In the dynamic landscape of global commerce, sourcing reliable autozone compressed air solutions presents a significant challenge for B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe. As industries increasingly rely on compressed air systems for a multitude of applications—ranging from automotive repair to industrial manufacturing—the need for high-quality, efficient air solutions becomes paramount. This comprehensive guide is designed to equip international buyers with the knowledge and tools necessary to navigate the complexities of sourcing autozone compressed air products.

Throughout this guide, we will delve into various aspects critical to informed purchasing decisions. Buyers will gain insights into the types of compressed air products available, including air compressors, tools, and accessories, as well as their specific applications across different industries. We will also cover essential supplier vetting processes to ensure quality and reliability, alongside a detailed analysis of cost considerations that can affect your procurement strategy.

By empowering B2B buyers with actionable insights and expert guidance, this resource aims to streamline the purchasing process, helping you make informed decisions that align with your business needs. Whether you are in Nigeria, Germany, or beyond, understanding the global market for autozone compressed air is key to driving operational efficiency and ensuring your projects succeed.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Inflador de pneus portátil | Compact, easy to store, powered by electricity or battery | Automotive repair shops, roadside assistance | Prós: Lightweight, convenient; Contras: Limited air volume for larger tasks. |

| Compressor de ar | Versatile power source for various tools, available in different sizes | Manufacturing, automotive, construction | Prós: High air volume, multiple tool compatibility; Contras: Requires maintenance, can be expensive. |

| Air Impact Wrench | Delivers high torque with minimal effort, pneumatic or electric options | Auto repair, assembly lines | Prós: Efficient for heavy-duty tasks; Contras: Noise levels can be high. |

| Air Spray Gun | Used for painting and coating, varying nozzle sizes for different applications | Automotive refinishing, furniture production | Prós: Smooth finish, adjustable spray patterns; Contras: Requires skill for optimal use. |

| Air Hose and Reel | Flexible tubing available in various lengths, with retractable options | Workshop organization, mobile mechanics | Prós: Reduces clutter, easy access; Contras: Potential for wear and tear over time. |

Portable tire inflators are compact devices designed for quick and easy inflation of vehicle tires. Their lightweight design makes them ideal for automotive repair shops and roadside assistance services, where mobility is essential. Buyers should consider the power source (battery vs. electric) and the maximum pressure output when selecting a model. While these inflators offer convenience and ease of use, they may not be suitable for larger inflation tasks due to their limited air volume capacity.

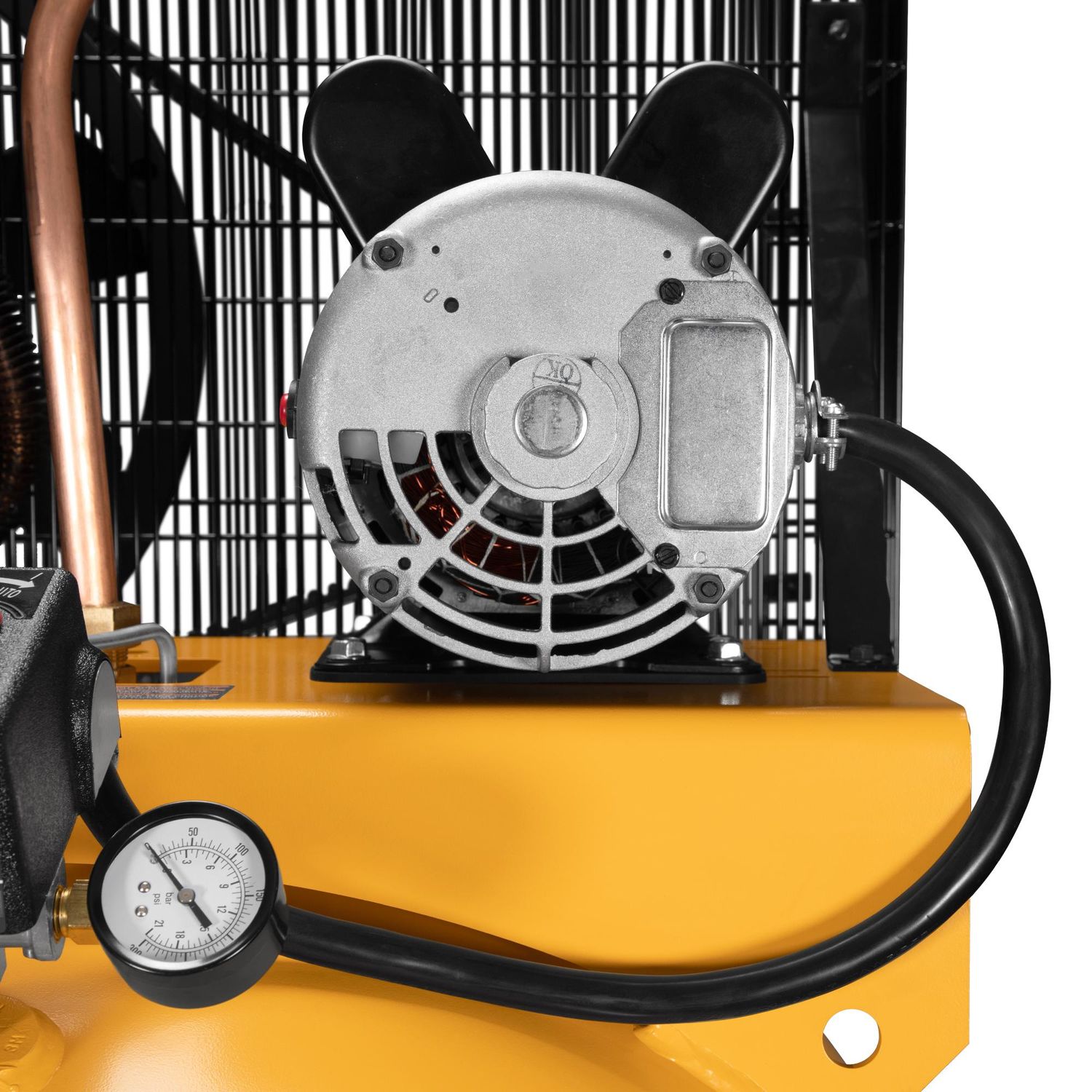

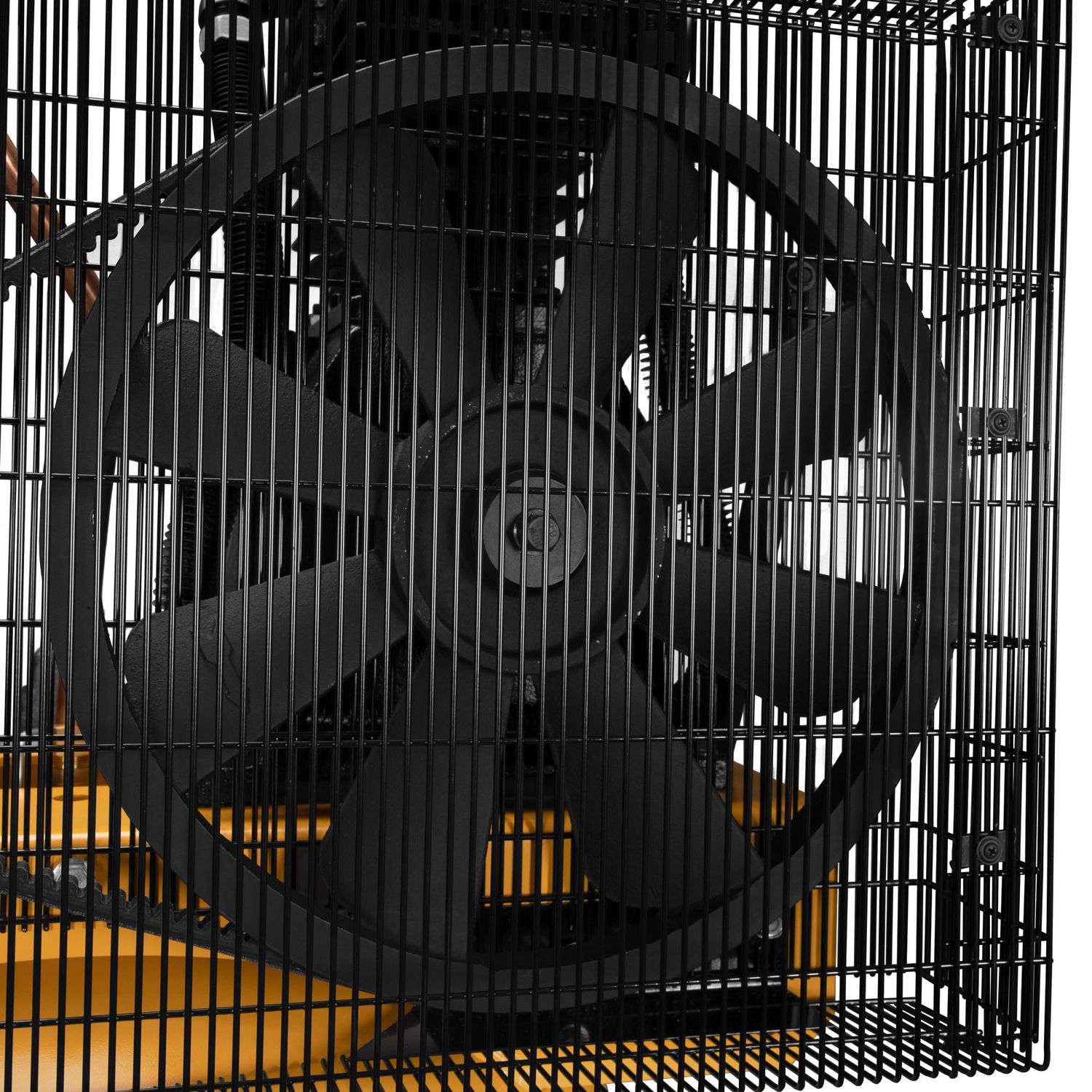

Air compressors are a fundamental tool in various industries, providing a reliable power source for pneumatic tools. They come in different sizes and capacities, making them suitable for applications ranging from automotive repairs to construction. B2B buyers should evaluate their specific needs, such as the required air pressure and volume, as well as maintenance requirements. While air compressors are versatile, they can require significant investment and upkeep, which is a critical consideration for budget-conscious businesses.

Air impact wrenches are designed to deliver high torque with minimal physical effort, making them indispensable in automotive repair and assembly line operations. Available in pneumatic and electric models, these tools enhance efficiency and productivity. Buyers should assess factors such as torque ratings and noise levels, as some models can be quite loud. While they excel in heavy-duty applications, the potential noise pollution can be a drawback in certain environments, necessitating appropriate hearing protection.

Air spray guns are essential for achieving high-quality finishes in automotive refinishing and furniture production. With various nozzle sizes and adjustable spray patterns, they allow for precise application of paints and coatings. B2B buyers should consider the type of material to be sprayed and the skill level of the operator, as optimal results require technique and experience. While air spray guns provide a superior finish compared to traditional methods, they may demand a higher initial investment and operator training.

Air hoses and reels are vital for maintaining organization and accessibility in workshops. They are available in various lengths and can be retractable, which reduces clutter and enhances mobility for mechanics and technicians. When purchasing, businesses should consider hose durability and compatibility with existing equipment. While air hoses improve efficiency, they can be subject to wear and tear, making it important for buyers to evaluate the quality and lifespan of the products they choose.

| Indústria/Setor | Specific Application of autozone compressed air | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Automotive Repair | Tire Inflation and Maintenance | Ensures optimal tire performance and safety | Availability of portable inflators and compatibility with local standards |

| Fabricação | Pneumatic Tools Operation | Increases efficiency and precision in production | Reliability of air supply and maintenance support |

| Construção | Powering Pneumatic Equipment | Enhances productivity and reduces manual labor | Durability of equipment and ease of transport |

| Agricultura | Crop Spraying and Fertilization | Improves crop yield and reduces chemical usage | Adaptability to various terrains and climate conditions |

| Food and Beverage Processing | Cleaning and Sanitizing Equipment | Maintains hygiene standards and operational efficiency | Compliance with health regulations and ease of sourcing parts |

In the automotive repair sector, compressed air is primarily utilized for tire inflation and maintenance. Properly inflated tires ensure optimal vehicle performance, enhance fuel efficiency, and improve safety. For international buyers, especially in regions like Nigeria or Germany, sourcing reliable tire inflators that comply with local safety standards is crucial. Additionally, ease of use and portability are essential features for businesses that operate in various locations.

Compressed air is vital in manufacturing for operating pneumatic tools, such as drills, impact wrenches, and grinders. These tools increase efficiency and precision, leading to higher production rates and reduced labor costs. B2B buyers in South America and Europe should consider the reliability of their air supply systems and the availability of maintenance services. Ensuring compatibility with existing equipment can also streamline operations and minimize downtime.

In the construction industry, autozone compressed air is used to power pneumatic equipment, including nail guns and air hammers. This application significantly enhances productivity, allowing workers to complete tasks more efficiently than manual methods. Buyers in the Middle East and Africa should prioritize the durability of compressors, as construction sites often face harsh conditions. Additionally, ease of transport and setup can be a deciding factor in equipment selection.

Compressed air serves a critical role in agriculture, particularly for crop spraying and fertilization. By using air-powered sprayers, farmers can achieve a more uniform application of chemicals, improving crop yield while minimizing waste. For B2B buyers in regions with varying climates, such as South America, adaptability to different terrains is essential. Furthermore, sourcing equipment that complies with environmental regulations can enhance a business’s reputation and operational efficiency.

In the food and beverage processing industry, compressed air is essential for cleaning and sanitizing equipment. Maintaining high hygiene standards is vital for compliance with health regulations and ensuring product safety. B2B buyers in Europe and Africa must consider the compliance of air systems with local health regulations and the availability of replacement parts. Additionally, sourcing equipment that can withstand the rigors of a processing environment is critical for long-term operational success.

O problema:

B2B buyers in automotive service industries often face issues with inconsistent air pressure when using AutoZone’s compressed air products, particularly during tire inflation. This inconsistency can lead to over-inflation or under-inflation, resulting in safety hazards, uneven tire wear, and potential damage to vehicles. Such problems can significantly impact service quality and customer satisfaction, leading to lost business opportunities and increased operational costs.

A solução:

To mitigate these issues, it’s crucial to invest in high-quality air pressure regulators and gauges that are compatible with AutoZone’s compressed air systems. Regularly calibrate your pressure gauges to ensure accuracy. Additionally, implementing a routine maintenance schedule for your air compressors can help maintain consistent air pressure. Train staff on the importance of checking tire pressure before and after inflation to ensure optimal performance. Utilizing digital inflators that provide precise readings can further enhance accuracy and efficiency.

O problema:

In many B2B settings, buyers encounter compatibility issues between AutoZone compressed air products and their existing tools and equipment. This can lead to downtime as teams struggle to find the right fittings or adapters, causing frustration and inefficiencies in workflow. For businesses that rely on air tools for operations—such as auto repair shops—this can result in delayed service delivery and increased labor costs.

A solução:

Before purchasing, it’s essential to thoroughly assess the specifications of both your existing tools and the AutoZone compressed air products. Buyers should consult product compatibility charts available on the AutoZone website or directly contact their customer support for assistance. Additionally, investing in a universal adapter kit can save time and effort in the long run, allowing for seamless integration of various tools. Regularly reviewing your equipment inventory and aligning it with your compressed air system can also prevent future compatibility issues.

O problema:

Another common pain point for B2B buyers is the maintenance and repair of compressed air systems. Over time, components such as air hoses, filters, and compressors can wear out, leading to decreased efficiency and increased risk of breakdowns. This not only affects productivity but can also lead to costly repairs and extended downtime.

A solução:

To address these challenges, implement a proactive maintenance strategy. Start by establishing a regular inspection schedule for all components of your compressed air system, including hoses and filters. Use high-quality replacement parts from AutoZone to ensure longevity and reliability. Train your staff on basic troubleshooting techniques to quickly identify and resolve minor issues before they escalate. Consider investing in a monitoring system that tracks the performance and condition of your air compressor, allowing for timely interventions and reducing the risk of unexpected failures.

When selecting materials for compressed air systems, particularly those offered by AutoZone, it is essential to consider various factors that impact performance, durability, and compliance with international standards. Below, we analyze four common materials used in compressed air applications, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Aluminum is a widely used material in compressed air systems due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 200°F (93°C) and can handle pressures up to 150 psi.

Prós: Aluminum is durable and resistant to rust, making it suitable for various environments. Its lightweight characteristic simplifies installation and reduces transportation costs.

Contras: While aluminum is generally cost-effective, it can be more expensive than some alternatives like steel. It may also be prone to denting under heavy impact.

Illustrative image related to autozone compressed air

Impacto no aplicativo: Aluminum is compatible with most air tools and accessories, making it a versatile choice for automotive applications.

Considerações para compradores internacionais: Buyers from regions such as Africa and South America should ensure that aluminum components meet local standards, such as ASTM or ISO certifications, to guarantee quality and safety.

Steel is another common material used in the construction of compressed air systems, particularly for hoses and tanks. It has a high temperature rating, often exceeding 300°F (149°C), and can withstand high pressures, typically up to 300 psi.

Prós: Steel is incredibly durable and offers excellent tensile strength, making it suitable for high-pressure applications. It is also relatively inexpensive compared to other materials.

Illustrative image related to autozone compressed air

Contras: Steel is susceptible to rust and corrosion if not properly coated or maintained. It is also heavier than aluminum, which can complicate installation and transport.

Impacto no aplicativo: Steel is ideal for heavy-duty applications, such as industrial air compressors, where high pressure and durability are critical.

Considerações para compradores internacionais: Buyers in Europe, particularly Germany, should be aware of the DIN standards that govern steel quality and corrosion resistance, which can impact product selection.

Polyvinyl Chloride (PVC) is commonly used for air hoses in compressed air systems due to its flexibility and lightweight properties. PVC hoses can typically handle temperatures up to 150°F (65°C) and pressures around 150 psi.

Prós: PVC is cost-effective and flexible, making it easy to maneuver in tight spaces. It is also resistant to many chemicals, enhancing its usability in various applications.

Illustrative image related to autozone compressed air

Contras: PVC may not be as durable as metal options and can become brittle over time, especially when exposed to extreme temperatures.

Impacto no aplicativo: PVC hoses are suitable for low to medium-pressure applications, making them ideal for automotive repairs and maintenance tasks.

Considerações para compradores internacionais: Buyers in the Middle East should ensure that PVC products comply with local environmental regulations regarding plastic use and disposal.

Rubber is often used in seals and gaskets within compressed air systems due to its excellent elasticity and sealing properties. It can typically withstand temperatures ranging from -20°F to 180°F (-29°C to 82°C) and pressures up to 150 psi.

Prós: Rubber provides a reliable seal, preventing air leaks and enhancing system efficiency. It is also resistant to wear and tear, extending the lifespan of components.

Illustrative image related to autozone compressed air

Contras: Rubber can degrade over time when exposed to oils and certain chemicals, which may limit its application in some environments. It can also be more expensive than other materials.

Impacto no aplicativo: Rubber is crucial for maintaining the integrity of compressed air systems, making it essential for any application where air leakage could compromise performance.

Considerações para compradores internacionais: Buyers from Africa should check for compliance with local quality standards, as rubber products can vary significantly in quality and durability.

Illustrative image related to autozone compressed air

| Material | Typical Use Case for autozone compressed air | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Air tanks and hoses | Leve e resistente à corrosão | Prone to denting | Médio |

| Aço | High-pressure air compressors | Durable and cost-effective | Susceptible to rust | Baixa |

| PVC | Air hoses for low to medium pressure | Flexible and cost-effective | Pode se tornar frágil com o tempo | Baixa |

| Borracha | Vedações e gaxetas | Excellent sealing properties | Degrades with exposure to oils | Médio |

This guide provides a comprehensive overview of material selection for compressed air systems, enabling B2B buyers to make informed decisions that align with their operational needs and compliance requirements.

The manufacturing process for compressed air products at Autozone involves several critical stages that ensure both functionality and reliability. The typical stages are material preparation, forming, assembly, and finishing.

Preparação de materiais: The process begins with the selection of high-quality materials, often including durable metals and plastics. These materials must meet specific industry standards to ensure longevity and performance. Suppliers are typically vetted for their ability to provide materials that adhere to international regulations, which is crucial for B2B buyers focused on quality.

Formação: During the forming stage, materials are shaped into the required components using advanced techniques such as stamping, forging, or machining. Precision is key here, as even slight deviations can affect the efficiency of the compressed air tools. Automated systems often play a significant role in achieving the necessary accuracy and repeatability.

Montagem: The assembly process involves integrating various components into a final product. This may include assembling air compressors, hoses, fittings, and other accessories. Skilled technicians ensure that each part is correctly installed and functions as intended. Automated assembly lines may also be employed to increase efficiency while maintaining quality.

Acabamento: Finally, finishing processes such as painting, coating, or surface treatment are applied to enhance durability and aesthetic appeal. These processes also help protect against corrosion and wear, extending the product’s lifecycle.

Quality assurance (QA) is paramount in manufacturing compressed air products, particularly for international B2B buyers who prioritize reliability. Autozone employs a multi-faceted QA strategy that aligns with both international and industry-specific standards.

Illustrative image related to autozone compressed air

Aderência aos padrões internacionais: Autozone’s manufacturing processes comply with ISO 9001, a globally recognized standard for quality management systems. This ensures that all operations are consistently monitored and improved over time. Additionally, products may need to meet CE (Conformité Européenne) or API (American Petroleum Institute) certifications, depending on the market and application.

Pontos de verificação de controle de qualidade: The quality control (QC) process includes several checkpoints:

– Controle de qualidade de entrada (IQC): Raw materials and components are inspected upon arrival to ensure they meet specified standards.

– Controle de qualidade durante o processo (IPQC): During manufacturing, ongoing inspections are conducted to identify defects early in the process, which helps minimize waste and rework.

– Controle de qualidade final (FQC): Finished products undergo rigorous testing to verify functionality, safety, and compliance with specifications.

Métodos de teste comuns: Various testing methods are employed to evaluate product performance. These may include pressure tests, leak tests, and functionality tests, ensuring that products can withstand the demands of their intended applications. Vibration and durability tests may also be performed to simulate real-world conditions.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps buyers can take:

Realizar auditorias de fornecedores: Regular audits of suppliers can provide insight into their manufacturing processes and QA systems. This includes reviewing documentation, observing production lines, and assessing compliance with industry standards.

Solicitar relatórios de controle de qualidade: Buyers should ask for detailed QA reports that outline the supplier’s processes, including results from IQC, IPQC, and FQC. These reports should detail any corrective actions taken in response to defects or non-conformities.

Utilize Third-Party Inspection Services: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control measures. These agencies can conduct pre-shipment inspections and provide reports that detail product quality and compliance with specified standards.

When sourcing compressed air products, international buyers must navigate various quality control and certification nuances. Understanding these factors can help mitigate risks and ensure product quality.

Regional Compliance Requirements: Different regions may have specific compliance requirements that affect product certifications. For instance, buyers in Europe may require CE marking, while those in the Middle East may look for certifications aligned with local standards. Understanding these requirements upfront can prevent costly compliance issues.

Cultural and Operational Differences: Buyers should be aware that manufacturing practices and quality expectations can vary significantly between regions. For instance, suppliers in Europe may have more stringent QA processes compared to those in emerging markets. It’s essential to communicate specific quality expectations clearly and be prepared for potential variations in manufacturing capabilities.

Building Long-Term Relationships: Establishing long-term relationships with suppliers can enhance trust and improve communication regarding quality control. Buyers should consider engaging in collaborative improvement initiatives that foster shared goals for product quality and reliability.

In summary, the manufacturing processes and quality assurance systems for Autozone compressed air products are designed to meet rigorous standards and deliver reliable performance. For international B2B buyers, understanding these processes, verifying supplier practices, and being aware of regional compliance requirements are essential steps in sourcing high-quality products. By prioritizing these factors, buyers can ensure that they receive durable and effective compressed air solutions tailored to their specific needs.

This guide serves as a practical checklist for B2B buyers seeking to procure compressed air systems and related accessories from AutoZone. Whether you are involved in automotive repair, manufacturing, or maintenance services, understanding the right sourcing process is essential for ensuring quality and efficiency in your operations.

Begin by outlining the specific requirements for the compressed air system you need. Consider factors such as the intended application, pressure requirements, and air volume needed for your tools and machinery. Clearly defined specifications will help streamline your search and ensure compatibility with existing equipment.

Explore the range of compressed air products offered by AutoZone, including air compressors, tools, and accessories. Familiarize yourself with the different types of compressors available, such as reciprocating, rotary screw, or oil-free models.

Before making a purchase, assess potential suppliers thoroughly. Request detailed company profiles, product catalogs, and case studies from clients in similar sectors.

Ensure that your chosen supplier complies with industry standards and holds relevant certifications. This step is crucial for maintaining safety and quality in your operations.

Obtain quotes from multiple suppliers to compare pricing structures. Pay close attention to not just the initial costs but also the total cost of ownership, including maintenance and warranty coverage.

Consider the logistics involved in the delivery of your compressed air systems. Ensure that the supplier can meet your timeline and that they have a reliable shipping process.

Once you have completed your evaluations, draft a purchase agreement that outlines all terms, including pricing, delivery, and warranties. This step ensures that both parties are aligned and helps prevent misunderstandings.

By following these steps, B2B buyers can effectively source high-quality compressed air products from AutoZone, ensuring they meet their operational needs while optimizing cost and efficiency.

When sourcing compressed air products from AutoZone, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Illustrative image related to autozone compressed air

Materiais: The raw materials used in the manufacturing of air compressors, hoses, and tools significantly affect the overall cost. High-quality materials often lead to better performance and durability, but they also increase the base price.

Trabalho: Labor costs encompass the wages of workers involved in production, assembly, and quality checks. In regions with higher labor costs, such as Europe, this can represent a significant portion of the final price.

Custos indiretos de fabricação: This includes expenses related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can reduce these costs, which may be reflected in pricing.

Ferramentas: The initial setup costs for manufacturing equipment and molds can be substantial, especially for custom products. This cost is often amortized over the volume produced, influencing pricing strategies.

Controle de qualidade: Implementing rigorous QC processes ensures product reliability but adds to costs. Certifications for quality standards can also drive up expenses, though they are often necessary for international markets.

Logística: Transportation and warehousing costs vary significantly by region and can influence the final price. Import duties and tariffs may apply, particularly for buyers in Africa and South America, adding layers of cost to international sourcing.

Margem: Finally, the profit margin set by suppliers will impact pricing. This margin can fluctuate based on market demand, competition, and the supplier’s positioning strategy.

Several factors influence the pricing of AutoZone compressed air products, making it critical for buyers to understand these elements to negotiate effectively.

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Bulk purchases often lead to discounts, so buyers should assess their needs and negotiate for better terms.

Especificações e personalização: Customized products typically come at a premium. Buyers should clearly define their requirements to avoid unnecessary costs associated with alterations.

Qualidade do material e certificações: The choice of materials and the presence of certifications (such as ISO or CE) can drive prices higher. Buyers should weigh the benefits of higher-quality products against their budget constraints.

Fatores do fornecedor: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers may offer competitive rates to gain market share.

Incoterms: Understanding Incoterms is crucial for international transactions. They dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, all of which affect the total landed cost of products.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, mastering negotiation and cost-efficiency techniques can lead to significant savings.

Negotiate Based on Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes maintenance, operational costs, and potential downtime. This broader perspective can justify higher upfront costs for more reliable products.

Pesquisa de preços de mercado: Understanding the market landscape helps in negotiating better deals. Buyers should compare pricing from multiple suppliers and leverage this data during negotiations.

Explore Financing Options: For large purchases, financing can ease cash flow challenges. Suppliers may offer payment terms that can help manage costs effectively.

Utilize Local Partnerships: Collaborating with local distributors or agents familiar with the market can streamline logistics and reduce costs associated with customs and tariffs.

Stay Informed About Market Trends: Keeping abreast of industry trends and material costs can provide leverage in negotiations, allowing buyers to make informed decisions.

Prices and cost structures can vary significantly based on numerous factors, including market conditions, regional economic factors, and supplier pricing strategies. Buyers should conduct thorough research and obtain multiple quotes to ensure they are making informed purchasing decisions.

When evaluating options for compressed air solutions, it’s essential to consider various alternatives that can meet the specific needs of B2B buyers across different industries. This analysis compares Autozone compressed air products with two viable alternatives: electric air compressors and portable air tanks. Each option presents unique advantages and challenges that can influence purchasing decisions based on performance, cost, ease of implementation, maintenance requirements, and best-use scenarios.

Illustrative image related to autozone compressed air

| Aspecto de comparação | Autozone Compressed Air | Electric Air Compressor | Portable Air Tank |

|---|---|---|---|

| Desempenho | Consistent, high pressure | High efficiency, versatile | Limited pressure capacity |

| Custo | Moderate pricing | Higher initial investment | Lower initial cost |

| Facilidade de implementação | User-friendly setup | Requires electrical outlet | Simple, portable setup |

| Manutenção | Low maintenance needs | Regular maintenance required | Minimal maintenance needed |

| Melhor caso de uso | Automotive repairs, tire inflation | Workshops, home garages | On-the-go tire inflation, small tasks |

Electric air compressors are powerful tools that provide high efficiency and versatility for various applications. They are well-suited for workshops or home garages, where access to electrical outlets is available. While the initial investment may be higher than Autozone compressed air solutions, electric compressors often deliver superior performance and longer lifespans. However, they do require regular maintenance, including oil changes and filter replacements, which can add to operational costs over time.

Portable air tanks offer a more cost-effective solution for businesses that need a mobile, easy-to-use option for inflating tires or performing minor tasks. These tanks are lightweight and can be easily transported, making them ideal for on-the-go applications. However, they typically have a limited pressure capacity compared to Autozone compressed air systems, which may restrict their use for more demanding tasks. Maintenance is minimal, as these tanks do not have complex mechanical components, but they require regular refilling to remain functional.

Selecting the appropriate compressed air solution depends on various factors, including the specific needs of your business, budget constraints, and application requirements. If your operations require high performance and versatility, investing in an electric air compressor may be worthwhile despite the higher upfront costs. Conversely, if mobility and cost-effectiveness are top priorities, a portable air tank could be the ideal choice for simpler tasks. Ultimately, understanding the unique advantages and limitations of each alternative will enable B2B buyers to make informed decisions that align with their operational needs and budgetary considerations.

When selecting compressed air systems from AutoZone, several technical properties are essential for ensuring optimal performance and reliability. Understanding these specifications can help international B2B buyers make informed purchasing decisions.

Illustrative image related to autozone compressed air

The pressure rating, typically measured in pounds per square inch (PSI), indicates the maximum pressure the compressor can generate. This specification is crucial for determining whether the compressor can handle the demands of specific air tools and applications. Higher pressure ratings allow for more efficient operation of tools such as impact wrenches and spray guns, making it a vital consideration for businesses in automotive repair and manufacturing.

Tank capacity, measured in gallons, defines how much compressed air the system can store at any given time. A larger tank capacity means longer run times between cycles, which is essential for continuous operations in busy workshops. For B2B buyers, selecting the right tank size can lead to increased productivity and reduced downtime.

Horsepower measures the motor’s power that drives the compressor. This specification is vital for understanding the compressor’s ability to deliver air consistently and efficiently. Higher horsepower ratings typically mean faster recovery times, enabling the compressor to maintain pressure during heavy usage, which is especially important in high-demand settings.

Illustrative image related to autozone compressed air

Airflow rate, measured in cubic feet per minute (CFM), indicates the volume of air the compressor can supply. For businesses utilizing multiple air tools simultaneously, selecting a compressor with an adequate CFM rating is critical. Ensuring that the airflow rate matches or exceeds the requirements of all connected tools prevents performance issues and enhances operational efficiency.

The noise level of a compressor, measured in decibels (dBA), is an important specification for workplaces. High noise levels can lead to uncomfortable working conditions and potential hearing loss over time. B2B buyers should consider quieter models to create a more pleasant working environment, especially in settings where employees are in close proximity to the equipment.

Understanding industry jargon is essential for effective communication and negotiation in the compressed air sector. Here are some key terms that B2B buyers should be familiar with:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. When purchasing compressed air systems or components, recognizing OEM products can ensure compatibility and quality, as these parts are often designed specifically for certain brands or models.

MOQ is the smallest amount of product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory levels and cost-effectiveness. Buying in larger quantities may lead to discounts, but it also requires careful planning to avoid excess stock.

An RFQ is a document sent to suppliers asking for a price quote on specific products or services. This term is fundamental in the procurement process, as it allows businesses to compare pricing, terms, and conditions from multiple suppliers, ensuring they get the best deal.

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects such as shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers navigate cross-border transactions effectively, ensuring clarity in delivery responsibilities and costs.

A TDS provides detailed information about a product, including specifications, usage instructions, and safety data. For B2B buyers, referring to TDS can aid in understanding product capabilities and compliance with industry standards, ensuring informed purchasing decisions.

Illustrative image related to autozone compressed air

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their procurement strategies and ensure they select the most suitable compressed air solutions for their operations.

The global market for autozone compressed air systems is experiencing significant transformation driven by technological advancements and evolving buyer preferences. Increased demand for efficient and reliable air tools and compressors is fueled by the automotive sector’s growth, particularly in emerging markets like Nigeria and South America. B2B buyers are increasingly looking for high-performance, durable products that can withstand the rigors of diverse working conditions. Additionally, the rise of e-commerce platforms allows international buyers greater access to a wider range of products, enhancing competition and driving prices down.

Current sourcing trends highlight the importance of digital solutions in procurement processes. Many businesses are adopting cloud-based inventory management systems to streamline their supply chain operations. This shift allows for real-time tracking of inventory levels and automated reordering, ensuring that businesses can meet demand without overstocking. Furthermore, the integration of IoT (Internet of Things) technology in air compressors is becoming prevalent, providing features such as predictive maintenance and energy efficiency monitoring. This not only reduces operational costs but also extends equipment lifespan, which is particularly appealing to B2B buyers focused on long-term investments.

Illustrative image related to autozone compressed air

Sustainability has become a cornerstone of modern B2B operations, particularly in the compressed air sector. The environmental impact of air compressor manufacturing and operation cannot be overlooked; energy consumption is a significant contributor to carbon emissions. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability through energy-efficient products and responsible manufacturing practices.

Ethical sourcing is equally important, as buyers seek suppliers who adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can provide buyers with assurance regarding the ethical standards of their suppliers. Moreover, opting for products made from recycled or eco-friendly materials not only enhances a company’s sustainability profile but also appeals to environmentally conscious consumers. As a result, B2B buyers in regions like Europe and the Middle East, where regulatory frameworks around sustainability are becoming more stringent, are keen to align their sourcing strategies with these values.

The autozone compressed air market has evolved significantly over the decades, transitioning from manual tools to sophisticated, automated systems. Initially, compressed air was primarily used for simple tasks like tire inflation and powering basic pneumatic tools. However, as technology advanced, the applications for compressed air expanded into more complex uses, such as automotive assembly lines and specialized maintenance tasks.

The introduction of electric and portable air compressors marked a significant turning point, making compressed air tools more accessible to a broader range of users, including small workshops and individual mechanics. Today, the market continues to innovate with the incorporation of smart technologies, reflecting a shift towards efficiency and sustainability that resonates with modern B2B buyers. Understanding this historical context is vital for international buyers, as it provides insights into product development trends and future market potential.

How do I choose the right air compressor for my business needs?

Selecting the right air compressor depends on your specific applications and the required pressure and airflow. Consider factors such as the type of tools you’ll be using, their CFM (Cubic Feet per Minute) requirements, and the operating pressure needed. For industrial use, higher capacity compressors may be necessary, while smaller, portable models can suffice for light-duty tasks. Additionally, assess the power source availability—electric or gas—and the potential for expansion in your operations.

What is the best air tool for automotive applications?

For automotive applications, air impact wrenches are among the best tools due to their efficiency in loosening and tightening bolts. They provide high torque output and significantly reduce the time needed for mechanical repairs. Other essential tools include air ratchets for quick fastening, spray guns for painting, and air blow guns for cleaning. Ensure that the tools you select are compatible with the air compressor specifications to optimize performance.

What is the minimum order quantity (MOQ) for autozone compressed air products?

The minimum order quantity (MOQ) for autozone compressed air products can vary based on the supplier and specific product lines. Typically, MOQs may range from a few units for smaller tools to larger quantities for bulk orders of compressors and accessories. It is advisable to directly consult with the supplier to negotiate MOQs that align with your business requirements and inventory management strategy.

What payment terms are commonly offered for B2B purchases of autozone compressed air?

Payment terms can differ widely among suppliers but generally include options such as net 30, net 60, or upfront payments. Some suppliers may offer discounts for early payments or bulk purchases. It’s crucial to clarify these terms before finalizing any order to ensure they meet your cash flow requirements. Consider discussing flexible payment options if your order volume justifies it.

How can I ensure quality assurance (QA) for autozone compressed air products?

To ensure quality assurance, request certifications and compliance documents from your supplier, verifying that their products meet international standards. Implement a quality inspection process upon receiving goods, focusing on key performance indicators like functionality and durability. Building a strong relationship with suppliers that prioritize QA can also facilitate better communication about product issues and returns.

What logistics considerations should I keep in mind when sourcing autozone compressed air?

Logistics considerations include shipping methods, lead times, and import duties. Choose a reliable shipping partner that can handle international freight and understand the specific regulations for your region. Calculate total landed costs, including shipping fees and customs tariffs, to assess the true cost of your purchase. Additionally, ensure that the supplier can provide tracking information for your shipments.

How do I vet suppliers for autozone compressed air products?

Vetting suppliers involves researching their reputation, financial stability, and compliance with industry standards. Request references from other B2B clients and verify their experience in handling international orders. Additionally, assess their responsiveness to inquiries and willingness to provide product samples. Platforms like Alibaba or trade associations can also provide insights into supplier credibility.

Can I customize autozone compressed air products for my specific needs?

Many suppliers offer customization options for autozone compressed air products, such as branding, specifications, or unique configurations. Discuss your requirements with the supplier to understand the feasibility of custom orders and associated costs. Customization can enhance your brand visibility and ensure that the products meet your operational demands, but it’s essential to factor in lead times for these tailored solutions.

Could not verify enough suppliers for autozone compressed air to create a list at this time.

In conclusion, the strategic sourcing of AutoZone’s compressed air products presents a pivotal opportunity for international B2B buyers across Africa, South America, the Middle East, and Europe. By focusing on quality air tools and accessories, businesses can significantly enhance operational efficiency, reduce downtime, and ensure the reliability of their equipment. Sourcing from a reputable supplier like AutoZone allows buyers to benefit from a diverse range of high-quality products, including air compressors, impact wrenches, and specialized accessories tailored to various automotive needs.

Understanding the value of strategic sourcing goes beyond mere procurement; it involves building lasting relationships with suppliers that can adapt to market changes and support your business growth. This approach not only streamlines supply chains but also fosters innovation and cost-effectiveness, vital for maintaining a competitive edge.

Looking ahead, B2B buyers are encouraged to explore the extensive catalog of AutoZone’s compressed air solutions, leveraging their expertise to optimize operations. By investing in reliable tools and fostering strategic partnerships, businesses can position themselves for success in an increasingly competitive landscape. Embrace the future of automotive service with confidence—your next step in strategic sourcing starts today.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.