In the ever-evolving landscape of global commerce, sourcing reliable air tire compressors can pose a significant challenge for B2B buyers, particularly in diverse regions such as Africa, South America, the Middle East, and Europe. The demand for efficient and durable tire inflation solutions is on the rise, driven by the growing automotive industry and the need for effective vehicle maintenance. This comprehensive guide delves into the multifaceted world of air tire compressors, addressing key considerations such as types, applications, supplier vetting, and cost analysis.

By equipping international buyers with actionable insights, this guide empowers stakeholders to make informed purchasing decisions that align with their operational needs and budget constraints. We explore various compressor models, from portable inflators to industrial-grade units, ensuring that businesses can select the right solution tailored to their specific requirements. Additionally, we provide a framework for evaluating suppliers, which is crucial for establishing long-term partnerships that enhance reliability and quality.

Navigating the complexities of the air tire compressor market requires a strategic approach; this guide serves as an essential resource for B2B buyers looking to optimize their procurement processes and enhance their operational efficiency.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Portable Tire Inflators | Compact, battery-operated, often cordless | Automotive repair shops, roadside assistance | Prós: Easy to use, lightweight, suitable for quick fixes. Contras: Limited power for larger vehicles. |

| Heavy-Duty Air Compressors | High PSI capacity, designed for extensive use | Commercial vehicle maintenance, construction | Prós: Suitable for large tire sizes, robust performance. Contras: Bulky, higher initial investment. |

| 12V Tire Inflators | Connects to vehicle’s cigarette lighter, portable | Automotive service, personal use | Prós: Convenient for on-the-go inflation. Contras: Limited air pressure capacity compared to larger models. |

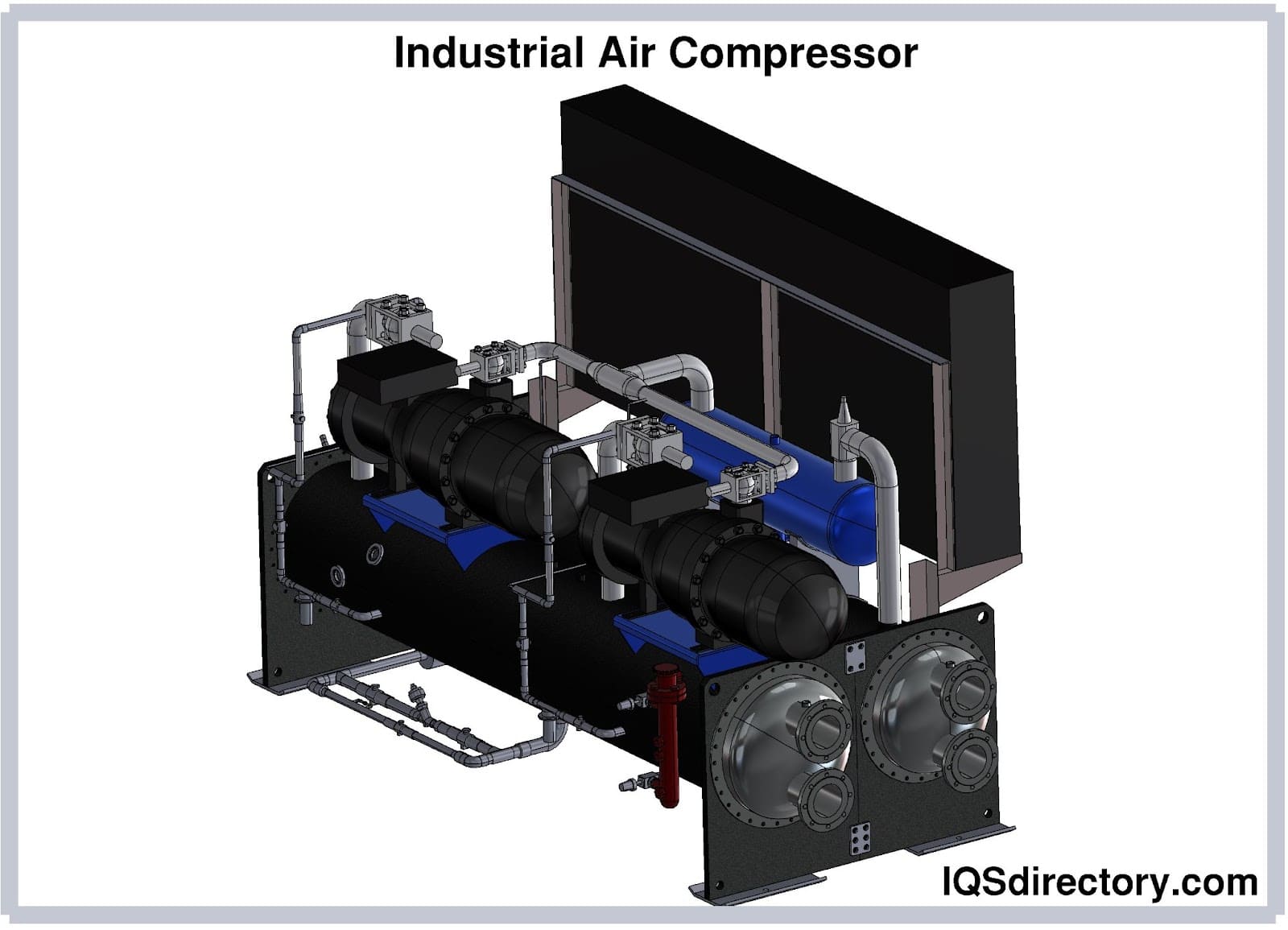

| Industrial Air Compressors | High-volume output, typically stationary, multi-functional | Manufacturing, heavy machinery maintenance | Prós: High efficiency, versatile for various applications. Contras: Requires dedicated space and infrastructure. |

| Dual-Power Tire Inflators | Operates on both battery and AC power | Automotive service, emergency response | Prós: Flexibility in power sources, reliable for various situations. Contras: Heavier and more complex than single-source models. |

Portable tire inflators are lightweight and compact devices primarily designed for quick tire inflation. They are typically battery-operated and cordless, making them ideal for roadside assistance and personal use. B2B buyers should consider their ease of use and portability, which allows for quick fixes in various settings, such as automotive repair shops. However, their limited power may not be suitable for larger vehicles, making it essential to evaluate the specific needs of the target market.

Illustrative image related to air tire compressor

Heavy-duty air compressors are built to deliver high PSI capacity, catering specifically to commercial applications such as vehicle maintenance and construction. Their robust performance allows them to handle larger tire sizes and demanding inflation tasks efficiently. For B2B buyers, investing in these compressors means ensuring longevity and reliability for high-volume operations. However, their bulkiness and higher initial investment can be a deterrent for smaller businesses or those with limited space.

12V tire inflators are designed to connect to a vehicle’s cigarette lighter, offering a convenient solution for inflation on-the-go. They are particularly useful for automotive service providers and personal vehicle owners. B2B buyers should appreciate their portability and ease of use, which makes them a practical choice for emergency situations. However, their air pressure capacity is limited compared to larger models, which may not meet the requirements for heavy-duty applications.

Industrial air compressors are crucial for high-volume output and are typically stationary, serving multiple functions within manufacturing environments. They are designed to handle various applications, including powering pneumatic tools and maintaining heavy machinery. B2B buyers in industrial sectors should consider the efficiency and versatility of these compressors. However, they require dedicated space and proper infrastructure, which may involve additional costs and planning.

Dual-power tire inflators can operate on both battery and AC power, providing flexibility in various scenarios, from automotive service to emergency response. Their reliability and adaptability make them appealing to B2B buyers who require dependable inflation solutions in diverse environments. While they offer the advantage of versatility, their complexity and weight compared to single-source models can be a consideration for potential purchasers.

Illustrative image related to air tire compressor

| Indústria/Setor | Specific Application of air tire compressor | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Automotive Repair | Tire inflation for vehicle servicing and maintenance | Ensures optimal tire pressure, enhancing safety and fuel efficiency | Compatibility with various tire sizes, durability, service support |

| Transportation & Logistics | Fleet maintenance for trucks and delivery vehicles | Reduces downtime and maintenance costs through regular tire pressure checks | Availability of portable options, power source flexibility |

| Construction & Heavy Equipment | Inflation of construction vehicle tires | Enhances operational efficiency and safety on job sites | Robust design for heavy-duty use, ease of transport |

| Agricultura | Tire inflation for farm machinery and vehicles | Increases productivity by minimizing tire-related issues | Adaptability to different machinery, ruggedness, and reliability |

| Aviation | Pre-flight tire pressure checks for aircraft | Critical for safety and performance in aviation operations | Precision in pressure measurement, compliance with aviation standards |

In the automotive repair sector, air tire compressors are essential for maintaining optimal tire pressure during vehicle servicing. They allow technicians to quickly inflate tires, ensuring vehicles are road-ready and enhancing safety. Regular tire pressure checks can lead to improved fuel efficiency and prolonged tire life. International B2B buyers in this industry should consider compressors that are compatible with various tire sizes and equipped with durable components to withstand frequent use. Service support and availability of spare parts are also crucial factors for ensuring long-term operational efficiency.

In the transportation and logistics industry, air tire compressors are used for fleet maintenance, ensuring that delivery vehicles and trucks operate at optimal tire pressure. This practice minimizes downtime and reduces maintenance costs, as properly inflated tires lead to better fuel economy and lower wear and tear. B2B buyers in regions like Africa and South America should seek portable compressors that can accommodate different vehicle types and provide flexible power sources, such as battery or vehicle-adaptable options, to maximize utility during on-the-go inspections.

Construction sites often utilize air tire compressors to inflate tires on heavy machinery, such as bulldozers and excavators. Proper tire pressure is crucial for safety and operational efficiency, as under-inflated tires can lead to accidents and equipment failures. Buyers in the construction sector must prioritize compressors with a robust design that can withstand harsh environments and provide easy transport to various job sites. Additionally, features like quick-connect hoses and high PSI capabilities are vital for meeting the demands of heavy-duty applications.

In the agriculture sector, air tire compressors are vital for maintaining the tire pressures of farm machinery and vehicles, such as tractors and harvesters. Proper inflation enhances productivity by reducing the likelihood of tire blowouts and improving fuel efficiency. Buyers in this industry should consider compressors that are adaptable to different machinery types and rugged enough to endure outdoor conditions. Reliability and ease of use are also key considerations, as farmers often require quick inflation solutions to minimize downtime during critical harvesting periods.

In aviation, air tire compressors are used for pre-flight tire pressure checks, which are critical for ensuring the safety and performance of aircraft. Accurate tire pressure directly affects landing and takeoff performance, making it essential for ground crews to have reliable inflation equipment. B2B buyers in the aviation sector should focus on compressors that offer precision in pressure measurement and compliance with strict aviation standards. Additionally, the ability to provide consistent performance in various environmental conditions is crucial for operational safety and efficiency.

Illustrative image related to air tire compressor

O problema: B2B buyers managing fleets often face the challenge of selecting the right air tire compressor that meets the varying needs of different vehicle types. For example, a fleet might include passenger cars, delivery vans, and heavy-duty trucks, each requiring different inflation pressures and capacities. This can lead to significant downtime if the chosen compressor is unable to efficiently service all vehicles, resulting in lost productivity and increased operational costs.

A solução: To address this issue, buyers should conduct a thorough assessment of their fleet’s tire inflation requirements before sourcing an air tire compressor. This includes considering the maximum PSI needed for the largest vehicle in the fleet, the average tire sizes, and any special features that could enhance efficiency, such as dual power sources (battery and AC) or automatic shut-off functions. When sourcing, look for suppliers that offer a range of models, or consider modular systems that can be tailored to fit various vehicle types. Engage with manufacturers or distributors to obtain detailed specifications and seek advice on the best compressors for multi-vehicle operations. This proactive approach ensures that the compressor chosen can effectively handle the diverse needs of the fleet, minimizing downtime and maintenance issues.

O problema: In regions with extreme weather conditions—such as high heat in the Middle East or cold in parts of Europe—maintaining consistent tire pressure becomes a daunting task. Tires can lose pressure quickly due to temperature fluctuations, leading to safety concerns and increased fuel consumption. B2B buyers often struggle to find reliable inflation solutions that can adapt to these environmental challenges and maintain optimal tire pressure.

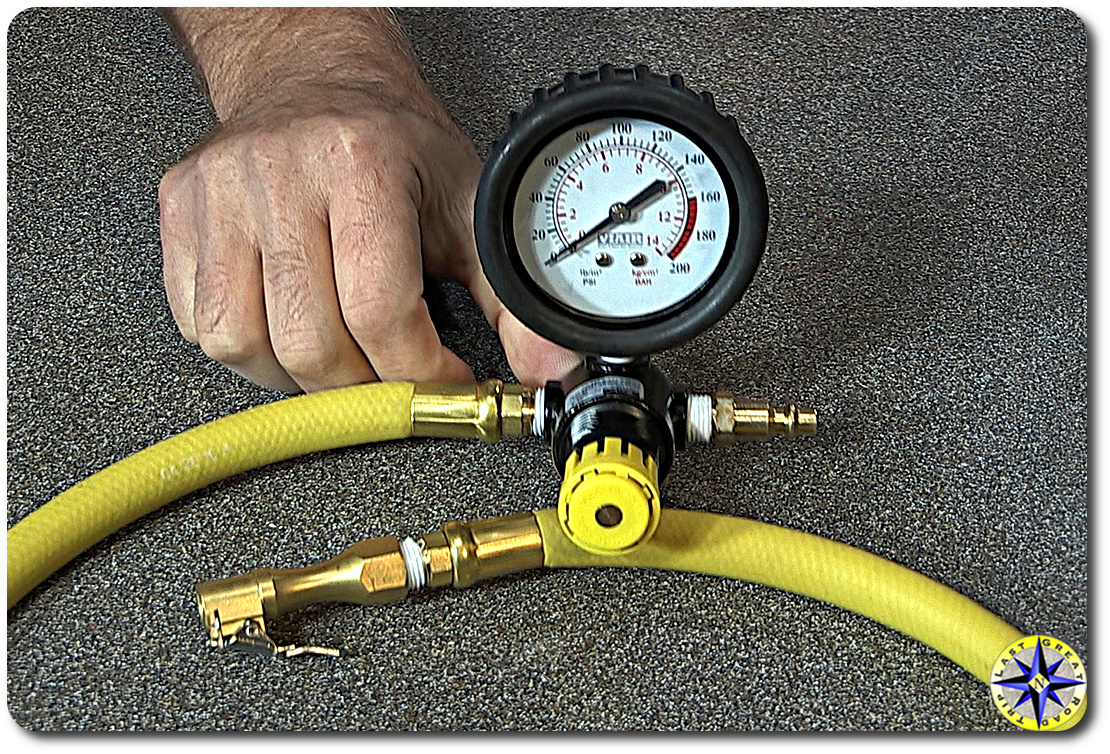

A solução: Buyers should invest in high-quality digital tire compressors that feature built-in pressure gauges and automatic shut-off capabilities. These features help ensure that tires are inflated accurately and efficiently, regardless of the external temperature. Furthermore, consider compressors that allow for easy adjustment of pressure settings, enabling quick adaptations to varying tire specifications. Regular training for maintenance staff on the importance of tire pressure and the use of the compressors can also enhance overall vehicle safety and efficiency. Additionally, implementing a routine tire pressure monitoring system can be beneficial, allowing for proactive inflation before issues arise. This comprehensive strategy not only ensures safety but also helps in reducing fuel costs, leading to long-term savings.

Illustrative image related to air tire compressor

O problema: After purchasing an air tire compressor, many B2B buyers find themselves frustrated with inadequate support and after-sales service. This can manifest in the form of delayed responses to inquiries, lack of replacement parts, or insufficient guidance on maintenance and troubleshooting. Such challenges can render the compressor ineffective and lead to further operational disruptions.

A solução: To mitigate this issue, B2B buyers should prioritize suppliers that offer robust after-sales support as part of their purchasing decision. Before finalizing a purchase, inquire about the warranty terms, availability of spare parts, and the provider’s responsiveness to service requests. Establishing a relationship with a reliable supplier who can offer training sessions on the maintenance and operation of the compressor can also enhance user competence and confidence. Regular maintenance checks and creating a service schedule can preemptively address potential issues, ensuring the compressor remains functional over time. Buyers should also consider joining industry forums or networks where they can share experiences and gain insights about effective maintenance practices and recommended suppliers, fostering a collaborative approach to overcoming common challenges in tire compressor management.

When selecting materials for air tire compressors, it is essential to consider various factors that influence performance, durability, and cost. This analysis explores four common materials used in the manufacturing of these compressors: aluminum, steel, plastic, and rubber. Each material offers unique properties that cater to different applications and market requirements, particularly for international B2B buyers.

Aluminum is a popular choice for air tire compressors due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating that allows it to withstand high-pressure environments without deforming. The primary advantage of aluminum is its durability combined with low weight, making it ideal for portable tire inflators. However, aluminum can be more expensive than other materials and may require specialized manufacturing processes that increase production costs.

For international buyers, especially in regions like Europe and the Middle East, aluminum components must comply with standards such as EN 573 and EN 755. Countries like Germany may have stringent regulations regarding material quality, making it crucial for manufacturers to source high-grade aluminum.

Illustrative image related to air tire compressor

Steel, particularly stainless steel, is another common material used in air tire compressors. It boasts high tensile strength and excellent pressure ratings, making it suitable for heavy-duty applications. Steel’s resistance to wear and tear ensures a long lifespan, which is a critical factor for B2B buyers looking for reliability.

However, steel is heavier than aluminum, which can impact the portability of tire inflators. Additionally, while stainless steel offers corrosion resistance, it is generally more expensive than carbon steel. Buyers in Africa and South America may prefer steel for its robustness, especially in rugged conditions, but must consider the weight implications for transport.

Plastic is frequently used in non-structural components of air tire compressors, such as housing and casings. Its lightweight nature and resistance to corrosion make it an attractive option for manufacturers aiming to reduce costs. Plastics can be molded into complex shapes, allowing for innovative designs that enhance usability.

Illustrative image related to air tire compressor

On the downside, plastic may not withstand high pressures as well as metal counterparts, limiting its application in heavy-duty compressors. International buyers should be aware of material compliance with standards like ASTM D638 for tensile properties, especially in regions where product safety is paramount, such as Europe.

Rubber is primarily used for seals and gaskets in air tire compressors, providing essential flexibility and sealing capabilities. It can withstand a range of temperatures and pressures, making it suitable for various compressor designs. Rubber’s elasticity allows it to absorb vibrations, enhancing the overall performance of the compressor.

However, rubber can degrade over time, especially when exposed to ozone and UV light, which can be a concern in regions with harsh climates. Buyers from Africa and the Middle East should consider the environmental conditions when selecting rubber components, ensuring they meet local standards and performance expectations.

| Material | Typical Use Case for air tire compressor | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Portable tire inflators | Leve e resistente à corrosão | Custo mais alto e fabricação complexa | Médio |

| Aço | Heavy-duty compressors | Alta resistência e durabilidade | Heavier and potentially more expensive | Alta |

| Plástico | Non-structural components | Cost-effective and versatile | Limited pressure resistance | Baixa |

| Borracha | Vedações e gaxetas | Flexible and vibration-absorbing | Degrades over time under harsh conditions | Médio |

This material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance, cost, and regional compliance standards. Understanding the properties and implications of each material will ensure that buyers choose the best options for their specific applications in air tire compressors.

Manufacturing air tire compressors involves several critical stages, each contributing to the overall quality and performance of the final product. The primary stages include material preparation, forming, assembly, and finishing.

Preparação de materiais:

The manufacturing process begins with the selection of high-quality materials, typically metals like aluminum and steel, along with various plastics and rubber components. The materials are subjected to rigorous testing to ensure they meet specific mechanical and chemical properties. Suppliers often need to provide certification that materials comply with international standards to assure buyers of their quality.

Formação:

After materials are prepared, they undergo forming processes such as casting, machining, and stamping. Advanced techniques like CNC machining are often employed to achieve precise tolerances, especially for critical components like the cylinder and piston. The forming stage is crucial as it lays the groundwork for the compressor’s efficiency and durability.

Montagem:

Following the forming stage, components are assembled using automated and manual processes. This includes the integration of electrical systems, pressure gauges, and safety valves. Quality assurance checks are often integrated into this stage, ensuring that every assembly line worker adheres to specific protocols that mitigate the risk of defects.

Acabamento:

The final stage involves surface treatments such as painting, powder coating, or anodizing, which enhance the compressor’s aesthetic appeal and protect against corrosion. This stage may also include final inspections and testing to ensure that all components meet design specifications before the product is packaged for shipment.

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that air tire compressors meet both industry standards and customer expectations. The QA process typically adheres to various international standards and includes multiple checkpoints throughout the production cycle.

Padrões internacionais:

Compliance with standards such as ISO 9001 is crucial for manufacturers targeting international markets. ISO 9001 establishes a framework for quality management systems, focusing on continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be required, depending on the application and market.

Pontos de verificação de controle de qualidade:

Effective QA involves several critical checkpoints:

– Controle de qualidade de entrada (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter the manufacturing process.

– Controle de qualidade durante o processo (IPQC): Throughout the manufacturing stages, IPQC ensures that processes are being followed correctly and that any deviations are addressed immediately.

– Controle de qualidade final (FQC): This final inspection phase verifies that the finished product meets all specifications and standards before it is shipped to customers.

Métodos de teste comuns:

Manufacturers utilize a variety of testing methods, including pressure tests, performance evaluations, and reliability assessments. These tests often simulate real-world conditions to ensure that the compressors can withstand the rigors of use. For instance, tests may include checking for leaks, verifying pressure readings, and assessing the durability of components under stress.

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensuring product reliability.

Realização de auditorias:

Buyers can perform on-site audits to assess the manufacturing process and quality control measures in place. This not only provides insight into the supplier’s operations but also helps establish a relationship based on transparency and trust.

Reviewing Quality Control Reports:

Suppliers should be willing to provide documentation related to their quality control processes, including inspection reports, testing results, and certifications. Buyers can assess these documents to ensure compliance with international standards and industry-specific requirements.

Engaging Third-Party Inspection Services:

Utilizing third-party inspection services can provide an additional layer of assurance. These services can conduct independent evaluations of the manufacturing process and the final products, ensuring that they meet the agreed-upon specifications.

Understanding the nuances of quality control can significantly impact the purchasing decisions of international B2B buyers. Here are some key considerations:

Diferenças culturais:

Quality expectations may vary by region, necessitating an understanding of local standards and practices. Buyers must be aware of these differences to communicate their quality requirements effectively.

Conformidade regulatória:

Different markets may have unique regulatory requirements. Buyers should ensure that suppliers are familiar with and compliant with regulations specific to their target markets, such as safety standards in Europe or environmental regulations in Africa.

Transparência na cadeia de suprimentos:

The complexity of global supply chains can complicate quality assurance efforts. Buyers should seek suppliers who provide transparency regarding their sourcing and manufacturing processes, ensuring that all components meet the required standards.

Continuous improvement in quality assurance processes is vital for manufacturers looking to maintain a competitive edge. Here are some strategies manufacturers can adopt:

Implementing Lean Manufacturing Principles:

By focusing on waste reduction and process efficiency, manufacturers can enhance their quality assurance practices. Lean principles encourage regular evaluation of processes to identify areas for improvement.

Investing in Training:

Regular training programs for employees can ensure that everyone involved in the manufacturing and quality control processes is up-to-date with best practices and standards.

Utilizing Advanced Technologies:

Incorporating technologies such as IoT (Internet of Things) for real-time monitoring can enhance quality control efforts. These technologies can provide immediate feedback on production processes, allowing for quick adjustments as needed.

By understanding the manufacturing processes and quality assurance protocols involved in air tire compressors, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to improved product quality and customer satisfaction.

This sourcing guide is designed to assist B2B buyers in procuring air tire compressors effectively and efficiently. Given the diverse needs across various regions, including Africa, South America, the Middle East, and Europe, understanding the critical factors in selecting the right compressor is essential for ensuring optimal performance and value.

Illustrative image related to air tire compressor

Begin by assessing the specific requirements of your operations. Consider the types of vehicles that will be serviced and the environments in which the compressors will operate.

– Pressure Requirements: Determine the maximum PSI needed for your applications.

– Portability: Consider whether you need a stationary unit or a portable compressor for on-the-go service.

Stay informed about the latest advancements in air tire compressor technology. This can help you identify models that offer improved efficiency and features tailored to your needs.

– Energy Efficiency: Look for compressors that consume less power, reducing operational costs.

– Smart Features: Consider models with digital gauges and automatic shut-off features for ease of use.

When selecting suppliers, prioritize those with a proven track record in the industry. A reputable supplier can provide reliability and support throughout the purchasing process.

– Check Reviews and Testimonials: Look for feedback from other B2B buyers in your sector.

– Years in Business: Suppliers with extensive experience are more likely to understand market needs and offer quality products.

Ensure that potential suppliers possess the necessary certifications and compliance with industry standards. This step is crucial to guarantee product quality and safety.

– Quality Assurance Standards: Look for ISO certifications or equivalent.

– Local Regulations Compliance: Ensure the compressors meet regulations in your target market, such as CE marking in Europe.

Before making a bulk purchase, request samples of the air tire compressors. Testing the product can provide valuable insights into its performance and suitability for your needs.

– Teste de desempenho: Evaluate the compressor’s ability to meet specified pressure levels and refill times.

– Durability Assessment: Assess how well the unit holds up under various working conditions.

Gather quotes from multiple suppliers to compare pricing, but consider the total cost of ownership rather than just the upfront price.

– Flexibilidade de pagamento: Look for suppliers who offer favorable payment terms or financing options.

– Warranty and After-Sales Support: Ensure that the pricing includes adequate warranty and support services.

Once you have selected a supplier, engage in negotiations to secure the best terms. This includes price, delivery timelines, and after-sales support.

– Clear Agreement: Ensure that all terms are documented to avoid misunderstandings.

– Delivery and Installation: Confirm logistics for delivery and whether installation services are included or available.

By following these steps, B2B buyers can make informed decisions when sourcing air tire compressors, ensuring they select the right product and supplier for their operational needs.

In the competitive landscape of air tire compressor sourcing, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. This analysis will delve into the various cost components, price influencers, and offer strategic buyer tips to optimize procurement decisions.

Illustrative image related to air tire compressor

The total cost of an air tire compressor can be broken down into several key components:

Materiais: The quality and type of materials used—such as metal casings, plastic components, and electrical parts—significantly impact the cost. High-quality materials ensure durability and performance but may increase upfront expenses.

Trabalho: Labor costs vary by region and can be a major factor in manufacturing. Skilled labor may command higher wages, influencing the overall production cost.

Custos indiretos de fabricação: This includes expenses related to utilities, factory maintenance, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs.

Ferramentas: The initial investment in tooling for production can be substantial, especially for customized or specialized compressors. This cost is often amortized over large production runs.

Controle de qualidade (QC): Implementing rigorous QC processes ensures product reliability and compliance with international standards. While this may add to costs, it can prevent costly returns and warranty claims.

Logística: Shipping and handling costs are critical, particularly for international transactions. Factors like distance, mode of transport, and local tariffs can influence logistics expenses.

Margem: Suppliers typically add a profit margin on top of the total production costs. This margin can vary widely based on market conditions and competition.

Several factors can influence the pricing of air tire compressors:

Volume e quantidade mínima de pedidos (MOQ): Higher purchase volumes often lead to lower per-unit costs. Negotiating favorable MOQs can enhance cost-efficiency.

Especificações e personalização: Custom features or specifications can raise costs. Buyers should weigh the necessity of customization against potential price increases.

Materiais e certificações de qualidade: Compressors made from premium materials or those with certifications (like ISO or CE) may command higher prices but offer greater reliability and performance.

Fatores do fornecedor: The supplier’s reputation, production capacity, and geographical location can affect pricing. Established suppliers may charge more due to their brand reliability.

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly impact total costs. Understanding responsibilities for shipping, insurance, and tariffs is essential for accurate cost assessment.

Negotiation Tactics: Leverage volume purchases and long-term contracts to negotiate better pricing. Building a relationship with suppliers can also lead to favorable terms.

Understanding Total Cost of Ownership (TCO): Consider the entire lifecycle costs, including maintenance, energy consumption, and potential repair costs. A lower purchase price may not always equate to lower overall costs.

Nuances de preços para compradores internacionais: Be aware of currency fluctuations and local market conditions in regions like Nigeria or Germany, as these can impact final costs. Additionally, familiarize yourself with regional import duties and regulations that could affect pricing.

Requesting Quotes from Multiple Suppliers: Obtaining quotes from various suppliers can provide valuable insights into market pricing and help identify the best value options.

Evaluating Long-Term Supplier Relationships: Establishing long-term partnerships with reliable suppliers can lead to improved pricing and service levels over time.

Understanding the intricacies of cost components and pricing influencers in the air tire compressor market is essential for B2B buyers looking to make informed purchasing decisions. By leveraging strategic insights and negotiation tactics, businesses can optimize their sourcing efforts, ensuring they procure high-quality compressors at competitive prices. As prices can vary widely based on the factors discussed, it is advisable to obtain indicative quotes tailored to specific needs and conditions.

In the realm of tire maintenance, air tire compressors are widely recognized for their efficiency in inflating tires. However, various alternative solutions exist that can also fulfill this critical function. This section delves into a comparative analysis of air tire compressors against other viable methods, helping B2B buyers make informed decisions tailored to their specific operational needs.

| Aspecto de comparação | Air Tire Compressor | Portable Electric Tire Inflator | Manual Foot Pump |

|---|---|---|---|

| Desempenho | High efficiency, quick inflation | Moderate efficiency, slower than compressors | Low efficiency, labor-intensive |

| Custo | Medium to high (varies by brand) | Low to medium | Very low |

| Facilidade de implementação | Simple plug-and-play operation | User-friendly, minimal setup required | Requires physical effort, straightforward |

| Manutenção | Low maintenance, occasional checks needed | Minimal maintenance, battery checks required | Very low, no mechanical parts |

| Melhor caso de uso | Commercial fleets, heavy-duty vehicles | Personal use, small vehicles, emergencies | Casual use, low-pressure needs |

Portable electric tire inflators serve as a compact alternative to traditional air tire compressors. These devices are typically battery-operated or plug into a vehicle’s power outlet, making them convenient for on-the-go inflation. Their performance is generally sufficient for standard passenger vehicles, allowing users to inflate tires at a moderate speed. However, they may struggle with high-pressure tires, such as those found on larger vehicles. The initial cost is usually lower than that of air compressors, making them an appealing option for individual users or small businesses. On the downside, their reliance on battery life can be a limitation during prolonged use.

Illustrative image related to air tire compressor

Manual foot pumps provide a simple, cost-effective solution for tire inflation, particularly for low-pressure applications such as bicycles and small vehicles. They are incredibly affordable, making them accessible to a wide range of users, including those in developing regions. The design is straightforward, with no electrical components, resulting in minimal maintenance needs. However, the performance is significantly lower than that of air tire compressors and electric inflators, requiring considerable physical effort to achieve desired tire pressure. They are best suited for casual users who infrequently deal with tire inflation.

Selecting the appropriate tire inflation solution hinges on various factors, including the scale of operations, budget, and specific use cases. For businesses managing a fleet or heavy-duty vehicles, air tire compressors are often the best choice due to their high performance and efficiency. In contrast, portable electric tire inflators offer a balance of convenience and cost-effectiveness for personal use or smaller operations. Lastly, manual foot pumps remain a viable option for occasional users seeking an economical solution. By assessing these alternatives against operational needs, B2B buyers can ensure they invest in a solution that enhances their tire maintenance practices effectively.

When evaluating air tire compressors, several technical specifications play a crucial role in determining their suitability for specific applications. Understanding these properties is essential for B2B buyers to make informed purchasing decisions.

Illustrative image related to air tire compressor

The maximum pressure rating, typically measured in pounds per square inch (PSI), indicates the highest pressure the compressor can achieve. This specification is vital for ensuring that the compressor can handle the tire pressure requirements of different vehicles, particularly those with larger tires, such as trucks and SUVs. A compressor with a higher PSI capability can inflate tires more quickly and efficiently, which is especially important in commercial settings where time is money.

The duty cycle refers to the percentage of time a compressor can operate continuously without overheating. For example, a 50% duty cycle means the unit can run for 5 minutes and then needs a 5-minute rest. Understanding the duty cycle is critical for businesses that need reliable, continuous operation, such as automotive workshops or tire repair shops. A higher duty cycle allows for more extended use without the risk of failure.

Measured in cubic feet per minute (CFM), the airflow rate indicates how much air the compressor can deliver. This specification is particularly important for tasks requiring rapid inflation, as a higher CFM means quicker inflation times. For B2B buyers, selecting a compressor with an appropriate CFM rating ensures efficiency, particularly in high-volume tire servicing environments.

Illustrative image related to air tire compressor

For portable compressors, tank size can affect performance. Larger tanks store more compressed air, allowing for longer usage periods before the compressor needs to recharge. This is particularly beneficial in commercial applications where multiple tires may need inflation in a single session. Buyers should consider their specific needs to determine the optimal tank size.

Air tire compressors can be powered by electricity, batteries, or gas. The power source affects portability, operation cost, and where the compressor can be used. For instance, battery-powered models offer greater portability for on-the-go applications, whereas electric models may be more suitable for stationary use in workshops.

Understanding industry jargon is essential for effective communication in B2B transactions. Here are some common terms related to air tire compressors:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of air tire compressors, OEM parts are often used for replacements or upgrades. Buyers should be aware of OEM products to ensure compatibility and quality.

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for businesses looking to manage inventory costs while ensuring they meet supplier requirements. This term is particularly relevant for bulk buyers seeking to negotiate better pricing.

Illustrative image related to air tire compressor

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ for air tire compressors allows for comparison of pricing and specifications from multiple suppliers, facilitating better purchasing decisions.

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms is essential for businesses importing or exporting air tire compressors, as they clarify shipping costs, risks, and delivery responsibilities.

The warranty period refers to the time frame during which the manufacturer guarantees the compressor against defects. Understanding warranty terms is essential for buyers to mitigate risks associated with equipment failure and to ensure long-term reliability.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing air tire compressors, ultimately enhancing operational efficiency and cost-effectiveness.

The air tire compressor market is undergoing significant transformation driven by several global factors. A primary driver is the increasing demand for efficient tire inflation solutions as vehicle ownership rises in developing regions, particularly in Africa and South America. Additionally, the surge in e-commerce and logistics has led to a growing need for portable and reliable tire inflators that can accommodate a wide variety of vehicles, including passenger cars, trucks, and SUVs.

Emerging technologies, such as smart tire pressure monitoring systems, are influencing sourcing trends, encouraging manufacturers to integrate advanced features like automatic shut-off and digital pressure gauges into their products. International B2B buyers are increasingly looking for suppliers who offer innovative solutions that enhance user experience and operational efficiency. Furthermore, the demand for compact and lightweight designs is on the rise, as consumers seek convenience and portability.

Market dynamics also reveal a shift toward online purchasing platforms, providing opportunities for international buyers to access a broader range of products and competitive pricing. This trend is particularly relevant in regions like Europe, where e-commerce is well-established, and in emerging markets where online shopping is gaining traction.

Illustrative image related to air tire compressor

Sustainability and ethical sourcing have become paramount concerns within the air tire compressor sector. The environmental impact of manufacturing processes and the materials used in production are under scrutiny, with many buyers now prioritizing eco-friendly options. The push for sustainable practices is leading manufacturers to explore alternative materials and processes that minimize carbon footprints.

Ethical supply chains are critical, especially for international buyers who want to align their procurement strategies with corporate social responsibility (CSR) initiatives. As a result, suppliers that offer transparency in sourcing and adhere to ethical labor practices are increasingly favored. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications are becoming essential for companies looking to differentiate themselves in the marketplace.

Moreover, the integration of recycled materials into the production of air tire compressors is gaining traction. This not only reduces waste but also appeals to consumers looking for sustainable product options. Buyers should seek out suppliers who can demonstrate their commitment to sustainability through certifications and environmentally friendly practices.

The air tire compressor has evolved significantly since its inception in the late 19th century, originally designed for industrial applications. Over the decades, the technology has transitioned to serve consumer needs, particularly with the rise of the automobile. By the mid-20th century, portable tire inflators became increasingly popular, driven by the necessity of maintaining tire pressure for safety and fuel efficiency.

In recent years, the market has seen a shift towards compact and efficient designs that cater to the modern consumer’s lifestyle. The introduction of cordless and battery-operated models has revolutionized convenience, making tire inflation accessible for all types of vehicles. This evolution is crucial for B2B buyers, as understanding the historical context of product development can inform sourcing decisions and highlight manufacturers that are at the forefront of innovation in the air tire compressor sector.

Illustrative image related to air tire compressor

Navigating the air tire compressor market requires a keen understanding of current trends, sustainability practices, and historical developments. As international B2B buyers seek reliable and innovative solutions, aligning procurement strategies with market dynamics and ethical sourcing principles will be key to success in this evolving landscape.

How do I choose the right air tire compressor for my business needs?

Selecting the appropriate air tire compressor involves assessing your specific requirements, such as the types of vehicles you service and the volume of tires needing inflation. Consider factors like maximum PSI, flow rate, portability, and power source (cordless or corded). Additionally, evaluate the compressor’s features, such as built-in pressure gauges and automatic shut-off functions, which enhance usability and efficiency. Lastly, consult with suppliers to understand their product offerings and gauge compatibility with your operational needs.

What is the best air tire compressor for high-pressure tires?

For high-pressure tires, especially those used in trucks and SUVs, a robust compressor like the Viair 88P is recommended due to its ability to handle pressures up to 120 PSI and its rapid inflation capabilities. If portability is a concern, the AstroAI Cordless Tire Inflator is a great option, offering a maximum pressure of 160 PSI while being compact and user-friendly. Evaluate your operational context to determine which model aligns with your specific tire inflation requirements.

What are common payment terms when sourcing air tire compressors internationally?

Payment terms vary by supplier but often include options such as 30% upfront deposit with the balance due before shipment, or net 30/60 days after delivery. It’s essential to clarify these terms during negotiations and consider using secure payment methods like letters of credit or escrow services for larger transactions. Always ensure that payment terms align with your cash flow capabilities and risk tolerance, especially when dealing with international suppliers.

What should I look for when vetting suppliers for air tire compressors?

When vetting suppliers, prioritize their experience in the industry, product quality certifications, and client testimonials. Request samples to assess product performance and reliability. Additionally, check their compliance with international standards and regulations, such as ISO certification. A reliable supplier should also provide transparent communication and after-sales support. Consider conducting site visits if feasible, or utilize third-party inspection services to validate their manufacturing processes.

What is the minimum order quantity (MOQ) for air tire compressors?

MOQs for air tire compressors can significantly vary based on the supplier and the model. Typically, MOQs range from 50 to 100 units for bulk orders, but some suppliers may offer lower quantities for specific models or during promotional periods. Discuss your requirements with potential suppliers, as they may be willing to accommodate smaller orders, especially if you establish a long-term business relationship.

How can I customize air tire compressors to fit my brand?

Customization options often include branding through logos, color schemes, and packaging design. Many manufacturers offer OEM (Original Equipment Manufacturer) services, allowing you to specify technical features or modifications to suit your needs. Engage with suppliers early in the sourcing process to discuss available customization options and any associated costs. Ensure that any customizations do not compromise the product’s performance or compliance with safety standards.

What quality assurance measures should I expect from suppliers?

Reputable suppliers should implement stringent quality assurance (QA) measures, including product testing for performance, durability, and safety compliance. Look for suppliers that have quality certifications, such as ISO 9001, which indicates adherence to international quality management standards. Request documentation of their QA processes, including inspection reports and testing results, to ensure that their products meet your expectations and regulatory requirements.

What logistics considerations should I keep in mind when importing air tire compressors?

Logistics is crucial when importing air tire compressors. Factors to consider include shipping methods (air vs. sea), lead times, and customs regulations in your country. Ensure that you have a reliable freight forwarder to manage shipping and customs clearance efficiently. Additionally, factor in costs such as duties and taxes, which can impact your overall budget. Communicate with your supplier about packaging standards to minimize damage during transit and ensure compliance with international shipping regulations.

Domínio: store.arbusa.com

Registrado: 1998 (27 anos)

Introdução: Portable and vehicle-mounted air compressor systems designed for reliable, on-the-go air. Key features include powering tires, tools, and Air Lockers with durable, high-performance compressors. Product categories include mounted compressors, portable compressors, and brushless compressors. Notable products include: 1. Twin Motor Onboard 12V Air Compressor CKMTA12 – $593.95 2. Single Motor Onboard …

As the global demand for efficient air tire compressors continues to rise, strategic sourcing emerges as a crucial factor for international B2B buyers. By carefully evaluating suppliers and leveraging competitive advantages, businesses can secure high-quality products that meet diverse market needs. Key takeaways include the importance of product reliability, performance metrics, and after-sales support, which directly influence customer satisfaction and operational efficiency.

Moreover, with the evolving landscape of tire maintenance technologies, businesses must stay informed about the latest innovations in tire inflators, such as cordless options and models capable of handling larger tires. Understanding regional market dynamics in areas like Africa, South America, the Middle East, and Europe will enable buyers to navigate pricing strategies and logistics effectively.

In conclusion, the strategic sourcing of air tire compressors not only enhances operational capabilities but also drives long-term partnerships and growth. International buyers are encouraged to explore diverse sourcing options and build relationships with reputable manufacturers to secure the best solutions for their needs. Embrace this opportunity to innovate and stay ahead in a competitive marketplace.

Illustrative image related to air tire compressor

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.