Navigating the global market for inflated tires presents unique challenges for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. With the increasing demand for vehicle safety and efficiency, sourcing high-quality inflated tires that meet both performance and regulatory standards is crucial. However, the complexities of varying tire specifications, local market conditions, and supplier reliability can make informed purchasing decisions daunting.

This comprehensive guide delves into the multifaceted world of inflated tires, providing insights into different types, applications, and the critical factors to consider when vetting suppliers. We will explore the nuances of tire inflation, the risks associated with over and underinflation, and how these can impact vehicle performance and safety. Furthermore, we will discuss cost considerations, including how to balance quality with budget constraints, ensuring that you make sound financial decisions.

By equipping international B2B buyers with actionable strategies and essential knowledge, this guide empowers you to navigate the complexities of the inflated tire market confidently. Whether you’re sourcing for fleet management, transportation services, or automotive manufacturing, understanding these dynamics will enhance your procurement process, ensuring that you secure the best products for your needs while mitigating potential risks.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Standard Pneumatic Tires | Conventional tires inflated with air | Passenger vehicles, light trucks | Prós: Widely available, cost-effective. Contras: Prone to punctures and pressure loss. |

| Run-Flat Tires | Designed to be driven on after a puncture | Emergency services, delivery vans | Prós: Enhanced safety, no immediate need for change. Contras: Heavier, often pricier. |

| Low-Profile Tires | Shorter sidewalls for improved handling | Sports cars, performance vehicles | Prós: Better traction, enhanced aesthetics. Contras: Less comfort, more susceptible to damage. |

| All-Season Tires | Versatile tires for various weather conditions | Fleet vehicles, general use | Prós: Year-round usability, balanced performance. Contras: May compromise on extreme conditions. |

| Off-Road Tires | Aggressive tread patterns for rugged terrain | Construction, agriculture | Prós: Superior traction, durability. Contras: Noisy on highways, reduced fuel efficiency. |

Standard pneumatic tires are the most common type of tires used in passenger vehicles and light trucks. They are filled with air to provide cushioning and traction. Their widespread availability and cost-effectiveness make them an attractive option for businesses operating fleets of vehicles. However, their susceptibility to punctures and pressure loss can lead to increased maintenance costs, a crucial consideration for B2B buyers aiming for operational efficiency.

Run-flat tires are engineered to allow vehicles to continue driving for a limited distance after suffering a puncture. This feature is particularly beneficial for emergency services and delivery vans, where immediate tire replacement might not be feasible. While they provide enhanced safety and reduce downtime, buyers should consider their higher cost and increased weight, which may impact fuel efficiency.

Illustrative image related to inflated tires

Low-profile tires feature shorter sidewalls, which improve handling and stability, making them ideal for sports cars and performance vehicles. Businesses involved in the automotive sector, such as car rental services or performance car dealerships, may find these tires appealing. However, while they offer better traction and a sleek look, they can compromise ride comfort and are more prone to damage from road hazards.

All-season tires are designed to perform well in various weather conditions, making them a versatile choice for fleet vehicles. They provide balanced performance, which can be cost-effective for businesses looking to simplify their tire inventory. However, B2B buyers should be aware that while all-season tires are convenient, they may not perform optimally in extreme weather, necessitating seasonal changes for specific applications.

Off-road tires are characterized by their aggressive tread patterns, designed for rugged terrain and challenging conditions. They are essential for industries such as construction and agriculture, where traction and durability are paramount. While they excel in off-road conditions, businesses should consider their noise levels on highways and potential impacts on fuel efficiency when integrating these tires into their operations.

| Indústria/Setor | Specific Application of inflated tires | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Transportation | Fleet Management for Commercial Vehicles | Improved fuel efficiency and reduced maintenance costs | Reliable suppliers with quality assurance and certifications |

| Agricultura | Agricultural Machinery and Equipment | Enhanced traction and stability on uneven terrain | Sourcing durable tires that withstand harsh conditions |

| Construção | Heavy-Duty Construction Equipment | Increased safety and reduced risk of equipment downtime | Tires designed for load-bearing and rough terrain |

| Mining | Off-Road Vehicles in Mining Operations | Enhanced durability and resistance to punctures | Specialty tires with robust materials for extreme conditions |

| Logistics & Warehousing | Material Handling Equipment (e.g., forklifts) | Improved operational efficiency and reduced operational costs | Tires with specific load ratings and compatibility |

In the transportation sector, inflated tires are crucial for fleet management, especially for commercial vehicles. Properly inflated tires enhance fuel efficiency, leading to significant cost savings over time. Additionally, they reduce uneven tread wear, which can lead to frequent replacements and maintenance costs. International buyers should prioritize suppliers who provide high-quality tires with accurate pressure ratings, as well as those who offer ongoing support and monitoring solutions to maintain optimal tire performance across diverse climates and road conditions.

Agricultural machinery relies heavily on inflated tires for effective performance on varied terrains. Proper tire inflation ensures enhanced traction and stability, which are vital for heavy equipment operating in muddy or uneven fields. This is particularly important for international buyers from regions with challenging agricultural landscapes. Sourcing durable tires that can withstand harsh conditions, such as high loads and rough surfaces, is essential for minimizing downtime and maximizing productivity in agricultural operations.

In the construction industry, inflated tires are critical for heavy-duty equipment, such as bulldozers and excavators. Proper tire inflation contributes to increased safety by providing better handling and stability, which is crucial on construction sites where uneven surfaces are common. Additionally, well-maintained tires reduce the risk of blowouts and equipment failures. Buyers in this sector should focus on sourcing tires that are specifically designed for load-bearing applications and can handle the rigors of construction environments, ensuring compliance with safety standards.

In the mining sector, inflated tires are essential for off-road vehicles that navigate rugged terrains. The durability and puncture resistance of these tires are paramount, as they encounter sharp rocks and uneven surfaces. Properly inflated tires not only enhance the vehicle’s performance but also minimize the risk of accidents and downtime due to tire failures. For international buyers, sourcing specialty tires that meet the specific demands of mining operations is crucial, particularly those that comply with local regulations and environmental standards.

In logistics and warehousing, inflated tires are vital for material handling equipment, including forklifts and pallet jacks. Proper tire inflation improves operational efficiency, allowing for smoother and safer transport of goods. This can lead to reduced operational costs and increased productivity. Buyers in this sector should consider tires with specific load ratings and compatibility with their equipment, ensuring that they can handle the demands of high-volume operations while adhering to safety regulations.

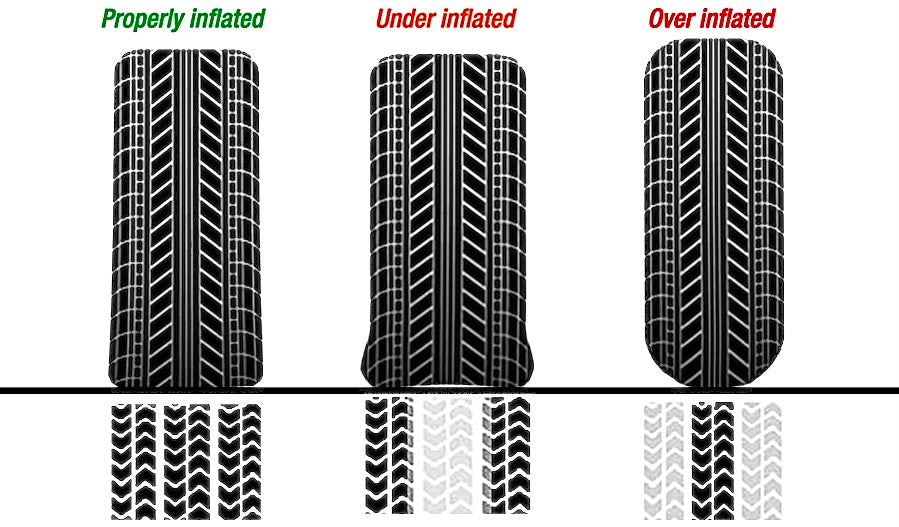

O problema: For businesses that rely on a fleet of vehicles, the cost implications of uneven tire wear can be substantial. When tires are not inflated correctly, they wear unevenly, leading to premature replacements and unexpected downtime. This not only disrupts operations but also significantly increases maintenance costs. Fleet managers may find it challenging to monitor tire conditions across multiple vehicles, especially when drivers are not trained to recognize signs of improper inflation. This scenario is particularly pressing in regions with variable climates, where temperature fluctuations can cause tire pressure to change dramatically.

A solução: To mitigate uneven tire wear, fleet managers should implement a systematic tire maintenance program. This includes regular tire pressure checks, ideally using high-quality, calibrated gauges, and establishing a routine schedule for inspections. Investing in a centralized monitoring system can also streamline this process, allowing managers to track tire pressure across the fleet in real time. Moreover, training drivers to recognize signs of tire wear and providing them with guidelines for maintaining correct pressure can empower them to contribute to the overall health of the fleet. By adhering to the manufacturer’s recommended tire pressure and adjusting for temperature changes, businesses can extend tire lifespan and reduce costs.

O problema: In the logistics and transport sector, the safety of drivers and cargo is paramount. Overinflated or underinflated tires can significantly increase the risk of blowouts, which can lead to accidents, cargo damage, and legal liabilities. Companies operating in regions with poor road conditions or high temperatures may find their vehicles more susceptible to these issues, creating an urgent need for proactive solutions. The pressure to ensure fleet safety while maintaining operational efficiency adds an additional layer of complexity for fleet operators.

Illustrative image related to inflated tires

A solução: To enhance safety and minimize blowout risks, companies should adopt a proactive tire management strategy. This involves regular training for drivers on the importance of maintaining proper tire pressure and recognizing the signs of tire distress. Using tire pressure monitoring systems (TPMS) can provide real-time data on tire conditions, allowing for immediate adjustments. Additionally, businesses should consider investing in high-quality tires designed for their specific operating conditions, as these can offer better performance and durability. Regular inspections and maintenance, including checking for signs of wear and damage, should be mandated. By prioritizing tire safety, companies can protect their assets and reduce the likelihood of costly incidents.

O problema: Fuel efficiency is a critical concern for businesses, particularly in the transportation and logistics sectors where fuel costs can account for a significant portion of operational expenses. Underinflated tires create more rolling resistance, causing vehicles to consume more fuel. This not only affects the bottom line but can also impact service delivery times if vehicles require more frequent refueling. For companies operating in regions with fluctuating temperatures, maintaining optimal tire pressure can be particularly challenging, further complicating fuel efficiency efforts.

A solução: To enhance fuel efficiency and reduce operational costs, businesses should establish a comprehensive tire inflation program. This includes regular pressure checks, ideally every month or before long-haul trips, to ensure that tires are always at the recommended pressure levels. Fleet managers can also implement training sessions to educate drivers on the impact of tire pressure on fuel consumption. Additionally, utilizing high-quality tires that are specifically engineered for lower rolling resistance can improve fuel efficiency. Tracking fuel consumption metrics against tire condition data can help identify patterns and encourage timely maintenance. By focusing on proper tire inflation, companies can significantly reduce fuel costs and improve overall operational efficiency.

When selecting materials for inflated tires, it is crucial to consider the properties that directly affect performance, durability, and safety. The most common materials include natural rubber, synthetic rubber, steel, and fabric reinforcements. Each material has distinct characteristics that influence its application in tire manufacturing.

Illustrative image related to inflated tires

Natural rubber is renowned for its excellent elasticity and resilience. It can withstand a wide range of temperatures, typically rated for use between -30°C and 70°C. This material offers good abrasion resistance and is less prone to cracking, making it suitable for various terrains.

Prós: Natural rubber provides superior grip and traction, enhancing vehicle control and safety. Its biodegradability is also a plus for environmentally conscious buyers.

Contras: However, natural rubber can be more expensive than synthetic alternatives and has a lower resistance to ozone and UV radiation, which can lead to degradation over time.

For international buyers, particularly in regions like Africa and South America, where environmental conditions can vary significantly, it’s essential to consider the local climate’s impact on rubber longevity and performance.

Synthetic rubber, such as styrene-butadiene rubber (SBR) and butyl rubber, is commonly used in tire manufacturing due to its versatility and cost-effectiveness. Synthetic rubbers generally have better resistance to heat, ozone, and aging compared to natural rubber.

Prós: They can be engineered to meet specific performance requirements, such as improved fuel efficiency and lower rolling resistance. This adaptability makes synthetic rubber suitable for a wide range of vehicles and driving conditions.

Contras: The primary drawback is that synthetic rubber may not provide the same level of grip as natural rubber, especially in wet conditions.

For B2B buyers in Europe and the Middle East, understanding the compliance with local regulations regarding synthetic materials is crucial, as some regions have strict environmental standards.

Steel belts are often incorporated into tires to improve structural integrity and performance. They provide high tensile strength and help maintain tire shape under varying loads and speeds. Steel belts can withstand high pressure and offer excellent puncture resistance.

Prós: The inclusion of steel belts enhances durability and extends tire life, making them ideal for heavy-duty applications, such as commercial vehicles.

Contras: However, steel belts can increase the overall weight of the tire, which may negatively impact fuel efficiency.

International buyers should consider the weight limitations and regulations in their respective markets, particularly in regions like Brazil and Saudi Arabia, where fuel efficiency may be a priority.

Fabric reinforcements, typically made from polyester or nylon, are used to enhance the tire’s strength and flexibility. These materials are crucial for maintaining tire shape and improving ride comfort.

Prós: Fabric reinforcements can absorb shocks and vibrations, leading to a smoother ride. They are also lightweight, which helps in maintaining fuel efficiency.

Contras: On the downside, fabric reinforcements may not offer the same level of puncture resistance as steel belts, making them less suitable for certain heavy-duty applications.

Illustrative image related to inflated tires

For B2B buyers, understanding the specific requirements for fabric reinforcements in different vehicle types is essential, especially in diverse markets like Africa and the Middle East, where road conditions can vary widely.

| Material | Typical Use Case for inflated tires | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Natural Rubber | Passenger vehicles, off-road tires | Excellent grip and traction | Higher cost, lower ozone resistance | Alta |

| Synthetic Rubber | All types of vehicles, especially performance tires | Better heat and ozone resistance | May have lower grip in wet conditions | Médio |

| Steel Belts | Heavy-duty and commercial tires | High durability and puncture resistance | Increases weight, may reduce efficiency | Médio |

| Fabric Reinforcements | Light trucks, passenger vehicles | Lightweight, improves ride comfort | Lower puncture resistance | Baixa |

This strategic material selection guide provides valuable insights for B2B buyers, enabling informed decisions tailored to specific regional needs and compliance standards.

The manufacturing of inflated tires involves several critical stages, each designed to ensure the final product meets the highest standards of performance and safety. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers.

The first step in tire manufacturing is the preparation of materials. Tires are primarily made from rubber, textiles, and steel. The rubber is sourced from both natural and synthetic sources. Natural rubber is valued for its elasticity and durability, while synthetic rubber is engineered to provide specific performance characteristics, such as resistance to wear and temperature fluctuations.

Illustrative image related to inflated tires

In addition to rubber, tire manufacturers utilize reinforcing materials like steel belts, which provide strength and stability. Textiles, often made from polyester or nylon, enhance flexibility and help maintain tire shape. Quality control begins here, as the raw materials undergo rigorous testing for consistency and compliance with international standards.

Once the materials are prepared, the next phase is forming and assembling the tires. This process typically involves several techniques, including:

Extrusion: Rubber is heated and forced through a die to create various components, such as treads and sidewalls. This ensures uniform thickness and surface quality.

Calendering: In this step, layers of rubber are combined with reinforcing materials to create a composite structure. The calendering process is crucial for achieving the desired performance characteristics.

Building: The tire components are assembled on a tire-building machine. This machine layers the components in a specific order, ensuring proper alignment and adhesion.

Curing: Once assembled, tires are placed in a curing press where heat and pressure are applied. This process, also known as vulcanization, cross-links the rubber molecules, enhancing durability and elasticity.

After curing, tires undergo finishing processes that include trimming, inspection, and branding. Trimming removes any excess rubber, while thorough inspections check for defects or irregularities. The final step involves branding, where the manufacturer’s logo and other identifying marks are added.

Quality assurance is integral to the tire manufacturing process, ensuring that every tire produced meets safety and performance standards. B2B buyers should be familiar with the key quality control measures that manufacturers implement.

Tire manufacturers often adhere to various international standards, such as ISO 9001, which establishes a framework for quality management systems. Compliance with these standards indicates that a manufacturer has a systematic approach to ensuring product quality.

In addition to ISO standards, industry-specific certifications like the European CE marking and API (American Petroleum Institute) standards are relevant. These certifications demonstrate compliance with safety regulations and performance benchmarks, particularly important for international buyers who may have different regional requirements.

Quality control checkpoints are critical throughout the manufacturing process. The main checkpoints include:

Controle de qualidade de entrada (IQC): This initial stage involves inspecting raw materials upon delivery. Suppliers must provide certificates of compliance to ensure that materials meet specified standards.

Controle de qualidade durante o processo (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and detect any deviations from quality standards. This includes checking for dimensional accuracy, surface quality, and adherence to design specifications.

Controle de qualidade final (FQC): After the tires are finished, a comprehensive inspection is performed. This includes tests for uniformity, balance, and durability, ensuring that each tire meets performance specifications.

For international buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial.

Conducting supplier audits is one of the most effective ways to verify a manufacturer’s quality control processes. Buyers should consider the following:

On-site Audits: Visiting the manufacturing facility allows buyers to observe processes, inspect materials, and engage with quality control personnel.

Reviewing Quality Assurance Documentation: Buyers should request documentation, including quality control manuals, inspection reports, and certifications, to assess compliance with international standards.

Third-party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s manufacturing processes and quality control measures. These agencies can conduct inspections at various stages of production and offer detailed reports.

To ensure the reliability and safety of tires, manufacturers employ several common testing methods, including:

Treadwear Testing: Evaluates how well a tire will perform over time under various driving conditions.

High-speed Tests: Assess the tire’s performance at high speeds, which is critical for safety.

Testes ambientais: Tires are subjected to extreme temperatures and humidity levels to evaluate their performance in different climates.

Static and Dynamic Balance Tests: These tests ensure that tires maintain stability during operation, reducing vibrations and enhancing vehicle control.

International buyers should be aware of the nuances in quality control that may vary by region. For example, regulations and standards in Europe may differ significantly from those in Africa or South America. Buyers should ensure that suppliers are familiar with and compliant with local regulations to avoid potential legal issues.

Additionally, understanding regional market demands can influence quality assurance practices. Buyers in emerging markets may prioritize cost-effectiveness, while those in developed markets might focus more on advanced safety features and environmental sustainability.

Illustrative image related to inflated tires

In summary, the manufacturing processes and quality assurance measures for inflated tires are complex and multifaceted. B2B buyers must be diligent in evaluating suppliers based on their manufacturing capabilities and quality control practices. By understanding the intricacies of tire production and the applicable international standards, buyers can make informed decisions that ensure safety, performance, and value in their tire procurement strategies.

This practical sourcing guide is designed for B2B buyers looking to procure inflated tires, ensuring they make informed decisions that enhance vehicle performance and safety. Inflated tires play a critical role in vehicle operation, impacting everything from fuel efficiency to safety. By following this step-by-step checklist, buyers can streamline their procurement process and select the best products for their needs.

Establishing clear technical specifications is essential for selecting the right tires for your fleet or business needs. Consider factors such as tire size, load capacity, tread design, and intended use (e.g., off-road, highway). This ensures compatibility with your vehicles and optimal performance in various conditions.

Evaluating the reputation of potential suppliers is a vital step in ensuring quality and reliability. Investigate suppliers through online reviews, industry forums, and testimonials from other businesses in your region.

Before proceeding with a purchase, it is crucial to verify the certifications of your potential suppliers. Certifications ensure that the tires meet specific safety and performance standards.

Illustrative image related to inflated tires

Understanding pricing structures and payment terms is critical for managing your budget effectively. Request detailed quotes from multiple suppliers to compare costs and identify the best value.

Implementing quality assurance checks is essential to ensure that the tires you procure meet your specifications and safety standards. Before finalizing a purchase, verify the quality of the tires through inspections or third-party testing.

Efficient logistics and timely delivery are crucial for minimizing downtime and ensuring your operations run smoothly. Discuss delivery timelines and logistics capabilities with suppliers to ensure they can meet your needs.

Building a strong relationship with your tire supplier can lead to better service and support in the long run. Open lines of communication can facilitate quick resolutions to any issues that arise post-purchase.

Illustrative image related to inflated tires

In sourcing inflated tires, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materiais: The most significant portion of the cost structure, materials encompass rubber, fabric, steel belts, and other components essential for tire manufacturing. The prices of raw materials can fluctuate based on global supply chains, impacting overall costs.

Trabalho: Labor costs vary by region and can significantly influence the final price of tires. Regions with higher labor costs, such as parts of Europe, may see increased pricing, while countries with lower labor costs can offer more competitive rates.

Custos indiretos de fabricação: This includes utilities, rent, equipment maintenance, and indirect labor costs. Efficient manufacturing processes can help reduce overhead costs, ultimately benefiting the buyer.

Ferramentas: This refers to the costs associated with the machinery and tools used in the production of tires. High-quality tooling can enhance production efficiency and reduce defects, but it also adds to the initial cost.

Controle de qualidade (QC): Ensuring tires meet safety and performance standards incurs costs related to inspections and testing. Investing in rigorous QC processes can prevent costly recalls or safety issues down the line.

Logística: Transportation costs are critical, especially for international buyers. Shipping, customs duties, and insurance can add significant expenses, making it essential to consider logistics in the overall cost analysis.

Margem: Suppliers will incorporate their desired profit margin into the pricing. Understanding typical margins in the tire industry can aid in negotiating better deals.

Several factors influence the pricing of inflated tires beyond the base cost components:

Volume/MOQ: Manufacturers often offer discounts for larger orders due to economies of scale. Understanding the minimum order quantities (MOQs) can help buyers negotiate better pricing.

Especificações e personalização: Tires designed for specific applications (e.g., off-road, high-performance) or customized specifications will typically carry higher prices. Buyers should evaluate whether they require specialized tires or if standard options will suffice.

Materiais e certificações de qualidade: The choice of materials directly impacts pricing. Tires made from premium materials or those certified by recognized quality standards (like ISO) may command higher prices but can offer better performance and safety.

Fatores do fornecedor: Established suppliers with a strong reputation may charge more due to perceived reliability and quality assurance. Buyers should weigh the benefits of supplier reliability against potential cost savings from lesser-known manufacturers.

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can significantly affect pricing. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, influencing the total expense for the buyer.

To maximize cost efficiency in tire sourcing, B2B buyers should consider the following negotiation strategies:

Leverage Volume Discounts: Consolidating orders can provide leverage in negotiations. Suppliers are often more willing to reduce prices for bulk orders, which can lead to significant cost savings.

Assess Total Cost of Ownership (TCO): Beyond the initial price, consider the long-term costs associated with tire performance, maintenance, and replacements. A cheaper tire may incur higher operational costs over its lifespan.

Understand Pricing Nuances in International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of regional pricing differences influenced by local regulations, tariffs, and market demand.

Criar relacionamentos: Establishing a strong relationship with suppliers can lead to better pricing and terms over time. Trust and reliability can often result in more favorable negotiations.

Stay Informed: Keeping abreast of market trends, material costs, and global supply chain dynamics can empower buyers in discussions and negotiations, ensuring they make informed decisions.

Prices for inflated tires can vary significantly based on various factors, including market conditions, supplier pricing strategies, and regional economic factors. Therefore, the information provided should be used as a guideline, and buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

In the realm of vehicular technology, traditional inflated tires have long been the standard for providing vehicle stability and traction. However, advancements in tire technology have led to the emergence of alternative solutions that aim to enhance performance, safety, and cost-effectiveness. This section will compare inflated tires with two notable alternatives: airless tires and run-flat tires.

| Aspecto de comparação | Inflated Tires | Airless Tires | Run-Flat Tires |

|---|---|---|---|

| Desempenho | Good traction and comfort; sensitive to inflation levels | Consistent performance; no risk of deflation | Maintains performance after puncture; limited range |

| Custo | Generally lower initial cost; replacement needed due to wear | Higher upfront cost; potentially longer lifespan | Moderate cost; may require specific rims |

| Facilidade de implementação | Widely available and easy to install | More complex installation; limited availability | Standard installation; compatible with many vehicles |

| Manutenção | Requires regular pressure checks; prone to wear and tear | Minimal maintenance; no pressure checks needed | Requires monitoring for wear; can still wear out |

| Melhor caso de uso | Everyday driving; versatile for different terrains | Off-road vehicles; urban mobility | Emergency situations; long-distance travel |

Airless Tires:

Airless tires, often made from advanced materials such as polyurethane or rubber composites, provide a solid solution that eliminates the risk of punctures and deflation. The performance is consistent, as they maintain their shape and rigidity regardless of external conditions. However, the initial investment is higher, and they may not yet be as widely available or compatible with all vehicle types. Their durability can lead to a longer lifespan, making them a cost-effective choice over time, particularly for applications in rugged terrains or urban environments.

Run-Flat Tires:

Run-flat tires are designed to allow a vehicle to continue operating for a limited distance after a puncture. This feature is particularly valuable for long-distance travel or in emergency situations where stopping to change a tire may pose safety risks. While they offer convenience and peace of mind, run-flat tires typically come at a moderate cost and may require specific rims for installation. Additionally, they can provide a stiffer ride and may wear out quicker than traditional tires, necessitating careful monitoring.

When evaluating the best tire solution for your business or fleet, consider the unique demands of your operations. Inflated tires are a reliable choice for everyday driving and offer a lower initial investment, but they require regular maintenance and monitoring. Airless tires may be ideal for companies focused on durability and reduced maintenance, particularly in challenging environments. Conversely, run-flat tires provide a safety net for long-distance travel but come with specific installation requirements and potential trade-offs in comfort. By assessing your specific use cases, budget constraints, and maintenance capabilities, you can select the most suitable tire technology to meet your operational needs.

Illustrative image related to inflated tires

When sourcing inflated tires, understanding their technical properties is crucial for ensuring performance, safety, and longevity. Here are several key specifications to consider:

The tire pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure the tire can safely handle. Proper inflation is vital; overinflation can lead to uneven wear and increased risk of blowouts, while underinflation can reduce fuel efficiency and handling. For B2B buyers, adhering to the recommended PSI helps in maintaining vehicle safety and operational efficiency.

The load index represents the maximum load a tire can support at its designated pressure. This numerical code is critical for businesses that rely on transporting goods or passengers. Selecting tires with an appropriate load index ensures that the tires can handle the weight of the vehicle and its cargo without compromising safety or performance.

Tread depth affects traction, handling, and water dispersion. Tires typically have a tread depth of 8-12 mm when new. B2B buyers should consider this property as it directly influences safety, especially in adverse weather conditions. Regularly checking tread depth can help prevent accidents and reduce long-term costs associated with tire replacements.

Tires are made from various materials, including rubber compounds, fabric, and steel belts. The quality of these materials affects durability, performance, and resistance to punctures. Sourcing tires with high-grade materials can lead to lower maintenance costs and increased operational efficiency, making it a critical consideration for businesses.

Illustrative image related to inflated tires

Tires must perform optimally across a range of temperatures. High-quality tires often feature compounds designed to withstand extreme heat and cold, which is vital for businesses operating in diverse climates. Understanding temperature resistance helps in selecting tires that can perform reliably under specific environmental conditions.

The aspect ratio is the ratio of the tire’s height to its width, expressed as a percentage. A lower aspect ratio typically indicates better handling and performance, while a higher ratio can provide a smoother ride. Businesses should assess their vehicle’s intended use to select the appropriate aspect ratio for optimal performance.

Understanding industry jargon is essential for effective communication and negotiation in the tire supply chain. Here are some key terms:

OEM refers to tires that are produced by the original manufacturer for specific vehicle models. B2B buyers often seek OEM tires to ensure compatibility and performance standards set by vehicle manufacturers. This term is crucial when discussing replacements or upgrades.

MOQ is the minimum number of units a supplier is willing to sell. For B2B buyers, understanding MOQ is essential for budgeting and inventory management. Knowing the MOQ can help businesses negotiate better terms and avoid excess stock.

Illustrative image related to inflated tires

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When purchasing tires, a well-prepared RFQ can streamline the procurement process, ensuring that buyers receive competitive pricing and favorable terms.

Incoterms are a series of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk management, and logistics, ensuring a smoother transaction process.

Retreading is the process of applying a new tread to a worn tire. This practice can be cost-effective and environmentally friendly. B2B buyers should consider retread options to maximize tire usage and reduce waste, particularly for fleets.

Illustrative image related to inflated tires

A tire warranty outlines the terms under which a manufacturer will replace or repair a tire. Understanding warranty details is crucial for B2B buyers to assess potential risks and ensure that they are making a sound investment in their tire purchases.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance safety, performance, and cost-effectiveness in their tire procurement strategies.

The inflated tire market is currently experiencing significant shifts driven by various global factors. One of the primary drivers is the rising demand for vehicles in emerging markets, particularly in Africa and South America, where increased disposable income has led to higher vehicle ownership rates. Additionally, advancements in tire technology are fostering innovation, with smart tires equipped with sensors for real-time monitoring of tire pressure and temperature gaining traction. Such technological integration is particularly appealing to B2B buyers seeking to enhance fleet management efficiency and reduce operational costs.

Illustrative image related to inflated tires

Current sourcing trends indicate a growing reliance on digital platforms and e-commerce channels for procurement. International buyers are leveraging these platforms to access a wider range of products and suppliers, thus fostering competitive pricing and improved supply chain transparency. Moreover, the emphasis on just-in-time inventory practices is becoming more prevalent, allowing companies to minimize holding costs while ensuring the timely availability of tires.

In regions like the Middle East and Europe, regulatory frameworks emphasizing safety and environmental standards are influencing purchasing decisions. Buyers are increasingly prioritizing suppliers who can demonstrate compliance with these regulations, particularly in terms of quality and sustainability. This shift signifies a broader trend towards integrating safety and environmental considerations into procurement strategies.

Sustainability has emerged as a critical consideration for B2B buyers in the inflated tire sector. The environmental impact of tire production and disposal is significant, leading to a pressing need for ethical sourcing practices. Many buyers are now seeking suppliers who adhere to sustainable manufacturing processes, which include the use of eco-friendly materials and energy-efficient production techniques. This focus on sustainability is not just about compliance; it enhances brand reputation and appeals to environmentally conscious consumers.

Illustrative image related to inflated tires

The importance of ethical supply chains cannot be overstated. Buyers are increasingly demanding transparency regarding the sourcing of raw materials, including natural rubber and synthetic compounds. Suppliers who can provide certifications, such as ISO 14001 for environmental management, are more likely to gain favor in the marketplace. Additionally, the adoption of recycled materials in tire production is gaining momentum, with many manufacturers exploring innovative ways to incorporate recycled rubber into their products.

Green certifications and materials are becoming essential criteria in the sourcing process. Buyers are encouraged to partner with manufacturers that hold certifications like the Global Recycled Standard (GRS) or the Forest Stewardship Council (FSC). These certifications not only validate a supplier’s commitment to sustainability but also mitigate risks associated with environmental compliance.

The inflated tire market has evolved significantly since the introduction of the first pneumatic tire in the late 19th century. Initially designed for horse-drawn carriages, the technology advanced rapidly with the advent of the automobile. By the mid-20th century, innovations such as radial tires and tubeless designs revolutionized performance and safety standards.

Illustrative image related to inflated tires

As the global automotive industry expanded, so did the tire market, with manufacturers focusing on enhancing durability, efficiency, and safety. The late 20th century saw the introduction of performance tires, catering to the growing demand for high-speed vehicles. In recent years, the emphasis has shifted towards sustainability, with manufacturers investing in research and development to create eco-friendly tire solutions. This historical evolution reflects the ongoing adaptation of the industry to meet changing consumer demands and regulatory pressures, shaping the current landscape of the inflated tire sector.

How do I solve uneven tire wear issues?

To address uneven tire wear, regularly monitor tire pressure and ensure it aligns with the manufacturer’s specifications. Overinflated tires typically wear out faster in the center, while underinflated tires show wear on the edges. Implement a routine tire inspection schedule, including visual checks for tread wear and alignment issues. Additionally, consider rotating your tires every 5,000 to 7,500 miles to promote even wear and extend the lifespan of your tires.

What is the best tire pressure for optimal performance?

The ideal tire pressure varies by vehicle and tire type, so always refer to the manufacturer’s guidelines located in the owner’s manual or on the door jamb sticker. Maintaining the recommended pressure ensures optimal performance, fuel efficiency, and safety. Regularly check tire pressure, especially before long trips or when temperatures fluctuate, as pressure can change with temperature.

How can I ensure the quality of the tires I purchase?

To ensure tire quality, source from reputable manufacturers or distributors with a proven track record. Request product certifications and compliance with international safety standards. Conduct thorough supplier vetting, including checking references and customer reviews. Additionally, consider requesting samples or visiting production facilities to assess quality control processes firsthand before making bulk orders.

What are the typical minimum order quantities (MOQ) for tires?

Minimum order quantities for tires can vary significantly by supplier, but generally, they range from 100 to 1,000 units. Discuss MOQs with potential suppliers during negotiations to find a balance that meets your inventory needs while ensuring cost-effectiveness. Some suppliers may offer flexibility in MOQs based on your purchasing history or long-term partnership potential.

What payment terms should I expect when sourcing tires internationally?

Payment terms can vary, but common options include letters of credit, wire transfers, or payment upon delivery. It is advisable to negotiate terms that provide security for both parties, such as partial upfront payments and the balance upon delivery. Ensure that you understand any fees associated with international transactions and currency conversions to avoid unexpected costs.

How do logistics and shipping impact the cost of tires?

Logistics and shipping significantly affect tire costs due to factors like distance, shipping method, and import duties. Choose a shipping method that balances cost and delivery time, such as sea freight for bulk orders. Additionally, collaborate with logistics providers experienced in international shipping to navigate customs regulations efficiently. Consider establishing relationships with local distributors to minimize transportation costs and streamline distribution.

What customization options are available for B2B tire orders?

Customization options can include variations in tread patterns, sizes, and branding. Many manufacturers offer tailored solutions to meet specific industry needs, such as specialized tires for off-road or commercial vehicles. Discuss your requirements with suppliers to explore available customization options and understand any associated costs or minimum order quantities that may apply.

What quality assurance practices should I look for in a tire supplier?

Seek suppliers that implement rigorous quality assurance practices, including regular inspections, testing protocols, and compliance with international safety standards. Request documentation of quality certifications, such as ISO 9001, and inquire about their warranty policies. Establish a clear communication channel for reporting and resolving any quality issues that may arise during the ordering process.

Domínio: michelinman.com

Registrado: 2001 (24 anos)

Introdução: Michelin offers a complete range of tires for various mobility needs, including passenger cars, SUVs, light commercial vehicles, and electric/hybrid vehicles. Tire families include CrossClimate, Defender, Pilot Sport, Primacy, LTX, X Ice, Energy™, Latitude Sport, Pilot Alpin, and Premier. Tires are categorized by driving experience (durability, confidence, sport, winter, efficiency) and by season …

Domínio: eastcoasttoyota.com

Registrado: 2000 (25 anos)

Introdução: The article discusses the hidden risks associated with overinflated and underinflated tires, emphasizing the importance of maintaining proper tire pressure for vehicle safety and performance. Key points include: 1. Uneven tread wear caused by incorrect inflation, leading to costly replacements and alignment issues. 2. Reduced vehicle control, making steering and braking more difficult. 3. Increase…

Domínio: jiffylube.com

Registrado: 1995 (30 anos)

Introdução: 5 Signs of Overinflated Tires: 1. Uneven Tire Tread – Center treads wear out faster than edges. 2. Poor Traction – Less surface area contacts the road, leading to skidding. 3. Negatively Impacted Suspension – Rougher ride and premature wear on suspension components. 4. Less Vehicle Control – Harder to control, especially at high speeds. 5. Tire Blowout – Increased risk due to overstretching. Cause…

Domínio: justtires.com

Registrado: 2000 (25 anos)

Introdução: Proper tire inflation is crucial for safety, performance, and tire longevity. The right air pressure is specified by the vehicle’s manufacturer and can be found on the door edge, door jamb, glove box door, or fuel door, as well as in the owner’s manual. Tires should be checked when cool, and the process includes unscrewing the valve cap, connecting a tire gauge, adding air to reach the recommended…

Domínio: mastercrafttires.com

Registrado: 1997 (28 anos)

Introdução: Recommended inflation pressures for tires are specified in pounds per square inch (psi) or kilopascals (kPa) as indicated on the vehicle’s tire placard, certification label, or in the owner’s manual. Underinflation causes excessive heat buildup and internal structural damage, leading to tire failure. Overinflated tires are more likely to be damaged by impacts. Proper inflation is critical for tire…

Domínio: etenwolf.com

Registrado: 2021 (4 anos)

Introdução: Etenwolf Vortex S6 Tire Inflator: Features a user-friendly interface, automatic shut-off when desired PSI is reached, compact design for easy storage, and provides precise and efficient inflation. Ideal for maintaining optimal tire pressure, enhancing fuel efficiency, improving handling, and reducing the risk of tire blowouts.

In today’s competitive global market, strategic sourcing of inflated tires is essential for ensuring vehicle safety, performance, and cost efficiency. By understanding the risks associated with both overinflation and underinflation, B2B buyers can make informed decisions that not only enhance the lifespan of tires but also improve overall vehicle control and fuel efficiency.

Investing in high-quality tires from reputable suppliers will mitigate the dangers of uneven tread wear, blowouts, and compromised safety, particularly in regions with diverse driving conditions like Africa, South America, the Middle East, and Europe. Establishing strong relationships with suppliers who prioritize quality and compliance with safety standards is critical for maximizing value.

Illustrative image related to inflated tires

Looking ahead, international buyers should remain proactive in monitoring tire performance and embracing innovations in tire technology that enhance durability and efficiency. As the market evolves, staying informed about new sourcing strategies and trends will empower businesses to adapt and thrive.

Take action now: prioritize strategic sourcing for your tire needs and ensure your fleet is equipped for success on the road ahead.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.