In the dynamic landscape of cycling accessories, sourcing a reliable bike tire inflator air compressor can present a daunting challenge for B2B buyers. With an increasing demand for efficient and portable inflation solutions, companies across Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Nigeria, are seeking products that not only deliver performance but also align with their operational needs and budget constraints. This comprehensive guide addresses the complexities of navigating the global market for bike tire inflators, providing valuable insights into the various types available, their applications, and the critical factors to consider when vetting suppliers.

As cycling continues to gain popularity, the demand for high-quality tire inflators is on the rise. This guide empowers international B2B buyers by offering a thorough examination of the key features to look for in a bike tire inflator air compressor, including portability, efficiency, and compatibility with different valve types. Additionally, we delve into cost considerations, helping buyers understand pricing structures and the potential return on investment. By equipping businesses with the knowledge they need to make informed purchasing decisions, this guide not only simplifies the sourcing process but also enhances the operational readiness of companies in the competitive cycling market.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Bombas de ar elétricas | Battery-operated, portable, often with digital gauges | Retail bike shops, mobile repair services | Prós: Easy to use, quick inflation, portable. Contras: Limited battery life, may require charging. |

| Manual Hand Pumps | Operated by hand, lightweight, typically more affordable | Bike rental services, budget-conscious shops | Prós: No power needed, durable, cost-effective. Contras: Trabalho intensivo, inflação mais lenta. |

| Compressor Systems | High-capacity, designed for rapid inflation, often tubeless-capable | Professional workshops, racing teams | Prós: Fast inflation, suitable for multiple bikes. Contras: Higher initial investment, requires power source. |

| Infladores de CO2 | Compact, uses CO2 cartridges for rapid inflation | Emergency kits, competitive cycling events | Prós: Lightweight, very fast inflation. Contras: Limited number of uses per cartridge, ongoing costs for cartridges. |

| Hybrid Inflators | Combines electric and manual operation, versatile | Versatile bike shops, repair stations | Prós: Flexible usage, can adapt to various situations. Contras: More complex design may lead to maintenance issues. |

Electric air pumps are battery-operated devices that provide quick and efficient inflation for bike tires. These pumps often feature digital gauges, ensuring precise pressure readings. Ideal for retail bike shops and mobile repair services, they cater to customers who prioritize convenience and speed. When considering these pumps, B2B buyers should assess battery life, charging time, and the overall ease of use, especially in high-demand environments.

Manual hand pumps are simple devices powered by human effort, making them an affordable option for budget-conscious bike rental services and smaller shops. Their lightweight design and durability make them easy to transport and store. However, B2B buyers should be aware that while these pumps are cost-effective, they require more physical effort and time to inflate tires compared to electric options.

Compressor systems are designed for rapid inflation and are often tubeless-capable, making them essential in professional workshops and racing teams. Their high-capacity output allows for quick service across multiple bikes, saving time during busy periods. B2B buyers should consider the initial investment cost and the need for a power source but can benefit from the efficiency and reliability these systems provide.

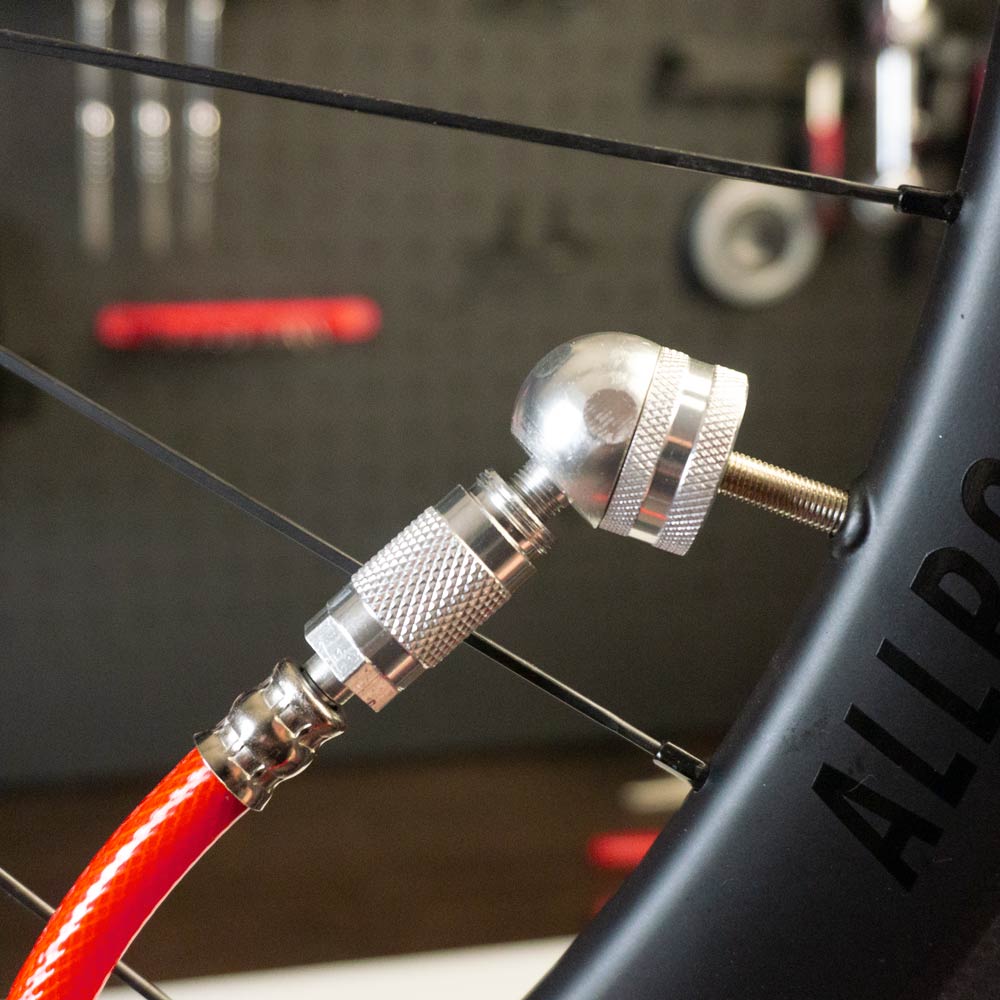

Illustrative image related to bike tire inflator air compressor

CO2 inflators are compact devices that utilize CO2 cartridges for rapid inflation, making them ideal for emergency kits and competitive cycling events. Their lightweight nature ensures that cyclists can easily carry them without adding significant weight. However, B2B buyers must consider the recurring costs of CO2 cartridges and the limited number of inflations each cartridge provides, which may not be suitable for all businesses.

Hybrid inflators combine both electric and manual operation, offering versatility for various inflation needs. They are particularly beneficial in versatile bike shops and repair stations where different tire types and inflation scenarios are common. While these inflators provide flexibility, B2B buyers should evaluate their complexity and potential maintenance needs, ensuring they align with the operational capabilities of their businesses.

| Indústria/Setor | Specific Application of bike tire inflator air compressor | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Bicycle Retailers | In-store tire inflation services for customers | Enhances customer experience and satisfaction | Reliability, ease of use, and compatibility with various valve types |

| Serviços de aluguel de bicicletas | On-site maintenance for rental bicycles | Reduces downtime, ensuring bikes are always ready | Portability, battery life, and speed of inflation |

| Logística e entrega | Tire inflation for delivery bikes and scooters | Optimizes fleet efficiency and reduces maintenance costs | Durability, pressure accuracy, and quick inflation times |

| Cycling Events | Support at cycling races and events | Ensures quick tire service, enhancing participant experience | Compact design, ease of transport, and operational reliability |

| Serviços de emergência | Tire inflation for emergency response vehicles | Ensures operational readiness in critical situations | Robustness, fast inflation capability, and multi-functionality |

Bicycle retailers utilize bike tire inflator air compressors to provide immediate tire inflation services for customers. This application not only enhances the customer experience but also encourages repeat business by ensuring customers leave with well-maintained bikes. Retailers should prioritize compressors that are reliable and compatible with various valve types, as this versatility can accommodate a broader range of bicycles. In regions like Africa and South America, where cycling is a popular mode of transport, having a dependable inflation solution can significantly improve service quality.

In the bike rental industry, maintaining the fleet is crucial to minimizing downtime. Bike tire inflator air compressors are used for on-site maintenance, allowing staff to quickly inflate tires and ensure that bicycles are always ready for customers. This application is particularly valuable in tourist-heavy areas or urban centers where bikes are in constant use. Buyers in this sector should focus on portable compressors with good battery life and quick inflation capabilities to ensure efficiency and convenience in their operations.

Logistics and delivery companies often rely on a fleet of delivery bikes and scooters. Utilizing bike tire inflator air compressors helps optimize fleet efficiency by ensuring that all vehicles maintain proper tire pressure, which in turn enhances fuel efficiency and reduces wear on tires. Businesses should consider sourcing durable compressors that provide accurate pressure readings and quick inflation times to minimize operational delays. In regions such as the Middle East and Europe, where delivery services are expanding rapidly, this investment can lead to significant cost savings.

Illustrative image related to bike tire inflator air compressor

At cycling events, organizers use bike tire inflator air compressors to provide quick tire service to participants, ensuring that they can address any issues promptly. This application enhances the overall experience for cyclists, making events more enjoyable and professionally managed. For sourcing, event organizers should look for compact and easily transportable compressors that can withstand heavy use and provide reliable performance. Events in Europe and South America, where cycling culture is vibrant, can particularly benefit from this service.

Emergency services often require bike tire inflator air compressors for their response vehicles to ensure operational readiness. Quick inflation capabilities are essential in critical situations where time is of the essence. When sourcing these compressors, emergency service providers should prioritize robust designs that offer multi-functionality and fast inflation times. In regions like Nigeria and Saudi Arabia, where emergency response times can be critical, having reliable equipment can make a significant difference in service delivery.

O problema: Many B2B buyers, especially those in emerging markets like Africa and South America, struggle to find reliable suppliers of bike tire inflator air compressors that meet local demands. The challenge lies not only in sourcing quality products but also in ensuring that these inflators are compatible with various bike valve types (Presta and Schrader). Additionally, buyers often face issues with fluctuating prices and inconsistent product availability, making it difficult to maintain inventory and meet customer needs.

A solução: To address these sourcing challenges, B2B buyers should develop relationships with manufacturers and suppliers that specialize in bicycle components. Establishing direct communication can lead to better pricing negotiations, bulk purchasing options, and insights into upcoming product releases. It’s crucial to evaluate suppliers based on their track record in product quality and reliability. Buyers can also consider attending trade shows or industry events where they can meet manufacturers face-to-face, sample products, and establish contracts that ensure product availability over time. Furthermore, utilizing local distributors who understand regional market dynamics can help streamline the supply chain and offer a wider range of compatible inflators for different bike valve types.

Illustrative image related to bike tire inflator air compressor

O problema: B2B buyers often face the problem of inefficient inflation processes that can frustrate end-users, particularly in high-traffic settings like bike rental shops or repair centers. Many inflators are slow or cumbersome to use, leading to longer wait times for customers who need quick service. This inefficiency can result in customer dissatisfaction and loss of business, particularly in competitive markets where service speed is critical.

A solução: To enhance the inflation process, buyers should prioritize investing in high-performance tire inflators that feature quick inflation capabilities and user-friendly designs. Look for models that offer dual compatibility for Presta and Schrader valves and have features like automatic shut-off and digital pressure gauges for precise inflation. Training staff on the proper use of these inflators can also significantly improve efficiency. Providing quick reference guides or videos on how to operate the inflators can empower employees to serve customers faster, thereby reducing wait times and increasing overall satisfaction. Additionally, consider implementing a maintenance schedule for the inflators to ensure they operate at peak efficiency, minimizing downtime and service disruptions.

O problema: Another common issue faced by B2B buyers is the high maintenance and replacement costs associated with low-quality bike tire inflators. Frequent breakdowns and the need for repairs can lead to unexpected expenses and operational delays. Buyers may find themselves continually investing in subpar inflators that do not withstand the rigors of daily use, ultimately affecting profitability.

A solução: To mitigate high maintenance costs, it is essential for buyers to conduct thorough research before purchasing inflators. Prioritize brands that have a strong reputation for durability and reliability. Look for products that come with warranties or service agreements, as these can help cover repair costs over time. It is also beneficial to read reviews and testimonials from other businesses in similar industries to understand the long-term performance of the inflators. When selecting inflators, consider investing in models that have interchangeable parts, allowing for easier repairs rather than complete replacements. Establishing a routine maintenance program can also help identify issues early, reducing the likelihood of costly breakdowns and ensuring that equipment remains in good working order.

When selecting materials for bike tire inflator air compressors, it is crucial to consider their properties, performance, and suitability for various applications. Below is an analysis of four common materials used in the manufacturing of these devices: aluminum, steel, plastic, and rubber.

Illustrative image related to bike tire inflator air compressor

Aluminum is widely used in the construction of bike tire inflators due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C and can handle moderate pressure levels, making it suitable for inflating tires.

Prós: Aluminum is durable and resistant to rust, which is particularly beneficial in humid or coastal environments. Its lightweight characteristic also enhances portability, making it ideal for cyclists who need to carry inflators on their rides.

Contras: While aluminum is relatively strong, it can be prone to denting under impact. Additionally, it is generally more expensive than some alternatives, which may affect cost-sensitive buyers.

Impacto no aplicativo: Aluminum’s compatibility with various media is excellent, ensuring that it can be used with both Presta and Schrader valves without degradation.

Illustrative image related to bike tire inflator air compressor

Considerações para compradores internacionais: Compliance with ASTM standards is essential, particularly in regions like Europe and the Middle East, where quality assurance is critical. Buyers should also consider the impact of local manufacturing costs on the final product price.

Steel, particularly stainless steel, is another common material used in bike tire inflators. It offers high strength and can withstand high pressures, making it suitable for heavy-duty applications.

Prós: Steel’s durability ensures that inflators can handle rigorous use, making them ideal for professional or commercial settings. Its high-temperature resistance also allows for safe operation in various environments.

Contras: The primary drawback of steel is its weight, which can hinder portability. Additionally, if not properly coated, steel can be susceptible to rust, particularly in humid climates.

Impacto no aplicativo: Steel is highly compatible with various gases and air mixtures, ensuring reliable performance in different conditions.

Illustrative image related to bike tire inflator air compressor

Considerações para compradores internacionais: Buyers in regions like Africa and South America should ensure that products meet local standards for safety and performance, as well as consider the availability of maintenance services for steel components.

Plastic is often utilized for components such as housings and fittings in bike tire inflators due to its lightweight and cost-effective nature.

Prós: Plastic is resistant to corrosion and can be molded into complex shapes, allowing for innovative designs. It is also significantly cheaper than metals, making it an attractive option for budget-conscious buyers.

Illustrative image related to bike tire inflator air compressor

Contras: The main limitation of plastic is its lower durability compared to metals, making it less suitable for high-pressure applications. It can also degrade over time when exposed to UV light.

Impacto no aplicativo: Plastic is generally compatible with air, but care must be taken when using it with chemicals or oils, which may cause degradation.

Considerações para compradores internacionais: Buyers should verify that plastics used comply with international safety standards, particularly in Europe, where regulations are stringent.

Illustrative image related to bike tire inflator air compressor

Rubber is primarily used for seals and hoses in bike tire inflators. Its elasticity and ability to create airtight seals make it indispensable.

Prós: Rubber is excellent for vibration dampening and provides a secure seal, preventing air leaks. It is also flexible, allowing for easy connections to various valve types.

Contras: Rubber can degrade over time due to exposure to ozone and UV light, leading to potential failures in seals or hoses.

Illustrative image related to bike tire inflator air compressor

Impacto no aplicativo: Rubber is compatible with air and various gases, ensuring reliable performance in diverse conditions.

Considerações para compradores internacionais: Buyers should seek rubber components that meet international standards for durability and safety, especially in regions with extreme weather conditions.

| Material | Typical Use Case for bike tire inflator air compressor | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Body and housing components | Leve e resistente à corrosão | Prone to denting | Médio |

| Aço | High-pressure components | Alta resistência e durabilidade | Heavier and can rust | Alta |

| Plástico | Housings and fittings | Cost-effective and moldable | Less durable under high pressure | Baixa |

| Borracha | Seals and hoses | Excellent sealing properties | Degrada-se com o tempo | Médio |

This analysis provides a comprehensive overview of the materials used in bike tire inflator air compressors, highlighting their advantages and limitations. Understanding these factors will aid international B2B buyers in making informed purchasing decisions tailored to their specific market requirements.

The manufacturing process of bike tire inflator air compressors involves several critical stages, each requiring precision and adherence to quality standards. Understanding these stages helps B2B buyers assess the quality and reliability of the products they intend to procure.

Illustrative image related to bike tire inflator air compressor

The first stage involves sourcing high-quality materials that meet the specifications necessary for durability and functionality. Common materials include high-grade plastics for the housing, aluminum for structural components, and rubber for seals and hoses. Suppliers often conduct material testing to ensure properties like tensile strength and heat resistance are adequate. B2B buyers should verify that suppliers maintain certifications for raw materials, ensuring compliance with international standards.

Once the materials are prepared, the next step is forming, which typically includes processes such as injection molding for plastic components and die casting for metal parts. Precision in forming is crucial, as it directly affects the performance and longevity of the inflator. Advanced techniques like CNC machining may be employed to achieve high tolerances in metal parts. Buyers should inquire about the technologies used in the forming stage to ensure they align with the required quality benchmarks.

After forming, the components move to the assembly stage, where skilled technicians or automated systems bring the inflator to life. This stage involves integrating various parts, including the motor, pump, and electronic circuitry. A focus on ergonomic design is essential, especially for portable units, to ensure user-friendliness. B2B buyers should assess whether the assembly process includes provisions for easy maintenance and repair, enhancing the product’s lifecycle.

The final manufacturing stage is finishing, which may include surface treatments, painting, or coating to enhance aesthetics and protect against corrosion. Quality finishing not only improves the product’s appearance but also its durability. Buyers should look for suppliers that offer finishing options compliant with environmental regulations, particularly in regions like Europe where strict guidelines apply.

Illustrative image related to bike tire inflator air compressor

Quality assurance (QA) is integral to the manufacturing process, ensuring that every bike tire inflator air compressor meets the required standards before reaching the market. The QA process typically follows international and industry-specific standards.

For manufacturers, adhering to international standards such as ISO 9001 is essential. This standard outlines the requirements for a quality management system, focusing on continuous improvement and customer satisfaction. Additionally, industry-specific certifications, such as CE marking in Europe, indicate compliance with safety and environmental regulations. For B2B buyers, these certifications serve as indicators of a supplier’s commitment to quality.

Quality control (QC) checkpoints are established at various stages of production to ensure the inflators meet predefined specifications. Common QC checkpoints include:

Controle de qualidade de entrada (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet quality standards before they enter the production process.

Controle de qualidade durante o processo (IPQC): Ongoing inspections during the manufacturing stages help identify defects early. Techniques such as visual inspections, dimensional checks, and functional testing are employed.

Controle de qualidade final (FQC): Before shipping, final inspections are conducted to confirm that each product operates as intended and meets safety and performance standards.

Manufacturers typically use a combination of testing methods to ensure product reliability:

Pressure Testing: To verify that the inflators can withstand operational pressures without leaking.

Electrical Testing: Ensuring the electrical components function correctly and meet safety standards.

Performance Testing: Assessing airflow rates and inflation times to meet the promised specifications.

B2B buyers should ask suppliers for detailed testing reports to validate that these methods are employed consistently.

B2B buyers must take proactive steps to ensure they are partnering with reliable suppliers. Here are some effective methods:

Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control systems in place. Audits can reveal the supplier’s commitment to quality and adherence to standards.

Relatórios de qualidade: Requesting detailed quality reports, including test results and compliance certifications, can provide insight into the supplier’s quality assurance practices.

Inspeções de terceiros: Engaging independent third-party inspection agencies to evaluate the supplier’s products can offer an unbiased assessment of quality. These inspections can be particularly valuable in ensuring adherence to international standards.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control. Understanding regional regulations and standards is crucial:

Cultural and Regulatory Differences: Buyers must be aware of local regulations that may affect product compliance. For instance, CE marking is mandatory in Europe but may not be relevant in African markets.

Logistical Considerations: Importing products may involve additional inspections and certifications based on local laws. Buyers should factor these into their procurement processes.

Supplier Relationships: Establishing strong relationships with suppliers can enhance communication about quality expectations and lead times. Regular engagement can also facilitate better problem resolution.

In conclusion, understanding the manufacturing processes and quality assurance mechanisms for bike tire inflator air compressors is vital for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control, buyers can make informed decisions and ensure they procure high-quality products that meet their operational needs.

The following practical sourcing guide provides a step-by-step checklist for B2B buyers looking to procure bike tire inflator air compressors. This guide is designed to help you navigate the procurement process effectively, ensuring you select the right products that meet your business needs and customer expectations.

Illustrative image related to bike tire inflator air compressor

Before initiating the sourcing process, establish clear technical specifications for the bike tire inflators you require. Consider factors such as compatibility with Presta and Schrader valves, maximum pressure capabilities, and power source (electric vs. manual). Defining these specifications upfront helps streamline your search for suppliers who can meet your exact needs.

Stay informed about the latest trends and technological advancements in the bike tire inflator market. Innovations such as digital pressure gauges, rechargeable batteries, and compact designs can enhance user experience and operational efficiency. Understanding market dynamics will help you identify products that stand out and provide competitive advantages.

Thoroughly vet potential suppliers to ensure they can deliver quality products. Request company profiles, product catalogs, and references from other businesses in your industry. Look for suppliers that have a track record of reliability and customer satisfaction, as this will significantly impact your procurement success.

Before making a bulk purchase, request samples of the bike tire inflators you are considering. Testing samples allows you to assess the product’s performance, durability, and ease of use. Pay attention to factors like inflation speed and noise levels, as these can affect customer satisfaction.

Illustrative image related to bike tire inflator air compressor

Analyze pricing structures from different suppliers to ensure you receive competitive offers. Be clear about your budget and negotiate terms that align with your financial strategy. Consider bulk discounts, payment flexibility, and shipping costs, as these can significantly affect the total cost of acquisition.

Evaluate the after-sales support offered by suppliers, including warranty terms and customer service availability. A robust support system can save you time and resources in case of product issues. Ensure that the supplier provides clear guidance on warranty claims and repair services, which is vital for maintaining customer trust.

After gathering all necessary information and assessing your options, make a well-informed purchasing decision. Consider not only the product features and prices but also the supplier’s reliability and support services. This holistic approach will help you build a strong foundation for your procurement strategy and ensure long-term satisfaction with your chosen products.

By following this checklist, you can effectively navigate the complexities of sourcing bike tire inflator air compressors and ensure you meet the demands of your customers while optimizing your procurement process.

When sourcing bike tire inflator air compressors, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materiais: The quality of materials used, such as durable plastics, metals, and electronic components, significantly impacts the overall cost. High-quality materials often lead to better performance and durability, justifying a higher price point.

Trabalho: Labor costs vary by region and can influence the final price. In regions with higher labor costs, such as Europe, expect to see a corresponding increase in product pricing.

Custos indiretos de fabricação: This encompasses costs related to utilities, rent, and administrative expenses associated with production. Efficient manufacturing processes can help mitigate these costs.

Ferramentas: The investment in tooling for production can be substantial, especially for customized or high-spec inflators. Tooling costs are typically amortized over production runs, affecting the pricing structure.

Controle de qualidade (QC): Rigorous QC processes ensure that products meet safety and performance standards. While this adds to the cost, it enhances the product’s reliability, which is particularly important for international markets.

Logística: Shipping and handling costs can vary widely based on the destination, weight, and dimensions of the compressors. International shipping often incurs additional fees, including customs duties.

Margem: Suppliers typically apply a profit margin that reflects their operational costs and market positioning. This can vary based on brand reputation and exclusivity.

Several factors influence the pricing of bike tire inflator air compressors, including:

Volume/MOQ (quantidade mínima de pedido): Purchasing in bulk can significantly reduce the per-unit cost. Suppliers often offer discounts for larger orders, making it essential for buyers to negotiate favorable terms.

Specifications/Customization: Custom features or specifications can increase costs. Buyers should determine if the additional investment aligns with their market needs and customer expectations.

Materiais: The choice of materials directly affects durability and performance. Buyers should weigh the benefits of higher-cost materials against potential long-term savings in maintenance and replacements.

Quality/Certifications: Products that meet specific certifications (e.g., CE, ISO) may command higher prices due to their assurance of quality and safety. Understanding these certifications can help buyers justify costs.

Fatores do fornecedor: The supplier’s reputation, reliability, and location can influence pricing. Established suppliers may charge more due to their proven track record and customer service.

Incoterms: Understanding international shipping terms can help buyers manage logistics costs effectively. Incoterms dictate who bears the cost of shipping, insurance, and tariffs, which can significantly impact the total cost.

To optimize sourcing strategies, buyers should consider the following tips:

Entenda o custo total de propriedade (TCO): Evaluate the long-term costs associated with the product, including maintenance, warranty, and potential replacements. A higher upfront cost may result in lower overall expenses.

Leverage Relationships: Building strong relationships with suppliers can facilitate better pricing and terms. Regular communication and feedback can enhance collaboration.

Negotiate Payment Terms: Flexible payment terms can improve cash flow. Buyers should discuss options such as extended payment periods or installment plans.

Assess Market Trends: Being informed about market trends and pricing fluctuations can empower buyers during negotiations. Monitoring competitor pricing can also provide leverage.

Consider Regional Variances: For international buyers, understanding local market conditions in regions like Africa, South America, the Middle East, and Europe can help tailor negotiations to specific contexts.

The prices referenced in various sources are indicative and subject to change based on market conditions, supplier negotiations, and other factors. Buyers are encouraged to conduct thorough research and engage directly with suppliers to obtain the most accurate and current pricing information.

In the competitive landscape of bicycle maintenance, the bike tire inflator air compressor stands out for its efficiency and convenience. However, various alternatives offer unique benefits that may align better with specific operational needs. This analysis compares bike tire inflator air compressors with other inflation solutions, helping B2B buyers make informed decisions.

| Aspecto de comparação | Bike Tire Inflator Air Compressor | Bomba manual de mão | Inflador de CO2 |

|---|---|---|---|

| Desempenho | Quick inflation, high PSI output | Slower, manual effort required | Very fast, but limited air supply |

| Custo | Medium to high ($49 – $362) | Low ($20 – $50) | Medium ($30 – $80) |

| Facilidade de implementação | Easy to use, plug-and-play | Requires physical effort | Simple, requires CO2 cartridges |

| Manutenção | Moderate, occasional servicing needed | Low, minimal parts | Low, but cartridge replacement required |

| Melhor caso de uso | Regular use for multiple bikes | Occasional use, home mechanics | Emergency or race situations |

Manual hand pumps are a cost-effective alternative to bike tire inflator air compressors, typically priced between $20 and $50. They are straightforward to use and require no electricity or batteries, making them highly portable. However, they demand physical effort and can be time-consuming, especially for larger tires or when inflating multiple bikes. They are best suited for occasional use or by cyclists who prefer a traditional, simple solution for tire inflation.

CO2 inflators offer a rapid inflation solution, making them ideal for emergency situations or racing scenarios where time is crucial. Priced between $30 and $80, they are lightweight and portable, using disposable CO2 cartridges for quick inflation. The downside is that the air supply is limited; once the cartridge is depleted, it must be replaced. CO2 inflators are not suitable for regular tire maintenance since they cannot provide the ongoing air supply that compressors can offer, making them a supplementary tool rather than a primary solution.

Illustrative image related to bike tire inflator air compressor

When choosing between a bike tire inflator air compressor and its alternatives, consider your specific operational requirements. If your business involves frequent bike maintenance or servicing multiple bicycles, investing in an air compressor may provide the best long-term value due to its efficiency and performance. For businesses focusing on occasional maintenance or those operating in remote areas, a manual hand pump may suffice. Conversely, if speed is critical—such as in competitive cycling environments—CO2 inflators can be an invaluable addition to your toolkit.

Ultimately, the right solution hinges on balancing performance, cost, and intended use case, ensuring that your investment aligns with your operational demands.

When evaluating bike tire inflator air compressors, several technical specifications are critical for ensuring optimal performance and reliability. Understanding these properties can significantly influence purchasing decisions for B2B buyers in diverse markets.

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure the compressor can achieve. For bike tire inflators, a PSI range of 30-150 is common, depending on the intended use (e.g., road bikes vs. mountain bikes). A higher PSI rating is essential for efficiently inflating tubeless tires or those requiring higher pressure. For B2B buyers, this specification ensures that the inflator can meet the demands of various bicycle types and customer needs.

The airflow rate, measured in cubic feet per minute (CFM), determines how quickly the inflator can deliver air to the tire. A higher CFM allows for faster inflation, which is crucial in a retail or service environment where time efficiency is essential. For B2B buyers, understanding the airflow rate helps evaluate whether the compressor will meet the operational needs of a bicycle shop or rental service.

The material used in the construction of the inflator affects its durability, weight, and overall performance. Common materials include high-grade plastics and metals like aluminum or steel. For B2B buyers, selecting compressors made from robust materials ensures longevity and reduces the need for frequent replacements, thereby lowering operational costs.

Bike tire inflators can be powered by electricity (AC or DC) or batteries. Electric inflators are typically more powerful and suitable for regular shop use, while battery-operated versions offer portability for on-the-go repairs. Understanding the power source is vital for B2B buyers to align the product with their operational requirements and customer preferences.

Inflators must be compatible with various valve types, primarily Presta and Schrader valves. Many modern inflators come with interchangeable heads to accommodate both. For B2B buyers, ensuring compatibility with popular valve types is crucial to cater to a broad customer base and avoid additional costs associated with purchasing multiple inflators.

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms relevant to bike tire inflator air compressors.

Illustrative image related to bike tire inflator air compressor

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of inflators, OEM parts ensure compatibility and quality assurance. B2B buyers should consider OEM products for reliability and warranty benefits.

MOQ indicates the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is critical for B2B buyers to manage inventory costs and meet demand without overcommitting financially.

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. For B2B buyers, issuing an RFQ is a vital step in ensuring competitive pricing and securing the best supplier terms.

Illustrative image related to bike tire inflator air compressor

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers understand their obligations and rights during international transactions, minimizing disputes.

Lead time refers to the period between placing an order and receiving the goods. Understanding lead time is essential for B2B buyers to manage their supply chain effectively and ensure timely delivery of products to customers.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing bike tire inflator air compressors, ultimately enhancing their business operations and customer satisfaction.

The global bike tire inflator air compressor market is witnessing significant growth, driven by a surge in cycling popularity, particularly in regions like Africa, South America, the Middle East, and Europe. The increasing awareness of health and environmental benefits associated with cycling has led to a rise in demand for efficient and portable inflators. Key trends include the adoption of electric and portable models that cater to the on-the-go lifestyle of modern cyclists. Notably, products featuring advanced technology such as digital gauges, preset pressures, and rapid inflation capabilities are becoming essential in both retail and B2B sectors.

International B2B buyers are increasingly focusing on sourcing products that offer high durability and reliability, as these attributes are crucial for maintaining customer satisfaction in the competitive cycling market. As e-commerce continues to expand, buyers are also leveraging digital platforms to source high-quality inflators from manufacturers globally. Furthermore, the integration of smart technology in inflators, such as Bluetooth connectivity for pressure monitoring, is emerging as a significant selling point, appealing to tech-savvy consumers and businesses alike.

Sustainability is becoming a vital consideration in the sourcing of bike tire inflator air compressors. The environmental impact of manufacturing processes and the materials used is under increasing scrutiny. B2B buyers are now prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable practices. This includes the use of recyclable materials, energy-efficient manufacturing processes, and the implementation of waste reduction strategies.

Additionally, certifications such as ISO 14001 for environmental management and adherence to the Global Reporting Initiative (GRI) guidelines are becoming essential for suppliers seeking to establish credibility in the market. Buyers are encouraged to seek out products that are not only functional but also environmentally friendly, as this aligns with the growing consumer preference for sustainable products. This trend not only enhances brand reputation but also positions companies favorably in a market that increasingly values corporate social responsibility.

The bike tire inflator air compressor sector has evolved significantly over the past few decades. Initially, inflators were primarily manual devices, requiring significant effort and time to operate. The introduction of electric inflators revolutionized the market, offering quicker and more efficient solutions for cyclists. As cycling technology advanced, so did the inflators, with innovations such as portable, battery-operated models and dual-function compressors that cater to both bicycles and vehicles.

Illustrative image related to bike tire inflator air compressor

In recent years, the focus has shifted towards smart technology integration, with features that allow for precise pressure settings and user-friendly interfaces. This evolution reflects broader trends in consumer electronics, where ease of use and efficiency are paramount. The current market is characterized by a diverse range of options that cater to varying consumer needs, emphasizing the importance of adaptability and innovation in product development for B2B suppliers.

Navigating the bike tire inflator air compressor market requires an understanding of key trends and dynamics influencing purchasing decisions. B2B buyers are encouraged to prioritize sustainability and ethical sourcing while remaining attuned to technological advancements that enhance product efficiency and user experience. As the cycling market continues to grow, aligning with these trends will be essential for suppliers aiming to capture and maintain market share.

1. How do I choose the right bike tire inflator air compressor for my business needs?

Selecting the right bike tire inflator involves considering various factors such as the inflator type (electric or manual), compatibility with valve types (Presta and Schrader), and pressure capabilities. Assess your target market’s needs—whether it’s for retail, workshops, or mobile services. Evaluate the inflator’s airflow rate, portability, and ease of use, especially for high-volume operations. Additionally, consider the warranty and customer support offered by suppliers to ensure reliability and service continuity.

2. What is the best air compressor for inflating bike tires?

The best air compressor for bike tires should offer a balance of performance, portability, and versatility. Look for models with a dual function for both bike and vehicle use, as this increases utility. Features like a digital pressure gauge for accuracy, a lightweight design for easy transport, and quick inflation capabilities are crucial. Brands that have a proven track record in the cycling industry, such as VIAIR and Prestacycle, often deliver high-quality products suited for both casual and professional cyclists.

3. What should I consider when vetting suppliers for bike tire inflator air compressors?

When vetting suppliers, assess their industry reputation, product quality, and compliance with international standards. Request samples to evaluate performance and reliability. Check for certifications like ISO or CE, which indicate adherence to quality management systems. Review customer testimonials and case studies to gauge supplier reliability and customer service. Additionally, consider their capacity to meet your volume demands and their willingness to accommodate customization requests.

4. How can I ensure the quality of bike tire inflators during international trade?

To ensure quality, establish clear specifications and standards in your purchase agreements. Request a Certificate of Quality Assurance from the supplier and consider third-party inspections before shipment. Building strong relationships with suppliers can facilitate better communication regarding quality expectations. It’s also beneficial to stay informed about the supplier’s production processes and any quality control measures they implement. Regular audits of suppliers can further ensure compliance with your quality requirements.

5. What are the common payment terms for sourcing bike tire inflators internationally?

Payment terms can vary significantly based on the supplier and your negotiation power. Common methods include letters of credit, wire transfers, and PayPal. Many suppliers may require an upfront deposit (typically 30-50%) with the balance due upon shipment or delivery. Ensure that payment terms are documented in the contract to avoid disputes. Additionally, consider using escrow services for larger transactions to secure your investment until the goods are received and verified.

6. What is the minimum order quantity (MOQ) for bike tire inflator air compressors?

MOQs can vary widely based on the supplier and the specific product. Typically, manufacturers may set MOQs ranging from 50 to 500 units to cover production costs. However, some suppliers may offer flexibility for smaller orders, especially for established relationships. It’s advisable to negotiate MOQs based on your business needs and explore options for samples or trial orders to assess product quality before committing to larger quantities.

7. What logistics considerations should I keep in mind when importing bike tire inflators?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose reliable shipping partners with experience in international freight to minimize delays. Understand the customs regulations of your importing country, including tariffs and taxes, which can affect overall costs. Additionally, plan for potential delays in shipping and customs processing by allowing extra time in your supply chain timelines. Consider insurance for valuable shipments to mitigate risk.

8. Can I customize bike tire inflator air compressors for my brand?

Many suppliers offer customization options, including branding, color schemes, and packaging tailored to your specifications. Customization can enhance brand visibility and appeal to your target market. Discuss your requirements with potential suppliers during the vetting process to understand their capabilities. Be mindful that customization may affect MOQs and lead times, so plan accordingly to ensure timely delivery while meeting your branding needs.

Domínio: cycplus.com

Registrado: 2017 (8 anos)

Introdução: [{‘name’: ‘AS2 Ultra Tiny E-pump for Bike’, ‘price’: ‘$119.00’}, {‘name’: ‘AS2 Pro Tiny E-Pump For Bike’, ‘price’: ‘$109.00’}, {‘name’: ‘AS2 Pro Max Tiny E-Pump For Bike’, ‘price’: ‘$129.00’, ‘discounted_price’: ‘$114.00’}, {‘name’: ‘AS2 Tiny E-Pump For Bike’, ‘price’: ‘$69.00’}, {‘name’: ‘Electric Air Pump A2 Pro’, ‘price’: ‘$49.00’}, {‘name’: ‘Electric Air Pump A8’, ‘price’: ‘$49.00’}, {‘name’: …

Domínio: reddit.com

Registrado: 2005 (20 anos)

Introdução: 1. Park Tool INF-2: Price – $150, features a gauge, recommended for tubeless tire setup.

2. Prestaflator: Suggested as a worthwhile alternative, available at https://prestacycle.com/products/prestaflator-professional-multipurpose-bicycle-inflation-tool.

3. Inexpensive digital inflator: Mentioned as a viable option, available on Amazon, compatible with a JACO Lightning XP chuck.

Domínio: parktool.com

Registrado: 1996 (29 anos)

Introdução: {“item_number”: “INF-2”, “description”: “Used in conjunction with an air compressor and hose, the INF-2 can pump up any bicycle tire in seconds.”, “features”: {“dual_sided_head”: “Compatible with Presta and Schrader valves, rotates 360 degrees.”, “body”: “Lightweight, ergonomically-shaped with an integrated hook for easy hanging.”, “pressure_gauge”: “Built-in, easy-to-read with a protective rubber…

Domínio: trainerroad.com

Registrado: 2010 (15 anos)

Introdução: Wolf 6L Air Compressor Whisper Air Portable 9CFM 1500w 2HP 116psi 8BAR Oil Lubricated 230V – 2 Years Warranty; Harbor Freight compressor; Milwaukee cordless compressor; Bauer model; Airshot.

In navigating the competitive landscape of bike tire inflator air compressors, strategic sourcing emerges as a pivotal factor for international B2B buyers. By leveraging global supplier networks, businesses can secure high-quality products that meet diverse market demands, particularly in regions such as Africa, South America, the Middle East, and Europe. Understanding the varying needs of customers in these markets, from portable solutions for casual cyclists to robust systems for professional use, is crucial for making informed purchasing decisions.

Investing in reliable and innovative inflators, such as those with dual functionality for both bicycles and vehicles, not only enhances customer satisfaction but also fosters brand loyalty. Additionally, the emphasis on features like precision gauges and user-friendly designs can differentiate your offerings in a crowded marketplace.

As we look to the future, the demand for efficient and effective tire inflation solutions will continue to grow. B2B buyers are encouraged to explore partnerships that prioritize quality, sustainability, and innovation. By doing so, you position your business at the forefront of the cycling industry, ready to meet the evolving needs of cyclists worldwide. Engage with suppliers who understand your market and can provide tailored solutions that drive success in your business endeavors.

Illustrative image related to bike tire inflator air compressor

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.