In the ever-evolving landscape of the global market, sourcing reliable tyre air filling solutions poses significant challenges for B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With variations in vehicle types, local regulations, and customer expectations, understanding the nuances of tyre air filling is crucial for maintaining operational efficiency and safety. This comprehensive guide delves into the multifaceted world of tyre air filling, covering essential topics such as types of air filling systems, applications across various industries, supplier vetting processes, and cost considerations.

By providing actionable insights and expert recommendations, this guide empowers international B2B buyers to make informed purchasing decisions tailored to their unique market conditions. Whether you are a fleet manager in Nigeria seeking cost-effective solutions or a distributor in Brazil looking to expand your product offerings, the information presented here will help navigate the complexities of tyre air filling. From understanding the importance of maintaining optimal tire pressure to exploring innovative air filling technologies, this resource serves as a strategic tool for optimizing your operations and enhancing customer satisfaction. Equip yourself with the knowledge needed to thrive in a competitive marketplace and ensure the longevity and safety of your fleet.

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Air Filling | Uses standard atmospheric air for inflation. | General automotive maintenance and service. | Pro: Widely available; cost-effective. Contro: May lead to pressure loss due to temperature changes. |

| Nitrogen Filling | Utilizes nitrogen gas, reducing moisture and pressure fluctuations. | High-performance vehicles, fleet management. | Pro: Improved tire longevity; better fuel efficiency. Contro: Higher initial cost; requires specialized equipment. |

| Compressed Air | High-pressure air systems for rapid inflation. | Industrial applications, heavy machinery. | Pro: Quick inflation; suitable for large tires. Contro: Potential for over-inflation; requires monitoring. |

| Portable Air Compressors | Compact and battery-operated, suitable for on-the-go inflation. | Mobile service providers, roadside assistance. | Pro: Convenient; easy to use anywhere. Contro: Limited power; may not handle larger tires effectively. |

| Inflation with Sealants | Incorporates sealants to prevent leaks during inflation. | Commercial fleets, off-road vehicles. | Pro: Reduces downtime; enhances safety. Contro: May require specialized training; potential for residue buildup. |

Air Filling is the most common method, utilizing standard atmospheric air. It is easily accessible and cost-effective, making it suitable for general automotive maintenance and service. However, air can expand and contract with temperature changes, leading to potential pressure loss. B2B buyers should consider the trade-off between convenience and the need for regular pressure checks.

Nitrogen Filling offers a more advanced solution by using nitrogen gas, which minimizes moisture and pressure fluctuations. This method is particularly beneficial for high-performance vehicles and fleet management, where tire longevity and fuel efficiency are critical. While the initial investment may be higher, the long-term benefits can justify the cost for businesses focused on optimizing vehicle performance.

Compressed Air systems provide high-pressure air for rapid inflation, often used in industrial applications and heavy machinery. These systems can quickly inflate large tires, making them ideal for businesses that require immediate service. However, they can pose a risk of over-inflation, necessitating careful monitoring during use.

Portable Air Compressors are compact and battery-operated, designed for on-the-go inflation. They cater to mobile service providers and roadside assistance, offering convenience and ease of use. However, their limited power may not be suitable for larger tires, which could be a drawback for businesses with diverse fleets.

Inflation with Sealants combines air filling with sealants that prevent leaks. This method is popular among commercial fleets and off-road vehicles, as it reduces downtime and enhances safety. While it offers significant advantages, businesses should consider the need for specialized training to manage the application and any potential residue buildup in the tires.

| Industria/Settore | Specific Application of tyre air filling | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Trasporto e logistica | Fleet maintenance for trucks and buses | Enhances fuel efficiency and extends tire lifespan | Reliable air filling equipment; availability of local service providers |

| Agricoltura | Inflation of agricultural vehicle tires | Improves traction and reduces crop damage | Durable compressors; compatibility with various tire types |

| Mining & Construction | Heavy machinery tire inflation | Ensures safety and operational efficiency | High-capacity compressors; ruggedness for harsh environments |

| Automotive Service Centers | Routine tire pressure checks and refills | Increases customer satisfaction and safety | Access to high-quality air compressors; training for staff on usage |

| Public Transport | Maintenance of public transport vehicle tires | Reduces downtime and enhances passenger safety | Consistent supply of air filling stations; compliance with safety regulations |

In the transportation and logistics sector, proper tyre air filling is crucial for maintaining fleet vehicles such as trucks and buses. Regularly inflated tires enhance fuel efficiency, reduce wear and tear, and ultimately lower operational costs. For international buyers, especially in regions like Africa and South America, sourcing reliable air filling equipment, as well as establishing local service partnerships, is essential to ensure timely maintenance and minimize vehicle downtime.

In agriculture, the inflation of tires on tractors and other heavy machinery is vital for optimizing performance. Properly inflated tires provide better traction on uneven terrain, reducing the risk of crop damage during planting and harvesting. Buyers in agricultural sectors must consider durable air compressors that can withstand outdoor conditions and are compatible with various tire sizes, ensuring their equipment remains operational throughout the farming season.

For the mining and construction industries, the inflation of heavy machinery tires is critical to safety and efficiency. Proper tire pressure helps prevent blowouts and ensures that machinery operates effectively under demanding conditions. Businesses in these sectors should focus on sourcing high-capacity air compressors that can handle the rugged environment and the large tire sizes typical in this industry, ensuring that equipment remains functional and safe.

Automotive service centers benefit significantly from providing tyre air filling services. Regular checks and refills not only enhance customer satisfaction but also contribute to vehicle safety. Buyers should prioritize high-quality air compressors and ensure their staff is trained to perform these services efficiently. Additionally, having access to reliable suppliers for equipment and maintenance parts is essential for sustaining service quality.

In public transport, maintaining proper tire pressure is vital for the safety of passengers and the efficiency of operations. Regular tyre air filling can significantly reduce downtime caused by tire issues, ensuring that buses and trains run on schedule. Public transport authorities must ensure a consistent supply of air filling stations and adhere to safety regulations, which are critical for maintaining operational integrity and public trust in their services.

Il problema:

Many B2B buyers managing fleets or automotive services face the challenge of locating reliable air filling stations, especially in regions with limited infrastructure. This can lead to downtime, increased operational costs, and frustration for drivers who need quick access to air filling services. For instance, a logistics company operating in remote areas may find that nearby gas stations either lack functional air compressors or charge exorbitant fees, disrupting their schedule and inflating operational costs.

La soluzione:

To mitigate this issue, businesses should establish partnerships with local tire shops or automotive service centers that offer free or affordable air filling services. Developing a network of reliable air filling stations can ensure that drivers have access to the necessary resources without incurring excessive costs. Additionally, investing in portable air compressors for fleet vehicles can provide an immediate solution for filling tires on-site. These compressors can be powered by the vehicle’s battery and are compact enough to fit in the trunk, allowing drivers to address tire pressure issues quickly and efficiently, thus minimizing downtime and maintaining operational efficiency.

Il problema:

Another pain point for B2B buyers involves the inconsistency and unreliability of tire pressure monitoring systems (TPMS) across different vehicle models and brands. This inconsistency can lead to discrepancies in tire pressure readings, causing some tires to be under-inflated while others are over-inflated. For businesses managing mixed fleets, such as delivery services, this can result in compromised safety, reduced fuel efficiency, and increased tire wear, ultimately affecting the bottom line.

La soluzione:

To address this challenge, B2B buyers should standardize TPMS across their fleets whenever possible. Investing in vehicles equipped with advanced TPMS technology that offers real-time monitoring can enhance accuracy and reliability. Additionally, regular training for drivers on interpreting TPMS alerts correctly is essential. Implementing a routine tire maintenance schedule, including monthly pressure checks and air filling, can help maintain optimal tire performance. Businesses can also utilize fleet management software that tracks tire health, providing alerts for pressure discrepancies and facilitating timely interventions.

Il problema:

A common issue faced by B2B buyers, particularly those new to fleet management, is a lack of knowledge regarding optimal tire inflation practices. Many drivers may not understand how temperature changes affect tire pressure or how to identify the correct PSI (pounds per square inch) for their specific vehicles. This ignorance can lead to improper inflation, resulting in safety hazards, increased fuel consumption, and premature tire degradation, which can be costly for businesses.

La soluzione:

To combat this knowledge gap, organizations should invest in comprehensive training programs for their drivers and maintenance staff. These programs should cover essential topics such as reading the vehicle’s tire information placard, understanding the impact of temperature on tire pressure, and the importance of checking tire pressure when tires are cool. Creating easy-to-follow reference materials, like quick guides or infographics, can reinforce this knowledge. Additionally, companies might consider implementing a system where tire pressure checks are part of routine vehicle inspections, ensuring that all vehicles are maintained at optimal tire pressure, thereby enhancing safety and efficiency across the fleet.

When selecting materials for tyre air filling, it is essential to consider the properties and performance characteristics of various options. This analysis focuses on four common materials: rubber, thermoplastic elastomers (TPE), metal, and composite materials. Each material presents unique advantages and challenges that can significantly impact the efficiency, durability, and overall performance of tyre air filling systems.

Rubber is the most traditional material used in tyre air filling applications, primarily for valve stems and seals. It boasts excellent elasticity, allowing it to maintain a tight seal under varying pressure conditions. Rubber typically has a temperature rating of -40°C to 120°C and is resistant to ozone and UV light, enhancing its longevity.

Pros and Cons: The primary advantage of rubber is its cost-effectiveness and ease of manufacturing. However, it may degrade over time due to exposure to certain chemicals and high temperatures, which can lead to leaks. For international buyers, understanding local rubber quality standards is crucial, as compliance with ASTM or ISO standards may vary by region.

Thermoplastic elastomers (TPE) are gaining popularity in tyre air filling due to their flexibility and chemical resistance. TPE can withstand temperatures ranging from -50°C to 100°C and offers excellent resistance to oils and solvents, making it suitable for diverse environments.

Pros and Cons: The key advantage of TPE is its recyclability and lower environmental impact compared to traditional rubber. However, TPE can be more expensive and complex to manufacture, which may deter some buyers. International buyers should consider compliance with environmental regulations, especially in regions like Europe where sustainability is prioritized.

Metal components, such as brass or stainless steel, are often used for valve cores and fittings in tyre air filling systems. Metals provide high durability and pressure resistance, typically handling pressures well above standard tyre requirements.

Pros and Cons: The primary advantage of metal is its robustness and long lifespan. However, metals can be prone to corrosion, especially in humid or saline environments, necessitating protective coatings. Buyers in regions like Africa or South America should be aware of local corrosion resistance standards to ensure long-term performance.

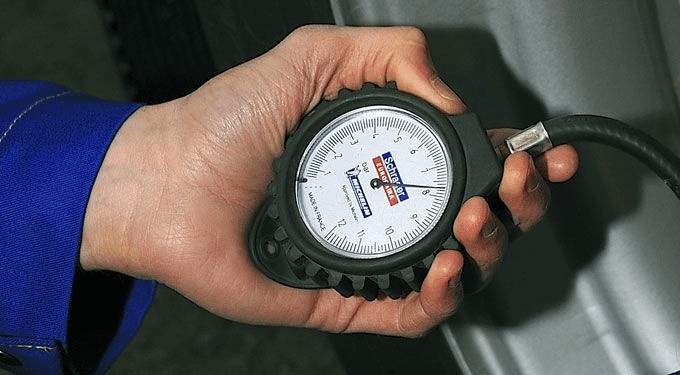

Illustrative image related to tyre air filling

Composite materials, which combine polymers with reinforcing agents, are emerging as a viable option for tyre air filling applications. These materials can be engineered to provide specific properties, such as enhanced strength and reduced weight.

Pros and Cons: The key advantage of composites is their versatility in design and performance. They can be tailored to meet specific requirements, such as temperature and pressure ratings. However, composites can be more expensive and complex to manufacture. International buyers should evaluate the availability of composite materials in their region and any associated compliance standards.

| Materiale | Typical Use Case for tyre air filling | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Gomma | Valve stems and seals | Cost-effective and easy to manufacture | Degrades over time with exposure | Basso |

| Thermoplastic Elastomers | Guarnizioni e componenti flessibili | Recyclable and chemically resistant | Maggiore complessità di produzione | Medio |

| Metallo | Valve cores and fittings | High durability and pressure resistance | Prone to corrosion | Medio |

| Materiali compositi | Custom engineered components | Versatile and tailored performance | Costi più elevati e complessità di produzione | Alto |

In conclusion, selecting the right material for tyre air filling involves a careful assessment of performance properties, manufacturing complexities, and regional compliance standards. By understanding the pros and cons of each material, international B2B buyers can make informed decisions that align with their operational needs and market conditions.

The manufacturing process for tyre air filling systems involves several critical stages that ensure the production of high-quality, reliable products. Understanding these stages helps B2B buyers identify suppliers who adhere to industry standards and deliver superior products.

The first step in manufacturing tyre air filling systems is the preparation of materials. This stage involves sourcing high-grade components such as durable plastics, metals, and rubber. Suppliers often conduct tests on raw materials to check for consistency and quality, ensuring that they meet the required specifications. This is crucial for maintaining the integrity and safety of the final product.

Illustrative image related to tyre air filling

Additionally, manufacturers may use advanced technologies like computer-aided design (CAD) software to design components that optimize performance and durability. For B2B buyers, it is essential to inquire about the material sourcing process and the standards applied to ensure quality.

Once materials are prepared, the next step is forming the various components of the tyre air filling system. This can include the production of hoses, nozzles, and pressure gauges. Techniques such as injection molding, extrusion, and CNC machining are commonly used to create precise parts that fit together seamlessly.

Quality assurance during this stage is paramount. Manufacturers typically implement in-process quality control (IPQC) measures to monitor the forming process. This includes real-time inspections and measurements to ensure that components meet dimensional tolerances. Buyers should request documentation of these processes to verify compliance with quality standards.

Illustrative image related to tyre air filling

The assembly stage is where all the components come together to create the final tyre air filling system. This process can involve manual assembly or automated systems, depending on the scale of production. Each assembly line is typically designed to minimize errors and maximize efficiency.

Quality checks are integrated into the assembly process, often involving final assembly inspections (FQC) to ensure that the product functions as intended. Buyers should look for suppliers who have robust assembly protocols and can provide evidence of their assembly quality checks.

Finishing is the final stage of the manufacturing process, where products undergo treatments such as surface coating, labeling, and packaging. This stage is critical for ensuring the durability and aesthetic appeal of the tyre air filling systems.

Quality assurance at this stage may include visual inspections and performance testing to confirm that the products are ready for distribution. Buyers should ensure that suppliers comply with international packaging and labeling standards, which can vary by region.

Quality assurance in the tyre air filling industry is governed by various international standards. Understanding these standards is essential for B2B buyers who wish to ensure that their suppliers maintain high-quality production practices.

ISO 9001 is an international standard that outlines the requirements for a quality management system (QMS). Manufacturers of tyre air filling systems that are ISO 9001 certified have demonstrated their commitment to quality and customer satisfaction. This certification involves regular audits and continuous improvement processes.

B2B buyers should prioritize suppliers with ISO 9001 certification, as it indicates a systematic approach to quality management and a commitment to meeting customer requirements.

In addition to ISO certifications, tyre air filling systems may also require compliance with industry-specific standards. For instance, the CE mark indicates that a product meets European safety, health, and environmental protection standards. Similarly, the American Petroleum Institute (API) standards may apply to systems used in petroleum-related applications.

Buyers should verify that their suppliers possess the necessary certifications relevant to their specific market and application.

Quality control checkpoints are critical to ensuring that tyre air filling systems meet the required standards throughout the manufacturing process. These checkpoints typically include:

Before production begins, manufacturers conduct IQC to assess the quality of incoming materials. This step is vital for preventing defects in the final product. B2B buyers can request reports detailing IQC findings to gain insight into the supplier’s material sourcing and quality assurance processes.

During the manufacturing process, IPQC measures are implemented to monitor production quality in real time. This includes regular inspections of forming and assembly operations. Buyers should inquire about the frequency of these checks and the criteria used for evaluation.

Once the product is assembled, FQC involves comprehensive testing to ensure that the tyre air filling systems meet performance and safety standards. This may include pressure testing and functional evaluations. Buyers should seek documentation of FQC results to verify product reliability before purchase.

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are several strategies to ensure that quality standards are met:

Regular supplier audits can provide invaluable insights into a manufacturer’s quality control processes. Buyers should consider scheduling on-site audits to assess compliance with international standards and to evaluate the effectiveness of quality management systems.

Suppliers should be able to provide detailed quality assurance reports that outline their processes and results. These reports should include documentation of IQC, IPQC, and FQC findings, as well as any corrective actions taken in response to identified issues.

For added assurance, buyers can engage third-party inspection services to conduct independent evaluations of their suppliers’ quality control processes. These services can provide unbiased assessments and help identify potential areas for improvement.

International B2B buyers must navigate various quality control and certification nuances that can vary by region. For instance, regulatory requirements in Africa may differ significantly from those in Europe or South America. Buyers should familiarize themselves with the specific standards applicable in their target markets.

Furthermore, cultural differences can influence the interpretation and implementation of quality control practices. It is essential for buyers to establish clear communication with suppliers regarding expectations and requirements to ensure mutual understanding.

In conclusion, the manufacturing processes and quality assurance practices for tyre air filling systems are critical for ensuring product reliability and safety. B2B buyers must understand the stages of manufacturing, the relevant international standards, and the quality control checkpoints involved. By verifying supplier practices through audits, reports, and third-party inspections, buyers can ensure that they are partnering with manufacturers who prioritize quality and compliance. This diligence will ultimately lead to better product performance and customer satisfaction in the competitive global market.

This guide serves as a practical checklist for B2B buyers looking to procure tyre air filling solutions. Ensuring proper tyre inflation is critical not only for vehicle performance and safety but also for optimizing operational efficiency. This checklist will help you navigate the sourcing process effectively, ensuring you choose reliable suppliers and the right equipment for your needs.

Before initiating the procurement process, it’s essential to outline your specific requirements. This includes the type of vehicles you are servicing, the range of tyre sizes, and the desired air pressure levels.

– Considerations: What is the typical usage (commercial vs. personal) of the tyres? Will you require portable or stationary air filling equipment?

Conduct thorough research on suppliers who specialize in tyre air filling solutions. Look for companies with a solid reputation and extensive experience in your target market regions, such as Africa, South America, the Middle East, and Europe.

– Evaluation Criteria: Check their product range, customer reviews, and case studies to gauge their reliability and service quality.

Before finalizing any supplier, ensure they possess the necessary certifications and compliance with international standards. This step is crucial to guarantee that the equipment meets safety and quality benchmarks.

– Key Certifications to Look For: ISO certifications, CE marking, and any region-specific compliance that may apply to your market.

Illustrative image related to tyre air filling

Engage suppliers to provide demonstrations of their tyre air filling equipment. This allows you to evaluate the functionality, ease of use, and maintenance requirements of the products.

– Focus Areas: Pay attention to the speed of inflation, accuracy of pressure gauges, and the presence of safety features.

A robust after-sales support system is vital for minimizing downtime and ensuring your equipment remains operational. Inquire about warranty terms and the availability of spare parts or maintenance services.

– What to Ask: What is included in the warranty? How quickly can they provide service or parts if needed?

Gather quotes from multiple suppliers to compare pricing structures and payment terms. Ensure you understand the total cost of ownership, including installation, maintenance, and operational costs.

– Negotiation Points: Look for bulk purchasing discounts or favorable financing options that can improve your cash flow.

Illustrative image related to tyre air filling

Once you’ve selected a supplier, ensure all agreements are clearly documented in a contract. This should include delivery timelines, payment terms, and service level agreements.

– Important Clauses: Include penalties for late delivery or non-compliance with the agreed specifications to protect your interests.

By following this checklist, B2B buyers can streamline their sourcing process for tyre air filling solutions, ensuring they make informed decisions that enhance their operational efficiency and safety standards.

When sourcing tyre air filling services, understanding the cost structure is essential for B2B buyers. The main components of the cost include:

I materiali: This encompasses the air compressors and hoses used for filling, which vary based on quality and specifications. Higher-quality compressors may incur a higher initial cost but can provide better durability and efficiency.

Lavoro: Skilled technicians are often required to ensure proper filling and maintenance of equipment. Labor costs can differ significantly based on regional wage standards and the complexity of the services offered.

Spese generali di produzione: This includes costs associated with the operation of facilities, utilities, and administrative expenses. These costs can vary widely depending on the location of the supplier and their operational efficiency.

Utensili: Equipment used for air filling must be regularly maintained and updated. The costs associated with tooling will depend on the technology and methods employed by the supplier.

Controllo qualità (CQ): Ensuring that air filling processes meet industry standards necessitates a robust QC system, which can add to the overall cost.

Logistica: Transportation of equipment and supplies can introduce additional costs, particularly for international buyers. Factors such as distance, shipping method, and customs duties all play a role in logistics expenses.

Margine: Suppliers will add a margin to cover their costs and generate profit. Understanding the typical margins in the industry can help buyers negotiate better pricing.

Several factors influence the pricing of tyre air filling services:

Volume/MOQ (quantità minima d'ordine): Larger orders typically lead to lower per-unit costs. Buyers should assess their needs to take advantage of bulk pricing.

Specifiche/Personalizzazione: Customized services may incur additional costs. Buyers should clarify their requirements upfront to avoid unexpected charges.

I materiali: The choice of materials used in the air filling process can significantly affect costs. Premium materials may enhance performance but come with a higher price tag.

Qualità e certificazioni: Suppliers offering certified services may charge more, but this often translates to better reliability and safety, which is crucial for businesses operating in high-stakes environments.

Fattori di fornitura: The reputation and location of the supplier can affect pricing. Established suppliers may command higher prices due to their reliability and service quality.

Incoterms: Understanding the Incoterms used in the transaction is crucial. They define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, influencing the overall cost.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are some strategic tips:

Negoziare i termini: Always negotiate pricing and terms before finalizing contracts. Suppliers may offer discounts for long-term commitments or larger orders.

Focus sull'efficienza dei costi: Consider the total cost of ownership rather than just upfront costs. This includes maintenance, durability, and potential savings from improved efficiency.

Comprendere le sfumature dei prezzi: Be aware of the local economic conditions, currency fluctuations, and import tariffs that can impact prices. This knowledge can provide leverage in negotiations.

Establish Relationships: Building a strong relationship with suppliers can lead to better pricing and service in the long run. Regular communication can also ensure that you stay informed about any changes in costs or services.

Prices in the tyre air filling industry can vary widely based on the aforementioned factors. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing. Always consult with suppliers to understand the specifics that may affect pricing in your region.

Illustrative image related to tyre air filling

In the realm of tyre management, maintaining optimal air pressure is critical for vehicle safety and performance. While traditional tyre air filling remains a common method, various alternatives have emerged that can offer unique advantages. This analysis compares tyre air filling with two viable alternatives: nitrogen tyre inflation and portable air compressors, providing B2B buyers with insights to make informed decisions.

| Aspetto di confronto | Tyre Air Filling | Nitrogen Tyre Inflation | Portable Air Compressors |

|---|---|---|---|

| Prestazioni | Standard performance | Improved stability and reduced pressure loss | Variable, depends on compressor quality |

| Costo | Low (often free at stations) | Higher initial cost, but longer-term savings | Moderate (one-time purchase) |

| Facilità di implementazione | Simple, widely available | Requires specific setups and training | User-friendly, portable options available |

| Manutenzione | Minimal upkeep | Requires specific maintenance | Regular checks for functionality |

| Il miglior caso d'uso | General use, quick fills | Long-distance travel, commercial vehicles | Personal and emergency use |

Nitrogen tyre inflation involves filling tyres with nitrogen gas instead of regular air. The primary advantage of this method is the reduced pressure loss over time, as nitrogen molecules are larger and less likely to escape through tyre walls. This leads to more stable tyre pressure, improved fuel efficiency, and extended tyre lifespan. However, the initial setup cost can be higher due to the need for specialized equipment and training. Additionally, nitrogen inflation is not as readily available as air filling, which may pose logistical challenges for some businesses.

Portable air compressors offer flexibility and convenience, allowing users to inflate tyres anywhere, whether at home or on the go. These devices can be powered by a vehicle’s battery or a standard electrical outlet, making them highly accessible. Their ease of use and the ability to adjust pressure settings according to specific requirements are significant advantages. However, the performance of portable compressors can vary widely depending on the model and brand, which necessitates careful selection. Moreover, they require regular maintenance to ensure optimal functionality, adding to the overall ownership cost.

For B2B buyers evaluating tyre inflation solutions, the choice between traditional air filling, nitrogen inflation, and portable air compressors should align with operational needs and budget constraints. Businesses that prioritize cost-effectiveness and ease of access may find conventional air filling to be sufficient. In contrast, companies focused on long-term vehicle performance and safety may benefit from investing in nitrogen inflation. Meanwhile, portable air compressors can serve well for emergency situations or businesses with a mobile workforce. Ultimately, understanding the unique benefits and limitations of each solution will empower buyers to select the method that best supports their specific operational goals.

When engaging in tyre air filling, understanding the technical specifications is crucial for ensuring optimal performance and safety. Here are some key properties that B2B buyers should consider:

Pressione nominale (PSI)

– Definizione: PSI (pounds per square inch) is a unit of pressure that indicates the amount of air pressure required for optimal tyre performance.

– B2B Importance: Ensuring correct PSI is vital for vehicle safety, fuel efficiency, and tyre longevity. Incorrect pressure can lead to tyre blowouts or uneven wear, impacting operational costs.

Composizione del materiale

– Definizione: The materials used in the tyre and valve construction, typically rubber and metal alloys.

– B2B Importance: The choice of materials affects durability, resistance to wear, and environmental factors. High-quality materials can reduce maintenance needs and enhance the overall lifespan of tyres, which is critical for fleet operators.

Valve Type

– Definizione: The type of valve used for inflation, commonly Schrader or Presta.

– B2B Importance: Different valve types require specific equipment for inflation. Understanding valve specifications ensures compatibility with air filling stations or compressors, reducing downtime in operations.

Temperature Tolerance

– Definizione: The ability of the tyre to maintain performance across varying temperature ranges.

– B2B Importance: Temperature fluctuations can significantly affect air pressure. Knowledge of a tyre’s temperature tolerance helps in maintaining optimal inflation levels and ensures safety, particularly in regions with extreme climates.

Tread Design

– Definizione: The pattern and depth of the tyre tread that impacts traction and handling.

– B2B Importance: Proper tread design is essential for ensuring safety and performance in different driving conditions. B2B buyers must evaluate tread specifications to match vehicle use cases, particularly in diverse geographical markets.

Familiarity with industry jargon is essential for effective communication and negotiation in tyre air filling. Here are some key terms:

OEM (Original Equipment Manufacturer)

– Definizione: Un'azienda che produce parti o apparecchiature che possono essere commercializzate da un altro produttore.

– Importanza: Understanding OEM products is critical for sourcing high-quality tyres that meet manufacturer specifications, ensuring compatibility and reliability.

MOQ (quantità minima d'ordine)

– Definizione: La quantità minima di un prodotto che un fornitore è disposto a vendere.

– Importanza: Knowing the MOQ helps buyers plan inventory levels and manage budgets effectively. It is especially relevant for businesses looking to maintain consistent supply without overstocking.

RFQ (Richiesta di offerta)

– Definizione: A document issued by a buyer to request pricing and terms from suppliers.

– Importanza: Issuing an RFQ allows businesses to compare offers from multiple suppliers, ensuring competitive pricing and favorable terms.

Incoterms (Termini commerciali internazionali)

– Definizione: A set of predefined international trade terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

– Importanza: Understanding Incoterms is crucial for managing logistics and shipping costs effectively, helping buyers navigate international procurement seamlessly.

Tire Pressure Monitoring System (TPMS)

– Definizione: An electronic system that monitors the air pressure inside the tyres and alerts the driver when it falls below a predetermined threshold.

– Importanza: TPMS is essential for maintaining tyre safety and performance, making it a key consideration for B2B buyers involved in fleet management or vehicle manufacturing.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions regarding tyre air filling, ensuring safety, efficiency, and cost-effectiveness in their operations.

The tyre air filling sector is experiencing significant transformation driven by technological advancements and evolving market demands. Key global drivers include the rising importance of vehicle safety, fuel efficiency, and regulatory compliance. The trend towards smart vehicles equipped with advanced tire pressure monitoring systems (TPMS) is gaining traction, particularly in regions like Europe and North America. This technology not only alerts drivers to low tire pressure but also emphasizes the need for regular air filling, thereby creating a consistent demand for air filling services.

For international B2B buyers in Africa, South America, the Middle East, and Europe, there are emerging sourcing trends to consider. The rise of mobile tire filling services—where equipment is transported to the customer—offers convenience and aligns with the growing consumer preference for on-demand services. Moreover, the integration of IoT in air filling stations allows for real-time monitoring and predictive maintenance, enhancing operational efficiency. Buyers should also be aware of the competitive landscape, where local suppliers often outperform international players due to better understanding of regional market needs and logistics.

Sustainability is becoming a crucial consideration in the tyre air filling sector, as environmental concerns and consumer awareness grow. The environmental impact of tyre maintenance, including air filling, is significant, particularly in terms of energy consumption and emissions. Therefore, adopting eco-friendly practices such as using energy-efficient compressors and promoting regular tire maintenance can minimize the carbon footprint.

For B2B buyers, emphasizing ethical sourcing is not just about compliance; it is also a competitive advantage. Suppliers who prioritize sustainable practices, such as using recycled materials for air filling equipment or obtaining green certifications, can attract environmentally conscious clients. Furthermore, implementing an ethical supply chain ensures transparency and social responsibility, which are increasingly important to end consumers. As regulations tighten around environmental standards, buyers should seek partnerships with suppliers who align with these values, thereby enhancing their brand reputation and customer loyalty.

Historically, tyre air filling was a straightforward task often performed at service stations or garages. However, as automotive technology has advanced, so too has the complexity of tyre maintenance. The introduction of TPMS and the increasing awareness of the impact of tire pressure on fuel efficiency and vehicle safety have made regular air filling a critical aspect of vehicle maintenance. Over the years, this sector has transitioned from a reactive approach to a proactive one, with a strong emphasis on preventive maintenance. As the market continues to evolve, B2B buyers must stay informed about technological advancements and consumer expectations to remain competitive in this dynamic landscape.

Illustrative image related to tyre air filling

How do I solve the issue of inconsistent tire pressure across different vehicles in my fleet?

To address inconsistent tire pressure, implement a standardized tire maintenance protocol across your fleet. Start by equipping each vehicle with a reliable tire pressure monitoring system (TPMS) that alerts drivers when pressure is low. Regular training sessions for drivers on the importance of tire maintenance can also help. Additionally, schedule routine checks with a trusted tire service provider to ensure all vehicles are inspected and maintained consistently, thus enhancing safety and improving fuel efficiency.

What is the best method for sourcing tire air filling solutions for my business?

The best method for sourcing tire air filling solutions involves conducting thorough market research to identify reputable suppliers. Look for manufacturers with a strong track record in tire services and positive reviews from other businesses. Attend industry trade shows to connect directly with suppliers and assess their offerings. Additionally, consider suppliers who provide comprehensive after-sales support and can offer customized solutions tailored to your specific operational needs.

How can I ensure the quality of tire air filling equipment I purchase internationally?

To ensure the quality of tire air filling equipment, establish a rigorous vetting process for potential suppliers. Request certifications and quality assurance documentation that align with international standards, such as ISO certifications. It’s also beneficial to conduct factory visits or audits if feasible. Engage in sample testing before placing large orders and ask for references from other clients to gauge the supplier’s reliability and product performance.

What are the typical minimum order quantities (MOQs) for tire air filling products?

Minimum order quantities (MOQs) for tire air filling products can vary significantly based on the supplier and the type of equipment. Generally, MOQs can range from a few units to several hundred. When negotiating with suppliers, clarify the MOQ to align with your inventory management strategy. Some suppliers may offer flexibility for smaller businesses, especially if you establish a long-term relationship or commit to future orders.

What payment terms should I expect when sourcing tire air filling equipment internationally?

Payment terms for international sourcing typically range from upfront payment to net 30 or 60 days after delivery, depending on the supplier’s policies and your negotiation leverage. Common methods include bank transfers, letters of credit, or escrow services for added security. It’s crucial to discuss and agree upon terms that protect both parties, ensuring timely payment while maintaining a steady cash flow for your business.

How can I customize tire air filling solutions to meet my specific business needs?

Customization of tire air filling solutions can often be arranged by directly communicating your requirements to potential suppliers. Many manufacturers offer tailored solutions, such as specific compressor sizes, digital pressure gauges, or integration with existing tire management systems. Providing detailed specifications and discussing your operational challenges will help suppliers propose the most effective solutions, ensuring that the equipment aligns perfectly with your business model.

What logistics considerations should I keep in mind when importing tire air filling equipment?

When importing tire air filling equipment, consider logistics factors such as shipping methods, customs clearance, and lead times. Ensure you understand import regulations in your country, including tariffs and taxes that may apply. Collaborate with experienced freight forwarders who specialize in automotive equipment to streamline the shipping process. Additionally, plan for potential delays by allowing extra time for customs inspections and delivery to your location.

How do I assess the reliability of tire air filling suppliers before making a purchase?

To assess the reliability of tire air filling suppliers, start by researching their reputation through online reviews and industry forums. Verify their business credentials and check for any certifications relevant to the tire industry. Request case studies or references from previous clients to evaluate their service quality and responsiveness. Engaging in direct communication can also provide insights into their customer service approach and willingness to support your business needs.

Dominio: goodyearautoservice.com

Registrato: 2006 (19 anni)

Introduzione: This company, Goodyear – Tire Inflation Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In conclusion, the strategic sourcing of tire air filling solutions is essential for businesses looking to optimize their operations and enhance customer satisfaction. By prioritizing partnerships with reliable suppliers, companies can ensure consistent access to high-quality air filling equipment and services, which directly impacts tire performance, safety, and longevity.

Furthermore, implementing efficient processes for tire inflation not only extends the lifespan of tires but also contributes to fuel economy and overall vehicle performance—key factors that resonate with cost-conscious B2B buyers across regions such as Africa, South America, the Middle East, and Europe.

As the global market evolves, organizations must remain agile, adapting to technological advancements and shifting consumer demands. The future of tire air filling lies in leveraging innovative solutions and maintaining robust supplier relationships. We encourage international B2B buyers to engage with local and global suppliers, explore new technologies, and stay informed about best practices in tire maintenance. Together, let’s drive towards a more efficient and sustainable future in tire care.

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Illustrative image related to tyre air filling

Pur avendo compiuto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. È necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.