In the competitive landscape of global logistics and transportation, the quest for cost efficiency is paramount. One often overlooked yet impactful factor in this pursuit is the role of properly inflated tires in enhancing gas mileage. For international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe, understanding the intricacies of tire inflation can lead to significant operational savings. This guide aims to equip businesses with comprehensive insights into tire types, applications, and the crucial aspects of supplier vetting, ensuring that informed purchasing decisions can be made.

With tire-related expenses accounting for a notable portion of operational costs, the correlation between tire pressure and fuel efficiency is a critical consideration. This guide delves into the optimal tire pressure specifications, the potential pitfalls of under- and over-inflation, and how these factors affect vehicle performance and longevity. Furthermore, we will explore the varying regulations and market conditions in different regions, providing actionable strategies for sourcing high-quality tires that meet specific operational needs.

By navigating the complexities of tire procurement and maintenance, international buyers can not only enhance their fuel efficiency but also contribute to a sustainable operational model that aligns with global best practices. This guide serves as a vital resource for businesses looking to make strategic investments that drive both cost savings and performance enhancements in their fleet operations.

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Inflation | Maintains manufacturer-recommended PSI | Fleet management, logistics companies | Pros: Optimal balance of safety and fuel efficiency. Cons: Requires regular monitoring. |

| Under-Inflated Tires | Below recommended PSI leading to increased rolling resistance | Delivery services, transport companies | Pros: Lower initial costs. Cons: Increased fuel consumption and tire wear. |

| Over-Inflated Tires | Exceeds recommended PSI causing a bulging shape | Performance vehicles, racing teams | Pros: Potential slight fuel savings. Cons: Decreased traction and safety risks. |

| Adaptive Inflation Systems | Automated systems adjusting tire pressure based on load | Commercial trucking, heavy machinery | Pros: Maximizes fuel efficiency and tire lifespan. Cons: Higher initial investment and maintenance costs. |

| Eco-Friendly Tires | Designed with materials that enhance fuel efficiency | Green logistics, eco-conscious companies | Pros: Reduces carbon footprint. Cons: Often more expensive than standard tires. |

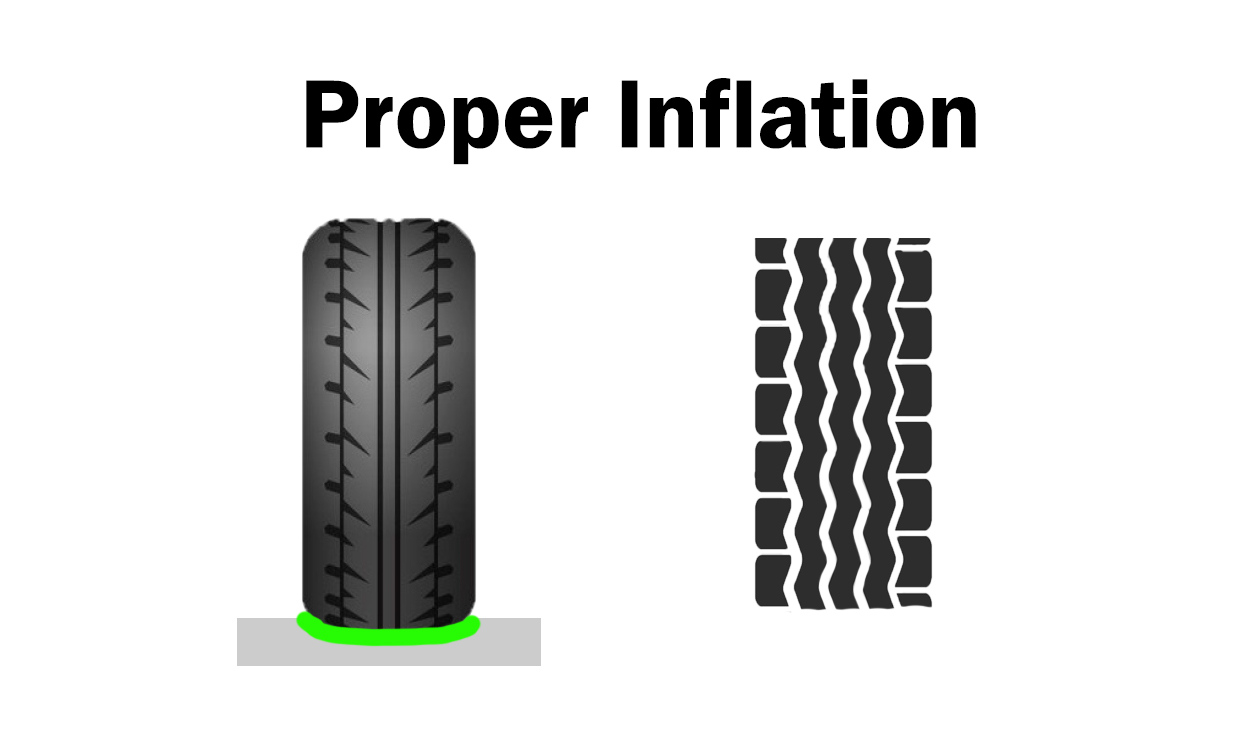

Standard inflation refers to maintaining the tire pressure at the manufacturer-recommended PSI. This optimal pressure ensures that tires are shaped correctly for efficient rolling, which minimizes fuel consumption. For B2B buyers, particularly those managing fleets or logistics companies, adhering to this standard is crucial for balancing safety, performance, and fuel efficiency. Regular monitoring and maintenance are essential but can lead to significant savings in fuel costs and tire longevity.

Under-inflated tires operate below the recommended PSI, leading to increased rolling resistance. This condition can be tempting for businesses looking to cut costs initially, but it results in higher fuel consumption and more rapid tire wear. For companies in delivery or transport sectors, this can mean increased operational costs over time. Buyers should consider the long-term implications of under-inflation and the importance of regular tire pressure checks to maintain efficiency.

Over-inflated tires exceed the recommended PSI, creating a bulging effect that can reduce rolling resistance. While this may yield minor fuel savings, the risks often outweigh the benefits. Businesses operating performance vehicles or in racing may experiment with this, but for most B2B applications, the decreased traction and increased risk of blowouts pose significant safety concerns. Buyers should prioritize safety and tire longevity over slight fuel efficiency gains.

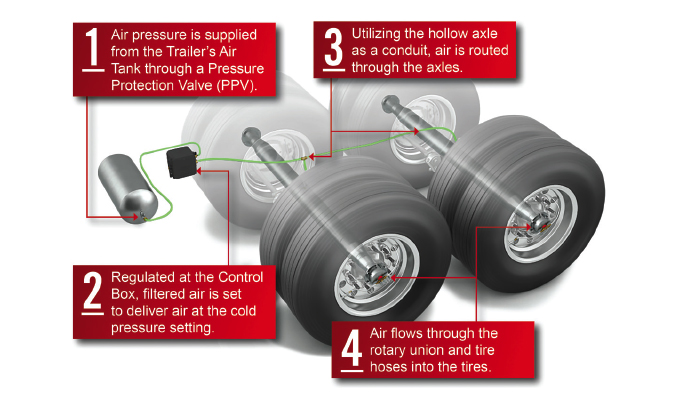

Adaptive inflation systems automatically adjust tire pressure based on load and driving conditions. This technology is particularly beneficial for commercial trucking and heavy machinery operations, where varying loads can significantly impact fuel efficiency. While the initial investment in these systems may be higher, the long-term savings in fuel costs and extended tire life can justify the expense. B2B buyers should evaluate the cost-benefit ratio of implementing such systems in their operations.

Eco-friendly tires are designed with materials and technologies that enhance fuel efficiency and reduce environmental impact. Companies focused on sustainability, such as those in green logistics, may find eco-friendly tires align with their corporate values and goals. Although these tires can be more expensive initially, the potential for reduced fuel consumption and a lower carbon footprint makes them an attractive option for environmentally conscious businesses. Buyers should assess their budget and sustainability objectives when considering this option.

| Industry/Sector | Specific Application of properly inflated tires help increase gas mileage | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Fleet management for delivery services | Improved fuel efficiency leads to reduced operational costs | Reliable suppliers of tire pressure monitoring systems (TPMS) |

| Agriculture | Agricultural machinery tire maintenance | Enhanced fuel economy supports sustainable farming practices | Access to specialized agricultural tires with optimal PSI |

| Construction | Heavy equipment tire optimization | Lower fuel consumption translates to cost savings | Durable tires suited for rough terrain and high load capacity |

| Mining | Mining truck tire management | Increased efficiency and reduced downtime | Sourcing tires with high load ratings and puncture resistance |

| Automotive Services | Tire service and maintenance for consumer vehicles | Better customer satisfaction through improved vehicle performance | Partnerships with tire manufacturers for quality assurance |

In the transportation and logistics sector, fleet management relies heavily on fuel efficiency. Properly inflated tires reduce rolling resistance, leading to improved gas mileage for delivery vehicles. This efficiency not only lowers fuel costs but also extends the lifespan of tires, resulting in significant savings over time. For international buyers, sourcing reliable tire pressure monitoring systems (TPMS) is crucial to ensure optimal tire inflation across diverse fleet operations.

Agricultural machinery, such as tractors and harvesters, benefits from properly inflated tires, which enhance fuel economy and operational efficiency. Ensuring that tires are at the correct PSI can lead to better traction and reduced soil compaction, promoting sustainable farming practices. Buyers in the agricultural sector should consider sourcing specialized tires that meet the unique demands of their machinery while maintaining optimal inflation for fuel savings.

In the construction industry, heavy equipment like bulldozers and excavators requires proper tire management to optimize fuel use. Properly inflated tires reduce drag and improve fuel efficiency, which can significantly lower project costs. When sourcing tires, companies should focus on durability and the ability to maintain optimal PSI under heavy loads, ensuring longevity and performance in challenging environments.

Mining operations depend on heavy trucks that face rugged terrains, making tire management crucial for efficiency. Properly inflated tires minimize fuel consumption and enhance vehicle performance, thereby reducing downtime. For international B2B buyers in mining, sourcing tires with high load ratings and puncture resistance is essential to ensure safety and reliability in harsh conditions, ultimately supporting operational efficiency.

Automotive service providers can enhance customer satisfaction by emphasizing the importance of properly inflated tires. This not only improves vehicle performance but also boosts fuel efficiency for consumers. Establishing partnerships with reputable tire manufacturers can ensure that service providers offer high-quality tires and maintenance solutions, which are vital for meeting customer expectations and fostering loyalty in a competitive market.

The Problem: For B2B buyers managing transportation fleets, ensuring that all vehicles maintain optimal tire pressure is a significant challenge. Fluctuating tire pressure can lead to inconsistent fuel efficiency, ultimately increasing operational costs. With various factors—such as weather changes, road conditions, and driving habits—affecting tire inflation, fleet managers often struggle to keep up. A single under-inflated tire can not only lead to decreased gas mileage but also increase the risk of tire wear and potential blowouts, which can jeopardize safety and reliability.

The Solution: To address this issue, B2B buyers should implement a regular tire maintenance schedule that includes periodic tire pressure checks. Investing in a centralized tire pressure monitoring system (TPMS) can provide real-time data on tire conditions across the fleet, alerting managers to any deviations from the recommended PSI. Additionally, training drivers on the importance of maintaining proper tire pressure and conducting pre-trip inspections can enhance accountability. By establishing a protocol for routine checks, buyers can ensure that all vehicles operate at peak efficiency, which translates to better fuel economy and reduced costs over time.

The Problem: Many B2B buyers mistakenly believe that over-inflating tires will lead to better fuel efficiency. This misconception can arise from anecdotal evidence or misinformation, leading businesses to operate vehicles with excessively high tire pressures. While slightly over-inflated tires may reduce rolling resistance, the risks far outweigh the benefits, including decreased traction, increased tire wear, and a heightened risk of blowouts. These issues can lead to costly repairs and pose safety hazards for drivers.

The Solution: To counteract this misunderstanding, companies should focus on educating their teams about the importance of adhering to manufacturer-recommended tire pressures. Distributing clear guidelines that outline the consequences of both under- and over-inflation can help reinforce best practices. Furthermore, leveraging technology, such as mobile apps or digital dashboards that provide tire pressure recommendations based on vehicle specifications, can simplify compliance. By prioritizing education and technology, businesses can ensure that their vehicles are both safe and efficient, leading to improved gas mileage without compromising safety.

The Problem: B2B buyers often face the challenge of seasonal changes impacting tire pressure, particularly in regions with extreme temperature variations. Cold weather can cause tire pressure to drop significantly, leading to increased fuel consumption and reduced vehicle performance. Conversely, heat can cause tire pressure to rise, which may lead to over-inflation if not monitored properly. These fluctuations can complicate fleet management and increase operational costs, making it difficult to maintain optimal fuel efficiency year-round.

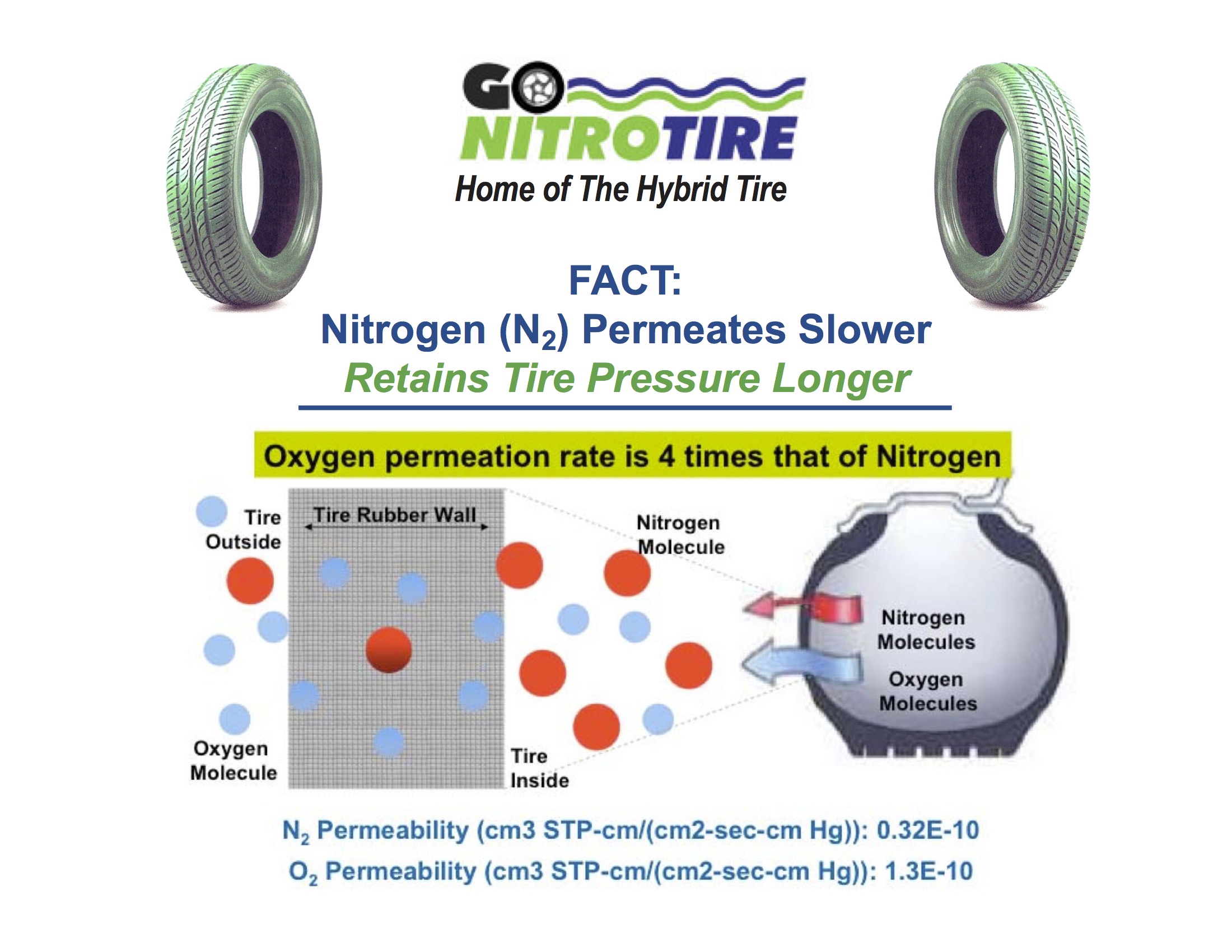

The Solution: To mitigate the effects of seasonal temperature changes, companies should implement a proactive tire management strategy. This includes establishing seasonal maintenance schedules that involve checking and adjusting tire pressure based on forecasted weather conditions. Utilizing nitrogen inflation instead of regular air can also help maintain tire pressure stability, as nitrogen is less affected by temperature fluctuations. Additionally, educating drivers about the importance of checking tire pressure regularly, especially during seasonal transitions, can further ensure that vehicles operate efficiently. By adopting a comprehensive approach to tire management, businesses can optimize fuel economy and reduce costs associated with fluctuating tire pressures.

When selecting materials for tires that maintain proper inflation and contribute to improved gas mileage, it is crucial for B2B buyers to consider various factors, including material properties, performance characteristics, and regional compliance standards. Below, we analyze four common materials used in tire manufacturing, focusing on their suitability for enhancing fuel efficiency.

Rubber is the primary material used in tire manufacturing due to its excellent elasticity and durability. The key properties of rubber relevant to tire performance include:

Pros & Cons: Rubber tires are durable and provide good traction, but they can wear out faster if not properly maintained. The manufacturing process is relatively straightforward, but high-quality rubber compounds can be costly.

Illustrative image related to properly inflated tires help increase gas mileage

Impact on Application: Rubber is compatible with various road conditions and is essential for maintaining proper tire pressure, which directly affects fuel efficiency.

Considerations for International Buyers: Buyers in regions like Africa, South America, and the Middle East should be aware of local climate conditions that can affect rubber performance. Compliance with international standards such as ASTM is critical for ensuring safety and efficiency.

Synthetic Polymers, such as styrene-butadiene rubber (SBR) and polybutadiene, are increasingly used in tire manufacturing.

Pros & Cons: The primary advantage of synthetic polymers is their ability to be tailored for specific applications, improving fuel efficiency. However, they can be more expensive to produce than natural rubber.

Illustrative image related to properly inflated tires help increase gas mileage

Impact on Application: Synthetic polymers help reduce rolling resistance, which is crucial for improving gas mileage.

Considerations for International Buyers: Buyers should consider the availability of synthetic materials and their cost implications. Compliance with local regulations regarding synthetic materials is also essential.

Steel is commonly used in tire belts and beads to provide structural integrity.

Pros & Cons: Steel-reinforced tires have improved durability and performance, but the added weight can slightly reduce fuel efficiency. Manufacturing complexity increases with steel integration.

Impact on Application: Steel enhances the tire’s ability to maintain proper inflation under varying loads, contributing to better gas mileage.

Considerations for International Buyers: Buyers should ensure that steel components meet local standards for safety and performance, such as DIN or JIS.

Illustrative image related to properly inflated tires help increase gas mileage

Composite Materials, which combine rubber with other materials like carbon black and silica, are used to enhance performance.

Pros & Cons: Composites offer a balanced performance, enhancing both durability and fuel efficiency. However, they can be more expensive to manufacture.

Impact on Application: The use of composites can significantly lower rolling resistance, which is essential for maximizing gas mileage.

Considerations for International Buyers: Understanding the local market’s preference for composite materials is vital, especially in regions with varying road conditions.

| Material | Typical Use Case for properly inflated tires help increase gas mileage | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Standard tire manufacturing | Excellent elasticity and durability | Can wear out faster if not maintained | Medium |

| Synthetic Polymers | High-performance tires | Tailored for specific performance | Higher production costs | High |

| Steel | Reinforcement in tire belts and beads | Improved durability and structural integrity | Increased weight may reduce fuel efficiency | Medium |

| Composite Materials | Advanced tire designs for enhanced performance | Low rolling resistance and better traction | Higher manufacturing complexity | High |

In conclusion, selecting the right materials for tires is crucial for optimizing fuel efficiency and ensuring safety. International buyers must consider local conditions, compliance with standards, and the specific performance requirements of their markets.

The manufacturing of tires specifically designed for optimal fuel efficiency involves several critical stages. These stages not only ensure the quality and performance of the tires but also play a significant role in how well they maintain proper inflation, which is essential for increasing gas mileage.

The first step in tire manufacturing is the preparation of raw materials. This includes rubber compounds, fabric, and steel wires. The choice of rubber is crucial; manufacturers often use a blend that includes natural and synthetic rubber to achieve the desired balance of durability, flexibility, and fuel efficiency. Additives such as carbon black and silica are included to enhance strength, grip, and rolling resistance.

Additionally, the fabric layers, typically made from polyester or nylon, provide structural integrity. Steel belts are also integrated to improve tire stability and reduce deformation during use. Each of these materials must meet rigorous specifications to ensure that the final product can maintain proper inflation and contribute to fuel savings.

Once materials are prepared, the next stage involves forming the tire components. This process includes creating the tire tread, sidewalls, and inner linings. Modern manufacturing employs advanced techniques such as extrusion, where rubber is forced through a die to create consistent shapes, and calendaring, which layers rubber and fabric to ensure even distribution of materials.

The assembly stage follows, where the tire components are combined. This includes layering the inner liner, fabric plies, and tread. Manufacturers often utilize automated machinery to enhance precision and reduce the risk of human error. Proper alignment during this stage is critical, as any misalignment can lead to uneven wear and affect fuel efficiency.

After assembly, tires undergo finishing processes, which may involve curing or vulcanization. This chemical process strengthens the rubber and ensures the tire retains its shape under various driving conditions. The curing process also affects the tire’s rolling resistance, which is directly related to fuel efficiency.

Moreover, finishing may include quality checks such as uniformity testing, where tires are spun at high speeds to identify any imbalances. Proper finishing techniques are essential to ensure that the tires can maintain proper inflation and perform optimally throughout their lifespan.

Quality assurance is a critical aspect of tire manufacturing, especially when it comes to ensuring that tires maintain proper inflation and contribute to fuel efficiency. International standards, such as ISO 9001, provide a framework for quality management systems that manufacturers must adhere to. This standard emphasizes continuous improvement and customer satisfaction, which are vital for B2B buyers seeking reliable suppliers.

In addition to ISO standards, various industry-specific certifications can indicate a manufacturer’s commitment to quality. For example, the CE marking indicates conformity with European health, safety, and environmental protection standards, while the American Petroleum Institute (API) certification can be relevant for tires designed for use in rugged environments or specific applications.

For international buyers, understanding these certifications is crucial. They not only ensure that the tires meet safety and performance standards but also facilitate smoother trade across borders.

Quality control (QC) is embedded at multiple checkpoints throughout the tire manufacturing process. Key QC stages typically include:

Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet specified standards before they are used in production.

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor the quality of materials and assembly. This includes verifying the dimensions, weight, and alignment of components.

Final Quality Control (FQC): Once the tires are completed, they undergo rigorous testing for performance metrics such as inflation retention, tread wear, and overall durability. This final inspection is crucial for ensuring that the tires can maintain proper inflation and improve fuel efficiency.

Various testing methods are employed to ensure the quality and performance of tires. Common techniques include:

Rolling Resistance Testing: This method measures how much energy is lost as a tire rolls, which directly affects fuel efficiency.

Uniformity Testing: Tires are spun to detect any variations that could lead to uneven wear or instability during driving.

Durability and Endurance Testing: Tires are subjected to extreme conditions to assess their performance over time, ensuring they can maintain proper inflation under various loads and temperatures.

B2B buyers must adopt a proactive approach to verify the quality control measures of potential suppliers. Here are several strategies:

Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality assurance practices of potential suppliers. This allows buyers to assess compliance with international standards and industry certifications.

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand their QC processes, testing methods, and any certifications obtained.

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control measures, ensuring that the products meet the required standards.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of several nuances when it comes to quality control:

Regulatory Differences: Different countries may have varying standards and regulations regarding tire manufacturing. Understanding these differences can help buyers ensure compliance and avoid potential issues in logistics and trade.

Cultural Considerations: Relationships with suppliers can vary by region, impacting communication and negotiation styles. Building strong partnerships can facilitate better quality assurance and responsiveness to concerns.

Logistical Challenges: Importing tires from international suppliers may involve additional logistical considerations, such as customs regulations and shipping times. Buyers should factor these elements into their procurement strategy to ensure timely delivery of quality products.

By understanding the manufacturing processes and quality assurance practices related to tire production, B2B buyers can make informed decisions that enhance their procurement strategies, ultimately contributing to increased fuel efficiency and cost savings.

This practical sourcing guide is designed for B2B buyers seeking to procure solutions that ensure properly inflated tires, which are essential for maximizing fuel efficiency. By following this checklist, businesses can make informed decisions that enhance operational efficiency and reduce overall transportation costs.

Establishing clear tire specifications is vital to ensure compatibility with your fleet or vehicles. Consider factors such as load capacity, tire type (e.g., all-season, performance), and recommended PSI levels. Having precise specifications helps streamline the sourcing process and ensures that the tires meet the specific needs of your operations.

Conduct thorough research on potential suppliers to gauge their credibility and reliability. Look for suppliers with a proven track record in the tire industry and those who specialize in the types of tires you require. Utilize industry reports, customer reviews, and trade publications to gather insights into their reputation.

Before making a purchase, confirm that your chosen suppliers hold relevant certifications and comply with industry standards. This includes certifications such as ISO for quality management and compliance with local safety regulations. Verified suppliers are more likely to provide reliable products that can withstand the demands of your operations.

Illustrative image related to properly inflated tires help increase gas mileage

Evaluating product samples is a crucial step before finalizing your order. Request samples to assess the quality and performance of the tires firsthand. This can help you determine if the tires meet your specifications for fuel efficiency and durability.

Understanding the pricing structure and payment terms is essential for budgeting and financial planning. Compare quotes from multiple suppliers to ensure you receive competitive pricing while maintaining quality. Look for any hidden fees that might affect the overall cost.

Once the tires are procured, create a comprehensive maintenance plan to ensure they remain properly inflated and functional. Regular checks on tire pressure and tread wear are crucial for maintaining fuel efficiency and safety.

After implementing your new tire solution, continuously monitor performance and gather feedback from drivers and maintenance staff. This feedback loop will help you identify any issues early and make necessary adjustments to your tire management strategy.

By following this checklist, B2B buyers can effectively source tires that are crucial for enhancing fuel efficiency, ultimately leading to cost savings and improved operational performance.

When sourcing tires that promote fuel efficiency through proper inflation, several cost components come into play. Understanding these components can help B2B buyers make informed decisions.

Materials: The primary materials for tire production include natural and synthetic rubber, fabric, steel belts, and various chemicals. The quality of these materials directly impacts the tire’s durability and performance. Higher-grade materials typically lead to better fuel efficiency and longer tire life, justifying a higher upfront cost.

Labor: Labor costs can vary significantly based on geographic location and the complexity of manufacturing processes. Regions with lower labor costs may offer competitive pricing; however, this can sometimes come at the expense of quality. Skilled labor is essential for ensuring proper tire construction, which is crucial for maintaining optimal inflation levels.

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Companies that invest in advanced manufacturing technologies may incur higher overhead but can benefit from improved efficiency and product consistency.

Tooling: The initial costs for molds and machinery required for tire production can be significant. However, these costs are amortized over the production run, making them less impactful per unit when larger quantities are ordered.

Quality Control (QC): Ensuring that tires meet specific standards for inflation and performance involves rigorous testing and quality assurance processes. While this adds to the overall cost, it is essential for minimizing defects and ensuring safety.

Logistics: Transportation costs can vary widely based on the supplier’s location and the buyer’s destination. International shipping can introduce additional costs, such as tariffs and customs fees, which should be factored into the overall price.

Margin: Suppliers will generally apply a markup on their production costs to maintain profitability. This margin can vary based on market conditions, competition, and the supplier’s brand reputation.

Several factors influence the pricing of tires, particularly for international buyers looking to optimize their fuel efficiency.

Volume/MOQ: Bulk purchasing often leads to discounts. Suppliers may have minimum order quantities (MOQs) that impact pricing. Buyers should negotiate terms that allow for lower MOQs if they are not prepared to invest in large quantities.

Specifications and Customization: Tires designed for specific applications or custom specifications may incur higher costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

Materials and Quality Certifications: The use of premium materials and obtaining relevant certifications (e.g., ISO, DOT) can drive up costs. However, these investments often lead to better fuel efficiency and longevity, resulting in a lower total cost of ownership.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may command higher prices due to their track record of quality and service.

Incoterms: Understanding Incoterms is crucial for international buyers. These terms define the responsibilities of buyers and sellers in the shipping process and can significantly affect overall costs, including insurance and logistics.

Negotiation: Always negotiate pricing and terms with suppliers. Leverage competitive quotes to secure the best deal.

Cost-Efficiency: Consider the total cost of ownership rather than just the initial purchase price. Investing in quality tires can lead to savings on fuel and maintenance over time.

Pricing Nuances for International Buyers: For buyers in regions like Africa, South America, the Middle East, and Europe, currency fluctuations and regional tariffs can impact costs. It’s important to factor these elements into budget planning.

Research and Compare Suppliers: Take the time to research multiple suppliers. Compare not just prices but also the quality of materials, customer service, and delivery times to ensure the best overall value.

Stay Updated on Market Trends: Keep abreast of market trends and technological advancements in tire manufacturing. Innovations can lead to better fuel efficiency, affecting long-term savings.

The prices and cost structures mentioned are indicative and can vary based on market conditions, supplier negotiations, and geographical factors. Always conduct thorough research and consult multiple suppliers before making purchasing decisions.

In the pursuit of enhancing fuel efficiency, properly inflated tires are widely recognized as a key factor. However, businesses looking to optimize their operational costs and fuel consumption may also consider alternative strategies. This section compares the benefits of maintaining proper tire inflation against other viable solutions that can achieve similar goals, providing B2B buyers with actionable insights.

| Comparison Aspect | Properly Inflated Tires Help Increase Gas Mileage | Tire Pressure Monitoring Systems (TPMS) | Fuel Additives |

|---|---|---|---|

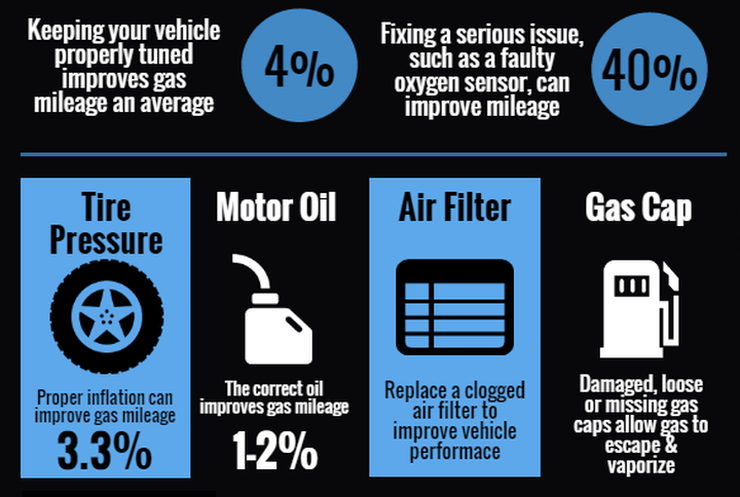

| Performance | Significant improvement in fuel economy, 3-10% increase | Real-time monitoring prevents under-inflation | Can enhance combustion, varying results |

| Cost | Minimal cost, primarily maintenance | Moderate initial investment, low maintenance | Variable cost, ongoing expense |

| Ease of Implementation | Requires regular checks and adjustments | Easy installation, requires monitoring | Simple to use, must be added regularly |

| Maintenance | Regular checks needed, easy to manage | Minimal once installed | Requires consistent application |

| Best Use Case | Fleet operations needing cost control | Businesses with high vehicle turnover | Companies focused on immediate fuel savings |

Tire Pressure Monitoring Systems (TPMS) offer a technological solution to maintaining tire pressure. These systems provide real-time data on tire inflation levels, alerting drivers when tires are under-inflated. The primary advantage of TPMS is its ability to prevent issues before they escalate, ensuring tires are consistently at optimal pressure. However, the initial investment for TPMS can be moderate, and while maintenance is minimal, the technology still requires occasional calibration. This solution is best suited for businesses with a high turnover of vehicles, where maintaining proper tire pressure can directly impact operational efficiency.

Fuel additives represent another alternative for enhancing fuel efficiency. These products are designed to improve combustion and reduce engine deposits, which can lead to better gas mileage. The primary advantage of fuel additives is their ease of use; they can be added directly to the fuel tank without any specialized equipment. However, results can be inconsistent, and the ongoing cost of purchasing these additives can add up over time. Companies looking for immediate fuel savings may find this approach beneficial, but it should be viewed as a complementary strategy rather than a standalone solution.

When selecting the best strategy for improving fuel efficiency, B2B buyers should consider their specific operational needs, budget constraints, and vehicle management practices. Properly inflated tires remain a foundational approach due to their low cost and significant impact on fuel economy. However, integrating technologies like TPMS can enhance this strategy by providing real-time monitoring and alerts. Alternatively, fuel additives can serve as a short-term solution for immediate savings. By evaluating these options against their unique circumstances, businesses can develop a comprehensive approach to optimize fuel efficiency while managing overall costs effectively.

When it comes to fuel efficiency, the technical specifications of tires play a crucial role. Here are some essential properties to consider:

Tire Pressure (PSI)

Tire pressure, measured in pounds per square inch (PSI), is vital for optimal tire performance. Proper inflation reduces rolling resistance, which is the energy required to keep the tires rolling. For B2B buyers, maintaining the correct PSI can lead to significant cost savings in fuel consumption and extend tire life, thereby reducing overall operational expenses.

Tread Depth

Tread depth affects traction and performance on different surfaces. Tires with adequate tread depth improve grip and reduce the likelihood of hydroplaning, which can enhance safety and fuel efficiency. In the B2B sector, choosing tires with the right tread depth for specific applications can optimize fleet performance and reduce maintenance costs.

Material Composition

The materials used in tire construction, including rubber compounds and reinforcements, influence rolling resistance and durability. Tires made from advanced materials can provide lower rolling resistance, enhancing fuel efficiency. Understanding material properties helps B2B buyers select tires that offer a balance between performance and cost-effectiveness.

Load Index

The load index indicates the maximum weight a tire can safely support. Choosing the right load index is crucial for maintaining proper tire shape and performance under load. For businesses operating fleets, selecting tires with an appropriate load index ensures safety, efficiency, and compliance with regulations.

Speed Rating

Speed ratings indicate the maximum speed at which a tire can safely operate. Higher speed ratings often correlate with lower rolling resistance, which can improve fuel efficiency. B2B buyers should consider speed ratings that align with their operational requirements to maximize both safety and fuel economy.

Rolling Resistance Coefficient (RRC)

The rolling resistance coefficient measures how much energy a tire consumes while rolling. Tires designed with lower RRC can significantly enhance fuel efficiency. For businesses, investing in low-rolling-resistance tires can yield substantial savings over time, particularly for fleets with high mileage.

Understanding industry terminology is crucial for effective communication and decision-making. Here are some common terms relevant to tire performance and procurement:

OEM (Original Equipment Manufacturer)

OEM refers to the company that manufactures the original parts of a vehicle, including tires. B2B buyers often prefer OEM tires for their reliability and compatibility with specific vehicle models, ensuring optimal performance and safety.

MOQ (Minimum Order Quantity)

MOQ indicates the smallest order size a supplier is willing to accept. For businesses purchasing tires in bulk, understanding MOQ is essential for managing inventory costs and ensuring a steady supply of products.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request price quotes for specific products or services. B2B buyers should use RFQs to compare prices and terms from different suppliers, ensuring they receive the best value for their tire procurement.

Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in a transaction. Familiarity with Incoterms is vital for B2B buyers engaged in international tire procurement, as it clarifies shipping responsibilities, costs, and risks.

Treadwear Warranty

A treadwear warranty is a guarantee from the tire manufacturer regarding the lifespan of the tire tread. Understanding these warranties can help businesses make informed decisions when selecting tires, as they can indicate the expected performance and longevity.

Fuel Efficiency Rating

This rating indicates how effectively a tire converts fuel into distance traveled. B2B buyers should prioritize tires with high fuel efficiency ratings to minimize fuel costs and reduce their carbon footprint, aligning with sustainability initiatives.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance fuel efficiency, improve operational performance, and reduce overall costs.

Illustrative image related to properly inflated tires help increase gas mileage

The global market for properly inflated tires that enhance gas mileage is influenced by several key dynamics. As fuel prices fluctuate, businesses are increasingly seeking cost-efficient solutions to minimize operational expenses. Proper tire inflation plays a crucial role in this regard, as under-inflated tires can lead to a 10% increase in fuel consumption. This is particularly pertinent for international buyers from regions like Africa, South America, the Middle East, and Europe, where fuel costs can significantly impact logistics and transportation budgets.

Emerging technologies are reshaping the landscape of tire maintenance and monitoring. The adoption of smart tire pressure monitoring systems (TPMS) is on the rise, allowing fleet operators to maintain optimal tire conditions in real-time. These innovations not only enhance fuel efficiency but also extend tire lifespan, providing a dual benefit for B2B buyers. Furthermore, trends towards electric vehicles (EVs) and sustainability in transportation are encouraging companies to invest in technologies that optimize tire performance, thereby reducing overall emissions.

International buyers are also navigating regulatory landscapes that increasingly emphasize fuel efficiency and environmental standards. For example, the European Union has implemented strict regulations on vehicle emissions, pushing companies to adopt best practices in tire maintenance. As a result, the demand for reliable suppliers who can provide high-quality tires that meet these standards is growing.

Sustainability has become a focal point for businesses worldwide, and the tire industry is no exception. The environmental impact of tire production and disposal is significant, prompting buyers to prioritize ethically sourced materials. Properly inflated tires contribute to fuel efficiency, which in turn reduces greenhouse gas emissions. By sourcing tires from manufacturers that adhere to sustainable practices, businesses can align their operations with global sustainability goals.

The importance of ethical supply chains cannot be overstated. Companies are increasingly scrutinizing their suppliers to ensure they comply with environmental regulations and social responsibility standards. Certifications such as ISO 14001 for environmental management systems and other green certifications serve as benchmarks for assessing supplier sustainability. Buyers are advised to engage with manufacturers that utilize eco-friendly materials and processes, as this not only minimizes environmental impact but also enhances brand reputation.

Moreover, the shift towards circular economy principles is gaining traction. Many companies are exploring partnerships with tire manufacturers that offer recycling programs, ensuring that used tires are repurposed rather than ending up in landfills. This commitment to sustainability not only addresses regulatory pressures but also resonates with consumers and stakeholders who prioritize environmental responsibility.

Illustrative image related to properly inflated tires help increase gas mileage

The evolution of tire inflation practices has been marked by a growing awareness of its impact on fuel efficiency and safety. Historically, tire inflation was often overlooked in routine vehicle maintenance, leading to inefficiencies and increased operational costs. However, as fuel prices have risen and environmental concerns have gained prominence, the importance of maintaining proper tire pressure has come to the forefront.

In the early 2000s, basic tire pressure gauges became common tools for fleet operators, but the advent of digital monitoring systems has revolutionized the approach to tire maintenance. Today, many vehicles come equipped with advanced TPMS that alert drivers to low tire pressure, allowing for timely interventions. This technological advancement has not only improved safety but has also empowered businesses to optimize their fuel consumption.

As the B2B landscape continues to evolve, it is clear that properly inflated tires will remain a critical component of effective transportation and logistics strategies. By prioritizing tire maintenance and sourcing sustainable solutions, companies can achieve significant cost savings while contributing positively to environmental goals.

How do I ensure my tires are properly inflated to improve gas mileage?

To maximize gas mileage, regularly check your tire pressure using a reliable gauge. The optimal pressure (measured in PSI) is typically found on a sticker inside the driver’s side door or in the vehicle’s owner manual. Tires should be checked when cold, as heat from driving can increase pressure readings. Maintain the recommended PSI for your specific vehicle to reduce rolling resistance and enhance fuel efficiency.

What is the best tire pressure for maximizing fuel efficiency?

The ideal tire pressure for maximizing fuel efficiency varies by vehicle but is generally specified by the manufacturer. Most passenger vehicles recommend a PSI range between 30 to 35. Adhering to this range ensures optimal tire performance, reducing drag and enhancing gas mileage. Regularly monitoring and maintaining this pressure is crucial, especially in regions with fluctuating temperatures, as temperature changes can impact tire pressure significantly.

How can I verify the quality of tires from international suppliers?

To verify tire quality from international suppliers, request certifications such as ISO 9001 or relevant safety standards that are recognized in your market. Conduct thorough research on the supplier’s reputation, including reviews and testimonials from other B2B buyers. Consider requesting samples for testing or arrange factory visits if feasible. Additionally, utilize third-party inspection services to ensure compliance with quality standards before making bulk purchases.

What customization options are available for tires in B2B transactions?

Many suppliers offer customization options, including tread design, rubber compounds, and sidewall branding. When sourcing tires, inquire about the possibility of tailored specifications to meet your business needs. Customization may also extend to sizes and load ratings, which can be particularly beneficial for fleet operations. Ensure to discuss minimum order quantities (MOQs) for customized products, as they may differ from standard offerings.

What are the typical payment terms in international tire procurement?

Payment terms in international tire procurement can vary widely depending on the supplier and the buyer’s negotiation leverage. Common terms include letters of credit, advance payments, or net 30/60/90 days after delivery. It’s crucial to clarify these terms upfront to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees when negotiating payment options, especially when dealing with suppliers from different continents.

How do logistics and shipping impact tire procurement costs?

Logistics and shipping significantly affect tire procurement costs, especially when importing or exporting tires internationally. Factors such as shipping method (air, sea, or land), distance, and customs duties can influence overall expenses. To optimize costs, work with logistics experts who can provide insights into efficient shipping routes and methods. Additionally, consider bulk purchasing to take advantage of lower shipping rates and negotiate better terms with freight forwarders.

What are the risks associated with over-inflating tires for fuel efficiency?

While maintaining proper tire inflation can enhance fuel efficiency, over-inflating tires poses significant risks. It can lead to decreased traction, uneven tire wear, and an increased likelihood of blowouts, compromising vehicle safety. Furthermore, over-inflated tires do not absorb shocks effectively, potentially damaging the vehicle’s suspension. Therefore, it is essential to adhere to manufacturer-recommended PSI levels to balance fuel efficiency and safety.

How can I educate my team about the importance of tire maintenance for fuel savings?

Educating your team on tire maintenance’s importance can be achieved through training sessions, workshops, or informational materials that outline best practices. Highlight the connection between proper tire inflation and fuel savings, emphasizing the financial benefits for the company. Implement regular maintenance checks and create a schedule for monitoring tire pressure and condition. Encouraging a culture of proactive vehicle maintenance can lead to long-term savings and improved operational efficiency.

Domain: highlandtire.com

Registered: 2000 (25 years)

Introduction: Highland Tire offers a selection of tires including Michelin®, BFGoodrich®, and Uniroyal®. They provide tire services such as tire balancing, wheel alignments, tire installation, and tire repair. Proper tire inflation is emphasized for improving fuel efficiency, handling, stability, reducing tire wear, and increasing tire lifespan.

In conclusion, the importance of properly inflated tires extends beyond mere fuel efficiency; it is a strategic imperative for businesses aiming to optimize operational costs. By maintaining the recommended tire pressure, companies can enhance fuel economy, reduce wear and tear on vehicles, and ultimately lower maintenance expenses. Under-inflated tires significantly diminish gas mileage, while over-inflation poses safety risks and accelerates tire degradation, making adherence to optimal tire pressure essential for vehicle longevity and performance.

Illustrative image related to properly inflated tires help increase gas mileage

International B2B buyers, particularly in emerging markets such as Africa, South America, and the Middle East, should prioritize strategic sourcing of tire maintenance solutions and technologies. Investing in tire pressure monitoring systems and regular maintenance routines can lead to substantial long-term savings and improved fleet efficiency.

As we look to the future, companies that adopt a proactive approach to tire management will not only drive down operational costs but also enhance their sustainability profiles. Embrace these best practices today and position your business for success in an increasingly competitive landscape.

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to properly inflated tires help increase gas mileage

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.