The growing demand for nitrogen inflated tires presents a unique challenge for international B2B buyers seeking to optimize their fleet performance and operational costs. As businesses across Africa, South America, the Middle East, and Europe explore the benefits of nitrogen-filled tires, understanding the nuances of this market becomes essential. This guide delves into the various types of nitrogen inflated tires, their specific applications in diverse sectors such as transportation, aviation, and construction, and the critical factors in supplier vetting.

With insights into cost considerations and the long-term advantages of nitrogen inflation—including reduced pressure loss and enhanced tire longevity—this resource equips decision-makers with the knowledge needed to make informed purchasing choices. By addressing common misconceptions and highlighting the practical benefits of nitrogen over traditional air, we aim to empower B2B buyers to confidently navigate their procurement strategies.

Furthermore, the guide emphasizes the importance of regular tire maintenance and monitoring, ensuring that businesses not only invest wisely but also sustain optimal tire performance. As the global market for nitrogen inflated tires continues to evolve, this comprehensive resource will serve as a vital tool for buyers looking to enhance safety, efficiency, and cost-effectiveness in their operations.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Standard Nitrogen Tires | Filled with high-purity nitrogen; reduces pressure loss | Passenger vehicles, light trucks | Prós: Better pressure retention; Contras: Minimal difference in everyday use compared to air. |

| High-Performance Nitrogen Tires | Designed for racing and high-speed applications; optimized for temperature stability | Motorsports, performance vehicles | Prós: Enhanced handling; Contras: Higher cost; not necessary for everyday use. |

| Aviation Nitrogen Tires | Specialized for aircraft; extreme pressure stability | Aviation industry | Prós: Essential for safety; Contras: Very niche market; specific regulations apply. |

| Industrial Nitrogen Tires | Built for heavy machinery; robust design for harsh conditions | Construction, mining, agriculture | Prós: Increased durability; Contras: Heavier; may require specialized inflation equipment. |

| Recreational Nitrogen Tires | Used in recreational vehicles; maintains pressure in varying conditions | RVs, trailers, off-road vehicles | Prós: Improved safety and performance; Contras: Higher initial investment. |

Standard nitrogen tires are filled with high-purity nitrogen, which significantly reduces pressure loss compared to conventional air-filled tires. They are primarily used in passenger vehicles and light trucks. For B2B buyers, the key consideration is the balance between cost and performance. While they offer better pressure retention, the benefits may not justify the price for businesses with standard operational needs. Regular pressure checks remain essential regardless of the inflation method.

Illustrative image related to nitrogen inflated tires

High-performance nitrogen tires are specifically designed for racing and high-speed applications, ensuring optimal temperature stability and handling. They are crucial for motorsports and performance vehicles, where precision and responsiveness are vital. B2B buyers in this sector should consider the advantages of enhanced handling and stability against the higher costs. These tires are not typically necessary for everyday driving, making them more suitable for specialized applications.

Aviation nitrogen tires are engineered to withstand extreme conditions and maintain pressure stability, which is critical for aircraft safety. They are used exclusively in the aviation industry, adhering to strict regulations and standards. B2B buyers in aviation must prioritize safety and compliance over cost, as the implications of tire failure can be catastrophic. The specialized nature of these tires means they are not suitable for other applications.

Industrial nitrogen tires are designed for heavy machinery operating in harsh environments, such as construction and mining. Their robust construction provides increased durability and resistance to punctures. For B2B buyers in these sectors, the long-term savings from reduced downtime and maintenance costs are significant. However, the heavier weight and potential need for specialized inflation equipment should be considered.

Illustrative image related to nitrogen inflated tires

Recreational nitrogen tires are utilized in RVs, trailers, and off-road vehicles, providing improved pressure retention in varying conditions. They are particularly advantageous for businesses that rely on recreational vehicle rentals or off-road excursions. B2B buyers should weigh the initial investment against the benefits of enhanced safety and performance. These tires are suitable for companies that prioritize reliability and performance in their fleet.

| Indústria/Setor | Specific Application of nitrogen inflated tires | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Aviation | Use in aircraft tires | Enhanced safety and performance at high altitudes | Compliance with aviation standards and certifications |

| Mining | Tires for heavy machinery | Improved durability and reduced maintenance costs | Sourcing from specialized suppliers for rugged conditions |

| Construção | Tires for construction vehicles | Better pressure retention and safety in harsh environments | Need for tires that withstand extreme loads and terrain |

| Motorsports | Tires for race cars | Consistent performance and handling at high speeds | Suppliers must provide high-purity nitrogen filling systems |

| Agricultura | Tires for agricultural machinery | Increased efficiency and reduced soil compaction | Consideration for tire types suitable for diverse terrains |

In the aviation industry, nitrogen inflated tires are essential for aircraft, where safety and performance are paramount. The inert properties of nitrogen prevent moisture and oxidation, which can degrade tire integrity at high altitudes. This leads to enhanced safety during takeoff and landing. International buyers in this sector should ensure that suppliers meet stringent aviation standards and provide certified nitrogen filling systems to guarantee tire reliability.

In mining, heavy machinery operates under extreme conditions, making tire durability critical. Nitrogen inflated tires help maintain consistent pressure, reducing the risk of blowouts and improving the lifespan of tires in rugged terrains. This translates to lower maintenance costs and less downtime for mining operations. Buyers must source tires specifically designed for heavy-duty applications and ensure that they can access reliable nitrogen inflation services on-site.

Illustrative image related to nitrogen inflated tires

Construction vehicles often face harsh environments that can lead to rapid tire degradation. Nitrogen inflated tires provide better pressure retention, reducing the frequency of inflating and enhancing safety. The stable pressure helps prevent tire blowouts, which can be costly in terms of both safety and project delays. Buyers in the construction sector should prioritize tires that are engineered for heavy loads and consider suppliers that offer comprehensive tire maintenance services.

In motorsports, the performance of race cars is critically dependent on tire pressure. Nitrogen inflated tires minimize pressure fluctuations, allowing for optimal handling and traction at high speeds. This is particularly important in competitive racing environments where precision is key. Buyers in this field should seek suppliers that specialize in high-performance tires and have the capability to provide high-purity nitrogen filling systems to ensure competitive advantages.

Agricultural machinery benefits from nitrogen inflated tires, which help reduce soil compaction and improve fuel efficiency. Maintaining optimal tire pressure is crucial for maximizing the performance of equipment on varied terrains. Buyers in the agriculture sector must consider the types of tires that are suitable for their specific farming practices and ensure that they have access to nitrogen inflation services that can accommodate the scale of their operations.

O problema: Many B2B buyers, especially those managing fleets in regions like Africa and South America, face significant cost considerations when evaluating the switch from air to nitrogen for tire inflation. The initial investment for nitrogen filling equipment and ongoing maintenance can be daunting. Additionally, they may worry about whether the purported benefits justify the costs, particularly if their operational environment does not demand high-performance tires.

A solução: To mitigate these cost concerns, buyers should conduct a comprehensive cost-benefit analysis that includes the long-term advantages of nitrogen inflation, such as reduced pressure loss and extended tire life. Investing in a nitrogen generation system can be more economical over time, especially for businesses with large fleets. By estimating the total cost of ownership, including potential savings on fuel due to improved tire pressure maintenance and longer tire lifespan, businesses can present a compelling case to stakeholders. Moreover, seeking partnerships with suppliers who offer competitive pricing or financing options can further alleviate upfront costs, making the transition smoother.

O problema: B2B buyers often encounter issues with maintaining optimal nitrogen tire pressure, especially in regions with extreme temperature fluctuations, such as the Middle East and Europe. Tires filled with nitrogen still require regular pressure checks, and if the nitrogen levels drop due to leakage or improper refilling, it can lead to underinflation, impacting vehicle safety and performance.

A solução: To address this challenge, businesses should implement a robust tire maintenance program that includes regular monitoring and a Tire Pressure Monitoring System (TPMS). This system will provide real-time data on tire pressure, allowing for timely interventions. Additionally, training personnel on the importance of maintaining nitrogen levels and how to properly refill tires with nitrogen can reduce the risk of errors. Establishing a routine schedule for pressure checks, especially before long hauls or seasonal changes, will help ensure that nitrogen-filled tires remain at optimal pressure, thus enhancing safety and performance.

O problema: Many B2B buyers are misinformed about the advantages of nitrogen inflation, leading to skepticism regarding its benefits. This misunderstanding can stem from marketing claims that may exaggerate the advantages, causing potential buyers to hesitate in adopting nitrogen inflation, fearing they might be making a poor investment.

Illustrative image related to nitrogen inflated tires

A solução: To overcome this knowledge gap, businesses should invest in education and training for decision-makers and fleet managers. Hosting informational workshops or webinars that present data from reputable studies can clarify the actual benefits of nitrogen inflation, such as improved pressure retention and reduced oxidation of tire materials. Collaborating with trusted tire manufacturers or industry experts to create informative content can further reinforce the credibility of nitrogen inflation. Additionally, providing case studies from similar businesses that have successfully transitioned to nitrogen can serve as persuasive evidence of its advantages, helping to build confidence in this tire management strategy.

When considering the strategic material selection for nitrogen inflated tires, several materials play a crucial role in ensuring optimal performance and durability. This analysis focuses on four common materials: rubber compounds, tire beads, valve stems, and inner linings. Each of these materials contributes to the overall functionality and longevity of nitrogen inflated tires, particularly in diverse international markets.

Rubber compounds are fundamental to tire construction, influencing flexibility, grip, and wear resistance. The key properties of rubber compounds include temperature resistance, which typically ranges from -40°C to 80°C, and pressure ratings that can withstand significant loads.

Illustrative image related to nitrogen inflated tires

Prós: Rubber compounds are highly durable and provide excellent traction, making them suitable for various driving conditions. They can be engineered for specific performance characteristics, such as low rolling resistance for fuel efficiency.

Contras: The complexity of manufacturing rubber compounds can lead to higher costs, especially for specialized formulations. Additionally, rubber is susceptible to degradation from UV exposure and ozone, which may affect longevity.

Impacto no aplicativo: The choice of rubber compound can significantly influence the tire’s performance in different climates, which is particularly relevant for international buyers in regions like Africa and the Middle East, where temperature fluctuations are common.

Tire beads, typically made from steel or other robust materials, help maintain tire shape and provide a secure seal against the rim. Their key properties include high tensile strength and corrosion resistance, essential for maintaining tire integrity under pressure.

Prós: Steel tire beads offer excellent durability and are effective in preventing air loss, which is crucial for nitrogen inflation. They also provide stability, enhancing vehicle handling.

Illustrative image related to nitrogen inflated tires

Contras: The manufacturing complexity of steel beads can lead to increased costs. Additionally, if not properly coated, they may be prone to rust, particularly in humid environments.

Impacto no aplicativo: In regions with high humidity, such as parts of South America, corrosion-resistant coatings are essential for maintaining tire performance. Buyers should ensure that the beads comply with local standards for corrosion resistance.

Valve stems, often made from rubber or metal, are critical for controlling the inflation and deflation of tires. Their key properties include pressure tolerance and resistance to environmental factors.

Prós: Metal valve stems are more durable and less prone to damage than rubber ones, making them suitable for high-performance applications. They also provide a better seal for nitrogen inflation.

Contras: Metal valve stems can be more expensive than rubber options, and their installation may require specialized equipment.

Impacto no aplicativo: In regions like Europe, where compliance with safety standards is stringent, selecting valve stems that meet specific regulations (e.g., DIN standards) is essential for market acceptance.

Inner linings are typically made from synthetic rubber compounds designed to minimize gas permeation. Their key properties include low permeability to gases and resistance to heat.

Illustrative image related to nitrogen inflated tires

Prós: Enhanced inner linings help maintain nitrogen levels longer than standard air-filled tires, improving efficiency and performance. They also reduce the risk of oxidation, which can degrade tire materials over time.

Contras: The cost of high-quality inner linings can be significant, and their production may involve complex processes that increase manufacturing time.

Impacto no aplicativo: For international buyers, particularly in regions with extreme temperatures, selecting tires with effective inner linings can ensure better performance and safety.

| Material | Typical Use Case for nitrogen inflated tires | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Rubber Compounds | Tire tread and sidewalls | Excellent traction and durability | Susceptível à degradação por UV | Médio |

| Tire Beads | Structural integrity and sealing | High tensile strength, prevents air loss | Manufacturing complexity and cost | Alta |

| Valve Stems | Inflation control | Better sealing for nitrogen | Higher cost and installation complexity | Médio |

| Inner Linings | Gas retention | Reduces gas permeation and oxidation | Higher production costs | Alta |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their operational needs and regional compliance standards.

Illustrative image related to nitrogen inflated tires

The manufacturing process of nitrogen inflated tires closely resembles that of conventional tires, with an emphasis on specialized techniques to ensure optimal performance. The process can be broken down into several key stages: material preparation, forming, assembly, and finishing.

The first stage in tire manufacturing involves the selection and preparation of raw materials. High-quality rubber compounds, fabric, and steel belts are crucial for creating tires that can withstand the pressures of nitrogen inflation. Manufacturers typically source materials based on stringent specifications to ensure durability and performance.

During this stage, the rubber is mixed with various additives, including sulfur for vulcanization, carbon black for strength, and other chemicals to enhance performance characteristics. The mixing process must be precise, as the formulation directly impacts the tire’s longevity and performance, particularly under the unique conditions associated with nitrogen inflation.

Once the materials are prepared, the next step is forming. This stage involves shaping the rubber compounds into the various components of the tire, including the tread, sidewall, and inner liner. Advanced machinery is employed to ensure uniform thickness and precise dimensions.

Illustrative image related to nitrogen inflated tires

Key techniques during this phase include extrusion, where the rubber is forced through a die to create the desired shape, and calendering, which produces sheets of rubber that can be layered. The inner liner, which is critical for maintaining the tire’s airtight properties when filled with nitrogen, is typically made from a specially formulated rubber compound that reduces gas permeation.

After forming, the components move to the assembly stage. Here, the tire’s various parts are meticulously assembled. The inner liner is placed inside the tire, followed by the steel belts and tread. This process often involves the use of automated systems to enhance precision and efficiency.

Quality control is paramount during assembly. Each tire must be thoroughly inspected for alignment and adhesion. Any defects at this stage can lead to performance issues later on, particularly for tires designed to operate under the unique conditions of nitrogen inflation.

The finishing stage involves curing or vulcanizing the assembled tires. This process uses heat and pressure to bond the materials together, forming a solid and durable product. Curing time and temperature are critical, as they determine the tire’s final properties, including elasticity, strength, and resistance to wear.

Post-curing, tires undergo additional inspections and tests to ensure they meet industry standards. This includes checking for uniformity, balance, and overall structural integrity. The finished tires are then labeled, packed, and prepared for distribution.

Illustrative image related to nitrogen inflated tires

Quality assurance is a cornerstone of tire manufacturing, especially when producing nitrogen inflated tires, which require specific performance characteristics. Compliance with international standards such as ISO 9001 is essential, as it outlines requirements for a quality management system.

Additionally, industry-specific certifications, such as CE marking in Europe and API standards in certain contexts, ensure that the tires meet safety and performance criteria. B2B buyers should be aware that adherence to these standards not only guarantees product quality but also enhances the reputation of manufacturers in the global marketplace.

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

Controle de qualidade de entrada (IQC): This involves inspecting raw materials before they enter the production line. Suppliers must provide certifications for materials, and samples may be tested to ensure compliance with specifications.

Controle de qualidade durante o processo (IPQC): Throughout the manufacturing stages, continuous monitoring occurs. This includes checks during the mixing, forming, and assembly processes to identify any deviations from established standards.

Controle de qualidade final (FQC): After curing, each tire undergoes a comprehensive inspection. This may involve tests for pressure retention, tread wear, and overall structural integrity. Tires that pass this stage are deemed ready for distribution.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are several actionable steps:

Conduct Supplier Audits: Regular audits of suppliers can help assess compliance with international standards and internal quality control measures. Audits should review documentation, processes, and facilities.

Request Quality Reports: Suppliers should provide detailed reports on their quality control processes, including results from IQC, IPQC, and FQC stages. These reports can reveal insights into the supplier’s commitment to quality.

Utilize Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. This is especially valuable when entering new markets or working with unfamiliar suppliers.

Understand Regional Compliance Nuances: B2B buyers should be aware of specific compliance requirements in their regions. For instance, CE marking is essential in Europe, while other regions may have different standards. Familiarity with these regulations can prevent costly compliance issues.

Assess Traceability and Transparency: Suppliers should maintain traceability of materials and processes. This transparency is vital for understanding the quality of the final product and addressing any potential issues that arise post-purchase.

The manufacturing and quality assurance processes for nitrogen inflated tires are complex and require adherence to rigorous standards. B2B buyers must prioritize suppliers who demonstrate a commitment to quality through established processes, certifications, and transparency. By understanding these manufacturing dynamics and implementing effective verification strategies, buyers can ensure they procure high-quality products that meet their operational needs.

This guide serves as a practical checklist for B2B buyers interested in procuring nitrogen inflated tires. The decision to source these specialized tires requires careful consideration of various factors, including supplier reliability, technical specifications, and market trends. Following this checklist will help ensure that you make informed purchasing decisions that align with your operational needs.

Clearly outline the specifications you require for nitrogen inflated tires, including size, load capacity, and intended use (e.g., passenger vehicles, commercial trucks, or specialized applications). Understanding your technical requirements is crucial as it directly impacts performance and safety. Ensure that the specifications align with your fleet or vehicle needs to avoid compatibility issues.

Before making a procurement decision, familiarize yourself with the advantages and limitations of nitrogen inflated tires. While they can reduce pressure loss and improve tire longevity, they may not provide significant benefits over traditional air-filled tires for everyday use. Understanding these factors will help you assess whether the investment aligns with your operational goals.

Conduct thorough evaluations of potential suppliers. Request company profiles, certifications, and references from clients in similar industries or regions. Look for suppliers who specialize in nitrogen tire technology and have a solid reputation for quality and service. A supplier’s track record can offer valuable insights into their reliability and product performance.

Ensure that your chosen suppliers possess the necessary certifications and comply with international standards relevant to tire manufacturing. Certifications such as ISO 9001 for quality management and specific automotive standards demonstrate a commitment to quality and safety. This verification process mitigates risks associated with subpar products and enhances your procurement strategy.

Request detailed quotes from multiple suppliers to compare pricing structures. Be cautious of pricing that seems unusually low, as it may indicate inferior quality or hidden costs. Consider the total cost of ownership, including potential savings from improved fuel efficiency and reduced tire maintenance over time, when evaluating pricing.

Evaluate the support services offered by suppliers, such as installation, maintenance, and tire pressure monitoring systems (TPMS). Reliable after-sales support is essential for maximizing the performance and longevity of nitrogen inflated tires. A supplier that provides comprehensive support can significantly enhance your operational efficiency and safety.

Finally, establish a plan for ongoing tire maintenance and pressure monitoring. Regularly check tire pressure and ensure that any top-offs are performed with nitrogen to maintain the benefits of nitrogen inflation. This proactive approach will help prevent issues related to under-inflation and prolong the lifespan of your tires, ultimately contributing to your overall operational efficiency.

When evaluating the cost structure for sourcing nitrogen inflated tires, several key components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

Materials: The primary materials include the rubber compounds used for the tire body, the nitrogen gas for inflation, and any additional components such as steel belts and sidewall additives. The quality and sourcing of these materials can significantly impact costs, especially if specialized compounds are required for high-performance applications.

Labor: Labor costs encompass the workforce involved in manufacturing, assembling, and quality checking the tires. Skilled labor may be necessary for specialized production processes, which can elevate costs.

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, maintenance, and administrative expenses. Efficient operations can help mitigate these costs.

Tooling: The initial investment in molds and machinery for tire production can be substantial. These costs are typically spread over the production volume, making them a critical factor in pricing.

Quality Control (QC): Ensuring that tires meet safety and performance standards requires a robust QC process. This can involve testing materials, inspecting finished products, and adhering to international certification standards, which can add to the overall cost.

Logistics: Transportation and warehousing costs are vital in the global supply chain. Factors such as distance, shipping methods, and import/export duties must be considered, especially for international buyers.

Margin: Finally, manufacturers will add a margin to cover their operational risks and provide profitability. This margin can vary widely based on market conditions and competitive dynamics.

Several price influencers can affect the sourcing of nitrogen inflated tires. Understanding these factors is crucial for B2B buyers looking to negotiate favorable terms.

Volume/MOQ: Manufacturers often offer better pricing for bulk purchases. Buyers should consider their inventory needs and negotiate minimum order quantities (MOQs) that align with their operational requirements.

Specifications and Customization: Customizing tires for specific applications can lead to higher costs. Buyers should weigh the benefits of customization against the potential for increased expenses.

Materials and Quality Certifications: Premium materials and certifications (like ISO standards) can drive up costs. However, investing in higher-quality tires may reduce the total cost of ownership (TCO) through improved durability and lower maintenance needs.

Supplier Factors: Reliability, reputation, and service levels of suppliers can influence pricing. Buyers should conduct thorough supplier assessments to ensure they receive quality products at competitive prices.

Incoterms: The choice of Incoterms (International Commercial Terms) will dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This can have significant implications for overall costs, particularly for international transactions.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective strategies can enhance sourcing efficiency.

Negotiate Terms: Leverage volume commitments to negotiate better pricing and payment terms. Engaging in discussions about long-term partnerships can also yield favorable conditions.

Focus on Cost-Efficiency: Consider the total cost of ownership, not just the upfront price. Factors such as tire longevity, fuel efficiency, and maintenance costs should inform purchasing decisions.

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local market conditions that could impact pricing. Staying informed will help in making strategic purchasing decisions.

Regularly Review Suppliers: Establish a system for evaluating supplier performance and pricing competitiveness. This will ensure that you are consistently sourcing the best value for your needs.

Stay Informed on Market Trends: Being aware of industry trends, technological advancements, and competitor activities can provide insights into pricing strategies and help you anticipate future cost changes.

By carefully considering these cost components, price influencers, and buyer tips, B2B buyers can navigate the complexities of sourcing nitrogen inflated tires effectively and strategically.

Illustrative image related to nitrogen inflated tires

As the market for tire inflation options evolves, B2B buyers must evaluate various solutions to determine the best fit for their needs. While nitrogen inflated tires offer unique benefits, it is essential to compare them against other viable alternatives such as standard air inflation and tire sealant technologies. This comparison will help organizations make informed decisions regarding tire management and maintenance.

| Aspecto de comparação | Nitrogen Inflated Tires | Standard Air Inflation | Tire Sealant Technologies |

|---|---|---|---|

| Desempenho | Reduces pressure loss; consistent pressure over time; less oxidation | Acceptable performance; more pressure loss over time | Provides immediate puncture repair; maintains pressure |

| Custo | Higher initial cost (approx. $5+ per tire) | Low to no cost (air is generally free) | Moderate cost (varies by product) |

| Facilidade de implementação | Requires specialized equipment for inflation | Readily available; no special equipment needed | Simple application; often DIY |

| Manutenção | Requires periodic checks; may lead to complacency in monitoring | Frequent checks needed due to higher pressure loss | Minimal maintenance; effective until sealant is exhausted |

| Melhor caso de uso | Ideal for specialized applications (racing, aviation, heavy machinery) | Suitable for everyday passenger vehicles | Best for emergency repairs and commercial vehicles prone to punctures |

Standard air inflation remains the most widely used method for tire inflation due to its accessibility and cost-effectiveness. Air is available at most service stations without charge, making it an attractive option for regular consumers and businesses alike. However, air contains moisture and oxygen, which can lead to oxidation and a higher rate of pressure loss. While adequate for most passenger vehicles, it requires more frequent checks and adjustments to maintain optimal tire pressure.

Tire sealant technologies offer a unique solution for maintaining tire pressure and repairing punctures. These products contain a liquid sealant that coats the inside of the tire and seals small punctures as they occur. The main advantage is the ability to provide immediate repair, reducing downtime and improving vehicle safety. However, the effectiveness of sealants can diminish over time, and they may not work for larger punctures or damage. Additionally, some sealants can complicate future tire repairs or replacements, as they may need to be cleaned out before installation.

When selecting the appropriate tire inflation method, B2B buyers should consider their specific operational needs, cost constraints, and performance requirements. For specialized applications requiring maximum performance and minimal pressure fluctuations, nitrogen inflated tires may be worth the investment. Conversely, standard air inflation offers a practical solution for everyday use, while tire sealant technologies provide an effective means of managing unexpected punctures. By assessing these factors, organizations can choose the tire inflation solution that best aligns with their operational goals and budget.

Understanding the technical specifications of nitrogen inflated tires is crucial for B2B buyers. These properties help in making informed purchasing decisions, especially for businesses operating in sectors like transportation, logistics, and automotive services.

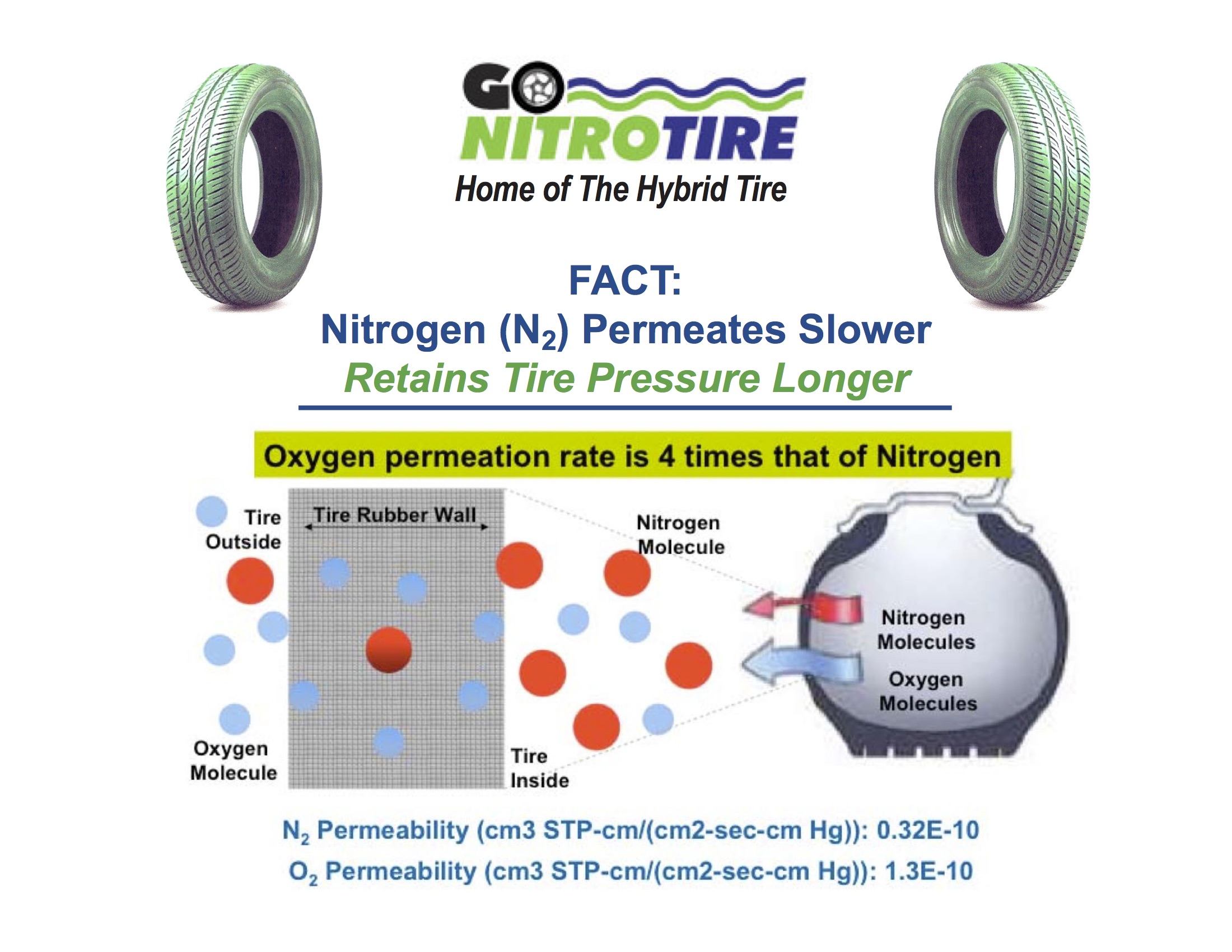

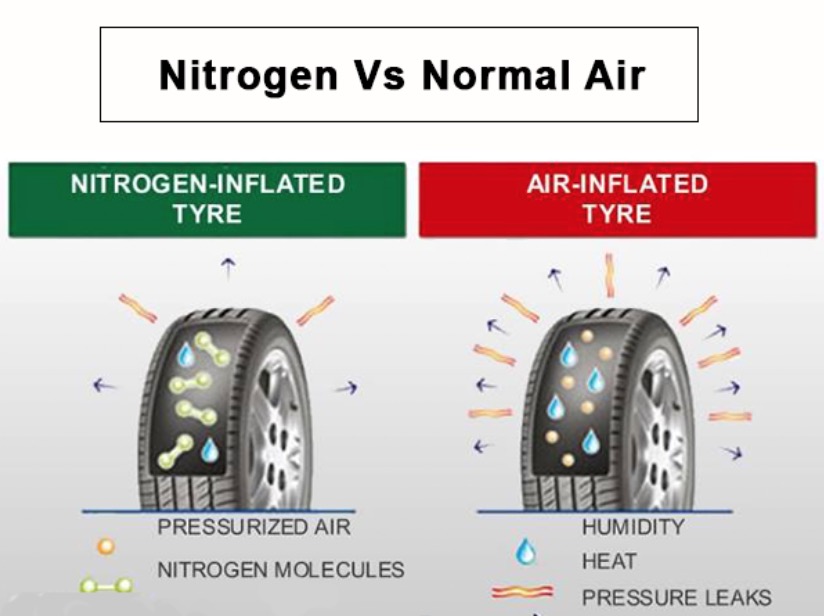

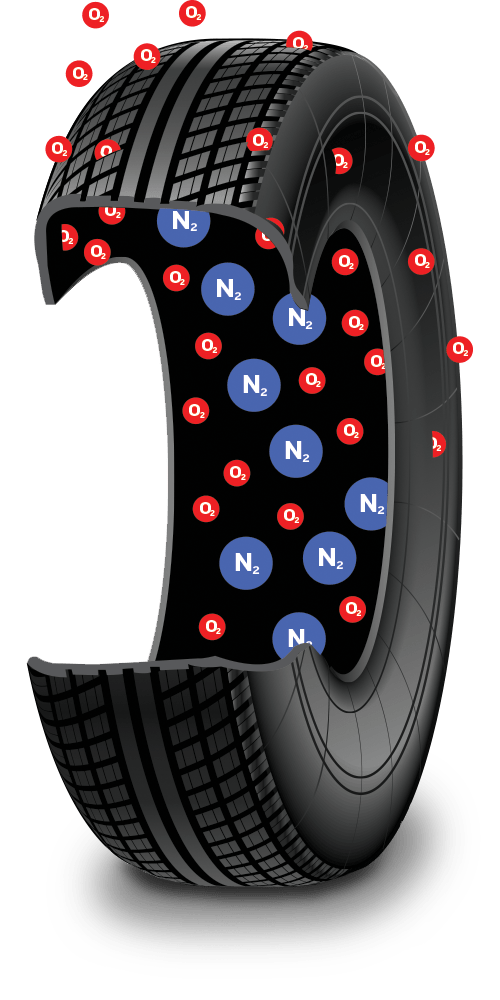

Nitrogen inflated tires primarily consist of dry nitrogen gas, which is devoid of moisture and contaminants found in atmospheric air. This unique composition helps minimize oxidation and reduces pressure loss over time, making it particularly advantageous in industries requiring consistent tire performance, such as aviation and motorsports.

One of the most significant benefits of nitrogen is its superior pressure retention capabilities. Tires inflated with nitrogen typically experience less pressure loss compared to those filled with regular air. Studies indicate that nitrogen-filled tires can lose approximately 1.3 psi less over a year than air-filled tires. For B2B applications, this translates to lower maintenance costs and improved vehicle safety due to more consistent tire pressure.

Nitrogen has a more stable thermal expansion rate compared to air, which means that tire pressure is less affected by temperature fluctuations. This characteristic is particularly important for businesses operating in extreme climates or those that require precise tire performance, such as in mining or construction.

The absence of oxygen in nitrogen-filled tires reduces the risk of rubber degradation due to oxidation. While this may not be a pressing concern for all consumers, for commercial fleets that utilize tires over extended periods, this property can enhance tire longevity and overall performance.

Dry nitrogen prevents moisture-related issues, such as corrosion of the tire’s internal components. This is particularly crucial for businesses that operate in humid environments or utilize specialized tires in high-stress applications, such as race cars or heavy machinery.

Familiarity with industry terminology is vital for effective communication in the B2B landscape, especially for international transactions involving nitrogen inflated tires.

This term refers to companies that produce components or products that are used in another company’s end product. In the tire industry, OEMs often specify nitrogen-filled tires for their vehicles to ensure optimal performance and safety standards.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory effectively and negotiate favorable terms with suppliers of nitrogen inflated tires.

An RFQ is a document sent to suppliers to solicit price quotes for specific products. B2B buyers should utilize RFQs when sourcing nitrogen inflated tires to ensure competitive pricing and comprehensive understanding of product specifications.

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Knowing these terms is crucial for B2B buyers when negotiating shipping and delivery terms for nitrogen inflated tires.

TPMS refers to a technology that monitors the air pressure inside tires. This system is vital for maintaining optimal tire performance and safety. B2B buyers should consider integrating TPMS in vehicles utilizing nitrogen inflated tires to enhance safety and operational efficiency.

Understanding these technical properties and trade terminologies will empower B2B buyers to make informed decisions regarding nitrogen inflated tires, ultimately leading to improved operational efficiency and safety in their respective industries.

The nitrogen inflated tires market is experiencing robust growth, driven by several global factors. The increasing emphasis on vehicle safety and performance, particularly in regions with extreme temperatures, is pushing B2B buyers to consider nitrogen as a viable alternative to conventional air. Additionally, the automotive industry’s focus on improving fuel efficiency has led to a greater awareness of tire performance, where nitrogen’s lower pressure loss over time can be advantageous.

Emerging technologies, such as advanced tire pressure monitoring systems (TPMS), are further enhancing the appeal of nitrogen-filled tires. These technologies allow fleet operators and individual consumers to maintain optimal tire pressure easily, which is crucial for maximizing safety and efficiency. Furthermore, the rising demand for high-performance tires in motorsports and specialized applications, such as aviation and construction, underscores the need for nitrogen in tires, reinforcing its market position.

For B2B buyers from Africa, South America, the Middle East, and Europe, understanding these dynamics is essential. Countries like Brazil and Saudi Arabia are witnessing infrastructure developments that demand reliable tire solutions. Consequently, international buyers should consider partnerships with suppliers who can provide not just nitrogen inflation but also integrated tire maintenance solutions that align with evolving market expectations.

Sustainability is becoming a critical consideration for B2B buyers in the nitrogen inflated tires market. As environmental regulations tighten globally, companies are increasingly focused on reducing their carbon footprints and promoting ethical sourcing practices. The production of nitrogen itself, when sourced from renewable energy, can significantly lower environmental impact compared to traditional air filling processes, which often involve energy-intensive methods.

Moreover, the demand for ‘green’ certifications is on the rise. B2B buyers should prioritize suppliers who adhere to sustainable practices and can provide transparency in their supply chains. Certifications such as ISO 14001 for environmental management systems can indicate a commitment to sustainability, which is becoming a differentiator in the marketplace.

Ethical sourcing also extends to the materials used in tire manufacturing. Buyers are encouraged to seek out suppliers who utilize recycled materials and eco-friendly compounds, thereby contributing to a circular economy. This focus on sustainability not only aligns with corporate social responsibility goals but can also enhance brand reputation and customer loyalty.

Illustrative image related to nitrogen inflated tires

The use of nitrogen in tires dates back to the early 20th century, primarily in aviation and racing sectors where performance and safety are paramount. However, it wasn’t until the late 1990s and early 2000s that nitrogen inflation gained traction in consumer and commercial markets. This shift was fueled by advancements in tire technology and a growing understanding of the benefits nitrogen provides, such as reduced pressure loss and improved tire longevity.

As the market evolved, suppliers began to target fleet operators and high-performance vehicle markets, emphasizing the operational cost savings associated with nitrogen-filled tires. This historical context is crucial for B2B buyers, as it highlights the longstanding reliability of nitrogen in demanding applications and its growing acceptance in broader automotive contexts. Understanding this evolution can help buyers make informed decisions regarding tire sourcing, maintenance, and overall fleet management strategies.

By recognizing these trends and historical insights, international B2B buyers can navigate the complexities of the nitrogen inflated tires market more effectively, positioning themselves for success in a rapidly evolving landscape.

How do I determine if nitrogen inflated tires are suitable for my fleet?

To assess whether nitrogen inflated tires are right for your fleet, consider the operational environment and specific usage patterns. Nitrogen-filled tires can maintain pressure better in extreme temperatures and demanding conditions, such as construction or mining. If your vehicles frequently operate in such environments, the reduced pressure loss may enhance tire longevity and performance. However, for standard passenger vehicles, the benefits may not justify the additional cost. Evaluate your unique needs and consider consulting with tire experts to make an informed decision.

What is the best way to find reliable suppliers of nitrogen inflated tires?

Finding reputable suppliers involves thorough market research and vetting processes. Start by exploring industry directories, attending trade shows, and leveraging professional networks. Check suppliers’ certifications, customer reviews, and their experience in the market. Request product samples and assess their quality. Additionally, consider suppliers who can provide technical support and after-sales service. Establishing relationships with local distributors in your region can also enhance communication and logistics efficiency.

What customization options are available for nitrogen inflated tires?

Many manufacturers offer customization options for nitrogen inflated tires, including varying tread patterns, sizes, and rubber compounds tailored to specific applications. Discuss your fleet’s unique requirements with potential suppliers to explore available options. Custom branding, such as logos or colors, may also be available for promotional purposes. Ensure that any customization does not compromise the tire’s performance characteristics, and request samples to evaluate quality before making a bulk order.

What are the minimum order quantities (MOQs) for nitrogen inflated tires?

Minimum order quantities for nitrogen inflated tires can vary significantly based on the supplier and tire type. Typically, MOQs range from a few dozen to several hundred tires. It’s advisable to inquire directly with potential suppliers about their MOQs, as some may offer flexibility for first-time buyers or larger orders. Additionally, consider negotiating terms that align with your purchasing strategy, especially if you plan to establish a long-term relationship.

What payment terms should I expect when sourcing nitrogen inflated tires?

Payment terms vary by supplier and may include options such as upfront payments, net 30/60/90 days, or even installment plans for larger orders. It’s crucial to clarify terms during negotiations, as well as any discounts for early payment or bulk purchases. Ensure that you understand any additional fees related to shipping, customs, or handling, especially in international transactions. Establishing clear payment terms upfront can help mitigate risks and ensure smooth transactions.

How can I ensure quality assurance (QA) for nitrogen inflated tires?

To ensure quality assurance, request certifications from suppliers that meet international standards, such as ISO or specific tire industry certifications. It’s advisable to conduct on-site inspections during production or to request third-party quality control reports. Implement a quality check process upon receiving tires, including visual inspections and pressure tests. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations and any issues that may arise.

What logistics considerations should I keep in mind when sourcing nitrogen inflated tires?

Logistics considerations include shipping methods, lead times, and customs regulations, especially for international transactions. Determine the most cost-effective shipping options that balance speed and budget. Understanding the import/export regulations for your country can prevent delays and additional costs. Collaborate with logistics experts to streamline the supply chain and ensure timely delivery of your tires. Also, consider warehousing options if you plan to stock tires for future use.

How does the use of nitrogen in tires affect fuel efficiency?

While nitrogen-filled tires are often marketed for improved fuel efficiency, studies suggest the impact is minimal compared to properly inflated air-filled tires. Nitrogen may reduce pressure loss over time, which can maintain optimal tire performance and rolling resistance. However, regular maintenance and pressure checks are critical for both nitrogen and air-filled tires to achieve fuel efficiency gains. Educate your drivers on the importance of tire pressure management to maximize savings on fuel costs.

Domínio: reddit.com

Registrado: 2005 (20 anos)

Introdução: The use of nitrogen in car tires is primarily seen in commercial and military aircraft and racing cars due to extreme forces and temperatures. For passenger cars, nitrogen offers minimal benefits as it is chemically inert and dry, potentially leading to a slight decrease in oxidation of the tire’s inner lining. However, this effect is negligible since tires wear out before oxidation becomes a sign…

Domínio: cars.usnews.com

Registrado: 1995 (30 anos)

Introdução: Nitrogen in tires offers several pros and cons. Pros include: 1) Nitrogen escapes from a tire more slowly than air due to the larger atomic radius of nitrogen, leading to less frequent inflation. 2) Nitrogen helps maintain more consistent tire pressure, especially in fluctuating temperatures, which can enhance safety and performance. 3) Nitrogen is inert and does not react with tire materials, pot…

Domínio: continental-tires.com

Registrado: 2000 (25 anos)

Introdução: Nitrogen can be used to inflate tires instead of air, and it is becoming popular among driving enthusiasts. The benefits of nitrogen-filled tires include improved tire pressure maintenance, as temperature changes affect tire pressure. Continental emphasizes the importance of maintaining proper tire pressure for long-term tire care.

Domínio: robertson-tire.com

Registrado: 1999 (26 anos)

Introdução: Nitrogen-filled tires are an alternative to conventional air-filled tires, containing up to 98% pure nitrogen. They lose pressure about 40% slower than regular air tires, which are composed of approximately 78% nitrogen and just under 21% oxygen, along with water vapor and other gases. Key benefits of nitrogen-filled tires include: increased tread life, better tire pressure retention, cooler-runni…

As the tire industry continues to evolve, the strategic sourcing of nitrogen inflated tires presents unique opportunities for international B2B buyers. Key takeaways indicate that while nitrogen offers benefits such as reduced pressure loss and improved tire longevity, its advantages are often marginal compared to standard air inflation for everyday applications. However, in specialized sectors like aviation, mining, and racing, the inert properties of nitrogen can lead to enhanced performance and safety.

For buyers in Africa, South America, the Middle East, and Europe, understanding the specific needs of your operational environment is crucial. Strategic sourcing of nitrogen inflated tires can lead to significant cost savings in maintenance and fuel efficiency, particularly in demanding conditions.

Looking ahead, businesses should consider partnerships with reputable suppliers who can provide high-quality nitrogen inflation services. Investing in tire pressure monitoring systems alongside nitrogen inflation can further optimize performance and safety. By aligning procurement strategies with technological advancements, organizations can position themselves competitively in the market. Engage with suppliers today to explore the potential of nitrogen inflated tires for your fleet and drive your business forward.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Illustrative image related to nitrogen inflated tires

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.