In the competitive landscape of the cycling industry, understanding how to inflate bike tire Presta valves effectively is crucial for B2B buyers seeking to enhance their product offerings. The intricacies involved in inflating these specialized valves can pose significant challenges, particularly for suppliers in regions like Africa, South America, the Middle East, and Europe. This comprehensive guide addresses the essential techniques, equipment types, and common pitfalls associated with Presta valve inflation, ensuring that businesses can provide their customers with reliable solutions and maintain a competitive edge.

Throughout this guide, we will explore various aspects of Presta valves, including their specific applications in high-performance bicycles, the optimal tools required for inflation, and best practices for supplier vetting. Additionally, we will provide insights into cost considerations, allowing buyers to make informed purchasing decisions tailored to their market needs. By arming international B2B buyers with the knowledge to navigate the complexities of Presta valve inflation, this guide empowers them to source high-quality components and accessories that meet the diverse demands of their customer base, ultimately driving growth and profitability in their operations.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Manual Floor Pumps | Operated by foot, suitable for high-pressure inflation. | Bicycle shops, rental services, workshops. | Prós: Cost-effective, durable. Contras: Requires physical effort, space-consuming. |

| Bombas elétricas | Battery or mains-powered, offers quick inflation. | Mobile bike repair services, events. | Prós: Fast and easy to use. Contras: Higher cost, dependency on power source. |

| Infladores de CO2 | Compact, uses CO2 cartridges for quick inflation. | Professional racing teams, emergency kits. | Prós: Lightweight, portable. Contras: Limited number of uses per cartridge. |

| Valve Adapters | Converts Presta to Schrader, enhancing compatibility. | Retailers, bicycle repair shops. | Prós: Versatile, inexpensive. Contras: Additional component needed, potential for loss. |

| Digital Pressure Gauges | Integrated gauges for precise pressure readings. | Quality control in manufacturing, bike shops. | Prós: Accurate measurements, user-friendly. Contras: Potentially more expensive. |

Manual floor pumps are a staple in many bicycle repair shops and rental services. They operate through a foot pedal mechanism, allowing users to generate high pressure efficiently. These pumps are particularly suitable for high-pressure tires common in road bikes. When considering a purchase, buyers should assess the pump’s build quality and ease of use, as these can significantly affect the inflation experience.

Electric pumps offer a modern solution for inflating Presta valves quickly and with minimal effort. They are particularly valuable for mobile bike repair services and events where time is of the essence. Buyers should consider the power source and battery life, as these factors influence the pump’s usability in various environments. While they tend to be pricier, the convenience they provide can justify the investment.

CO2 inflators are designed for speed and portability, making them ideal for professional racing teams and emergency repair kits. They utilize CO2 cartridges to inflate tires rapidly, which is crucial during races or when time is limited. Buyers should be aware of the cost of cartridges and their limited lifespan, as this can affect long-term usability and costs.

Valve adapters serve as a bridge between Presta and Schrader valves, enhancing the compatibility of various pumps. They are particularly useful for retailers and bicycle repair shops that cater to a diverse clientele. When purchasing, buyers should consider the durability and ease of attachment of these adapters, as they can significantly streamline the inflation process.

Digital pressure gauges provide precise pressure readings, which are essential for maintaining optimal tire performance. They are particularly beneficial in manufacturing quality control and bike shops where accurate measurements are critical. Buyers should evaluate the gauge’s accuracy and ease of use, as these features will impact their effectiveness in a professional setting. While they may come at a higher price, the investment in accuracy can lead to better customer satisfaction and safety.

| Indústria/Setor | Specific Application of how to inflate bike tire presta valve | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Fabricação de bicicletas | Quality control during production of bikes with Presta valves | Ensures product reliability and customer satisfaction | Need for precise inflation tools compatible with Presta valves |

| Bike Rentals | Maintenance of rental bikes in urban environments | Reduces downtime and enhances customer experience | Access to portable pumps and valve adapters for quick service |

| Sports and Recreation | Support for cycling events and competitions | Guarantees optimal performance and safety for participants | Requirement for high-pressure pumps and knowledgeable staff |

| Logística e entrega | Delivery of bicycles and related products | Ensures safe transport with properly inflated tires | Consideration for inflation tools that are compact and easy to use |

| Bike Repair Shops | Routine service and repairs of bicycles | Increases customer retention through quality service | Demand for reliable pumps and valve components for diverse bike models |

In the bicycle manufacturing sector, the inflation of bike tires equipped with Presta valves is critical for quality control. Manufacturers must ensure that tires are inflated to the correct pressure during assembly to meet safety and performance standards. Failure to do so can lead to product defects or customer dissatisfaction. For international buyers, sourcing high-quality floor pumps and valve adapters that are compatible with Presta valves is essential to streamline the production process and maintain product integrity.

Bike rental services rely heavily on the proper inflation of tires with Presta valves to ensure a seamless user experience. Regular maintenance checks are necessary to keep rental bikes in optimal condition, reducing the likelihood of flat tires that can lead to customer complaints. For businesses operating in diverse regions, including Africa and South America, having portable pumps and valve adapters on hand enables quick and efficient service, enhancing customer satisfaction and operational efficiency.

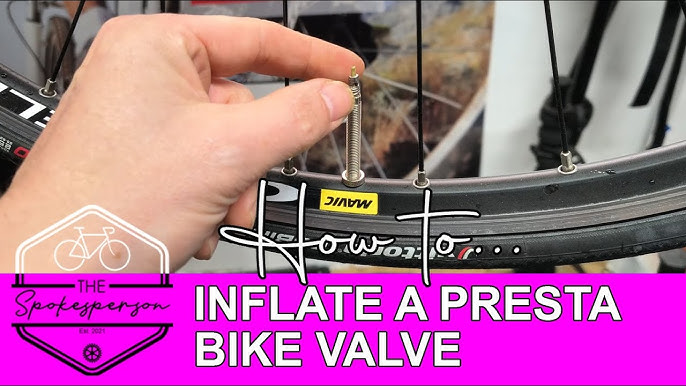

Illustrative image related to how to inflate bike tire presta valve

In the sports and recreation sector, particularly during cycling events, the correct inflation of Presta valve tires is vital for participant safety and performance. Properly inflated tires can significantly affect speed, handling, and overall ride quality. Event organizers must ensure that they have access to high-pressure pumps and knowledgeable staff to assist participants. This requirement emphasizes the need for reliable equipment and trained personnel, particularly in regions with a growing cycling culture.

For logistics and delivery services that handle bicycles, ensuring that tires with Presta valves are properly inflated is crucial for safe transport. Properly inflated tires reduce the risk of damage during transit and ensure that bicycles arrive in excellent condition. Businesses should consider sourcing compact and easy-to-use inflation tools that can be used on-the-go, particularly in regions with limited access to specialized equipment.

In bike repair shops, routine service involving the inflation of Presta valve tires is essential for maintaining customer loyalty and satisfaction. Repair technicians need reliable pumps and valve components that can accommodate various bike models. This demand highlights the importance of sourcing high-quality, durable inflation equipment that can withstand frequent use, ensuring that repair shops can meet customer expectations efficiently.

O problema: B2B buyers often face challenges when attempting to inflate bike tires equipped with Presta valves, particularly in settings where multiple bicycles are serviced, such as rental shops or maintenance facilities. The difficulty arises from the unique design of the Presta valve, which requires precise alignment and attachment of the pump head. Many users report frustration when the pump does not connect properly, leading to air leaks or a complete failure to inflate the tire. This issue not only consumes valuable time but can also impact customer satisfaction if bicycles are not ready for use in a timely manner.

A solução: To overcome this challenge, it is crucial to ensure that the pump head is compatible with Presta valves. Invest in high-quality pumps specifically designed for Presta valves, as they often feature adjustable fittings that accommodate various valve lengths. When attaching the pump, position the valve at the 6 o’clock position, allowing gravity to stabilize the bike and prevent movement. Before pushing the pump head onto the valve, briefly tap the valve to ensure it is not stuck. Once aligned, press down firmly and engage the locking mechanism on the pump head to create a secure seal. Practicing this technique will significantly reduce the time spent inflating tires and improve overall efficiency in service operations.

Illustrative image related to how to inflate bike tire presta valve

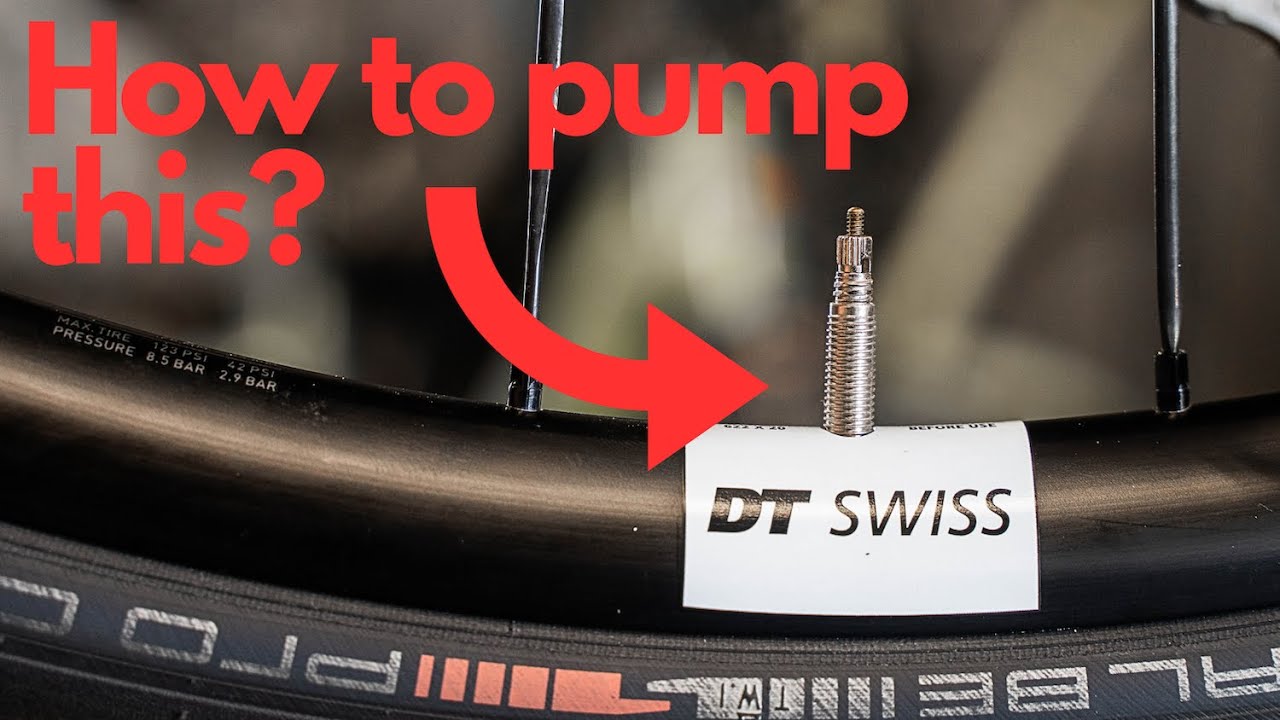

O problema: In many instances, B2B buyers encounter bikes with deep rims that require longer Presta valve stems. Short valve stems can make it challenging to attach pumps securely, leading to ineffective inflation and potential damage to the valve. This issue is particularly prevalent in racing bikes or those designed for high-pressure applications. Buyers need to ensure that their service teams can effectively manage these situations without risking damage to the tires or valves, which could lead to costly repairs.

A solução: To address this issue, it is advisable to stock a range of inner tubes with various valve lengths. Providing your service team with valve extenders is another practical solution, allowing them to connect pumps easily to short-stem valves. When purchasing bicycles, consider sourcing models that come with longer valve stems or those that can accommodate valve extenders without compromising performance. Educating staff on the different valve lengths and their implications can also empower them to make quick adjustments, ensuring that service operations run smoothly and efficiently.

O problema: Accurate tire pressure is critical for safe and efficient cycling, yet many B2B buyers struggle with pressure gauges that fail to provide reliable readings when inflating Presta valves. This problem can stem from incompatible pump designs or faulty gauge mechanisms, leading to potential over-inflation or under-inflation of tires. Such inconsistencies not only affect the performance of the bicycles but can also pose safety risks for users, making it essential for service providers to find reliable solutions.

A solução: To combat inaccurate pressure readings, invest in digital pressure gauges that are compatible with Presta valves. These gauges provide precise readings and are often easier to read than traditional analog gauges. Additionally, ensure that the pump being used has a built-in pressure gauge that accurately displays readings while inflating. Before inflating tires, instruct service personnel to check the gauge’s calibration against a known standard. Regular maintenance and calibration of pressure gauges will help maintain their accuracy over time, ensuring that all bikes are inflated to the correct specifications, thus enhancing safety and performance for end-users.

When selecting materials for components involved in inflating bike tires with Presta valves, it is essential to consider performance characteristics, durability, and compatibility with various operating conditions. Below, we analyze four common materials used in this context: rubber, aluminum, brass, and plastic.

Rubber is often used for sealing components in Presta valve systems due to its excellent flexibility and ability to create airtight seals. Key properties include a temperature rating typically between -40°C to 100°C and good resistance to ozone and UV exposure, which is crucial for outdoor applications.

Prós: Rubber offers high elasticity, which allows it to maintain a tight seal even under varying pressures. It is also relatively inexpensive and easy to manufacture.

Contras: While rubber is durable, it can degrade over time, especially in extreme temperatures or exposure to certain chemicals. This could lead to failures in sealing, resulting in air leaks.

Impacto no aplicativo: Rubber is compatible with air and various gases, making it suitable for inflating tires. However, buyers should ensure that the rubber used meets specific standards to guarantee performance.

Considerações para compradores internacionais: Buyers in regions like Africa and South America should check compliance with local standards for rubber materials, such as ASTM D2000, to ensure quality and safety.

Aluminum is frequently used for the valve body and pump heads due to its lightweight and corrosion-resistant properties. It can withstand high pressures, typically rated up to 300 PSI, making it suitable for high-performance applications.

Prós: Aluminum is strong yet lightweight, enhancing the portability of pumps. It also resists corrosion, which is vital in humid or saline environments.

Contras: The cost of aluminum is generally higher than rubber, and it can be more complex to manufacture due to machining requirements.

Impacto no aplicativo: Aluminum components provide excellent pressure retention and durability, which is crucial for effective tire inflation.

Considerações para compradores internacionais: Compliance with standards like DIN 17615 for aluminum alloys is vital for ensuring product quality, especially in regions like Europe and the Middle East.

Brass is another common material used in valve components due to its strength and resistance to corrosion. It typically has a pressure rating of around 150 PSI, making it suitable for standard bike tire inflation.

Prós: Brass is durable and has excellent machinability, allowing for precise fittings. Its resistance to corrosion makes it suitable for various environmental conditions.

Contras: Brass can be relatively heavy compared to aluminum and may be more expensive due to the cost of raw materials.

Impacto no aplicativo: Brass is compatible with air and various gases, making it a reliable choice for tire inflation.

Illustrative image related to how to inflate bike tire presta valve

Considerações para compradores internacionais: Buyers should ensure that brass components comply with standards such as ASTM B16 for brass fittings, particularly in regions with strict regulations.

Plastic is often used in lower-cost pump heads and adapters due to its lightweight and ease of manufacturing. It can be engineered to handle moderate pressures, typically up to 100 PSI.

Prós: Plastic is lightweight and cost-effective, making it an attractive option for budget-conscious buyers. It also allows for versatile designs.

Contras: Plastic may not offer the same durability as metal options and can degrade under UV exposure or extreme temperatures.

Impacto no aplicativo: While suitable for basic tire inflation, plastic components may not withstand high-pressure applications as effectively as metal counterparts.

Considerações para compradores internacionais: Buyers should check for compliance with relevant standards, such as ISO 9001, to ensure quality and performance.

| Material | Typical Use Case for how to inflate bike tire presta valve | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Borracha | Sealing components in pumps and valves | Excellent elasticity and sealing capability | Degrades over time under extreme conditions | Baixa |

| Alumínio | Valve bodies and pump heads | Leve e resistente à corrosão | Custo mais alto e fabricação complexa | Med |

| Brass | Valve components and fittings | Durável e resistente à corrosão | Heavier and more expensive than aluminum | Med |

| Plástico | Pump heads and adapters | Leve e econômico | Less durable and can degrade with UV exposure | Baixa |

This analysis provides a comprehensive overview of the materials involved in Presta valve inflation, allowing international B2B buyers to make informed decisions based on their specific needs and regional standards.

The manufacturing of Presta valves involves several critical stages, each designed to ensure the final product meets the high-quality standards expected by B2B buyers in the cycling industry.

Preparação de materiais:

The initial stage involves selecting high-grade materials that can withstand high-pressure conditions. Common materials include brass for the valve body, rubber for seals, and high-strength plastics for valve caps. Suppliers often source these materials from certified vendors to ensure compliance with international quality standards.

Formação:

During the forming phase, the raw materials are shaped into the desired components. This typically involves precision machining for the valve body, where CNC (Computer Numerical Control) machines are employed to achieve the required dimensions and tolerances. The rubber components are often molded, utilizing techniques that ensure durability and flexibility.

Montagem:

Once individual components are ready, the assembly process begins. Skilled technicians assemble the valve, ensuring that seals are correctly positioned to prevent leaks. Automated assembly lines may be utilized for efficiency, but manual inspections are critical to catch any defects during this phase.

Acabamento:

The final stage includes surface finishing and treatment, which may involve anodizing or plating to enhance corrosion resistance and aesthetic appeal. Each valve is then cleaned and prepared for packaging. Quality checks are conducted to ensure that each valve meets the required specifications before it leaves the factory.

Quality assurance is a cornerstone of the manufacturing process, especially for components that need to maintain high pressure. A comprehensive QC program is essential for B2B buyers looking for reliability and safety in their products.

Manufacturers often adhere to several international standards to ensure product quality:

ISO 9001: This is a globally recognized standard that outlines criteria for a quality management system. Companies certified under ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

Marcação CE: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. This is particularly relevant for components that will be used in bicycles sold within the EU.

Padrões API: While more common in the oil and gas industry, certain API standards may apply to the manufacturing of high-pressure components, ensuring they can withstand rigorous conditions.

Quality control checkpoints are integrated throughout the manufacturing process to catch defects early and ensure product integrity.

Controle de qualidade de entrada (IQC):

This phase checks raw materials and components upon arrival at the factory. Materials are inspected for quality and compliance with specifications before being allowed into production.

Controle de qualidade durante o processo (IPQC):

During manufacturing, operators conduct regular inspections at various stages. This includes measuring the dimensions of machined parts and checking for proper assembly. Any deviations from the standards can be corrected in real-time, reducing waste and improving efficiency.

Controle de qualidade final (FQC):

After assembly and finishing, a final inspection is carried out. This includes pressure testing the Presta valves to ensure they can withstand the required PSI without leaks. Additionally, visual inspections for cosmetic defects are performed to ensure aesthetic quality.

Various testing methods are employed to ensure that Presta valves function correctly under pressure and perform reliably in the field.

Hydrostatic Testing: This method involves filling the valve with water and applying pressure to check for leaks. It is a standard practice to validate the integrity of high-pressure components.

Teste funcional: The valve is attached to a pump to verify that it operates as intended, allowing air to flow in and preventing backflow. This testing ensures that the design works seamlessly in real-world applications.

Teste de durabilidade: This involves subjecting the valves to repeated cycles of inflation and deflation to simulate long-term use. The goal is to ensure that the seals remain intact and the valve operates smoothly after extensive use.

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial for ensuring reliability and safety in products.

Auditorias de fornecedores:

Conducting on-site audits allows buyers to assess a supplier’s manufacturing processes, QC protocols, and adherence to international standards. This firsthand evaluation can provide insights into the supplier’s commitment to quality.

Revisão de relatórios de qualidade:

Requesting quality assurance reports can help buyers understand the supplier’s QC metrics, including defect rates and compliance with standards. These reports should detail the results of various tests and inspections conducted during manufacturing.

Inspeções de terceiros:

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These inspections can confirm that the products meet the required specifications and standards before shipment.

International buyers must be aware of specific nuances when it comes to quality control and certification:

Illustrative image related to how to inflate bike tire presta valve

Conformidade regulatória: Different regions may have varying regulations regarding product safety and quality. Buyers must ensure that suppliers meet local standards, such as CE marking in Europe or specific safety certifications in the Middle East.

Cultural and Logistical Considerations: Differences in manufacturing practices and cultural approaches to quality can impact the effectiveness of QC measures. Buyers should be prepared to adapt their expectations and communication styles when dealing with suppliers from diverse backgrounds.

Documentation and Traceability: Ensuring that suppliers provide thorough documentation of their quality control processes is essential. This includes records of testing, compliance certifications, and any corrective actions taken during production.

In conclusion, understanding the manufacturing processes and quality assurance practices for Presta valves is vital for B2B buyers seeking reliable and high-quality products. By focusing on manufacturing stages, quality standards, testing methods, and effective supplier verification, buyers can make informed decisions that align with their operational needs and market expectations.

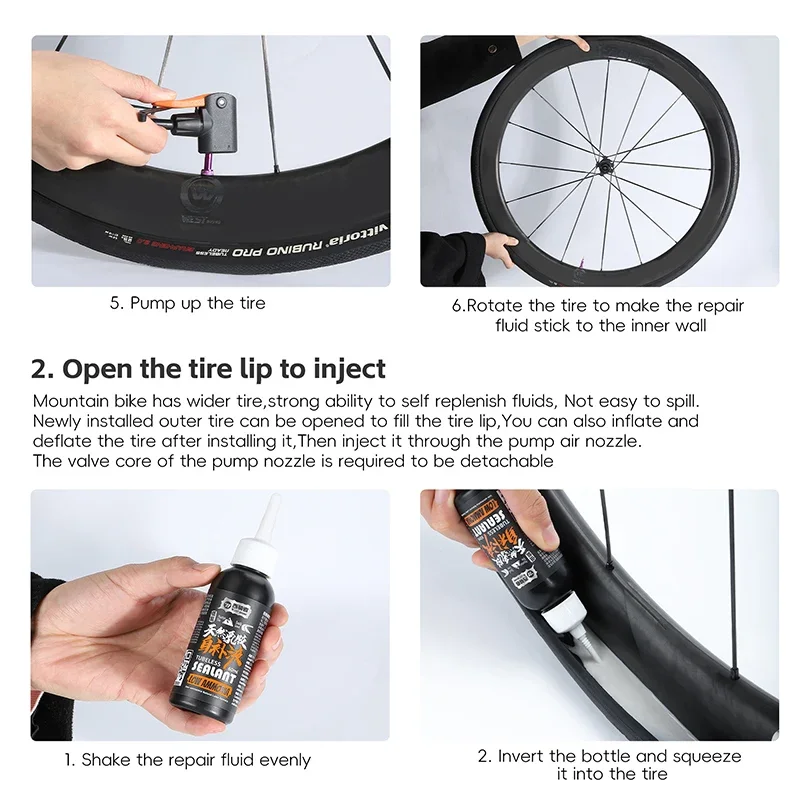

This guide serves as a practical checklist for B2B buyers seeking to understand the process of inflating bike tires with Presta valves. Given the popularity of these valves in high-performance bicycles, particularly in regions like Africa, South America, the Middle East, and Europe, it’s essential to have a clear understanding of the proper techniques and equipment needed. This checklist will help you ensure that your procurement decisions align with industry best practices and technical specifications.

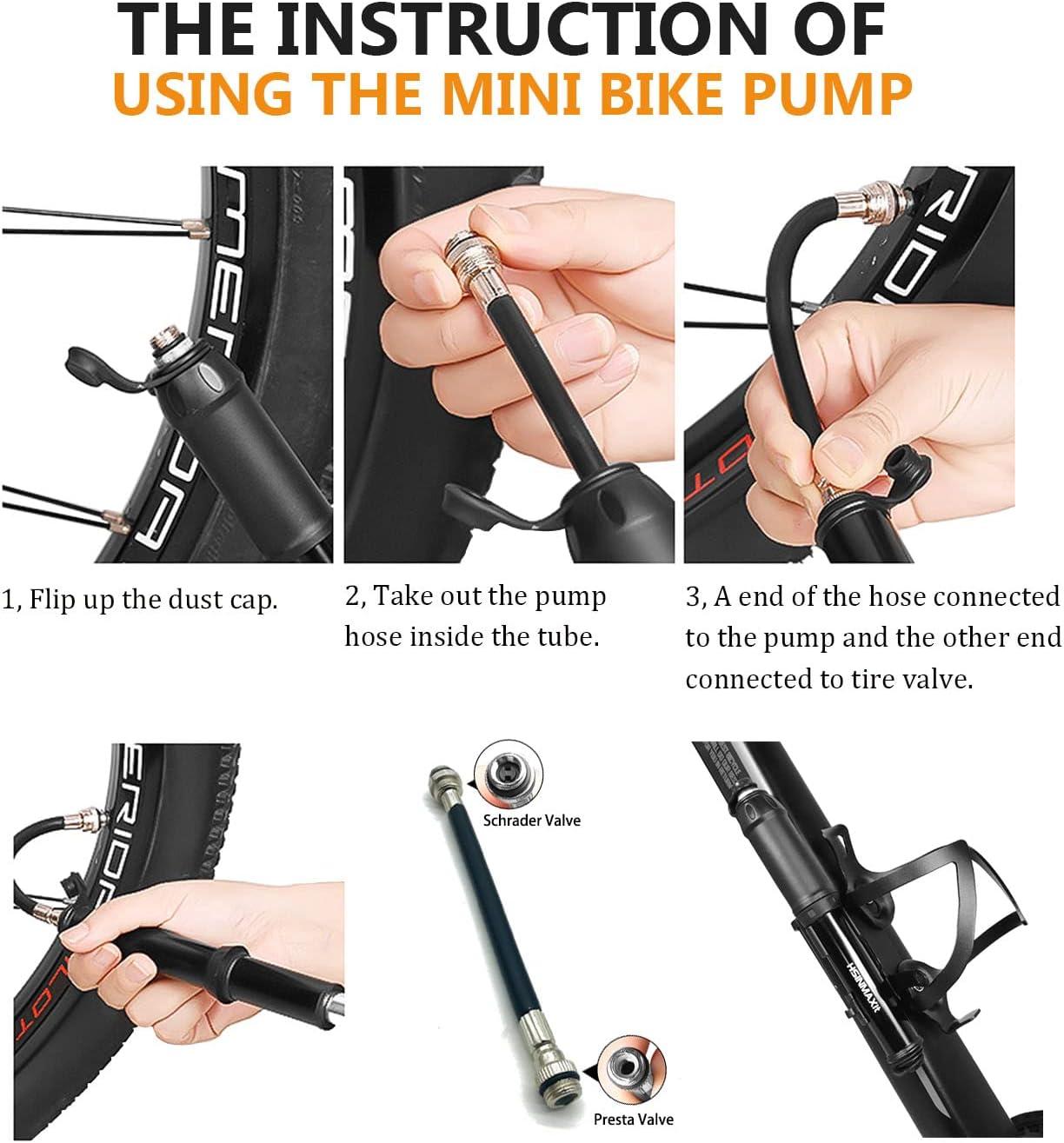

Before purchasing equipment, familiarize yourself with how Presta valves function. These valves are designed to maintain high pressure and are typically narrower than their Schrader counterparts. Understanding their unique mechanics will help you select compatible pumps and accessories, ensuring effective inflation without damaging the valve.

Choose a pump that is compatible with Presta valves. Floor pumps with a dual-head design or specific Presta adapters are ideal for this purpose. Ensure the pump has a pressure gauge that can measure up to the required PSI for your tires, as accurate pressure readings are critical for performance and safety.

When procuring inner tubes or tires, check the length of the Presta valve stem. A longer stem is often necessary for deeper rims, which are common in performance cycling. Ensuring the correct valve length will prevent difficulties in attaching the pump head, reducing the risk of air leaks.

Source products from reputable suppliers known for high-quality cycling accessories. Look for brands that specialize in bicycle components and have a proven track record of durability and performance. Quality materials in both the inner tubes and pumps will ensure a longer lifespan and better performance.

Ensure that your suppliers comply with relevant industry standards and regulations. Certifications can indicate adherence to quality management systems and safety practices, which is crucial for maintaining product integrity.

Identify suppliers who can consistently meet your demand for Presta valve-related products. Establishing a reliable supply chain will minimize delays and ensure you can meet customer needs efficiently.

Lastly, inquire whether your suppliers offer technical support or training resources for your team. Understanding the intricacies of Presta valve maintenance and inflation can enhance operational efficiency and customer satisfaction.

By following this checklist, B2B buyers can ensure they are well-equipped to manage the intricacies of inflating bike tires with Presta valves, ultimately supporting better product offerings and enhanced customer satisfaction.

Illustrative image related to how to inflate bike tire presta valve

When considering the costs associated with inflating bike tires fitted with Presta valves, various components come into play. These include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

Materiais: The primary materials involve the pump itself, which may be constructed from plastic and metal. Additionally, any adapters for Presta valves will add to material costs. The quality of these materials significantly impacts durability and functionality.

Trabalho: Labor costs encompass both direct and indirect labor. Direct labor includes the workforce involved in assembling pumps and valves, while indirect labor covers administrative support and maintenance. In regions with lower labor costs, such as parts of Africa and South America, this can lead to significant savings.

Custos indiretos de fabricação: Overhead costs are crucial as they include utilities, rent, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs, impacting the final pricing structure.

Ferramentas: Specific tools are required for the production of pumps and valves. These can be a one-time cost but require consideration in the overall pricing strategy, especially for custom or specialized products.

Controle de qualidade (QC): QC is vital to ensure the reliability of pumps and valves, especially in regions where tire pressure management is critical for safety. The cost of implementing QC processes should be factored into the overall pricing.

Logística: Transportation and warehousing costs are essential, particularly for international B2B buyers. Efficient logistics can minimize costs but may vary significantly depending on the region. For example, shipping to Africa may incur higher costs due to distance and infrastructure challenges.

Margem: Finally, the profit margin must be calculated based on the total costs. Competitive pricing strategies can influence market share and profitability, especially in regions with varying purchasing power.

Several factors influence the pricing of inflation solutions for Presta valves, impacting B2B buyers significantly.

Volume/MOQ: Bulk purchasing often leads to discounts, making it more cost-effective for businesses. Establishing minimum order quantities (MOQ) can also influence pricing negotiations.

Especificações e personalização: Customization of pumps and valves can lead to higher costs. Buyers should weigh the need for bespoke solutions against standard products to optimize costs.

Materiais e certificações de qualidade: The quality of materials used and any certifications (ISO, CE) can affect pricing. Higher quality typically commands a premium but can lead to lower total costs through reduced failure rates.

Fatores do fornecedor: The reputation and reliability of suppliers can greatly influence pricing. Established suppliers may offer better warranties and support, justifying a higher price point.

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. These terms dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and tariffs, significantly impacting the total cost of ownership.

Negociação: Engage suppliers in negotiations to explore volume discounts or long-term contracts. Building a strong relationship with suppliers can also lead to better pricing.

Eficiência de custo: Analyze the total cost of ownership rather than just the purchase price. Consider factors like durability, maintenance, and potential for failure when evaluating products.

Nuances de preços: Be aware of pricing trends in different regions. For instance, buyers in Europe may face higher prices due to stricter regulations and higher quality standards compared to other regions like Africa or South America.

Local Sourcing: Explore local suppliers to reduce logistics costs and lead times. Local sourcing may also provide flexibility in terms of customization and support.

Market Research: Conduct thorough market research to understand pricing benchmarks within your specific region. This knowledge can empower negotiations and strategic purchasing decisions.

Isenção de responsabilidade: Prices and cost structures can vary significantly based on market conditions, specific supplier offerings, and geographic factors. Always conduct due diligence before making purchasing decisions.

When it comes to inflating bike tires equipped with Presta valves, several methods and technologies are available. Each method presents its unique advantages and disadvantages, affecting performance, cost, ease of implementation, maintenance, and suitability for specific use cases. Understanding these alternatives is crucial for B2B buyers in the cycling industry, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

| Aspecto de comparação | How To Inflate Bike Tire Presta Valve | Bomba manual de mão | Inflador de CO2 |

|---|---|---|---|

| Desempenho | High; suitable for high pressure (up to 110 PSI) | Moderate; limited pressure capability (up to 80 PSI) | High; quick inflation (up to 120 PSI) |

| Custo | Moderate; requires investment in a quality pump | Low; affordable and widely available | Moderate; costs vary by brand and model |

| Facilidade de implementação | Requires practice; can be tricky for beginners | Simple; intuitive design | Very easy; quick setup and use |

| Manutenção | Baixa; é necessária uma limpeza ocasional | Low; minimal maintenance | Low; disposable cartridges can be wasteful |

| Melhor caso de uso | Frequent cyclists needing regular inflation | Casual riders; emergency use | Competitive cyclists needing rapid inflation |

Manual hand pumps are a traditional solution for inflating bike tires, particularly in areas where electricity or advanced technology might be limited. They are generally affordable and simple to use, making them suitable for casual cyclists or those in developing regions. However, their performance can be limited, as many models do not reach the higher pressures required for road bikes. Additionally, they may require more physical effort, which can be a drawback for some users.

Illustrative image related to how to inflate bike tire presta valve

CO2 inflators offer a modern, efficient method for inflating bike tires quickly. Utilizing pressurized CO2 cartridges, these devices can inflate tires to high pressures in seconds, making them ideal for competitive cyclists or those who experience frequent flat tires during rides. While they are easy to use, the cost of replacement cartridges can add up, especially for frequent users. Furthermore, CO2 inflation is not always sustainable, as cartridges are single-use and contribute to waste.

When selecting the most suitable method for inflating bike tires with Presta valves, B2B buyers should consider their specific operational needs and customer demands. For businesses focused on performance and regular maintenance, investing in high-quality pumps may provide long-term value. In contrast, retailers catering to casual cyclists or those needing quick solutions might find manual hand pumps or CO2 inflators more appealing. Ultimately, the choice will depend on factors such as budget constraints, target market preferences, and the frequency of tire inflation needs. By carefully evaluating these alternatives, businesses can enhance their product offerings and meet the diverse needs of their clientele.

Understanding the essential technical properties involved in inflating bike tires with Presta valves is critical for B2B buyers in the cycling industry. Here are some key specifications to consider:

Composição do material

The materials used in Presta valves, typically aluminum or brass, affect durability and performance. Aluminum is lightweight, making it ideal for competitive cycling, while brass offers superior strength and resistance to corrosion. Buyers should prioritize valves made from materials that align with their target market’s needs, whether they focus on lightweight racing bikes or durable commuter models.

Valve Length

Presta valves come in various lengths, generally ranging from 32mm to 60mm. The valve length must be compatible with the rim depth of the bicycle wheel. A mismatch can hinder proper inflation and lead to air leaks. B2B buyers should ensure they stock various lengths to accommodate diverse bike models, enhancing customer satisfaction and reducing returns.

Pressure Rating

Presta valves are designed to withstand high pressures, often exceeding 120 PSI. It’s essential for buyers to consider the maximum pressure requirements for the bikes they sell. Ensuring that the valves can handle these pressures prevents blowouts and enhances safety, which is crucial for maintaining brand reputation.

Sealing Mechanism

The sealing mechanism of a Presta valve is vital for preventing air leaks. Most valves feature a rubber gasket that ensures a tight seal when the valve is closed. Buyers should evaluate the quality of these components, as a superior seal enhances the user experience and reduces the likelihood of inflation issues.

Compatibility with Pumps

Not all pumps are compatible with Presta valves. It’s essential for buyers to understand the types of pump heads available, such as screw-on or lever-lock designs. Ensuring compatibility can significantly impact customer satisfaction, as users may experience frustration with ill-fitting pumps.

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B landscape. Here are some common trade terms relevant to the inflation of Presta valve bike tires:

OEM (fabricante original do equipamento)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of Presta valves, understanding OEM relationships can help buyers source high-quality components directly from manufacturers, ensuring better pricing and product reliability.

MOQ (Quantidade mínima de pedido)

MOQ refers to the smallest amount of a product that a supplier is willing to sell. Buyers should be aware of MOQs when sourcing Presta valves, as high MOQs can affect inventory management and cash flow. Negotiating favorable MOQs can lead to better purchasing decisions.

RFQ (Request for Quotation, solicitação de cotação)

An RFQ is a document that a buyer sends to suppliers to request pricing information for specific products. For B2B buyers in the cycling industry, issuing RFQs for Presta valves allows them to compare prices and terms from various suppliers, facilitating informed purchasing decisions.

Incoterms (Termos Comerciais Internacionais)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping costs, risk transfer, and delivery responsibilities when importing Presta valves from global suppliers.

Cycle Supply Chain

This term encompasses the entire process from manufacturing to delivery of bicycle components, including Presta valves. A solid understanding of the cycle supply chain helps buyers optimize inventory levels and enhance operational efficiency, ultimately leading to cost savings.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Presta valves, ensuring they meet customer needs and enhance overall business performance.

The global market for bike tire inflation, particularly for Presta valves, is witnessing significant transformations driven by multiple factors. The increasing popularity of cycling as a sustainable mode of transport and recreational activity has led to a surge in demand for high-performance bicycles, which often utilize Presta valves due to their ability to handle higher pressures. This trend is particularly evident in regions such as Europe and the Middle East, where cycling is promoted as an eco-friendly alternative.

Emerging technologies, including smart pumps equipped with pressure sensors and digital displays, are enhancing the user experience by simplifying the inflation process. These innovations cater to B2B buyers looking for efficient solutions that minimize time spent on maintenance. Additionally, the rise of e-commerce platforms is facilitating easier access to specialized bike accessories, including Presta valve inflators, thus expanding market reach for suppliers.

In Africa and South America, the emphasis on affordability and accessibility is shaping sourcing strategies. Local manufacturers are increasingly focusing on producing cost-effective solutions that meet the needs of the growing cycling community. Furthermore, the integration of mobile payment systems is streamlining transactions, making it easier for B2B buyers to acquire necessary tools and equipment.

Sustainability and ethical sourcing are becoming pivotal considerations for B2B buyers in the bike tire inflation sector. The environmental impact of manufacturing processes and materials used in Presta valves is under scrutiny. Buyers are encouraged to seek suppliers who prioritize eco-friendly practices, such as utilizing recycled materials and minimizing waste during production.

The importance of ethical supply chains cannot be overstated. Suppliers that adhere to fair labor practices and transparent sourcing methods are increasingly favored by discerning buyers. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical standards.

Moreover, the trend towards “green” certifications is gaining traction. Buyers should look for products that are certified for their environmental impact, which not only enhances brand reputation but also appeals to environmentally conscious consumers. In a market that increasingly values sustainability, aligning sourcing practices with these principles can provide a competitive edge.

Presta valves have a storied history that dates back to the early 20th century, when they were introduced as a lightweight alternative to the Schrader valve. Originally designed for racing bikes, Presta valves gained popularity due to their ability to withstand higher pressures, making them ideal for performance-oriented cycling. Over the decades, advancements in materials and design have further enhanced their functionality, leading to widespread adoption across various bike types.

The evolution of Presta valves has paralleled changes in cycling technology, with innovations such as threaded valve stems and removable cores improving usability and maintenance. For B2B buyers, understanding this historical context can provide insights into the reliability and performance features of current products available in the market. As the cycling industry continues to evolve, the Presta valve remains a cornerstone of tire inflation technology, reflecting the balance between tradition and innovation.

How do I solve common issues when inflating a bike tire with a Presta valve?

To effectively address common issues such as air leakage or difficulty attaching the pump, ensure the valve stem is sufficiently long for your pump head. If the stem is too short, consider using a valve extender or replacing the inner tube with one featuring a longer valve. Additionally, make sure to fully unscrew the valve before attaching the pump, and check that the pump’s head is compatible with Presta valves. If problems persist, examining the pump’s functionality may be necessary.

What is the best pump for inflating Presta valves?

The best pump for Presta valves is one that explicitly states compatibility with both Presta and Schrader valves, typically a high-pressure floor pump or a portable hand pump designed for road bikes. Look for pumps with a dual-head system or a dedicated Presta valve head, ensuring ease of use and effective sealing. Additionally, consider a pump with a built-in pressure gauge for accurate inflation, especially if you need to reach high pressures, such as 110 PSI.

How can I ensure quality when sourcing bike tire pumps for Presta valves?

To ensure quality when sourcing bike tire pumps, conduct thorough research on potential suppliers. Verify their reputation through reviews and testimonials, and request samples to assess pump performance. Additionally, consider certifications or compliance with international quality standards. Establishing clear communication regarding your quality expectations will help avoid misunderstandings. Regular quality assurance checks during production can further ensure that the products meet your specifications.

What are the minimum order quantities (MOQ) for bike tire pumps?

Minimum order quantities (MOQ) for bike tire pumps can vary significantly based on the supplier and your specific needs. Generally, MOQs range from 100 to 1,000 units, depending on the manufacturer and product type. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are testing a new market or product line. Building a long-term relationship with your supplier may also lead to more favorable terms.

What payment terms should I consider when sourcing bike accessories?

When sourcing bike accessories, consider payment terms that align with your cash flow and risk tolerance. Common terms include a 30% deposit upon order confirmation and the remaining 70% before shipment. Alternatively, some suppliers may offer Letter of Credit (LC) terms, which can provide security for both parties. Ensure that the payment method you choose is reliable and recognized internationally to facilitate smooth transactions.

How do I vet suppliers for bike tire pumps effectively?

To vet suppliers for bike tire pumps, start by researching their business history, certifications, and customer feedback. Request references from previous clients to gain insights into their reliability and product quality. It’s also beneficial to visit their manufacturing facility if possible or arrange for a virtual tour. Additionally, consider working with suppliers who provide transparent information about their manufacturing processes and quality control measures.

What logistics considerations should I keep in mind when importing bike accessories?

When importing bike accessories, consider logistics aspects such as shipping methods, customs regulations, and lead times. Assess whether air freight or sea freight is more suitable based on your urgency and budget. Familiarize yourself with import duties and taxes specific to your region, which can impact overall costs. Finally, ensure that your supplier has experience with international shipping to minimize delays and complications during the import process.

Can I customize bike tire pumps for my brand?

Yes, many manufacturers offer customization options for bike tire pumps, including branding with your logo and specific color schemes. Discuss your requirements with potential suppliers to understand the extent of customization available, such as packaging and design elements. Be prepared to meet minimum order quantities for custom products and consider the lead time necessary for production and branding. Customization can enhance your brand’s visibility and appeal in competitive markets.

Domínio: bicycles.stackexchange.com

Registrado: 2009 (16 anos)

Introdução: Presta valve, tire pressure 110 psi (7.5 atm), floor pump, valve cap, valve adapter, valve stem length issues, gauge not showing pressure, difficulty in attaching pump head, need for jam nut to stabilize valve stem.

In summary, effectively inflating a bike tire with a Presta valve involves understanding the valve mechanics and utilizing the right tools. Key takeaways for international B2B buyers include investing in high-quality pumps designed for Presta valves, ensuring proper valve stem length, and considering the use of valve extenders when necessary. These elements not only enhance the efficiency of the inflation process but also contribute to the longevity of the bike tires, reducing maintenance costs in the long run.

Strategic sourcing plays a critical role in securing reliable suppliers who can provide the necessary components and tools tailored to the needs of diverse markets, including Africa, South America, the Middle East, and Europe. By fostering relationships with reputable manufacturers and distributors, businesses can ensure a steady supply of high-quality products that meet regional demands.

Illustrative image related to how to inflate bike tire presta valve

Looking ahead, as the cycling market continues to grow globally, now is the time for B2B buyers to assess their sourcing strategies. Collaborating with trusted suppliers will not only streamline operations but also empower businesses to capitalize on emerging opportunities in the biking sector. Embrace the evolution of cycling equipment, and position your business for success in this dynamic market.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Illustrative image related to how to inflate bike tire presta valve

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.