In the fast-evolving landscape of global commerce, sourcing reliable air inflation solutions poses a significant challenge for B2B buyers across diverse markets, particularly in regions like Africa, South America, the Middle East, and Europe. The demand for high-quality air inflation products—ranging from tire inflation systems to precision gauges—requires buyers to navigate a complex web of options and suppliers. This guide serves as a comprehensive resource, designed to empower international B2B buyers by providing insights into various types of air inflation products, their applications, and the critical factors to consider when vetting suppliers.

As businesses increasingly prioritize efficiency and reliability in their operations, understanding the nuances of air inflation technology becomes paramount. This guide outlines essential aspects such as cost analysis, product specifications, and application scenarios, ensuring that buyers are equipped with the knowledge to make informed purchasing decisions. By addressing common challenges and offering actionable insights, we aim to streamline the procurement process for B2B buyers, enabling them to select the best solutions tailored to their unique needs. Whether you are in Brazil, Nigeria, or elsewhere, this guide is your roadmap to navigating the global market for air inflation, enhancing your operational efficiency and competitive edge.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Single Tire Inflation | Designed for inflating one tire at a time; portable units available. | Automotive repair shops, fleet services | Prós: Compact, easy to use. Contras: Slower process for multiple tires. |

| Multi-Tire Inflation | Capable of inflating multiple tires simultaneously; often features a manifold system. | Transportation companies, off-road vehicle services | Prós: Efficient for large operations. Contras: Higher upfront cost. |

| Digital Air Inflation | Equipped with digital pressure gauges and programmable settings for precision inflation. | Automotive manufacturers, tire retailers | Prós: Accurate, user-friendly. Contras: May require more maintenance. |

| Portable Air Compressors | Compact, battery or 12V powered compressors for on-the-go inflation. | Field service providers, outdoor equipment suppliers | Prós: Versatile, easy to transport. Contras: Limited power for heavy-duty tasks. |

| Inflation/Deflation Kits | Systems that allow for both inflating and deflating tires efficiently. | Off-road enthusiasts, emergency response teams | Prós: Versatile, saves time. Contras: Can be complex to set up. |

Single tire inflation systems are designed for simplicity and portability, making them ideal for smaller automotive repair shops and fleet services. These systems typically involve handheld units or small compressors that allow technicians to inflate one tire at a time. While they are easy to use and transport, the downside is that inflating multiple tires can be time-consuming, which may not be suitable for high-volume operations.

Multi-tire inflation systems can inflate several tires simultaneously through a manifold system, significantly enhancing operational efficiency for businesses like transportation companies and off-road vehicle services. These systems often come equipped with hoses and connectors for multiple tires, allowing for quick inflation during routine maintenance. The initial investment may be higher compared to single tire systems, but the time saved in busy environments can justify the cost.

Digital air inflation systems are equipped with advanced features such as digital pressure gauges and programmable settings, ensuring precise inflation for various applications. They are particularly useful for automotive manufacturers and tire retailers, where accuracy is critical. While these systems provide user-friendly interfaces and higher accuracy, they may require more frequent maintenance and calibration, which can add to operational costs.

Portable air compressors are designed for flexibility and convenience, making them an excellent choice for field service providers and outdoor equipment suppliers. These compressors can be powered by batteries or 12V connections, allowing for on-the-go inflation in various environments. However, their limited power output may restrict usage for heavy-duty applications, which buyers should consider based on their specific needs.

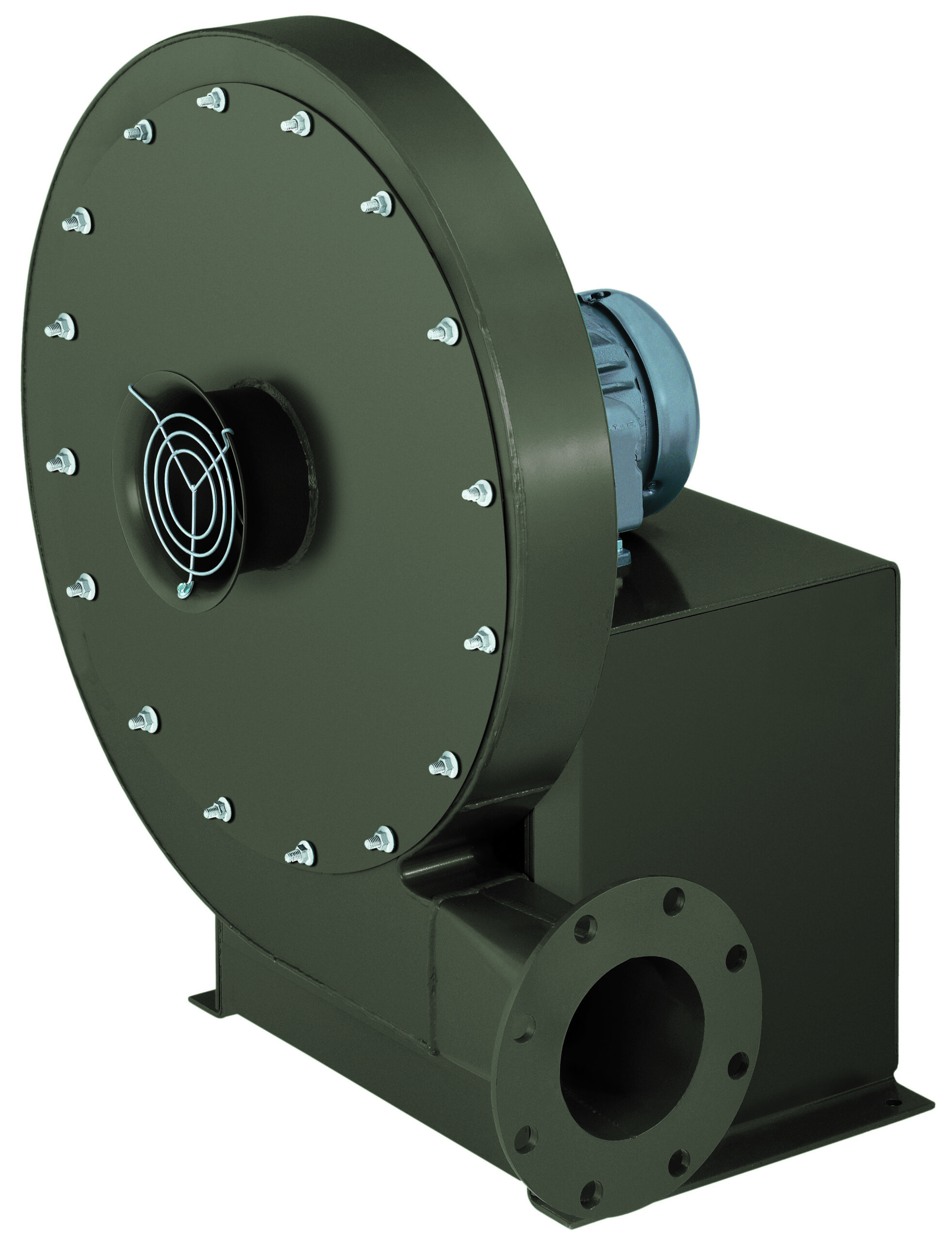

Illustrative image related to air inflation

Inflation/deflation kits are designed to facilitate both inflating and deflating tires efficiently, making them invaluable for off-road enthusiasts and emergency response teams. These systems allow users to adjust tire pressure quickly based on terrain requirements, thereby optimizing vehicle performance. While they offer significant versatility and time savings, the complexity of setup and operation can be a drawback for some users, necessitating training or experience to utilize effectively.

| Indústria/Setor | Specific Application of air inflation | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Automotivo | Tire inflation systems for vehicles | Improved safety and fuel efficiency | Quality of inflation equipment, compatibility with vehicle types, and ease of use. |

| Construção | Inflatable formwork for concrete structures | Enhanced efficiency in construction processes | Durability of materials, resistance to environmental factors, and ease of transport. |

| Agricultura | Inflatable irrigation systems | Efficient water management and reduced labor costs | Compatibility with existing irrigation setups and maintenance requirements. |

| Oil & Gas | Air inflation for downhole tools and equipment | Increased operational efficiency and safety | Reliability in extreme conditions and availability of service support. |

| Recreational Vehicles (RVs) | Portable air compressors for tire inflation | Convenience and safety for off-road travel | Portability, power source options, and versatility for different tire sizes. |

In the automotive sector, air inflation systems are crucial for maintaining optimal tire pressure, which directly influences vehicle safety and fuel efficiency. Regularly inflated tires enhance grip and reduce wear, leading to lower operational costs. For international buyers, particularly from regions like Africa and South America, sourcing high-quality inflation equipment that is compatible with a variety of vehicle types is essential. Buyers should prioritize ease of use, reliability, and the availability of service support to ensure that their investments yield long-term benefits.

Air inflation is increasingly utilized in the construction industry through inflatable formwork, which allows for the rapid creation of concrete structures. This method streamlines the construction process, reduces labor costs, and improves the quality of the finished product. For B2B buyers in Europe and the Middle East, selecting durable materials that can withstand harsh conditions is vital. Additionally, the ease of transport and setup of these inflatable systems should be a key consideration to maximize efficiency on job sites.

In agriculture, air inflation technologies are employed in inflatable irrigation systems that optimize water distribution across fields. These systems facilitate efficient water management, significantly reducing labor costs and ensuring that crops receive adequate hydration. Buyers from regions like Nigeria and Brazil should consider compatibility with existing setups and the maintenance requirements of these systems. Choosing reliable suppliers who offer robust and easy-to-maintain products is crucial for maximizing productivity in agricultural operations.

In the oil and gas industry, air inflation is utilized for various downhole tools and equipment, enhancing operational efficiency and safety. Proper inflation ensures that tools function effectively in extreme conditions, thereby minimizing downtime and operational risks. For international buyers in this sector, sourcing reliable equipment that can withstand harsh environments is paramount. Additionally, the availability of local service support can significantly influence purchasing decisions, ensuring that equipment remains operational with minimal interruptions.

For recreational vehicles (RVs), portable air compressors are essential for on-the-go tire inflation, enhancing safety and convenience during travels. These compressors allow RV owners to quickly address tire pressure issues, especially in remote areas. Buyers from regions with diverse terrains should focus on the portability and power source options of these compressors, ensuring they can operate effectively in various conditions. Versatility in accommodating different tire sizes is also a critical factor for those looking to purchase air inflation solutions for recreational use.

O problema: A logistics company managing a fleet of delivery trucks often faces delays due to inconsistent tire inflation across different vehicles. This issue not only affects fuel efficiency but also raises safety concerns, as under-inflated tires can lead to blowouts or accidents. The company struggles to find a reliable and efficient method to ensure that all tires are inflated to the correct pressure before each trip, especially when dealing with a large number of vehicles.

A solução: To address this challenge, the company should invest in a multi-tire inflation system, such as a quad-tire inflation kit that allows simultaneous inflation of multiple tires. When sourcing this equipment, it’s crucial to select high-quality components, including durable hoses, pressure gauges, and quick connect fittings that can withstand frequent use. Training staff on the correct usage of the system will enhance efficiency and ensure that all tires are inflated to the recommended PSI. Additionally, implementing a routine maintenance schedule for the inflation equipment can prevent breakdowns, ensuring that the inflation process remains seamless.

O problema: A construction firm operating in remote locations encounters difficulties in monitoring and adjusting tire pressures on heavy machinery and vehicles. The lack of precise pressure readings leads to either over-inflation or under-inflation, which can cause equipment malfunctions, increase wear on tires, and result in costly downtime.

Illustrative image related to air inflation

A solução: The firm should implement digital tire pressure monitoring systems (TPMS) that provide real-time readings and alerts for each tire. These systems can be integrated with existing machinery and vehicles, allowing operators to receive immediate notifications on tire pressure status. When selecting a TPMS, it’s important to choose a system that is ruggedized for harsh environments and offers wireless connectivity for easy monitoring. Regular training sessions for operators on interpreting TPMS data will further enhance their ability to make timely adjustments, ensuring optimal tire performance and prolonging the lifespan of both tires and machinery.

O problema: An agricultural enterprise dealing with various types of machinery for planting and harvesting is often hindered by inconsistent air inflation equipment. Frequent equipment malfunctions or inadequate inflation tools lead to downtime during critical planting or harvest periods, resulting in lost productivity and revenue.

A solução: To mitigate this issue, the enterprise should standardize its air inflation tools across all machinery, opting for high-quality, reliable compressors and inflation kits. Investing in portable air compressors designed for agricultural use can provide flexibility and ensure that inflation can occur on-site, reducing the need to transport equipment back to a central location. It’s also advisable to establish a partnership with a reputable supplier that offers ongoing support and maintenance services. Regularly scheduled inspections and maintenance of the inflation equipment can prevent unexpected failures during peak operational periods, ensuring that the enterprise remains productive and efficient throughout the agricultural cycle.

When selecting materials for air inflation systems, it is crucial to understand the properties, advantages, and limitations of various materials. This knowledge helps B2B buyers make informed decisions that align with their operational needs and compliance requirements, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

Rubber is widely used in air hoses and seals due to its excellent flexibility and resilience under pressure. It can withstand a range of temperatures, typically from -40°F to 200°F (-40°C to 93°C), making it suitable for various environments. The material also has good abrasion resistance, which is essential for applications involving frequent movement or contact with rough surfaces.

Prós: Rubber is durable and cost-effective, offering good performance in many applications. Its flexibility allows for easy handling and installation.

Contras: It can degrade over time when exposed to UV light and certain chemicals, limiting its lifespan. Additionally, rubber may not perform well at extreme temperatures or in high-pressure applications.

Impacto no aplicativo: Rubber is compatible with air and gases but may not be suitable for aggressive chemicals or high-temperature fluids.

Considerações para compradores internacionais: Compliance with local standards (e.g., ASTM, DIN) is essential. Buyers should also consider the availability of rubber products in their region and the potential for UV exposure.

Illustrative image related to air inflation

Polyurethane is increasingly popular for air inflation applications due to its superior abrasion resistance and flexibility. It can handle temperatures ranging from -40°F to 180°F (-40°C to 82°C) and has excellent tensile strength, making it suitable for high-pressure applications.

Prós: This material is lightweight and resistant to oil and chemicals, which enhances its versatility. It also maintains its flexibility over a wide temperature range.

Contras: Polyurethane can be more expensive than rubber and may require more complex manufacturing processes. It can also be sensitive to UV exposure, leading to potential degradation.

Impacto no aplicativo: Polyurethane is ideal for applications requiring durability and chemical resistance, making it suitable for various industrial environments.

Illustrative image related to air inflation

Considerações para compradores internacionais: Buyers should ensure that polyurethane products meet relevant international standards and assess the availability of this material in their local markets.

PVC is commonly used in air hoses and fittings due to its affordability and ease of manufacturing. It can withstand temperatures from 32°F to 140°F (0°C to 60°C) and is resistant to corrosion, making it suitable for a variety of applications.

Prós: PVC is cost-effective and offers good chemical resistance. Its lightweight nature makes it easy to handle and transport.

Contras: It has lower flexibility compared to rubber and polyurethane, which can limit its use in dynamic applications. Additionally, PVC may become brittle over time, especially in cold conditions.

Impacto no aplicativo: PVC is suitable for general-purpose air inflation but may not perform well in extreme temperatures or high-pressure scenarios.

Illustrative image related to air inflation

Considerações para compradores internacionais: Compliance with local regulations regarding PVC use is critical, as some regions may have restrictions on its use due to environmental concerns.

Stainless steel is often used for fittings, valves, and connectors in air inflation systems due to its strength and corrosion resistance. It can withstand high pressures and temperatures, making it suitable for demanding applications.

Prós: Stainless steel is highly durable and resistant to corrosion, which extends its lifespan in harsh environments. It also has excellent mechanical properties.

Contras: The cost of stainless steel is significantly higher than other materials, and its weight can be a disadvantage in portable applications. Additionally, it may require specialized manufacturing processes.

Impacto no aplicativo: Stainless steel is ideal for high-pressure applications and environments where corrosion resistance is critical.

Considerações para compradores internacionais: Buyers should ensure that stainless steel products comply with international standards (e.g., ASTM, JIS) and consider the availability of specific grades suitable for their applications.

| Material | Typical Use Case for air inflation | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Borracha | Hoses and seals | Cost-effective and flexible | Degrades under UV exposure | Baixa |

| Polyurethane | High-pressure hoses | Superior abrasion resistance | More expensive and UV sensitive | Médio |

| PVC | General-purpose hoses | Affordable and lightweight | Less flexible and can become brittle | Baixa |

| Aço inoxidável | Fittings and valves | Highly durable and corrosion resistant | Alto custo e peso | Alta |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in air inflation systems, helping them make informed purchasing decisions that align with their operational needs and compliance requirements.

The manufacturing of air inflation products typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the final product meets quality standards and customer expectations.

Preparação de materiais: This initial stage focuses on selecting high-quality raw materials. Common materials used in air inflation products include rubber, plastics, and metal components. These materials must meet specific standards for durability and performance, particularly in high-stress applications like tire inflation.

Formação: During this stage, raw materials are shaped into the desired forms using various techniques such as injection molding, extrusion, or stamping. For instance, rubber parts may be molded into specific shapes, while metal components can be stamped or machined to precise dimensions. Precision in forming is essential to ensure compatibility and functionality in the final assembly.

Montagem: The assembly process integrates various components into a complete product. This can involve manual labor or automated systems, depending on the scale of production. Quality control is critical at this stage to ensure that all components fit together correctly and function as intended.

Acabamento: The final stage includes processes that enhance the product’s appearance and functionality. This may involve painting, coating, or applying surface treatments. Finishing also includes quality checks to ensure that the product meets aesthetic and performance standards.

Several advanced techniques are employed in the manufacturing of air inflation products to enhance efficiency and quality. These include:

Moldagem por injeção: This process is commonly used for producing complex plastic parts with high precision. It allows for the mass production of consistent parts, which is crucial for components like air chucks and valves.

Extrusion: Often used for creating hoses and tubing, extrusion involves forcing material through a die to create a continuous shape. This technique is particularly useful for producing long lengths of air lines with uniform cross-sections.

CNC Machining: For metal components, CNC (Computer Numerical Control) machining ensures high precision and repeatability. This is essential for parts that require tight tolerances, such as fittings and connectors.

Quality Assurance Technologies: Modern manufacturing employs various technologies for quality assurance, including laser measurement systems and automated inspection tools, to detect defects early in the production process.

Quality control (QC) is integral to the manufacturing process, ensuring that products meet international and industry-specific standards. Key aspects of QC include:

Padrões internacionais: Adhering to standards such as ISO 9001 is vital for ensuring consistent quality. ISO 9001 outlines a framework for quality management systems, focusing on continuous improvement and customer satisfaction.

Industry-Specific Certifications: Products may also need to comply with specific certifications, such as CE marking in Europe or API standards for oil and gas applications. These certifications often require rigorous testing and documentation to demonstrate compliance.

QC Checkpoints: Quality control is typically conducted at various checkpoints throughout the manufacturing process:

– Controle de qualidade de entrada (IQC): This involves inspecting raw materials before they are used in production.

– Controle de qualidade durante o processo (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify issues in real-time.

– Controle de qualidade final (FQC): The finished products undergo thorough testing and inspection to ensure they meet all specifications and quality standards.

Métodos de teste comuns: Testing methods may include pressure testing for leaks, tensile strength testing for durability, and visual inspections for defects. Each method is designed to validate the product’s performance and safety.

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential to mitigate risks. Here are several strategies to ensure suppliers adhere to high-quality standards:

Auditorias de fornecedores: Conducting on-site audits allows buyers to assess a supplier’s manufacturing processes, quality control measures, and compliance with industry standards. This firsthand evaluation can provide invaluable insights into the supplier’s operations.

Solicitação de relatórios de qualidade: Suppliers should provide documentation detailing their quality control processes, including results from testing and compliance with relevant standards. These reports can help buyers gauge the supplier’s commitment to quality.

Inspeções de terceiros: Engaging independent third-party inspection services can validate the supplier’s claims regarding quality. These inspectors can provide objective assessments of the manufacturing processes and final products.

Understanding QC/CERT Nuances: International buyers should be aware of the specific quality certifications recognized in their regions. For instance, while CE marking is essential in Europe, other regions may have different requirements. Understanding these nuances helps buyers ensure compliance and reduces the risk of sourcing subpar products.

In the competitive landscape of air inflation products, robust manufacturing processes and stringent quality control measures are critical. B2B buyers must prioritize suppliers that adhere to international standards and demonstrate a commitment to quality through transparent practices. By understanding the intricacies of manufacturing and QC, buyers can make informed decisions that enhance their operational efficiencies and product reliability.

In the competitive landscape of air inflation products, sourcing the right equipment and suppliers is crucial for operational efficiency and cost-effectiveness. This step-by-step checklist will guide B2B buyers through the procurement process, ensuring that they make informed decisions tailored to their specific needs.

Understanding the specific requirements for your air inflation needs is the foundation of a successful procurement process. Consider the types of inflation systems—whether single, dual, or multi-tire setups—that best fit your operations. Additionally, assess the pressure ranges, compatibility with existing equipment, and any special features like digital gauges or automated inflation technology.

Stay informed about the latest trends in air inflation technology. This includes advancements in compressor efficiency, automation in inflation systems, and eco-friendly options that reduce energy consumption. Understanding these trends can help you identify innovative products that enhance productivity and sustainability.

Compile a list of suppliers that specialize in air inflation products. Look for manufacturers with a solid reputation and experience in your specific industry. Utilize online platforms, industry trade shows, and referrals to identify potential partners who align with your technical specifications.

Before engaging with suppliers, ensure they meet relevant industry standards and certifications. Compliance with safety and quality standards is essential, as it reflects the reliability of their products and services. Request documentation of certifications such as ISO, CE, or local regulatory compliance.

Engage potential suppliers by requesting product samples or live demonstrations. This step is crucial for assessing the quality and functionality of their products firsthand. Evaluate how well the equipment performs under conditions similar to your operational environment.

Obtain detailed pricing information from shortlisted suppliers, including any additional costs for maintenance, parts, or warranties. Consider the total cost of ownership over the product’s lifespan, not just the initial purchase price. This analysis will help you make a more informed financial decision.

Once you have selected a preferred supplier, negotiate contract terms that protect your interests. Pay attention to delivery timelines, warranty conditions, and service agreements. Clear communication during this phase can prevent misunderstandings and ensure a smooth procurement process.

By following this checklist, B2B buyers can streamline their sourcing process for air inflation products, ensuring they select the best options for their operational needs while minimizing risks and maximizing value.

When evaluating the cost and pricing structure for air inflation products, understanding the various cost components and pricing influencers is essential for international B2B buyers. This analysis will provide insights into how to navigate the complexities of sourcing air inflation solutions effectively.

Materiais: The primary materials used in air inflation products include durable plastics, metals, and rubber. The choice of materials directly impacts the product’s performance and longevity. High-quality materials may increase initial costs but can reduce maintenance and replacement expenses over time.

Trabalho: Labor costs vary significantly by region. In manufacturing hubs, labor may be more affordable, but this can be offset by shipping costs for international buyers. Understanding local labor rates can help buyers evaluate total costs accurately.

Custos indiretos de fabricação: This encompasses utilities, facility costs, and indirect labor. Efficient production processes can minimize overhead, allowing suppliers to offer competitive pricing. Buyers should inquire about the supplier’s production capabilities to gauge efficiency.

Ferramentas: Initial tooling costs can be substantial, especially for customized products. Buyers looking for unique specifications should consider how these costs will affect pricing. It is often beneficial to partner with suppliers who have flexible tooling options to minimize these expenses.

Controle de qualidade (QC): Investing in stringent QC processes can enhance product reliability but may also increase costs. Buyers should evaluate suppliers’ QC certifications and practices to ensure they align with their quality expectations.

Logística: Shipping costs, tariffs, and customs duties are critical factors for international sourcing. Understanding Incoterms is essential, as they define responsibilities for shipping, insurance, and tariffs between buyers and suppliers.

Margem: Suppliers typically add a margin to cover risks and profit. The margin can vary based on market demand, competition, and supplier reputation. Buyers should compare quotes from multiple suppliers to ensure they receive fair pricing.

Volume/MOQ: Pricing often scales with order volume. Buyers can negotiate better rates with larger orders, but they must balance inventory costs and storage capabilities.

Especificações e personalização: Custom products usually come with higher costs due to additional design and manufacturing requirements. Buyers should clearly define their specifications to avoid unexpected costs.

Materiais e certificações de qualidade: Products with certifications for safety and performance often command higher prices. However, these certifications can add value, especially in regulated markets.

Fatores do fornecedor: Supplier reputation, stability, and production capacity can influence pricing. A well-established supplier may offer reliability and quality assurance, justifying a higher price.

Incoterms: The choice of Incoterms can significantly affect total costs. Buyers should select terms that align with their logistics capabilities and financial strategies.

Negotiate Strategically: Engage suppliers in discussions about pricing structures. Understanding their cost drivers can provide leverage in negotiations.

Foco no custo total de propriedade (TCO): Rather than just looking at the purchase price, consider long-term costs, including maintenance, repairs, and potential downtime. This holistic view can justify higher upfront costs for quality products.

Be Aware of Pricing Nuances in International Markets: Different regions may have varying pricing structures due to local economic conditions. For instance, buyers from Africa or South America might face higher logistics costs, while European buyers may benefit from established trade agreements.

Request Samples and Prototypes: Before committing to a large order, ask for samples to assess quality. This practice can prevent costly mistakes and ensure that the product meets expectations.

Illustrative image related to air inflation

Stay Informed About Market Trends: Keeping abreast of market trends and pricing fluctuations can empower buyers during negotiations and help identify the best timing for purchases.

Prices for air inflation products can vary widely based on the factors discussed above. The figures provided in this analysis are indicative and should be confirmed with suppliers to ensure accuracy. Always seek multiple quotes to secure the best pricing tailored to your specific needs.

In the realm of tire maintenance and inflation, businesses often seek the most efficient and cost-effective solutions. While traditional air inflation systems have been the go-to method for many, there are viable alternatives that cater to diverse operational needs and environments. Below is a comparative analysis of air inflation against two alternatives: CO2 inflation systems and electric tire inflators.

| Aspecto de comparação | Air Inflation | CO2 Inflation System | Electric Tire Inflator |

|---|---|---|---|

| Desempenho | Reliable for standard use; fast inflation for multiple tires. | Quick inflation for off-road or emergency situations; limited by CO2 cartridge size. | Consistent performance; dependent on power source; slower than air inflation. |

| Custo | Moderate initial investment; ongoing costs for air compressor maintenance. | Higher initial cost for CO2 tanks and cartridges; lower ongoing costs. | Varies; generally affordable, but higher-end models can be costly. |

| Facilidade de implementação | Requires installation of compressor and hoses; can be complex for large setups. | Simple setup; requires CO2 tank and hose; portable but limited to cartridge availability. | Plug-and-play functionality; easy to use; portable models available. |

| Manutenção | Regular maintenance required for compressors; potential for air leaks. | Minimal maintenance; replace cartridges as needed. | Low maintenance; occasional check-up for electrical components. |

| Melhor caso de uso | Ideal for workshops and fleets needing frequent tire changes. | Best for off-road vehicles and emergency kits; limited use for regular maintenance. | Suitable for personal use, small businesses, and occasional inflation needs. |

CO2 inflation systems utilize compressed carbon dioxide to inflate tires rapidly, making them ideal for off-road and emergency situations. One of their significant advantages is speed; they can inflate a tire in seconds. However, the limitation lies in their reliance on cartridges, which can run out, necessitating careful planning for long trips or operations. Additionally, while the initial investment can be higher due to the cost of tanks and cartridges, the ongoing costs are minimal compared to air compressors. Businesses that require quick, portable solutions for irregular tire inflation may find CO2 systems particularly beneficial.

Electric tire inflators offer a modern approach to tire inflation, leveraging electricity for consistent performance. They are user-friendly, often equipped with digital displays and automatic shut-off features for precision. These inflators are ideal for smaller operations and individual users, as they can be plugged into a vehicle’s power outlet or an electrical socket. However, their performance can be hindered by the availability of power sources, especially in remote locations. While electric inflators are generally more affordable than traditional air inflation systems, high-end models can be costly. They are best suited for occasional use, making them less ideal for heavy-duty applications.

Illustrative image related to air inflation

When selecting the appropriate tire inflation solution, B2B buyers should consider their specific operational needs, including frequency of use, portability, and the nature of the tasks at hand. For businesses with a high volume of tire maintenance, traditional air inflation systems may offer the best reliability and efficiency. Conversely, those needing a quick, portable solution for off-road scenarios might find CO2 systems advantageous. Electric tire inflators serve well for personal or low-frequency commercial use, providing ease of access without the complexity of larger systems. Ultimately, the choice should align with operational requirements, budget constraints, and the expected usage environment to ensure optimal performance and value.

Understanding the technical properties and trade terminology associated with air inflation is crucial for B2B buyers navigating this specialized market. This guide provides insights into essential specifications and common jargon that will aid in making informed purchasing decisions.

Grau do material

– Definição: Refers to the quality and type of materials used in the construction of inflation equipment, such as hoses, valves, and fittings. Common materials include rubber, metal alloys, and high-density plastics.

– Importância: The material grade affects durability, resistance to wear and tear, and suitability for specific applications (e.g., high-pressure environments). Selecting the right material can enhance the longevity of the equipment and reduce replacement costs.

Operating Pressure Range

– Definição: This specification indicates the range of pressure (usually measured in PSI) within which the air inflation system can safely operate.

– Importância: Understanding the operating pressure range is vital for ensuring safety and efficiency. Equipment that operates outside its designated range can fail, leading to accidents or costly repairs.

Níveis de tolerância

– Definição: Tolerance refers to the permissible limit of variation in a physical dimension or measured value, such as pressure accuracy in gauges.

– Importância: High tolerance levels ensure precision in inflation, which is particularly important in industries where exact pressure levels are critical (e.g., automotive, aviation). Poor tolerance can lead to performance issues or equipment failure.

Flow Rate

– Definição: The flow rate measures how quickly air can be delivered through the system, typically expressed in cubic feet per minute (CFM).

– Importância: A higher flow rate means faster inflation or deflation times, which can significantly improve operational efficiency, especially in environments where time is critical.

Compatibility Standards

– Definição: Refers to the adherence to industry standards for fittings and connections, ensuring that components from different manufacturers can work together seamlessly.

– Importância: Compatibility is essential for flexibility in purchasing and maintenance. Equipment that meets international standards can be integrated with existing systems, reducing the need for custom solutions.

OEM (fabricante original do equipamento)

– Definição: Uma empresa que produz peças e equipamentos que podem ser comercializados por outro fabricante.

– Importância: Understanding OEM components is crucial for buyers looking for replacements or upgrades, as they ensure compatibility and maintain warranty conditions.

MOQ (Quantidade mínima de pedido)

– Definição: A menor quantidade de um produto que um fornecedor está disposto a vender.

– Importância: Knowing the MOQ helps buyers assess budget constraints and inventory requirements, especially when dealing with large-scale procurement.

RFQ (Request for Quotation, solicitação de cotação)

– Definição: A document sent to suppliers requesting a quote for specific products or services.

– Importância: An RFQ streamlines the procurement process, enabling buyers to compare prices and terms from multiple suppliers, ultimately leading to better negotiation outcomes.

Incoterms (Termos Comerciais Internacionais)

– Definição: A set of pre-defined international rules that clarify the responsibilities of buyers and sellers in international transactions.

– Importância: Familiarity with Incoterms is essential for understanding shipping responsibilities, costs, and risk management, particularly for international buyers from diverse regions.

PSI (Pounds per Square Inch)

– Definição: A unit of pressure used to measure inflation levels in tires and other inflatable products.

– Importância: Knowing the PSI specifications is critical for ensuring that products are inflated to the correct levels for safety and performance.

Deflation Rate

– Definição: The speed at which air escapes from an inflatable product, typically measured in PSI per hour.

– Importância: Understanding the deflation rate is key for applications where maintaining pressure is vital, such as in emergency response or off-road environments.

By grasping these essential properties and terminology, B2B buyers can enhance their decision-making processes, ensuring they select the right air inflation equipment for their needs while fostering smoother supplier relationships.

The air inflation sector is witnessing significant growth driven by global demand for efficient tire inflation solutions across various industries, including automotive, agriculture, and construction. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly leveraging advancements in technology to enhance operational efficiency. Key trends include the integration of digital technologies such as smart compressors and automated inflation systems, which allow for precise pressure control and reduced downtime. For instance, innovations like the MORRFlate Air Hub enable users to set desired PSI levels automatically, facilitating both inflation and deflation processes.

Moreover, the rise in electric vehicles (EVs) is reshaping the air inflation market, as specialized inflation solutions are necessary for different tire types and sizes. As the industry evolves, buyers must stay abreast of emerging technologies and adaptable solutions that meet specific regional needs. Additionally, the shift towards online sourcing platforms simplifies procurement processes, allowing B2B buyers to access a broader range of products and suppliers, enhancing competition and price transparency.

Sustainability and ethical sourcing are becoming increasingly critical in the air inflation sector as global awareness of environmental impacts grows. Buyers are now prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using eco-friendly materials and minimizing waste. The demand for ‘green’ certifications, such as ISO 14001, is on the rise, signifying a supplier’s adherence to environmental management standards.

For instance, companies that utilize recycled materials in their air inflation products or implement energy-efficient manufacturing processes are more likely to attract conscientious buyers. This trend not only aligns with corporate social responsibility goals but also enhances brand reputation in a competitive marketplace. International buyers should carefully assess the sustainability credentials of suppliers and consider the lifecycle impacts of products when making purchasing decisions.

The evolution of the air inflation sector can be traced back to the advent of the automobile, where the need for reliable tire inflation became paramount. Early inflation methods relied heavily on manual pumps and gauges, which were often inefficient and inaccurate. The introduction of electric compressors in the late 20th century marked a significant turning point, providing users with faster and more convenient inflation options.

Illustrative image related to air inflation

In recent years, the focus has shifted towards automation and connectivity, with smart inflation systems emerging as a key innovation. These advancements not only improve user experience but also cater to the growing demand for precision and efficiency in various industrial applications. As the market continues to evolve, B2B buyers must remain informed about historical trends to understand current product offerings and anticipate future developments.

Navigating the complexities of the air inflation sector requires a keen understanding of market dynamics, sustainability considerations, and historical context. International B2B buyers, particularly from emerging markets, stand to benefit significantly by leveraging technological advancements and prioritizing ethical sourcing practices. Engaging with suppliers who align with these values will not only enhance operational efficiency but also contribute to a sustainable future.

How do I choose the right air inflation system for my business needs?

When selecting an air inflation system, consider factors such as the type of vehicles or equipment you will be inflating, the required pressure range, and the volume of inflation needed. Evaluate whether a single, dual, or multi-tire inflation system suits your operational requirements. Additionally, assess the durability and portability of the system, especially if you operate in rugged environments. Consulting with suppliers for product specifications and usage scenarios can provide valuable insights tailored to your specific industry needs.

What are the advantages of using a multi-tire inflation system?

Multi-tire inflation systems offer significant time savings and efficiency, especially for businesses managing a fleet of vehicles. These systems allow simultaneous inflation of multiple tires, reducing downtime and increasing productivity. Moreover, they often come equipped with features like pressure gauges and automatic shut-off, ensuring accurate inflation and minimizing the risk of over-inflation. For businesses in sectors like transportation, construction, or agriculture, investing in such systems can lead to operational cost reductions and improved safety.

What is the process for vetting suppliers of air inflation products?

Vetting suppliers involves assessing their reliability, product quality, and service capabilities. Start by reviewing their certifications, customer testimonials, and case studies. Request product samples to evaluate quality firsthand. It’s also beneficial to inquire about their manufacturing processes and quality assurance practices. Establish communication to gauge their responsiveness and willingness to address your concerns. Finally, check their adherence to international trade regulations, especially if you are importing products to regions like Africa or South America.

What are the typical minimum order quantities (MOQs) for air inflation products?

Minimum order quantities for air inflation products can vary widely depending on the supplier and the specific product type. Generally, MOQs can range from a few units for specialized equipment to larger quantities for bulk orders. It’s advisable to discuss your requirements with suppliers to negotiate MOQs that align with your business needs. Additionally, some suppliers may offer flexibility for first-time orders or smaller businesses, allowing you to test their products without a significant upfront investment.

What payment terms should I expect when sourcing air inflation products internationally?

Payment terms can differ based on the supplier’s policies and your negotiation outcomes. Common terms include advance payment, letter of credit, or payment upon delivery. For international transactions, it’s essential to clarify currency, payment methods, and timelines to avoid misunderstandings. Many suppliers may require a deposit upfront, particularly for custom orders. Establishing a clear agreement on payment terms early in the negotiation process can help streamline transactions and foster a positive supplier relationship.

How can I ensure the quality of air inflation products I purchase?

To ensure product quality, request detailed specifications and compliance certificates from your supplier. Consider conducting factory audits or third-party inspections to verify manufacturing standards. Additionally, inquire about warranty and return policies to safeguard your investment. Building a relationship with reputable suppliers who prioritize quality assurance can also enhance your confidence in the products you source. Regularly testing the equipment upon delivery will help identify any discrepancies early on.

What logistics considerations should I keep in mind when importing air inflation products?

Logistics plays a crucial role in the successful importation of air inflation products. Evaluate shipping methods, transit times, and associated costs, which can vary based on your location and the supplier’s base. Be aware of customs regulations and duties that may apply to your shipment. Establish a reliable logistics partner to handle transportation and customs clearance, ensuring timely delivery. Additionally, consider the packaging and handling requirements of the products to prevent damage during transit.

Can I customize air inflation products to meet specific needs?

Many suppliers offer customization options for air inflation products, allowing you to tailor specifications such as hose lengths, fitting types, and branding. Discuss your requirements during initial consultations to determine what customization options are available. Be prepared to provide detailed specifications and possibly a prototype if your needs are unique. Customization can enhance the usability of the products in your operations, making them more effective for your specific applications.

Domínio: apexdesignsusa.com

Registrado: 2019 (6 anos)

Introdução: This company, Apex Designs – Compact Reel System, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domínio: target.com

Registrado: 1997 (28 anos)

Introdução: This company, Target – Electric Inflation Air Pumps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domínio: morrflate.com

Registrado: 2019 (6 anos)

Introdução: MORRFlate offers a range of off-road air inflation and deflation tools and accessories, including:

1. **Air Hub**: Digital user PSI selection, automagic inflation and deflation, patent pending Set Your Pressure Technology.

2. **MORRFlate TenSix™ PSI Pro™**: A 12v portable compressor that allows users to set their PSI and walk away. Stronger and faster than previous models.

3. **Hose Kits**:

-…

Domínio: shop.aperiatech.com

Registrado: 2010 (15 anos)

Introdução: Product Name: Halo Tire Inflator

Price: $770.00

Limited Time Offer: 22% Off with code “22” at checkout

Principais recursos:

– Only tire management platform for all wheel positions

– Extends tire life, improves fuel economy, maximizes uptime, enhances safety

– Each kit includes all Halos, brackets, and necessary hoses for full vehicle installation

– Each Halo arrives pre-set to fleet’s target cold inflat…

Domínio: pcltireinflationusa.com

Registrado: 2019 (6 anos)

Introdução: PCL TIRE INFLATION USA offers a range of tire inflation products including: 1. Nitrogen Inflation for Service Centers – designed to extend tire life and minimize TPMS alerts. 2. Heavy Commercial Solutions – high pressure devices that are performance-driven. 3. High Performance Off-Road Kit – capable of inflating/deflating all 4x tires simultaneously. 4. Racing Inspired Products – professional grad…

In today’s competitive landscape, strategic sourcing of air inflation products is essential for enhancing operational efficiency and ensuring cost-effectiveness. International B2B buyers must prioritize relationships with reliable suppliers who offer a comprehensive range of products, such as tire inflation systems, compressors, and accessories tailored to diverse market needs. By leveraging advanced technologies and innovative designs, companies can optimize their inflation processes, thereby reducing downtime and increasing productivity.

Furthermore, understanding regional market demands—particularly in Africa, South America, the Middle East, and Europe—can provide a competitive edge. For instance, adapting to the specific requirements of emerging markets like Brazil and Nigeria can facilitate tailored solutions that resonate with local consumers.

As we look ahead, the air inflation sector is poised for growth, driven by advancements in automation and sustainability. B2B buyers are encouraged to explore partnerships with forward-thinking suppliers who prioritize innovation and quality. By doing so, they can position themselves strategically to meet the evolving demands of their industries. Embrace these opportunities and ensure your organization is equipped for future challenges in the air inflation market.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.

Illustrative image related to air inflation