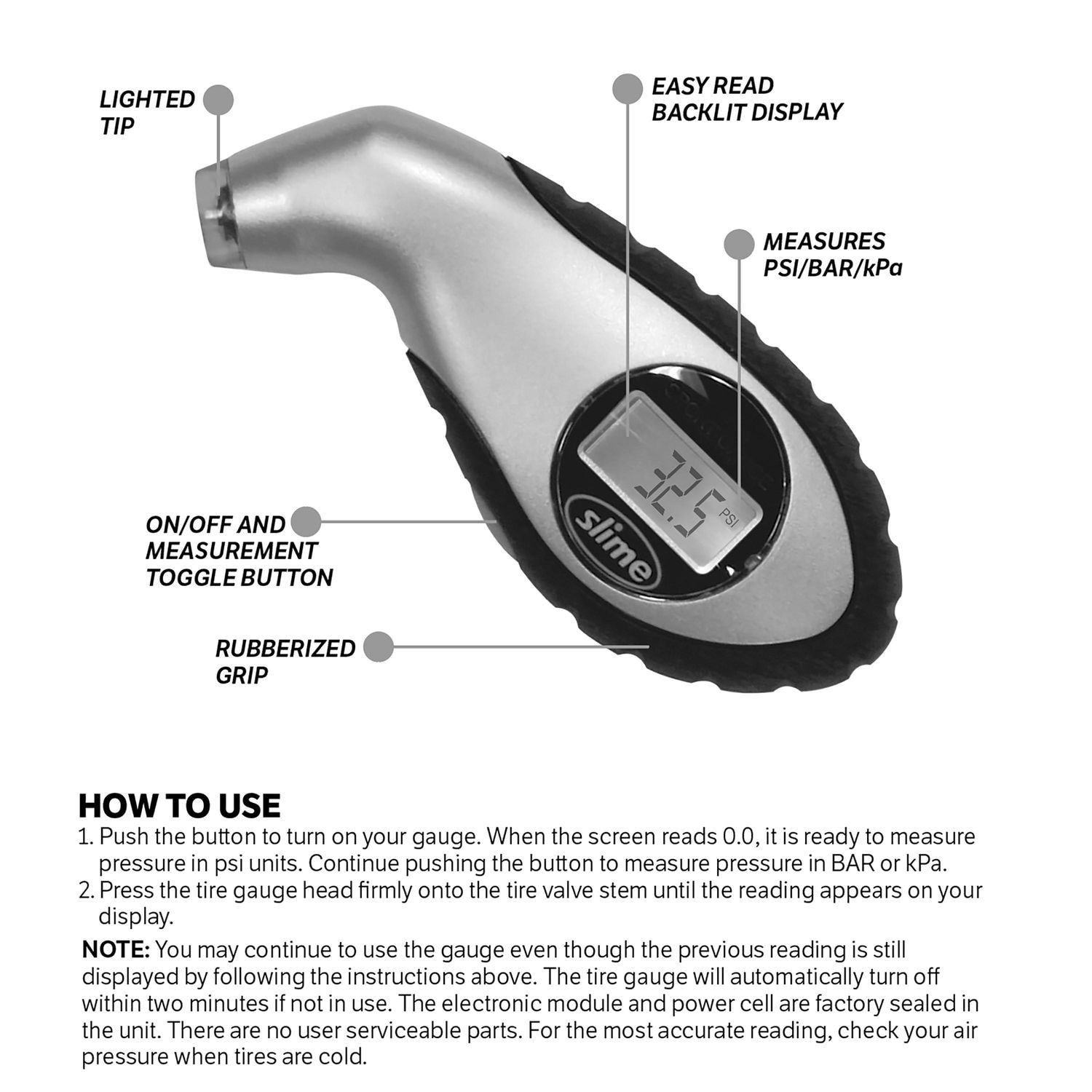

Digital tire gauges feature electronic displays that often include backlighting for easy reading in low-light conditions. Their high accuracy makes them suitable for applications in automotive manufacturing and logistics, where precise tire pressure measurements are critical. B2B buyers should consider the battery life and potential need for replacements, as well as the gauge’s overall durability. While digital gauges offer a modern solution, their reliance on batteries may deter buyers looking for low-maintenance options.

Stick tire gauges are compact and straightforward, making them an excellent choice for mobile tire service providers. Their lightweight design allows for easy transport, which is essential for businesses operating on the go. However, B2B buyers should be aware that these gauges may lack some advanced features and precision found in other types. When purchasing, businesses should weigh the benefits of portability against the need for accuracy, especially in high-volume tire service scenarios.

Bluetooth tire gauges connect to mobile devices, allowing for data tracking and analytics, which is particularly valuable for fleet management and automotive tech companies. These gauges can provide insights into tire pressure trends over time, helping businesses maintain optimal vehicle performance. However, buyers should consider the higher cost and reliance on technology, as well as the potential for connectivity issues. For companies focused on data-driven decision-making, the investment in Bluetooth gauges can yield significant long-term benefits.

Inflator tire gauges combine the functionality of measuring tire pressure with the ability to inflate tires, making them highly efficient tools for tire service centers and automotive workshops. Their multifunctional nature can save time during tire servicing, which is a key consideration for businesses aiming to improve operational efficiency. However, these gauges tend to be bulkier and may come at a higher price point. B2B buyers should assess the balance between functionality and space constraints in their operations when considering these tools.

| Industria/Settore | Specific Application of tire pressure gauge autozone | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Negozi di riparazione di autoveicoli | Routine tire pressure checks for customer vehicles | Enhances customer safety and satisfaction, reduces tire wear and fuel consumption | Quality and durability of gauges, calibration accuracy, ease of use |

| Logistics and Transportation | Fleet maintenance for commercial vehicles | Improves fuel efficiency and extends tire lifespan, ensuring timely deliveries | Bulk purchasing options, compatibility with various vehicle types |

| Agricoltura | Tire pressure monitoring for agricultural machinery | Increases operational efficiency and reduces downtime due to tire failures | Rugged design for harsh environments, ease of storage and handling |

| Costruzione | Tire pressure checks for heavy machinery | Minimizes equipment downtime and enhances safety on job sites | Calibration standards, ability to handle high-pressure tires |

| Retail Automotive Parts | Inventory for tire maintenance products | Meets customer demand for reliable tire care solutions | Variety of models available, competitive pricing, supplier reliability |

In automotive repair shops, tire pressure gauges from AutoZone are essential tools for conducting routine tire pressure checks on customer vehicles. Properly inflated tires ensure optimal vehicle performance, enhance safety, and improve fuel efficiency. Repair shops can solve common problems such as uneven tire wear and poor handling by regularly checking and adjusting tire pressures. International buyers, particularly in regions with varying climates, should prioritize gauges known for accuracy and durability to ensure consistent performance across diverse conditions.

Illustrative image related to tire pressure gauge autozone

For logistics and transportation companies, maintaining optimal tire pressure across fleets is crucial for operational efficiency. Using tire pressure gauges allows fleet managers to regularly monitor and adjust tire pressure, which can lead to significant savings in fuel costs and reduced tire wear. This practice ensures timely deliveries and minimizes the risk of tire-related breakdowns. Buyers in this sector should consider sourcing gauges that offer bulk purchasing options and are compatible with a variety of vehicle types to streamline their maintenance processes.

In the agricultural sector, tire pressure gauges are vital for monitoring the pressure of tractors and other machinery. Proper tire inflation is key to maximizing operational efficiency, reducing fuel consumption, and preventing tire blowouts in rugged terrains. Farmers can avoid costly downtime by ensuring that their equipment operates with the correct tire pressure. Buyers from agricultural regions should look for gauges that are rugged, capable of withstanding harsh environments, and easy to store and handle, ensuring reliability during peak operational seasons.

Construction companies rely on tire pressure gauges to maintain heavy machinery used on job sites. Regular checks help minimize equipment downtime caused by tire failures, thereby enhancing safety and productivity. Proper tire inflation contributes to better handling and reduces the risk of accidents. When sourcing gauges, construction firms should focus on calibration standards and the ability to handle high-pressure tires, ensuring that the tools meet the rigorous demands of construction environments.

Retail automotive parts suppliers benefit from offering tire pressure gauges as part of their inventory of tire maintenance products. By stocking these gauges, retailers can meet consumer demand for reliable tire care solutions, which are essential for vehicle maintenance. This can lead to increased customer loyalty and sales. When sourcing, retailers should consider the variety of models available, competitive pricing, and the reliability of suppliers to ensure they can offer customers high-quality products.

Il problema: B2B buyers, such as fleet managers or automotive service providers, often encounter inconsistent tire pressure readings due to fluctuating environmental conditions or faulty gauges. This inconsistency can lead to poor vehicle performance, increased fuel consumption, and accelerated tire wear, ultimately impacting operational costs and safety. For instance, a fleet vehicle operating under incorrect tire pressure may experience decreased handling capabilities, which poses a risk during transit, especially in challenging terrains common in regions like Africa or South America.

La soluzione: To address this issue, it’s essential to invest in high-quality tire pressure gauges from AutoZone that are designed for accuracy and durability. Buyers should look for gauges with features such as digital displays for precise readings and a robust design that can withstand harsh conditions. Regular calibration of these gauges is also critical; set a schedule for calibrating or replacing gauges every six months. Implementing a routine tire pressure check—ideally weekly or before long trips—can help ensure consistent monitoring, allowing for timely adjustments. This proactive approach not only enhances vehicle safety but also optimizes fuel efficiency and extends tire life.

Il problema: Many B2B buyers face challenges in understanding the correct tire pressure specifications for different vehicle models, particularly when dealing with a diverse fleet or when servicing various customer vehicles. Misinterpretation of tire pressure specifications can lead to over-inflation or under-inflation, both of which can drastically affect tire performance and longevity. This issue is especially prevalent in markets where tire standards may vary and where buyers may not have immediate access to manufacturer guidelines.

La soluzione: To mitigate this confusion, buyers should leverage resources available through AutoZone, including owner’s manuals and online databases that provide vehicle-specific tire pressure recommendations. It is advisable to maintain a comprehensive reference guide that lists the correct tire pressures for all vehicles in a fleet. Additionally, using a tire pressure gauge that includes preset pressure settings can simplify the process of adjusting to the correct pressure. Training staff on these specifications and the importance of adhering to them can further enhance understanding and compliance, ensuring the safety and efficiency of the fleet.

Illustrative image related to tire pressure gauge autozone

Il problema: For international B2B buyers, especially in remote areas of Africa, South America, or the Middle East, sourcing reliable tire pressure gauges can be a significant challenge. Many local suppliers may offer subpar products that fail to provide accurate readings, leading to compromised vehicle safety and operational efficiency. This issue can hinder the ability of businesses to maintain their fleets effectively, resulting in increased downtime and repair costs.

La soluzione: To overcome this sourcing challenge, B2B buyers should consider establishing partnerships with reputable suppliers like AutoZone that offer a consistent inventory of high-quality tire pressure gauges. Utilizing online platforms for direct ordering and ensuring that products meet international quality standards can significantly improve procurement efficiency. Buyers can also explore bulk purchasing options to secure better pricing and ensure a steady supply of reliable gauges. Additionally, setting up a network with local automotive service providers to share resources and knowledge can enhance the overall maintenance strategy for fleets, ensuring that all vehicles remain roadworthy and efficient.

When selecting materials for tire pressure gauges, several factors must be considered to ensure optimal performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the manufacturing of tire pressure gauges, highlighting their key properties, advantages and disadvantages, and specific considerations for international B2B buyers.

Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is frequently used in the casing of tire pressure gauges. These materials offer excellent resistance to impact and corrosion, making them suitable for various environmental conditions. They can withstand a wide temperature range, typically from -40°C to 80°C (-40°F to 176°F), which is essential for applications in diverse climates.

Pro: Plastic is lightweight, cost-effective, and easy to mold into complex shapes, which simplifies manufacturing. It also provides good insulation against electrical currents.

Illustrative image related to tire pressure gauge autozone

Contro: However, plastics can be less durable than metals, particularly under extreme temperatures or prolonged UV exposure. They may also be less accurate in pressure readings over time due to material fatigue.

Impatto sull'applicazione: Plastic gauges are generally suitable for consumer-grade applications but may not perform well in industrial settings where precision is critical.

Considerazioni per gli acquirenti internazionali: Compliance with material safety standards such as ASTM or ISO is crucial. Buyers in regions like Europe may prefer materials that are recyclable or have lower environmental impacts due to stringent regulations.

Metals, particularly aluminum and stainless steel, are also popular choices for tire pressure gauges. These materials offer high durability and resistance to corrosion, especially in humid or saline environments. They can withstand higher pressures and temperatures, making them ideal for more demanding applications.

Pro: Metal gauges tend to have a longer lifespan and provide more accurate readings than their plastic counterparts. They can also handle a wider range of environmental conditions without degrading.

Illustrative image related to tire pressure gauge autozone

Contro: The primary drawbacks include higher manufacturing costs and weight. Metal gauges can also be prone to rust if not properly treated, particularly in coastal regions.

Impatto sull'applicazione: Metal gauges are suitable for both consumer and industrial applications, especially where precision and durability are paramount.

Considerazioni per gli acquirenti internazionali: Buyers must consider compliance with international standards like DIN or JIS, especially in Europe and Asia, where quality assurance is critical.

Rubber is often used for seals and gaskets in tire pressure gauges. Its primary property is flexibility, which allows for a tight seal that prevents air leaks. Rubber can also withstand a range of temperatures, though it may degrade faster than plastics or metals under UV exposure.

Pro: Rubber components are generally inexpensive and easy to replace. They provide excellent sealing capabilities, which is crucial for maintaining accurate pressure readings.

Contro: The longevity of rubber can be a concern, especially in harsh environments where it may crack or become brittle over time.

Impatto sull'applicazione: Rubber seals are essential for maintaining the integrity of the gauge, particularly in high-pressure applications.

Considerazioni per gli acquirenti internazionali: Buyers should ensure that the rubber used complies with relevant health and safety regulations, especially in regions with strict environmental laws.

Glass is commonly used for the lens of tire pressure gauges, particularly in analog models. It offers excellent clarity and scratch resistance, which is crucial for readability.

Pro: Glass is durable and provides a clear view of the gauge’s reading, enhancing user experience. It is also resistant to chemical corrosion.

Contro: However, glass is heavier and more fragile than plastic or metal, making it less suitable for rugged environments.

Impatto sull'applicazione: Glass lenses are typically found in high-quality gauges designed for precision and aesthetics.

Considerazioni per gli acquirenti internazionali: Buyers should consider the fragility of glass in transport and storage, especially in regions prone to rough handling.

| Materiale | Typical Use Case for tire pressure gauge autozone | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Plastica | Consumer-grade tire pressure gauges | Leggero e conveniente | Less durable under extreme conditions | Basso |

| Metallo | Industrial and high-precision gauges | High durability and accuracy | Higher cost and weight | Alto |

| Gomma | Seals and gaskets in various gauges | Excellent sealing capabilities | Limited lifespan in harsh conditions | Basso |

| Vetro | Lenses in analog gauges | Scratch-resistant and clear | Fragile and heavier than alternatives | Medio |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in tire pressure gauges, helping them make informed decisions based on performance, cost, and compliance with international standards.

The manufacturing and quality assurance processes for tire pressure gauges, particularly those sourced from AutoZone, involve several critical stages that ensure the products meet international standards and customer expectations. This section outlines the typical manufacturing processes, quality control checkpoints, and considerations for B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe.

The manufacturing process of tire pressure gauges typically involves four main stages: material preparation, forming, assembly, and finishing. Each stage is crucial for producing a reliable and accurate product.

Material preparation begins with the selection of high-quality raw materials, primarily metals like aluminum or brass for the casing and plastic for the gauge housing. These materials are chosen for their durability and resistance to corrosion, which is essential for automotive applications.

Once materials are sourced, they undergo a cleaning process to remove any contaminants. This is critical as impurities can affect the performance and accuracy of the gauge. After cleaning, materials are cut and shaped into the required specifications, preparing them for the next stage of manufacturing.

The forming process involves shaping the prepared materials into the components of the tire pressure gauge. Common techniques include machining, injection molding, and stamping.

Illustrative image related to tire pressure gauge autozone

These techniques not only create the necessary components but also allow for scalability in production, which is vital for meeting demand in B2B markets.

Assembly is a critical stage where the individual components are brought together. Typically, this process is semi-automated to ensure precision while allowing for human oversight.

During assembly, components like the gauge head, valve stem, and casing are fitted together. Sealing mechanisms are applied to prevent air leakage, which is crucial for maintaining accuracy. Each gauge is then calibrated to ensure it provides precise readings, usually by comparing it against a reference standard.

Finishing processes enhance the durability and aesthetics of the tire pressure gauge. This may include anodizing metal parts to prevent corrosion, applying protective coatings, and printing measurement markings.

Quality checks are often integrated into the finishing stage, ensuring that any defects are identified and rectified before the product reaches the market. This attention to detail is essential for maintaining brand reputation and customer trust.

Quality control (QC) is a cornerstone of the manufacturing process for tire pressure gauges. It ensures that products meet both international standards and specific industry requirements.

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 indicates that a company consistently provides products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, particularly for gauges intended for specific applications in automotive and industrial settings. These certifications provide further assurance of quality and safety.

Quality control checkpoints are integrated throughout the manufacturing process to ensure product integrity:

These checkpoints are essential for identifying issues early in the production process, thereby reducing waste and ensuring high-quality outputs.

For international B2B buyers, especially those from diverse markets, verifying a supplier’s quality control processes is crucial for ensuring product reliability and compliance.

Buyers can conduct audits of potential suppliers to assess their manufacturing capabilities and QC measures. This may involve visiting the manufacturing facility, reviewing production processes, and evaluating the supplier’s adherence to international standards.

Additionally, requesting quality assurance reports and certifications can provide insight into a supplier’s commitment to quality. Third-party inspections can also be arranged to provide an unbiased evaluation of the supplier’s QC processes.

B2B buyers should be aware that certification requirements may vary by region. For instance, European markets often require CE marking for automotive components, while other regions may have different regulatory standards. Understanding these nuances is vital for ensuring compliance and avoiding potential legal issues.

Furthermore, cultural and operational differences in quality control practices may exist between regions. Buyers should consider these factors when assessing suppliers from different countries, ensuring that they align with their own quality expectations and operational standards.

The manufacturing processes and quality assurance measures for tire pressure gauges, particularly those available through AutoZone, are designed to meet stringent international standards and customer expectations. By understanding these processes, B2B buyers can make informed decisions when sourcing tire pressure gauges, ensuring they select suppliers who adhere to best practices in manufacturing and quality control. This knowledge not only aids in mitigating risks associated with product performance but also fosters stronger relationships with reliable suppliers in the global market.

In this guide, we provide a practical checklist for B2B buyers looking to procure tire pressure gauges from AutoZone. This resource is designed to streamline your sourcing process and ensure you select the right tools that meet your operational needs.

Define the specifications for the tire pressure gauges you need. Consider factors such as accuracy, type (analog or digital), and range of pressure measurement. Understanding these requirements will help narrow down your choices and ensure that the gauges you select are suitable for your vehicles and operational conditions.

Conduct thorough research on potential suppliers. Begin with AutoZone, but also explore other suppliers who offer similar products. Look for reviews, ratings, and testimonials from other businesses in your region, particularly in Africa, South America, the Middle East, and Europe, to gauge the reliability and quality of their products.

Assess the quality of the tire pressure gauges. Check for features such as durability, ease of use, and warranty options. High-quality gauges will provide accurate readings and withstand regular use, which is crucial for maintaining vehicle safety and performance.

Confirm that your chosen suppliers have the necessary certifications. This includes ISO certifications or compliance with local regulations. Certified suppliers are more likely to provide reliable products and services, reducing the risk of defects and ensuring compliance with safety standards.

Ask for product samples before making a bulk purchase. Testing samples allows you to evaluate the gauges’ performance and reliability firsthand. This step is crucial to ensure the products meet your specifications and quality expectations.

Analyze the pricing structures and purchasing terms of potential suppliers. Look for bulk purchase discounts, shipping costs, and payment terms. Ensure that you are getting the best value for your investment while considering quality and service levels.

Build a solid relationship with your chosen supplier. Good communication and rapport can lead to better service and support in the long run. Discuss your future needs, and ensure they understand your business requirements for ongoing support and product availability.

By following these steps, B2B buyers can effectively source tire pressure gauges from AutoZone and other suppliers, ensuring they make informed decisions that enhance their operational efficiency and vehicle safety.

When analyzing the cost structure of tire pressure gauges sourced from AutoZone or similar suppliers, several components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

I materiali: The primary materials used in tire pressure gauges typically include plastics for the casing, metal for the internal mechanisms, and rubber for seals. The quality of these materials can significantly influence the final cost. For instance, high-grade brass fittings or precision-engineered plastics will increase material costs but can enhance durability and accuracy.

Lavoro: Labor costs depend on the region of production. In countries with lower labor costs, such as certain areas in Southeast Asia, the production costs will be lower. However, labor costs in Europe or North America may be significantly higher, impacting the overall pricing structure.

Spese generali di produzione: This encompasses all indirect costs related to production, such as utilities, rent, and equipment depreciation. Efficient production processes can help reduce overhead, thus lowering the final price.

Utensili: Initial tooling costs can be substantial, especially for custom designs. This is often a fixed cost that can be amortized over larger production runs. Buyers should consider the expected order volume when assessing how tooling will affect pricing.

Controllo qualità: Implementing rigorous QC processes ensures product reliability and compliance with international standards, which can increase costs. However, investing in quality assurance can lead to fewer defects and lower warranty claims in the long run.

Logistica: Transportation costs vary based on the shipping method, distance, and Incoterms agreed upon. International shipping can introduce additional complexities and costs, especially with customs duties and tariffs.

Margine: Supplier margins can vary widely based on brand reputation, product features, and market competition. Understanding these margins can help buyers negotiate better pricing.

Several factors influence the pricing of tire pressure gauges, particularly for international buyers:

Volume/MOQ (quantità minima d'ordine): Higher order quantities often lead to lower per-unit costs. Buyers should assess their needs and negotiate volume discounts accordingly.

Specifiche e personalizzazione: Custom features can significantly impact pricing. If unique specifications are required, buyers should expect to pay a premium for customization.

Qualità e certificazioni: Gauges with certifications (e.g., ISO or CE) may command higher prices due to the assurance of quality and compliance with safety standards.

Fattori di fornitura: Established suppliers with a strong market presence may have higher prices due to brand trust and perceived quality. However, new entrants may offer competitive pricing to build market share.

Incoterms: The chosen Incoterm (e.g., FOB, CIF) can affect the total cost. Understanding who is responsible for shipping, insurance, and duties is essential for accurate cost assessment.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips to enhance their negotiation outcomes:

Illustrative image related to tire pressure gauge autozone

Comprendere il costo totale di proprietà (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential savings from higher quality products. This perspective can justify a higher upfront cost if it leads to savings over time.

Leverage Market Research: Gather information on market prices and competitor offerings to strengthen your negotiation position. Knowledge of prevailing prices can empower you to negotiate better terms.

Costruire relazioni: Establishing strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield mutual benefits, including loyalty discounts.

Be Clear on Requirements: Clearly articulate your specifications and expectations to avoid misunderstandings that could lead to increased costs later.

Consider Payment Terms: Negotiating favorable payment terms can improve cash flow and reduce financial strain. Explore options like staggered payments or extended credit terms.

Stay Informed on Currency Fluctuations: For international transactions, being aware of currency exchange rates can help in making timely purchasing decisions to maximize cost efficiency.

Prices for tire pressure gauges can fluctuate based on market conditions, supplier changes, and international trade dynamics. It is advisable for buyers to seek current quotes and consider all cost factors when making purchasing decisions.

In the realm of tire maintenance, ensuring optimal tire pressure is critical for vehicle performance and safety. While the Tire Pressure Gauge from AutoZone serves as a reliable tool for this purpose, various alternative solutions exist that can offer unique advantages. This analysis will compare the AutoZone tire pressure gauge with two notable alternatives: digital tire pressure monitors and smartphone tire pressure apps. By examining their performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions tailored to their operational needs.

| Aspetto di confronto | Tire Pressure Gauge Autozone | Digital Tire Pressure Monitor | Smartphone Tire Pressure App |

|---|---|---|---|

| Prestazioni | Accurate readings; manual check needed | Continuous monitoring; immediate alerts | Varies by sensor; may require calibration |

| Costo | Affordable (typically $10-$30) | Moderate ($50-$150) | Low to moderate (free to $30 for sensors) |

| Facilità di implementazione | Simple and straightforward | Requires installation | Easy setup; relies on compatible sensors |

| Manutenzione | Minimal (occasional calibration) | Low (battery replacement) | Low (app updates; sensor battery) |

| Il miglior caso d'uso | Personal vehicles; occasional checks | Fleet management; high usage | DIY enthusiasts; tech-savvy users |

Digital tire pressure monitors provide continuous monitoring of tire pressure, alerting users to any changes. These systems are ideal for fleet management or high-usage vehicles, where consistent tire performance is crucial. The advantages include real-time alerts that can prevent issues before they become severe. However, they come with higher upfront costs and require installation, which may not be feasible for all users. Additionally, they may need occasional battery replacements, adding to maintenance considerations.

Smartphone tire pressure apps are innovative solutions that leverage existing mobile technology to monitor tire pressure. When paired with compatible sensors, these apps can provide real-time data and alerts directly to a user’s smartphone. This option is particularly appealing to DIY enthusiasts and tech-savvy users, as it combines convenience with functionality. However, performance can vary depending on the quality of the sensors, and users may need to calibrate the system for accurate readings. While the initial costs can be low, investing in high-quality sensors may increase overall expenses.

When selecting a tire pressure monitoring solution, B2B buyers should consider their specific operational requirements and budget constraints. For businesses managing a fleet, investing in digital tire pressure monitors may yield significant long-term benefits through enhanced safety and efficiency. Conversely, for occasional users or those seeking a straightforward solution, the Tire Pressure Gauge from AutoZone remains a practical and cost-effective choice. Smartphone tire pressure apps offer a modern alternative for tech-savvy users but may require additional investment in sensors for optimal performance. Ultimately, the decision should align with the business’s operational scale, budget, and technological readiness.

When considering tire pressure gauges, several technical specifications are critical for ensuring accuracy, durability, and reliability in professional applications. Understanding these properties helps B2B buyers make informed purchasing decisions.

Accuracy is the degree to which the gauge measures the actual tire pressure. Precision refers to the gauge’s ability to consistently provide the same reading under the same conditions. For B2B buyers, choosing a gauge with high accuracy (typically ±1 psi) is essential for safety and performance, especially in commercial fleets where tire pressure directly impacts fuel efficiency and tire longevity.

The measurement range of a tire pressure gauge indicates the minimum and maximum pressure it can accurately measure, usually expressed in psi (pounds per square inch) or bar. A typical range for automotive gauges is 0-60 psi. Selecting a gauge with an appropriate range for the specific application ensures it can accommodate various vehicle types, which is particularly relevant for businesses that service multiple fleets.

The material used in the construction of the gauge affects its durability and resistance to environmental factors. Common materials include plastic, metal, and rubber. For B2B buyers, investing in gauges made from high-grade materials can lead to lower replacement costs and improved reliability, especially in harsh working environments.

Tire pressure gauges come with various display types, including analog (dial) and digital displays. Digital gauges often provide easier reading and additional features like backlighting. The choice of display impacts usability, especially in low-light conditions, which is vital for businesses operating in varied environments.

Calibration refers to the process of adjusting the gauge to ensure accurate readings. Gauges should meet industry standards such as ANSI (American National Standards Institute) or ISO (International Organization for Standardization). Ensuring that gauges are calibrated to these standards is critical for B2B operations that require compliance with safety regulations and accurate reporting.

Understanding industry jargon is crucial for effective communication and negotiation in the tire pressure gauge market. Below are key terms that B2B buyers should be familiar with.

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of tire pressure gauges, purchasing OEM products ensures compatibility and quality, which is crucial for businesses requiring reliable tools for service and repairs.

MOQ indicates the smallest number of units a supplier is willing to sell. For B2B buyers, understanding MOQ helps in budgeting and inventory management. It’s crucial to negotiate MOQs that align with operational needs to avoid excess stock or insufficient supply.

An RFQ is a formal process where buyers request pricing and terms from suppliers. It is essential for B2B transactions as it allows buyers to compare offers and negotiate better terms, ensuring they receive competitive pricing on tire pressure gauges.

Incoterms are international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is vital for B2B buyers involved in international trade, as they dictate shipping costs and risk transfer points.

Lead time refers to the time taken from placing an order to receiving it. For B2B buyers, understanding lead times is crucial for planning inventory and ensuring that tire pressure gauges are available when needed, particularly in industries with tight operational schedules.

By grasping these technical properties and trade terms, B2B buyers can make better-informed decisions when sourcing tire pressure gauges, optimizing their purchasing processes, and enhancing operational efficiency.

The global market for tire pressure gauges is being driven by a growing awareness of vehicle maintenance and safety among consumers and businesses. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where vehicle ownership is increasing and the importance of proper tire maintenance is being recognized. Key trends include the integration of smart technologies in tire pressure monitoring systems (TPMS), which provide real-time data and alerts to drivers.

Moreover, there is a shift towards digitalization in sourcing processes, with B2B buyers increasingly relying on online platforms for procurement. This is particularly relevant for international buyers who are looking to streamline their supply chains and reduce costs. The rise of e-commerce has facilitated easier access to a variety of tire pressure gauges and related products, enabling buyers to compare prices and features across different suppliers.

In addition, sustainability is becoming a critical consideration for international buyers. Companies are seeking suppliers that prioritize eco-friendly practices and offer products made from sustainable materials. This trend not only aligns with global environmental goals but also caters to consumer demand for greener products. As a result, suppliers that can demonstrate compliance with sustainability standards are likely to gain a competitive edge in the market.

The environmental impact of manufacturing processes in the tire pressure gauge sector cannot be overlooked. As the automotive industry faces increasing scrutiny regarding its carbon footprint, the demand for sustainable practices is becoming essential. B2B buyers are now prioritizing suppliers who implement ethical sourcing and manufacturing methods, including the use of recycled materials and energy-efficient production processes.

Ethical supply chains are crucial for ensuring that products are produced with minimal environmental impact and under fair labor conditions. Certifications such as ISO 14001 (Environmental Management) and other green credentials are gaining importance as buyers seek to verify the sustainability claims of their suppliers.

Illustrative image related to tire pressure gauge autozone

Furthermore, the emphasis on sustainability is also influencing product innovation. Manufacturers are exploring the use of biodegradable materials and developing tire pressure gauges with longer lifespans to reduce waste. For international buyers, sourcing from suppliers who adhere to these sustainability standards can enhance brand reputation and appeal to environmentally conscious consumers.

The tire pressure gauge has evolved significantly from its early mechanical forms to the advanced digital models available today. Initially, these tools were primarily used by mechanics and automotive professionals. However, as consumer awareness of vehicle safety has increased, tire pressure gauges have become essential tools for everyday drivers.

In the past, tire pressure gauges were basic instruments that required manual calibration and provided limited information. Today, technological advancements have led to the development of digital gauges that offer precise readings and additional features such as memory functions and Bluetooth connectivity for integration with mobile applications. This evolution reflects a broader trend within the automotive industry towards greater accuracy and user-friendliness in vehicle maintenance tools.

As the market continues to grow, B2B buyers can expect ongoing innovations that enhance the functionality and efficiency of tire pressure gauges, further solidifying their importance in automotive safety and maintenance.

1. How do I ensure the accuracy of tire pressure gauges purchased from AutoZone?

To ensure the accuracy of tire pressure gauges, consider purchasing models that come with calibration certificates or are known for their precision. Regularly check the gauges against a standard gauge to confirm their readings. Additionally, educate your team on proper usage techniques, such as ensuring a proper seal against the valve stem to avoid air leaks during measurement. Implementing a routine calibration schedule can also help maintain accuracy over time.

Illustrative image related to tire pressure gauge autozone

2. What is the best tire pressure gauge for commercial vehicles?

For commercial vehicles, it’s advisable to choose tire pressure gauges that can handle higher pressure ranges and offer durability, such as digital gauges or heavy-duty analog models. Look for features like backlit displays for easy reading, automatic shut-off to save battery, and rugged designs that withstand rough handling. Brands with positive reviews in the industry, such as Duralast available at AutoZone, are often reliable choices for commercial applications.

3. What minimum order quantity (MOQ) should I expect when sourcing tire pressure gauges?

The minimum order quantity (MOQ) for tire pressure gauges can vary significantly by supplier and region. Typically, MOQs for B2B purchases range from 50 to 500 units, depending on the manufacturer and product specifications. It is essential to discuss your needs with potential suppliers to negotiate favorable terms. Some suppliers may offer lower MOQs for first-time buyers or bulk purchases, which can be beneficial for establishing a long-term relationship.

4. How can I vet suppliers for tire pressure gauges from AutoZone?

Vetting suppliers involves checking their business credentials, reputation, and product quality. Start by reviewing online ratings and testimonials from other B2B buyers. Request samples of the tire pressure gauges to assess quality firsthand. Additionally, inquire about their manufacturing processes, compliance with international standards, and after-sales support. Building a relationship with suppliers through clear communication about your needs can also facilitate trust and reliability.

5. What payment terms are typically offered by suppliers for tire pressure gauges?

Payment terms can vary by supplier, but common arrangements include net 30, 60, or 90 days, with options for upfront payment discounts. Some suppliers may accept letters of credit or escrow services for larger orders. It’s important to clarify payment terms upfront to avoid misunderstandings. Establishing a strong credit history with suppliers may also lead to more favorable terms over time.

6. How can I customize tire pressure gauges for my brand?

Customization options for tire pressure gauges often include branding, packaging, and specific feature requests. Discuss your requirements with suppliers, as many are willing to accommodate custom designs, especially for bulk orders. Ensure that you provide clear specifications, such as logo placement and color preferences. Be prepared for potential minimum order requirements for customized items, as this may affect pricing and lead times.

7. What logistics considerations should I keep in mind when sourcing from AutoZone?

When sourcing tire pressure gauges, consider logistics factors such as shipping costs, lead times, and import/export regulations specific to your region. Collaborate with suppliers to choose the most cost-effective shipping methods, whether air freight for speed or sea freight for cost savings. Ensure you understand customs duties and taxes that may apply upon arrival in your country. Having a reliable logistics partner can simplify this process.

8. How can I ensure quality assurance (QA) for tire pressure gauges before purchase?

To ensure quality assurance, request detailed product specifications and standards from the supplier. Look for certifications that indicate compliance with international quality standards, such as ISO. Implement a quality inspection process, either through third-party services or in-house checks, prior to shipment. Establishing a clear return policy with your supplier can also provide a safety net if the products do not meet your quality expectations.

Dominio: facebook.com

Registrato: 1997 (28 anni)

Introduzione: This company, AutoZone – Tire Pressure Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In the evolving landscape of automotive maintenance, strategic sourcing of tire pressure gauges presents significant opportunities for international B2B buyers. The importance of maintaining optimal tire pressure cannot be overstated; it directly impacts vehicle performance, safety, and longevity of tires. By partnering with reputable suppliers like AutoZone, businesses can ensure they provide high-quality tools that meet the needs of their customers, thereby enhancing their service offerings.

Key takeaways for B2B buyers include understanding the critical role that proper tire pressure plays in fuel efficiency and tire wear, and the necessity of reliable gauges to facilitate regular checks. Sourcing from established brands not only guarantees quality but also fosters trust with end-users, which is crucial in competitive markets across Africa, South America, the Middle East, and Europe.

As we look to the future, the demand for tire pressure gauges is set to rise, particularly as awareness of vehicle maintenance grows globally. We encourage B2B buyers to leverage strategic sourcing practices that prioritize quality and reliability, ensuring they remain at the forefront of the automotive service industry. Engage with suppliers who understand your regional market dynamics, and invest in tools that will drive value for your customers and your business alike.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.