In the rapidly evolving landscape of global commerce, sourcing the right air pump solutions poses a significant challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The demand for efficient, portable, and versatile air pumps is on the rise, driven by various applications ranging from outdoor recreational activities to industrial uses. This comprehensive guide on pump air is designed to address these challenges head-on, offering insights into the diverse types of air pumps available, their applications, and essential factors for supplier vetting.

Understanding the nuances of the air pump market is crucial for making informed purchasing decisions. In this guide, we delve into the latest innovations, such as USB rechargeable models that enhance portability and efficiency, and explore their cost implications for businesses. Moreover, we provide a detailed analysis of the key players in the market, ensuring that you have access to reliable suppliers who meet international standards.

With actionable insights and practical advice, this guide empowers international B2B buyers to navigate the complexities of sourcing air pumps effectively. By equipping you with knowledge about product specifications, supplier qualifications, and market trends, we aim to facilitate smarter purchasing decisions that cater to the unique needs of your business in dynamic markets like Saudi Arabia and Nigeria. Embrace the opportunity to streamline your operations and enhance your product offerings with the right air pump solutions.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Bombas de ar elétricas | Rechargeable, high-speed inflation, USB-C connectivity | Camping gear, air mattresses, inflatable products | Prós: Fast inflation, portable; Contras: Battery dependency, limited deflation capability |

| Manual Hand Pumps | Lightweight, no electricity required, compact design | Outdoor activities, emergency kits | Prós: Reliable, low-cost; Contras: Labor-intensive, slower inflation |

| Battery-Powered Pumps | Cordless, versatile use with various power sources | Event setups, outdoor recreation | Prós: Flexible usage, convenient; Contras: Limited run time, may require frequent charging |

| Vacuum Pumps | Dual function for inflation and air compression | Storage solutions, travel packing | Prós: Space-saving, efficient; Contras: Complexity, may require specific bags or accessories |

| High-Pressure Pumps | Capable of reaching high PSI levels for specialized tasks | Industrial applications, automotive needs | Prós: Powerful performance; Contras: Bulkier, more expensive |

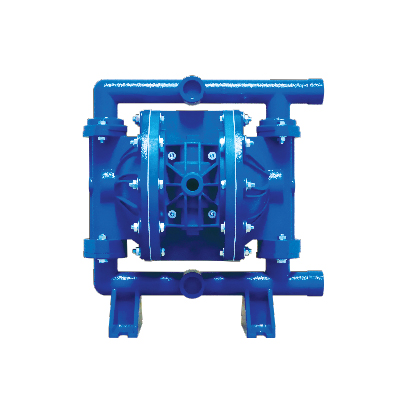

Electric air pumps are designed for rapid inflation and deflation, making them ideal for businesses involved in outdoor activities or hospitality. Their rechargeable batteries and USB-C connectivity allow for versatile usage, catering to various inflatable products like air mattresses and camping gear. When considering an electric air pump for purchase, B2B buyers should evaluate the pump’s inflation speed, battery life, and compatibility with their existing equipment.

Manual hand pumps are a staple for businesses that prioritize reliability and cost-effectiveness. These pumps require no electricity, making them suitable for remote areas or emergency situations. Their compact design allows for easy storage and transport. However, B2B buyers should be aware that while they are economical, manual pumps can be labor-intensive and slower in inflation, which might not meet the demands of high-volume operations.

Illustrative image related to pump air

Battery-powered pumps provide the convenience of cordless operation, making them a popular choice for event setups and outdoor recreation. These pumps can be used with various power sources, enhancing their versatility. For B2B buyers, the key considerations include the pump’s run time on a single charge and its ability to handle different types of inflatables. While they offer convenience, their limited battery life may require frequent recharging, which can be a drawback for extended use.

Vacuum pumps serve a dual purpose: they can inflate items and compress air out of storage bags, making them invaluable for businesses focused on logistics and packing efficiency. By removing excess air, these pumps help save space, allowing companies to maximize storage capacity. When purchasing vacuum pumps, B2B buyers should consider the compatibility with specific storage solutions and the pump’s suction power to ensure effective compression.

High-pressure pumps are specialized devices capable of delivering higher PSI levels, making them essential for industrial applications and automotive needs. These pumps are designed to handle demanding tasks, such as inflating tires or powering pneumatic tools. B2B buyers should assess the pump’s pressure capabilities, durability, and maintenance requirements, as these factors will influence operational efficiency and overall costs. However, the bulkier design and higher price point may limit their appeal for smaller businesses or less demanding applications.

| Indústria/Setor | Specific Application of pump air | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Fabricação | Pneumatic tools and machinery operation | Enhanced operational efficiency and reduced downtime | Reliability, pressure specifications, and compatibility with existing systems |

| Construção | Inflating formwork and air-supported structures | Improved project timelines and structural integrity | Durability, portability, and power source versatility |

| Healthcare | Inflating medical devices and equipment | Ensured patient comfort and operational readiness | Compliance with medical standards, ease of use, and maintenance requirements |

| Recreation & Sports | Inflating sports equipment and outdoor gear | Quick setup and enhanced customer experience | Lightweight design, multi-functionality, and battery life |

| Transport & Logistics | Inflating tires and air suspension systems | Improved vehicle performance and safety | Pressure accuracy, portability, and compatibility with various vehicle types |

In the manufacturing sector, pneumatic tools powered by pump air are critical for various operations, including assembly lines and material handling. These pumps provide consistent pressure for tools like drills and wrenches, enhancing efficiency and reducing downtime. Buyers in this sector should consider reliability and compatibility with existing systems, as downtime can lead to significant financial losses. Additionally, sourcing pumps that meet specific pressure specifications is vital to ensure optimal performance in demanding environments.

In construction, air pumps are essential for inflating formwork and air-supported structures, which are often used in large-scale projects. This application enables quicker project timelines and ensures structural integrity during construction. For international buyers, especially in regions like Africa and the Middle East where construction booms are prevalent, it is crucial to source durable and portable pumps that can withstand varying environmental conditions. Additionally, the versatility of power sources, such as battery or electric options, can be a decisive factor.

In the healthcare sector, pump air is used to inflate medical devices such as mattresses, cushions, and other equipment that enhance patient comfort. Ensuring that these devices are ready for use is critical for patient care and operational efficiency. Buyers in this sector must prioritize compliance with medical standards and consider the ease of use and maintenance requirements of the pumps. The reliability of air pumps in medical settings directly impacts patient outcomes, making it essential to choose high-quality, certified products.

For the recreation and sports industry, air pumps are vital for quickly inflating various equipment, including sports balls, inflatable boats, and camping gear. This capability enhances the customer experience by allowing for quick setup and use. B2B buyers should focus on lightweight designs and multi-functionality to cater to diverse needs, especially in outdoor and travel scenarios. Additionally, battery life is a crucial factor, particularly for products aimed at outdoor enthusiasts who may not have access to power sources.

In the transport and logistics sector, pump air is crucial for inflating tires and air suspension systems, which significantly impacts vehicle performance and safety. Proper tire inflation ensures better fuel efficiency and reduces wear and tear. Buyers should consider the accuracy of pressure readings and the portability of the pumps, as these factors influence operational efficiency. Compatibility with various vehicle types is also important, particularly for companies operating a diverse fleet across different geographic regions.

Illustrative image related to pump air

O problema: Many B2B buyers, especially those in sectors like outdoor recreation and logistics, struggle with the bulkiness and weight of traditional air pumps. When transporting equipment across diverse terrains or locations, the added weight can lead to inefficiencies in logistics and increased operational costs. Buyers in regions like Africa and South America, where conditions can be variable, need pumps that are not only lightweight but also reliable and capable of performing in remote areas without easy access to power sources.

A solução: To address this challenge, B2B buyers should invest in ultra-portable air pumps that are rechargeable via USB and designed for high efficiency. For instance, products like the GIGA PUMP Air offer a lightweight design, weighing only 1 ounce, which drastically reduces transportation burdens. When selecting air pumps, prioritize those that can be powered by a variety of sources—such as power banks, solar panels, or even vehicles. This versatility allows for greater flexibility in deployment, ensuring that the pump can be used in remote locations without reliance on traditional power sources. Additionally, choose models with high airflow rates and multiple nozzles to accommodate various inflation needs, ensuring that the equipment is ready for use in seconds.

O problema: In industries where air-filled products are routinely used, such as hospitality or event management, the process of inflating and deflating items can be time-consuming and cumbersome. Buyers often face delays due to slow inflation times or inadequate deflation capabilities, which can impact operational efficiency, particularly during peak seasons when quick turnaround is critical.

Illustrative image related to pump air

A solução: B2B buyers should look for multifunctional air pumps that provide both inflation and deflation capabilities in one device. For example, the Airback Compact Air Pump is designed to quickly inflate and deflate air mattresses and other inflatables, significantly reducing the time spent on setup and teardown. When sourcing these pumps, ensure they have robust suction capabilities for effective deflation, as this can save valuable time and labor costs. Additionally, consider integrating these pumps into your operational workflows by providing staff training on efficient usage and maintenance, which will enhance overall productivity and service delivery.

O problema: B2B buyers often express concerns about the durability and reliability of air pumps, particularly in harsh environments or for frequent use. Products that fail to withstand rigorous conditions can lead to increased maintenance costs and interruptions in service delivery, which can be detrimental in competitive markets.

A solução: To combat these issues, it’s essential to choose air pumps that are built with durable materials and designed for frequent travel use. Look for pumps that have been tested for resilience in various conditions, such as extreme temperatures or rugged terrains. For instance, selecting pumps with a strong, weather-resistant casing can ensure longevity. Additionally, prioritize suppliers that offer warranties or guarantees, which can provide peace of mind regarding the product’s reliability. Engage with manufacturers who understand your specific needs and can provide tailored solutions, ensuring you have a dependable tool that aligns with your operational demands. Regular maintenance checks and user feedback loops can also help identify any potential issues before they escalate, thereby enhancing reliability.

By addressing these common pain points, B2B buyers can make informed decisions that lead to improved operational efficiency, reduced costs, and enhanced customer satisfaction.

When selecting materials for air pumps, understanding the properties and implications of different materials is crucial for ensuring optimal performance and reliability. This analysis focuses on four common materials used in the manufacturing of air pumps: plastic, aluminum, stainless steel, and rubber. Each material has unique characteristics that can significantly impact the performance and suitability of the pump for various applications.

Illustrative image related to pump air

Plastic is often used in air pump construction due to its lightweight nature and versatility. Common types of plastics used include polyethylene and polypropylene, which offer good resistance to moisture and chemicals. The temperature and pressure ratings for plastic can vary, but they generally withstand moderate conditions, making them suitable for low-pressure applications.

Pros and Cons of Plastic:

– Prós: Lightweight, cost-effective, and resistant to corrosion. It can be molded into complex shapes, allowing for innovative designs.

– Contras: Limited durability compared to metals, especially under high temperatures or pressures. It may degrade over time when exposed to UV light or harsh chemicals.

Impacto no aplicativo: Plastic air pumps are ideal for consumer-grade products, such as inflatable toys and small air mattresses. However, they may not be suitable for industrial applications requiring high durability.

Aluminum is a popular choice for air pump components due to its excellent strength-to-weight ratio and resistance to corrosion. It can handle higher pressures than plastic, making it suitable for more demanding applications. Aluminum air pumps typically have a temperature rating that allows them to function well in a variety of environments.

Pros and Cons of Aluminum:

– Prós: Lightweight, strong, and resistant to corrosion. It can be anodized for additional protection and aesthetic appeal.

– Contras: Higher cost compared to plastic and may require more complex manufacturing processes. It can be prone to denting if not properly handled.

Illustrative image related to pump air

Impacto no aplicativo: Aluminum air pumps are often used in outdoor and industrial applications where durability is essential, such as in camping gear or automotive tools.

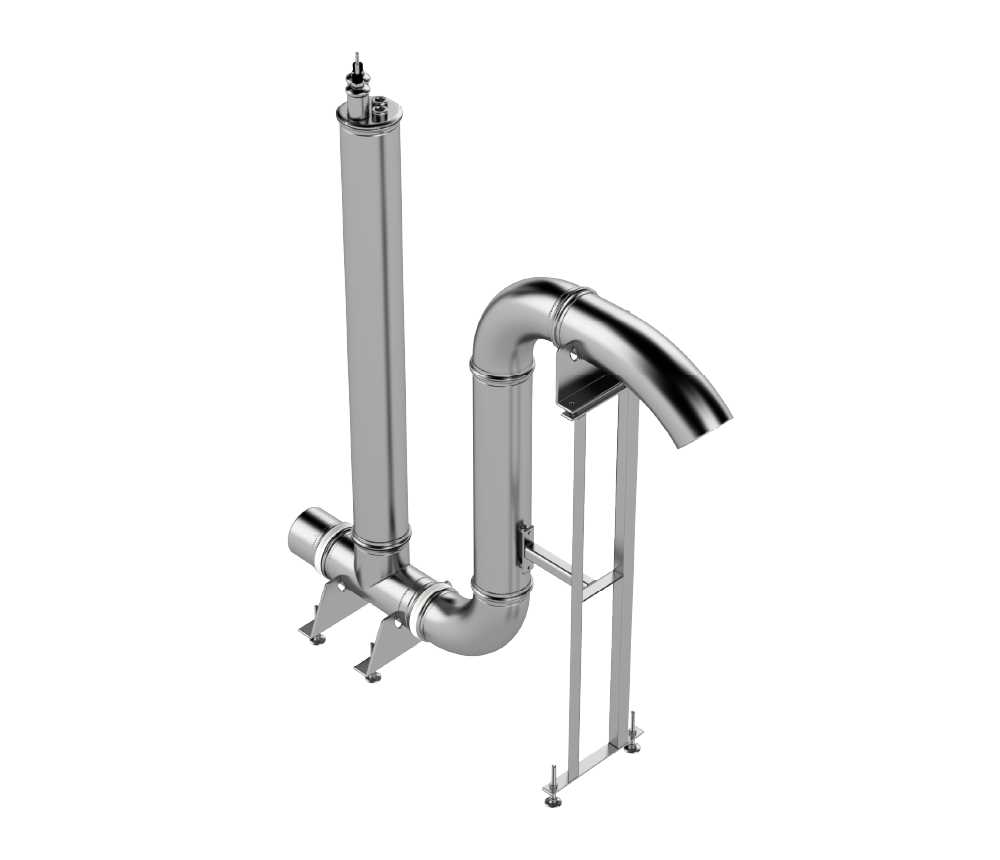

Stainless steel is known for its exceptional strength and corrosion resistance, making it a prime choice for high-performance air pumps. It can withstand extreme temperatures and pressures, making it suitable for industrial applications. The material’s durability ensures a long lifespan, even in harsh environments.

Pros and Cons of Stainless Steel:

– Prós: Extremely durable, resistant to corrosion, and can handle high pressures and temperatures. It has a professional appearance, which can enhance brand image.

– Contras: Higher manufacturing costs and weight compared to plastic and aluminum. It may require special handling to avoid scratches and maintain aesthetic quality.

Illustrative image related to pump air

Impacto no aplicativo: Stainless steel air pumps are ideal for heavy-duty applications, such as in the oil and gas industry, where reliability and performance are critical.

Rubber is primarily used in seals and gaskets within air pumps. It provides excellent flexibility and creates airtight seals, which are crucial for maintaining pressure. The temperature and pressure ratings of rubber can vary significantly depending on the type used, with some specialized rubbers designed for high-temperature applications.

Pros and Cons of Rubber:

– Prós: Excellent sealing properties, flexible, and can absorb vibrations, enhancing the overall performance of the pump.

– Contras: Limited durability under extreme temperatures and can degrade over time when exposed to certain chemicals.

Impacto no aplicativo: Rubber components are essential in ensuring the efficiency of air pumps across various applications, from consumer products to industrial machinery.

| Material | Typical Use Case for pump air | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Plástico | Consumer-grade inflatable products | Leve e econômico | Limited durability under stress | Baixa |

| Alumínio | Outdoor and industrial applications | Forte e resistente à corrosão | Higher cost and dent-prone | Médio |

| Aço inoxidável | Heavy-duty industrial applications | Extremely durable and high pressure | Higher cost and heavier weight | Alta |

| Borracha | Seals and gaskets in air pumps | Excellent sealing and flexibility | Limited durability under extremes | Baixa |

In conclusion, selecting the right material for air pumps involves a careful consideration of the application requirements, performance expectations, and cost implications. International B2B buyers should also factor in local compliance standards and preferences when making their decisions, ensuring that the selected materials meet both performance and regulatory criteria.

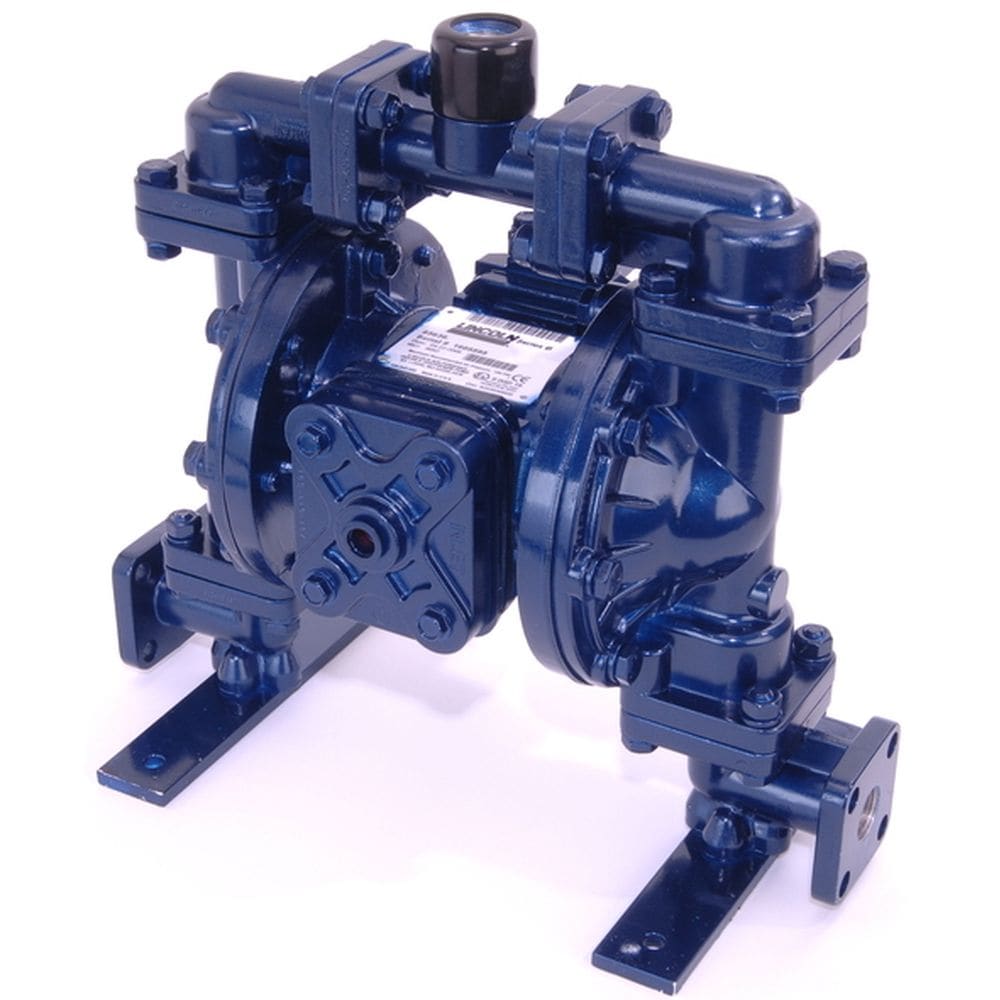

The manufacturing process of air pumps involves several critical stages, each designed to ensure that the final product meets the rigorous demands of efficiency and reliability.

The first stage in manufacturing air pumps is material preparation. Manufacturers typically utilize high-quality plastics, metals, and rubber materials, which are chosen for their durability and ability to withstand varying pressures. For electric air pumps, components such as electric motors and batteries must also be sourced. The selection of materials is crucial as it directly impacts the pump’s performance, longevity, and safety.

The forming stage includes processes like injection molding, extrusion, and machining, depending on the design and specifications of the air pump. Injection molding is commonly used for creating the body of the pump, allowing for intricate designs while maintaining uniformity. For the production of metal components, machining techniques such as CNC (Computer Numerical Control) milling and turning are employed to achieve precise dimensions. Each component must meet the design specifications to ensure seamless assembly later.

Once the individual components are formed, they move to the assembly stage. This process includes the integration of electrical and mechanical parts, ensuring that all pieces fit together correctly. Automated assembly lines are often used for mass production, which enhances efficiency and reduces human error. Quality checks are performed at various points during assembly to ensure that components are properly installed and functional.

The final stage is finishing, which may involve surface treatments such as painting, coating, or polishing. These processes not only improve the aesthetic appeal of the air pump but also provide protection against wear and corrosion. For instance, powder coating can enhance durability, making the product more suitable for outdoor use. Additionally, labeling and packaging are completed at this stage, ensuring compliance with international shipping standards.

Quality assurance (QA) is paramount in the manufacturing of air pumps, ensuring that products meet both safety standards and customer expectations.

B2B buyers should prioritize suppliers that adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific certifications, such as CE marking for European markets or API (American Petroleum Institute) standards for pumps used in oil and gas applications, can provide further assurance of product quality. These certifications indicate that the manufacturer has implemented a rigorous quality management system and complies with relevant safety regulations.

Quality control (QC) checkpoints are integrated into the manufacturing process to catch defects early. Common checkpoints include:

Controle de qualidade de entrada (IQC): This involves inspecting raw materials before they enter the production line to ensure they meet specified standards.

Controle de qualidade durante o processo (IPQC): During assembly, ongoing inspections help detect any deviations from quality standards in real-time, allowing for immediate corrective actions.

Controle de qualidade final (FQC): After assembly and finishing, a comprehensive inspection is performed to verify that each air pump meets performance and safety criteria before it is shipped to customers.

Testing methods for air pumps typically include pressure testing, performance testing, and durability testing. Pressure testing ensures that the pump can handle specified pressure levels without failure. Performance testing evaluates the pump’s efficiency in terms of airflow rate and power consumption, while durability testing simulates extended usage conditions to assess the product’s lifespan. These tests help ensure that the pumps will perform reliably under various conditions.

Illustrative image related to pump air

For B2B buyers, verifying a supplier’s quality control processes is essential to ensure a reliable partnership. Here are several actionable strategies:

Conduct Supplier Audits: Regular audits of the manufacturing facility can provide insights into the quality management practices in place. Buyers should assess the supplier’s compliance with international standards and their commitment to continuous improvement.

Request Quality Control Reports: Suppliers should be willing to provide documentation on their QC processes, including inspection reports and test results. These documents can serve as evidence of the supplier’s adherence to quality standards.

Inspeções de terceiros: Engaging third-party inspection agencies to evaluate products before shipment can provide an unbiased assessment of quality. This is particularly important for international transactions, where buyers may not be able to physically inspect products.

International buyers must navigate various nuances related to quality control and certification:

Regional Compliance Requirements: Different regions have specific compliance requirements. For instance, products sold in the European Union must comply with CE marking, while products in the U.S. may need to meet ANSI (American National Standards Institute) standards. Understanding these requirements is essential for successful market entry.

Language Barriers: When dealing with suppliers from different countries, language differences can pose challenges in understanding quality documentation. Buyers should ensure that all communications and documents are clear and accurately translated.

Cultural Differences in Quality Perception: Different regions may have varying standards for what constitutes acceptable quality. B2B buyers should engage in open discussions with suppliers to align expectations and ensure mutual understanding.

The manufacturing processes and quality assurance practices for air pumps are critical elements that B2B buyers must consider when selecting suppliers. By understanding the stages of manufacturing, the importance of quality standards, and the nuances of international trade, buyers can make informed decisions that lead to successful procurement and long-term partnerships.

To successfully source air pumps for your business, it is essential to follow a structured approach. This guide will help you navigate the complexities of selecting the right air pump suppliers, ensuring you make informed decisions that meet your operational needs.

Start by outlining the technical requirements for the air pumps you intend to procure. This includes pressure ratings, airflow capacity, power source, and size. Understanding your specific needs will help you narrow down options and communicate effectively with potential suppliers.

Conduct thorough market research to understand the current trends in air pump technology and pricing. This knowledge will help you identify reputable brands and innovative products.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

Illustrative image related to pump air

Always request samples before making bulk purchases. Testing the product allows you to evaluate its performance and compatibility with your requirements.

Once you’ve identified potential suppliers, it’s time to negotiate terms. Clear agreements on pricing, payment terms, delivery schedules, and warranty conditions are essential for a smooth transaction.

After negotiations, proceed with placing your order. Ensure that all agreed-upon terms are documented in a formal contract.

After receiving your air pumps, assess the supplier’s performance based on product quality, delivery timeliness, and customer service.

By following this checklist, B2B buyers can streamline their sourcing process for air pumps, ensuring they procure high-quality products that meet their operational needs effectively.

When assessing the cost structure of pump air products, several critical components come into play. Materiais represent the primary cost driver, as high-quality plastics, metals, and electronic components are essential for durability and performance. Depending on the design and specifications, the choice of materials can significantly influence the final price.

Illustrative image related to pump air

Trabalho costs also factor into the equation, particularly in regions with varying wage standards. Skilled labor is often necessary for assembly and quality control, which can add to the overall expenditure. Additionally, manufacturing overhead—which includes utilities, facility costs, and administrative expenses—must be calculated as part of the total production cost.

Ferramentas and setup costs are particularly relevant for customized or specialized pump air products. These costs can be amortized over larger production runs, making high-volume orders more cost-effective. Controle de qualidade (QC) is indispensable to ensure that the pumps meet safety and performance standards, which may involve additional testing and certification processes, further impacting costs.

Finalmente, logistics—encompassing shipping, warehousing, and distribution—can vary widely based on geographic location and transport methods. This is especially pertinent for international buyers, who must consider tariffs, customs duties, and freight costs.

Illustrative image related to pump air

Several factors can influence the pricing of pump air products, particularly in the B2B sector. Volume e quantidade mínima de pedidos (MOQ) are significant; larger orders often secure better pricing due to economies of scale. Customization—such as specific nozzle sizes or unique branding—can also affect pricing. Suppliers may charge a premium for tailored solutions, reflecting the additional costs involved in design and production adjustments.

The choice of materials directly correlates with pricing, as premium materials will increase costs but potentially enhance product longevity and performance. Quality certifications (e.g., ISO, CE) may also impact price, as compliant products often undergo rigorous testing, adding to production costs.

Fatores do fornecedor—including reputation, reliability, and geographic location—play a role as well. A supplier with a strong track record may charge higher prices but offer superior service and quality assurance. Understanding the Incoterms—the international rules for shipping—can also help buyers estimate total landed costs, including shipping and insurance.

Illustrative image related to pump air

When negotiating prices for pump air products, buyers should focus on the Custo total de propriedade (TCO) rather than just the purchase price. This involves considering long-term costs, such as maintenance, durability, and replacement rates, which can differ significantly between suppliers.

Buyers should also leverage volume discounts by consolidating orders or committing to long-term contracts, which can result in lower per-unit costs. Additionally, understanding market trends and competitor pricing can provide leverage during negotiations.

It’s essential for international buyers, particularly from regions like Africa, South America, and the Middle East, to be aware of nuances de preços that may arise due to local economic conditions, currency fluctuations, and shipping challenges. Establishing clear communication with suppliers about expectations and requirements can lead to more favorable terms.

While this analysis provides a framework for understanding costs and pricing in pump air sourcing, actual prices may vary based on specific supplier circumstances, market conditions, and regional factors. Buyers are encouraged to conduct thorough research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Illustrative image related to pump air

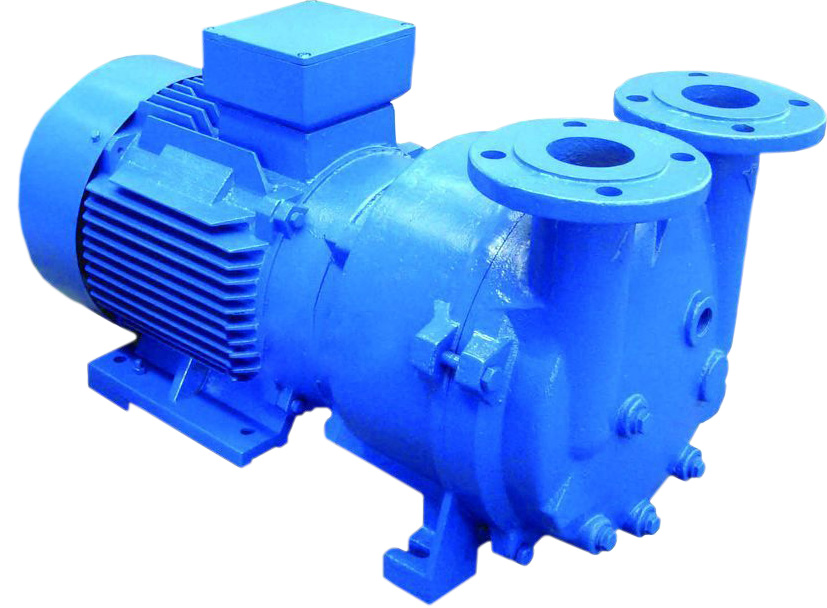

When evaluating air inflation solutions, it is essential to consider various alternatives to ‘pump air’ systems. Each solution offers unique advantages and limitations that cater to different business needs, especially for international B2B buyers in regions like Africa, South America, the Middle East, and Europe. This analysis will compare ‘pump air’ against two viable alternatives: manual air pumps and electric air compressors.

| Aspecto de comparação | Pump Air | Manual Air Pump | Electric Air Compressor |

|---|---|---|---|

| Desempenho | High-speed inflation (300L/min) | Slower inflation, requires physical effort | Fast inflation, varies by model |

| Custo | €40.85 – €49.02 | €10 – €30 | €50 – €150 |

| Facilidade de implementação | Plug-and-play with USB-C power | Simple, no setup required | Requires power source, often bulky |

| Manutenção | Minimal, rechargeable battery | Minimal, durable materials | Moderate, requires regular checks |

| Melhor caso de uso | Outdoor activities, travel | Casual use, camping | Heavy-duty use, continuous operation |

Manual air pumps are the most cost-effective option, ideal for casual users and occasional needs. They are lightweight and portable, making them suitable for camping trips and emergency situations. However, they require physical effort, which may not be ideal for larger items or frequent use. The performance is slower compared to ‘pump air’ solutions, which can inflate items rapidly. Moreover, while manual pumps are low-maintenance, they might not be as efficient for extensive commercial needs.

Electric air compressors provide a powerful alternative for those requiring high-volume inflation. They can inflate larger items quickly and often come with multiple attachments, making them versatile for various applications. However, they tend to be more expensive and require a reliable power source, which may be a drawback in remote locations. Maintenance can also be more intensive, as these machines have more moving parts that may require regular servicing. They are best suited for businesses needing consistent and heavy-duty inflation capabilities.

Selecting the right air inflation solution depends on your specific operational needs. If your business involves frequent travel or outdoor activities, ‘pump air’ systems like the GIGA PUMP Air offer unmatched portability and efficiency, particularly for smaller inflatable items. Conversely, if your operations require high-volume inflation, investing in an electric air compressor may be more beneficial despite the higher upfront costs. For occasional or low-demand applications, a manual air pump remains a reliable and economical choice. Assessing your performance requirements, budget, and maintenance capabilities will guide you in making the best decision tailored to your business context.

When sourcing air pumps for various applications, understanding the technical properties is crucial for making informed purchasing decisions. Here are key specifications that B2B buyers should consider:

The pressure rating indicates the maximum air pressure the pump can generate. For example, pumps like the GIGA PUMP Air can reach 3.5 kPa, making them suitable for inflating items that require firm support, such as air mattresses and inflatable boats. High-pressure ratings are essential for applications that demand robust inflation performance, ensuring that the products can withstand use in demanding environments.

This specification measures the volume of air the pump can deliver per minute, typically indicated in liters per minute (L/min). A higher airflow rate, such as the 300 L/min offered by certain compact pumps, allows for faster inflation and deflation of items. This is particularly advantageous for businesses in the hospitality or outdoor recreation sectors, where time efficiency is vital.

Understanding the power requirements is essential for operational efficiency. Many modern pumps, such as the GIGA PUMP Air, utilize low power consumption technologies, drawing only 40 mAh/min. This efficiency allows for prolonged usage without frequent recharging, making it ideal for outdoor and remote applications where power sources may be limited.

Illustrative image related to pump air

The material of the pump casing and internal components affects durability and performance. High-grade plastics or reinforced materials can provide resistance to wear and environmental factors, ensuring longevity. For B2B buyers, investing in pumps made from durable materials reduces replacement costs and improves reliability in various conditions.

For many applications, especially in travel and outdoor scenarios, the weight of the pump is a significant consideration. Lightweight models, such as those weighing around 213 grams, enhance portability and ease of use. This is particularly important for businesses in logistics and travel, where ease of transport can influence operational efficiency.

The inclusion of multiple nozzles or attachments allows pumps to cater to various inflation needs. Models with several nozzle sizes can adapt to different products, from inflatable mattresses to sports equipment. This versatility makes it easier for companies to standardize their equipment, simplifying inventory management.

Familiarizing yourself with industry terminology can enhance communication and negotiation with suppliers. Here are some essential trade terms:

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the pump air industry, OEM suppliers often provide components that are essential for creating branded air pumps. Understanding OEM relationships can help buyers negotiate better pricing and ensure quality standards.

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This is crucial for B2B buyers, as it affects inventory costs and the feasibility of bulk purchasing. Negotiating MOQs can lead to cost savings and better cash flow management.

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For B2B buyers, issuing an RFQ can streamline the procurement process and ensure competitive pricing, especially when sourcing multiple suppliers.

These are internationally recognized standard terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping costs, risk management, and delivery responsibilities, ensuring smoother cross-border transactions.

Lead time refers to the amount of time it takes from placing an order to receiving it. This metric is vital for B2B operations, particularly in industries where timely delivery impacts service quality and customer satisfaction.

Illustrative image related to pump air

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that they select the right pump air solutions for their specific needs.

The global pump air market is witnessing significant growth driven by increasing demand across various sectors, including outdoor recreation, travel, and emergency services. Notably, the rise in adventure tourism and outdoor activities has propelled the need for efficient and portable inflation solutions, particularly in regions like Africa, South America, the Middle East, and Europe. As international B2B buyers seek innovative products, trends such as the integration of smart technologies and sustainable materials are emerging. For example, pumps that can connect to power banks or utilize solar energy are gaining popularity, aligning with the growing focus on renewable energy sources.

Moreover, the market is becoming increasingly competitive, with manufacturers striving to differentiate their products through advanced features such as high-speed airflow and multi-functionality. The introduction of lightweight, compact designs that save space and enhance portability is particularly appealing to buyers in regions with challenging logistics, such as Nigeria and Saudi Arabia. Additionally, the proliferation of e-commerce platforms facilitates easier access to a diverse range of products, allowing B2B buyers to compare features, prices, and reviews seamlessly.

Sustainability is a paramount concern for B2B buyers in the pump air market, influencing purchasing decisions and supplier selection. The environmental impact of manufacturing processes and materials used in air pumps is under scrutiny, leading to a demand for products that minimize ecological footprints. Ethical sourcing practices have become crucial, as buyers increasingly prefer suppliers who prioritize transparency and responsible manufacturing.

In response, many manufacturers are adopting eco-friendly materials and processes, seeking certifications that demonstrate their commitment to sustainability. For instance, the use of recycled plastics and biodegradable materials is gaining traction, appealing to environmentally-conscious consumers. Furthermore, products designed for durability and longevity reduce waste and promote a circular economy, making them attractive options for B2B buyers looking to enhance their brand image and meet corporate social responsibility goals.

The evolution of the pump air market can be traced back to the early 20th century when manual pumps were the primary means for inflating air mattresses and recreational equipment. As technology advanced, the introduction of electric and battery-operated pumps revolutionized the industry, providing faster and more efficient inflation solutions. By the late 20th century, the demand for portable and compact designs led to innovations in materials and engineering, resulting in lightweight pumps that cater to the needs of outdoor enthusiasts and frequent travelers.

Today, the market continues to evolve with advancements in battery technology and smart connectivity features, reflecting broader trends in consumer electronics and sustainability. This historical context is essential for B2B buyers, as it highlights the continuous innovation that shapes product offerings and market dynamics, enabling them to make informed sourcing decisions.

How do I select the right air pump for my business needs?

Choosing the right air pump involves assessing your specific application requirements. Consider factors such as the pump’s pressure output, flow rate, and power source. If your operations include inflating large items like air mattresses or outdoor gear, opt for high-capacity pumps with quick inflation features. For portable needs, lightweight, rechargeable models can be beneficial. Additionally, evaluate the durability and warranty options to ensure long-term use, especially in demanding environments.

What are the key features to look for in a commercial air pump?

When sourcing commercial air pumps, prioritize features such as multi-functionality (inflation and deflation capabilities), energy efficiency, and compatibility with various nozzles. Look for pumps with high airflow rates for faster operation and those powered by reliable energy sources like USB-C, which can be charged via power banks or solar panels. Durability and ease of transport are also crucial, particularly for businesses that require mobility or frequent travel.

What is the minimum order quantity (MOQ) for bulk air pump purchases?

MOQs for air pumps can vary significantly among suppliers, often ranging from 100 to 500 units. Factors influencing MOQ include the manufacturer’s production capacity, the complexity of customization requests, and the type of pump. Always communicate your needs clearly to suppliers and inquire about potential flexibility in order sizes, especially if you are testing new products or entering a new market.

How can I ensure the quality of the air pumps I am sourcing?

To ensure quality, request certifications and compliance documents from suppliers, such as ISO or CE certifications. Conduct thorough due diligence by checking supplier reviews, previous client feedback, and product testing results. Consider ordering samples to evaluate performance firsthand. Establishing a quality assurance agreement that outlines specifications and acceptable tolerance levels can also help maintain product standards throughout production.

What payment terms are typically offered for international B2B purchases of air pumps?

Payment terms for international purchases often include options like Letters of Credit, wire transfers, or PayPal. Common arrangements may require a deposit (20-30%) upfront, with the balance due upon shipment or delivery. It’s essential to negotiate terms that provide security for both parties and to confirm the currency of transaction to avoid exchange rate fluctuations. Always review the supplier’s payment policies to understand any additional fees.

What shipping options should I consider when importing air pumps?

When importing air pumps, evaluate various shipping options such as sea freight, air freight, and express courier services based on urgency and cost. Sea freight is generally more economical for bulk shipments but takes longer, while air freight is faster but more expensive. Consider the supplier’s location and your destination when choosing logistics partners. Additionally, inquire about customs clearance services to ensure compliance with local regulations in your country.

How do I vet potential air pump suppliers effectively?

Effective supplier vetting involves conducting comprehensive research on potential partners. Start by checking their business credentials, including registration and compliance with local regulations. Use platforms like Alibaba or Global Sources to review ratings and feedback from other buyers. Request references and inquire about their production capabilities, lead times, and after-sales support. Engaging in direct communication can also provide insights into their responsiveness and customer service quality.

Can I customize air pumps to meet specific requirements?

Yes, many manufacturers offer customization options for air pumps, including color, branding, and specific features tailored to your needs. When approaching suppliers, clearly outline your customization requirements and any applicable technical specifications. Be prepared for potential minimum order quantities for customized products, as these may differ from standard offerings. Discuss timelines and costs associated with customization to align your expectations with the supplier’s capabilities.

Domínio: airback.store

Registered: 2023 (2 years)

Introdução: {“name”: “Air Pump”, “brand”: “Airback”, “regular_price”: “€79,00”, “sale_price”: “€39,00”, “rating”: “4.4/5.0”, “total_reviews”: 15, “features”: [“Rechargeable USB-C Battery (up to 20 uses on a single charge)”, “Inflates & Deflates (one device for both packing compression and air inflatables)”, “Ultra-Portable (fits easily in a pocket or bag)”, “Powerful Suction (quickly compresses Airback® bags)…

In the evolving landscape of air pump technology, strategic sourcing plays a pivotal role in optimizing procurement processes for international B2B buyers. The demand for efficient, portable, and multifunctional air pumps is on the rise, driven by consumer preferences for convenience and sustainability. Products like the GIGA PUMP Air and Airback Compact Air Pump exemplify innovations that not only enhance performance but also align with eco-conscious practices by utilizing rechargeable power sources.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of these products is essential. Identifying reliable suppliers who prioritize quality and customer service can significantly impact your supply chain efficiency and overall profitability. Additionally, considering diverse product features—such as high-pressure capabilities, fast inflation rates, and versatility—can help you meet varied market demands effectively.

Looking ahead, as technological advancements continue to shape the air pump industry, staying informed and adaptable will be crucial. Engage with suppliers who offer cutting-edge solutions and explore partnerships that can enhance your product offerings. Embrace strategic sourcing today to ensure your business thrives in tomorrow’s competitive landscape.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.

Illustrative image related to pump air