In today’s fast-paced automotive market, sourcing the right portable air inflator for car tires poses a significant challenge for international B2B buyers. With the rising demand for efficient tire maintenance solutions across regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—companies must navigate an increasingly competitive landscape. This guide offers a comprehensive analysis of portable air inflators, detailing various types, applications, and essential features that cater to diverse customer needs.

From compact inflators suitable for personal vehicles to robust models designed for heavy-duty trucks, understanding the nuances of each option is crucial for making informed purchasing decisions. Moreover, the guide emphasizes the importance of supplier vetting, providing insights into quality assurance, certifications, and after-sales support to ensure that buyers can trust their investments. We also cover cost considerations, helping businesses balance quality and budget constraints effectively.

By utilizing this guide, B2B buyers will be empowered to select the most suitable portable air inflators for their specific operational requirements, ultimately enhancing their service offerings and customer satisfaction. With actionable insights and expert recommendations, this resource serves as a vital tool for navigating the complexities of the global market for portable air inflators, ensuring that companies can maintain their competitive edge.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cordless Tire Inflators | Battery-powered, portable, and easy to use | Automotive repair shops, roadside assistance | Pros: Highly portable, no power outlet needed. Cons: Limited battery life may require recharging. |

| 12V Plug-In Tire Inflators | Requires vehicle’s 12V outlet, often compact | Fleet management, logistics companies | Pros: Reliable power source, often faster inflation. Cons: Limited mobility away from vehicle. |

| Heavy-Duty Tire Inflators | High PSI capacity, often with rugged construction | Construction, off-road vehicle maintenance | Pros: Suitable for larger tires, durable. Cons: Bulky and less portable. |

| Ultra-Compact Tire Inflators | Very small, designed for minimal storage | Motorcycle shops, personal vehicles | Pros: Extremely portable, fits in small spaces. Cons: Limited inflation capacity and speed. |

| Multi-Function Tire Inflators | Includes additional features like lights and USB ports | Outdoor recreation, emergency kits | Pros: Versatile for various inflatables. Cons: May compromise on tire inflation speed. |

Cordless tire inflators are designed for maximum portability, powered by rechargeable batteries. This type is ideal for businesses that require quick and convenient solutions for tire inflation without the need for a power outlet. They are particularly beneficial for roadside assistance services and automotive repair shops. However, buyers should consider the battery life, as frequent recharging may be necessary, especially in high-demand situations.

12V plug-in tire inflators connect directly to a vehicle’s 12V outlet, providing a reliable source of power for inflation tasks. This type is well-suited for fleet management and logistics companies that need to maintain tire pressure efficiently. They typically offer faster inflation rates compared to cordless options. However, their use is limited to locations where vehicles are accessible, which can be a drawback in remote areas.

Illustrative image related to portable air inflator for car tires

Heavy-duty tire inflators are specifically engineered to handle high PSI capacities, making them suitable for large vehicles such as trucks and construction equipment. These inflators are often built with rugged materials to withstand harsh working conditions, appealing to industries like construction and off-road vehicle maintenance. While they provide exceptional performance, their bulkiness can hinder portability, making them less ideal for everyday consumer use.

Ultra-compact tire inflators are designed for users who prioritize space and portability. These inflators can easily fit into a glove compartment or a small backpack, making them perfect for motorcycle shops or personal vehicle maintenance. However, they often have limited inflation capabilities and slower performance, which can be a concern for businesses that require rapid tire inflation.

Multi-function tire inflators come equipped with additional features such as built-in lights, USB ports, and various adapters for inflating other items like sports equipment. This versatility makes them attractive for outdoor recreation businesses and emergency kits. While they can handle multiple inflating tasks, their focus on added functionalities may compromise the speed and efficiency of tire inflation, which is a vital consideration for B2B buyers.

Illustrative image related to portable air inflator for car tires

| Industry/Sector | Specific Application of Portable Air Inflator for Car Tires | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Regular tire maintenance and emergency roadside assistance | Enhances customer satisfaction and loyalty | Durability, ease of use, and power source options |

| Transportation & Logistics | Fleet vehicle maintenance and tire inflation during transit | Reduces downtime and improves operational efficiency | Portability, inflation speed, and compatibility with various tire sizes |

| Car Rental Services | Quick tire inflation for rental vehicles before customer pickup | Minimizes vehicle turnaround time | Compact size, battery life, and reliability under varied conditions |

| Construction & Heavy Equipment | Inflation of tires on construction vehicles and machinery | Ensures operational readiness and safety | High PSI capability, rugged construction, and ease of transport |

| Outdoor Recreation & Tourism | Tire inflation for recreational vehicles and equipment | Enhances customer experience and safety | Versatility (multiple adapters), portability, and ease of use |

In automotive repair shops, portable air inflators are essential tools for tire maintenance and emergency services. These inflators enable mechanics to quickly assess and adjust tire pressure, ensuring optimal vehicle performance. They also provide a vital service during roadside assistance, allowing technicians to inflate flat tires on-site. Buyers in this sector should prioritize inflators that are durable, user-friendly, and capable of being powered by various sources, such as batteries or vehicle outlets, to accommodate different workshop setups.

In the transportation and logistics sector, portable air inflators are crucial for maintaining the tire health of fleet vehicles. These tools allow drivers to inflate tires during transit, minimizing the risk of breakdowns due to under-inflated tires. This proactive maintenance reduces downtime, thus enhancing operational efficiency. Buyers in this industry should look for inflators with fast inflation speeds and compatibility with a wide range of tire sizes, as well as features that ensure portability for use in varied environments.

Car rental services utilize portable air inflators to prepare vehicles for customer pickup efficiently. Quick tire inflation ensures that vehicles are in optimal condition, reducing turnaround time and enhancing customer satisfaction. These inflators are particularly valuable in high-demand rental environments, where time is of the essence. B2B buyers in this field should focus on compact models with reliable battery life and ease of use, as these features contribute to operational efficiency and customer service excellence.

In construction and heavy equipment sectors, portable air inflators are vital for ensuring that tires on machinery are adequately inflated, which is crucial for safety and efficiency. These inflators help maintain operational readiness, preventing delays caused by tire issues. Buyers in this industry should seek inflators with high PSI capabilities, rugged construction for durability on job sites, and ease of transport to facilitate quick inflation of various equipment types.

Illustrative image related to portable air inflator for car tires

For outdoor recreation and tourism businesses, portable air inflators are essential for ensuring that recreational vehicles, bikes, and other inflatable equipment are ready for use. These inflators improve customer experience by providing quick and easy tire inflation, which is especially important for safety during outdoor activities. Buyers in this sector should consider inflators that offer versatility with multiple adapters, portability for easy transport, and user-friendly features to cater to a diverse clientele.

The Problem: B2B buyers, such as fleet managers or automotive service providers, often face the challenge of ensuring accurate tire pressure across multiple vehicles. Inaccurate tire pressure can lead to reduced fuel efficiency, increased tire wear, and safety hazards. Many portable air inflators come with built-in gauges, but not all are reliable, leading to potential miscalculations. This inconsistency can be particularly problematic in regions where road conditions can cause rapid changes in tire pressure, such as in Africa or South America.

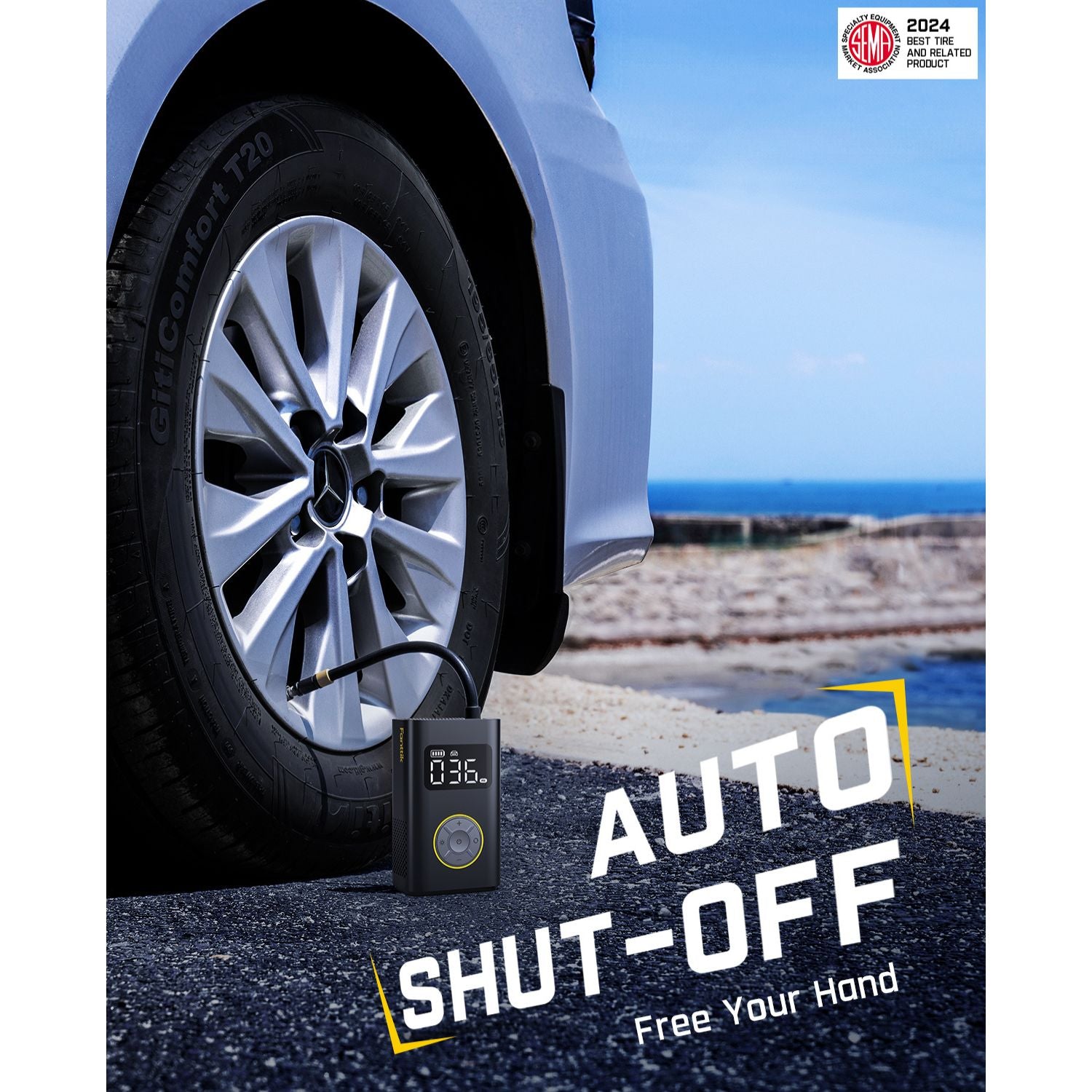

The Solution: To overcome this challenge, buyers should prioritize inflators with high-quality, digital pressure gauges that are tested for accuracy. It is advisable to source products that have received positive reviews for their pressure measurement capabilities. When using the inflator, compare its gauge readings with a calibrated pressure gauge to verify accuracy. Regular calibration checks can help maintain trust in the readings over time. Additionally, consider investing in inflators with automatic shut-off features that stop inflating once the desired pressure is reached, minimizing the risk of over-inflation.

The Problem: Many B2B buyers encounter issues with the portability of air inflators, especially when servicing large fleets or working in diverse locations. Some inflators require a direct power source, making them cumbersome and limiting their usability in remote areas. In regions with unreliable electricity, such as parts of the Middle East or rural Europe, this can severely hinder operations, leading to potential downtime and increased costs.

The Solution: To address these concerns, businesses should opt for cordless, rechargeable inflators that can efficiently operate on battery power. Look for models that offer multiple charging options, such as USB ports for convenience and versatility. When selecting inflators, consider their weight and compactness to ensure they can be easily stored and transported. Additionally, it is beneficial to establish a maintenance schedule for the inflators to ensure battery health, enabling them to perform optimally even after prolonged use without charging.

Illustrative image related to portable air inflator for car tires

The Problem: Efficiency is crucial in the B2B automotive sector, and slow inflation times can lead to delays, especially when dealing with multiple vehicles. Buyers often find that some portable air inflators take too long to bring tires to the required pressure, causing frustration and operational inefficiencies. This is particularly critical for service providers that need to complete tire services quickly to meet customer demands or keep fleets operational.

The Solution: To enhance efficiency, buyers should focus on high-performance inflators specifically designed for rapid inflation. Products that have been tested for speed and can inflate tires to high pressures (up to 80 psi) in minimal time should be prioritized. In addition, consider inflators with higher duty cycles, which allow for longer continuous use without overheating. Buyers can conduct a comparative analysis of inflation times from various models before purchasing and opt for those that demonstrate faster performance in real-world testing. Lastly, ensuring that the inflator is equipped with a long hose can facilitate easier access to tires without needing to reposition the inflator frequently, further saving time during operations.

When selecting materials for portable air inflators, several common options stand out based on their performance characteristics, cost, and suitability for various applications. Understanding these materials helps international B2B buyers make informed decisions that align with their operational needs and market conditions.

Plastic is a widely used material in portable air inflators, particularly for housing and components like pressure gauges. Key properties include lightweight, corrosion resistance, and good thermal stability, allowing it to perform well under varying temperatures.

Pros: Plastics are generally cost-effective and easy to mold, which simplifies manufacturing. They also provide sufficient durability for everyday use in consumer and light commercial applications.

Illustrative image related to portable air inflator for car tires

Cons: However, plastics can be less durable than metals, particularly under extreme temperatures or heavy impacts. They may also degrade over time when exposed to certain chemicals or UV light.

Impact on Application: Plastics are suitable for components that do not directly contact high-pressure air, ensuring safety and performance.

Considerations for International Buyers: Compliance with international standards such as ASTM for plastics is crucial. Buyers in regions like Europe may prefer materials that meet EU regulations for safety and environmental impact.

Aluminum is another common material, particularly for high-pressure components like the body of the inflator or the air chamber. Its key properties include a high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity.

Pros: Aluminum is lightweight yet strong, making it ideal for portable applications. Its resistance to corrosion ensures longevity, especially in humid or harsh environments.

Cons: The primary drawback is cost; aluminum is generally more expensive than plastic. Additionally, it can be more challenging to manufacture due to the need for specialized machining.

Impact on Application: Aluminum is suitable for high-pressure applications, ensuring safety and performance under demanding conditions.

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant standards, such as DIN in Germany, to guarantee quality and safety.

Illustrative image related to portable air inflator for car tires

Steel is often used in high-stress components, such as valves and connectors, due to its exceptional strength and durability. Key properties include high tensile strength and resistance to deformation under pressure.

Pros: Steel is highly durable and can withstand significant wear and tear, making it ideal for heavy-duty applications. It also offers excellent resistance to high temperatures.

Cons: The main disadvantages are its weight and susceptibility to corrosion if not properly treated. Steel components may require additional coatings or treatments to enhance their corrosion resistance.

Impact on Application: Steel is particularly suitable for components that experience high mechanical stress or require high-pressure ratings.

Considerations for International Buyers: Compliance with international standards like JIS in Japan is essential for steel components, especially when exporting to different regions.

Rubber is primarily used for seals and hoses in portable air inflators. Its key properties include flexibility, elasticity, and good resistance to wear and tear.

Pros: Rubber components are essential for creating airtight seals, ensuring efficient operation. They are also relatively inexpensive and easy to manufacture.

Cons: However, rubber can degrade over time due to exposure to sunlight and ozone, which may limit its lifespan.

Illustrative image related to portable air inflator for car tires

Impact on Application: Rubber is crucial for maintaining pressure and preventing air leaks in inflators.

Considerations for International Buyers: Buyers should consider the quality of rubber used, ensuring it meets relevant safety and performance standards.

| Material | Typical Use Case for portable air inflator for car tires | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and non-pressure components | Lightweight and corrosion-resistant | Less durable under extreme conditions | Low |

| Aluminum | High-pressure body and air chamber | High strength-to-weight ratio | More expensive and complex to manufacture | Medium |

| Steel | Valves and connectors | Exceptional durability and high-temperature resistance | Heavy and may corrode without treatment | High |

| Rubber | Seals and hoses | Excellent flexibility and airtight seals | Degrades over time with exposure | Low |

This guide provides a comprehensive overview of the materials used in portable air inflators, enabling B2B buyers to make strategic decisions based on performance, cost, and compliance with international standards.

The manufacturing process for portable air inflators involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is crucial to ensuring the final product meets quality standards and consumer expectations.

Material preparation begins with sourcing high-quality components such as plastic casings, motors, batteries, and pressure gauges. Manufacturers often select materials based on durability, weight, and cost-effectiveness. For instance, high-density polyethylene (HDPE) is commonly used for the casing due to its resistance to impact and environmental factors. Additionally, suppliers of raw materials should be vetted for compliance with international quality standards, ensuring that materials are free from defects and meet specific performance criteria.

The forming stage involves various techniques, including injection molding and die-casting. Injection molding is prevalent for producing plastic components, allowing for precise shapes and complex designs while maintaining consistency across batches. For metal parts, die-casting can provide strength and durability. Advanced CNC machining may also be employed for critical components that require high precision, such as the motor housing and air pressure gauge fittings.

Once the components are formed, the assembly process begins. This can be conducted through manual or automated assembly lines, depending on the scale of production. Key tasks include integrating the motor with the casing, installing the pressure gauge, and connecting any power sources. Ensuring that each part fits correctly is essential for the inflator’s performance. Many manufacturers employ lean manufacturing principles to minimize waste and enhance efficiency during this stage.

The finishing stage typically includes surface treatments, labeling, and packaging. Surface treatments may involve painting or applying protective coatings to enhance durability and aesthetics. Accurate labeling is critical for compliance with safety standards, providing users with necessary information about operation, safety, and maintenance. Finally, packaging should be designed to protect the product during transportation while appealing to the target market.

Illustrative image related to portable air inflator for car tires

Quality assurance (QA) is integral to manufacturing, particularly for portable air inflators, where safety and performance are paramount. Various international standards and industry-specific certifications guide the QA process.

ISO 9001 is the most recognized international standard for quality management systems, emphasizing a process-oriented approach to ensure consistent quality in products. Compliance with this standard helps manufacturers streamline their operations and improve customer satisfaction. In addition, other certifications like CE (Conformité Européenne) and API (American Petroleum Institute) can provide further assurance of product safety and performance, especially in specific markets.

Quality control (QC) checkpoints are essential throughout the manufacturing process. Key checkpoints include:

Testing methods for portable air inflators typically include performance testing, pressure testing, and electrical safety testing. Performance tests assess the inflator’s ability to reach and maintain specified pressure levels, while pressure tests ensure the unit can withstand its maximum operational pressure without failure. Electrical safety testing verifies that the inflator complies with safety standards regarding electrical components, minimizing risks of short circuits or overheating.

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers. This can be achieved through:

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different regions may have varying regulations and expectations regarding product safety and quality.

In Europe, for instance, compliance with CE marking is mandatory for products sold in the market, ensuring they meet safety and environmental requirements. In contrast, buyers in Africa may prioritize cost-effectiveness while still seeking assurance of quality through certifications like ISO 9001.

Moreover, cultural differences may impact communication regarding quality expectations. Buyers should clearly articulate their quality requirements and ensure that suppliers understand and can meet these standards. Building strong relationships with suppliers can facilitate better compliance and responsiveness to quality concerns.

The manufacturing processes and quality assurance protocols for portable air inflators are complex but essential for ensuring product reliability and safety. By understanding these processes, B2B buyers can make informed decisions when sourcing inflators for their markets, ultimately ensuring that they provide high-quality products to their customers.

To successfully procure portable air inflators for car tires, B2B buyers must navigate various factors that ensure they select the most suitable products for their needs. This checklist serves as a practical guide to streamline the sourcing process, providing clarity on essential criteria and actions to take.

Establishing clear technical specifications is fundamental to ensuring that the inflators meet your business requirements. Consider factors such as maximum pressure (psi), power source (cordless or corded), and additional features like built-in pressure gauges and portability. Each specification will influence the performance and usability of the inflators, affecting customer satisfaction and operational efficiency.

Understanding current market trends is crucial for making informed purchasing decisions. Analyze demand patterns for tire inflators in your target regions, such as Africa, South America, and Europe. This knowledge will help you identify which features are most sought after, such as compact designs for urban areas or high-pressure capabilities for larger vehicles.

Illustrative image related to portable air inflator for car tires

Before committing to a purchase, it’s essential to thoroughly vet potential suppliers. Request company profiles, product catalogs, and references from buyers in similar markets. Ensure the suppliers have a good reputation for quality and reliability, as this can significantly affect your supply chain and customer experience.

Confirm that your suppliers meet relevant industry standards and certifications, which can vary by region. Compliance with safety and environmental regulations ensures that the products are not only reliable but also safe for use. Look for certifications such as ISO 9001 for quality management and CE marking for compliance in Europe.

Obtaining product samples is a critical step in evaluating the quality and performance of the inflators. Test the inflators under real-world conditions to assess their usability, speed, and accuracy. This hands-on evaluation can provide insights that specifications alone may not reveal, allowing you to make a more informed decision.

Once you have shortlisted suppliers, compare pricing structures, payment terms, and delivery options. Consider not only the upfront cost but also the total cost of ownership, including warranty and service agreements. A more expensive inflator may offer better durability and lower long-term costs, making it a wiser investment.

Evaluate the after-sales support and warranty options provided by your chosen suppliers. A robust warranty and reliable customer service can save your business significant time and money in case of defects or issues with the inflators. Ensure that your suppliers offer prompt support and clear return policies to mitigate any risks associated with your purchase.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing portable air inflators for car tires, ensuring that they make informed decisions that align with their operational needs and market demands.

Illustrative image related to portable air inflator for car tires

When sourcing portable air inflators for car tires, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The choice of materials significantly impacts the cost. High-quality plastic casings, robust motors, and durable hoses contribute to higher production costs. For instance, inflators with lithium-ion batteries tend to be more expensive than those using traditional power sources.

Labor: Labor costs vary by region and can influence the overall price. In countries with lower labor costs, such as parts of Africa and South America, manufacturers may offer competitive pricing. However, skilled labor in Europe, especially in countries like Germany, may lead to higher costs.

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help reduce overhead and, in turn, lower prices.

Tooling: Custom tooling for specific designs increases initial costs. Standardized designs that appeal to a broader market can mitigate these costs, making them more attractive for bulk purchasing.

Quality Control (QC): Implementing stringent QC processes ensures product reliability but can add to the production costs. Certifications like ISO or CE can enhance marketability but also influence pricing.

Logistics: Shipping costs, including freight and insurance, are significant, especially for international buyers. The choice of Incoterms (e.g., FOB, CIF) will determine who bears these costs, impacting the total price.

Margin: Manufacturers typically apply a margin to cover risks and ensure profitability. This margin can vary based on market demand, competitive landscape, and brand reputation.

Several factors can influence the pricing of portable air inflators:

Volume/MOQ: Bulk purchasing often leads to lower unit costs. Buyers should negotiate minimum order quantities (MOQ) that align with their sales forecasts to maximize cost efficiency.

Specifications and Customization: Custom features, such as digital displays or multi-functionality, can increase costs. Buyers should assess the necessity of these features against their target market’s needs.

Materials and Quality Certifications: Higher-quality materials and certifications can justify premium pricing. However, it’s essential to balance quality with cost-effectiveness, especially in price-sensitive markets.

Supplier Factors: The reliability and reputation of suppliers can significantly affect pricing. Established suppliers may charge more for their proven quality and service, while newer suppliers might offer lower prices to gain market share.

Incoterms: Understanding Incoterms is vital for international transactions. They dictate shipping responsibilities and costs, which can dramatically alter the total cost of ownership.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance negotiation outcomes:

Negotiation Tactics: Always negotiate for better pricing, especially for bulk orders. Leverage competing offers to strengthen your position.

Cost-Efficiency Analysis: Conduct a Total Cost of Ownership (TCO) analysis that includes purchase price, shipping, tariffs, and potential returns. This comprehensive view can reveal hidden costs and help justify higher initial investments for better quality products.

Pricing Nuances for Different Markets: Be aware of regional pricing differences. For instance, the price elasticity in Nigeria may differ from that in Germany, influencing how much suppliers are willing to negotiate.

Long-Term Partnerships: Establishing long-term relationships with suppliers can lead to better pricing and terms. Building trust can also facilitate smoother negotiations and more favorable conditions.

Pricing for portable air inflators varies widely based on specifications, supplier, and market conditions. The prices mentioned are indicative and should be verified with suppliers to ensure accuracy in current market contexts.

Illustrative image related to portable air inflator for car tires

In the realm of maintaining optimal tire pressure, portable air inflators for car tires are a popular solution. However, various alternative methods and technologies can also serve the purpose of inflating tires. This analysis compares portable air inflators with two viable alternatives: manual foot pumps and air compressor stations. Each option has distinct attributes that may cater to different operational needs and preferences.

| Comparison Aspect | Portable Air Inflator For Car Tires | Manual Foot Pump | Air Compressor Station |

|---|---|---|---|

| Performance | Fast and efficient; can inflate multiple tires quickly | Slower; suitable for one tire at a time | High volume; can inflate multiple tires simultaneously |

| Cost | $40 – $90 (varies by model) | $15 – $30 | Free or pay-per-use (varies by location) |

| Ease of Implementation | Very user-friendly; requires minimal setup | Requires physical effort; can be cumbersome | Easy to use but may require travel to a station |

| Maintenance | Low; occasional battery checks needed | Low; minimal parts to maintain | Moderate; requires regular servicing and maintenance |

| Best Use Case | Ideal for roadside emergencies and convenience | Suitable for occasional use, especially in remote areas | Best for high-traffic areas or commercial use with frequent tire inflation needs |

Manual foot pumps are a traditional method for inflating tires, often favored for their simplicity and portability. The primary advantage of a foot pump is its cost-effectiveness, making it accessible for individuals and small businesses alike. They require no electricity and can be used anywhere, making them perfect for off-the-grid scenarios. However, the major drawback is the physical effort involved; inflating a tire can be labor-intensive and time-consuming, especially for larger tires. Additionally, foot pumps generally have lower efficiency compared to powered inflators, which may be a concern for businesses that require quick service.

Air compressor stations are another alternative, often found at gas stations or dedicated service areas. These stations can quickly inflate multiple tires, making them suitable for businesses with fleets or high tire turnover. The cost can vary, with some offering free service while others charge a fee. The convenience of having a powerful compressor at your disposal is a significant advantage, as it can handle a wide range of tire sizes and pressures. However, the reliance on external locations can be a disadvantage for those who need immediate access. Moreover, the quality and reliability of these stations can vary, leading to potential downtime if a station is out of service.

When evaluating tire inflation solutions, B2B buyers should consider their specific operational needs. For businesses that require mobility and rapid response, portable air inflators stand out as a practical choice. Conversely, if cost is a critical factor and inflation frequency is low, manual foot pumps may suffice. For organizations with a constant need for tire maintenance, investing in air compressor stations or ensuring access to reliable ones could optimize efficiency. Ultimately, the decision should align with the company’s operational demands, budget constraints, and the importance of convenience in maintaining vehicle readiness.

When sourcing portable air inflators for car tires, understanding their technical properties is essential for ensuring product quality and performance. Here are several critical specifications to consider:

The maximum pressure, measured in pounds per square inch (PSI), indicates how much air the inflator can deliver. Most car tires require a pressure between 30 to 35 PSI for optimal performance. Heavy-duty vehicles may need inflators that can reach up to 80 PSI. For B2B buyers, selecting an inflator with adequate PSI capabilities ensures it can service a wide range of vehicles, enhancing customer satisfaction and reducing returns.

The duty cycle refers to the duration an inflator can operate before needing a rest period. For instance, an inflator with a 20-minute duty cycle can run for 20 minutes before it requires a cooldown. This property is crucial for businesses that expect high usage rates, as it affects the inflator’s longevity and reliability in commercial settings. A higher duty cycle indicates a more robust product suited for frequent use.

Portable air inflators can be powered by batteries, car cigarette lighter sockets, or direct connections to vehicle batteries. Understanding the power source is essential for B2B buyers, as it affects usability and convenience. Battery-powered inflators offer portability, while those that connect to the vehicle’s power supply may provide continuous operation for larger tires. Buyers should consider their target market’s needs when evaluating power sources.

Illustrative image related to portable air inflator for car tires

Hose length is a practical specification that impacts usability. A longer hose allows for easier access to all tires without repositioning the inflator. For B2B buyers, ensuring the inflator has an adequate hose length can enhance the user experience, making it more appealing to end consumers and increasing sales potential.

The weight of the inflator influences its portability. Lightweight models are easier to store in vehicles and transport, which is an important factor for consumers looking for convenience. B2B buyers should assess the weight of inflators in relation to their intended market segment. Compact and lightweight models may attract customers who prioritize portability.

Familiarity with industry terminology is crucial for B2B transactions. Here are several common terms that buyers should know:

Illustrative image related to portable air inflator for car tires

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of portable air inflators, buyers may consider partnering with OEMs to source high-quality components that meet specific performance standards. This can enhance the reliability and marketability of the final product.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers as it affects inventory management and initial investment. Suppliers often set MOQs to ensure cost-effectiveness in production, and buyers should negotiate these terms to align with their purchasing capabilities.

An RFQ is a document that a buyer sends to suppliers requesting pricing and other relevant information about specific products. For buyers of portable air inflators, issuing an RFQ can facilitate competitive bidding among suppliers, ensuring they receive the best possible price and terms.

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers as they dictate shipping responsibilities, risk transfer, and cost obligations, ensuring smoother cross-border transactions.

CE certification indicates that a product meets European Union safety, health, and environmental protection requirements. For B2B buyers targeting markets in Europe, ensuring that portable air inflators have CE certification can enhance market access and consumer trust.

Illustrative image related to portable air inflator for car tires

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing portable air inflators for car tires, ultimately leading to better product offerings and increased customer satisfaction.

The portable air inflator market for car tires is experiencing significant growth, driven by several global factors. Increased vehicle ownership, especially in emerging markets in Africa and South America, is a primary driver. As urban populations grow and disposable incomes rise, the demand for efficient and convenient automotive solutions, such as portable tire inflators, has surged. Furthermore, the rising awareness of vehicle maintenance and safety is pushing consumers towards proactive measures, including regular tire pressure checks.

Technological advancements are also transforming the sector. Smart inflators equipped with digital gauges, automatic shut-off features, and multi-function capabilities (like built-in USB charging ports) are becoming more prevalent. These innovations not only enhance user experience but also cater to the diverse needs of international buyers, particularly in regions where vehicle types vary widely. Additionally, the trend towards cordless and battery-operated models is gaining traction, offering convenience and portability for users on the go.

From a sourcing perspective, international B2B buyers are increasingly looking for suppliers that offer competitive pricing, reliable product quality, and robust after-sales support. As manufacturers pivot towards sustainable practices, buyers are also prioritizing partners that demonstrate a commitment to ethical sourcing and environmentally friendly materials.

Illustrative image related to portable air inflator for car tires

Sustainability is becoming a crucial consideration in the sourcing of portable air inflators for car tires. Environmental concerns surrounding the production and disposal of automotive products have prompted buyers to seek out suppliers who prioritize eco-friendly practices. The use of recyclable materials and energy-efficient manufacturing processes can significantly reduce the environmental footprint of these products.

Additionally, the demand for ‘green’ certifications is on the rise. Buyers are increasingly favoring inflators that comply with international environmental standards, as these certifications not only reflect a commitment to sustainability but also enhance brand reputation. Suppliers who can demonstrate compliance with such standards are more likely to attract business from environmentally conscious B2B buyers.

Furthermore, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers to ensure fair labor practices and responsible sourcing of raw materials. This shift towards ethical sourcing is not just a trend; it’s becoming a standard expectation in the B2B marketplace, influencing purchasing decisions across various industries, including automotive accessories.

The evolution of portable air inflators for car tires can be traced back to their initial designs, which were primarily manual and cumbersome. Over the decades, the introduction of electric models revolutionized the market, making tire inflation quicker and more efficient. The emergence of battery-operated and cordless inflators marked a significant milestone, providing users with unprecedented convenience and portability.

Illustrative image related to portable air inflator for car tires

As consumer preferences shifted towards multifunctional tools, manufacturers began incorporating additional features such as built-in pressure gauges, LED lights, and adapters for various inflatables. This evolution reflects a broader trend in the automotive accessories market, where innovation and user-centric design are paramount. Today, portable air inflators not only serve their primary function of inflation but also enhance overall vehicle maintenance, contributing to safer driving experiences.

In summary, the portable air inflator sector continues to adapt to changing market dynamics, driven by technological advancements, sustainability initiatives, and evolving consumer expectations. For international B2B buyers, understanding these trends is essential for making informed sourcing decisions that align with both market demands and ethical considerations.

1. How do I choose the right portable air inflator for my business needs?

Choosing the right portable air inflator involves evaluating factors such as the inflator’s power source, maximum pressure, and portability. For businesses catering to various vehicle types, look for models that can handle a range of tire pressures, ideally up to 80 psi for heavy-duty vehicles. Additionally, consider the inflator’s speed and efficiency, especially if you expect high turnover. Features like built-in pressure gauges, multiple power options (like battery and 12V), and compact design for easy storage can enhance usability and customer satisfaction.

2. What is the best portable air inflator for commercial use?

The best portable air inflator for commercial use is typically one that balances performance, durability, and ease of use. For instance, the AstroAI Cordless Tire Inflator is highly recommended due to its ability to inflate multiple tires on a single charge, accurate pressure gauge, and compact design. If your business involves larger vehicles, the Viair 88P is ideal for its speed and capacity to handle larger tires, although it requires connection to a vehicle battery. Assess your specific needs to find the best fit for your operations.

3. What customization options are available for bulk purchases of portable air inflators?

When sourcing portable air inflators in bulk, many manufacturers offer customization options such as branding, color choices, and packaging designs. You can request specific features tailored to your target market, like enhanced battery life or additional adapters for different inflatables. Discussing your requirements with suppliers can lead to a product that better meets your business’s branding and functional needs, ultimately providing a competitive edge in your market.

4. What are the typical minimum order quantities (MOQs) for portable air inflators?

Minimum order quantities (MOQs) for portable air inflators can vary significantly based on the supplier and the specific product. Generally, MOQs may range from 50 to several hundred units for bulk orders. When negotiating with suppliers, inquire about their MOQ policies, as many are willing to accommodate smaller businesses or first-time buyers. Establishing a good relationship with suppliers may also lead to more favorable terms over time.

5. What payment terms should I expect when sourcing portable air inflators internationally?

Payment terms can vary widely among suppliers and regions, but common practices include options like upfront payments, partial payments, or payment upon delivery. International buyers often use secure payment methods such as letters of credit or escrow services to minimize risks. It’s advisable to clarify payment terms upfront and understand any currency exchange implications, especially when dealing with suppliers from different countries.

6. How can I ensure quality assurance (QA) for portable air inflators?

To ensure quality assurance for portable air inflators, request samples before committing to a bulk order. Evaluate the inflators based on performance, durability, and safety standards. Additionally, inquire about the supplier’s QA processes, including inspections and certifications. Many suppliers offer warranties or guarantees, which can also serve as a quality assurance measure. Regular communication with suppliers throughout the production process can help address any concerns early.

7. What logistics considerations should I keep in mind when importing inflators?

When importing portable air inflators, consider logistics factors such as shipping methods, customs regulations, and lead times. Depending on your location, air freight may be faster but more expensive, while sea freight is more economical but slower. Ensure compliance with import regulations and tariffs in your country to avoid unexpected costs. Partnering with a reliable freight forwarder can streamline the logistics process and help navigate any challenges.

8. How do I vet suppliers of portable air inflators for reliability?

Vetting suppliers for reliability involves several steps, including checking their business credentials, reviews, and references. Look for suppliers with a proven track record in the industry and those who can provide samples or detailed product specifications. Engaging in direct communication can help assess their responsiveness and professionalism. Additionally, consider visiting their manufacturing facilities if feasible, or utilizing third-party inspection services to verify quality and operational standards before placing large orders.

Domain: lasfit.com

Registered: 2016 (9 years)

Introduction: Lasfit Tire Inflator | Portable Tire Pumps for Pickup Trucks & Large SUVs & Off-Road Vehicles. Key features include: Fast & Accurate Inflation, Compact & Portable Design, Multi-Purpose Air Compressor, Digital Display & Auto Shut-Off. Designed for 12V DC outlets, suitable for various vehicles including sedans, SUVs, trucks, and motorcycles. Products include LASFIT X4 Off-Road Air Compressor, LASFIT…

Domain: avidpowertool.com

Registered: 2018 (7 years)

Introduction: [Tire Inflator] Avid Power Tire Inflator Portable Air Compressor, Triple Power Source, Car Air Pump w/Inflation & Deflation Modes, Dual Powerful Motors (Orange) – $79.99; [12V Tire Inflator] Portable Air Compressor, 60 PSI Display Gauge, LED Light, Compact, Lightweight (Red) – $21.99; [12V Tire Inflator] Portable Air Compressor, 60 PSI Display Gauge, LED Light, Compact, Lightweight (Dark Red) – $1…

As the demand for portable air inflators continues to rise across diverse markets, B2B buyers must prioritize strategic sourcing to ensure they acquire the best products that meet both quality and cost-effectiveness. Key takeaways from our analysis emphasize the importance of evaluating inflators based on performance metrics such as inflation speed, pressure capacity, and additional features like portability and versatility. This focus not only enhances customer satisfaction but also strengthens brand loyalty in competitive markets.

International buyers from regions like Africa, South America, the Middle East, and Europe should consider the unique needs of their local markets when selecting inflators. For instance, products that perform well under varied climatic conditions and offer multiple power sources may be particularly advantageous.

Illustrative image related to portable air inflator for car tires

Looking ahead, the market for portable tire inflators is poised for growth, driven by increasing vehicle ownership and a heightened focus on vehicle maintenance. B2B buyers are encouraged to engage with reliable suppliers and explore innovative inflator solutions that can meet evolving consumer demands. By leveraging strategic sourcing, you can position your business to capitalize on this expanding market while enhancing your product offering.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.