Navigating the global market for air hose pumps presents unique challenges for B2B buyers, particularly those sourcing equipment across diverse regions such as Africa, South America, the Middle East, and Europe. With varying standards, regulations, and supplier capabilities, making informed purchasing decisions can feel overwhelming. This comprehensive guide is designed to simplify that process, focusing on the essentials of air hose pump procurement. From understanding different types and applications to exploring supplier vetting techniques and cost considerations, this resource provides critical insights that empower international buyers.

Air hose pumps play a vital role in various industries, including construction, manufacturing, and automotive, where reliable pneumatic solutions are essential. The guide delves into the specifics of performance metrics, compatibility with existing systems, and maintenance requirements, ensuring that buyers can assess options effectively. Furthermore, we explore regional market dynamics and the implications of trade policies, enabling businesses to navigate potential hurdles in procurement.

By leveraging the information in this guide, B2B buyers will gain the knowledge needed to select the right air hose pumps that meet their operational needs and budget constraints. Whether you are in Brazil seeking robust performance or in Germany looking for energy-efficient models, this guide is your roadmap to making strategic purchasing decisions that drive success in the competitive global marketplace.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Single-Stage Air Pumps | Simple design, compresses air in one stroke | General manufacturing, automotive | Prós: Cost-effective, easy maintenance. Contras: Limited pressure output. |

| Two-Stage Air Pumps | Compresses air in two phases for higher PSI | Heavy-duty applications, industrial | Prós: Higher efficiency, greater pressure. Contras: More complex, higher initial cost. |

| Portable Air Pumps | Lightweight, often battery-operated | Construction, outdoor maintenance | Prós: Easy transport, versatile. Contras: Limited power and capacity. |

| Oil-Free Air Pumps | No lubrication required, cleaner output | Medical, food processing | Prós: Low maintenance, reduces contamination. Contras: Generally lower durability. |

| Rotary Screw Pumps | Continuous air flow, efficient for large volumes | Large-scale industrial operations | Prós: High efficiency, minimal downtime. Contras: High upfront investment, requires skilled maintenance. |

Single-stage air pumps are designed to compress air in a single stroke, making them ideal for applications requiring moderate pressure. Typically found in smaller workshops and light industrial settings, these pumps are user-friendly and cost-effective, appealing to small businesses. When considering a purchase, buyers should evaluate the pump’s capacity and intended use, ensuring it meets the specific pressure requirements of their operations.

Two-stage air pumps utilize a two-phase compression process to achieve higher pressure outputs, making them suitable for heavy-duty applications. Industries such as manufacturing and automotive benefit from their efficiency and ability to handle demanding tasks. Buyers should consider the increased complexity and initial investment costs, as well as the long-term energy savings and performance benefits they offer.

Portable air pumps are designed for ease of transport, often equipped with battery options for remote use. They are particularly useful in construction and outdoor maintenance, where mobility is crucial. While these pumps offer versatility and convenience, buyers must consider the trade-off in power and capacity, ensuring that they select a model that meets their operational needs without compromising performance.

Oil-free air pumps operate without lubrication, resulting in cleaner air output, which is essential in industries like medical and food processing. Their low maintenance requirements and reduced risk of contamination make them attractive to businesses focused on hygiene and safety. However, potential buyers should assess the durability and longevity of these pumps, as they may not withstand the same rigorous conditions as oil-lubricated alternatives.

Rotary screw pumps are engineered for continuous air flow and high efficiency, making them ideal for large-scale industrial applications. Their ability to run for extended periods without interruption can significantly enhance productivity. However, buyers must be prepared for a higher upfront investment and ensure they have the necessary expertise for maintenance, as these systems can be complex and require specialized knowledge to operate effectively.

| Indústria/Setor | Specific Application of air hose pump | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Construção | Pneumatic tool operation | Increases efficiency and productivity on job sites | Assess compatibility with existing tools and pressure requirements |

| Agricultura | Pulverização e irrigação de culturas | Enhances crop yield and resource management | Evaluate durability for harsh environments and ease of maintenance |

| Fabricação | Material transfer and pneumatic conveying | Streamlines production processes and reduces downtime | Consider flow rate, pressure specifications, and energy efficiency |

| Automotivo | Enchimento e manutenção de pneus | Improves safety and reduces vehicle downtime | Ensure compliance with safety standards and check for portability |

| Mining | Dust suppression and material handling | Enhances worker safety and operational efficiency | Look for rugged construction and resistance to wear in harsh conditions |

In the construction industry, air hose pumps are primarily used to power pneumatic tools such as nail guns, jackhammers, and air chisels. These tools require a reliable source of compressed air to operate effectively, and air hose pumps provide the necessary pressure. By using these pumps, construction companies can significantly enhance their productivity, completing projects faster while reducing labor costs. International buyers should consider factors such as the pump’s compatibility with existing tools and the required pressure levels to ensure optimal performance on-site.

Air hose pumps are essential in agriculture for applications like crop spraying and irrigation systems. They facilitate the efficient distribution of fertilizers and pesticides, ensuring even coverage and minimizing waste. This capability directly contributes to improved crop yields and better resource management. For buyers in regions like Africa and South America, it is crucial to evaluate the durability of air hose pumps in varying climates and their ease of maintenance to ensure long-term reliability in the field.

In manufacturing, air hose pumps are integral to material transfer and pneumatic conveying systems. They help move bulk materials efficiently throughout production lines, reducing the need for manual labor and minimizing downtime caused by material handling. This automation leads to streamlined processes and improved overall productivity. When sourcing these pumps, businesses should focus on flow rates, pressure specifications, and energy efficiency to align with their operational needs and sustainability goals.

In the automotive sector, air hose pumps are primarily used for tire inflation and general maintenance tasks. Properly inflated tires are crucial for vehicle safety and performance, making these pumps vital for workshops and service stations. They can also be used to power various pneumatic tools necessary for repairs. Buyers should ensure that the pumps comply with safety standards and consider portability features to facilitate ease of use in different service environments.

In the mining industry, air hose pumps play a critical role in dust suppression and material handling. By providing a consistent source of compressed air, these pumps help control dust levels, improving air quality and worker safety. Additionally, they are used to transport materials efficiently within mining operations. Buyers looking for air hose pumps for mining applications should prioritize rugged construction and resistance to wear, as these pumps will often be exposed to harsh conditions.

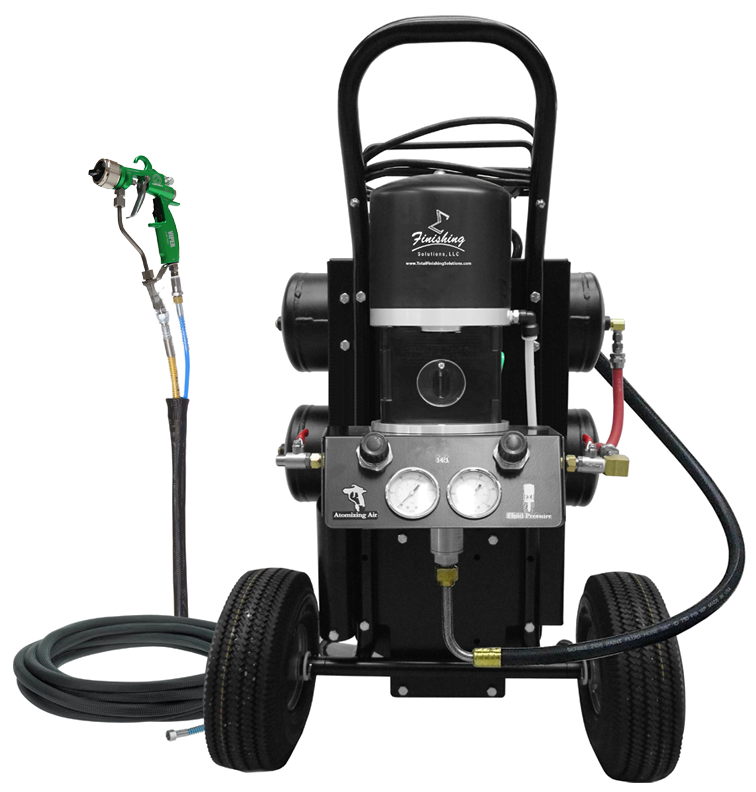

Illustrative image related to air hose pump

O problema: A common issue faced by B2B buyers of air hose pumps is inconsistent air pressure delivery, which can severely impact productivity. For instance, a manufacturing facility relying on pneumatic tools may experience fluctuations in air pressure, causing tools to underperform or even stall during operation. This can lead to increased downtime, wasted resources, and a frustrating work environment. The inconsistency might stem from a mismatch between the pump’s specifications and the tools being used, or from inadequate maintenance practices.

A solução: To mitigate this problem, it is crucial to thoroughly assess the air requirements of your pneumatic tools before purchasing an air hose pump. Buyers should ensure that the pump’s output pressure and flow rate align with the tools’ specifications. Additionally, regular maintenance should not be overlooked; this includes checking for leaks, replacing worn-out hoses, and ensuring that filters are clean. Buyers can also consider investing in pressure regulators and additional storage tanks to stabilize air pressure delivery. By taking these steps, facilities can enhance their operational efficiency and reduce the likelihood of disruptions.

O problema: In industries such as construction and mining, air hose pumps often face harsh operating conditions, including extreme temperatures, dust, and moisture. Buyers might find that standard pumps quickly deteriorate under these conditions, leading to frequent replacements and higher operational costs. The challenge is not only to find a durable product but also to ensure that it can withstand specific environmental factors unique to the buyer’s operational site.

A solução: When sourcing an air hose pump for challenging environments, buyers should prioritize products specifically designed for durability. Look for pumps made from high-quality materials that are resistant to corrosion and abrasion, such as anodized aluminum or stainless steel. Additionally, consider pumps with weatherproof enclosures and seals that protect against dust and moisture ingress. It’s also wise to consult manufacturers regarding their warranties and service agreements, as these can provide insight into product longevity and support. By selecting a robust air hose pump tailored to environmental conditions, buyers can significantly reduce maintenance costs and downtime.

O problema: Another pain point for B2B buyers is the difficulty in accurately sizing air hose pumps to meet their operational needs. Many companies struggle with determining the correct size and type of pump, leading to either underperformance or overinvestment in equipment. This can be particularly problematic in diverse operations where different tools require varying air pressures and flow rates, complicating the selection process.

A solução: To address sizing and compatibility issues, buyers should conduct a comprehensive analysis of their pneumatic tool requirements, including the CFM (cubic feet per minute) and PSI (pounds per square inch) needed for optimal performance. Utilizing a compatibility chart or consulting with pump manufacturers can provide valuable insights into which pumps will work best for specific applications. Additionally, buyers should consider modular systems that allow for scalability, enabling them to adjust their air supply as operational needs evolve. Engaging with knowledgeable suppliers who can offer tailored recommendations based on a buyer’s specific applications will also streamline the selection process and enhance overall productivity.

Illustrative image related to air hose pump

When selecting materials for air hose pumps, it is essential to consider properties that directly impact performance, durability, and overall cost. The most common materials used in the construction of air hose pumps include rubber, polyurethane, aluminum, and stainless steel. Each material has its unique characteristics, advantages, and limitations that can significantly affect the pump’s operation and suitability for specific applications.

Rubber is widely used in air hose pumps, particularly for seals, gaskets, and hoses. Its key properties include excellent flexibility and good resistance to wear and abrasion. Rubber can handle moderate temperature ranges, typically between -20°C to 80°C, and is suitable for low to medium-pressure applications.

Prós: Rubber is relatively inexpensive and easy to manufacture, making it a cost-effective choice for many applications. It provides good sealing capabilities, which is crucial for maintaining pressure in air systems.

Contras: However, rubber can degrade over time when exposed to UV light, ozone, and certain chemicals, leading to potential failure. Its limited temperature and pressure ratings may restrict its use in more demanding environments.

Illustrative image related to air hose pump

Impacto no aplicativo: Rubber is compatible with air and non-corrosive gases, but care should be taken when using it with oils or solvents, which can cause swelling or degradation.

Considerações para compradores internacionais: Buyers from regions like Africa and South America should ensure that the rubber used meets local standards for temperature and chemical resistance, as well as compliance with ASTM or DIN specifications.

Polyurethane is another common material used in air hose pumps, particularly for hoses and seals. It boasts excellent abrasion resistance, a wide temperature range (typically -40°C to 90°C), and good elasticity.

Prós: The durability of polyurethane makes it suitable for high-wear applications, and its resistance to oils and solvents enhances its versatility. It also maintains flexibility in colder temperatures, making it ideal for various climates.

Illustrative image related to air hose pump

Contras: While polyurethane is more durable than rubber, it can be more expensive and may require more complex manufacturing processes. Additionally, it has limited resistance to UV exposure, which can lead to degradation over time.

Impacto no aplicativo: Polyurethane is well-suited for air and gas applications, particularly where abrasion and wear are concerns. However, it may not be the best choice for high-temperature applications.

Considerações para compradores internacionais: Compliance with local standards is crucial, especially in Europe, where regulations around materials and environmental impact are stringent. Buyers should verify that the polyurethane used meets relevant certifications.

Aluminum is often used in the construction of air hose pump bodies and components due to its lightweight and corrosion-resistant properties. It typically withstands temperatures up to 150°C and can handle moderate pressure levels.

Prós: The lightweight nature of aluminum reduces the overall weight of the pump, making it easier to transport and install. Its corrosion resistance makes it suitable for various environments, including humid and coastal areas.

Contras: However, aluminum can be more expensive than other materials and may require additional surface treatments to enhance its durability. It is also less robust than steel, making it more susceptible to deformation under high pressure.

Impacto no aplicativo: Aluminum is ideal for applications where weight and corrosion resistance are critical, such as in portable air pumps. However, it may not be suitable for heavy-duty industrial applications requiring high strength.

Considerações para compradores internacionais: Buyers should ensure that aluminum components comply with international standards, such as ASTM or JIS, particularly in regions like Germany, where material quality is heavily regulated.

Stainless steel is often selected for components that require high strength and corrosion resistance, particularly in harsh environments. It can handle high temperatures (up to 300°C) and is suitable for high-pressure applications.

Prós: The durability and strength of stainless steel make it ideal for heavy-duty applications. It is also resistant to rust and corrosion, ensuring a longer lifespan even in challenging conditions.

Contras: The primary drawback of stainless steel is its cost; it is more expensive than aluminum and other materials. Additionally, the manufacturing process can be more complex, leading to longer lead times.

Impacto no aplicativo: Stainless steel is perfect for applications involving corrosive media or high pressures, making it a preferred choice in industrial settings.

Considerações para compradores internacionais: Buyers should ensure compliance with international standards and certifications, particularly in regions with stringent regulations, such as Europe and the Middle East.

| Material | Typical Use Case for air hose pump | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Borracha | Seals and hoses | Cost-effective and flexible | Degrades under UV and chemical exposure | Baixa |

| Polyurethane | Hoses and seals | Excellent abrasion resistance | More expensive and UV sensitive | Médio |

| Alumínio | Pump bodies and components | Leve e resistente à corrosão | Susceptible to deformation under pressure | Médio |

| Aço inoxidável | Heavy-duty applications | Alta força e resistência à corrosão | Custo mais alto e fabricação complexa | Alta |

This guide provides a comprehensive overview of the strategic material selection for air hose pumps, enabling B2B buyers to make informed decisions based on performance, application needs, and regional compliance standards.

The manufacturing of air hose pumps involves several critical stages, each designed to ensure the reliability and efficiency of the final product. Understanding these processes can help B2B buyers assess suppliers and ensure they are making informed purchasing decisions.

Illustrative image related to air hose pump

Material preparation is the foundational step in the production of air hose pumps. Manufacturers typically source high-quality raw materials such as aluminum, steel, and rubber, which are essential for the durability and performance of the pumps.

During this phase, materials undergo rigorous inspections to confirm they meet the necessary specifications. This may involve checking for impurities, measuring dimensions, and verifying material properties through methods like tensile strength testing. Suppliers should provide material certifications to prove compliance with international standards, which is particularly important for buyers from regions with strict regulatory requirements.

Once the materials are prepared, the next stage is forming. This process includes several techniques such as casting, machining, and extrusion.

Each technique used in forming must be carefully monitored to maintain quality standards, with regular checks for dimensional accuracy and surface finish.

Assembly involves bringing together the various components produced in the previous stages. This process can be manual or automated, depending on the complexity of the pump and the manufacturer’s capabilities.

Illustrative image related to air hose pump

During assembly, components are fitted together, and this step often includes the installation of seals, bearings, and other critical parts. Manufacturers typically implement standardized work instructions and checklists to ensure each assembly is consistent and meets quality standards.

Quality checkpoints during assembly are essential; they may include visual inspections and functional tests to verify that each pump operates as intended before moving to the finishing stage.

The finishing stage is crucial for enhancing the durability and aesthetic appeal of air hose pumps. This can involve processes such as painting, coating, and surface treatment.

Quality assurance is a critical aspect of air hose pump manufacturing, ensuring products meet both safety and performance standards.

Padrões internacionais: Many manufacturers adhere to ISO 9001, which outlines a framework for quality management systems. Compliance with this standard indicates a commitment to quality and customer satisfaction.

Industry-Specific Certifications: Depending on the market, additional certifications may be required. For instance, CE marking is crucial for compliance within the European Union, while API (American Petroleum Institute) certifications may be necessary for pumps used in the oil and gas industry.

Quality control (QC) is a multi-faceted process that includes several checkpoints throughout manufacturing to ensure that products meet specified standards.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential to mitigate risks.

Illustrative image related to air hose pump

International buyers should be aware of specific nuances in quality control that may vary by region. For instance, regulatory requirements can differ significantly, which may impact compliance and certification processes.

By comprehensively understanding the manufacturing processes and quality assurance protocols involved in air hose pump production, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who prioritize quality and compliance.

When sourcing an air hose pump for industrial applications, it is vital to follow a structured approach to ensure that you acquire a reliable and efficient product. This guide provides a step-by-step checklist designed for B2B buyers, helping you navigate the complexities of procurement while maximizing value and minimizing risks.

Illustrative image related to air hose pump

Clearly outline your requirements before initiating the sourcing process. This includes determining the pump’s pressure rating, flow rate, and compatibility with your existing systems. Knowing these specifications ensures that you select a pump that meets your operational needs and prevents costly mismatches.

Stay informed about the latest market trends and reputable brands in the air hose pump sector. Understanding industry standards and innovations can help you identify products that offer better efficiency and reliability.

Before committing, thoroughly vet potential suppliers to ensure they can deliver quality products and services. Request company profiles, product catalogs, and references from existing customers in your industry.

Ensure that the suppliers you consider comply with international standards and hold relevant certifications. This step is crucial for ensuring product safety and performance, especially in regulated industries.

Before finalizing your purchase, request samples or demonstrations of the air hose pumps. This allows you to evaluate the product’s performance and suitability for your specific applications.

Once you have selected a supplier, focus on negotiating favorable terms and conditions. This includes pricing, payment terms, warranty provisions, and delivery schedules.

After completing the procurement process, aim to establish a long-term relationship with your supplier. This can lead to better pricing, priority service, and access to new products in the future.

By following this checklist, B2B buyers can navigate the complexities of sourcing air hose pumps effectively, ensuring they make informed decisions that align with their operational needs and budget.

When analyzing the cost structure of air hose pumps, several key components come into play:

Materiais: The choice of materials significantly influences the overall cost. High-quality metals and composites used in pump construction enhance durability but come at a premium. Buyers should consider the balance between cost and longevity, particularly for pumps subjected to high usage.

Trabalho: Labor costs vary based on geographical location and the complexity of manufacturing processes. Regions with higher labor costs, such as Western Europe, may see increased pump prices. Conversely, sourcing from countries with lower labor rates may offer cost advantages, but quality must be monitored closely.

Custos indiretos de fabricação: This includes expenses related to factory operations, utilities, and administrative costs. A well-managed facility can reduce overhead, thus lowering product prices. Buyers should inquire about the supplier’s operational efficiency.

Ferramentas: Initial tooling costs can be significant, especially for custom designs. This is a critical factor for buyers requiring specialized pumps. Understanding whether these costs are included in the quoted price or charged separately is essential for accurate budgeting.

Controle de qualidade (QC): QC processes ensure that pumps meet industry standards and client specifications. While stringent QC can increase costs, it is a worthwhile investment for reliability and compliance, particularly for industries with strict regulatory requirements.

Logística: Shipping costs can vary widely based on distance, mode of transport, and weight of the pump. Buyers should account for logistics in their total cost analysis, especially when sourcing internationally, as tariffs and import duties can further impact expenses.

Margem: Suppliers typically build a margin into their pricing to ensure profitability. Understanding the industry standard margins can help buyers gauge whether a price is competitive.

Several factors can influence the pricing of air hose pumps, particularly for international buyers:

Volume e quantidades mínimas de pedidos (MOQ): Suppliers often provide discounts for bulk purchases. Negotiating MOQ can lead to significant savings, particularly for larger organizations or those planning long-term projects.

Especificações e personalização: Custom features or specific performance requirements can drive up costs. Buyers should clearly define their needs upfront to avoid unexpected price increases later in the procurement process.

Material Choices: The selection of materials not only affects durability but also pricing. For instance, stainless steel components may cost more than standard steel but offer better corrosion resistance, making them more cost-effective in the long run.

Certificações de qualidade: Pumps that meet international standards or possess certifications (like ISO or CE) may command higher prices. However, these certifications can also reduce liability and enhance marketability, particularly in regions with strict compliance regulations.

Fatores do fornecedor: The reputation, reliability, and location of suppliers play a crucial role in pricing. Established suppliers may charge more due to their proven quality, while newer or less-known manufacturers might offer lower prices to gain market share.

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international buyers as they define the responsibilities of buyers and sellers in the shipping process. Different terms can significantly affect total costs, including insurance, freight, and customs clearance.

Negociação: Always negotiate prices and payment terms. Suppliers are often willing to adjust pricing for committed buyers or those placing larger orders.

Foco no custo total de propriedade (TCO): Rather than just the purchase price, consider the long-term costs associated with maintenance, energy consumption, and replacement parts. A slightly higher upfront cost may lead to significant savings over time.

Understand Pricing Nuances for International Transactions: Factors such as currency fluctuations, local taxes, and tariffs can impact pricing. Buyers should stay informed about these elements when sourcing from different regions.

Request Samples or Prototypes: Before committing to a large order, request samples to evaluate quality. This can prevent costly mistakes associated with inadequate product performance.

Criar relacionamentos com fornecedores: Developing strong partnerships can lead to better pricing, priority service, and improved communication, all of which can enhance procurement efficiency.

Prices for air hose pumps can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure they receive competitive pricing that aligns with their specific needs.

In the realm of industrial applications, selecting the right equipment for inflation and air transfer is crucial for operational efficiency. Air hose pumps are popular choices for many businesses due to their versatility and ease of use. However, several alternative solutions can also meet similar needs, each with its own set of advantages and disadvantages. This analysis will compare air hose pumps with two viable alternatives: electric air compressors and manual hand pumps.

| Aspecto de comparação | Air Hose Pump | Electric Air Compressor | Bomba manual de mão |

|---|---|---|---|

| Desempenho | High airflow, suitable for continuous use | Variable airflow, high efficiency for power needs | Low airflow, suitable for small tasks |

| Custo | Moderate initial investment | Higher initial and operational costs | Low initial investment |

| Facilidade de implementação | Simple setup and operation | Requires electrical connections and setup | Requires physical effort, minimal setup |

| Manutenção | Low maintenance needs | Regular maintenance required for optimal performance | Minimal maintenance needed |

| Melhor caso de uso | Large-scale industrial tasks | Workshops and heavy-duty applications | Small-scale, portable tasks |

Electric air compressors are widely used in various industries due to their efficiency and power. They provide consistent airflow and can handle demanding applications such as powering pneumatic tools and inflating large items. While they have a higher upfront cost and may require additional electrical infrastructure, their performance and reliability in heavy-duty tasks make them a strong alternative. However, they necessitate regular maintenance, including oil changes and filter replacements, which can add to operational costs.

Manual hand pumps are a cost-effective solution for smaller tasks that require less power. They are portable, making them ideal for situations where electricity is not available or for quick inflation jobs. The low initial investment and minimal maintenance are attractive features for businesses on a budget. However, they are limited by their low airflow and require physical effort, which can be a drawback for larger projects or frequent use. They are best suited for small-scale operations or emergency situations rather than regular industrial applications.

When determining the best air transfer solution for your business, consider your specific operational requirements, budget constraints, and the scale of tasks at hand. Air hose pumps offer a balanced approach for continuous use in larger settings, while electric compressors excel in high-demand environments despite their higher costs. For smaller, less frequent tasks, manual hand pumps provide an economical option with minimal maintenance. Ultimately, the right choice will depend on the unique demands of your operations and your long-term business objectives.

Illustrative image related to air hose pump

Understanding the technical specifications of air hose pumps is essential for B2B buyers to ensure compatibility and performance in their applications. Here are some critical specifications to consider:

Grau do material

The material grade of an air hose pump typically refers to the quality and type of materials used in its construction, such as aluminum, steel, or composite materials. High-grade materials enhance durability, resistance to corrosion, and overall lifespan. B2B buyers should prioritize pumps made from robust materials, particularly in industries where harsh conditions may be present, such as construction or manufacturing.

Classificação de pressão (PSI)

This specification indicates the maximum pressure the pump can handle, often measured in pounds per square inch (PSI). A higher PSI rating means the pump can deliver more power and efficiency, making it suitable for heavy-duty applications. For international buyers, understanding the pressure rating is crucial, as it affects compatibility with existing systems and equipment.

Taxa de fluxo (CFM)

The flow rate, measured in cubic feet per minute (CFM), determines how much air the pump can deliver in a given time frame. A higher flow rate is essential for applications requiring rapid inflation or high air consumption tools. B2B buyers should assess the flow rate based on their operational needs to ensure optimal performance.

Tolerance

Tolerance refers to the allowable variation in dimensions and performance specifications. High precision in manufacturing tolerances ensures that the pump operates efficiently and fits correctly within the intended application. For B2B buyers, understanding tolerances is vital to prevent operational issues and ensure seamless integration with other components.

Fonte de energia

Air hose pumps can be powered by electricity, gasoline, or air compressors. Understanding the power source is crucial for B2B buyers, as it affects the pump’s portability, efficiency, and suitability for specific environments. Buyers should consider the availability of power sources in their operational regions, especially in emerging markets.

Weight and Portability

The weight of the air hose pump affects its portability and ease of use. Lightweight models are preferred for mobile applications where transportation is frequent. B2B buyers should evaluate the weight in relation to their operational needs to ensure ease of handling and setup.

Familiarity with trade terminology is essential for effective communication and negotiation in the B2B market. Here are some common terms you should know:

OEM (fabricante original do equipamento)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of air hose pumps, purchasing from an OEM can ensure compatibility and quality assurance, making it a preferred choice for many businesses.

MOQ (Quantidade mínima de pedido)

MOQ indicates the smallest quantity a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and budgeting. Buyers should negotiate MOQs based on their operational needs and forecasted demand.

RFQ (Request for Quotation, solicitação de cotação)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. For air hose pumps, issuing an RFQ allows businesses to compare prices, terms, and specifications from different suppliers, helping them make informed purchasing decisions.

Incoterms (Termos Comerciais Internacionais)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding Incoterms is essential for B2B buyers involved in cross-border transactions, as they outline who bears the costs and risks during shipping, ensuring clarity in contractual agreements.

Prazo de entrega

This refers to the amount of time it takes from placing an order to receiving the goods. For air hose pumps, understanding lead times is vital for planning and inventory management, particularly in industries where timely delivery is critical.

Período de garantia

The warranty period is the duration during which the manufacturer guarantees the pump’s performance and quality. A longer warranty period can indicate the manufacturer’s confidence in their product and provide assurance to buyers regarding durability and reliability.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when purchasing air hose pumps, ensuring they choose the right products for their specific needs.

The air hose pump sector is undergoing significant transformations driven by technological advancements, economic shifts, and changing consumer demands. Internationally, the market is experiencing robust growth due to the increasing demand for portable and efficient air solutions across various industries, including construction, manufacturing, and automotive. In regions like Africa and South America, infrastructure development projects are fueling the need for reliable air hose pumps, as businesses seek to enhance productivity and efficiency. Meanwhile, in Europe and the Middle East, there is a rising focus on energy-efficient and low-noise pumps, reflecting the stringent environmental regulations and consumer preferences in these regions.

Emerging B2B technology trends are reshaping sourcing strategies. Buyers are increasingly leveraging digital platforms for procurement, allowing for real-time comparisons of product specifications, prices, and supplier ratings. The rise of Industry 4.0 has also encouraged manufacturers to incorporate smart technologies into air hose pumps, enabling predictive maintenance and improved operational efficiency. Furthermore, the integration of IoT devices is becoming commonplace, providing users with data analytics that can optimize pump performance and minimize downtime.

Illustrative image related to air hose pump

Sustainability is becoming a critical consideration for international B2B buyers in the air hose pump sector. The environmental impact of manufacturing processes and product lifecycle management is under scrutiny, prompting companies to prioritize ethical sourcing and sustainability in their supply chains. Buyers are increasingly demanding transparency from suppliers regarding the materials used in production and the environmental practices in place.

To align with these sustainability goals, many manufacturers are adopting ‘green’ certifications and utilizing eco-friendly materials in their air hose pumps. Certifications such as ISO 14001 for environmental management systems and Energy Star for energy efficiency are becoming essential benchmarks for buyers looking to make responsible purchasing decisions. Additionally, the use of recyclable materials and reduced carbon footprints in production processes not only meets regulatory standards but also appeals to environmentally conscious consumers. By prioritizing sustainability, businesses can enhance their brand reputation and foster loyalty among customers who value ethical practices.

The evolution of the air hose pump market is marked by significant technological advancements and shifts in consumer preferences. Initially, air hose pumps were simple mechanical devices, primarily used in industrial applications. However, as technology progressed, manufacturers began to develop more sophisticated models that offered higher efficiency, portability, and versatility. The introduction of electric and battery-operated pumps has expanded their usability across various sectors, including home improvement and automotive repair.

In recent years, the focus has shifted towards integrating digital technologies, such as automation and IoT, which have revolutionized the operational capabilities of air hose pumps. This evolution reflects the broader trends in industrial automation and smart manufacturing, underscoring the importance of staying abreast of technological advancements to remain competitive in the B2B marketplace. As the sector continues to evolve, international buyers must adapt to these changes, ensuring that their sourcing strategies align with emerging trends and consumer demands.

How do I solve issues with air hose pump performance?

To address performance issues with air hose pumps, first check for air leaks in the hoses or connections, as these can significantly impact efficiency. Ensure that the pump is properly lubricated and that the air filter is clean to maintain optimal airflow. Additionally, confirm that the pump is not overloaded beyond its specified capacity, as this can cause overheating and reduce performance. Regular maintenance and timely replacement of worn parts can also help prevent problems.

What is the best air hose pump for industrial applications?

The best air hose pump for industrial applications typically features a high CFM (cubic feet per minute) rating and durability to withstand continuous use. Look for models that are designed for heavy-duty tasks, such as two-stage pumps that provide higher pressure and efficiency. Additionally, consider factors such as noise levels, energy consumption, and ease of maintenance. Brands like Ingersoll Rand and EMAX offer reliable options that are well-suited for industrial environments.

What factors should I consider when sourcing an air hose pump supplier?

When sourcing an air hose pump supplier, consider their experience in the industry, product range, and customer reviews. Assess their manufacturing capabilities, including quality control processes and certifications, to ensure they meet international standards. It’s also important to evaluate their logistics capabilities, such as shipping options and delivery times, especially if you are importing from regions like Europe or North America to Africa or South America.

What are the typical payment terms when purchasing air hose pumps internationally?

Payment terms for international purchases of air hose pumps can vary significantly based on the supplier and the buyer’s relationship. Common terms include a deposit upfront (usually 30% to 50%) with the balance payable upon shipment or delivery. Letters of credit are also popular for larger transactions as they provide security for both parties. Always clarify payment methods accepted (e.g., wire transfer, credit card) and ensure that currency exchange rates are agreed upon to avoid disputes.

Are there minimum order quantities (MOQs) for air hose pumps?

Many suppliers set minimum order quantities (MOQs) to ensure cost-effectiveness in production and shipping. MOQs can vary widely depending on the manufacturer and the specific model of the pump. Some suppliers may offer flexibility for first-time buyers or smaller businesses, allowing for lower MOQs or sample orders. It’s essential to discuss your requirements with potential suppliers to find a mutually beneficial arrangement.

How can I ensure the quality of the air hose pumps I am purchasing?

To ensure quality, request detailed product specifications and certifications from your supplier. Conduct a factory audit if feasible, or ask for third-party quality assurance inspections. Reviewing samples before placing large orders can also help you assess the product’s quality. Additionally, inquire about the warranty and return policy to protect your investment against defects or performance issues.

What logistics considerations should I keep in mind when importing air hose pumps?

Logistics considerations when importing air hose pumps include shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder who understands the import/export regulations of both the supplier’s and your country. Be aware of potential tariffs, taxes, and duties that may apply to your shipment. Planning ahead for customs clearance can prevent delays and ensure that your products arrive on time.

Can I customize air hose pumps to meet specific operational needs?

Yes, many manufacturers offer customization options for air hose pumps to meet specific operational needs, such as unique pressure ratings, sizes, or additional features. When discussing customization, provide clear specifications and requirements to the supplier. Keep in mind that customized orders may have longer lead times and potentially higher costs, so it’s essential to factor these elements into your purchasing decision.

Domínio: store.arbusa.com

Registrado: 1998 (27 anos)

Introdução: Portable & Vehicle Mounted Air Compressor Systems by ARB 4×4 USA. Key features include: durable, high-performance compressors for tires, tools, and Air Lockers; available in portable and onboard models; various options including Twin Motor and Single Motor configurations; prices range from $224.95 to $1,379.95; Black Friday deals offering 10% off and free shipping over $75; models include CKMTA12,…

Domínio: jacosuperiorproducts.com

Registrado: 2014 (11 anos)

Introdução: SmartPro™ Digital Tire Inflator – 100 PSI (12V DC) – Price: $49.95 (Original: $79.99) – Features: Ultra compact, powerful, highly efficient, designed for performance and reliability.

SmartPro 2.0™ AC/DC Digital Tire Inflator – 100 PSI (12V DC, 120V AC) – Price: $69.95 (Original: $99.99) – Features: Fast, powerful, quiet, efficient, automatic shut-off, inflation progress bar, runs on both AC and …

In the evolving landscape of air hose pump procurement, strategic sourcing emerges as a vital component for international B2B buyers. Understanding the diverse range of products available—from high-performance compressors to specialized accessories—enables businesses in Africa, South America, the Middle East, and Europe to make informed decisions that optimize their operations. The significance of aligning sourcing strategies with market demands cannot be overstated; it not only ensures cost-effectiveness but also enhances operational efficiency.

Illustrative image related to air hose pump

As companies navigate the complexities of global supply chains, leveraging local partnerships and understanding regional market nuances can provide a competitive edge. Buyers should prioritize quality, reliability, and after-sales support when selecting suppliers, as these factors directly impact long-term success.

Looking ahead, the demand for innovative air hose pump solutions is set to grow, driven by advancements in technology and increasing industrial applications. By adopting a proactive sourcing approach, businesses can position themselves to capitalize on emerging opportunities. Engage with suppliers that share a commitment to quality and sustainability, and take the next step in enhancing your operational capabilities.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.