In today’s fast-paced global market, sourcing reliable tire inflator compressors presents a significant challenge for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. With fluctuating supply chains and varying quality standards, ensuring you procure the right inflators can mean the difference between operational efficiency and costly downtime. This guide aims to demystify the complexities associated with tire inflator compressors, covering essential aspects such as types, applications, supplier vetting, and cost considerations.

Understanding the diverse range of tire inflators—from compact, portable models to heavy-duty compressors designed for larger vehicles—is crucial for making informed purchasing decisions. This comprehensive resource empowers international B2B buyers by providing insights into market trends, product specifications, and best practices for selecting the most suitable inflator for their specific needs. Additionally, we delve into key factors to consider when vetting suppliers, ensuring that you engage with reputable manufacturers who meet quality and service expectations.

Whether you are in Vietnam, Nigeria, or elsewhere, navigating the global market for tire inflator compressors can be a strategic advantage for your business. By leveraging the insights presented in this guide, you can enhance your procurement process, reduce operational risks, and ultimately drive better value for your organization.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Cordless Tire Inflators | Battery-powered, portable, often compact | Automotive repair shops, roadside assistance | Prós: High mobility, no power source needed. Contras: Limited battery life, may require recharging. |

| 12V Plug-in Inflators | Powered via vehicle’s 12V outlet, often more robust | Fleet maintenance, emergency services | Prós: Continuous operation, generally faster. Contras: Limited to vehicle proximity, cord can restrict movement. |

| Heavy-Duty Compressors | High PSI capability, often larger and more powerful | Trucking companies, construction sites | Prós: Suitable for large tires, high efficiency. Contras: Bulky, may require additional setup time. |

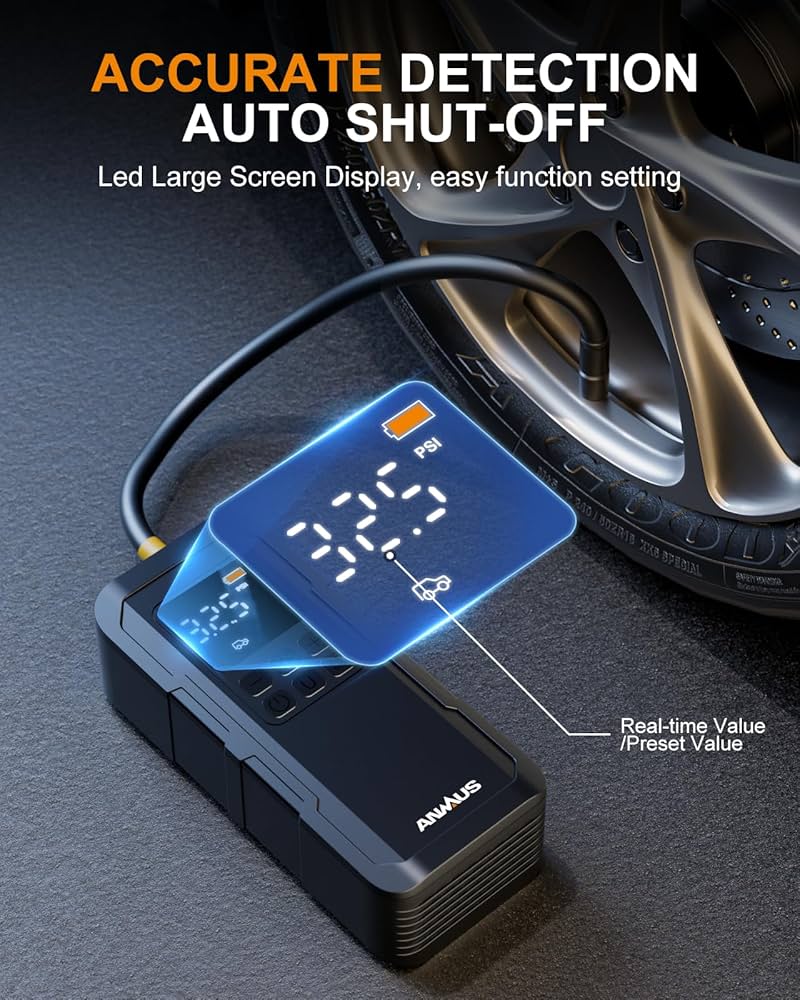

| Digital Tire Inflators | Built-in pressure gauges, automatic shutoff features | Automotive manufacturing, service stations | Prós: Accurate readings, ease of use. Contras: Potentially higher cost, reliance on electronics can lead to failures. |

| Multi-Purpose Inflators | Versatile attachments for various inflatables | Sports facilities, recreational vehicle maintenance | Prós: Multi-functional, good for diverse applications. Contras: May compromise on tire inflation speed or pressure. |

Cordless tire inflators are designed for high portability, making them ideal for businesses that require mobility, such as roadside assistance and automotive repair shops. They are powered by rechargeable batteries, allowing users to inflate tires without being tethered to a power source. However, their battery life can be a limitation, necessitating timely recharging, especially for businesses with high-volume needs.

12V plug-in inflators connect to a vehicle’s power outlet, making them a reliable option for fleet maintenance and emergency services. They can run continuously without the risk of battery depletion, which is essential for businesses that need to inflate multiple tires quickly. However, their dependence on vehicle proximity can limit their use in larger operations or remote locations.

Illustrative image related to tire inflator compressor

Heavy-duty compressors are built to handle high PSI requirements, making them suitable for industries such as trucking and construction, where larger tires are common. Their powerful performance allows them to inflate tires quickly and efficiently, which can minimize downtime. However, they tend to be bulkier and may require more setup time, which can be a consideration for space-constrained environments.

Digital tire inflators are equipped with built-in pressure gauges and often feature automatic shutoff capabilities. This technology enhances accuracy and user-friendliness, making them a preferred choice for automotive manufacturing and service stations. While they provide precise readings and ease of use, they can come at a higher price point and may be more prone to electronic failures.

Multi-purpose inflators offer versatility with attachments designed for various inflatables, making them suitable for businesses like sports facilities and recreational vehicle maintenance. Their adaptability allows businesses to address multiple needs without investing in separate tools. However, this versatility can sometimes compromise the speed or pressure of tire inflation, which businesses should consider based on their specific requirements.

Illustrative image related to tire inflator compressor

| Indústria/Setor | Specific Application of tire inflator compressor | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Automotive Repair Shops | Regular tire pressure checks and inflation for client vehicles | Enhances customer satisfaction and safety; reduces tire wear | Durability, ease of use, and compatibility with various tire sizes |

| Transportation & Logistics | Maintenance of fleet vehicles’ tire pressure | Improves fuel efficiency and reduces breakdowns | Portable models, power options (AC/DC), and fast inflation capabilities |

| Construction & Heavy Equipment | Inflation of tires on machinery and vehicles on-site | Minimizes downtime, ensuring continuous operations | Robust construction, high PSI capabilities, and easy mobility |

| Serviços de emergência | Quick inflation of tires for emergency response vehicles | Ensures readiness and reliability in critical situations | Compact design, rapid inflation speed, and multi-power options |

| Retail & Service Stations | Providing tire inflation services to customers | Generates additional revenue and enhances customer loyalty | User-friendly features, accuracy of pressure gauges, and maintenance support |

In automotive repair shops, tire inflator compressors are essential tools for maintaining optimal tire pressure for customer vehicles. Regular checks and inflation help prevent tire blowouts, enhance fuel efficiency, and extend tire lifespan. For B2B buyers, sourcing durable and easy-to-use models that can accommodate various tire sizes is crucial. Additionally, the ability to quickly inflate tires can significantly improve customer satisfaction and reduce waiting times, making it a valuable investment for repair businesses.

In the transportation and logistics sector, tire inflator compressors are vital for maintaining fleet vehicles. Proper tire pressure is directly linked to fuel efficiency and the overall safety of vehicles on the road. Companies often face challenges with breakdowns due to under-inflated tires, which can lead to costly delays. Buyers should prioritize portable models with multiple power options, ensuring they can inflate tires quickly and efficiently, thereby minimizing downtime and optimizing operational efficiency.

Construction sites rely heavily on tire inflator compressors for the maintenance of machinery and vehicles used on-site. These compressors help inflate tires of heavy equipment, ensuring they operate efficiently without interruptions. Downtime due to flat tires can be expensive, so having a reliable inflator that can handle high PSI capabilities is essential. Buyers in this sector should consider robust models designed for rugged environments, with features that facilitate easy transport to various job sites.

For emergency services, tire inflator compressors are crucial for ensuring that response vehicles are always ready for action. Quick inflation of tires in emergency situations can make the difference between timely intervention and delays. B2B buyers should look for compact models with rapid inflation speeds and multiple power options to ensure they can operate in various scenarios. Reliability and ease of use are key factors, as these tools must perform under pressure.

Retail and service stations can enhance their offerings by providing tire inflation services using tire inflator compressors. This not only generates additional revenue but also fosters customer loyalty by providing a valuable service. Buyers should focus on user-friendly models with accurate pressure gauges and quick inflation capabilities. Additionally, having maintenance support for these units can ensure they remain in top working condition, allowing businesses to consistently meet customer needs.

O problema: One of the main challenges B2B buyers face is sourcing reliable tire inflator compressors that meet specific operational needs and quality standards. Many suppliers may offer a range of products, but inconsistency in performance, durability, and specifications can lead to dissatisfaction and operational inefficiencies. This inconsistency is especially problematic for businesses in regions with diverse climates, such as Africa and South America, where the demand for robust and reliable equipment is critical.

A solução: To ensure that you source high-quality tire inflator compressors, start by establishing a clear set of criteria based on your operational requirements. Look for suppliers that provide comprehensive product specifications, including pressure ratings, duty cycles, and power sources. Utilize product testing reports or customer reviews to gauge reliability. Consider suppliers that offer warranties or service agreements, which can provide peace of mind. Engage with manufacturers directly to understand their quality control processes and ask for samples when possible to assess performance firsthand. Partnering with established brands known for their reliability can also mitigate risks associated with sourcing inferior products.

O problema: B2B buyers often encounter difficulties with the user-friendliness of tire inflator compressors, particularly when staff members have varying levels of technical expertise. Complicated operation instructions can lead to improper use, resulting in wasted time and resources. This issue can be particularly pronounced in environments such as construction sites or automotive shops where quick and effective tire inflation is essential.

Illustrative image related to tire inflator compressor

A solução: When selecting tire inflator compressors, prioritize models that feature intuitive designs and straightforward operation. Look for units with digital displays and preset pressure settings, which can minimize user error and make inflation tasks quicker. Additionally, consider investing in training sessions for your staff to familiarize them with the equipment. This can include on-site demonstrations or instructional videos that detail the compressor’s functions. Opt for inflators that come with clear and concise user manuals, and ensure that these resources are easily accessible. Regular maintenance checks and operational refreshers can also help keep your team proficient in using the equipment effectively.

O problema: Many businesses find that a single tire inflator compressor lacks the versatility required to handle various applications, such as inflating tires for different types of vehicles or other inflatable items. This limitation can lead to delays and increased operational costs, particularly for companies that manage a fleet of vehicles or provide roadside assistance.

A solução: To address the need for versatility, seek out tire inflator compressors that come with multiple adapters and nozzles, allowing them to accommodate a range of inflation tasks. Evaluate models that can inflate not just car tires but also those for trucks, bicycles, and even sports equipment. Consider investing in multi-functional units that combine tire inflating capabilities with additional features like built-in LED lights for roadside emergencies or USB ports for charging devices. Additionally, assess the compressor’s maximum pressure capacity to ensure it meets the needs of your diverse applications. Implement a systematic inventory approach that tracks the types of inflations required most frequently, allowing you to choose and maintain the most suitable equipment for your business needs.

When selecting materials for tire inflator compressors, understanding the properties and suitability of each material is crucial for optimizing performance and durability. Below, we analyze four common materials used in the manufacturing of tire inflator compressors, focusing on their key properties, advantages, disadvantages, and considerations for international buyers.

Aluminum is widely used in tire inflator compressors due to its lightweight nature and excellent corrosion resistance. Key properties include a temperature rating of up to 150°C and a pressure rating that can exceed 200 psi, making it suitable for high-performance applications.

Prós: Aluminum is durable, lightweight, and offers good thermal conductivity, which helps in heat dissipation during operation. It is also relatively easy to machine, allowing for complex designs.

Contras: While it is resistant to corrosion, aluminum can be prone to scratching and denting, which may affect aesthetics and performance over time. Additionally, the cost of aluminum is higher than some alternatives, which may impact overall pricing for B2B buyers.

Impacto no aplicativo: Aluminum is compatible with various media, including air and nitrogen, making it versatile for different tire inflating needs.

Considerações para compradores internacionais: Compliance with standards such as ASTM B221 for aluminum extrusions is essential. Buyers from regions like Africa and South America should consider local availability and potential tariffs on imported aluminum components.

Steel is another common material, particularly for components requiring high strength and durability. It typically has a temperature rating of around 300°C and can handle pressures up to 300 psi.

Prós: Steel is incredibly strong and durable, making it ideal for heavy-duty applications. It is also cost-effective compared to aluminum, which can be advantageous for budget-conscious buyers.

Contras: Steel is susceptible to rust and corrosion unless treated, which can lead to maintenance challenges over time. Additionally, its weight can be a disadvantage for portable inflators.

Impacto no aplicativo: Steel is suitable for high-pressure applications and can withstand harsh environments, making it ideal for industrial settings.

Illustrative image related to tire inflator compressor

Considerações para compradores internacionais: Buyers should ensure compliance with standards like ASTM A36 for structural steel. In regions with high humidity, such as parts of the Middle East, corrosion-resistant coatings may be necessary.

Plastics, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly used in tire inflator compressors for housing and non-structural components. These materials have a temperature rating of about 80°C and can handle moderate pressures.

Prós: Plastics are lightweight, cost-effective, and can be molded into complex shapes, allowing for innovative designs. They also offer good resistance to chemicals and moisture.

Contras: Plastics generally have lower strength compared to metals, which may limit their use in high-pressure applications. They can also degrade under UV exposure if not properly treated.

Illustrative image related to tire inflator compressor

Impacto no aplicativo: Plastic components are suitable for housing and accessories but may not be ideal for high-pressure areas of the inflator.

Considerações para compradores internacionais: Compliance with standards such as ASTM D638 for tensile properties of plastics is important. Buyers in Europe may prefer materials that meet REACH regulations for chemical safety.

Rubber is primarily used for seals and hoses in tire inflator compressors due to its flexibility and resilience. It can handle temperatures ranging from -30°C to 100°C and pressures up to 150 psi.

Prós: Rubber provides excellent sealing capabilities and flexibility, making it ideal for components that experience movement. It is also relatively inexpensive.

Illustrative image related to tire inflator compressor

Contras: Rubber can degrade over time due to exposure to ozone and UV light, which may necessitate regular replacements. Additionally, its performance can be affected by extreme temperatures.

Impacto no aplicativo: Rubber is essential for ensuring airtight seals, particularly in portable inflators that require reliable performance under various conditions.

Considerações para compradores internacionais: Buyers should ensure that rubber components comply with ASTM D2000 for rubber materials. In regions with high temperatures, such as parts of Africa, selecting high-temperature resistant rubber compounds is crucial.

| Material | Typical Use Case for tire inflator compressor | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Housing and structural components | Leve e resistente à corrosão | Prone to scratches and higher cost | Médio |

| Aço | Heavy-duty structural components | Alta resistência e durabilidade | Susceptible to rust without treatment | Baixa |

| Plástico | Non-structural components and housing | Cost-effective and moldable | Lower strength and UV degradation | Baixa |

| Borracha | Seals and hoses | Excellent sealing and flexibility | Degrada-se ao longo do tempo com a exposição | Baixa |

This material selection guide provides B2B buyers with critical insights to make informed decisions when sourcing tire inflator compressors, ensuring they choose materials that align with their performance, cost, and regulatory requirements.

Illustrative image related to tire inflator compressor

The manufacturing of tire inflator compressors involves several critical stages, each designed to ensure high-quality, reliable products.

The process begins with the careful selection and preparation of raw materials. Common materials include high-grade plastics for the casing, metal alloys for internal components, and rubber for seals and hoses. Suppliers often provide certifications to verify material quality, which is crucial for B2B buyers. It’s essential that materials meet international standards to ensure durability and safety.

In the forming stage, raw materials are shaped into usable parts through various techniques, including injection molding for plastic components and die casting for metal parts. Advanced technologies such as CNC machining may also be employed for precision parts. The accuracy of this stage directly influences the performance and longevity of the tire inflator. Manufacturers typically utilize CAD software to design components, ensuring they meet specified tolerances.

The assembly process integrates all components into a finished product. This stage often employs both manual and automated assembly lines. Key components like the motor, pump, and pressure gauge are installed, followed by rigorous checks to ensure correct fit and function. Manufacturers often implement lean manufacturing principles to optimize efficiency, reduce waste, and enhance productivity.

Finishing processes include painting, coating, and applying labels. These not only enhance aesthetics but also provide protective layers against corrosion and wear. Final assembly might also include the installation of features such as LED displays or integrated USB ports. Quality control checkpoints during this stage ensure that all functional and aesthetic aspects meet industry standards.

Quality assurance (QA) is paramount in the production of tire inflator compressors, as it directly affects product reliability and customer satisfaction.

Manufacturers often adhere to internationally recognized standards such as ISO 9001, which outlines criteria for a quality management system (QMS). Compliance with ISO standards demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications like CE (Conformité Européenne) for safety in Europe or API (American Petroleum Institute) standards may apply, especially for inflators designed for heavy-duty or specialized applications.

Quality control is typically integrated throughout the manufacturing process through various checkpoints:

Controle de qualidade de entrada (IQC): This is the first line of defense where raw materials are inspected upon arrival. This process ensures that only materials meeting specified standards enter the production line.

Controle de qualidade durante o processo (IPQC): During manufacturing, continuous monitoring is conducted at various stages. This may involve checks for dimensional accuracy, assembly integrity, and operational functionality.

Controle de qualidade final (FQC): Before products are packaged and shipped, they undergo final inspections to ensure they meet all specifications and performance criteria. This may include testing for pressure accuracy, inflation speed, and noise levels.

Testing methods vary but generally include the following:

Performance Testing: This assesses the inflator’s ability to inflate tires to specified pressures within a given time frame. It often simulates real-world conditions, such as inflating a flat tire.

Teste de durabilidade: Products are subjected to repeated use scenarios to evaluate their lifespan and reliability. This can involve continuous operation at maximum pressure for extended periods.

Safety Testing: Compliance with safety standards is verified through tests that check for electrical safety, overheating, and mechanical failures.

B2B buyers must conduct due diligence to ensure their suppliers maintain robust quality control processes.

Regular audits are a practical method for verifying a supplier’s adherence to quality standards. Buyers can assess manufacturing processes, quality control measures, and compliance with international standards during these audits. This proactive approach helps identify potential risks before they impact product quality.

Manufacturers should provide detailed quality reports that outline testing results, compliance with standards, and corrective actions taken in response to any quality issues. Buyers can review these documents to gauge the supplier’s commitment to quality.

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspectors can verify compliance with international standards and conduct random sampling of products before shipment.

Illustrative image related to tire inflator compressor

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding quality control nuances is essential.

Different regions may have varying certification requirements. For instance, products sold in the European market must comply with CE marking regulations, while North American buyers may prioritize Underwriters Laboratories (UL) certification for safety. Understanding these nuances helps buyers ensure compliance with local regulations.

Buyers should consider the language of quality documentation and certifications. Ensuring that all materials are available in a language understood by both parties can facilitate smoother transactions and clearer communication.

International buyers should be aware that some suppliers may have flexibility in their quality standards based on regional market demands. It is crucial for buyers to communicate their specific quality requirements upfront to avoid discrepancies.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing tire inflator compressors, ensuring they select reliable suppliers that meet their quality expectations.

In the competitive landscape of tire inflator compressors, making an informed procurement decision is crucial for B2B buyers. This step-by-step checklist serves as a comprehensive guide to ensure that you select the right tire inflator compressors tailored to your operational needs.

Establishing clear technical specifications is essential to align your purchase with your operational requirements. Consider factors such as maximum pressure (psi), power source (battery, 12V outlet, or AC), and size. Understanding your needs will help you narrow down the options and avoid overpaying for unnecessary features.

Stay informed about the latest trends in tire inflator technology and market demands. This involves exploring features like digital gauges, cordless capabilities, and additional functionalities (e.g., built-in USB ports). Researching these trends will help you anticipate customer preferences and ensure that your procurement aligns with current market expectations.

Illustrative image related to tire inflator compressor

Before committing to a supplier, conduct a thorough evaluation. Look for suppliers with a solid reputation and proven track records in the industry. Request detailed company profiles, case studies, and references from other businesses in similar markets to assess their reliability and service quality.

Ensure that the tire inflator compressors meet international quality standards and certifications. Look for compliance with ISO, CE, or other relevant certifications, which can indicate the product’s quality and safety. This step is crucial for mitigating risks associated with product liability and ensuring customer satisfaction.

Perform a detailed cost-benefit analysis to compare the total costs of ownership against the expected benefits. Consider not just the purchase price, but also factors like maintenance costs, warranty provisions, and the expected lifespan of the product. This analysis will help you make a financially sound decision that maximizes your return on investment.

Whenever possible, request samples of the tire inflator compressors for hands-on evaluation. Testing a unit allows you to assess its performance, ease of use, and reliability in real-world scenarios. Ensure that the sample meets your specifications and operational demands before proceeding with a bulk purchase.

Illustrative image related to tire inflator compressor

Once you have selected a supplier, engage in negotiations to finalize the terms and conditions of the purchase. Discuss aspects such as payment terms, delivery schedules, and after-sales support. Clear agreements will help prevent misunderstandings and ensure a smooth procurement process.

By following these steps, B2B buyers can navigate the procurement of tire inflator compressors with confidence, ensuring that they select products that meet their operational needs and provide value in the long term.

When sourcing tire inflator compressors for B2B transactions, understanding the cost structure is essential. The primary cost components include:

Materiais: The quality and type of materials used directly impact the cost. Common materials include plastics, metals for the casing, rubber for seals, and electronic components. Higher-quality materials can enhance durability but also increase costs.

Trabalho: Labor costs can vary significantly based on the manufacturing location. Regions with higher wage standards may see increased production costs, while countries with lower labor costs might offer savings. It’s essential to consider the skill level of the workforce, as specialized assembly can influence labor costs.

Custos indiretos de fabricação: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient production processes can help minimize these costs, allowing for better pricing.

Ferramentas: Initial setup costs for molds and tooling can be substantial, particularly for custom designs. These costs are often amortized over large production runs, making them less significant per unit for high-volume orders.

Controle de qualidade (QC): Implementing rigorous QC processes ensures that products meet specified standards. While this adds to the cost, it is critical for maintaining product reliability and customer satisfaction, ultimately affecting repeat business.

Logística: Shipping and handling costs are crucial, especially for international buyers. Factors like shipping mode, distance, and local tariffs can significantly influence the overall cost.

Margem: Suppliers typically build a profit margin into their pricing. Understanding industry standards for margins can aid in negotiations.

Several factors influence pricing in the tire inflator compressor market:

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to align with their purchasing needs.

Especificações e personalização: Customized products typically carry a premium price. Buyers should clearly define their specifications to avoid unexpected costs during production.

Materiais e certificações de qualidade: The choice of materials and adherence to quality certifications (like ISO standards) can significantly affect pricing. Higher quality often correlates with higher costs but may reduce long-term maintenance and replacement expenses.

Fatores do fornecedor: Supplier reliability, reputation, and financial stability can impact pricing. It’s advisable to conduct thorough due diligence before committing to a supplier.

Incoterms: Understanding Incoterms is vital for international transactions. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can influence total costs, including shipping and insurance.

To maximize cost-efficiency when sourcing tire inflator compressors, consider the following tips:

Negociação: Leverage your purchasing power by negotiating pricing and terms. Establishing long-term relationships with suppliers can lead to better pricing and service.

Custo total de propriedade (TCO): Evaluate the TCO, which includes purchase price, maintenance, and potential warranty costs. A lower initial price may not always be the most economical choice in the long run.

Nuances de preços para compradores internacionais: Be aware of currency fluctuations, local market conditions, and potential tariffs that can affect pricing. Understanding regional dynamics can help in negotiating better deals.

Research and Benchmarking: Conduct market research to benchmark prices against competitors. This information can be instrumental in negotiations and ensuring you are not overpaying.

Quality Over Price: While it may be tempting to opt for the lowest price, prioritize quality to ensure reliability and reduce future costs related to repairs or replacements.

Prices for tire inflator compressors can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and seek multiple quotes to establish a competitive price point. Always verify current pricing with suppliers, as fluctuations can occur due to market changes and currency exchange rates.

When evaluating tire inflators, it’s essential to consider alternatives that can also achieve effective tire inflation. This analysis will compare tire inflator compressors against two viable alternatives: portable air compressors and manual tire pumps. Each solution has its own strengths and weaknesses that can influence a B2B buyer’s decision based on specific operational needs and budget considerations.

| Aspecto de comparação | Tire Inflator Compressor | Portable Air Compressor | Manual Tire Pump |

|---|---|---|---|

| Desempenho | High PSI capability; quick inflation times; ideal for various tire types | Versatile; can inflate multiple tires quickly; often used in workshops | Labor-intensive; slower inflation; limited to smaller tires or vehicles |

| Custo | Moderate ($40 – $90) | Higher initial investment ($100 – $300) | Low-cost option ($15 – $50) |

| Facilidade de implementação | Plug-and-play; often battery-operated or 12V powered | Requires a power source; may need hoses and fittings | Requires physical effort; no power source needed |

| Manutenção | Low; occasional cleaning and checking for battery health | Moderate; periodic oiling and maintenance for moving parts | Minimal; mainly cleaning after use |

| Melhor caso de uso | Emergency roadside assistance; personal and small fleet vehicles | Commercial use; workshops; heavy-duty vehicles | Occasional use; emergency backup; bicycles |

Portable air compressors are versatile machines that can be employed in various settings, from home garages to commercial workshops. They typically offer higher PSI ratings and faster inflation times compared to tire inflator compressors, making them suitable for larger vehicles or multiple tires at once. However, they often come with a higher price point and require a power source, which might not be readily available in all situations, especially in remote areas. For B2B buyers, the investment may pay off in high-volume settings where speed and efficiency are critical.

Manual tire pumps represent the most cost-effective alternative, ideal for buyers looking for a budget-friendly solution. These pumps require no power and can be used in emergencies, making them a reliable backup option. However, they demand significant physical effort and are generally slower in inflating tires compared to their powered counterparts. While they are excellent for occasional use, especially for bicycles or small vehicles, they may not be practical for businesses that rely on quick service or have a high volume of vehicles to maintain.

Selecting the most suitable tire inflation solution depends on various factors, including your operational needs, budget, and the types of vehicles you manage. Tire inflator compressors offer a balance of performance and convenience, making them ideal for many businesses. However, if your operations involve heavy-duty vehicles or require rapid service, investing in a portable air compressor may yield better results. Conversely, for those with limited budgets or occasional needs, a manual tire pump can serve as an effective emergency solution. By carefully considering these alternatives, B2B buyers can ensure they choose the right tire inflation method that aligns with their specific requirements.

Illustrative image related to tire inflator compressor

When evaluating tire inflator compressors for B2B procurement, understanding their technical specifications is crucial for making informed decisions. Here are some essential properties to consider:

Maximum pressure, typically measured in pounds per square inch (PSI), indicates the highest air pressure the inflator can achieve. For standard passenger vehicles, a range of 30-35 PSI is common, while larger vehicles may require inflators with a maximum capacity of up to 150 PSI. B2B buyers must ensure the inflator can meet the pressure requirements for the vehicles in their fleet, as inadequate pressure can compromise safety and tire longevity.

The duty cycle defines the operational time versus the rest time required for the inflator. For instance, a 50% duty cycle means the unit can operate for 5 minutes before needing a 5-minute cool-down period. Understanding the duty cycle is essential for businesses that may need to inflate multiple tires consecutively, as it impacts productivity and efficiency.

Tire inflators can be powered by various sources, including AC power, DC power (from a vehicle’s battery), or rechargeable batteries. Each power source has implications for usability and convenience. For example, a battery-operated inflator offers portability, while an AC-powered model may provide continuous operation in a garage setting. Buyers should choose based on their typical use cases and accessibility to power sources.

Inflation speed refers to how quickly an inflator can fill a tire from a specific PSI to a target PSI. This is measured in minutes and is critical for businesses that require rapid tire maintenance to minimize downtime. Inflators that can fill tires quickly enhance operational efficiency, particularly in service stations or fleets with high vehicle turnover.

Illustrative image related to tire inflator compressor

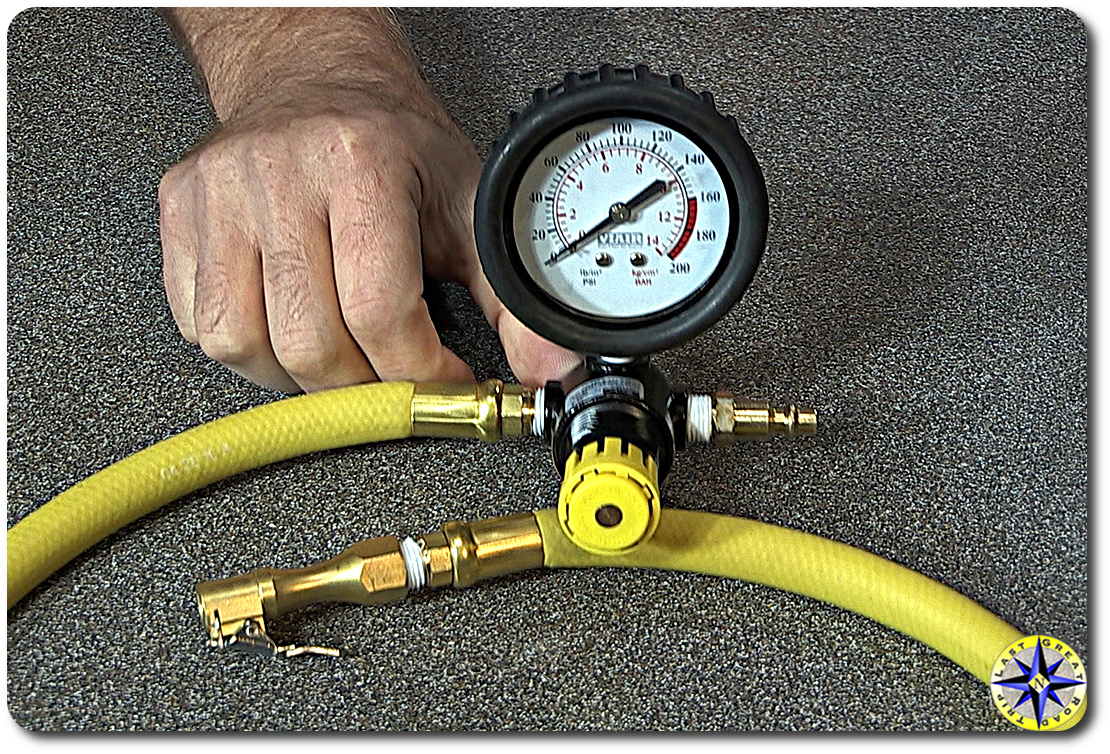

The type of pressure gauge—whether analog or digital—affects accuracy and ease of use. Digital gauges often provide more precise readings and are easier to read, especially in low-light conditions. For B2B operations, accurate pressure readings are vital to ensure tires are inflated to the correct specifications, thus enhancing safety and performance.

The size and weight of the inflator play a significant role in its portability. Compact and lightweight models can easily be stored in vehicles or service bags, making them ideal for on-the-go repairs. Businesses should consider their storage capabilities and the likelihood of needing to transport the inflator frequently.

Understanding industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms:

Illustrative image related to tire inflator compressor

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the tire inflator market, an OEM might supply components to a brand that assembles and sells the final product. B2B buyers often prefer OEM products for their quality assurance and compatibility.

MOQ is the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is crucial for businesses to manage inventory and cash flow effectively, especially when sourcing from international suppliers.

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. Including detailed specifications for tire inflators in an RFQ can help ensure that the responses received are relevant and competitive.

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps businesses navigate the complexities of global trade, ensuring clarity in shipping arrangements for tire inflator compressors.

This term refers to the terms under which a manufacturer will repair or replace a defective product. Understanding warranty conditions is vital for B2B buyers to mitigate risks associated with faulty equipment.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing tire inflator compressors, ensuring they meet operational needs while optimizing costs.

The tire inflator compressor market is experiencing significant growth, driven by an increasing demand for vehicle maintenance solutions across global markets, particularly in Africa, South America, the Middle East, and Europe. Key drivers include rising vehicle ownership, a growing emphasis on safety and fuel efficiency, and the expansion of e-commerce, which facilitates easier access to these products. The proliferation of electric and hybrid vehicles has also spurred demand for efficient tire maintenance tools, as maintaining optimal tire pressure is crucial for maximizing fuel efficiency.

Emerging technologies are reshaping the tire inflator landscape. Smart inflators equipped with IoT capabilities are gaining traction, allowing users to monitor tire pressure via mobile applications. This tech-savvy approach appeals to a younger demographic of vehicle owners who prioritize convenience and efficiency. Moreover, battery-operated and compact models are becoming increasingly popular due to their portability and ease of use, making them ideal for various applications, from personal vehicles to commercial fleets.

Illustrative image related to tire inflator compressor

For international B2B buyers, understanding local market dynamics is essential. In regions like Nigeria and Vietnam, the demand for affordable, reliable inflators is high, driven by a growing automotive market and infrastructure development. Conversely, European buyers may prioritize high-performance models with advanced features, reflecting a more mature market with a focus on quality and innovation. Thus, tailoring product offerings to specific regional preferences is vital for success.

Sustainability is becoming a crucial consideration for B2B buyers in the tire inflator compressor sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using recyclable materials and reducing carbon footprints in their production processes.

Ethical sourcing is equally important, as stakeholders demand transparency in supply chains. Companies that can demonstrate responsible sourcing of components—ensuring fair labor practices and minimizing environmental harm—are more likely to build trust and loyalty among B2B clients. Certifications such as ISO 14001 (Environmental Management) and other “green” labels can serve as valuable indicators of a supplier’s commitment to sustainability.

Additionally, the demand for products designed for longevity and energy efficiency is rising. Buyers are looking for tire inflators that not only perform well but also contribute to reduced energy consumption and waste. This trend aligns with the global push towards sustainable development, making it essential for suppliers to adapt their offerings to meet these evolving expectations.

Illustrative image related to tire inflator compressor

The tire inflator compressor industry has evolved significantly since its inception. Initially, inflators were basic, manually operated devices that required considerable physical effort and time to inflate tires. The introduction of electric models in the late 20th century revolutionized the market, offering greater convenience and efficiency.

With advancements in technology, tire inflators have transitioned towards more sophisticated designs, incorporating features like automatic shut-off, built-in pressure gauges, and portable battery options. The recent trend towards smart technology has further transformed the landscape, with IoT-enabled inflators that allow users to manage tire pressure through mobile apps, enhancing user experience and safety.

As the automotive industry continues to innovate, tire inflators are likely to integrate even more advanced technologies, ensuring they remain a vital component of vehicle maintenance solutions in the B2B market.

1. How do I choose the right tire inflator compressor for my business needs?

Choosing the right tire inflator compressor involves assessing your specific requirements, such as the types of vehicles you service and the frequency of use. Consider factors like power source (cordless vs. corded), maximum PSI capability, portability, and additional features like built-in pressure gauges and lighting. For businesses in regions with varying tire sizes, a model that can handle high pressures and has a robust build is essential. It’s also advisable to read product reviews and compare specifications to ensure you select an inflator that meets both performance and budgetary needs.

2. What is the best tire inflator compressor for commercial use?

For commercial use, the AstroAI Cordless Tire Inflator is highly recommended due to its versatility and efficiency. It can inflate multiple tires on a single charge, making it ideal for businesses that handle a fleet of vehicles. Another strong option is the Viair 88P, known for its rapid inflation capabilities, especially for larger tires found in trucks and SUVs. When selecting an inflator, ensure it has a sufficient duty cycle and can maintain performance under continuous use, which is crucial for commercial applications.

3. What are the common payment terms for purchasing tire inflator compressors internationally?

Payment terms can vary significantly depending on the supplier and the nature of the transaction. Common terms include payment in advance, letters of credit, or net payment terms such as 30, 60, or 90 days post-invoice. It is crucial to negotiate clear terms before finalizing a purchase to ensure both parties are protected. Additionally, consider the impact of currency fluctuations when engaging in international transactions, and explore options for escrow services to mitigate risks.

4. How can I vet suppliers of tire inflator compressors?

Vetting suppliers is critical to ensuring product quality and reliability. Start by researching the supplier’s reputation through online reviews, industry forums, and trade references. Request samples to assess product quality firsthand. Check for certifications that comply with international standards, such as ISO or CE markings. Establish direct communication with potential suppliers to gauge their responsiveness and willingness to address your concerns. Lastly, consider visiting their manufacturing facility if feasible, as this can provide valuable insights into their operational practices.

5. What are the typical minimum order quantities (MOQs) for tire inflator compressors?

Minimum order quantities (MOQs) for tire inflator compressors can vary widely based on the manufacturer and the product type. Typically, MOQs may range from 50 to 500 units, depending on factors such as customization requirements and production capabilities. For smaller businesses or those testing new products, it is advisable to negotiate lower MOQs with suppliers. Some manufacturers may offer flexibility, especially for repeat customers or larger contracts, so it’s beneficial to communicate your needs clearly.

6. What should I consider regarding logistics when importing tire inflator compressors?

When importing tire inflator compressors, logistics considerations include shipping methods, costs, and delivery timelines. Determine whether air freight or sea freight is more cost-effective based on the order size and urgency. Understand customs regulations and tariffs that may apply to your imports, as these can significantly impact the total cost. Collaborating with a reliable freight forwarder can streamline the process and help navigate any potential complications. Additionally, factor in warehousing needs and distribution logistics once the products arrive.

7. How can I ensure the quality of tire inflator compressors before making a bulk purchase?

To ensure quality, conduct thorough research on the manufacturer’s production processes and quality control measures. Request detailed product specifications and certifications to verify compliance with international standards. If possible, obtain samples for testing to evaluate performance, durability, and safety features. Establish a clear quality assurance protocol that includes inspections before shipment. Communicating your quality expectations upfront can also help align the supplier’s production with your standards.

8. Can I customize tire inflator compressors for my brand?

Yes, many manufacturers offer customization options for tire inflator compressors. This can include branding elements such as logos, colors, and packaging tailored to your business needs. Customization may also extend to specific features or functionalities, depending on the manufacturer’s capabilities. Be prepared to discuss your requirements in detail and understand that custom orders may have higher MOQs and longer lead times. It is advisable to request prototypes before committing to a larger order to ensure the final product meets your specifications.

Domínio: lasfit.com

Registrado: 2016 (9 anos)

Introdução: LASFIT Portable Cordless Tire Inflator – Model No: LAP-CR1 Pro – Price: $79.99 (originally $129.99) – Warranty: 2-year hassle-free warranty (excludes labor, diagnostics, towing, rental car, or other expenses related to defects/damage) – Return Policy: 45 days free return, 90 days for Lasfit club members – Shipping: Free U.S. shipping via USPS – Customer Reviews: 56 reviews with an average rating o…

In the competitive landscape of tire inflator compressors, strategic sourcing emerges as a crucial element for B2B buyers aiming to enhance operational efficiency and product reliability. By focusing on quality, durability, and user-friendly features, businesses can ensure they are investing in products that not only meet current demands but also anticipate future needs. The evaluation of inflators based on performance metrics—such as speed, power source versatility, and maximum pressure capabilities—enables buyers to make informed decisions that align with their specific market requirements.

As international buyers from regions like Africa, South America, the Middle East, and Europe continue to navigate unique challenges, the importance of sourcing reliable and efficient tire inflators cannot be overstated. These compressors are not merely tools; they are essential components that enhance vehicle safety and contribute to cost savings through improved tire longevity and fuel efficiency.

Looking ahead, B2B buyers should prioritize partnerships with manufacturers that emphasize innovation and sustainability in their product lines. By doing so, they position themselves to thrive in a rapidly evolving marketplace. Take the next step in your sourcing journey by exploring reliable suppliers that align with your business objectives, ensuring that you are well-equipped to meet the demands of your customers.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.