In the competitive landscape of global automotive services, sourcing reliable locations to put air in tires near me can pose a significant challenge for B2B buyers. As businesses expand their operations across borders, ensuring that vehicles are properly maintained becomes critical to operational efficiency and safety. This comprehensive guide delves into the myriad of options available for tire inflation, including service stations, tire shops, and innovative solutions such as mobile air compressors.

We will explore various types of suppliers, their geographic reach, and the applications suited for different markets, particularly focusing on the unique needs of buyers from Africa, South America, the Middle East, and Europe—countries like Saudi Arabia and Germany that have distinct automotive service landscapes. Additionally, we will provide essential insights into supplier vetting processes, potential costs associated with services, and best practices for maintaining tire pressure, which is vital for vehicle safety and performance.

By empowering international B2B buyers with actionable knowledge and a clear understanding of their options, this guide serves as an invaluable resource for informed purchasing decisions. Whether you are looking to enhance your fleet’s operational efficiency or ensure customer satisfaction through reliable service offerings, the insights provided herein will help streamline your sourcing strategy for tire inflation services.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gas Stations | Typically located on main roads; may charge for air; often have extended hours. | Fleet management, logistics, transportation | Pros: Convenient access; widespread locations. Cons: Variable availability of free air; potential fees. |

| Tire Shops | Dedicated to tire services; usually offer free air; knowledgeable staff. | Tire retailers, automotive service providers | Pros: Expertise in tire maintenance; reliable service. Cons: Limited hours; may require additional services. |

| Automotive Repair Shops | General vehicle maintenance; offer air as a courtesy; often have equipment on hand. | Vehicle service centers, fleet maintenance | Pros: Comprehensive vehicle care; reliable air supply. Cons: May prioritize other services over tire inflation. |

| Bicycle Shops | Specialized in bicycle maintenance; typically offer air for bicycles and some vehicles. | Cycling retailers, sports equipment suppliers | Pros: Community-focused; often free air services. Cons: Limited to bicycle tires; may not cater to larger vehicles. |

| Portable Air Compressors | Compact, user-friendly devices for personal use; can be used anywhere. | Individual consumers, small businesses | Pros: Convenient for personal use; no dependency on external locations. Cons: Initial investment; maintenance needed. |

Gas stations are ubiquitous and strategically located along major roads and highways, making them a convenient choice for tire inflation. While many gas stations offer free air, some may charge a nominal fee, and the availability can vary significantly by region. For B2B buyers, especially those managing fleets, gas stations provide essential services during long hauls, ensuring vehicles are roadworthy without needing to divert to specialized locations. However, the inconsistency in service quality and potential fees may require buyers to maintain a list of reliable stations.

Tire shops are dedicated facilities focused on tire sales and services, often providing complimentary air for tires. Their staff typically possesses in-depth knowledge of tire maintenance and can offer additional services such as rotations and repairs. For B2B applications, tire shops are invaluable for businesses that require regular tire maintenance and replacement, ensuring optimal vehicle performance. While they provide expert service, their operating hours may limit convenience for businesses needing after-hours access.

Automotive repair shops offer a range of services beyond tire inflation, including diagnostics and repairs. Many provide air as a courtesy to customers, making them a practical option for businesses seeking comprehensive vehicle maintenance. For fleet operators, these facilities can ensure that all aspects of vehicle upkeep are managed under one roof. However, tire inflation may not be their primary focus, which could lead to longer wait times or prioritization of other services over tire care.

Bicycle shops are ideal for cyclists needing air for their tires, often providing this service for free. They cater to a niche market, focusing on bicycles but sometimes accommodating small vehicles. For B2B buyers in the cycling industry or related sectors, these shops can offer community engagement and support, fostering customer loyalty. The downside is their limited service scope, as they primarily cater to bicycles and may not serve larger vehicles or fleets.

Portable air compressors are compact devices that allow users to inflate tires on demand, providing flexibility and independence from external locations. This is particularly beneficial for small businesses or individual consumers who may frequently require tire inflation. While they eliminate reliance on gas stations or repair shops, the initial investment and ongoing maintenance can be drawbacks for some users. B2B buyers should weigh the convenience of having a portable solution against the cost and potential upkeep involved.

| Industry/Sector | Specific Application of place to put air in tires near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Fleet maintenance and operational efficiency | Reduces downtime and enhances vehicle safety, ensuring timely deliveries | Proximity to air stations, cost of air services, reliability of equipment |

| Automotive Services | Customer service enhancement at repair shops | Increases customer satisfaction and loyalty through added convenience | Availability of free air services, maintenance of air pumps, customer feedback |

| Retail & Convenience Stores | Value-added service for customers | Attracts foot traffic, increases customer dwell time, and enhances brand loyalty | Location accessibility, maintenance of air pumps, customer demographics |

| Cycling & Recreation | Support for cycling events and community engagement | Promotes healthy lifestyles and community involvement, enhancing brand image | Availability of air pumps, partnerships with local cycling clubs, event sponsorship opportunities |

| Construction & Heavy Machinery | Tire inflation for construction vehicles | Ensures operational safety and efficiency, reducing the risk of accidents | Access to air supply, durability of equipment, compliance with safety regulations |

In the transportation and logistics sector, maintaining optimal tire pressure is crucial for fleet performance and safety. Businesses utilize nearby air stations to ensure that their vehicles are always road-ready, minimizing downtime due to flat tires or poor handling. For international buyers, especially from regions like Africa and South America, understanding local air service availability can significantly impact operational efficiency. Factors such as the reliability of air pumps and the proximity to major routes are essential when selecting service points.

Automotive repair shops often provide free air services to enhance customer experience. This convenience can lead to increased customer retention and satisfaction. For B2B buyers in the Middle East or Europe, sourcing reliable air services can also involve evaluating the maintenance of air pumps and the overall customer feedback regarding service quality. Offering complimentary air fills can differentiate a repair shop in a competitive market.

Retail and convenience stores can leverage air services as a value-added offering that attracts customers and encourages longer visits. By providing easy access to air pumps, these businesses can enhance customer loyalty and increase sales. For international buyers, key considerations include the location of the air service to maximize foot traffic and the cost of maintaining air pumps, ensuring that the service remains a profitable venture.

In the cycling industry, providing air services at events or community locations supports cyclists and promotes healthy lifestyles. Businesses can partner with local cycling clubs to sponsor events that include air services, enhancing community engagement. Buyers from Europe, particularly in countries with a robust cycling culture, should consider the availability of air pumps and the potential for partnerships with local organizations to maximize outreach.

Construction companies rely on properly inflated tires for heavy machinery to ensure safety and operational efficiency. Access to nearby air services is vital for avoiding delays caused by tire issues. For B2B buyers in regions like Saudi Arabia, factors such as the durability of air supply equipment and compliance with local safety regulations are critical when sourcing air services for their machinery.

Illustrative image related to place to put air in tires near me

The Problem: For B2B buyers managing fleets, ensuring that vehicles are maintained with proper tire pressure is essential for safety and operational efficiency. However, finding reliable and accessible locations that provide free air for tires can be a challenge. Many businesses are unaware of where these facilities are located, leading to increased downtime as drivers search for air stations or, worse, the risk of running on under-inflated tires, which can lead to costly accidents and repairs.

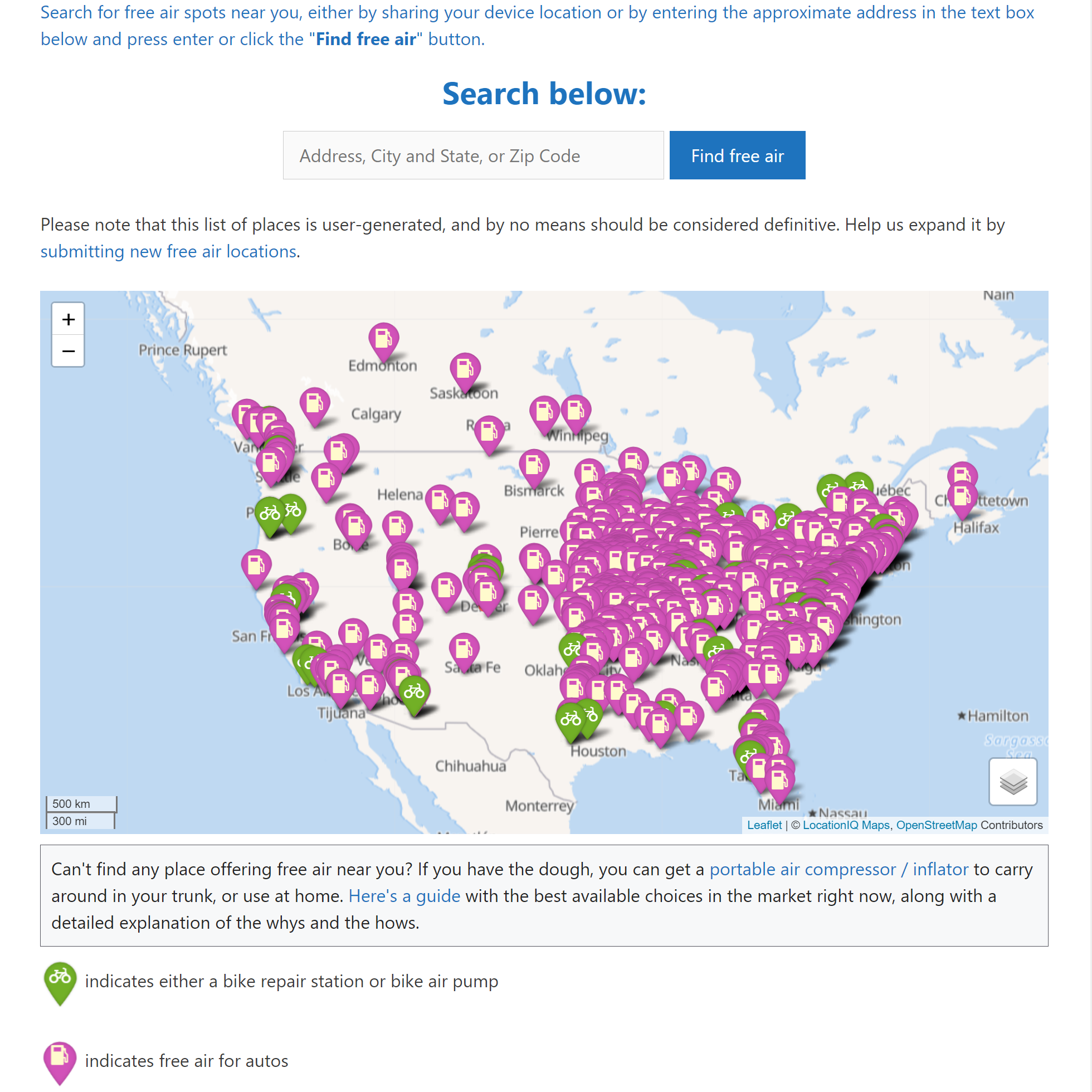

The Solution: To overcome this issue, B2B buyers should leverage updated databases and maps of air pump locations, such as those provided by user-generated platforms. Creating partnerships with local gas stations, tire shops, and auto repair facilities can also prove beneficial. By forming agreements that ensure these businesses maintain air pumps and offer services at no charge, fleet managers can ensure their drivers always have access to the resources they need. Furthermore, consider implementing a mobile app that allows drivers to quickly locate the nearest free air stations, complete with user ratings and real-time availability updates.

The Problem: Many B2B buyers often face the frustrating experience of arriving at a service station only to find that the air pump is out of order or requires payment. This inconsistency can lead to operational delays, especially for companies relying on timely deliveries or services. The uncertainty surrounding air pump availability can also result in extra costs when fleets are forced to seek alternative, often pricier solutions.

The Solution: To mitigate this issue, businesses should conduct thorough research to compile a list of reliable service stations that consistently offer free air. Establishing a network of preferred partners who guarantee the functionality of their air pumps can create a more dependable resource. Additionally, implementing a feedback system where drivers can report the status of air pumps can help maintain an up-to-date database. This proactive approach not only saves time and money but also enhances fleet management efficiency by ensuring that vehicles can be serviced without unnecessary delays.

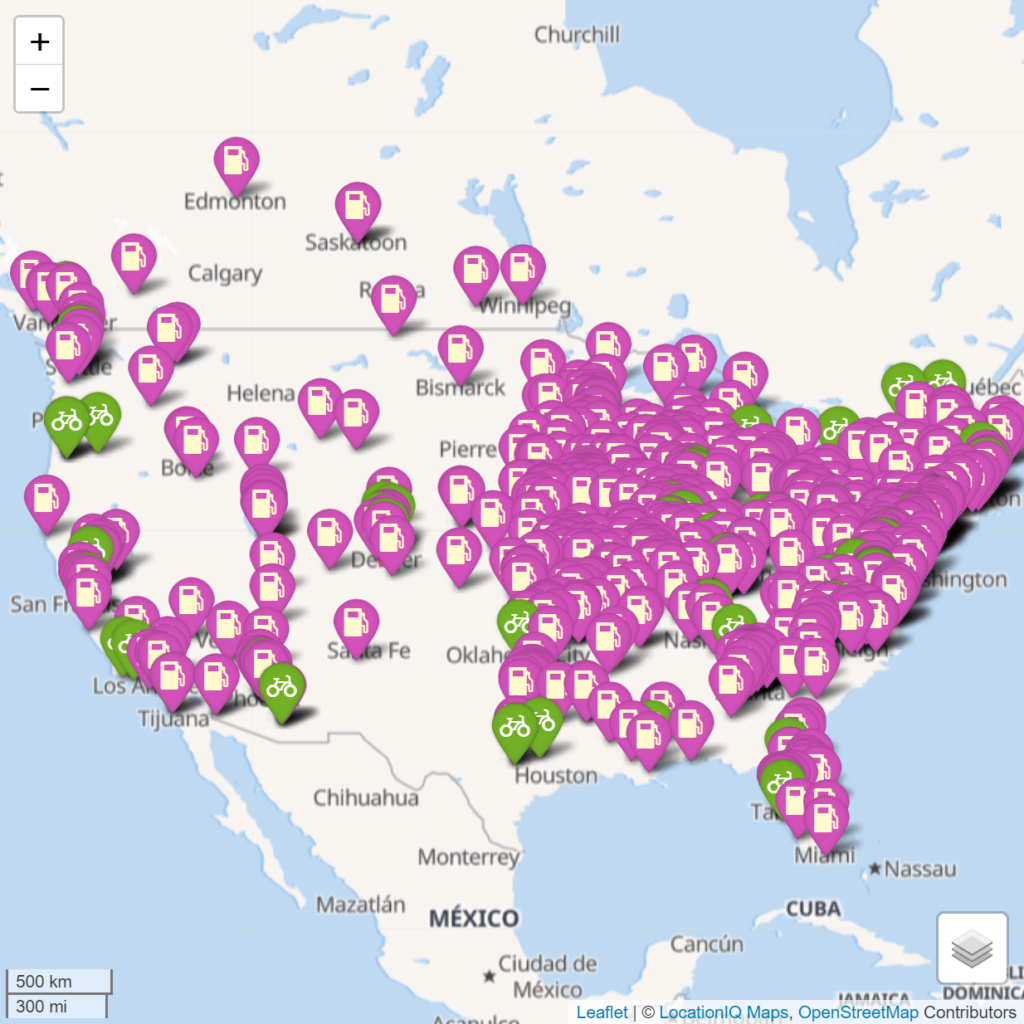

The Problem: Even when B2B buyers successfully identify locations to put air in tires, there can be a significant gap in knowledge regarding proper tire inflation techniques among drivers. Misunderstandings about tire pressure requirements can lead to improper inflation, resulting in safety hazards and increased fuel consumption. This lack of education can significantly impact the bottom line for businesses operating fleets.

The Solution: To address this knowledge gap, businesses should invest in comprehensive training programs for their drivers focused on tire maintenance, including how to check and adjust tire pressure correctly. Providing easy-to-follow instructional materials, such as videos or infographics, can facilitate understanding and retention. Additionally, consider equipping vehicles with portable air compressors, allowing drivers to manage tire pressure on-the-go. This dual approach not only empowers drivers with the knowledge they need to maintain tire health but also enhances overall fleet safety and efficiency, ultimately leading to reduced operational costs.

When selecting materials for air pumps and related infrastructure at locations where customers can inflate tires, it is essential to consider the properties, advantages, and limitations of various materials. This analysis focuses on four common materials: steel, aluminum, plastic, and rubber. Each material has unique characteristics that can impact performance, durability, and cost, particularly for international B2B buyers.

Steel is a widely used material for air pumps due to its high strength and durability. It can withstand high pressure and temperature, making it suitable for heavy-duty applications. Steel components often have excellent corrosion resistance when treated with coatings or galvanization. However, the weight of steel can be a disadvantage in portable applications.

Aluminum is another popular choice for air pumps due to its lightweight properties and resistance to corrosion. It is easier to manufacture and can be extruded into complex shapes, making it ideal for custom designs. However, aluminum may not withstand as much pressure as steel, which can be a limitation in certain applications.

Plastic is often used in components of air pumps, particularly in non-structural parts. It is lightweight and can be molded into intricate designs, which allows for versatility in product development. However, plastics generally have lower temperature and pressure ratings compared to metals, which may limit their use in high-demand applications.

Rubber is primarily used for seals and hoses in air pumps. Its elasticity allows for a snug fit, preventing air leaks. While rubber is resistant to many chemicals, it can degrade over time, especially when exposed to UV light or ozone.

| Material | Typical Use Case for place to put air in tires near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty air pumps and structures | High strength and durability | Heavier than alternatives | Medium |

| Aluminum | Portable air pumps and custom designs | Lightweight and corrosion-resistant | Lower pressure tolerance | High |

| Plastic | Non-structural components of air pumps | Cost-effective and customizable | Limited pressure and temperature resistance | Low |

| Rubber | Seals and hoses in air pumps | Excellent sealing properties | Limited lifespan and environmental susceptibility | Low |

This analysis provides a comprehensive overview of the materials commonly used in air pump applications for tire inflation. By understanding the properties and implications of each material, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

Illustrative image related to place to put air in tires near me

The manufacturing process for equipment used in tire inflation, such as air pumps and compressors, typically involves several stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the final product meets the required specifications and standards.

The first step in the manufacturing process is material preparation. Manufacturers select high-quality materials that can withstand the pressures and conditions associated with tire inflation. Common materials include metals like steel and aluminum for structural components, and durable plastics for housing and fittings. This stage also involves cutting, shaping, and treating materials to enhance their properties, such as corrosion resistance.

After preparing the materials, the next stage is forming. Techniques such as stamping, machining, and molding are employed to create the various components of the air pumps. For instance, metal parts might be stamped or machined into precise shapes, while plastic components may be injection-molded.

The assembly stage follows forming, where all individual components are brought together. This may include fitting motors, valves, and pressure gauges into the housing, ensuring that each part is correctly aligned and securely fastened. Automated assembly lines are increasingly common, which can enhance efficiency and reduce human error.

The final stage, finishing, involves processes that enhance both the aesthetic appeal and functional performance of the equipment. This includes painting, coating, or plating to protect against wear and tear, as well as to provide a polished appearance. Quality checks are often integrated at this stage to confirm that the product meets design specifications before it is packaged and shipped.

Quality assurance is vital in manufacturing tire inflation equipment to ensure reliability, safety, and performance. Various international and industry-specific standards guide these practices.

ISO 9001 is a key international standard that outlines the criteria for a quality management system. Adhering to ISO 9001 helps manufacturers consistently provide products that meet customer and regulatory requirements. B2B buyers should verify that their suppliers are ISO 9001 certified, as this indicates a commitment to quality processes.

Illustrative image related to place to put air in tires near me

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for oil-related products are crucial. These certifications ensure compliance with safety and performance regulations specific to the industry.

Quality control (QC) checkpoints are integral to the manufacturing process of tire inflation equipment. These checkpoints ensure that each stage of production meets established standards.

Incoming Quality Control (IQC) involves inspecting raw materials and components as they arrive at the manufacturing facility. This step ensures that all materials meet required specifications before they are used in production.

In-Process Quality Control (IPQC) occurs during the manufacturing process. Regular inspections and tests are conducted to ensure that the assembly and forming processes are maintained within specified tolerances. This proactive approach helps identify defects early, reducing waste and rework.

Illustrative image related to place to put air in tires near me

Final Quality Control (FQC) takes place after the product is fully assembled. This stage includes comprehensive testing of the finished equipment to ensure it meets performance criteria. Common tests include pressure testing, functional testing, and safety checks. Any units that do not pass these checks are either reworked or discarded.

B2B buyers must be diligent in verifying the quality control practices of their suppliers. This involves several strategies.

Conducting supplier audits is one of the most effective ways to assess a supplier’s quality control measures. During an audit, buyers can evaluate the manufacturing processes, quality management systems, and compliance with standards. Regular audits also foster a stronger relationship between buyers and suppliers.

Requesting quality control reports from suppliers is another way to ensure product quality. These reports often detail testing results and compliance with relevant standards. Additionally, third-party inspections can provide an unbiased assessment of the supplier’s quality processes, offering further assurance to buyers.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control.

Different regions may have varying regulatory requirements. For instance, products sold in the European Union must adhere to CE marking standards, while those in the Middle East might be subject to different local regulations. Understanding these regulations is crucial for compliance and market entry.

Cross-border quality assurance can pose challenges, including language barriers, differing standards, and logistical complexities. Buyers should ensure that suppliers have a clear understanding of their quality expectations and are capable of meeting them consistently. Engaging local experts or consultants can help navigate these challenges effectively.

In summary, the manufacturing processes and quality assurance measures for tire inflation equipment are intricate and critical for ensuring product reliability and performance. By understanding the main stages of manufacturing, relevant quality standards, and how to verify supplier practices, B2B buyers can make informed decisions and foster successful partnerships in their supply chains. This knowledge is especially valuable for international buyers navigating diverse regulatory landscapes and quality expectations.

This guide serves as a comprehensive checklist for B2B buyers seeking reliable locations to inflate tires, whether for vehicles or bicycles. Proper tire inflation is essential for safety and performance, making it crucial to identify accessible and trustworthy air supply points. This checklist will help you navigate the process of sourcing places that provide air for tires efficiently.

Understanding your geographic area is vital when searching for air supply locations. Determine whether you need services in urban, suburban, or rural areas, as this will influence the availability of facilities. Consider regions with higher traffic, such as commercial districts, where gas stations and tire shops are more likely to offer air.

Illustrative image related to place to put air in tires near me

Compile a list of potential locations where you can access air for tires. Focus on various types of establishments, including:

– Gas Stations: Many chains provide air as a courtesy to customers.

– Tire Shops: These are often equipped with air pumps and typically offer this service for free.

– Bicycle Shops: Especially useful if you also need air for bicycles.

Not all locations guarantee consistent service. It’s essential to verify that the identified places indeed offer air for tires. You can:

– Check Online Resources: Utilize user-generated maps and databases that list free air locations.

– Contact Facilities Directly: A quick phone call can confirm whether air is available and if there are any associated fees.

Evaluate the quality of the air supply services at each location. Key considerations include:

– Condition of Equipment: Ensure air pumps are well-maintained and functional.

– Accessibility: Look for locations that are easy to access and have adequate operating hours.

Some facilities may offer more than just air inflation. Check if they provide:

– Tire Maintenance Services: Such as pressure checks or repairs.

– Loyalty Programs: Some gas stations and tire shops have rewards programs that can benefit frequent users.

Familiarize yourself with local regulations regarding air service. In some regions, gas stations may not be legally required to provide free air. Knowing this can help you set expectations and avoid surprises. Additionally, inquire about any potential fees associated with air services at specific locations.

Create a comprehensive record of your findings, including:

– Location Addresses: Ensure you have exact addresses for easy navigation.

– Contact Information: Keep phone numbers handy for quick reference.

– Service Notes: Jot down any specific details regarding availability and condition.

Following this checklist will streamline your sourcing process for places to inflate tires, ensuring you find reliable and accessible options to meet your needs.

When sourcing air pump services for tire inflation, several cost components come into play. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Materials: The type and quality of air pumps, hoses, and fittings used can significantly impact costs. For instance, pumps that are durable and equipped with advanced features tend to be more expensive.

Labor: Labor costs involve both the workforce required to install and maintain the air pumps and the personnel needed to manage customer service. In regions like Africa and the Middle East, labor costs may vary significantly compared to Europe or South America, affecting overall pricing.

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and equipment maintenance. Companies with efficient overhead structures can offer more competitive pricing.

Tooling: Custom tooling for specialized air pump designs increases initial costs. However, this can be offset by higher prices for customized services.

Quality Control (QC): Investing in stringent QC processes ensures reliable and safe products, which can increase costs but ultimately enhances customer satisfaction and reduces returns.

Logistics: The cost of transporting air pumps to different locations must be considered. Factors such as distance, shipping methods, and regional tariffs can influence logistics costs.

Margin: Suppliers typically add a margin to cover their costs and generate profit. Understanding the margin expectations can assist buyers in negotiating more effectively.

Various price influencers can affect the final pricing of air pump services.

Volume/MOQ: Purchasing in bulk often results in lower prices per unit due to economies of scale. B2B buyers should consider negotiating minimum order quantities (MOQs) to optimize costs.

Specifications/Customization: Customized air pumps or services tailored to specific needs generally come at a premium. Buyers should weigh the benefits of customization against potential cost increases.

Materials: The quality of materials used in air pumps can significantly impact price. Higher-quality materials may lead to higher upfront costs but can result in long-term savings through durability.

Quality/Certifications: Products that come with certifications (e.g., ISO, CE) may have higher prices but can assure buyers of quality and compliance with safety standards, which is particularly important in regulated markets.

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge more but offer better service and product reliability.

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. These terms dictate who is responsible for shipping, insurance, and tariffs, which can significantly affect total costs.

B2B buyers can implement several strategies to enhance cost-efficiency when sourcing air pump services:

Negotiation: Engage in discussions with suppliers to negotiate better pricing, especially for bulk orders or long-term contracts. Highlighting potential future business can be a persuasive tactic.

Total Cost of Ownership (TCO): Consider the TCO rather than just the initial purchase price. This includes maintenance, energy consumption, and potential downtime costs. Investing in higher-quality pumps may reduce TCO over time.

Pricing Nuances for International Buyers: Buyers from regions such as Africa or South America should be aware of local economic conditions and currency fluctuations that can impact pricing. Understanding regional market dynamics can provide leverage during negotiations.

Research and Comparison: Conduct thorough market research to compare prices and services from multiple suppliers. This helps in identifying the most cost-effective options and understanding market standards.

Prices for air pump services can vary widely based on location, supplier, and other factors. It is advisable for buyers to conduct their own market research and consult multiple sources before making purchasing decisions.

When it comes to maintaining optimal tire pressure, having convenient access to air is essential for vehicle safety and efficiency. However, businesses and consumers alike can explore various alternatives to traditional air filling stations. This analysis delves into the effectiveness and practicality of these alternatives, helping B2B buyers make informed decisions.

| Comparison Aspect | Place To Put Air In Tires Near Me | Portable Air Compressor | Tire Inflation Services |

|---|---|---|---|

| Performance | Reliable for quick fills | Varies by model | High, professional-grade |

| Cost | Usually free or low-cost | $30 – $200 | $10 – $50 per service |

| Ease of Implementation | Simple; locate nearby | Requires purchase and some familiarity | Easy, but depends on availability |

| Maintenance | None, aside from location updates | Regular checks needed | None |

| Best Use Case | Quick, on-the-go tire filling | Personal use, emergencies | Fleet management or commercial use |

Portable air compressors are an excellent option for those who prioritize convenience and autonomy. They allow users to inflate tires anywhere, eliminating the need to find a nearby air station. However, the performance can vary significantly depending on the compressor model and brand. Additionally, while the initial investment ranges from $30 to $200, maintenance and battery management can add to the long-term costs. This option is best for individuals or businesses needing reliable tire maintenance during travel or in remote areas.

Tire inflation services provided by professional mechanics or tire shops offer a high level of performance and reliability. These services ensure that tires are inflated to the precise pressure required for optimal performance, which can enhance safety and fuel efficiency. However, this option typically incurs costs ranging from $10 to $50 per service, making it less ideal for casual users. Tire inflation services are particularly beneficial for businesses managing fleets, where consistent and accurate tire pressure is crucial for operational efficiency.

Choosing the right tire inflation solution depends largely on the specific needs of the business or individual. For companies managing fleets, professional tire inflation services may provide the best balance of performance and reliability. In contrast, businesses or individuals who prioritize convenience and flexibility may find portable air compressors more suitable. Ultimately, evaluating the cost, performance, and ease of use of each alternative will empower B2B buyers to make a decision that aligns with their operational requirements and budget constraints.

When assessing locations for air pumps suitable for tire inflation, several critical specifications come into play. Understanding these properties can enhance decision-making for B2B buyers seeking partnerships or services in tire care.

Pump Type and Capacity

Air pumps can vary in type—manual, electric, or compressor-based. Each type has different capacities, typically measured in PSI (pounds per square inch). For commercial buyers, understanding the pump’s capacity is essential to ensure it meets the inflation requirements of various vehicle types, from bicycles to heavy-duty trucks. The right pump type can influence customer satisfaction and operational efficiency.

Durability and Material Grade

The materials used in constructing air pumps significantly affect their longevity and reliability. Common materials include aluminum, plastic, and steel, each with different grades that indicate strength and corrosion resistance. B2B buyers should prioritize higher-grade materials to reduce maintenance costs and ensure that pumps can withstand heavy usage, especially in high-traffic locations.

Flow Rate

Flow rate, measured in cubic feet per minute (CFM), indicates how quickly the pump can deliver air. A higher flow rate leads to faster tire inflation, which is critical in busy service areas where time efficiency is paramount. Understanding flow rates can help businesses choose air pump locations that maximize customer throughput.

Power Source

Air pumps can be powered by electricity, batteries, or manual operation. Each power source presents unique advantages and challenges. For instance, electric pumps typically offer higher efficiency and faster inflation but require reliable power sources. B2B buyers must evaluate the power infrastructure of potential locations to ensure operational compatibility.

Safety and Compliance Standards

Ensuring that air pump locations comply with local safety regulations is crucial. This includes proper signage, maintenance routines, and operational guidelines. Non-compliance can lead to legal liabilities and damage to a company’s reputation. B2B buyers should prioritize partners who adhere to safety standards to mitigate risks.

In the tire inflation service sector, specific jargon is commonly used that B2B buyers should be familiar with to navigate partnerships effectively.

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of air pumps, knowing the OEM can help buyers ensure they are purchasing high-quality equipment that meets industry standards.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers as it can impact inventory levels and procurement strategies. Buyers should negotiate favorable MOQs to optimize their supply chain efficiency.

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. Utilizing RFQs is vital for B2B buyers to ensure competitive pricing and transparency in sourcing air pump services.

Incoterms (International Commercial Terms)

These are a series of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping, risk, and cost allocation when sourcing air pumps internationally.

Service Level Agreement (SLA)

An SLA is a contract that outlines the expected level of service between a service provider and a client. For air pump locations, SLAs can define uptime, maintenance schedules, and response times for service issues. B2B buyers should ensure SLAs are in place to protect their interests and maintain service quality.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions when seeking air pump services, ensuring optimal operations and customer satisfaction.

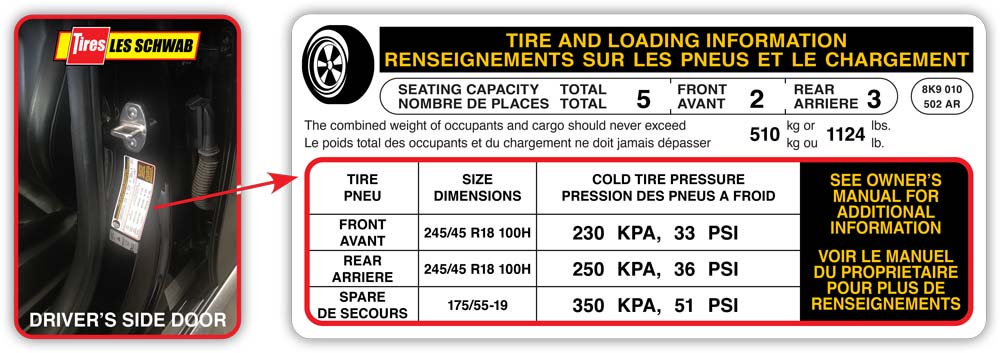

The market for locations offering air for tires is evolving, driven by a blend of consumer behavior shifts and technological advancements. Globally, there is a growing emphasis on convenience and accessibility, particularly in urban areas. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly focusing on partnerships with service providers that enhance customer experience. This includes businesses that provide easily accessible air pumps at gas stations, tire shops, and roadside assistance services.

Emerging technologies, including mobile apps and geolocation services, are also reshaping the landscape. These platforms enable users to quickly locate nearby air filling stations, thus improving service delivery and customer satisfaction. Additionally, the rise of electric vehicles (EVs) is influencing the market. As the number of EVs increases, so does the demand for services that support these vehicles, including tire maintenance.

Moreover, B2B buyers are becoming more attuned to the importance of data analytics in decision-making. Insights derived from consumer behavior can guide businesses in optimizing their locations and services. This trend is particularly relevant for companies looking to expand their networks across diverse geographical regions.

Sustainability has become a crucial consideration for B2B buyers in the tire service sector. The environmental impact of tire maintenance, including air pressure management, is significant. Proper tire inflation not only enhances fuel efficiency but also reduces greenhouse gas emissions. This awareness is prompting businesses to adopt eco-friendly practices, such as using sustainable materials for their air pumps and ensuring that their operations minimize waste.

Illustrative image related to place to put air in tires near me

Ethical sourcing is equally important. B2B buyers are increasingly seeking suppliers who demonstrate a commitment to responsible sourcing practices. This includes using materials that are certified as ‘green’ and ensuring fair labor practices in the supply chain. Certifications such as ISO 14001 (Environmental Management) and Fair Trade are becoming benchmarks for suppliers looking to prove their sustainability credentials.

In addition, the integration of renewable energy sources in the operation of air pumps can enhance the appeal of businesses in this sector. For example, solar-powered air pumps not only reduce operational costs but also align with the growing consumer demand for sustainable solutions. By prioritizing sustainability and ethical sourcing, companies can enhance their brand reputation and appeal to environmentally conscious consumers.

The concept of providing air for tires has evolved from a basic service offered by gas stations to a more structured industry segment. Initially, air pumps were a standard feature at service stations, often operated manually. Over the decades, as vehicle ownership surged globally, the demand for accessible tire maintenance solutions increased.

With the advent of technology, businesses began integrating automated air pumps that offer user-friendly interfaces, reducing the need for manual operation. The rise of digital platforms has further transformed the market, allowing consumers to locate air filling stations effortlessly. Today, businesses in this sector are leveraging data analytics and consumer insights to optimize their offerings, ensuring that they meet the evolving needs of B2B buyers and end consumers alike.

In summary, the ‘place to put air in tires near me’ market reflects broader trends in technology, sustainability, and consumer behavior, making it a dynamic sector for B2B engagement and investment.

How do I find reliable places to put air in tires near me?

To locate dependable places for tire inflation, utilize online databases and mapping services that list free air pump locations. Websites like FreeAirPump and FreeAirNearMe provide user-generated maps that can help you find nearby options. Additionally, consider checking with local gas stations, tire shops, and auto repair facilities, as many offer complimentary air services. When sourcing these locations, verify the information through customer reviews or direct inquiries to ensure the service is still available.

What types of businesses typically offer free air for tires?

Free air for tires is commonly available at various establishments, including gas stations, tire shops, auto repair centers, and some convenience stores. Major gas station chains often provide this service as a courtesy to customers, although it may vary by location. For B2B buyers, partnering with local tire shops or automotive service providers can also create opportunities for additional services, ensuring your clients’ needs for tire maintenance are met efficiently.

Are there any costs associated with using air pumps at gas stations?

While many gas stations offer free air pumps, it’s essential to understand that this is not universally mandated. In some regions, gas stations may charge for the service. Therefore, it is advisable to confirm whether a specific location provides complimentary air. This information can be beneficial for businesses that rely on transportation, as it aids in budgeting for maintenance costs and enhances operational efficiency.

What should I consider when sourcing air pump suppliers for my business?

When sourcing air pump suppliers, consider factors such as reliability, quality, and service support. Look for suppliers with a proven track record and positive customer feedback. Assess the variety of air pump models they offer, including portable options for added convenience. Additionally, inquire about customization possibilities, minimum order quantities (MOQs), and the availability of spare parts to ensure that your business can meet diverse customer needs effectively.

How can I ensure the quality of air pumps I purchase for my business?

To ensure the quality of air pumps, conduct thorough supplier vetting, focusing on certifications, customer reviews, and warranty offerings. Request samples or product demonstrations to evaluate performance and reliability firsthand. Establish clear quality assurance (QA) measures, including testing protocols and compliance with international safety standards. This diligence helps mitigate risks associated with product failure and enhances customer satisfaction in your business operations.

What are the typical payment terms when sourcing air pumps internationally?

Payment terms for international sourcing can vary significantly among suppliers. Common arrangements include letters of credit, advance payments, or net payment terms. It’s crucial to negotiate terms that align with your cash flow and risk management strategies. Additionally, consider the implications of currency exchange rates and transaction fees. Establishing a clear agreement on payment terms upfront can prevent misunderstandings and facilitate smoother transactions.

What logistics considerations should I keep in mind when importing air pumps?

Logistics plays a vital role in the importation of air pumps. Key considerations include shipping methods, customs clearance, and delivery timelines. Evaluate the cost-effectiveness of air versus sea freight based on your urgency and budget. Additionally, ensure compliance with local regulations and tariffs, which can impact overall costs. Collaborating with a reliable logistics partner can streamline the import process, helping you manage inventory effectively and meet customer demands promptly.

How do I handle disputes with suppliers in the air pump industry?

Dispute resolution should be approached proactively by establishing clear communication channels and expectations in contracts. Should issues arise, document all correspondence and agreements related to the dispute. Engage in open dialogue with the supplier to seek a mutual resolution, and consider mediation if necessary. Familiarizing yourself with the legal framework governing international trade can also provide guidance on resolving disputes effectively while preserving business relationships.

Domain: freeairpump.com

Registered: 2012 (13 years)

Introduction: Map of places that provide free air for tires, with over 12,000 locations in the U.S. User-generated content, allowing submissions of new free air spots. Search functionality available by device location or address. Recommendations for portable air compressors/inflators. Common locations for free air include tire shops, car repair stations, bike shops, and specific gas station chains like Co-op, F…

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Best Gas Stations with Air Pumps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In summary, strategic sourcing of locations that provide air for tires is essential for businesses seeking to enhance customer satisfaction and operational efficiency. By leveraging a comprehensive database of free air locations, companies can ensure that their clients have convenient access to tire maintenance services. This not only fosters customer loyalty but also positions your business as a reliable partner in vehicle upkeep.

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding the landscape of tire inflation services can present numerous opportunities. Investing in partnerships with local gas stations, tire shops, and repair centers that offer free air services can significantly reduce operational costs and improve service offerings.

Illustrative image related to place to put air in tires near me

As the demand for convenient vehicle maintenance solutions grows, now is the time to explore potential collaborations in your region. Engage with local businesses to identify strategic alliances that can enhance your service portfolio. By prioritizing access to air inflation services, you position your business to thrive in a competitive marketplace while addressing the evolving needs of your customers.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.