In today’s fast-paced global market, sourcing reliable tire inflators, such as those offered by Milton Industries, poses a significant challenge for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. With the increasing demand for efficient and durable tire maintenance solutions, understanding the myriad options available can be overwhelming. This guide aims to simplify the purchasing process by providing a comprehensive overview of Milton Industries tire inflators, encompassing various types, their applications, supplier vetting strategies, and cost considerations.

Navigating through the complexities of international procurement requires not only product knowledge but also insights into market trends and supplier reliability. Our guide equips decision-makers with essential information to make informed choices, ensuring that they select the right inflator to meet their specific business needs. Whether you are operating in a bustling automotive sector in Brazil or managing a fleet in Saudi Arabia, understanding the nuances of tire inflator specifications and supplier capabilities is crucial for maintaining operational efficiency and safety.

By synthesizing critical data and actionable insights, this resource empowers international B2B buyers to enhance their sourcing strategies, ultimately leading to better investments in tire maintenance equipment. With a focus on quality, performance, and value, this guide is your key to unlocking the potential of Milton Industries tire inflators in your market.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Electric Inflator | Compact design, battery-operated, high PSI output | Automotive repair shops, mobile tire services | Pros: Easy to transport, versatile; Cons: Limited run time on battery. |

| Pneumatic Tire Inflator | Operates via air compressor, high volume output | Commercial garages, fleet maintenance | Pros: Fast inflation, continuous operation; Cons: Requires air source, less portable. |

| Digital Inflator | Digital pressure gauge, programmable settings | Tire retailers, automotive service centers | Pros: Accurate readings, user-friendly; Cons: Higher cost, potential for electronic failure. |

| Manual Hand Pump | Simple mechanics, no power source required | Emergency kits, remote locations | Pros: Lightweight, reliable; Cons: Labor-intensive, slower inflation. |

| Heavy-Duty Industrial Inflator | Robust construction, designed for continuous use | Construction sites, heavy machinery | Pros: Durable, high performance; Cons: Bulky, higher initial investment. |

Portable electric inflators are ideal for businesses that require mobility and convenience. These units are compact, battery-operated, and capable of delivering high PSI outputs, making them suitable for quick tire inflation in various settings, such as automotive repair shops or mobile tire services. When purchasing, consider factors like battery life and charging options, as these can significantly affect operational efficiency in the field.

Pneumatic tire inflators are designed for heavy-duty applications, utilizing an air compressor to deliver high-volume inflation quickly. These inflators are commonly found in commercial garages and fleet maintenance operations where speed and reliability are crucial. While they offer the advantage of continuous operation, buyers must ensure they have a compatible air source, which may limit portability.

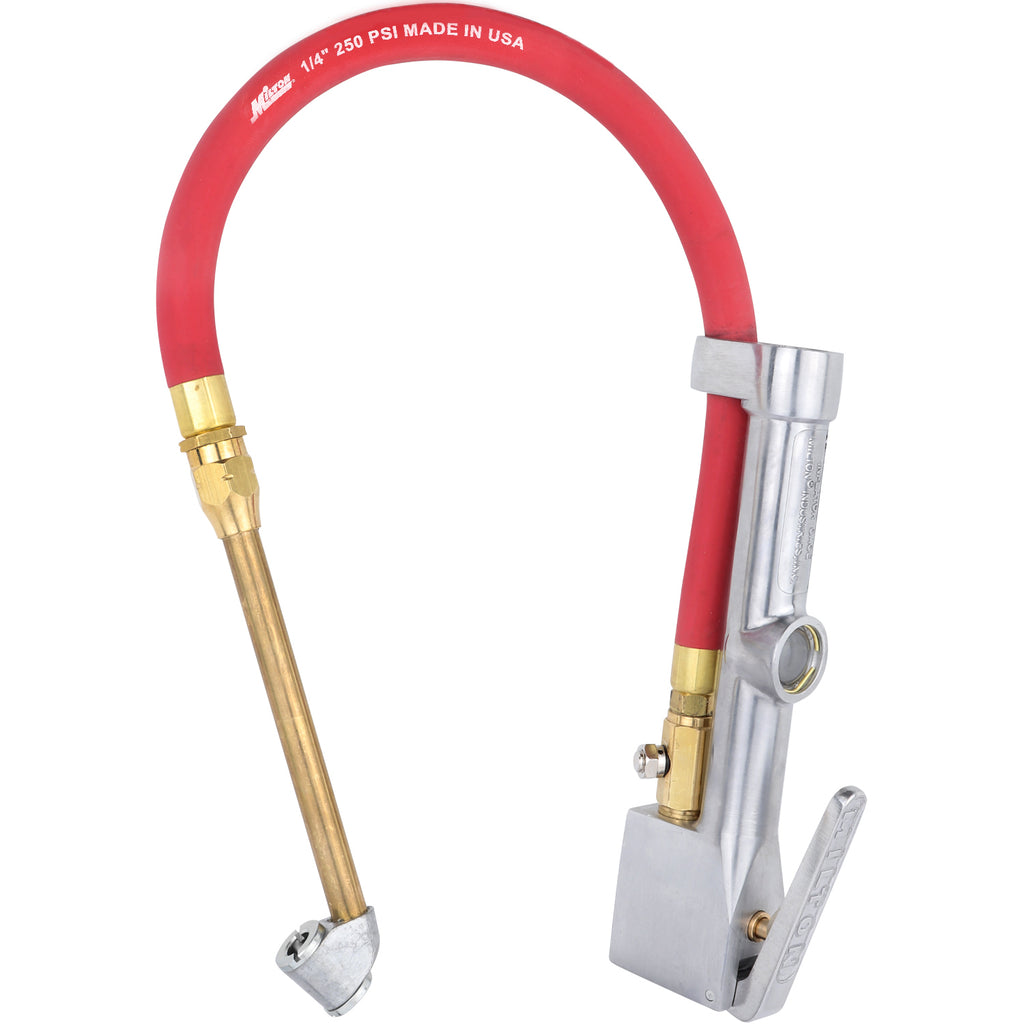

Illustrative image related to milton industries tire inflator

Digital inflators are equipped with advanced features like digital pressure gauges and programmable settings, making them a preferred choice for tire retailers and automotive service centers. Their accuracy and user-friendly interfaces enhance operational efficiency. However, the higher initial investment and reliance on electronic components can be a concern for some buyers, necessitating a thorough evaluation of long-term value.

Manual hand pumps are straightforward devices that require no power source, making them invaluable for emergency kits and remote locations where access to electricity is limited. Their lightweight design and reliability are significant advantages, although the labor-intensive nature of manual inflation may deter some businesses from relying solely on this option. Buyers should assess their specific operational needs when considering this type.

Heavy-duty industrial inflators are built to withstand the rigors of construction sites and heavy machinery operations. These robust units provide exceptional performance and durability, ensuring they can handle frequent use in challenging conditions. However, their bulkiness and higher upfront costs may be a drawback for some businesses. It’s essential for buyers to weigh the investment against the expected return in terms of performance and longevity.

| Industry/Sector | Specific Application of milton industries tire inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Quick tire inflation and deflation for service vehicles | Reduces downtime, enhances service efficiency | Durability, PSI accuracy, and compatibility with various tire types |

| Transportation & Logistics | Fleet maintenance and emergency roadside assistance | Ensures safety and reliability of vehicles | Portability, power source options, and ease of use |

| Construction | Tire inflation for heavy machinery and equipment | Minimizes operational delays, boosts productivity | Robustness, range of PSI settings, and repairability |

| Agriculture | Tire inflation for tractors and farming equipment | Increases efficiency in agricultural operations | Weather resistance, ease of transportation, and battery life |

| Aviation | Tire pressure management for ground support equipment | Enhances safety and compliance with aviation standards | Precision, reliability, and compliance with industry regulations |

In the automotive repair industry, the Milton Industries tire inflator serves as a critical tool for quick tire inflation and deflation of service vehicles. By enabling mechanics to adjust tire pressure efficiently, it reduces vehicle downtime, thereby enhancing overall service efficiency. International buyers, especially in regions like Africa and South America, should prioritize inflators that offer durability and precise PSI accuracy to cater to various tire types, ensuring they can meet diverse customer needs.

For businesses in transportation and logistics, the Milton Industries tire inflator is invaluable for fleet maintenance and emergency roadside assistance. It ensures that vehicles are always roadworthy, enhancing safety and reliability. Buyers from the Middle East and Europe should consider factors such as portability and power source options, as these will affect the inflator’s usability in different environments, including remote locations or during emergencies.

Illustrative image related to milton industries tire inflator

In the construction sector, tire inflation for heavy machinery and equipment is crucial to minimize operational delays. The Milton Industries tire inflator allows for quick adjustments, boosting productivity on job sites. B2B buyers in this sector should focus on the inflator’s robustness and the range of PSI settings it offers, as these features directly influence its effectiveness in demanding environments.

For the agricultural industry, the Milton Industries tire inflator is essential for maintaining the tire pressure of tractors and other farming equipment. Proper tire inflation leads to increased efficiency and productivity in agricultural operations. Buyers from regions like South America should seek inflators that are weather-resistant and portable, as these qualities ensure reliable performance in diverse farming conditions.

In aviation, the Milton Industries tire inflator plays a critical role in managing tire pressure for ground support equipment. Maintaining accurate tire pressure is essential for enhancing safety and compliance with aviation standards. International B2B buyers, particularly those in Europe and the Middle East, should focus on the inflator’s precision and reliability, as well as its compliance with industry regulations, to ensure optimal performance in airport operations.

The Problem:

B2B buyers, particularly those in sectors such as logistics and transportation, often face the challenge of maintaining optimal tire pressure across a fleet of vehicles. Inaccurate tire pressure can lead to increased fuel consumption, reduced tire lifespan, and safety issues. A common complaint is that tire inflators may deliver inconsistent pressure readings, leading to uncertainty and the potential for under-inflation or over-inflation.

Illustrative image related to milton industries tire inflator

The Solution:

To address this issue, buyers should prioritize the selection of Milton Industries tire inflators that feature built-in pressure gauges with high accuracy. It is advisable to conduct a thorough evaluation of the inflator’s specifications, ensuring it meets industry standards for precision. Additionally, implementing a regular calibration routine for the inflators can maintain accuracy over time. Establishing a standard operating procedure for users—where they verify tire pressure with a reliable gauge before and after using the inflator—can further mitigate inaccuracies. By promoting proper training on how to read and interpret the gauge readings, businesses can ensure their teams are equipped to achieve the desired tire pressure consistently.

The Problem:

In high-demand environments such as automotive service centers or fleet maintenance operations, time is of the essence. A common pain point is the inefficiency of inflators that are not designed for high-volume use. B2B buyers may find that standard inflators can struggle with prolonged use, leading to downtime and delays that can affect customer satisfaction and operational efficiency.

The Solution:

To overcome this challenge, businesses should invest in heavy-duty Milton Industries tire inflators that are specifically engineered for continuous operation. These models typically feature higher flow rates and robust motors that can handle extensive usage without overheating. Buyers should also assess the compatibility of the inflator with various tire types and sizes to ensure versatility in their operations. It’s beneficial to integrate these inflators into a well-organized tire service workflow, perhaps by placing them in strategic locations to minimize movement time and maximize efficiency. Training staff on the optimal use of these inflators can further enhance productivity, ensuring that each team member understands how to operate the equipment swiftly and effectively.

The Problem:

For businesses operating in diverse environments—such as construction sites or remote service locations—portability of tire inflators is often a significant concern. Users may encounter difficulties transporting heavier or less compact inflators, leading to delays in tire maintenance and added labor costs.

The Solution:

To effectively address this pain point, B2B buyers should seek out Milton Industries tire inflators designed with portability in mind. Models that are lightweight, compact, and equipped with carrying handles or wheels can significantly ease transportation challenges. Buyers should evaluate the inflator’s power source options—such as battery-operated or those that can connect to vehicles—ensuring they can operate effectively in various locations without needing a permanent power supply. Additionally, establishing a routine for inflator maintenance and storage can prevent damage during transport and extend the unit’s lifespan. Training staff on the best practices for transporting and deploying the inflator in different settings will further enhance operational efficiency, ensuring that tire maintenance can be performed swiftly regardless of location.

When selecting materials for Milton Industries tire inflators, it is essential to consider their properties, advantages, and limitations. The materials chosen not only affect the performance and durability of the inflators but also influence compliance with international standards, especially for B2B buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

Aluminum is a popular choice for various components in tire inflators due to its lightweight and excellent corrosion resistance. It typically has a good temperature and pressure rating, making it suitable for high-performance applications. The primary advantage of aluminum is its durability, which extends the lifespan of the inflator. However, it can be more expensive than other materials and may require specialized manufacturing processes, which could increase production costs.

For international buyers, aluminum components must comply with standards such as ASTM B221 for extruded aluminum products. Buyers in regions like Saudi Arabia and Brazil should also consider the availability of aluminum and any import tariffs that could affect overall costs.

Steel, particularly stainless steel, is another common material used in tire inflators. Known for its high strength and excellent pressure resistance, stainless steel is ideal for components that experience significant stress during operation. Additionally, it offers good corrosion resistance, especially in humid or saline environments, making it suitable for markets in coastal regions.

The main drawback of steel is its weight, which can affect the portability of the inflator. Furthermore, the manufacturing complexity can lead to higher production costs. B2B buyers should ensure that the steel used meets international standards such as ASTM A240 for stainless steel, especially when exporting to different regions.

Illustrative image related to milton industries tire inflator

Plastic materials, such as high-density polyethylene (HDPE) and polycarbonate, are often utilized for housing and non-structural components of tire inflators. These materials are lightweight, cost-effective, and resistant to impact and chemicals. They also offer good flexibility and can be molded into complex shapes, which can streamline the manufacturing process.

However, plastics generally have lower temperature and pressure ratings compared to metals, which may limit their use in high-performance applications. B2B buyers should consider the specific media compatibility of the plastic used, especially in regions with extreme temperatures. Compliance with standards like ASTM D638 for tensile properties of plastics is also crucial for ensuring product reliability.

Rubber is primarily used for seals and gaskets in tire inflators due to its excellent elasticity and ability to create airtight seals. This material can withstand a range of temperatures and pressures, making it suitable for various applications. The key advantage of rubber is its ability to absorb vibrations, which can enhance user experience.

On the downside, rubber can degrade over time when exposed to UV light and certain chemicals, potentially leading to premature failure. Buyers should be aware of the specific rubber compounds used and their compatibility with the intended environment. Compliance with international standards such as ASTM D2000 for rubber materials is essential for ensuring quality.

Illustrative image related to milton industries tire inflator

| Material | Typical Use Case for milton industries tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | Medium |

| Steel | High-stress components | High strength and pressure resistance | Heavier and more expensive | High |

| Plastic | Non-structural components and housing | Cost-effective and flexible | Lower temperature/pressure ratings | Low |

| Rubber | Seals and gaskets | Excellent elasticity and vibration absorption | Degradation over time | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers considering Milton Industries tire inflators. Understanding the properties and implications of each material will help in making informed purchasing decisions that align with regional standards and performance requirements.

Milton Industries employs a comprehensive manufacturing process to ensure that its tire inflators meet high standards of quality and performance. The process can be divided into four main stages: material preparation, forming, assembly, and finishing. Each stage incorporates advanced techniques tailored to enhance durability and efficiency.

The manufacturing process begins with material selection, focusing on high-grade metals and polymers that provide resilience and longevity. These materials are subjected to rigorous testing for durability, corrosion resistance, and flexibility. This ensures that the inflators can withstand the varying conditions they will face in different environments, particularly in regions with extreme temperatures such as Africa and the Middle East.

Once the materials are selected, they undergo preparation, which includes cutting, machining, and surface treatment. Techniques like CNC machining are utilized for precision parts, ensuring that components fit together seamlessly, which is crucial for maintaining performance standards.

After material preparation, the forming stage involves shaping the components that will make up the tire inflator. Techniques such as injection molding for plastic parts and stamping for metal components are commonly employed. These methods not only increase production efficiency but also minimize waste, making the process more cost-effective for B2B buyers.

During this stage, Milton Industries focuses on creating components that are not only functional but also ergonomic. The design considerations ensure that the inflators are user-friendly and suitable for various markets, addressing the specific needs of international buyers, including those in Brazil and Europe.

The assembly process is where all prepared and formed components come together. Milton Industries utilizes automated assembly lines equipped with advanced robotics to enhance precision and speed. This automation reduces human error and ensures consistent quality across production batches.

Quality assurance begins even at this stage, with in-line inspections (IPQC) conducted to verify that each component meets the required specifications before moving to the next step. This proactive approach helps in identifying potential defects early, minimizing waste and rework.

Quality assurance is paramount in manufacturing tire inflators, and Milton Industries adheres to several international standards. Notably, ISO 9001 certification demonstrates their commitment to maintaining a robust quality management system. This certification is recognized globally and assures B2B buyers of consistent product quality.

Illustrative image related to milton industries tire inflator

Additionally, compliance with industry-specific standards such as CE marking and API certifications is crucial. CE marking indicates that the inflators meet European health, safety, and environmental protection standards, while API certifications ensure that the products meet the rigorous requirements of the petroleum and natural gas industries.

Milton Industries implements a multi-tiered quality control system that includes several checkpoints throughout the manufacturing process. These checkpoints are categorized into three main areas:

Incoming Quality Control (IQC): This involves inspecting raw materials and components as they arrive at the facility. Ensuring that all incoming materials meet predefined standards is critical for maintaining overall product quality.

In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process. This includes regular checks at various stages of assembly to ensure adherence to specifications and to catch any deviations early.

Final Quality Control (FQC): Once assembly is complete, each tire inflator undergoes thorough testing. This includes functional testing, pressure testing, and performance evaluations to ensure that the product operates as intended.

Testing is a vital component of the quality assurance process. Milton Industries employs various methods to ensure that their tire inflators meet performance and safety standards. Some common testing methods include:

These testing methods not only help in verifying product quality but also provide valuable data that can be shared with B2B buyers, reinforcing trust in the product.

Illustrative image related to milton industries tire inflator

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial for ensuring product reliability. Here are some actionable steps that buyers can take:

Conduct Supplier Audits: Regular audits can provide insights into the supplier’s manufacturing processes and quality control measures. This can be done either in-person or through third-party inspection services.

Request Quality Assurance Reports: Suppliers should be able to provide documentation detailing their quality control processes, testing results, and certifications. This transparency builds confidence in the supplier’s commitment to quality.

Engage Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased assessment of the supplier’s quality control measures. This is particularly important for buyers in regions where they may not have the ability to conduct in-person inspections.

International buyers should be aware of certain nuances related to quality control and certifications when sourcing tire inflators. Different regions may have specific regulatory requirements that affect product compliance. For instance, products sold in Europe must meet CE marking requirements, while those in the Middle East might require adherence to local standards.

Additionally, understanding the certification process in the supplier’s country can provide insights into the reliability of the products. Buyers should ensure that their suppliers maintain current certifications and that these certifications are recognized in their own markets.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing tire inflators from Milton Industries, ensuring they receive products that meet their performance and safety expectations.

In today’s competitive market, sourcing high-quality equipment like the Milton Industries tire inflator requires a systematic approach. This checklist will guide B2B buyers through essential steps to ensure a successful procurement process, focusing on aspects that matter most to international buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

Illustrative image related to milton industries tire inflator

Establishing clear technical specifications is crucial for ensuring the inflator meets your operational needs. Consider factors such as pressure range, inflation speed, and compatibility with various tire types. This detailed understanding will help you communicate effectively with suppliers and narrow down your options.

Understanding current market trends and pricing is essential for making informed purchasing decisions. Conduct thorough market research to identify average costs, popular models, and emerging technologies. This knowledge will empower you to negotiate better terms and avoid overpaying for your equipment.

Before making any commitments, vet potential suppliers rigorously. Request detailed company profiles, case studies, and references from businesses in your industry or region. Pay attention to their track record for quality, reliability, and customer service, as these factors are critical for long-term partnerships.

Ensure that the suppliers you consider have the necessary certifications and comply with industry standards. Look for ISO certifications or other relevant quality assurance marks that indicate adherence to manufacturing and safety standards. This verification can help mitigate risks associated with product quality and compliance.

Understanding a supplier’s shipping and delivery capabilities is vital, especially for international transactions. Inquire about their shipping methods, lead times, and whether they can accommodate your specific logistics needs. Efficient delivery can significantly impact your operational timelines and overall satisfaction.

Illustrative image related to milton industries tire inflator

Whenever possible, request samples or live demonstrations of the Milton Industries tire inflator. This step allows you to evaluate the product’s performance and features firsthand, ensuring it aligns with your expectations. Observing the inflator in action can provide insights into its usability and effectiveness.

Once you have selected a supplier, negotiate the terms of your purchase agreement. Discuss payment terms, warranties, and return policies to ensure you are fully protected. A well-defined agreement can prevent misunderstandings and safeguard your investment in the long run.

By following this checklist, B2B buyers can streamline the sourcing process for Milton Industries tire inflators, ensuring they make informed decisions that align with their business goals.

Understanding the cost structure of Milton Industries tire inflators is essential for B2B buyers looking to optimize sourcing strategies. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials: The quality and type of materials used in tire inflators significantly impact pricing. Common materials include durable plastics and high-grade metals, which ensure longevity and reliability. Sourcing these materials can vary in cost based on geographical availability and market demand.

Labor: Labor costs can fluctuate based on the region of production. For instance, manufacturing in countries with lower labor costs can yield a more competitive pricing model. However, it’s essential to consider the skill level and training of the workforce, as this affects the overall quality of the product.

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help mitigate these overhead costs.

Tooling: Initial tooling costs for creating molds and specialized equipment are significant. These costs are typically amortized over the production run, making them a crucial consideration for volume pricing.

Quality Control (QC): Ensuring that tire inflators meet quality standards incurs additional costs. Rigorous QC processes can prevent costly recalls and enhance brand reputation, which justifies the investment.

Logistics: Transporting the finished products to various markets adds to the total cost. Factors such as shipping methods, distance, and customs duties play a significant role in logistics expenses.

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the average margin within the industry can help buyers gauge fair pricing.

Several factors can influence the pricing of Milton Industries tire inflators, particularly for international buyers.

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect unit pricing. Higher order volumes typically yield better pricing due to economies of scale.

Specifications and Customization: Custom features or specifications can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

Materials and Quality Certifications: Products that adhere to international quality standards or certifications often come at a premium but offer reliability and peace of mind.

Supplier Factors: The reliability and reputation of the supplier can impact pricing. Established suppliers may charge more due to their brand equity and proven track record.

Incoterms: Understanding Incoterms is crucial for international transactions. They define responsibilities in shipping, which can impact overall costs. For example, choosing “FOB” (Free on Board) versus “CIF” (Cost, Insurance, and Freight) can lead to different pricing dynamics.

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, being strategic can lead to significant cost savings.

Illustrative image related to milton industries tire inflator

Negotiation: Engage suppliers in negotiations to explore discounts for larger orders or long-term contracts. Be prepared to discuss market trends and competitor pricing to strengthen your position.

Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the tire inflators, including maintenance, potential downtime, and warranty claims. A lower purchase price may not always equate to cost-effectiveness.

Pricing Nuances: Understand regional pricing trends and tariffs that may apply when importing products. Knowledge of local market conditions can provide leverage in negotiations and help avoid unforeseen expenses.

Market Research: Conduct comprehensive research on different suppliers and their offerings. This can provide insights into competitive pricing and innovative features that might add value to your sourcing decision.

While this analysis provides a framework for understanding the costs and pricing of Milton Industries tire inflators, it is important to note that prices can vary widely based on the factors discussed. Buyers should approach sourcing with a clear strategy, leveraging insights into cost components and pricing influencers to make informed decisions that align with their business objectives.

When considering a tire inflator for commercial or industrial use, it’s crucial to evaluate various options available in the market. The right choice can significantly impact operational efficiency, maintenance costs, and overall productivity. In this analysis, we will compare the Milton Industries Tire Inflator with two viable alternatives: the Viair Portable Air Compressor and the Craftsman 6 Gallon Pancake Air Compressor. This comparison will help B2B buyers make informed decisions based on their specific needs.

| Comparison Aspect | Milton Industries Tire Inflator | Viair Portable Air Compressor | Craftsman 6 Gallon Pancake Air Compressor |

|---|---|---|---|

| Performance | Up to 150 PSI, quick inflation | Up to 150 PSI, durable | Up to 90 PSI, versatile for various tasks |

| Cost | Moderate | Higher-end | Affordable |

| Ease of Implementation | Simple, plug-and-play | Requires vehicle battery or AC | Requires stationary setup |

| Maintenance | Low, minimal moving parts | Moderate, filter changes needed | Moderate, tank rust prevention necessary |

| Best Use Case | Ideal for personal and light commercial use | Best for heavy-duty applications | Suitable for DIY projects and small workshops |

The Viair Portable Air Compressor is known for its robust performance, especially in heavy-duty applications. It can easily handle inflating larger tires and operates efficiently in various environments. However, its higher cost may be a barrier for budget-conscious buyers. Additionally, while it is portable, it requires connection to a vehicle’s battery or an AC outlet, which could limit its usability in remote areas without immediate access to power.

Illustrative image related to milton industries tire inflator

The Craftsman 6 Gallon Pancake Air Compressor offers an affordable solution for small workshops and DIY enthusiasts. With its larger tank, it can provide a steady airflow for extended periods, making it suitable for a variety of tasks, from inflating tires to powering pneumatic tools. However, it requires a stationary setup and is less portable than both the Milton and Viair options. Maintenance involves ensuring the tank is kept rust-free, which can add to the long-term costs if not properly managed.

Selecting the right tire inflator hinges on understanding specific operational requirements and budget constraints. The Milton Industries Tire Inflator offers a balanced solution for light commercial use, while the Viair Portable Air Compressor excels in heavy-duty scenarios but at a higher cost. Conversely, the Craftsman 6 Gallon Pancake Air Compressor is an economical choice for stationary applications. Buyers should assess their unique needs—such as portability, performance requirements, and maintenance capabilities—to make a well-informed decision that aligns with their business objectives.

When assessing tire inflators from Milton Industries, several technical specifications are crucial for international B2B buyers. Understanding these properties ensures that purchasing decisions are aligned with operational needs and quality standards.

Material Composition

The inflators are typically made from high-grade materials such as aluminum and reinforced plastics. These materials contribute to the durability and longevity of the product, which is essential for frequent use in commercial environments. B2B buyers should consider material properties as they impact both the performance and maintenance costs over time.

Pressure Range

Milton tire inflators often operate within a specified pressure range, commonly between 0 to 150 PSI. This range is vital for various applications, including automotive and industrial uses. Understanding the pressure capabilities helps buyers ensure that the inflator can meet the specific requirements of their tire types and sizes.

Flow Rate

The flow rate, measured in cubic feet per minute (CFM), indicates how quickly the inflator can fill a tire. A higher flow rate means faster inflation times, which is crucial for businesses that need to minimize downtime. Buyers should evaluate their operational needs to select inflators that provide optimal performance.

Tolerance Levels

Tolerance specifications relate to the precision of the inflator’s pressure gauge and valve mechanisms. High tolerance levels ensure accurate inflation and reduce the risk of over-inflation or under-inflation, which can lead to tire damage. Buyers should prioritize inflators with low tolerance levels for enhanced reliability.

Power Source

Milton tire inflators can be powered by either AC (alternating current) or DC (direct current), with some models featuring battery options. Understanding the power source is crucial for compatibility with existing equipment and for ensuring operational flexibility in various environments, particularly in remote locations.

Familiarity with trade terminology is essential for effective negotiations and procurement processes in international markets.

OEM (Original Equipment Manufacturer)

OEM refers to companies like Milton Industries that manufacture products to be sold under another company’s brand. Understanding OEM relationships helps buyers gauge the quality and reliability of the products they are purchasing, as OEMs often adhere to strict quality standards.

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is critical for budgeting and inventory planning, especially for businesses looking to optimize their supply chain and reduce costs. Knowing the MOQ can help buyers negotiate better terms and plan their purchasing strategies effectively.

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. For B2B buyers, issuing an RFQ is an essential step in the procurement process, allowing them to compare offers and make informed purchasing decisions based on detailed proposals.

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand their obligations and manage risks associated with international shipping, ensuring smoother transactions.

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This term is crucial for supply chain management, as longer lead times can affect inventory levels and operational efficiency. Buyers should consider lead times in their procurement strategies to ensure timely availability of inflators.

Warranty and Support Terms

Warranty terms outline the conditions under which a product can be returned or repaired. Understanding warranty policies is vital for B2B buyers to protect their investment and ensure they receive support if issues arise. Buyers should seek inflators with comprehensive warranty coverage to mitigate risks associated with product failure.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and budget constraints, ultimately enhancing their purchasing strategies for Milton Industries tire inflators.

The global tire inflator market is evolving rapidly, influenced by several key drivers. The rising demand for efficient and reliable tire maintenance solutions, particularly in developing regions such as Africa and South America, is a significant factor. Urbanization and increased vehicle ownership in these markets drive the necessity for accessible tire inflators. Additionally, the surge in e-commerce and online sales channels is reshaping how international buyers source these products, making it easier to compare features, prices, and reviews across borders.

Emerging technologies are also transforming the tire inflator landscape. Smart inflators equipped with IoT capabilities are gaining traction, allowing users to monitor tire pressure via mobile apps, enhancing convenience and safety. Furthermore, automation in manufacturing processes is leading to improved product quality and cost efficiencies, which are critical for B2B buyers looking to maximize their return on investment.

In terms of market dynamics, international buyers need to be aware of regional regulations and compliance standards, particularly in Europe and the Middle East, where safety and environmental regulations are stringent. Understanding these market nuances will enable B2B buyers to make informed decisions when sourcing Milton Industries tire inflators, ensuring that they align with local standards and consumer expectations.

Sustainability has become a cornerstone of modern B2B procurement strategies, especially in the tire inflator sector. The environmental impact of manufacturing processes and product lifecycle is under scrutiny, compelling companies to adopt greener practices. For B2B buyers, sourcing from suppliers that prioritize sustainability can enhance their brand reputation and appeal to environmentally conscious consumers.

Illustrative image related to milton industries tire inflator

Ethical sourcing practices are equally important. Buyers should consider suppliers that demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and labor practices are fair. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, integrating ‘green’ materials into tire inflator manufacturing—such as recyclable plastics and eco-friendly packaging—can further reduce environmental impact. By prioritizing suppliers that incorporate sustainable practices, international B2B buyers can not only fulfill their corporate social responsibility goals but also cater to a growing market segment that values sustainability.

Milton Industries has a rich history in the tire inflator sector, dating back to its inception in the early 1940s. Initially focused on producing high-quality air fittings, the company expanded its product line to include tire inflators as the automotive industry grew. Over the decades, Milton has established itself as a trusted brand, known for its commitment to innovation and quality.

The evolution of tire inflators from manual pumps to sophisticated electronic models reflects broader technological advancements in the automotive sector. Today, Milton Industries continues to lead in developing products that meet the changing needs of consumers and businesses, making it a reliable choice for international B2B buyers looking for quality and efficiency in tire maintenance solutions.

How do I choose the right Milton Industries tire inflator for my business needs?

When selecting a Milton Industries tire inflator, consider your specific operational requirements such as tire sizes, inflation speed, and frequency of use. Evaluate the inflator’s PSI range, portability, and whether it supports both high-volume and low-pressure applications. Additionally, assess the durability and warranty options to ensure long-term reliability. Engaging with a knowledgeable supplier can provide insights tailored to your industry, ensuring you select the most appropriate model for your business.

What are the main features to look for in a Milton Industries tire inflator?

Key features to consider include the inflator’s maximum PSI, power source (electric or manual), and ease of use. Look for inflators with integrated pressure gauges for accurate readings, built-in safety features like automatic shut-off, and portability options for easy transport. For businesses needing frequent use, consider models with quick-connect fittings and durable construction to withstand heavy-duty applications.

What are the minimum order quantities (MOQ) for Milton Industries tire inflators?

Minimum order quantities can vary based on the supplier and the specific model of tire inflator. Typically, for B2B purchases, MOQs may range from 10 to 50 units. It’s advisable to discuss your requirements directly with the supplier to negotiate suitable quantities that align with your business needs and budget, especially if you are exploring bulk purchasing options for distribution.

What payment terms are commonly offered for international buyers of Milton Industries tire inflators?

Payment terms for international transactions often include options such as upfront payment, letters of credit, or net payment terms (e.g., net 30 or net 60). Suppliers may require a deposit upon order confirmation, followed by the balance before shipment. Always clarify these terms upfront and consider using secure payment methods to protect your investment, particularly in cross-border transactions.

How do I ensure the quality of Milton Industries tire inflators before purchasing?

To ensure quality, request product samples or visit the supplier’s facility if possible. Verify certifications and compliance with international standards for safety and performance. Additionally, seek references or reviews from other B2B buyers who have previously sourced inflators from the supplier. Conducting thorough due diligence will help mitigate risks associated with quality assurance.

What shipping and logistics options are available for importing Milton Industries tire inflators?

Shipping options vary based on your location and the supplier’s capabilities. Common methods include air freight for faster delivery or sea freight for cost-effective bulk shipments. Confirm the supplier’s logistics support, including handling customs documentation and duties. It’s beneficial to work with a freight forwarder familiar with international trade regulations to streamline the process.

Can I customize Milton Industries tire inflators for my brand?

Many suppliers offer customization options, including branding with your logo, specific color choices, or tailored features to meet unique operational requirements. Discuss your customization needs with the supplier to understand the feasibility, additional costs, and lead times associated with producing customized inflators. This can enhance your brand visibility in the market.

What after-sales support is available for Milton Industries tire inflators?

After-sales support typically includes warranties, repair services, and customer assistance for troubleshooting issues. Inquire about the warranty period and what it covers, as well as the supplier’s policy on spare parts availability. A reputable supplier will also provide guidance on maintenance practices to extend the life of your inflators, ensuring your operations remain efficient.

Could not verify enough suppliers for milton industries tire inflator to create a list at this time.

In the competitive landscape of tire inflators, strategic sourcing emerges as a critical component for international B2B buyers. By leveraging Milton Industries’ robust product offerings, companies can not only enhance operational efficiency but also ensure compliance with quality standards across diverse markets. The focus on high-performance and durable inflators aligns perfectly with the increasing demand for reliable equipment in sectors such as automotive maintenance and logistics.

Investing in Milton Industries tire inflators allows businesses to capitalize on cost-effective solutions that do not compromise on quality. This strategic approach can lead to significant long-term savings and improved customer satisfaction, particularly in regions like Africa, South America, the Middle East, and Europe, where demand for dependable automotive products is surging.

Looking ahead, the landscape for tire inflators will likely evolve with advancements in technology and sustainability. B2B buyers are encouraged to stay informed and proactive in their sourcing strategies. Engaging with Milton Industries now will position your business to meet future challenges while enjoying the benefits of superior product quality. Take the next step in enhancing your supply chain by exploring the full range of Milton Industries tire inflators and solidifying your competitive edge in the market.

Illustrative image related to milton industries tire inflator

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.