In the competitive landscape of the automotive industry, sourcing portable auto tire inflators poses a significant challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As vehicle ownership continues to rise globally, the demand for efficient and reliable tire maintenance solutions has never been higher. This guide serves as an essential resource for businesses looking to navigate the complexities of the portable tire inflator market, offering insights into various types, their applications, and the critical factors to consider when selecting a supplier.

Our comprehensive exploration includes an analysis of the latest inflator technologies, such as cordless and compact models, to suit diverse operational needs. We address key considerations such as performance metrics, pricing structures, and the importance of vetting suppliers to ensure quality and reliability. By providing actionable insights into market trends and best practices, this guide empowers international buyers to make informed purchasing decisions.

Understanding the nuances of portable tire inflators is vital for businesses aiming to enhance their service offerings and meet customer expectations. Whether you operate in automotive repair, logistics, or fleet management, this guide equips you with the knowledge needed to select the right products that align with your operational goals and budget, ultimately contributing to greater efficiency and customer satisfaction.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cordless Tire Inflators | Battery-operated, portable, easy to use | Automotive service providers, fleet management | Pros: High portability, no need for power outlet. Cons: Limited battery life, may require recharging. |

| 12V Powered Tire Inflators | Connects to vehicle’s 12V outlet | Roadside assistance, emergency services | Pros: Continuous power supply, suitable for multiple inflations. Cons: Limited mobility; requires vehicle proximity. |

| Heavy-Duty Tire Inflators | Designed for high PSI, often with battery clamps | Off-road vehicle maintenance, commercial trucking | Pros: Fast inflation, can handle larger tires. Cons: Bulkier, may require knowledge of vehicle battery connections. |

| Ultra-Compact Tire Inflators | Small size, often fits in glove compartments | Personal vehicle maintenance, motorcycle shops | Pros: Highly portable, convenient for small tires. Cons: Limited inflation capacity, slower performance. |

| Multi-Functional Tire Inflators | Includes additional features like USB ports, lights | Automotive retail, emergency response teams | Pros: Versatile for various applications, added convenience. Cons: May be bulkier, higher price point. |

Cordless tire inflators are characterized by their battery-operated design, allowing for ultimate portability without the need for a power outlet. Ideal for automotive service providers and fleet management, these inflators can easily be stored in a vehicle and used anywhere. When purchasing, consider the battery life and the inflator’s ability to recharge quickly, as these factors can significantly impact operational efficiency.

12V powered tire inflators connect directly to a vehicle’s 12V outlet, providing a continuous power source for inflating tires. They are commonly used in roadside assistance and emergency services, where quick access to inflation tools is crucial. Buyers should evaluate the length of the power cord and the inflator’s ease of use, as these elements can affect the overall convenience during emergencies.

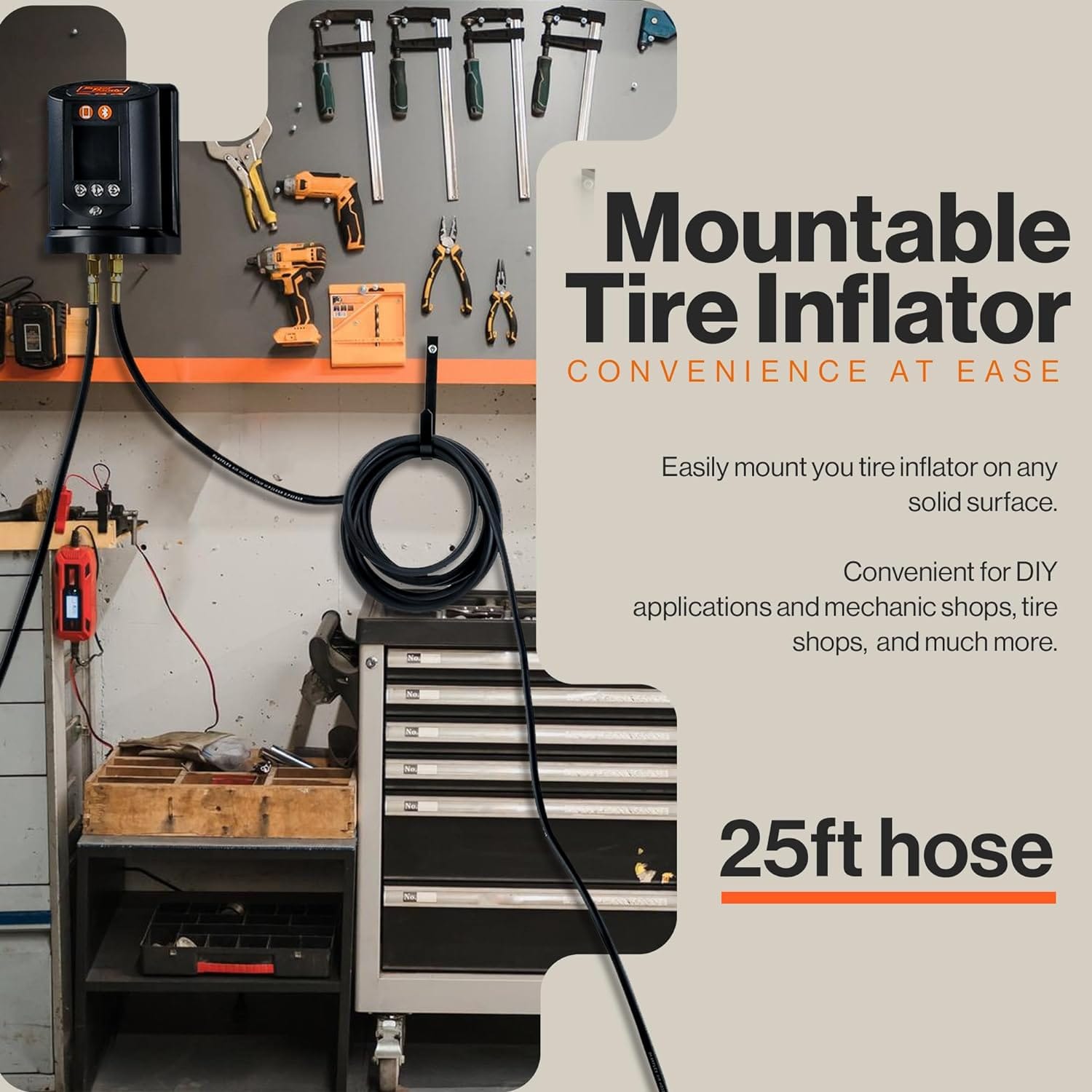

Illustrative image related to portable auto tire inflator

Heavy-duty tire inflators are specifically designed for high PSI applications, making them suitable for off-road vehicle maintenance and commercial trucking. They often feature battery clamps for direct connection to a vehicle’s battery, allowing for rapid inflation of larger tires. When considering these inflators, assess their inflation speed and durability, as these attributes are critical for high-demand environments.

Ultra-compact tire inflators are small enough to fit in glove compartments, making them ideal for personal vehicle maintenance and motorcycle shops. Their portability is a significant advantage, although they may have limited inflation capacity and slower performance. B2B buyers should prioritize size and weight when evaluating these products, ensuring they meet the specific needs of their operations.

Multi-functional tire inflators come equipped with additional features such as USB ports and built-in lights, making them versatile tools for automotive retail and emergency response teams. While they may be bulkier and come at a higher price point, their versatility can justify the investment. Buyers should weigh the benefits of additional functionalities against their specific use cases to determine the best fit for their needs.

| Industry/Sector | Specific Application of Portable Auto Tire Inflator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Fleet Maintenance | Ensures optimal tire pressure for fuel efficiency and safety | Durability, portability, and compatibility with various vehicles |

| Automotive Services | Mobile Tire Repair Services | Provides on-the-spot inflation for customer convenience | Speed of inflation, battery life, and ease of use |

| Agriculture | Agricultural Equipment Maintenance | Maintains tire pressure for tractors and other machinery | High PSI capabilities and rugged construction |

| Construction | Heavy Machinery Maintenance | Supports tire inflation for construction vehicles on-site | Power source options and inflation speed |

| Emergency Services | Roadside Assistance | Quickly inflates tires for stranded vehicles | Compact size, ease of transport, and reliability under pressure |

In the transportation and logistics industry, portable auto tire inflators are critical for maintaining the fleet’s operational efficiency. Regular tire pressure checks and adjustments can lead to improved fuel efficiency and reduced wear on tires, ultimately saving costs. Businesses must consider the inflator’s durability and compatibility with various vehicle types, especially in regions with diverse fleets, such as those found in Africa and South America, where road conditions can be challenging.

Mobile tire repair services leverage portable tire inflators to provide immediate assistance to customers, enhancing service delivery. These inflators allow technicians to inflate tires on-site, reducing downtime for clients. Key requirements include the speed of inflation and battery life, as service providers often face time constraints. Buyers in regions like the Middle East should prioritize models that offer quick inflation times to meet high customer expectations.

Illustrative image related to portable auto tire inflator

In agriculture, maintaining the correct tire pressure for tractors and other machinery is essential for optimal performance and longevity. Portable tire inflators enable farmers to address tire pressure issues promptly, minimizing downtime during critical planting or harvesting periods. Buyers need to ensure that the inflators can handle high PSI levels and are built to withstand rugged outdoor conditions, particularly in areas with extreme weather variations.

Construction sites often require heavy machinery that can be susceptible to tire pressure fluctuations. Portable auto tire inflators provide a convenient solution for on-site tire maintenance, ensuring that construction vehicles operate safely and efficiently. When sourcing these inflators, businesses should focus on power source options and inflation speed, as construction sites may lack immediate access to electrical outlets.

Emergency services rely on portable tire inflators to assist stranded motorists quickly. These devices are invaluable for roadside assistance teams, enabling them to inflate tires efficiently and get vehicles back on the road with minimal delay. The compact size and reliability of the inflator are crucial for these operations, especially in urban areas where response times are critical. Buyers should look for models that can withstand various environmental conditions and provide consistent performance under pressure.

The Problem: Many B2B buyers, particularly those managing fleets or automotive services, encounter the challenge of inaccurate tire pressure readings. This can lead to either over-inflation or under-inflation, which not only affects tire longevity but also poses safety risks. Misjudging tire pressure can result in increased fuel consumption and diminished vehicle performance, ultimately impacting operational costs.

Illustrative image related to portable auto tire inflator

The Solution: To address this issue, it is crucial for buyers to select portable auto tire inflators equipped with high-quality, built-in digital pressure gauges. When sourcing these inflators, look for models that offer automatic shut-off features, allowing for precise inflation to the desired PSI without the risk of over-inflation. Additionally, consider inflators that come with calibration instructions to ensure the pressure readings are accurate. Regularly calibrating the inflators against a certified gauge can help maintain accuracy, ensuring that your fleet operates efficiently and safely.

The Problem: In many regions, especially in remote areas of Africa or South America, access to power sources can be limited. B2B buyers often find themselves in situations where inflators need to be powered on the go, whether for roadside assistance or during outdoor operations. This lack of reliable power can severely hinder the ability to maintain tire pressure, leading to operational downtime and potential loss of business.

The Solution: To overcome this challenge, buyers should prioritize portable tire inflators that offer multiple power options, such as battery operation, 12V car outlets, and even solar charging capabilities. For instance, inflators like the AstroAI Cordless Tire Inflator provide a rechargeable lithium-ion battery as well as a 12-volt adapter, making them versatile for various environments. When purchasing, ensure the inflator’s battery life is sufficient to handle multiple tire inflation sessions on a single charge. Additionally, investing in solar-powered inflators can serve as a sustainable solution in areas with unreliable electricity, enabling continuous operation without dependency on traditional power sources.

The Problem: Businesses managing commercial vehicles or fleets often face the issue of needing to inflate multiple tires quickly. The time spent inflating tires can lead to operational delays, especially if the inflator is not capable of handling high-volume demands efficiently. This is particularly critical for transportation companies, where time is money, and delays can ripple through logistics chains.

Illustrative image related to portable auto tire inflator

The Solution: To cater to bulk inflation needs, buyers should focus on heavy-duty portable tire inflators that are specifically designed for commercial use. Look for inflators that can deliver high PSI (over 100 PSI) and have robust duty cycles to handle multiple tire inflations without overheating. Models such as the Viair 88P are excellent choices, as they are capable of inflating larger tires quickly and efficiently. Furthermore, consider investing in inflators that come with extended hoses or accessories to facilitate reaching multiple tires without needing to reposition the unit. Regular maintenance, including checking for wear and tear on hoses and fittings, can also ensure that the inflator remains operational and effective for high-demand situations. By selecting the right equipment and maintaining it properly, businesses can significantly reduce downtime and enhance overall productivity.

When selecting materials for portable auto tire inflators, several options stand out due to their unique properties and suitability for various applications. Here, we analyze four common materials: plastic, aluminum, steel, and rubber, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is frequently used for the outer casing and components of portable tire inflators. Key properties include lightweight construction, resistance to corrosion, and good impact resistance.

Pros of plastic include its low cost, ease of manufacturing, and versatility in design. However, the cons involve lower durability compared to metals, especially under extreme temperatures or pressures. Plastic components may not withstand high-pressure applications as effectively as metal counterparts. For international buyers, compliance with standards such as ASTM D638 for tensile strength is essential, especially in regions like Africa and the Middle East where environmental conditions can vary significantly.

Aluminum is another popular material, especially for internal components like the pump housing. It offers excellent strength-to-weight ratio, corrosion resistance, and good thermal conductivity, making it suitable for high-pressure applications.

Illustrative image related to portable auto tire inflator

The advantages of aluminum include its lightweight nature, which enhances portability, and its durability, which extends the product’s lifespan. On the downside, aluminum can be more expensive than plastic, and its manufacturing process is more complex, potentially leading to higher production costs. For B2B buyers in Europe, adhering to standards like EN 573 for aluminum alloys is crucial for ensuring quality and compatibility with local regulations.

Steel is often used in tire inflators designed for heavy-duty applications, such as those intended for trucks and SUVs. Its key properties include high tensile strength and excellent pressure resistance, making it ideal for demanding environments.

The pros of using steel include its exceptional durability and resistance to deformation under pressure. However, the cons are its weight and susceptibility to corrosion if not properly treated. For international buyers, particularly in humid regions like parts of South America, ensuring that the steel components are galvanized or coated to prevent rust is vital. Compliance with standards such as ASTM A36 for structural steel may also be necessary.

Rubber is commonly used for seals and hoses in tire inflators due to its flexibility and excellent sealing properties. Key properties of rubber include resistance to wear, temperature fluctuations, and pressure.

The advantages of rubber include its ability to maintain a seal under varying conditions and its cost-effectiveness. However, rubber can degrade over time, especially when exposed to UV light or extreme temperatures. For B2B buyers, especially those in regions with high temperatures like Saudi Arabia, selecting rubber that meets specific standards such as ASTM D2000 for rubber materials is essential for ensuring longevity and performance.

| Material | Typical Use Case for portable auto tire inflator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Outer casing and non-structural components | Lightweight and cost-effective | Lower durability under extreme conditions | Low |

| Aluminum | Pump housing and structural components | High strength-to-weight ratio | More expensive and complex to manufacture | Med |

| Steel | Heavy-duty applications for trucks/SUVs | Exceptional durability and pressure resistance | Heavy and prone to corrosion | Med/High |

| Rubber | Seals and hoses | Excellent sealing properties and flexibility | Can degrade over time with exposure | Low |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in portable auto tire inflators, helping them make informed decisions based on performance, cost, and compliance with international standards.

The manufacturing process for portable auto tire inflators involves several critical stages, each contributing to the final product’s quality and performance. These stages typically include material preparation, forming, assembly, and finishing.

The first step in the manufacturing process is the selection and preparation of materials. Common materials used in tire inflators include high-quality plastics for the casing, metal components for the pump mechanism, and rubber for hoses and seals. Manufacturers often source materials that comply with international safety and durability standards to ensure product reliability.

During material preparation, manufacturers may conduct checks to verify that the materials meet specified standards, including tensile strength and flexibility. This process ensures that the inflators can withstand the rigors of use in various environments, from hot climates in the Middle East to humid conditions in South America.

The next stage is forming, where raw materials are shaped into components of the tire inflator. This may involve injection molding for plastic parts, machining for metal components, and extrusion for hoses. Advanced manufacturing techniques, such as 3D printing, are increasingly being used to produce prototypes and complex parts more efficiently.

Each component must adhere to precise specifications to ensure compatibility during assembly. Manufacturers often use CAD (Computer-Aided Design) software to design components, which helps in maintaining quality and reducing waste during production.

Assembly is a crucial stage where all components come together to form a complete tire inflator. This process may be manual or automated, depending on the scale of production. Automated assembly lines improve efficiency and consistency, while manual assembly allows for greater attention to detail.

During assembly, quality checks are conducted at various points to ensure that parts fit correctly and function as intended. This includes verifying that seals are properly installed to prevent air leaks and that electrical connections are secure.

The finishing stage involves applying coatings, labels, and final inspections. Finishing techniques may include painting, powder coating, or applying anti-corrosive treatments to metal components. These processes not only enhance the aesthetic appeal of the inflators but also improve their durability and resistance to environmental factors.

Final inspections involve checking the inflator for any defects, ensuring that all components are functioning correctly, and confirming that the product meets regulatory standards. This thorough quality control ensures that only high-quality products reach the market.

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that products meet both industry standards and customer expectations. Various international and industry-specific standards guide these QA processes.

ISO 9001 is one of the most recognized international standards for quality management systems. Compliance with this standard indicates that a manufacturer has established effective processes to enhance customer satisfaction through consistent quality. B2B buyers should prioritize suppliers who demonstrate ISO 9001 certification as it reflects a commitment to quality.

Illustrative image related to portable auto tire inflator

Additionally, standards such as CE marking in Europe and API (American Petroleum Institute) certifications for specific components may be relevant, depending on the target market. These certifications assure buyers that the products comply with safety and performance standards.

Quality control (QC) checkpoints are essential throughout the manufacturing process. These checkpoints typically include:

Incoming Quality Control (IQC): This phase involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers should provide certificates of conformity to ensure materials meet specified standards.

In-Process Quality Control (IPQC): During production, ongoing inspections verify that each stage of manufacturing adheres to quality standards. This includes monitoring machine calibrations and conducting functional tests on components.

Final Quality Control (FQC): After assembly, the final product undergoes comprehensive testing to ensure it meets performance specifications. This may include pressure testing and functional assessments of electronic components.

B2B buyers looking to ensure the quality of their suppliers can take several actionable steps:

Conduct Audits: Regular audits of suppliers can help verify their adherence to quality standards and manufacturing processes. Buyers can request audits from third-party organizations that specialize in manufacturing compliance.

Request Quality Reports: Suppliers should provide detailed quality assurance reports, including test results and compliance certifications. These reports should document the QA processes and results for each batch of products.

Engage Third-Party Inspectors: Buyers may choose to hire third-party inspection services to conduct independent assessments of the products before shipment. This ensures that the products meet the required quality standards.

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Different regions may have varying standards and regulations that affect the import and sale of tire inflators.

B2B buyers must familiarize themselves with the specific regulations applicable to their region. For instance, products sold in the European Union must comply with CE marking requirements, while Middle Eastern countries may have unique safety regulations. Buyers should ensure that suppliers are aware of and compliant with these regional standards.

To ensure the highest quality of portable auto tire inflators, B2B buyers should consider the following best practices:

Establish Clear Specifications: Clearly define product specifications and quality standards in purchase agreements to align expectations between buyers and suppliers.

Build Long-term Relationships: Foster strong relationships with suppliers to encourage transparency in their manufacturing processes and quality control measures.

Monitor Market Trends: Stay informed about industry trends and technological advancements in tire inflator manufacturing to assess the competitiveness and reliability of potential suppliers.

By following these guidelines, international B2B buyers can effectively navigate the complexities of manufacturing processes and quality assurance for portable auto tire inflators, ensuring they partner with reliable suppliers that meet their quality expectations.

Illustrative image related to portable auto tire inflator

In the competitive landscape of B2B procurement, sourcing a portable auto tire inflator requires a strategic approach to ensure you select a product that meets your operational needs. This guide provides a step-by-step checklist to assist international buyers in making informed decisions.

Establishing clear technical specifications is essential to ensure the inflator meets your operational requirements. Consider factors such as maximum pressure output, power source (battery-operated vs. corded), and size dimensions for storage. Specific needs may vary depending on the types of vehicles serviced (e.g., passenger cars vs. trucks).

Understanding current market trends and product reviews can provide insights into the best-performing models. Look for recent reviews from reputable automotive publications or consumer feedback platforms. This will help you gauge reliability and performance, as well as identify any common issues faced by users.

Before committing to a supplier, it’s crucial to conduct thorough due diligence. Request detailed company profiles, customer testimonials, and case studies, particularly from buyers in similar markets or regions. This information can provide insights into the supplier’s reliability and their capacity to meet your demands.

A robust warranty and after-sales support can significantly impact your long-term satisfaction with the product. Verify the warranty period and what it covers, as well as the availability of customer support for troubleshooting. This is especially important for businesses relying on inflators for regular operations.

Illustrative image related to portable auto tire inflator

When evaluating products, consider not only the upfront cost but also the total cost of ownership, which includes maintenance, potential repairs, and operational efficiency. Obtain quotes from multiple suppliers to ensure competitive pricing. Look for any hidden costs, such as shipping fees or import duties, that may affect your budget.

Before finalizing your purchase, request samples to test the inflators in real-world conditions. This step allows you to evaluate performance, ease of use, and any additional features that may enhance functionality, such as built-in pressure gauges or USB charging ports. Testing ensures the product meets your expectations.

Once you have selected a supplier and tested the product, ensure that the purchase agreement is comprehensive. It should include terms related to delivery timelines, payment methods, and return policies. Clear agreements can help prevent disputes and ensure smooth transactions.

Illustrative image related to portable auto tire inflator

By following this checklist, B2B buyers can confidently navigate the sourcing process for portable auto tire inflators, ensuring they select products that enhance their operational efficiency and meet their specific needs.

Understanding the cost structure of portable auto tire inflators is crucial for B2B buyers aiming to make informed purchasing decisions. The primary cost components include:

Materials: The choice of materials significantly impacts the overall cost. High-quality plastic casings, robust motors, and efficient battery systems tend to be more expensive but can enhance durability and performance. Sourcing materials locally can also reduce costs related to logistics.

Labor: Labor costs can vary widely based on the manufacturing location. Regions with lower wage standards may offer competitive pricing, but this can sometimes compromise quality. Skilled labor is essential for ensuring that the inflators meet safety and performance standards.

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help mitigate these costs.

Tooling: Initial setup costs for molds and machinery can be significant, especially for custom designs. However, these costs are usually amortized over larger production runs.

Quality Control (QC): Rigorous QC processes are necessary to ensure product reliability, which can add to the overall cost. Investing in quality can reduce returns and increase customer satisfaction.

Logistics: Shipping and handling costs vary based on the distance from the manufacturer to the buyer. Incoterms play a crucial role in determining who bears these costs, impacting overall pricing.

Margin: Suppliers typically mark up their prices to cover costs and generate profit. Understanding a supplier’s margin can provide insight into pricing flexibility during negotiations.

Several factors can influence the pricing of portable auto tire inflators:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should inquire about MOQs to optimize pricing.

Specifications and Customization: Custom features such as enhanced pressure capacities or additional functionalities can drive up costs. Buyers should weigh the necessity of these features against their budget.

Materials: Premium materials can lead to higher prices, but they may also result in a longer product lifespan and reduced maintenance costs.

Quality and Certifications: Products that comply with international standards or possess relevant certifications may command higher prices. Buyers should consider whether these certifications are necessary for their target markets.

Supplier Factors: Reputation, reliability, and past performance of suppliers can affect pricing. Established suppliers may charge more due to their proven track record.

Incoterms: The choice of Incoterms can significantly affect pricing. Terms that place more responsibility on the buyer may lower initial costs but could lead to higher expenses later.

B2B buyers can leverage several strategies to enhance their purchasing power:

Negotiation: Always be prepared to negotiate prices based on volume, payment terms, or long-term contracts. Suppliers may be willing to offer discounts for large orders or prompt payments.

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, repair, and replacement costs over time. A lower initial price may lead to higher long-term costs if the product is of inferior quality.

Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, understanding local market conditions and import tariffs is essential. This knowledge can help in negotiating better terms and prices.

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide leverage in negotiations and help identify competitive pricing.

Prices for portable auto tire inflators can vary widely based on the above factors and market dynamics. It is advisable for buyers to conduct thorough market research and engage directly with suppliers to obtain accurate and up-to-date pricing.

As businesses and consumers seek efficient solutions for maintaining vehicle performance, the portable auto tire inflator stands out as a popular choice. However, various alternative technologies and methods exist that can serve similar purposes. In this analysis, we will compare the portable auto tire inflator against two viable alternatives: traditional foot pumps and electric air compressors. Each option has its own set of advantages and drawbacks, which can influence purchasing decisions for B2B buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

| Comparison Aspect | Portable Auto Tire Inflator | Traditional Foot Pump | Electric Air Compressor |

|---|---|---|---|

| Performance | Quick inflation, portable, suitable for multiple tires | Slower inflation, limited to one tire at a time | Fast inflation, can handle multiple tires and high pressures |

| Cost | Moderate ($40-$90) | Low ($15-$30) | Higher ($100-$300) |

| Ease of Implementation | Simple setup, user-friendly | Requires physical effort | Requires power source, often more complex setup |

| Maintenance | Minimal, occasional battery replacement | Minimal, durable | Moderate, requires regular checks and possible repairs |

| Best Use Case | Emergency tire inflation, on-the-go use | Occasional use, low-pressure applications | Frequent use, heavy-duty applications, workshops |

A traditional foot pump is a manual device that uses human power to inflate tires. While it is cost-effective and requires no electricity, its performance is limited. Foot pumps can be slow to inflate, often taking longer to achieve the desired pressure compared to their powered counterparts. They are best suited for occasional use, such as topping off bike tires or inflating sports equipment. However, the manual effort required can be a drawback, particularly for users who need to inflate multiple tires quickly or frequently.

Illustrative image related to portable auto tire inflator

Electric air compressors provide a powerful alternative for tire inflation, especially for heavy-duty vehicles and situations where high pressure is needed. These devices can inflate tires quickly and are suitable for multiple applications, including workshops and automotive maintenance. However, they tend to be more expensive and require a stable power source, which may limit their portability. Maintenance is also a consideration, as electric compressors may need regular checks and repairs over time. They are ideal for businesses that require frequent and reliable tire inflation but may not be the best choice for casual users or those needing a portable solution.

When selecting a tire inflation solution, B2B buyers must consider their specific operational requirements, budget constraints, and frequency of use. Portable auto tire inflators are excellent for emergency situations and provide convenience for users who need to maintain tire pressure on the go. In contrast, traditional foot pumps offer an economical choice for occasional use, while electric air compressors are best suited for businesses with regular high-demand inflation needs. Understanding the strengths and weaknesses of each alternative can help buyers make informed decisions that align with their operational needs and enhance vehicle maintenance efficiency.

Understanding the essential technical specifications of portable auto tire inflators is crucial for B2B buyers. These specifications not only influence the performance and durability of the inflators but also affect their suitability for different applications. Here are several critical specs to consider:

Illustrative image related to portable auto tire inflator

The maximum pressure, often measured in pounds per square inch (PSI), indicates the highest air pressure the inflator can deliver. For most passenger vehicles, a range of 30-35 PSI is standard, while larger vehicles like trucks may require inflators that can reach 80 PSI or more. B2B buyers must ensure that the inflator can accommodate the specific pressure needs of the vehicles being serviced, particularly in regions with diverse vehicle types.

The duty cycle refers to the amount of time an inflator can operate before needing a cooldown period. For instance, a unit with a 25-minute duty cycle can run continuously for that duration before it must rest. This specification is crucial for commercial buyers who may need to inflate multiple tires consecutively, as it affects operational efficiency and productivity.

Portable tire inflators can operate on various power sources, including rechargeable batteries, 12-volt car sockets, or direct battery clamps. Understanding the power source is essential for B2B buyers, especially those operating in remote areas or markets with limited access to electrical outlets. Choosing the right power option ensures reliability and convenience in different environments.

The accuracy of the pressure gauge is vital for ensuring tires are inflated to the correct pressure. Digital gauges tend to provide more precise readings compared to analog ones. B2B buyers should prioritize inflators with reliable pressure gauges to minimize the risk of under- or over-inflation, which can lead to safety issues and increased operational costs.

The compactness and weight of an inflator impact its portability and ease of use. A lightweight and compact design is ideal for businesses that require frequent transportation of the unit, such as roadside assistance services. Buyers should consider how the size and weight will affect their storage and transportation logistics.

Navigating the tire inflator market involves familiarity with specific trade terms that can impact purchasing decisions and negotiations. Here are key terms to understand:

OEM refers to companies that manufacture products that are then sold under another brand name. In the context of tire inflators, B2B buyers may seek OEM products for reliability, as these often meet the original specifications of vehicle manufacturers.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory effectively and ensure that they are not overcommitting to products that may not sell.

Illustrative image related to portable auto tire inflator

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. B2B buyers use RFQs to gather pricing information, negotiate terms, and compare offers from different suppliers, making it a critical tool in the procurement process.

Incoterms are standardized trade terms used in international transactions to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers understand their obligations and risks in cross-border purchases of tire inflators.

The warranty period indicates the duration for which the manufacturer guarantees the product against defects. For B2B buyers, a longer warranty period can signify product reliability and reduce long-term costs associated with repairs or replacements.

By grasping these technical properties and trade terms, B2B buyers can make informed purchasing decisions that align with their operational needs and market demands.

Illustrative image related to portable auto tire inflator

The global portable auto tire inflator market is experiencing significant growth, driven by rising vehicle ownership and increasing awareness of vehicle maintenance. International B2B buyers, especially in Africa, South America, the Middle East, and Europe, are witnessing a surge in demand for efficient and portable solutions due to the need for convenience and emergency preparedness. Key trends include the adoption of cordless technology, enhanced battery life, and multi-functional designs that cater to diverse needs—such as inflating not just tires but also sports equipment and recreational items.

Emerging technologies, such as smart tire inflators with integrated pressure sensors and smartphone connectivity, are reshaping the market. These devices provide real-time pressure readings and alerts, making maintenance easier for consumers. Furthermore, the trend toward compact designs allows for greater portability, appealing to urban consumers who may have limited storage space. As a result, B2B buyers should focus on sourcing products that offer a balance between performance, portability, and technological advancements to stay competitive in their respective markets.

Sustainability and ethical sourcing are becoming increasingly critical for B2B buyers in the portable auto tire inflator sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, has led companies to seek suppliers that prioritize eco-friendly practices. Buyers should look for manufacturers that utilize sustainable materials and processes, such as recyclable plastics and energy-efficient production methods.

Illustrative image related to portable auto tire inflator

Furthermore, certifications like ISO 14001 for environmental management and adherence to ethical labor practices are vital for ensuring that the supply chain aligns with global sustainability standards. By sourcing from companies committed to these principles, buyers can not only enhance their brand reputation but also meet the growing consumer demand for environmentally responsible products. This trend is particularly important in regions like Europe, where regulatory frameworks increasingly emphasize sustainability.

The portable auto tire inflator market has evolved significantly over the past few decades. Initially, tire inflators were bulky, corded devices primarily used in professional settings. However, advancements in battery technology and materials have led to the development of compact, cordless models that are user-friendly and accessible for everyday consumers. The introduction of features such as automatic shut-off and built-in pressure gauges has further enhanced their usability, catering to a broader audience, including casual drivers and outdoor enthusiasts.

As consumers become more reliant on technology, the integration of smart features into tire inflators is likely to continue. This evolution not only reflects changing consumer preferences but also highlights the importance of innovation and adaptability in the B2B landscape. Companies that invest in R&D to develop next-generation inflators are positioned to capture emerging market opportunities and meet the demands of a more tech-savvy customer base.

1. How do I choose the right portable auto tire inflator for my business needs?

Selecting the appropriate portable auto tire inflator involves evaluating several factors. Consider the inflator’s maximum pressure capability, especially if your fleet includes vehicles with larger tires. Look for features such as a built-in pressure gauge, portability, and power options (battery vs. corded). Assess the inflator’s speed and efficiency; faster models save time during operations. Additionally, check for compatibility with various tire types and any extra functionalities like USB charging or adapters for inflating other items.

2. What is the best portable auto tire inflator for commercial use?

The best portable auto tire inflator for commercial use typically balances power, speed, and durability. The AstroAI Cordless Tire Inflator stands out due to its ability to quickly inflate tires to high pressures and its dual power options, making it versatile for various environments. For larger vehicles, the Viair 88P offers rapid inflation and ruggedness, ideal for trucks and SUVs. Assess your specific needs, such as tire sizes and frequency of use, to make the best choice for your business.

3. What are the common payment terms for sourcing portable auto tire inflators internationally?

Payment terms can vary widely based on the supplier and the region. Common terms include advance payment, letter of credit, or payment upon delivery. For larger orders, many suppliers may accept a 30% deposit with the balance due before shipping. It’s crucial to negotiate terms that align with your cash flow and risk tolerance. Always ensure that payment methods offer adequate protection, particularly in international transactions, to safeguard against fraud.

4. How can I vet suppliers of portable auto tire inflators?

Vetting suppliers requires thorough research. Start by checking their business credentials, such as registration and compliance with local laws. Request references and conduct background checks on their reputation in the industry. Evaluate product quality through samples and certifications. Additionally, review their capacity to meet your order volume and delivery timelines. Engaging with other businesses that have sourced from them can provide valuable insights into their reliability and service.

5. What is the minimum order quantity (MOQ) when sourcing portable auto tire inflators?

The minimum order quantity (MOQ) for portable auto tire inflators can vary significantly among suppliers. Some may offer MOQs as low as 50 units, while others may require orders of 500 or more for wholesale pricing. Factors influencing MOQ include the supplier’s production capacity, inventory levels, and pricing structures. It’s advisable to discuss your specific requirements with potential suppliers and negotiate terms that suit your business needs.

6. Can I customize portable auto tire inflators for my brand?

Yes, many manufacturers offer customization options for portable auto tire inflators, including branding, color schemes, and specific features tailored to your market. Customization may involve additional costs and longer lead times, so it’s essential to communicate your requirements early in the sourcing process. Ensure that the supplier has a clear process for handling custom orders, including design proofs and production timelines, to avoid any misunderstandings.

7. What quality assurance measures should I expect from suppliers?

Reputable suppliers should implement stringent quality assurance (QA) measures to ensure product reliability and safety. This includes regular inspections during manufacturing, adherence to international quality standards, and providing certifications such as ISO or CE. Request documentation of QA processes and results from previous orders. Additionally, inquire about their return and warranty policies to protect your investment against defects or performance issues.

8. What logistics considerations should I keep in mind when importing tire inflators?

When importing portable auto tire inflators, consider logistics aspects such as shipping methods, costs, and transit times. Determine whether you prefer air freight for speed or sea freight for cost efficiency. Understand customs regulations in your country to avoid unexpected delays or additional fees. Partnering with a reliable freight forwarder can streamline the process, ensuring that your products arrive on time and in good condition. Additionally, factor in storage and distribution logistics for effective inventory management.

Domain: avidpowertool.com

Registered: 2018 (7 years)

Introduction: Tire Inflator – Avid Power Tools

1. Avid Power Tire Inflator (Orange)

– Price: $79.99

– Features: Portable air compressor, triple power source (120V AC, 12V DC, 20V rechargeable battery), inflation & deflation modes, dual powerful motors.

2. Avid Power 12V Tire Inflator (Red)

– Price: $21.99

– Features: Portable air compressor, 60 PSI display gauge, LED light, compact and lightweight…

Domain: automoblog.com

Registered: 2004 (21 years)

Introduction: Best Portable Tire Inflators for 2025: 1. Slime Cordless Tire Inflator – Easy to use and stow. 2. 20V Avid Power – Drill-style design and carrying case. 3. Fanttik X8 Apex – Overall good quality and functionality. 4. DeWalt 20V MAX – Built for lifetime usage and ownership. 5. Milwaukee M18 – Robust and powerful with four different memory settings. Price range: $80 to $180. Features to consider: ro…

In today’s competitive automotive market, strategic sourcing of portable auto tire inflators presents a unique opportunity for international B2B buyers. By focusing on high-quality, reliable products like the AstroAI Cordless Tire Inflator, businesses can ensure they meet customer demands for efficiency and convenience. The ability to quickly and accurately inflate tires not only enhances vehicle performance but also contributes to safety and cost savings for end-users.

Illustrative image related to portable auto tire inflator

As suppliers across Africa, South America, the Middle East, and Europe continue to innovate, it is crucial for buyers to assess the features that align with their market needs—such as portability, power source versatility, and additional functionalities like built-in pressure gauges. By prioritizing these aspects in procurement strategies, businesses can secure products that not only satisfy consumer expectations but also enhance brand reputation.

Looking ahead, the demand for portable auto tire inflators is set to grow, driven by increasing vehicle ownership and a rising focus on vehicle maintenance. International B2B buyers should take proactive steps to establish partnerships with reliable manufacturers, ensuring access to the latest technology and competitive pricing. Embrace this opportunity to elevate your product offerings and stay ahead in the evolving automotive landscape.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to portable auto tire inflator

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.