The global market for air up tires presents a unique set of challenges for B2B buyers, particularly those operating in diverse and dynamic regions such as Africa, South America, the Middle East, and Europe. As companies seek to source efficient and reliable air up tire solutions, they often grapple with issues related to product quality, supplier reliability, and cost-effectiveness. This guide serves as a comprehensive resource, addressing these challenges head-on by exploring various types of air up tires, their applications across different industries, and essential criteria for vetting suppliers.

From understanding the technological advancements in tire inflation systems to analyzing market trends that influence pricing, this guide empowers international buyers to make informed purchasing decisions. Whether you are operating in the bustling automotive markets of Nigeria or the emerging economies of Vietnam, the insights provided will help you navigate the complexities of sourcing air up tires.

In this guide, we delve into crucial topics such as the different types of air up tires available, their suitability for various applications, and practical tips for assessing supplier credibility. Additionally, we will discuss cost considerations and strategies for optimizing your procurement process. By equipping yourself with this knowledge, you will be better positioned to enhance your business’s operational efficiency and ensure the safety and performance of your fleet.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Standard Tires | Conventional design, air-filled, various sizes | Commercial vehicles, logistics | Prós: Widely available, cost-effective. Contras: Vulnerable to punctures, requires regular maintenance. |

| Run-Flat Tires | Reinforced sidewalls, allows driving on deflation | Emergency services, delivery vehicles | Prós: Enhanced safety, no immediate need for a spare. Contras: Higher cost, limited availability. |

| All-Season Tires | Versatile tread design for various conditions | Fleet vehicles, transport services | Prós: Year-round usability, good performance. Contras: May not excel in extreme conditions. |

| Off-Road Tires | Aggressive tread patterns for rugged terrain | Construction, agriculture | Prós: Superior traction, durability. Contras: Noisy on highways, lower fuel efficiency. |

| High-Performance Tires | Designed for speed and handling, optimized for grip | Sports cars, racing teams | Prós: Enhanced performance, improved handling. Contras: Higher wear rate, more expensive. |

Standard tires are the most commonly used type, designed to provide a balance of performance, durability, and cost. They are suitable for a wide range of vehicles, including passenger cars and light trucks, making them a staple in fleet operations and logistics companies. B2B buyers should consider factors such as tire longevity and maintenance costs, as these can impact overall operational efficiency. While standard tires are cost-effective, their susceptibility to punctures necessitates regular inspections and maintenance.

Run-flat tires feature reinforced sidewalls that allow vehicles to continue driving even when they are deflated. This attribute is particularly beneficial for emergency services and delivery vehicles, where time is critical. B2B buyers should evaluate the higher upfront costs against the potential savings from reduced downtime and the need for spare tires. While run-flat tires enhance safety and convenience, their limited availability and higher purchase price may be a consideration for some businesses.

Illustrative image related to air up tires

All-season tires are designed to perform well in a variety of weather conditions, making them an ideal choice for fleet vehicles that operate year-round. They offer a good compromise between performance and durability, which is crucial for businesses aiming to minimize tire replacement costs. However, while they provide versatility, B2B buyers should be aware that they may not perform as well in extreme conditions compared to specialized tires, which could affect safety and performance.

Off-road tires are engineered with aggressive tread patterns, making them suitable for rugged terrains encountered in construction and agricultural applications. These tires provide superior traction and durability, essential for vehicles operating in challenging environments. B2B buyers should consider the trade-off between off-road capabilities and highway performance, as off-road tires can be noisier and less fuel-efficient on paved roads. The investment in off-road tires can lead to improved productivity in demanding work conditions.

High-performance tires are designed for superior grip and handling, making them a popular choice for sports cars and racing teams. These tires are engineered to enhance vehicle performance, which can be a critical factor for businesses in the automotive sector focused on speed and agility. However, B2B buyers should be mindful of the increased wear rate and higher costs associated with these tires. Investing in high-performance tires can yield significant advantages in competitive environments, where performance is paramount.

| Indústria/Setor | Specific Application of air up tires | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Automotive Repair | Tire maintenance services for fleets | Extended tire life, improved safety, reduced downtime | Supplier reliability, quality of air compressors, cost-effectiveness |

| Transportation & Logistics | Fleet management for shipping companies | Enhanced fuel efficiency, reduced operational costs | Capacity of inflators, compatibility with various tire types, ease of use |

| Construção | Heavy machinery tire inflation | Increased operational efficiency, minimized equipment failures | Durability of equipment, availability of spare parts, service support |

| Agricultura | Inflation of agricultural vehicles and machinery | Improved traction, reduced soil compaction | Adaptability to different tire sizes, maintenance support, pricing structures |

| Public Transportation | Maintenance of public transit vehicles | Safety assurance, improved passenger comfort | Compliance with safety standards, bulk purchasing options, service contracts |

In the automotive repair industry, air up tires are essential for maintaining the performance and safety of vehicles, particularly for fleet services. Regular tire inflation checks and maintenance can significantly extend tire life, ensuring that vehicles operate efficiently and safely. For B2B buyers in this sector, sourcing reliable suppliers who provide high-quality air compressors and inflation equipment is crucial. They must consider the reliability of these suppliers, the quality of the equipment, and cost-effectiveness to manage operational budgets effectively.

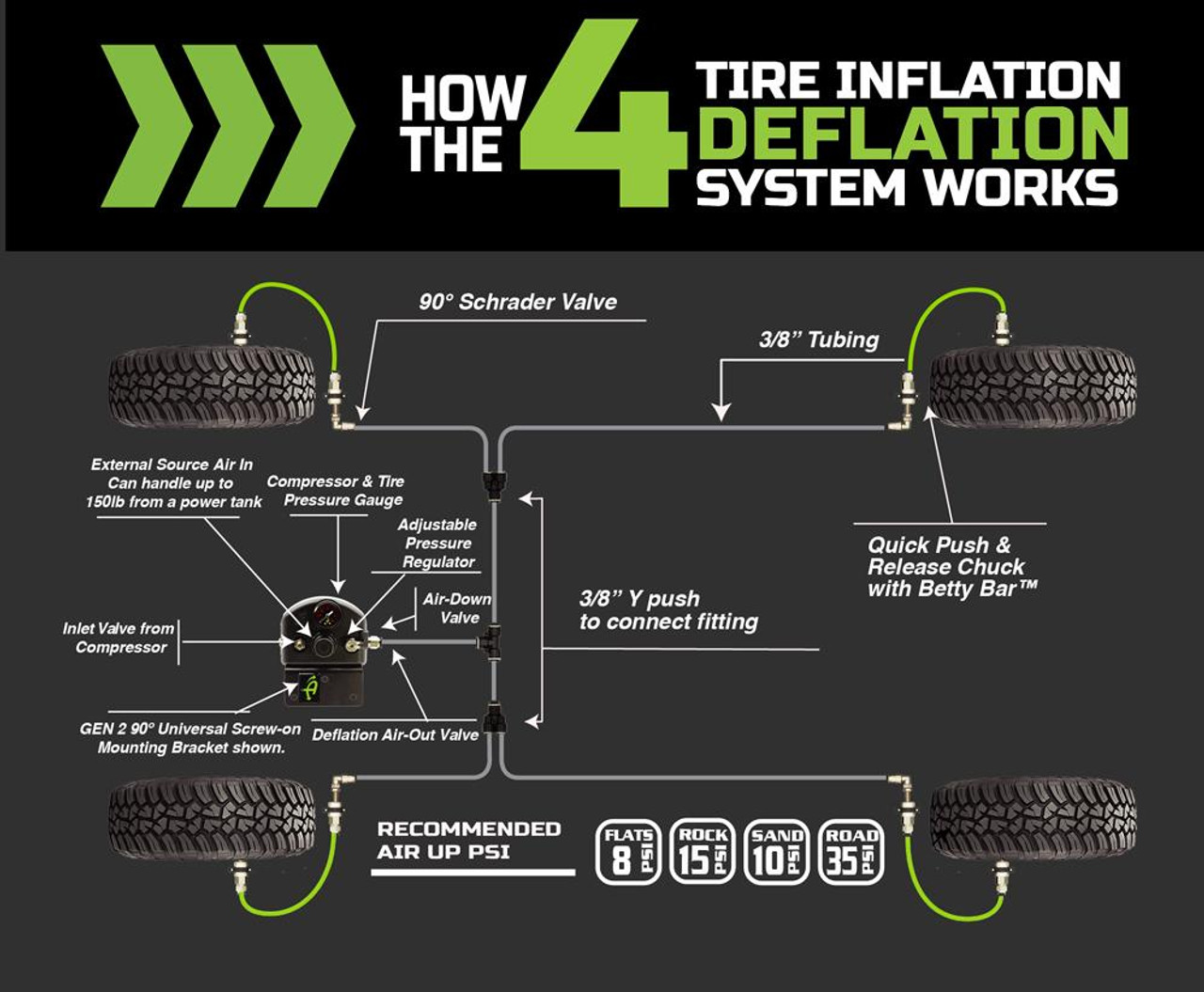

In transportation and logistics, air up tires are vital for fleet management, particularly in shipping companies that rely on heavy-duty vehicles. Properly inflated tires enhance fuel efficiency and reduce operational costs by minimizing rolling resistance. B2B buyers in this sector should focus on the capacity of inflators to handle various tire types and sizes, ensuring compatibility with their fleet. Additionally, ease of use and maintenance support are critical considerations to ensure that tire inflation processes are efficient and do not disrupt logistics operations.

In the construction sector, air up tires are used to inflate tires on heavy machinery and equipment. Proper inflation is essential for maximizing operational efficiency and minimizing equipment failures, which can lead to costly downtime. B2B buyers in this industry should prioritize sourcing durable equipment that can withstand rigorous conditions and ensure availability of spare parts. Furthermore, service support is a key consideration, as timely maintenance can prevent disruptions in construction schedules.

Agricultural vehicles and machinery require proper tire inflation for optimal performance, particularly in maintaining traction and minimizing soil compaction. Air up tires help farmers and agricultural businesses enhance the efficiency of their operations. B2B buyers in this sector should look for inflation solutions that can adapt to various tire sizes used in farming equipment. Maintenance support and competitive pricing structures are also essential factors, as they contribute to the overall cost-effectiveness of agricultural operations.

In public transportation, maintaining the correct tire pressure is crucial for ensuring the safety and comfort of passengers. Air up tires are used to regularly check and inflate the tires of buses and other public transit vehicles. B2B buyers in this industry must ensure compliance with safety standards while considering bulk purchasing options for tire maintenance supplies. Service contracts that offer ongoing support and maintenance are also valuable to guarantee consistent performance and safety for public transit systems.

Illustrative image related to air up tires

O problema: In many regions, particularly in Africa and South America, inconsistent access to reliable tire inflation services can lead to significant operational challenges for businesses relying on vehicle fleets. Fluctuations in ambient temperature can cause tire pressure to drop or rise, leading to under-inflation or over-inflation. This results in decreased fuel efficiency, increased tire wear, and potential safety hazards. Fleet managers often struggle to keep track of the tire pressure across multiple vehicles, especially when drivers do not regularly check tire conditions.

A solução: To effectively manage tire pressure, businesses should invest in a centralized tire management system that includes tire pressure monitoring systems (TPMS) for each vehicle. These systems provide real-time data about tire pressure, alerting fleet managers and drivers when adjustments are needed. Additionally, educating drivers on the importance of checking tire pressure regularly, especially before long trips, can be invaluable. To further enhance tire care, establishing partnerships with local service stations for scheduled tire pressure checks can ensure that vehicles are always operating at optimal levels, minimizing downtime and maximizing safety.

O problema: B2B buyers managing logistics and transportation services often face the financial burden of frequent tire repairs due to improper inflation. Inconsistent tire pressure can lead to uneven tire wear, causing premature tire failures. This not only incurs direct costs related to tire replacement but also indirect costs from vehicle downtime and delays in delivery schedules. For companies in competitive markets, these delays can severely impact customer satisfaction and retention.

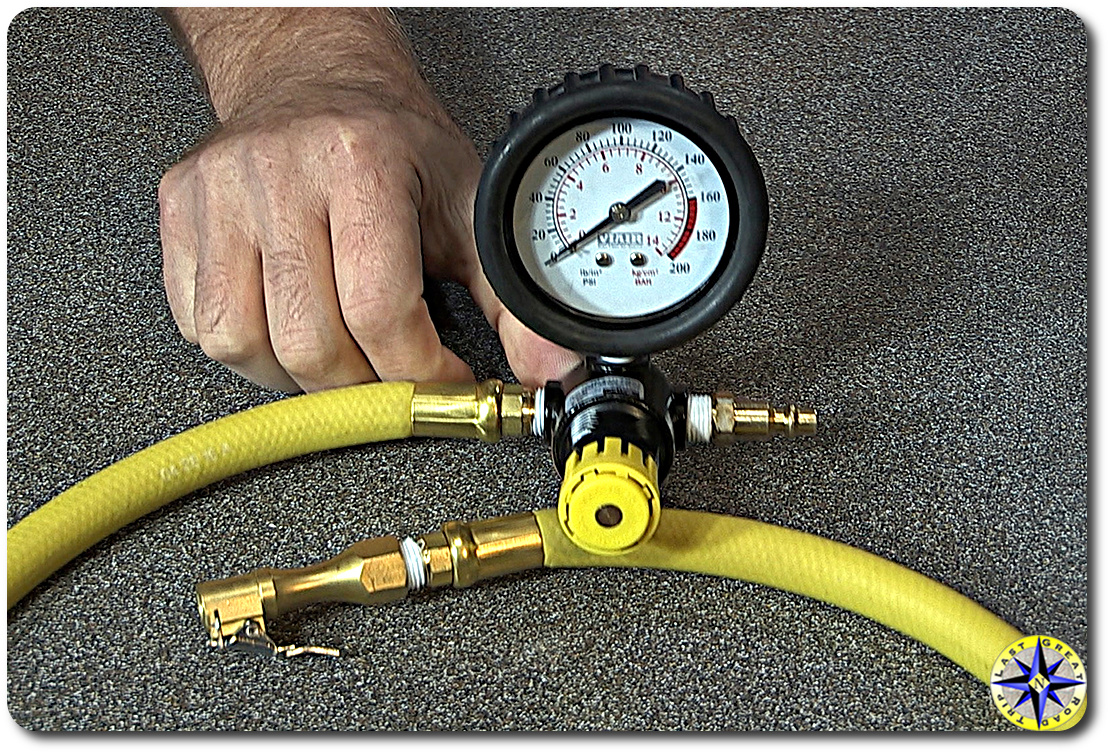

A solução: Implementing a proactive tire maintenance strategy is crucial. Companies should conduct regular tire inspections and maintenance routines that emphasize proper inflation techniques. Investing in high-quality, portable air compressors can allow drivers to inflate tires conveniently at any location, reducing reliance on external service stations. Additionally, training staff on best practices for tire inflation—including checking pressures when tires are cold and using a reliable tire gauge—will enhance tire longevity. Establishing a budget for tire maintenance and repairs, along with tracking tire performance data, can also help in forecasting costs and optimizing fleet operations.

O problema: In many regions, particularly in the Middle East and parts of Africa, businesses face a significant challenge due to limited access to tire inflation resources. Remote locations may lack adequate service stations or air pumps, resulting in delays for fleets that require immediate tire maintenance. This can lead to a frustrating cycle of downtime and inefficiency, where vehicles are unable to operate effectively due to under-inflated tires.

A solução: To mitigate this issue, businesses should consider investing in portable tire inflators that can easily be stored in vehicles. These inflators can be powered through various sources, including vehicle batteries, making them versatile for use in remote locations. Additionally, establishing a network of partnerships with local automotive service providers can create a safety net for on-the-road assistance. Training employees on how to use these portable devices effectively, as well as implementing a routine check-up protocol for tire pressure before starting any journey, can further enhance fleet reliability and reduce the risk of operational disruptions.

By addressing these pain points with proactive solutions, B2B buyers can enhance their operational efficiency, reduce costs, and improve overall vehicle safety and performance.

When selecting materials for air up tires, several options are commonly used in the industry. Each material comes with distinct properties, advantages, and limitations that can significantly impact performance and suitability for various applications. Understanding these factors is essential for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Illustrative image related to air up tires

Rubber compounds are the most prevalent material used in tire manufacturing due to their elasticity and durability. The key properties of rubber include excellent flexibility, temperature resistance, and the ability to withstand high pressure. Additionally, rubber can be formulated to enhance its resistance to wear and tear, making it suitable for various driving conditions.

Pros and Cons: The primary advantage of rubber is its durability and performance under a range of environmental conditions. However, it can be sensitive to extreme temperatures and UV exposure, leading to degradation over time. The manufacturing complexity can vary based on the specific formulation, which may affect costs.

Impacto no aplicativo: Rubber is compatible with various media, including air and moisture, making it ideal for air-filled tires. However, buyers should consider the local climate conditions, as extreme heat or cold can affect tire performance.

Considerações para compradores internacionais: Compliance with local standards such as ASTM or DIN is crucial. Buyers in regions like Africa and South America should also consider the availability of high-quality rubber compounds to ensure optimal performance.

Synthetic polymers, such as styrene-butadiene rubber (SBR) and polyisoprene, are increasingly used in tire manufacturing due to their enhanced performance characteristics. These materials offer improved resistance to aging, ozone, and chemicals, which can be beneficial in harsh environments.

Pros and Cons: The key advantage of synthetic polymers is their consistent quality and performance, which can lead to longer tire life. However, they can be more expensive than natural rubber and may require specialized manufacturing processes, increasing overall production costs.

Impacto no aplicativo: Synthetic polymers are compatible with air and can provide better performance in high-pressure scenarios, making them suitable for high-performance tires.

Considerações para compradores internacionais: Buyers should be aware of regional preferences for synthetic versus natural materials, as well as any regulatory requirements related to their use.

Steel belts are often incorporated into tire construction to provide structural integrity and enhance performance. The key properties of steel include high tensile strength and resistance to deformation, which are critical for maintaining tire shape under load.

Pros and Cons: The primary advantage of steel belts is their ability to improve handling and stability, especially at high speeds. However, they can add weight to the tire, potentially affecting fuel efficiency. Additionally, the manufacturing process for steel belts can be more complex, impacting costs.

Impacto no aplicativo: Steel belts are particularly suited for heavy-duty applications, such as trucks and SUVs, where load-bearing capacity is essential.

Considerações para compradores internacionais: Compliance with international standards for steel quality and manufacturing processes is critical. Buyers should also consider the local availability of steel and potential tariffs or import duties.

Composite materials, which combine different materials to leverage their strengths, are gaining traction in tire manufacturing. These can include a mix of rubber, polymers, and reinforcing materials like aramid or carbon fiber.

Illustrative image related to air up tires

Pros and Cons: The key advantage of composites is their ability to provide a balance of performance characteristics, such as weight reduction and enhanced durability. However, they can be costly and may require advanced manufacturing techniques.

Impacto no aplicativo: Composites can offer improved performance in specialized applications, such as racing or off-road tires, where weight and strength are critical.

Considerações para compradores internacionais: Buyers should be aware of the technological capabilities of local manufacturers to produce composite materials and the associated costs.

| Material | Typical Use Case for air up tires | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Rubber Compounds | Standard passenger and light truck tires | Excellent flexibility and durability | Sensitive to extreme temperatures | Médio |

| Synthetic Polymers | High-performance and specialty tires | Enhanced resistance to aging and chemicals | Higher cost than natural rubber | Alta |

| Steel Belts | Heavy-duty and performance tires | Improved handling and stability | Adds weight, complex manufacturing | Médio |

| Materiais compostos | Racing and specialized off-road tires | Balance of performance characteristics | Costly and requires advanced manufacturing | Alta |

This guide provides a comprehensive overview of the materials used in air up tires, helping international B2B buyers make informed decisions based on performance, cost, and regional considerations.

The manufacturing of air up tires involves several key stages, each critical to ensuring the product’s performance, safety, and durability. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to air up tires

The first stage is material preparation, where raw materials such as rubber compounds, fabric, and steel are sourced. High-quality synthetic and natural rubber is blended with additives to enhance properties like durability and resistance to wear. This rubber compound is often tested for elasticity and strength before moving on to the next stage. Additionally, fabric and steel reinforcements are treated to ensure optimal adhesion and performance under load.

Once materials are prepared, the forming stage begins. This typically involves the use of specialized machinery that shapes the rubber into tire components, including the tread, sidewalls, and inner linings. Techniques such as extrusion and molding are commonly employed. In extrusion, heated rubber is forced through a die to create long strips, while molding involves placing pre-measured rubber into a mold that shapes it into a tire. Each component undergoes precise temperature and pressure control to ensure consistency and quality.

The assembly stage combines all the individual components into a complete tire. This involves layering the different rubber components and integrating the steel belts and fabric. Automated systems often assist in this process to ensure precision in alignment and bonding. Once assembled, the tires are inflated to check for any leaks, a critical step in maintaining tire integrity.

Illustrative image related to air up tires

The final stage is finishing, which includes curing the tires in a controlled environment. Curing, or vulcanization, involves heating the assembled tire to set its shape and enhance its durability. After curing, tires are inspected for defects, and surface treatments may be applied to improve aesthetics and performance. This stage often includes balancing and alignment checks to ensure optimal performance during operation.

Quality assurance (QA) is paramount in the tire manufacturing process to ensure safety and performance. Various international standards guide these processes, with ISO 9001 being one of the most recognized. This standard focuses on maintaining a quality management system that ensures consistent product quality and customer satisfaction.

In addition to ISO certifications, industry-specific standards such as the European CE marking and the American API certification are crucial. These certifications indicate that the product meets specific safety and performance criteria relevant to the respective markets. For B2B buyers, verifying these certifications can provide assurance of product quality and compliance with regional regulations.

Quality control (QC) involves several checkpoints throughout the manufacturing process to identify and address defects early. Key checkpoints include:

Testing methods for air up tires are diverse and include:

These tests are critical for ensuring that the tires perform as expected in real-world conditions.

For B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is vital. Here are several methods to achieve this:

Illustrative image related to air up tires

International B2B buyers must navigate various certification and quality nuances based on regional regulations and market expectations. For instance, while some countries may prioritize CE marking, others may focus on local certifications. Understanding these differences is crucial for ensuring compliance and avoiding potential market entry barriers.

Additionally, buyers should be aware of the implications of sourcing from different regions. For example, suppliers in Europe may have stricter regulations compared to those in other regions, impacting the QC measures in place. As such, it is advisable for buyers to engage with suppliers who have a proven track record of meeting international standards and maintaining high-quality manufacturing processes.

In summary, the manufacturing processes and quality assurance practices for air up tires are comprehensive and critical for ensuring product reliability and safety. By understanding the manufacturing stages, quality control checkpoints, testing methods, and certification requirements, B2B buyers can make informed decisions when sourcing tires. This knowledge not only enhances procurement strategies but also fosters long-term partnerships with reliable suppliers in the global market.

Illustrative image related to air up tires

To assist B2B buyers in the procurement of tire inflation solutions, this guide provides a structured checklist to ensure effective sourcing. Whether you are looking to purchase air compressors, tire inflators, or related services, this checklist will help you navigate the essential steps involved in making informed purchasing decisions.

Understanding your unique requirements is the first step in the procurement process. Consider factors such as the types of vehicles you service (cars, trucks, etc.), the volume of tires you need to inflate, and the environment (workshop, roadside assistance). This clarity will help you target suppliers that specialize in your specific needs.

Conduct thorough research on the various tire inflation products available in the market. Look for both portable and stationary air compressors, ensuring you understand their capabilities, such as PSI ratings and air flow rates. Additionally, consider the energy source (electric, battery-operated, or manual) that best fits your operational context.

Before making a purchase, it’s crucial to vet potential suppliers comprehensively. Request company profiles, product specifications, and customer testimonials. Pay attention to suppliers that demonstrate experience in your industry or region, as they are likely to understand specific challenges and requirements.

Illustrative image related to air up tires

Pricing can vary widely based on quality, brand, and features. Request detailed quotations from multiple suppliers, ensuring they include all associated costs such as shipping, installation, and after-sales support. This transparency will allow for better comparisons and budget management.

A reliable warranty can be a significant factor in your purchasing decision. Ensure the products come with a comprehensive warranty that covers parts and labor. Additionally, assess the supplier’s customer support services to guarantee assistance is available when needed.

Consider the logistics of installation and ongoing maintenance of the tire inflation systems. Determine whether the supplier offers installation services or if you will need to manage this internally. Regular maintenance is vital for longevity and efficiency, so ensure you understand the requirements and costs associated with it.

Illustrative image related to air up tires

After evaluating all factors, make an informed decision and proceed with the order. Ensure that you have a clear understanding of the delivery timeline and any training or support that will be provided post-purchase.

By following this checklist, B2B buyers can streamline their procurement process for tire inflation solutions, ensuring they select the best products and suppliers to meet their operational needs.

Understanding the cost structure for sourcing air up tires is crucial for international B2B buyers looking to optimize their procurement process. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and margin.

Materiais: The raw materials for air up tires generally include synthetic rubber, fabric, and steel wires. Prices can fluctuate based on global supply chain dynamics and market demand. Buyers should consider sourcing from regions with abundant raw materials to mitigate costs.

Trabalho: Labor costs vary significantly across different countries. In regions such as Africa and South America, labor costs may be lower, which can be an advantage for manufacturers. However, it’s essential to ensure that the labor force is skilled enough to meet quality standards.

Custos indiretos de fabricação: This includes costs associated with facility maintenance, utilities, and indirect labor. Efficient manufacturing processes can help reduce overhead costs, which is beneficial for both manufacturers and buyers.

Ferramentas: Custom tooling can be a significant upfront cost, especially for specialized tire designs. Buyers should evaluate whether the investment in custom tooling aligns with their long-term purchasing plans.

Controle de qualidade (QC): Implementing robust QC processes ensures that the tires meet international standards, which can prevent costly recalls or defects. Buyers should inquire about the supplier’s QC certifications to ensure product reliability.

Logística: Shipping and handling costs can vary based on distance, shipping methods, and Incoterms. For international buyers, understanding the logistics involved in transporting tires, including tariffs and duties, is essential for accurate cost estimation.

Margem: Suppliers will add a margin to cover their costs and ensure profitability. This margin can vary based on the supplier’s market position, brand reputation, and customer relationships.

Several factors can influence the pricing of air up tires, particularly for international buyers:

Volume e quantidade mínima de pedidos (MOQ): Larger orders typically lead to lower per-unit costs. Buyers should assess their purchasing volume and negotiate favorable terms based on projected sales.

Especificações e personalização: Custom tire specifications can lead to increased costs due to specialized materials or manufacturing processes. Buyers must weigh the benefits of customization against potential cost increases.

Qualidade do material e certificações: Higher quality materials and certifications (such as ISO or DOT) can justify a higher price. Buyers should consider the long-term benefits of investing in higher quality tires, which may lead to lower total ownership costs.

Fatores do fornecedor: The supplier’s reputation, reliability, and production capabilities can significantly impact pricing. Establishing relationships with trusted suppliers can lead to better pricing and terms.

Incoterms: Understanding the terms of sale (e.g., FOB, CIF) is crucial for calculating total costs. Buyers should clarify responsibility for shipping, insurance, and duties to avoid unexpected expenses.

To effectively manage sourcing costs, international B2B buyers should consider the following strategies:

Negociação: Don’t hesitate to negotiate pricing and terms. Building a strong rapport with suppliers can lead to more favorable deals.

Eficiência de custo: Regularly review and assess the total cost of ownership, including maintenance and replacement costs, to identify potential savings.

Nuances de preços para compradores internacionais: Be aware of currency fluctuations and geopolitical factors that may impact pricing. Establishing contracts in stable currencies can mitigate risk.

Local Market Knowledge: Understanding regional market dynamics in Africa, South America, the Middle East, and Europe can provide insights into pricing trends and supplier capabilities.

Prices are indicative and can vary based on market conditions, supplier negotiations, and other factors. Buyers are encouraged to conduct thorough research and engage in discussions with multiple suppliers to secure the best possible terms.

When evaluating tire solutions, it’s essential to consider alternatives that can meet similar needs while offering distinct benefits and drawbacks. Below is a comparison of ‘air up tires’ with two viable alternatives: traditional air-filled tires and self-sealing tires. This analysis will help B2B buyers make informed decisions tailored to their operational requirements.

| Aspecto de comparação | Air Up Tires | Traditional Air-Filled Tires | Self-Sealing Tires |

|---|---|---|---|

| Desempenho | Offers adjustable pressure control and improved fuel efficiency | Standard performance; pressure must be manually maintained | Automatically seals punctures, reducing downtime |

| Custo | Generally higher initial investment, but potential long-term savings on fuel and maintenance | Lower initial cost, but ongoing costs for air filling and maintenance | Moderate cost; may require occasional replacements |

| Facilidade de implementação | Requires specialized equipment for installation and maintenance | Widely available and easy to implement | Installation may require specialized knowledge |

| Manutenção | Needs regular monitoring and occasional adjustments; more complex | Requires consistent air pressure checks and maintenance | Minimal maintenance; self-sealing feature reduces need for frequent checks |

| Melhor caso de uso | Ideal for businesses needing flexible tire pressure for varying loads | Suitable for standard vehicles and applications | Best for fleets operating in puncture-prone areas |

Traditional air-filled tires are the most common type, widely utilized in various vehicles. Their primary advantage lies in their lower initial cost, making them accessible for businesses with budget constraints. However, they require regular maintenance, including checks for air pressure, which can be time-consuming. Additionally, improper inflation can lead to decreased performance and safety risks.

Self-sealing tires come with an internal sealant that automatically fills small punctures, significantly minimizing downtime and maintenance needs. This technology is particularly beneficial for fleets operating in areas with a high risk of tire damage. While they can be more expensive than traditional tires, their self-maintaining aspect can lead to cost savings over time. However, they may not offer the same level of adjustability in tire pressure as air up tires.

Selecting the most suitable tire solution requires a thorough understanding of your operational context. B2B buyers should consider factors such as the typical terrain, load requirements, and frequency of tire maintenance. For businesses operating in diverse environments where tire pressure adjustments are critical, air up tires may be the ideal choice. Conversely, companies looking for cost-effective solutions with minimal maintenance might prefer traditional air-filled tires or self-sealing options. By aligning the tire solution with operational needs, businesses can enhance their vehicle performance and reduce long-term costs.

When considering air up tires, several critical specifications must be evaluated to ensure optimal performance and safety. Understanding these properties not only aids in selecting the right product but also helps in negotiating and maintaining quality standards.

Air up tires are typically made from a combination of synthetic rubber and natural rubber, which offers durability and flexibility. The material grade can significantly affect tire performance, including wear resistance, traction, and heat dissipation. For B2B buyers, selecting tires with higher material grades can lead to reduced maintenance costs and longer lifespan, translating into better ROI.

This specification indicates the maximum air pressure that a tire can safely handle. TPR is vital for ensuring that the tires operate efficiently under various load conditions. Under-inflated or over-inflated tires can lead to poor handling, increased wear, and even tire failure. B2B buyers should ensure that the tires they procure meet or exceed the TPR recommended by vehicle manufacturers to enhance safety and performance.

The load index specifies the maximum load a tire can carry while maintaining the recommended air pressure. This is crucial for businesses involved in logistics or transportation, as it directly impacts vehicle capacity and efficiency. Choosing tires with an appropriate load index can prevent premature wear and potential accidents, making it a critical factor in procurement decisions.

The aspect ratio is the ratio of the tire’s sidewall height to its width. A lower aspect ratio generally indicates a wider tire that can provide better handling and stability, particularly for high-performance vehicles. B2B buyers should consider aspect ratios that align with their operational needs, whether for everyday transportation or specialized applications.

The tread pattern affects traction, handling, and noise levels. Different patterns are designed for various terrains and weather conditions. For instance, all-terrain tires have a more aggressive tread for off-road capabilities, while highway tires offer smoother rides on paved roads. Understanding the implications of tread patterns can help businesses choose tires that optimize vehicle performance in specific environments.

Familiarity with industry terminology is essential for effective communication and negotiation in tire procurement. Here are some common trade terms that B2B buyers should understand:

This term refers to companies that manufacture products that are used as components in another company’s product. For air up tires, OEM specifications are critical as they define the quality and performance standards required for vehicles. Buyers often seek OEM tires to ensure compatibility and reliability.

Illustrative image related to air up tires

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory levels and cash flow. Buyers should negotiate MOQs that align with their purchasing needs while considering storage and demand forecasts.

An RFQ is a document that businesses send to suppliers to solicit price quotes for specific products or services. It typically includes detailed specifications, quantities, and delivery requirements. Preparing a comprehensive RFQ can facilitate better pricing and terms, enabling buyers to make informed procurement decisions.

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping contracts. Familiarity with Incoterms helps B2B buyers understand cost responsibilities, risk transfer, and delivery obligations, which are essential for international transactions.

This term refers to the depth of the grooves in a tire’s tread. Tread depth is critical for safety, as it affects traction and water dispersion. Buyers should ensure that tires meet minimum tread depth requirements to maintain safety and performance standards.

Understanding these technical properties and trade terms will empower B2B buyers in making informed decisions regarding air up tires, ultimately enhancing operational efficiency and safety.

The air up tires market is currently experiencing notable growth driven by several global factors. The increasing demand for sustainable and efficient transportation solutions is a primary driver, particularly in regions like Africa, South America, and the Middle East, where urbanization and vehicle ownership are on the rise. Furthermore, innovations in tire technology, such as self-inflating systems and smart tires equipped with sensors, are gaining traction among B2B buyers who prioritize performance and safety in their fleet management.

Emerging sourcing trends include the adoption of digital platforms for procurement and inventory management. Buyers are increasingly utilizing online marketplaces to compare suppliers, analyze pricing, and streamline their supply chains. This trend is particularly pronounced in regions with developing logistics infrastructures, such as Nigeria and Vietnam, where digital solutions can enhance access to high-quality products and services. Additionally, collaborations between manufacturers and tech companies are becoming common, as they seek to integrate advanced analytics and IoT capabilities into tire production and maintenance processes.

Sustainability is becoming a pivotal concern for B2B buyers in the air up tires sector. Environmental impacts associated with tire production and disposal have prompted a shift toward ethical sourcing practices. Companies are increasingly focused on sourcing materials that are recyclable or derived from sustainable resources, such as bio-based rubbers or recycled plastics. This not only minimizes environmental footprints but also aligns with global sustainability goals, appealing to eco-conscious consumers and businesses alike.

Illustrative image related to air up tires

Moreover, certification for ‘green’ materials is gaining importance in procurement decisions. B2B buyers are now seeking suppliers who provide transparency in their supply chains and possess certifications that demonstrate compliance with environmental standards. This includes looking for products with certifications like ISO 14001 for environmental management or those labeled as ‘eco-friendly’ or ‘sustainable.’ Such certifications not only enhance a company’s brand image but also mitigate risks associated with regulatory compliance and consumer backlash over environmental issues.

The evolution of air up tires can be traced back to the early 20th century when pneumatic tires began to replace solid rubber tires due to their superior performance and comfort. As vehicle technology advanced, the need for enhanced safety and efficiency in tire performance became paramount. The introduction of air up tires revolutionized the industry by providing a solution that combined improved grip, reduced rolling resistance, and better fuel efficiency.

Over the decades, air up tires have undergone significant transformations, incorporating advancements such as run-flat technology and smart sensors. These innovations have not only enhanced user safety but also attracted the attention of B2B buyers looking for high-performance solutions for their fleets. Today, the focus on sustainability and technological integration continues to shape the development of air up tires, making them a critical component in the future of transportation logistics and fleet management.

Illustrative image related to air up tires

How do I ensure the quality of air up tires before purchasing?

To ensure the quality of air up tires, start by vetting suppliers thoroughly. Request product samples to evaluate durability and performance. Check for compliance with international safety and quality standards, such as ISO certifications. Customer reviews and testimonials can provide insights into reliability. Additionally, consider visiting the supplier’s manufacturing facility, if feasible, to assess their processes and quality control measures.

What is the best air pressure for air up tires?

The optimal air pressure for air up tires varies by manufacturer and tire model. It’s essential to refer to the specifications provided by the tire manufacturer, typically found on the sidewall of the tire or within the vehicle’s manual. Maintaining the correct air pressure is crucial for performance, fuel efficiency, and tire longevity. Regularly check tire pressure, especially in regions with fluctuating temperatures, to ensure optimal performance.

What are the minimum order quantities (MOQ) for air up tires?

Minimum order quantities (MOQ) for air up tires can differ significantly between suppliers. Typically, MOQs can range from a few dozen to several hundred units, depending on the supplier’s production capabilities and your negotiation. When sourcing, it’s beneficial to discuss your specific needs and explore options for bulk purchasing, which may lead to better pricing and terms.

What payment terms should I expect when sourcing air up tires internationally?

Payment terms for international purchases of air up tires can vary widely, often influenced by the supplier’s policies and your negotiation power. Common terms include upfront payment, partial payments with balance upon delivery, or letters of credit. It’s advisable to establish clear terms before finalizing any agreement to mitigate risks. Be mindful of currency exchange rates and transaction fees, which can affect the overall cost.

How can I customize air up tires for my business needs?

Many suppliers offer customization options for air up tires, including branding, tread patterns, and sizes. To initiate customization, communicate your specific requirements to potential suppliers during the negotiation phase. Ensure they have the capability to produce customized products and discuss any minimums or additional costs associated with these modifications. Request prototypes to verify that the final product meets your expectations.

What logistics considerations should I keep in mind when importing air up tires?

When importing air up tires, consider several logistics factors, including shipping methods, costs, and lead times. Choose a reliable freight forwarder familiar with the import regulations of your destination country. Be aware of customs duties and taxes that may apply. Proper packaging is essential to prevent damage during transit. Also, confirm that the supplier adheres to international shipping standards to ensure compliance.

What should I know about quality assurance (QA) processes for air up tires?

Quality assurance (QA) processes are crucial in ensuring the reliability of air up tires. Inquire about the supplier’s QA protocols, including testing methods for durability, performance, and safety. Request documentation of their testing results and certifications. Establish a clear understanding of their return and warranty policies in case the tires do not meet your standards or specifications.

How do I handle disputes with suppliers of air up tires?

Handling disputes with suppliers requires a structured approach. Begin by reviewing the terms of your contract to understand your rights and obligations. Maintain open communication with the supplier to resolve issues amicably. If necessary, escalate the matter to mediation or arbitration, as outlined in your agreement. Keeping detailed records of all communications and transactions can support your case if formal dispute resolution becomes necessary.

Domínio: freeairpump.com

Registrado: 2012 (13 anos)

Introdução: Map of places that provide free air for tires; over 12k locations in the U.S.; user-generated database; ability to submit new locations; search by device location or address; indicates bike repair stations and free air for autos; suggests portable air compressors as an alternative; mentions common places offering free air: tire shops, car repair stations, bike shops, and specific gas station chain…

Domínio: acg.aaa.com

Registered: 1990 (35 years)

Introdução: AAA Auto Club Group provides services in Colorado, Florida, Georgia, Illinois, Indiana, Iowa, Michigan, Minnesota, Nebraska, North Carolina, North Dakota, Puerto Rico, South Carolina, Tennessee, and Wisconsin. The guide emphasizes the importance of maintaining correct tire pressure for vehicle safety, fuel efficiency, and performance. Key tools needed include a tire pressure gauge, knowledge of ve…

Domínio: goodyearautoservice.com

Registrado: 2006 (19 anos)

Introdução: Proper tire inflation is critical for overall performance, safety, and tire longevity. Recommended air pressure is specified by the vehicle’s manufacturer and can be found on the vehicle door edge, door jamb, glove box door, or fuel door, as well as in the owner’s manual. It is important to check tire pressure when tires are cool, as heat from driving can increase pressure. The process includes re…

In the rapidly evolving landscape of tire technology, strategic sourcing of air up tires presents a unique opportunity for international B2B buyers. By emphasizing the importance of proper tire inflation, businesses can not only enhance vehicle safety and performance but also significantly extend the lifespan of their tire inventory. This proactive approach to tire management is crucial in regions such as Africa, South America, the Middle East, and Europe, where varying climates can impact tire performance.

Buyers should focus on sourcing high-quality air up tires from reputable manufacturers to ensure reliability and compliance with local regulations. Establishing partnerships with suppliers who offer comprehensive support, including maintenance and inflation services, can further bolster operational efficiency. Additionally, exploring innovative solutions like portable air compressors can empower businesses to maintain optimal tire pressure, thereby improving overall fleet performance.

As we look to the future, the demand for advanced tire technologies will only grow. Now is the time to invest in strategic sourcing initiatives that align with market trends and consumer expectations. By prioritizing these efforts, B2B buyers can position themselves at the forefront of the tire industry, ensuring competitive advantage and sustainable growth.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Illustrative image related to air up tires

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.