In an increasingly competitive global marketplace, sourcing the right tools for operational efficiency can be a significant challenge for international B2B buyers. The Merlin Digital Tire Pressure Gauge stands out as a reliable solution, ensuring precise tire inflation and maintenance, which is crucial for industries reliant on vehicle fleets. With its easy-to-read backlit LCD display and high accuracy, this gauge is designed for professional use across various sectors, from logistics to automotive repair.

This comprehensive guide delves into the multifaceted aspects of the Merlin Digital Tire Pressure Gauge, equipping buyers with the knowledge to make informed purchasing decisions. It covers various types and specifications of the gauge, its diverse applications across different industries, supplier vetting processes to ensure quality and reliability, and cost considerations to optimize procurement budgets.

By focusing on the unique needs of international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Vietnam—this guide empowers businesses to enhance their operational efficiency and safety measures. Understanding the nuances of this essential tool not only aids in effective sourcing but also contributes to the longevity and performance of vehicles, ultimately leading to reduced operational costs and improved service delivery.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Standard Digital Tire Pressure Gauge | Backlit LCD, pressure range up to 150 PSI, auto on/off | Automotive service centers, fleet management | Prós: Accurate readings, user-friendly; Contras: Limited to standard applications. |

| Professional Digital Tire Pressure Gauge | Enhanced accuracy (1% at 150 PSI), multiple pressure units | Heavy-duty vehicles, industrial applications | Prós: High precision, versatile; Contras: Slightly higher cost. |

| Compact Digital Tire Pressure Gauge | Lightweight, portable design, easy storage | Mobile tire services, roadside assistance | Prós: Portability, ease of use; Contras: Smaller display may be harder to read. |

| Digital Tire Pressure Gauge with Inflation Function | Integrated inflator, pressure measurement, and inflation | Tire shops, automotive workshops | Prós: Multi-functional, saves time; Contras: Higher complexity may require training. |

| Bluetooth-enabled Digital Tire Pressure Gauge | Connects to mobile devices for data tracking | Fleet monitoring, logistics companies | Prós: Real-time data access, remote monitoring; Contras: Dependent on battery and connectivity. |

The Standard Digital Tire Pressure Gauge is designed for general use, featuring a backlit LCD display that enhances visibility in various lighting conditions. It typically measures pressure up to 150 PSI and is equipped with an automatic on/off feature to conserve battery life. This gauge is ideal for automotive service centers and fleet management operations where accurate and quick tire pressure readings are essential. Buyers should consider the gauge’s ease of use and maintenance, as well as its affordability, making it a suitable choice for everyday applications.

The Professional Digital Tire Pressure Gauge stands out due to its enhanced accuracy, boasting a 1% precision rating at 150 PSI. It offers multiple pressure measurement units, making it versatile for different markets and vehicles. This type is particularly beneficial for heavy-duty vehicles and industrial applications, where precise tire pressure is critical for safety and performance. B2B buyers should weigh the investment against the potential for reduced downtime and improved vehicle safety, which can justify the higher price point.

Compact Digital Tire Pressure Gauges are designed for portability, making them perfect for mobile tire services and roadside assistance. Their lightweight design allows for easy storage and transport. While they provide accurate readings, the smaller display may pose readability challenges for some users. B2B buyers looking for convenience and mobility will find these gauges advantageous, especially in environments where space and weight are considerations.

This type combines pressure measurement with an inflation function, streamlining the process for tire shops and automotive workshops. The integrated inflator saves time and enhances workflow efficiency. While these gauges are multifunctional, their complexity may require additional training for staff. B2B buyers should assess whether the benefits of increased efficiency outweigh the potential learning curve associated with this advanced equipment.

Bluetooth-enabled Digital Tire Pressure Gauges offer the ability to connect to mobile devices, providing real-time data tracking and monitoring. This feature is particularly useful for fleet monitoring and logistics companies, enabling them to maintain optimal tire pressure across their vehicle fleet. While the advantages of remote monitoring and data access are significant, buyers must consider the reliance on battery life and connectivity for consistent performance. This technology represents a forward-thinking investment for businesses focused on data-driven operations.

| Indústria/Setor | Specific Application of merlin digital tire pressure gauge | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Automotive Repair | Used for tire pressure checks during vehicle servicing | Ensures optimal tire performance and safety, reducing liability | Ensure accuracy specifications and battery life for continuous use. |

| Transportation & Logistics | Regular tire pressure monitoring for fleet vehicles | Enhances fuel efficiency and prolongs tire lifespan | Consider bulk purchasing options and compatibility with various vehicles. |

| Agricultura | Tire pressure checks for agricultural machinery | Improves operational efficiency and reduces equipment wear | Look for rugged designs suitable for harsh environments. |

| Construção | Ensuring proper tire pressure for heavy machinery | Increases machinery reliability and decreases downtime | Assess the gauge’s durability and ease of use in the field. |

| Fabricação | Monitoring tire pressure on production equipment | Maintains production quality and operational safety | Evaluate calibration options and service support availability. |

In the automotive repair sector, the MERLIN Digital Tire Pressure Gauge is a vital tool for technicians during vehicle servicing. It allows for quick and accurate tire pressure checks, ensuring that tires are inflated to the manufacturer’s specifications. This precision is crucial, as improper tire pressure can lead to reduced fuel efficiency, increased tire wear, and safety hazards. International buyers in regions like Africa and South America may prioritize gauges that are both durable and easy to use, given the varying conditions of service environments.

For transportation and logistics companies, maintaining the correct tire pressure across fleets is essential for operational efficiency. The MERLIN gauge facilitates regular checks, helping to optimize fuel consumption and extend tire life. Given the high costs associated with fleet maintenance, businesses benefit from investing in reliable tools that ensure vehicles operate at peak performance. Buyers should consider bulk purchasing options to equip their entire fleet while ensuring that the gauges are compatible with a variety of vehicle types.

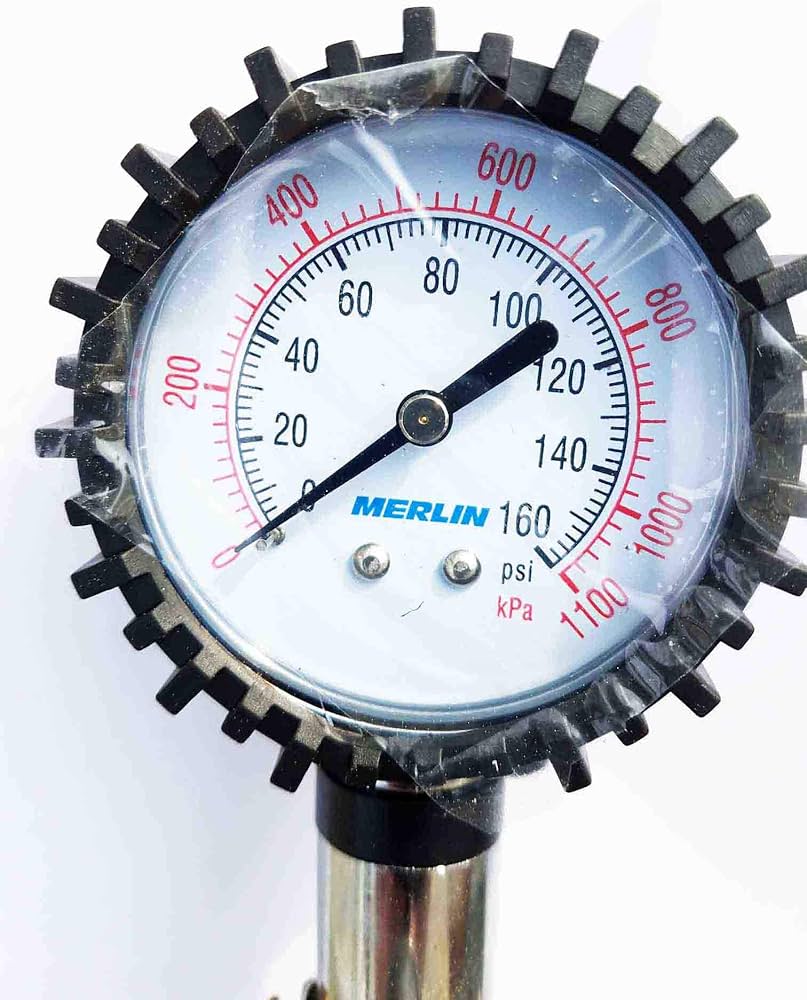

Illustrative image related to merlin digital tire pressure gauge

In agriculture, the MERLIN Digital Tire Pressure Gauge is used to monitor the tire pressure of various machinery, such as tractors and harvesters. Proper tire inflation is critical for maximizing traction and minimizing soil compaction, which can affect crop yields. For agricultural operations, especially in remote areas of Africa or Brazil, the gauge’s rugged design and ease of use are essential factors. Buyers should look for gauges that can withstand harsh working conditions while providing accurate readings.

In the construction industry, the MERLIN Digital Tire Pressure Gauge ensures that heavy machinery operates safely and efficiently. Regular checks help prevent tire blowouts and equipment failures, which can lead to costly downtime. Construction professionals require tools that are durable and can perform under challenging conditions. When sourcing, businesses should evaluate the gauge’s resistance to dust and moisture, ensuring it remains operational on job sites.

Manufacturers utilize the MERLIN Digital Tire Pressure Gauge to monitor tire pressure on production equipment, such as forklifts and conveyor systems. Proper tire inflation is essential for maintaining operational safety and product quality. In regions with strict manufacturing regulations, ensuring consistent tire pressure can prevent accidents and enhance productivity. Buyers should assess the gauge’s calibration options and after-sale service support to ensure compliance with industry standards.

O problema: B2B buyers in industries such as transportation or logistics often face challenges related to maintaining accurate tire pressure across their fleet. Misreading tire pressure can lead to significant operational inefficiencies, increased fuel consumption, and potential safety hazards. For instance, if a tire is under-inflated, it can wear out faster, resulting in costly replacements and downtime. Buyers may find it challenging to trust manual gauges or older models that do not provide reliable readings.

A solução: To ensure accurate tire pressure readings, it is crucial to invest in the MERLIN Digital Tire Pressure Gauge due to its 1% accuracy rating at 150 PSI, which translates to a maximum deviation of just 1.5 PSI. Buyers should ensure they properly train their staff on how to use the gauge effectively, emphasizing the importance of checking tire pressure at least once a month and before long trips. Additionally, establishing a routine maintenance schedule can help mitigate issues caused by fluctuating tire pressures. The gauge’s backlit LCD display allows for easy reading in low-light conditions, which is beneficial for operations that require tire checks during early mornings or late evenings.

O problema: In high-usage environments such as tire service stations or vehicle maintenance shops, the frequent use of tire pressure gauges can quickly drain battery life, leading to interruptions in service and increased operational costs. Buyers may find that they are replacing batteries more often than anticipated, which can disrupt workflow and lead to delays in customer service.

A solução: The MERLIN Digital Tire Pressure Gauge features an auto on/off function that preserves battery life, making it ideal for high-usage scenarios. To maximize this feature, businesses should educate their teams on proper usage practices, such as turning off the gauge after each use and storing it in a designated area where it is easily accessible. Furthermore, buyers should consider bulk purchasing two AAA batteries as a cost-effective measure to ensure that replacements are readily available. By integrating these practices, businesses can enhance efficiency and minimize downtime associated with battery replacements.

O problema: B2B buyers in automotive repair or tire retail may encounter issues when servicing a variety of tire types and sizes. The need for different chucks and fittings can complicate the tire inflation process and lead to inefficiencies. For instance, using the wrong chuck can result in inaccurate readings or even damage to the valve stem, which can be particularly problematic in diverse fleets or when servicing customer vehicles.

A solução: The MERLIN Digital Tire Pressure Gauge comes with both angled and ball-type chucks, providing the versatility needed to service various tire types effectively. Buyers should assess their specific needs and ensure that their team is familiar with the different chucks included. A practical approach is to create a quick reference guide that associates each chuck type with its appropriate use case, ensuring that technicians can easily select the right tool for the job. Additionally, regular training sessions can help reinforce the importance of using the correct chuck to avoid costly mistakes, thereby improving service quality and customer satisfaction. By leveraging the gauge’s versatility, businesses can enhance their operational efficiency and reduce the likelihood of errors.

Illustrative image related to merlin digital tire pressure gauge

When selecting materials for the Merlin Digital Tire Pressure Gauge, it is essential to consider properties that enhance performance, durability, and user experience. The following analysis examines four common materials used in the gauge’s construction: plastic, aluminum, stainless steel, and rubber.

Plastic is often utilized in the casing of digital tire pressure gauges due to its lightweight nature and cost-effectiveness. Key properties include good insulation against temperature fluctuations and a decent resistance to corrosion. However, while plastics can be durable, they are generally less robust than metals and may degrade over time, especially under extreme conditions.

Prós: Lightweight, cost-effective, and easy to mold into complex shapes.

Contras: Lower durability compared to metals, potential for degradation under UV exposure or high temperatures.

Impacto no aplicativo: Suitable for general use; however, extreme environments may lead to material failure.

Considerações para compradores internacionais: Compliance with environmental regulations such as RoHS in Europe may affect plastic selection.

Aluminum is frequently chosen for components like the gauge housing and internal structures due to its excellent strength-to-weight ratio and resistance to corrosion. It can withstand significant pressure and temperature variations, making it suitable for various environments.

Prós: Lightweight, strong, and resistant to corrosion; offers good thermal conductivity.

Contras: Higher cost than plastic and may require special coatings for enhanced corrosion resistance in humid environments.

Impacto no aplicativo: Ideal for applications requiring a lightweight yet durable solution, particularly in automotive settings.

Considerações para compradores internacionais: Must meet standards such as ASTM for material quality and performance.

Stainless steel is often used for critical components like the pressure sensor and connectors due to its exceptional corrosion resistance and durability. Its ability to withstand high pressures and temperatures makes it a reliable choice for tire pressure measurement.

Prós: Highly durable, excellent corrosion resistance, and suitable for high-pressure applications.

Contras: Heavier than aluminum and more expensive, potentially increasing the overall cost of the gauge.

Impacto no aplicativo: Highly effective in harsh environments, ensuring long-term reliability and accuracy.

Considerações para compradores internacionais: Compliance with standards like DIN and JIS for mechanical properties is crucial in many markets.

Illustrative image related to merlin digital tire pressure gauge

Rubber is typically used for seals and grips in the tire pressure gauge. Its key properties include flexibility, excellent shock absorption, and resistance to various chemicals, making it suitable for automotive applications.

Prós: Provides excellent sealing capabilities, shock absorption, and chemical resistance.

Contras: Can degrade over time due to exposure to ozone and UV light, which may necessitate replacement.

Impacto no aplicativo: Ensures accurate readings by preventing air leaks and providing a comfortable grip for users.

Considerações para compradores internacionais: Different rubber grades may be required to meet specific environmental regulations in various regions.

| Material | Typical Use Case for merlin digital tire pressure gauge | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Plástico | Casing and non-critical components | Leve e econômico | Lower durability under extreme conditions | Baixa |

| Alumínio | Housing and internal structures | Strong, lightweight, and corrosion-resistant | Higher cost and potential for corrosion without coatings | Med |

| Aço inoxidável | Pressure sensors and connectors | Highly durable and corrosion-resistant | Mais pesado e mais caro | Alta |

| Borracha | Seals and grips | Excellent sealing and shock absorption | Degrada-se ao longo do tempo com a exposição | Baixa |

This detailed analysis of materials used in the Merlin Digital Tire Pressure Gauge provides B2B buyers with actionable insights into material properties, advantages, and limitations, enabling informed purchasing decisions tailored to their specific market needs.

The manufacturing of the Merlin Digital Tire Pressure Gauge involves several crucial stages that ensure both functionality and durability. These stages include material preparation, forming, assembly, and finishing. Understanding these processes can help B2B buyers assess the quality and reliability of the products they are sourcing.

Material preparation is the first step in the manufacturing process. For the Merlin Digital Tire Pressure Gauge, the primary materials typically include high-grade plastic for the housing, metal for the internal components (like the pressure sensors), and electronic components for the display and circuitry.

Before manufacturing begins, materials are subjected to rigorous inspections to ensure they meet specified standards for strength and durability. Suppliers often provide Material Safety Data Sheets (MSDS) to confirm the quality and safety of materials used, which is crucial for compliance with international standards.

The forming stage involves transforming raw materials into usable parts. For the Merlin gauge, plastic components are produced through injection molding, allowing for precise and consistent shapes that fit the design specifications. Metal parts may be stamped or machined to achieve the necessary tolerances required for accurate pressure readings.

This stage is critical as it directly influences the gauge’s performance. Manufacturers often utilize Computer Numerical Control (CNC) machines to ensure high precision in machining metal parts, contributing to the overall accuracy of the tire gauge.

Once the components are formed, they move to the assembly stage. In this phase, electronic components are integrated with the housing and sensors. Automated assembly lines may be used for efficiency, while skilled technicians conduct manual assembly for complex or sensitive components.

Quality assurance during assembly is vital. Manufacturers typically implement a verification process at this stage to ensure that each unit meets design specifications. This includes functional testing of the electronic systems, ensuring the backlit LCD display operates correctly and the pressure sensors provide accurate readings.

The finishing stage enhances the product’s aesthetics and functionality. For the Merlin Digital Tire Pressure Gauge, this may involve applying protective coatings to the plastic housing to improve durability and resistance to environmental factors. Additionally, surface treatments may be applied to metal components to prevent corrosion.

Final inspections are performed to ensure that all finishing touches meet quality standards. This is particularly important for international markets where environmental conditions may vary significantly.

Quality assurance is a critical aspect of the manufacturing process, particularly for products like the Merlin Digital Tire Pressure Gauge, which require high precision and reliability. B2B buyers should be aware of the various international standards and quality checkpoints involved in the manufacturing process.

Manufacturers of the Merlin Digital Tire Pressure Gauge typically adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with this standard indicates that the manufacturer has implemented effective processes for continuous improvement and customer satisfaction.

In addition to ISO standards, industry-specific certifications may be relevant. For example, CE marking is essential for products sold in the European Union, indicating compliance with safety, health, and environmental protection standards. B2B buyers should verify that suppliers possess the necessary certifications for their target markets.

Quality control checkpoints are integrated throughout the manufacturing process. These include:

Controle de qualidade de entrada (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

Controle de qualidade durante o processo (IPQC): Monitoring during the manufacturing stages to detect and rectify defects early.

Controle de qualidade final (FQC): Comprehensive testing of the finished product to ensure it meets design specifications and performance criteria.

Common testing methods for the Merlin Digital Tire Pressure Gauge may include functional tests for the pressure readings, durability tests to assess the gauge’s resilience, and battery life tests to evaluate the auto on/off feature.

Illustrative image related to merlin digital tire pressure gauge

For B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring the reliability of products like the Merlin Digital Tire Pressure Gauge. Here are some actionable steps:

Realização de auditorias: Regular audits of the manufacturing facilities can provide insights into the quality control processes in place. Buyers should inquire about the frequency and scope of these audits.

Solicitar relatórios de controle de qualidade: Suppliers should provide documentation of their quality control measures, including inspection and testing results.

Engage Third-Party Inspection Services: Utilizing third-party inspectors can provide an unbiased assessment of the manufacturing processes and product quality. This is particularly beneficial for international buyers who may not have direct access to the manufacturing facilities.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of the nuances in quality control and certification that may affect their purchasing decisions.

Regional Regulations: Different regions have varying regulations regarding product safety and quality. Buyers should familiarize themselves with the specific requirements of their target market to ensure compliance.

Transparência na cadeia de suprimentos: Understanding the supply chain can help buyers assess potential risks. Manufacturers with transparent sourcing and production processes are more likely to produce reliable products.

Considerações culturais: Cultural differences may influence manufacturing practices and quality assurance approaches. Buyers should consider these factors when evaluating suppliers from diverse backgrounds.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for the Merlin Digital Tire Pressure Gauge can empower B2B buyers to make informed purchasing decisions. By focusing on the key stages of production, international standards, quality checkpoints, and verification methods, buyers can enhance their procurement strategies and ensure they source high-quality products.

This practical sourcing guide is designed to assist B2B buyers in procuring the MERLIN Digital Tire Pressure Gauge effectively. By following this step-by-step checklist, you will ensure that you make informed decisions, optimize your procurement process, and secure a product that meets your business needs.

Before initiating the sourcing process, clearly outline your technical requirements. Consider factors such as accuracy, display type, pressure range, and measurement units (PSI, kPa, etc.). This clarity helps in comparing different suppliers and ensures that the products you evaluate meet your operational standards.

Conduct thorough research to identify suppliers who specialize in tire pressure gauges. Utilize online directories, trade shows, and industry contacts to compile a list of potential candidates. Understanding the market landscape will help you find reputable suppliers who can meet your specifications.

Verify that potential suppliers hold relevant certifications and comply with international quality standards. This is essential for ensuring product reliability and safety, particularly when sourcing from overseas manufacturers.

Before making a bulk purchase, request samples of the MERLIN Digital Tire Pressure Gauge. Testing samples allows you to evaluate the product’s performance, durability, and accuracy firsthand. This step is critical to mitigate risks associated with large orders.

Illustrative image related to merlin digital tire pressure gauge

Once you’ve selected a supplier based on your evaluation, engage in negotiations regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to favorable terms that enhance your overall procurement strategy and budget management.

After settling on terms, draft a purchase agreement that outlines all agreed-upon details. This document should include payment schedules, delivery timelines, and product specifications. A well-structured agreement protects both parties and ensures clarity.

Finally, develop a logistics plan for the delivery and distribution of the gauges. Ensure that your supply chain can handle the incoming products efficiently, taking into account local customs regulations if importing.

By following this comprehensive checklist, B2B buyers can streamline their sourcing process for the MERLIN Digital Tire Pressure Gauge, ensuring they select the best possible product to meet their operational needs.

Understanding the cost structure for sourcing the Merlin Digital Tire Pressure Gauge is essential for international B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materiais: The gauge is primarily made from durable plastic and electronic components, which can vary in cost depending on global supply chain fluctuations. Buyers should consider sourcing from suppliers who can provide high-quality materials at competitive prices.

Trabalho: Labor costs can differ significantly based on the manufacturing location. In regions with lower labor costs, such as parts of Asia, the overall production expenses may be reduced, allowing for better pricing strategies.

Custos indiretos de fabricação: This includes costs associated with utilities, equipment maintenance, and factory management. Buyers should evaluate suppliers that have efficient operations to minimize overhead costs, which can indirectly affect the final price.

Ferramentas: Initial tooling costs can be high, especially for custom designs. However, these costs are amortized over larger production runs, making it essential to assess minimum order quantities (MOQs) to lower per-unit costs.

Controle de qualidade (QC): Ensuring that the product meets international standards requires investment in QC processes. This is crucial for maintaining accuracy and reliability, particularly in regions where certification is mandatory.

Logística: Shipping costs can vary based on distance, shipping methods, and freight terms. Buyers should consider the total logistics cost, including potential tariffs and duties, when evaluating suppliers.

Margem: Suppliers typically mark up prices to cover costs and ensure profit. Understanding the expected margins in the market can help buyers negotiate better deals.

Several factors can influence the pricing of the Merlin Digital Tire Pressure Gauge, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe.

Volume/MOQ: Suppliers often offer tiered pricing based on order volume. Higher quantities can lead to significant cost savings, making it beneficial for buyers to consolidate orders.

Especificações e personalização: Custom features or specifications can increase the cost. Buyers should clarify their requirements upfront to avoid unexpected expenses.

Materiais: The choice of materials impacts both quality and cost. Opting for higher-grade materials may increase the price but can enhance durability and customer satisfaction.

Qualidade e certificações: Compliance with international quality standards can add to costs but is essential for market acceptance. Buyers should verify that suppliers possess the necessary certifications.

Fatores do fornecedor: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

Incoterms: Understanding Incoterms is crucial as they determine the cost responsibilities between buyers and sellers. This can significantly influence overall pricing and risk.

For international B2B buyers, particularly from regions like Africa and South America, here are actionable tips to enhance cost-efficiency when sourcing the Merlin Digital Tire Pressure Gauge:

Negotiate Wisely: Always negotiate pricing and payment terms. Suppliers may have flexibility in pricing, especially for larger orders or repeat business.

Considere o custo total de propriedade (TCO): Beyond the purchase price, evaluate the TCO, which includes logistics, maintenance, and potential replacement costs. This approach ensures a more comprehensive understanding of the investment.

Stay Informed on Market Trends: Regularly monitor market trends and pricing fluctuations to make timely purchasing decisions. Being informed can help buyers secure better deals.

Leverage Local Partnerships: Establishing relationships with local distributors or suppliers can reduce logistics costs and lead to better pricing and service.

Esteja ciente das nuances dos preços: Different regions may have unique pricing strategies influenced by local market conditions. Understanding these nuances can aid in making informed sourcing decisions.

By considering these cost components, price influencers, and strategic tips, international B2B buyers can make more informed decisions when sourcing the Merlin Digital Tire Pressure Gauge, ensuring a balance between quality and cost-efficiency.

When evaluating options for measuring tire pressure in a B2B context, it’s essential to consider various alternatives that can meet the needs of different industries and applications. The MERLIN Digital Tire Pressure Gauge is a strong contender, but several other solutions exist that may better align with specific requirements. This analysis compares the MERLIN gauge with two viable alternatives: the Accutire Digital Tire Pressure Gauge and the traditional analog tire pressure gauge.

| Aspecto de comparação | Merlin Digital Tire Pressure Gauge | Accutire Digital Tire Pressure Gauge | Traditional Analog Tire Pressure Gauge |

|---|---|---|---|

| Desempenho | 1% accuracy up to 150 PSI | 0.5% accuracy up to 100 PSI | Generally less precise, varies widely |

| Custo | $16.99 | $18.00 | $5.00 – $20.00 |

| Facilidade de implementação | Simple, battery-operated | Simple, battery-operated | No batteries required |

| Manutenção | Requires battery replacements | Requires battery replacements | Minimal maintenance |

| Melhor caso de uso | Automotive, light commercial use | Automotive, DIY enthusiasts | General use, less frequent checks |

The Accutire Digital Tire Pressure Gauge stands out with its higher accuracy of 0.5% up to 100 PSI, making it suitable for precision-focused applications. Priced slightly higher than the MERLIN gauge, this model is still affordable and offers a backlit display for easy reading. However, like the MERLIN, it relies on batteries, which necessitate periodic replacements. Its digital nature makes it user-friendly, although it may not be as robust as some analog alternatives for heavy-duty applications.

Traditional analog tire pressure gauges are often more affordable, with prices ranging from $5 to $20, and they do not require batteries, making them a reliable choice for environments where battery failure could be an issue. They are typically more durable and can withstand harsher conditions. However, analog gauges generally lack the precision of digital models and can be more challenging to read, especially in low-light conditions. They may be best suited for general use or in situations where the absolute precision of tire pressure is less critical.

When selecting a tire pressure measurement solution, B2B buyers should consider the specific requirements of their operations. If precision is a priority, especially in automotive or light commercial applications, the MERLIN or Accutire digital gauges are preferable due to their accuracy and ease of use. Conversely, for cost-sensitive environments or where durability is paramount, a traditional analog gauge may be the best fit. Ultimately, evaluating the performance, cost, maintenance needs, and best use cases of each option will help buyers make informed decisions that align with their operational goals.

Understanding the essential technical properties of the Merlin Digital Tire Pressure Gauge is crucial for B2B buyers. These specifications not only ensure product quality but also enhance operational efficiency and cost-effectiveness. Here are some of the critical specs:

Pressure Range (5-150 PSI)

The gauge measures tire pressure within a range of 5 to 150 PSI, providing versatility for various vehicle types, from passenger cars to commercial trucks. This wide range is significant for businesses that manage fleets, allowing them to maintain optimal tire performance, thereby reducing operational costs related to fuel efficiency and tire wear.

Accuracy (±1% at 150 PSI)

The gauge boasts an accuracy of ±1%, translating to a maximum deviation of 1.5 PSI across its measurement range. High accuracy is vital in commercial settings to ensure safety and compliance with industry standards. Inaccurate readings can lead to under- or over-inflated tires, compromising vehicle safety and increasing maintenance costs.

Display Type (Backlit LCD)

The easy-to-read backlit LCD display enhances usability in low-light conditions, which is essential for tire maintenance in various environments. A clear display minimizes the risk of misreading pressure values, thus supporting timely and accurate tire inflation—an important factor for businesses operating in diverse geographical regions.

Battery Type (Two AAA Alkaline Batteries)

The gauge operates on two AAA alkaline batteries, which are easily replaceable and widely available. This feature is advantageous for international buyers, as it reduces downtime associated with battery issues. Furthermore, the auto on/off feature conserves battery life, ensuring prolonged usability, which is beneficial for businesses that require regular tire maintenance.

Measurement Units (PSI, Kg/cm², kPa, Bar)

The gauge displays pressure in multiple units, including PSI, Kg/cm², kPa, and Bar. This versatility is particularly important for international B2B buyers, as it accommodates different measurement standards used across various regions. Being able to switch between units can streamline operations for companies that operate in multiple countries.

Hose Length (18 inches)

With an 18-inch hose, the gauge provides adequate reach for various tire types, enhancing its practicality. This feature is essential for workshops and service stations, allowing technicians to access hard-to-reach valves without hassle, thereby improving efficiency in tire maintenance operations.

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common trade terms relevant to the purchase and distribution of the Merlin Digital Tire Pressure Gauge:

OEM (fabricante original do equipamento)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for B2B buyers looking to ensure compatibility and quality in replacement parts or accessories.

MOQ (Quantidade mínima de pedido)

MOQ indicates the smallest number of units a supplier is willing to sell. This is critical for businesses to consider when planning inventory and budgeting. A low MOQ can be advantageous for smaller companies or new market entrants.

RFQ (Request for Quotation, solicitação de cotação)

An RFQ is a document sent to suppliers asking for price quotes on specific products. This process is essential for B2B buyers to obtain competitive pricing and terms, allowing for informed purchasing decisions.

Incoterms (Termos Comerciais Internacionais)

These are international rules that define the responsibilities of buyers and sellers in global trade. Understanding Incoterms is crucial for B2B transactions to clarify shipping obligations, risks, and costs associated with the delivery of goods.

Garantia

A warranty is a guarantee provided by the manufacturer regarding the condition of the product. For B2B buyers, knowing the warranty terms can impact purchasing decisions and long-term service planning, ensuring protection against defects and quality issues.

Prazo de entrega

This term refers to the time taken from placing an order to the delivery of the product. Understanding lead times is essential for businesses to manage inventory effectively and maintain operational efficiency, especially in industries reliant on timely equipment maintenance.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions when purchasing the Merlin Digital Tire Pressure Gauge, ultimately enhancing their operational efficiency and safety standards.

The global market for digital tire pressure gauges, including the MERLIN brand, is driven by increasing awareness of vehicle maintenance and safety. As more businesses prioritize efficient fleet management, the demand for reliable tire pressure monitoring tools is on the rise. In regions such as Africa and South America, where vehicle populations are growing rapidly, there’s an escalating need for cost-effective solutions that enhance vehicle performance and fuel efficiency. Additionally, the burgeoning e-commerce landscape is enabling international buyers to access high-quality products like the MERLIN digital tire pressure gauge with greater ease.

Emerging technologies are also influencing sourcing trends. The integration of IoT (Internet of Things) capabilities in tire pressure management systems is gaining traction, allowing for real-time data collection and analysis. This trend is particularly relevant for B2B buyers looking to enhance fleet operations and reduce downtime. Moreover, the shift towards online marketplaces is reshaping how businesses procure equipment, with a focus on transparency in pricing, availability, and product specifications. As B2B buyers from Europe and the Middle East navigate this landscape, they must adapt to these technological advancements and consider suppliers who can offer innovative solutions alongside traditional products.

Illustrative image related to merlin digital tire pressure gauge

Sustainability is becoming a pivotal factor in the purchasing decisions of B2B buyers, particularly in regions like Europe where environmental regulations are stringent. The production of the MERLIN digital tire pressure gauge involves materials that can have significant environmental impacts, from resource extraction to manufacturing processes. Thus, businesses are increasingly seeking suppliers who prioritize sustainable practices, such as using recyclable materials and reducing carbon footprints.

Ethical sourcing is equally important, as buyers are more inclined to partner with companies that demonstrate social responsibility. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance the credibility of suppliers. For the MERLIN digital tire pressure gauge, buyers should look for manufacturers who not only comply with these standards but also provide transparency in their supply chains. This approach not only helps mitigate environmental risks but also aligns with corporate social responsibility goals, which can strengthen brand reputation and customer loyalty.

The digital tire pressure gauge has evolved significantly since its inception. Initially, mechanical gauges dominated the market, providing basic pressure readings without the precision and ease of use that digital models offer today. The introduction of digital technology in tire pressure measurement has transformed the industry by providing more accurate readings, often with features like backlit displays and multiple measurement units.

MERLIN, as a brand, has capitalized on this evolution by integrating user-friendly designs and advanced functionality into their products. With innovations such as auto shut-off features to conserve battery life and the inclusion of various chuck types for different tire valves, MERLIN has positioned itself as a reliable choice for both consumers and businesses. This evolution reflects a broader trend in the automotive sector towards enhancing user experience and operational efficiency, making digital tire pressure gauges essential tools for vehicle maintenance and safety.

By understanding these dynamics, B2B buyers can make informed decisions that align with their operational goals and sustainability commitments.

1. How do I solve discrepancies in tire pressure readings?

Discrepancies in tire pressure readings can often be attributed to improper calibration or environmental factors. To resolve this, ensure the MERLIN Digital Tire Pressure Gauge is calibrated according to the manufacturer’s instructions. Regularly check the gauge against a known accurate gauge. If issues persist, consider reaching out to the supplier for potential warranty service or replacement options. Additionally, educate your team on proper usage techniques to mitigate human error during readings.

2. What is the best way to maintain the MERLIN Digital Tire Pressure Gauge?

To maintain the MERLIN Digital Tire Pressure Gauge, store it in a dry, temperature-controlled environment to prevent damage from humidity or extreme temperatures. Regularly replace the AAA batteries to ensure optimal performance and utilize the auto shut-off feature to extend battery life. Clean the gauge with a soft cloth to avoid dirt buildup on the LCD display. Lastly, review the user manual for any specific maintenance recommendations to maximize its lifespan.

3. What are the customization options available for the MERLIN Digital Tire Pressure Gauge?

Customization options for the MERLIN Digital Tire Pressure Gauge typically include branding with your company logo and specific packaging designs. It’s advisable to discuss your needs with the supplier prior to placing an order. Depending on the order quantity, some suppliers may offer tailored features such as alternative display units or additional accessories. Ensure you confirm the minimum order quantity (MOQ) for customized products to align with your business requirements.

4. What is the minimum order quantity (MOQ) for bulk purchases?

The minimum order quantity (MOQ) for the MERLIN Digital Tire Pressure Gauge can vary by supplier. Generally, for bulk purchases, the MOQ can range from 50 to 100 units. It’s essential to communicate directly with your chosen supplier to confirm their specific MOQ and explore potential pricing benefits for larger orders. Discussing your purchasing plans in advance can also help in negotiating better terms.

5. What payment terms are typically offered for international B2B transactions?

Payment terms for international B2B transactions can vary widely depending on the supplier’s policies and the buyer’s creditworthiness. Common terms include a 30% deposit upon order confirmation with the balance payable before shipment, or net 30 days after delivery. Some suppliers may accept letters of credit or escrow services for added security. Always clarify payment terms upfront to avoid misunderstandings and ensure smooth transaction processing.

6. How can I ensure quality assurance when sourcing the MERLIN Digital Tire Pressure Gauge?

To ensure quality assurance when sourcing the MERLIN Digital Tire Pressure Gauge, request certifications and compliance documents from the supplier. Conducting a factory audit can provide insights into their manufacturing processes and quality control measures. Additionally, consider placing a trial order to evaluate product quality firsthand. Establishing a clear communication channel with the supplier can facilitate prompt resolution of any quality issues that may arise.

7. What logistics options are available for shipping the MERLIN Digital Tire Pressure Gauge internationally?

International shipping logistics for the MERLIN Digital Tire Pressure Gauge typically include air freight and sea freight options. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Discuss shipping preferences with your supplier and confirm which logistics partners they work with. Ensure that all shipping documentation, including customs clearance, is prepared in advance to avoid delays at the border.

8. How do I vet suppliers for the MERLIN Digital Tire Pressure Gauge?

Vetting suppliers for the MERLIN Digital Tire Pressure Gauge involves researching their reputation, checking references, and reviewing customer feedback. Utilize platforms such as Alibaba or trade directories to assess supplier ratings and certifications. Request samples to evaluate product quality and ensure compliance with your specifications. Engaging in direct communication can also provide insights into their reliability and customer service capabilities. Consider participating in trade shows to meet potential suppliers in person.

Domínio: facebook.com

Registrado: 1997 (28 anos)

Introdução: Apex Automotor tests 40 tire pressure gauges.

The MERLIN Digital Tire Pressure Gauge stands out in the market due to its precision, ease of use, and versatility. With an accuracy of 1% at 150 PSI and multiple pressure measurement units, it caters to a wide range of applications across various industries. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, investing in reliable tire pressure gauges is critical for optimizing vehicle performance and ensuring safety standards.

Strategic sourcing of the MERLIN gauge not only enhances operational efficiency but also enables businesses to maintain cost-effective inventory management. The competitive pricing and high-quality specifications make it an attractive option for bulk purchasing, especially for companies looking to maximize value while minimizing costs.

As global demand for quality automotive tools continues to rise, now is the opportune time to align your procurement strategies with reliable suppliers of the MERLIN Digital Tire Pressure Gauge. Take the next step in elevating your business operations by sourcing products that meet international quality standards and cater to your market needs. Partner with trusted suppliers to ensure a steady supply of this essential tool, enhancing your competitive edge in the marketplace.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.