In today’s competitive landscape, sourcing the right plug-in air compressor can significantly impact operational efficiency and cost management for businesses across various sectors. As international B2B buyers grapple with the challenge of identifying reliable suppliers and high-quality products, this comprehensive guide serves as a critical resource. Whether you are in manufacturing, automotive, or construction, understanding the diverse types of air compressors, their applications, and performance specifications is vital to making informed purchasing decisions.

This guide delves into the myriad types of plug-in air compressors available in the global market, from compact models suitable for personal use to heavy-duty variants designed for industrial applications. It also explores the essential factors to consider when vetting suppliers, including certifications, customer feedback, and after-sales support. Furthermore, we provide insights into cost considerations, helping you balance quality with budget constraints.

Empowering international B2B buyers from Africa, South America, the Middle East, and Europe—including markets like Vietnam and Germany—this guide is designed to streamline your purchasing process. By equipping you with the knowledge needed to navigate the complexities of the air compressor market, we aim to enhance your operational capabilities and ensure your investments yield maximum returns.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Corded Electric Compressors | Plugged into an AC outlet; continuous power supply | Automotive repair, manufacturing | Pros: Reliable, consistent pressure; Cons: Limited mobility due to cord length. |

| Portable Battery-Powered Compressors | Rechargeable, cordless design; lightweight and compact | Fieldwork, emergency services | Pros: High mobility, suitable for remote areas; Cons: Limited run time based on battery life. |

| Dual-Power Compressors | Operates on both AC and DC power; versatile usage | Automotive, construction, and home use | Pros: Flexibility in power sources; Cons: Heavier and may require more maintenance. |

| High-Pressure Compressors | Capable of achieving higher PSI levels; robust construction | Heavy machinery, industrial applications | Pros: Suitable for demanding tasks; Cons: Typically more expensive and requires more space. |

| Inflator Compressors | Specifically designed for inflating tires and sports equipment; often features built-in gauges | Automotive, sports, and recreation | Pros: Quick inflation, user-friendly; Cons: Limited to specific inflation tasks. |

Corded electric compressors are primarily designed for continuous operation, making them ideal for businesses that require consistent air pressure for tools and equipment. These compressors are connected to an AC outlet, providing a steady power supply. They are widely used in automotive repair shops and manufacturing facilities due to their reliability. When purchasing, consider the cord length and the compressor’s flow rate, as these factors can impact usability in larger workspaces.

Portable battery-powered compressors are highly valued for their mobility and convenience. These units are lightweight and can be used in remote locations without access to electrical outlets, making them perfect for fieldwork or emergency situations. However, their battery life is a critical consideration; buyers should assess the compressor’s runtime and charging time to ensure it meets their operational needs. While they offer freedom of movement, they may not provide the same power as corded models.

Dual-power compressors offer the flexibility of operating on both AC and DC power, making them suitable for various applications. This versatility is particularly beneficial in industries like automotive and construction, where power sources may vary based on the job site. Buyers should evaluate the weight and portability of these compressors, as they can be bulkier than single-source models. Their adaptability makes them a solid investment for businesses that require equipment capable of functioning in different environments.

High-pressure compressors are specifically engineered to handle demanding tasks that require elevated PSI levels. These robust units are commonly used in industrial applications, such as heavy machinery maintenance and construction work. When considering a high-pressure compressor, buyers should focus on the unit’s durability and the types of fittings available, as these factors can affect compatibility with existing equipment. While they are typically more expensive, their performance in challenging conditions justifies the investment.

Inflator compressors are specialized tools designed for quick inflation of tires and sports equipment. These units often come with built-in pressure gauges, enhancing usability for end-users. They are particularly popular in automotive sectors and recreational industries. Buyers should consider the maximum PSI capabilities and the range of attachments included with the inflator, as these features can greatly enhance functionality. Although they are limited to inflation tasks, their speed and ease of use make them valuable for businesses focused on efficiency.

| Industry/Sector | Specific Application of plug in air compressor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire inflation and maintenance for vehicles | Enhances vehicle safety and reduces downtime | Ensure compatibility with various tire sizes and types. |

| Construction | Powering pneumatic tools for construction projects | Increases productivity and efficiency on-site | Look for durability and portability to withstand job site conditions. |

| Manufacturing | Operating air-driven machinery and tools | Improves production speed and machinery reliability | Assess air pressure requirements and maintenance support. |

| Agriculture | Inflating equipment such as sprayers and pneumatic tools | Enhances operational efficiency and crop management | Consider power source availability and mobility in the field. |

| Home Services | Providing air for cleaning and painting tools | Improves service quality and customer satisfaction | Evaluate noise levels and ease of transport for residential use. |

In the automotive repair industry, plug-in air compressors are essential for tire inflation and maintenance. These compressors allow mechanics to quickly and efficiently inflate tires, which is crucial for vehicle safety and performance. They can also power various pneumatic tools used in repairs. For international buyers, especially from regions like Africa and South America, sourcing compressors that are compatible with diverse vehicle types and tire sizes is vital, ensuring they can address a wide range of customer needs effectively.

In construction, plug-in air compressors are used to power pneumatic tools such as nail guns, drills, and jackhammers. This significantly increases productivity and efficiency on job sites. A reliable air compressor can reduce downtime by ensuring tools are consistently powered. Buyers from the Middle East and Europe should prioritize durability and portability, as compressors must withstand harsh conditions and be easily transportable across various sites.

Manufacturers utilize plug-in air compressors to operate air-driven machinery, which is integral to many production processes. These compressors enhance production speed and ensure machinery runs reliably, minimizing downtime. For B2B buyers in Europe, particularly in sectors with stringent quality standards, evaluating the compressor’s air pressure capabilities and maintenance support is crucial for sustaining operational efficiency.

In the agricultural sector, plug-in air compressors are used to inflate equipment such as sprayers and pneumatic tools, facilitating effective crop management. This enhances operational efficiency, allowing farmers to cover larger areas more quickly. Buyers from regions like Africa should consider the mobility and power source of these compressors, ensuring they can be used in remote areas without reliable electricity.

Home service providers, such as cleaners and painters, utilize plug-in air compressors to power tools for cleaning and painting applications. These compressors improve service quality and customer satisfaction by providing consistent air pressure for tools. When sourcing compressors, buyers should evaluate noise levels and transportability to ensure they can operate effectively in residential areas without disturbing clients.

The Problem: In regions with unreliable electricity, B2B buyers often face significant challenges when using plug-in air compressors. Frequent power outages can interrupt workflow, leading to delays in production or service delivery. This inconsistency can not only waste time but also result in increased operational costs and unsatisfied customers. Buyers in sectors such as automotive repair or construction, where consistent air pressure is vital for tools and equipment, particularly feel the strain of this issue.

The Solution: To mitigate power supply issues, businesses should consider investing in plug-in air compressors that include dual power options, allowing operation on both AC and DC power sources. This versatility ensures that even during outages, compressors can be powered by vehicle batteries or generators, maintaining productivity. Additionally, sourcing compressors with built-in battery backups or those that are compatible with portable power stations can further enhance reliability. Establishing partnerships with suppliers who provide robust warranties and after-sales support can also help ensure that equipment remains functional, minimizing downtime.

The Problem: Many plug-in air compressors come without integrated pressure gauges or with unreliable analog gauges. For B2B buyers, particularly in sectors like manufacturing or automotive services, this can lead to over-inflation or under-inflation of tires and other equipment, causing safety hazards or equipment damage. Buyers often experience frustration when they cannot accurately monitor the air pressure, leading to potential liability issues and additional costs for repairs or replacements.

The Solution: B2B buyers should prioritize sourcing plug-in air compressors that feature digital pressure gauges with preset options and auto shut-off capabilities. This ensures that users can easily set desired pressure levels without the risk of human error. When evaluating compressors, buyers should seek models that have undergone rigorous testing for accuracy and reliability. Additionally, incorporating regular training for staff on the importance of monitoring air pressure can significantly reduce risks. Establishing a preventive maintenance schedule can also ensure that the compressors are calibrated correctly, further enhancing operational safety and efficiency.

The Problem: B2B buyers often find that plug-in air compressors are limited in their functionality, which can restrict their use across different applications. In industries like construction, automotive, or agriculture, the ability to inflate tires, operate pneumatic tools, and support various inflatables is critical. Buyers may feel constrained if their compressor cannot adapt to various tasks, leading to additional expenditures on multiple units and wasted storage space.

The Solution: To address versatility concerns, B2B buyers should look for multi-functional plug-in air compressors that come with a range of attachments and accessories. This includes nozzles for different inflatables, adaptors for various tools, and sufficient hose lengths to reach all areas of a worksite. Additionally, investing in a compressor with adjustable pressure settings can allow for usage across a wider variety of applications, from inflating high-pressure tires to powering lower-pressure pneumatic tools. Engaging with suppliers that offer customizable solutions or packages can provide businesses with tailored equipment that meets their specific operational needs, ultimately streamlining processes and reducing overhead costs.

When selecting materials for plug-in air compressors, it is essential to consider their properties, advantages, and limitations, particularly in the context of international markets. Below is an analysis of four common materials used in the construction of these devices: aluminum, steel, plastic, and rubber.

Key Properties: Aluminum is lightweight and has excellent corrosion resistance. It can withstand moderate pressures and temperatures, making it suitable for various compressor applications.

Pros & Cons: The primary advantage of aluminum is its weight, which facilitates portability. Additionally, its resistance to rust makes it ideal for humid environments. However, aluminum can be more expensive than other materials and may not handle extreme pressures as effectively as steel.

Impact on Application: Aluminum is compatible with air and non-corrosive gases, making it ideal for general-purpose compressors. However, it may not be suitable for applications involving aggressive chemicals.

Considerations for International Buyers: In regions like Africa and South America, where humidity can be high, aluminum’s corrosion resistance is a significant advantage. Compliance with standards such as ASTM can also guide material selection, ensuring quality and safety.

Key Properties: Steel offers high strength and durability, with excellent pressure and temperature ratings. It is often coated to enhance corrosion resistance.

Pros & Cons: Steel’s durability makes it ideal for heavy-duty applications, and it is generally more cost-effective than aluminum. However, its weight can be a disadvantage for portable models, and it may require additional coatings to prevent rust.

Impact on Application: Steel is suitable for high-pressure applications and can handle a variety of media, including air and some gases. However, its susceptibility to corrosion can limit its use in certain environments unless properly treated.

Considerations for International Buyers: Buyers in Europe, such as Germany, may prefer steel due to its robust performance in industrial applications. Compliance with DIN standards is crucial for ensuring that steel components meet safety and performance requirements.

Key Properties: Plastic is lightweight and can be molded into complex shapes. It typically has lower temperature and pressure ratings compared to metals.

Pros & Cons: The main advantage of plastic is its low cost and ease of manufacturing. It is also resistant to corrosion. However, plastic may not withstand high pressures and can degrade over time when exposed to UV light.

Impact on Application: Plastic is often used for housing and non-structural components. It is suitable for applications where weight is a concern, but its limitations in pressure ratings can restrict its use.

Considerations for International Buyers: In regions with stringent regulations, such as Europe, buyers should ensure that plastics used comply with safety standards, including RoHS and REACH, to avoid legal complications.

Key Properties: Rubber is flexible and has excellent sealing properties, making it ideal for hoses and gaskets. It can handle a range of temperatures but may have limitations in extreme conditions.

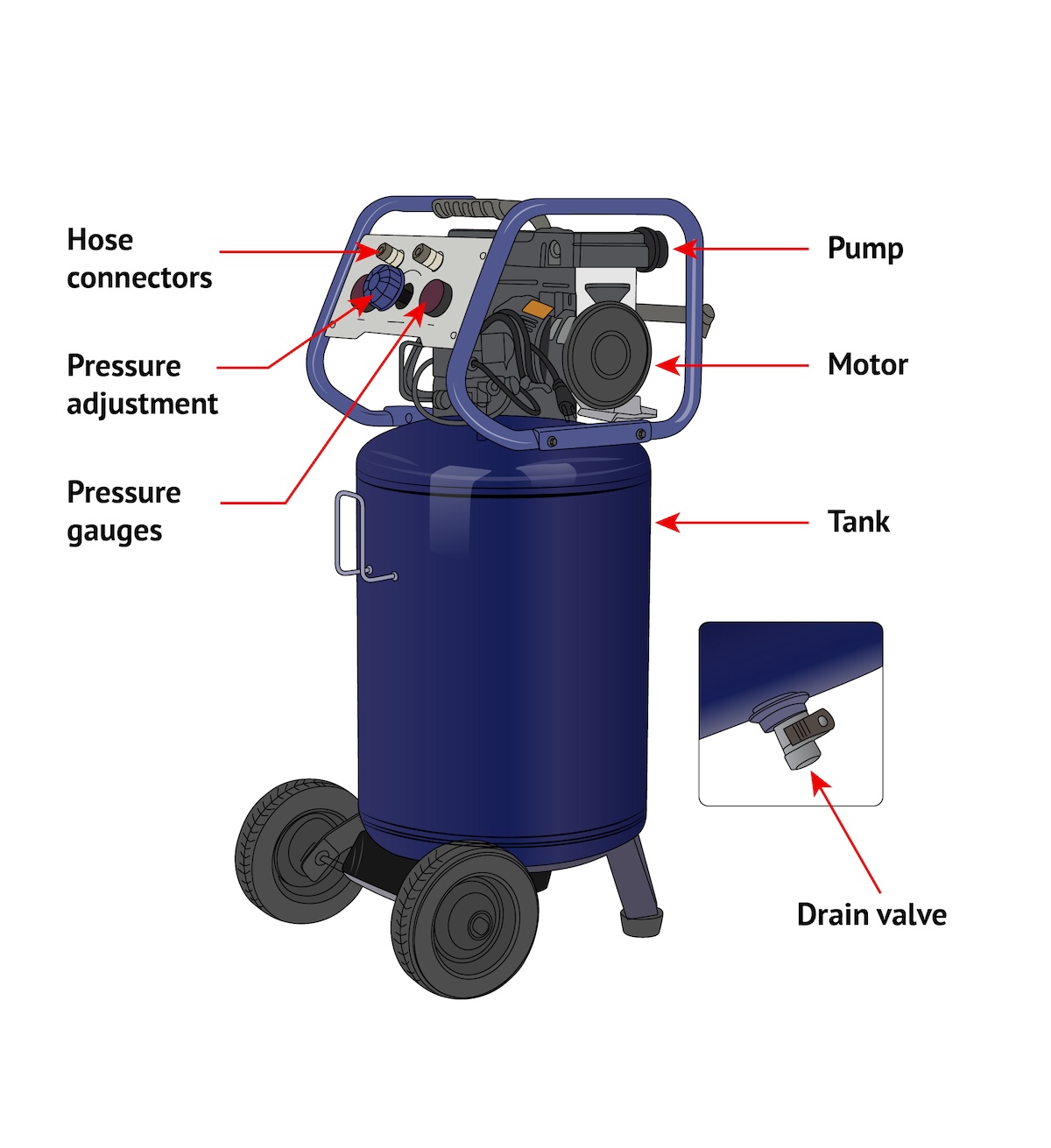

Illustrative image related to plug in air compressor

Pros & Cons: The flexibility of rubber allows for easy installation and maintenance. However, it can wear out over time and may not be suitable for high-pressure applications without reinforcement.

Impact on Application: Rubber is primarily used in components that require sealing, such as hoses and gaskets. Its compatibility with air makes it a common choice, but its durability can be a concern in industrial settings.

Considerations for International Buyers: Buyers in the Middle East, where high temperatures can affect rubber performance, should consider materials that are specifically designed for heat resistance. Compliance with international standards for materials can also ensure reliability.

| Material | Typical Use Case for plug in air compressor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Higher cost and limited pressure handling | Medium |

| Steel | Pressure vessels and frames | High strength and durability | Heavier and prone to corrosion | Low |

| Plastic | Non-structural components and housing | Low cost and easy to manufacture | Limited pressure ratings and UV degradation | Low |

| Rubber | Seals and hoses | Excellent sealing properties and flexibility | Wear over time and limited high-pressure use | Medium |

This guide provides a comprehensive overview of material selection for plug-in air compressors, catering to the specific needs of international B2B buyers. Understanding the properties, advantages, and limitations of each material can significantly influence purchasing decisions and product performance in diverse market conditions.

The manufacturing process of plug-in air compressors involves several critical stages, each of which plays a vital role in ensuring the final product meets high-performance standards. These stages typically include material preparation, forming, assembly, and finishing.

The first step in manufacturing a plug-in air compressor is the selection and preparation of raw materials. Key materials include high-grade metals for the compressor body, durable plastics for housing components, and rubber for seals and hoses. Manufacturers often rely on suppliers that meet international standards to ensure quality and reliability.

Once materials are sourced, they undergo rigorous inspection to assess their quality and suitability for use. This initial quality control (IQC) process helps to eliminate any defects before production begins. Materials are then processed, which may involve cutting, machining, or molding, depending on the component’s specifications.

Illustrative image related to plug in air compressor

The forming stage is crucial for shaping the raw materials into usable parts. Common techniques include:

These methods not only create the necessary parts but also help maintain consistency and reduce waste, which is essential for cost-effective manufacturing.

Once all parts are prepared, the assembly process begins. This stage typically follows a systematic approach:

Quality checks, known as In-Process Quality Control (IPQC), are conducted throughout the assembly phase. This ensures that any issues are identified and rectified immediately, minimizing the risk of defects in the final product.

Illustrative image related to plug in air compressor

Finishing processes enhance both the aesthetics and functionality of plug-in air compressors. Common techniques include:

This stage is crucial for maintaining the compressor’s durability and visual appeal, which can significantly impact a buyer’s perception of quality.

Quality assurance is an integral part of the manufacturing process for plug-in air compressors. Adhering to international and industry-specific standards is essential for ensuring product reliability and safety.

Manufacturers often comply with several international standards, such as:

Understanding these standards allows B2B buyers to assess the credibility and reliability of their suppliers.

Quality control in manufacturing involves multiple checkpoints:

These checkpoints help maintain high standards throughout the production cycle.

Testing methods play a vital role in validating the performance and safety of plug-in air compressors. Common methods include:

Illustrative image related to plug in air compressor

These tests help identify any potential issues before the product reaches the market, ensuring a higher level of customer satisfaction.

For international B2B buyers, verifying a supplier’s quality control practices is crucial for ensuring product reliability. Here are several strategies to consider:

Conducting audits of potential suppliers can provide insight into their manufacturing and quality assurance processes. Buyers should:

These audits can help identify any discrepancies in quality assurance practices and ensure compliance with international standards.

Illustrative image related to plug in air compressor

Utilizing third-party inspection services can offer an unbiased evaluation of a supplier’s quality control measures. These services often conduct:

Engaging third-party inspectors can help mitigate risks and provide assurance of product quality.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be mindful of specific nuances in quality control:

By considering these factors, international buyers can make informed decisions and establish successful partnerships with manufacturers of plug-in air compressors.

This practical sourcing guide is designed to assist B2B buyers in the procurement of plug-in air compressors. Whether for automotive maintenance, industrial applications, or construction needs, understanding the critical factors in sourcing these tools can lead to better purchasing decisions and enhanced operational efficiency.

Establishing clear technical specifications is the first step in sourcing a plug-in air compressor. Consider factors such as maximum pressure (PSI), flow rate (CFM), and power source (AC voltage). This clarity will ensure that the selected compressor meets your operational requirements and can effectively handle the tasks at hand.

Different applications require varying features and capabilities from air compressors. For instance, if you plan to use the compressor for inflating tires, ensure it can achieve the necessary PSI quickly. Identify any additional features you may need, such as portability, noise levels, or integrated tools, to match your specific use case.

Before committing to a supplier, it’s crucial to thoroughly vet their capabilities and reliability. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. Consider their experience with international shipping and compliance with local regulations to avoid potential sourcing issues.

Ensure that the air compressors you are considering comply with relevant international standards and certifications. Look for certifications such as ISO 9001 for quality management or CE marking for European compliance. This verification can protect your business from liability issues and ensure product quality and safety.

Compare pricing structures among potential suppliers while also considering the total cost of ownership. Look beyond the initial purchase price to include maintenance, warranty, and potential shipping costs. Understanding the payment terms and conditions can also facilitate smoother transactions.

Investigate the warranty and after-sales support offered by suppliers. A robust warranty can safeguard your investment, while reliable customer support can be critical for troubleshooting and maintenance. Ensure you have access to service centers or support teams that can assist you efficiently.

Illustrative image related to plug in air compressor

If possible, conduct performance testing or request demonstrations of the air compressors. Evaluating their efficiency, noise levels, and operational ease will provide insights into their real-world performance. This step is crucial to ensure that the product meets your expectations before finalizing the purchase.

By following this checklist, B2B buyers can navigate the complexities of sourcing plug-in air compressors effectively, ensuring they select the right equipment for their specific needs.

When sourcing plug-in air compressors, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

Materials: The choice of materials significantly affects the cost. High-quality steel and durable plastic components are common in compressors, but variations in material sourcing can lead to price fluctuations. Buyers should assess whether lower-cost materials impact performance and longevity.

Labor: Labor costs vary by region and can impact the total price of the compressor. Countries with lower labor costs may offer more competitive pricing, but this should be weighed against quality and reliability.

Manufacturing Overhead: This includes factory utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can reduce overhead, enabling suppliers to offer lower prices.

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should inquire about tooling costs when seeking specific features or specifications, as these can influence the overall pricing.

Quality Control (QC): Effective QC processes ensure product reliability and performance, which can be a significant cost factor. Products with higher QC standards may carry a premium but can lead to cost savings in the long run through reduced warranty claims and returns.

Logistics: Transportation and shipping costs can vary widely based on distance, mode of transport, and the chosen Incoterms. Understanding the logistics involved can help buyers anticipate additional costs.

Margin: Supplier margins vary depending on the market, competition, and perceived product value. Buyers should seek transparency regarding the margin applied to the products they are sourcing.

Several factors can influence the pricing of plug-in air compressors, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

Volume/MOQ: Bulk purchases often lead to discounted pricing due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to optimize costs without compromising their inventory needs.

Specifications and Customization: Custom features can increase costs. Buyers should weigh the necessity of specific features against their budget and consider standard models if customization is not critical.

Materials and Quality: Higher quality materials and certifications (like ISO or CE) often come at a premium. Buyers should assess the importance of these factors in their specific applications to ensure they are making cost-effective decisions.

Supplier Factors: Supplier reputation, reliability, and geographic location can impact pricing. It’s advisable to conduct thorough research on potential suppliers to identify those who offer the best balance between price and quality.

Incoterms: Understanding Incoterms is essential for managing shipping and logistics costs. Different terms can affect who bears the costs and risks during transportation, influencing the overall price.

To navigate the complexities of sourcing plug-in air compressors effectively, buyers can employ several strategies:

Negotiation: Engage in direct negotiations with suppliers to obtain better pricing, especially for bulk orders. Building a strong relationship with suppliers can also lead to favorable terms and conditions.

Cost-Efficiency: Evaluate the total cost of ownership rather than just the initial purchase price. Consider factors such as energy efficiency, maintenance costs, and durability, which can significantly affect long-term expenses.

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, trade tariffs, and import duties that may impact final pricing. Conducting thorough market research can help mitigate these risks.

Market Insights: Keep abreast of market trends and competitor pricing to make informed purchasing decisions. This knowledge can empower buyers to negotiate effectively and secure the best deals.

In conclusion, understanding the intricate cost structure and pricing influencers associated with plug-in air compressors can empower B2B buyers to make informed sourcing decisions. By leveraging negotiation strategies and considering the total cost of ownership, buyers can achieve significant savings while ensuring they procure reliable and high-quality products.

As businesses seek efficient solutions for air compression needs, evaluating alternatives to plug in air compressors is essential. This analysis compares plug in air compressors with portable tire inflators and cordless air compressors. Each option presents unique advantages and considerations that can influence purchasing decisions, particularly for B2B buyers in diverse international markets.

| Comparison Aspect | Plug In Air Compressor | Portable Tire Inflator | Cordless Air Compressor |

|---|---|---|---|

| Performance | High PSI, suitable for heavy-duty tasks | Moderate PSI, ideal for light use | High PSI, versatile for various tasks |

| Cost | Moderate to high ($100-$500) | Low to moderate ($30-$100) | Moderate to high ($50-$150) |

| Ease of Implementation | Requires stable power source and setup | Plug and play; minimal setup | Quick setup; battery-powered |

| Maintenance | Regular maintenance needed; check oil and filters | Low maintenance; simple cleaning | Moderate; battery checks required |

| Best Use Case | Industrial applications, automotive repair | Personal use, emergency situations | Versatile use; automotive, sports, home tasks |

Portable tire inflators are compact devices specifically designed for inflating tires and small items like sports balls. They are cost-effective and user-friendly, often powered by a car’s 12V outlet or a battery. The primary advantage of portable inflators lies in their convenience and affordability, making them ideal for emergency situations or personal use. However, their performance is limited, typically only providing moderate PSI levels suitable for small tires and requiring longer inflation times compared to larger compressors.

Cordless air compressors offer the flexibility of portability without being tethered to an outlet. These devices are particularly useful for various applications, from inflating tires to powering pneumatic tools. They often come with rechargeable batteries, providing the freedom to operate in remote locations. While cordless compressors are versatile, they may have limitations in terms of PSI and runtime, particularly when compared to plug in models. Additionally, the initial investment can be moderate, but ongoing battery maintenance and replacements may add to the long-term costs.

When selecting an air compression solution, B2B buyers should consider their specific requirements, including performance needs, budget constraints, and operational contexts. Plug in air compressors are ideal for heavy-duty applications requiring high PSI and consistent performance, making them suitable for industrial environments. Conversely, portable tire inflators serve well for personal or low-demand situations, while cordless air compressors strike a balance between portability and functionality. Evaluating these factors will enable buyers to make informed decisions that align with their operational goals and financial considerations.

When selecting a plug-in air compressor for business needs, understanding key technical properties is essential for ensuring optimal performance and reliability. Here are several critical specifications to consider:

The maximum pressure rating, measured in pounds per square inch (PSI), indicates the highest pressure the compressor can achieve. For B2B applications, this specification is crucial because it determines the compressor’s suitability for various tasks, such as inflating tires or powering pneumatic tools. A higher PSI allows for more versatility in applications, particularly in industries like automotive or manufacturing.

Illustrative image related to plug in air compressor

Cubic Feet per Minute (CFM) measures the compressor’s air delivery rate. This specification is vital when determining how quickly tools can operate and how efficiently the compressor can support multiple tools simultaneously. A higher CFM is essential for applications requiring continuous airflow, making it a key consideration for businesses that rely heavily on pneumatic tools.

Plug-in air compressors typically operate on either 120V or 240V power sources. Understanding the voltage requirement is essential for compatibility with existing electrical systems in your facility. Additionally, a dual-power option, such as 12V for vehicle use and 120V for standard outlets, provides flexibility for various work environments, enhancing operational efficiency.

The duty cycle indicates the compressor’s operational time versus the rest time required for cooling. Expressed as a percentage (e.g., 50% duty cycle means 5 minutes of operation followed by 5 minutes of rest), this property affects productivity. A compressor with a higher duty cycle can operate longer without overheating, making it suitable for more demanding applications.

The size of the air tank, measured in gallons, affects the compressor’s efficiency and performance. A larger tank allows for more air storage, reducing the frequency of compressor cycling and providing a steady air supply for tools. This is particularly important in high-demand environments where consistent airflow is critical.

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several common terms relevant to plug-in air compressors:

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of air compressors, understanding OEM relationships is vital for ensuring that replacement parts or accessories are compatible and of high quality.

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers looking to purchase plug-in air compressors in bulk, as it can affect pricing and inventory management.

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For businesses seeking plug-in air compressors, issuing an RFQ helps gather competitive quotes, enabling informed purchasing decisions based on cost and specifications.

Illustrative image related to plug in air compressor

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers, as they dictate aspects like shipping costs, insurance, and liability, impacting the total cost of acquiring air compressors.

Understanding warranty terms and service agreements is crucial for B2B buyers to ensure long-term support and maintenance for their air compressors. These agreements can cover repairs, replacements, and service schedules, providing peace of mind in operational continuity.

By familiarizing yourself with these technical properties and trade terms, you can make informed decisions that enhance operational efficiency and support your business’s specific needs in air compressor procurement.

The global plug-in air compressor market is undergoing significant transformation driven by technological advancements and evolving consumer preferences. Key trends include the increasing demand for portable, lightweight, and multi-functional compressors. These units are becoming essential for various applications, from automotive maintenance to industrial uses, particularly in developing regions like Africa and South America where infrastructure development is on the rise. International buyers are increasingly seeking models that offer dual power capabilities (AC and DC) to enhance usability in diverse environments, particularly in areas where electricity supply may be inconsistent.

Furthermore, the integration of smart technology is reshaping the sector. Features such as digital pressure gauges, auto shut-off capabilities, and mobile app connectivity are becoming standard. This trend is particularly appealing to B2B buyers in Europe, where regulatory standards are stringent and product quality is paramount. Additionally, the rise of e-commerce platforms is facilitating easier access to various brands and models, allowing buyers to compare specifications and prices effortlessly.

The market is also experiencing a shift towards environmentally friendly products, as consumers increasingly prioritize sustainability. This shift is not only a response to regulatory pressures but also reflects a broader commitment to corporate social responsibility, making it essential for B2B buyers to stay informed about emerging technologies and sourcing practices.

Sustainability has become a critical factor influencing sourcing decisions in the plug-in air compressor sector. With growing environmental awareness, B2B buyers are now placing greater emphasis on the ecological impact of their procurement choices. This includes evaluating the life cycle of products, from raw material sourcing to end-of-life disposal. Ethical sourcing practices are gaining traction, with companies increasingly prioritizing suppliers who adhere to sustainable manufacturing processes and ethical labor practices.

Illustrative image related to plug in air compressor

Incorporating ‘green’ certifications and materials is becoming a competitive advantage in the market. Buyers are looking for products that not only meet performance standards but also align with their sustainability goals. Manufacturers that utilize recyclable materials, energy-efficient production techniques, and non-toxic components are more likely to attract business from environmentally conscious buyers. Moreover, certifications such as ISO 14001 for environmental management systems and Energy Star ratings for energy efficiency are becoming increasingly relevant in procurement discussions.

As the demand for sustainable products grows, international buyers must consider how their sourcing strategies can reflect their commitment to environmental stewardship. This shift not only enhances brand reputation but also meets regulatory requirements in various regions, particularly in Europe and North America.

The plug-in air compressor has evolved significantly since its inception. Initially designed for simple tasks like inflating tires, these devices have transformed into versatile tools capable of handling various industrial applications. The introduction of electric-powered models in the late 20th century marked a significant shift, allowing for greater efficiency and reduced noise compared to their gas-powered counterparts.

Over the years, innovations in technology have led to the development of compact, portable models that cater to the needs of both consumers and businesses. Features such as digital pressure monitoring, automatic shut-off, and various nozzle attachments have expanded the functionality of these compressors, making them indispensable in sectors ranging from automotive to construction.

Illustrative image related to plug in air compressor

As the market continues to evolve, manufacturers are increasingly focused on integrating smart technology and sustainable practices, ensuring that plug-in air compressors meet the demands of modern users. This evolution reflects broader trends in the B2B landscape, where efficiency, versatility, and environmental responsibility are paramount for success.

How do I choose the right plug-in air compressor for my business needs?

Choosing the right plug-in air compressor involves assessing your specific requirements such as airflow (CFM), pressure (PSI), and application. Consider the types of tools you’ll be using it with; for instance, nail guns and spray guns have different airflow needs. Additionally, evaluate the size and portability if you require a unit for multiple job sites. Understanding the voltage requirements (e.g., 120V vs. 240V) is crucial, especially for international operations, to ensure compatibility with local power supplies.

What is the best plug-in air compressor for automotive applications?

For automotive applications, a dual-power plug-in air compressor that operates at both 120V and 12V is ideal. Models like the PITTSBURGH™ 12/120V Inflator are excellent due to their versatility and ability to inflate tires quickly. Look for features such as integrated pressure gauges, auto shut-off functions, and the capacity to handle high PSI requirements for larger vehicles. These features ensure efficiency and safety when inflating tires or powering automotive tools.

What should I consider when vetting suppliers for air compressors?

When vetting suppliers, prioritize their industry reputation, years of experience, and customer reviews. Verify certifications and compliance with international standards, particularly in your target market regions such as Africa and Europe. Request product samples to assess quality, and inquire about their warranty and after-sales support. Additionally, evaluate their ability to provide customization options to meet your specific requirements and their responsiveness to inquiries, which reflects their customer service level.

What are the typical minimum order quantities (MOQ) for plug-in air compressors?

MOQs for plug-in air compressors can vary significantly based on the supplier and the product specifications. Generally, MOQs range from 50 to 500 units, depending on the manufacturer’s production capabilities and the level of customization requested. Smaller orders may incur higher per-unit costs, so it’s essential to balance your immediate needs with potential future demand. Discussing your projected needs with suppliers can sometimes lead to more favorable terms.

What payment terms should I expect when purchasing from international suppliers?

Payment terms can vary, but common practices include a deposit (typically 30% to 50%) upfront, with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or payment through escrow services for added security. It’s crucial to clarify payment methods, including options for wire transfers or online payment platforms. Always ensure that payment terms are clearly documented in the purchase agreement to avoid disputes later.

How can I ensure the quality of the air compressors I am sourcing?

To ensure quality, request certifications and compliance documents from the supplier, such as ISO certification or CE marking for products sold in Europe. Conduct factory audits if possible, or consider third-party inspections before shipment. Additionally, establish clear quality assurance protocols, including specifications and testing methods, to be followed during production. Implementing a robust quality control process can help mitigate risks associated with defects and ensure that the products meet your standards.

What logistics considerations should I keep in mind when importing air compressors?

Logistics for importing air compressors involve understanding shipping methods, customs duties, and local regulations in your destination country. Choose reliable freight forwarders who have experience with heavy machinery and can navigate customs clearance efficiently. Be aware of the costs associated with shipping, including insurance and potential tariffs. Additionally, establish a clear timeline for delivery to ensure that your operations are not disrupted due to delays in shipment.

Are there customization options available for plug-in air compressors?

Many manufacturers offer customization options for plug-in air compressors, including modifications to size, power output, and additional features like digital gauges or built-in lights. Custom branding can also be requested, which is particularly beneficial for businesses looking to enhance their brand visibility. Discuss your specific needs with potential suppliers early in the negotiation process to explore available options, as this can significantly impact your product’s functionality and marketability.

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Recommended tire air compressors for RVs that can plug into a wall outlet include: 1. Milwaukee M18 compressor – noted for its quality. 2. Harbor Freight Tools 1-gallon air compressor – considered better than Viair. 3. Porter Cable 6-gallon air compressor – capable of running an impact wrench for tire changes. 4. Viair compressors – popular choice but typically require battery clamps. Suggestions …

In the evolving landscape of industrial equipment, the strategic sourcing of plug-in air compressors offers significant advantages for international B2B buyers. By prioritizing factors such as efficiency, dual-power options, and compact designs, companies can enhance their operational productivity while reducing downtime. The emphasis on robust features like integrated pressure gauges and quick inflation capabilities ensures that buyers can select models that best meet their specific needs, whether for automotive, industrial, or recreational applications.

Furthermore, as markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for reliable and versatile air compressor solutions will grow. Engaging with reputable suppliers who prioritize quality and innovation will be crucial for organizations looking to secure a competitive edge.

Illustrative image related to plug in air compressor

Looking ahead, businesses should adopt a proactive approach to sourcing, ensuring that they not only meet current demands but are also prepared for future challenges. The strategic acquisition of plug-in air compressors can serve as a foundational element in enhancing operational efficiency and driving growth. Now is the time to explore partnerships that can provide the right solutions for your specific requirements and position your business for success in the global marketplace.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.