In the ever-evolving landscape of global cycling markets, understanding how to inflate a bike tire with a pump is not just a fundamental skill; it is a pivotal aspect of ensuring performance and safety for cyclists around the world. For B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe, sourcing reliable and efficient tire inflation solutions is critical. Whether you’re supplying local bike shops, manufacturing facilities, or rental services, selecting the right pumps and understanding the nuances of tire inflation can significantly impact your operations and customer satisfaction.

This comprehensive guide delves into the intricacies of bike tire inflation, covering various valve types, pump options, and the best practices for achieving optimal tire pressure. It addresses the challenges faced by international buyers, including the vetting of suppliers and understanding the cost dynamics associated with different pump technologies. By equipping B2B buyers with actionable insights, this guide empowers you to make informed purchasing decisions that enhance product offerings and drive business growth.

From the selection of the right pump—be it a track pump for home use or a portable mini pump for on-the-go repairs—to the nuances of tire pressure management, this resource serves as a valuable tool for navigating the complexities of the cycling market. Unlock the potential for improved sales and customer retention by mastering the essentials of bike tire inflation and elevating your business strategy in the global marketplace.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Track Pump | Floor-based, high volume, pressure gauge, compatible with both valve types | Bicycle shops, rental services, workshops | Prós: Fast inflation, accurate pressure control. Contras: Bulky, not portable. |

| Mini Pump | Compact, lightweight, often with a hose for valve protection | Retailers, cycling events, mobile mechanics | Prós: Portable, easy to carry. Contras: Slower inflation, less accurate pressure readings. |

| Inflador de CO2 | Uses compressed CO2 cartridges for quick inflation | Emergency kits, racing teams, bike tours | Prós: Very fast inflation, compact size. Contras: Limited use, cartridges can be costly. |

| Bomba elétrica | Battery-operated, automatic inflation, digital pressure settings | Bike manufacturing, repair shops, rental fleets | Prós: Operação sem esforço, pressão consistente. Contras: Higher upfront cost, requires charging. |

| Bomba de piso | Similar to track pumps but typically without pressure gauge | Home use, casual cyclists, small shops | Prós: Affordable, easy to use. Contras: Less precision without gauge. |

Track Pump

Track pumps, also known as floor pumps, are essential for high-volume inflation and are equipped with pressure gauges. They are ideal for bicycle shops and workshops where efficiency and accuracy are paramount. When purchasing, businesses should consider compatibility with both Presta and Schrader valves to cater to a wider clientele. Their bulkiness may limit mobility, but their rapid inflation capabilities make them indispensable for high-volume operations.

Mini Pump

Mini pumps are designed for portability and convenience, making them perfect for cyclists on the go. These pumps are lightweight and can easily fit into a jersey pocket or be mounted on a bike frame. B2B buyers, such as retailers and event organizers, should focus on mini pumps with hoses to prevent valve damage during inflation. While they may take longer to inflate tires, their compact size makes them a valuable addition to any cyclist’s toolkit.

Illustrative image related to how to inflate a bike tire with a pump

Inflador de CO2

CO2 inflators offer a quick solution for emergency tire inflation, using compressed gas cartridges. They are commonly found in emergency kits and are favored by racing teams for their speed. B2B buyers should consider the ongoing cost of CO2 cartridges and whether the rapid inflation speed outweighs the limited number of uses. Their compact size is advantageous, but they are not a complete replacement for traditional pumps.

Bomba elétrica

Electric pumps provide effortless inflation with digital pressure settings, making them suitable for bike manufacturers and repair shops. These pumps can save time and ensure consistent pressure, appealing to businesses that prioritize efficiency. However, the higher initial investment and the need for charging may deter some buyers. Businesses should evaluate their volume of usage to justify the cost.

Bomba de piso

Floor pumps are similar to track pumps but are often more affordable and may lack a pressure gauge. They are suitable for casual cyclists and small shops that need a reliable inflation method without the need for precision. B2B buyers should consider the trade-off between cost and functionality, ensuring they meet the needs of their customer base without overspending.

Illustrative image related to how to inflate a bike tire with a pump

| Indústria/Setor | Specific Application of how to inflate a bike tire with a pump | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Fabricação de bicicletas | Quality control in production lines for bike assembly | Ensures optimal performance and safety of final products | Compatibility with various valve types, durability, and efficiency |

| Serviços de aluguel de bicicletas | Maintenance of rental fleet bicycles | Maximizes customer satisfaction and minimizes downtime | Easy-to-use pumps, portable options for field repairs |

| Sports and Recreation | Support for cycling events and competitions | Enhances participant experience and safety | High-volume pumps, quick inflation capabilities, and pressure gauges |

| Logistics and Distribution | Delivery and maintenance of bicycles in urban areas | Reduces operational costs and enhances service reliability | Compact and lightweight pumps for easy transport and storage |

| Repair Shops | Tire inflation services for customers | Provides a quick service that enhances customer loyalty | Versatile pumps that accommodate different bike types and valves |

In the bicycle manufacturing industry, proper tire inflation is critical during the quality control phase of production. By ensuring that tires are inflated to the correct pressure, manufacturers can guarantee the safety and performance of their bicycles. This process helps mitigate issues such as poor handling and increased risk of punctures. Buyers in this sector need pumps that are compatible with various valve types, durable enough for continuous use, and efficient to streamline the assembly process.

Bike rental services rely heavily on the proper maintenance of their fleets to ensure customer satisfaction. Regularly inflating tires not only enhances the ride quality but also minimizes the risk of breakdowns during rentals. This results in happier customers and fewer complaints. For this application, sourcing easy-to-use and portable pumps is essential, as staff may need to conduct maintenance on-site or during busy rental periods.

In the sports and recreation sector, particularly during cycling events and competitions, proper tire inflation is vital for participant safety and performance. Inflated tires provide better traction, speed, and overall ride quality. Event organizers must ensure they have high-volume pumps that can quickly inflate multiple tires and include pressure gauges to meet specific requirements. These considerations help improve the overall experience for participants and contribute to the event’s success.

Illustrative image related to how to inflate a bike tire with a pump

For logistics and distribution companies that handle bicycles, maintaining proper tire pressure is essential for operational efficiency. Well-inflated tires reduce wear and tear during transportation and ensure that bicycles are ready for use upon delivery. Buyers in this sector should look for compact and lightweight pumps that can be easily transported and stored, facilitating quick maintenance checks and reducing operational costs.

Repair shops provide tire inflation services to customers, which enhances their service offerings and fosters customer loyalty. By ensuring that customers’ tires are properly inflated, shops can prevent common issues such as flat tires and improve overall bike performance. Sourcing versatile pumps that accommodate different bike types and valve systems is crucial for repair shops to meet diverse customer needs efficiently.

O problema:

B2B buyers, especially those managing bike fleets or retail operations, often face challenges when it comes to identifying compatible pumps for different valve types. With various bicycles utilizing Schrader, Presta, and Dunlop valves, selecting the right pump can be confusing and lead to inefficiencies. This mismatch can result in wasted time and resources, as staff may struggle to inflate tires properly, causing frustration among customers who need immediate service.

Illustrative image related to how to inflate a bike tire with a pump

A solução:

To overcome this issue, it is essential to invest in versatile pumps that accommodate multiple valve types. When sourcing pumps, prioritize models with adjustable heads or dual compatibility features. Additionally, consider equipping your team with an easy reference guide outlining the different valve types and their characteristics. Training staff on how to quickly identify valve types and properly use the pumps can significantly enhance operational efficiency. For large-scale purchases, negotiate with suppliers for bulk options that ensure a consistent supply of compatible pumps, reducing downtime and improving customer satisfaction.

O problema:

Inconsistent tire pressure can lead to performance issues, affecting the riding experience and potentially damaging bicycles in a fleet. B2B buyers might find that their staff often inflate tires improperly, either over-inflating or under-inflating them due to a lack of understanding of the required pressure levels. This not only impacts the safety and comfort of riders but can also lead to increased maintenance costs due to tire wear and tear.

A solução:

To address this pain point, it is crucial to standardize tire pressure guidelines across your fleet. Provide a clear chart indicating the optimal pressure range for each bicycle model, and ensure that this information is readily accessible near the pump stations. Investing in pumps with integrated pressure gauges can facilitate accurate inflation, allowing staff to monitor pressure levels easily. Additionally, regular training sessions on the importance of maintaining proper tire pressure can foster a culture of diligence among employees, ultimately improving overall fleet performance and rider satisfaction.

O problema:

For B2B buyers managing bike rental services or delivery operations, tire repair and maintenance in remote locations can be a significant challenge. When tires become flat, staff may not have the appropriate tools or knowledge to inflate them properly, which can lead to delays in service and dissatisfied customers. This issue is particularly pressing in regions where access to repair shops is limited.

A solução:

Implementing a robust toolkit that includes portable mini pumps and CO2 inflators is essential for operations in remote areas. Equip each bike with a mini pump that is compatible with both Schrader and Presta valves, ensuring versatility. Additionally, train staff on quick repair techniques and the use of CO2 inflators for emergency situations. Providing a simple instructional manual for tire inflation can also empower employees to handle common issues independently. By preparing your team for on-the-spot repairs, you can enhance service reliability and customer trust, even in challenging environments.

When selecting materials for bike tire inflation pumps, various factors such as performance, durability, cost, and compliance with international standards must be considered. Here, we analyze four common materials used in the construction of these pumps: aluminum, plastic, rubber, and steel. Each material has distinct properties and implications for B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe.

Principais propriedades: Aluminum is known for its excellent strength-to-weight ratio, corrosion resistance, and ability to withstand high pressures. It typically has a temperature rating of around -50°C to 150°C, making it suitable for varying climates.

Prós e contras: The lightweight nature of aluminum makes it ideal for portable mini-pumps, while its durability ensures longevity. However, aluminum can be more expensive than plastic, and if not treated properly, it may corrode over time, especially in humid environments.

Impacto no aplicativo: Aluminum’s compatibility with high-pressure applications makes it suitable for both Presta and Schrader valves. Its lightweight design is advantageous for mobile solutions, appealing to markets with a high demand for portable products.

Considerações para compradores internacionais: Compliance with ASTM standards for aluminum products is crucial. Buyers in regions like Germany may prioritize products with high corrosion resistance, while those in Africa might focus on cost-effectiveness.

Principais propriedades: Plastics such as polypropylene and ABS are commonly used for pump bodies due to their lightweight and moldability. They generally have a lower temperature resistance compared to metals, with a range of -20°C to 80°C.

Prós e contras: The primary advantage of plastic is its low cost and ease of manufacturing, allowing for mass production. However, plastic may not withstand high pressures as effectively as metals, limiting its use in professional-grade pumps.

Impacto no aplicativo: Plastic pumps are often used in entry-level products, making them accessible to emerging markets. However, their lower durability may lead to increased replacement rates, impacting long-term cost-efficiency.

Considerações para compradores internacionais: Buyers should ensure that the plastic used complies with international safety standards, such as REACH in Europe. In South America, the focus may be on affordability and availability.

Principais propriedades: Rubber is primarily used for seals and hoses in bike pumps due to its flexibility and excellent air retention properties. It can handle a temperature range of -30°C to 100°C.

Prós e contras: Rubber’s elasticity allows for effective sealing, preventing air leaks during inflation. However, rubber can degrade over time, especially when exposed to UV light or ozone, which may necessitate more frequent replacements.

Impacto no aplicativo: Rubber’s compatibility with various media makes it suitable for both Schrader and Presta valves. Its sealing capabilities are critical for maintaining pressure, making it essential in high-performance applications.

Considerações para compradores internacionais: Compliance with ASTM and ISO standards regarding rubber quality is vital. Buyers in the Middle East may prioritize products that can withstand extreme temperatures, while those in Europe may focus on environmental sustainability.

Principais propriedades: Steel is known for its high strength and durability, withstanding significant pressure and wear. It typically has a temperature rating similar to aluminum, making it suitable for various environments.

Prós e contras: Steel’s robustness makes it ideal for high-performance pumps, but it is heavier and more expensive than other materials. Additionally, steel is prone to rust if not properly coated or maintained.

Impacto no aplicativo: Steel is often used in the construction of track pumps, where durability is paramount. Its ability to handle high pressures makes it suitable for professional cycling applications.

Considerações para compradores internacionais: Buyers should look for products that adhere to DIN standards for steel quality. In regions with high humidity, such as parts of Africa, rust-resistant coatings may be a necessity.

| Material | Typical Use Case for how to inflate a bike tire with a pump | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Mini-pumps and high-end track pumps | Leve e resistente à corrosão | Higher cost and potential corrosion | Médio |

| Plástico | Entry-level pumps | Low cost and ease of manufacturing | Limited pressure resistance | Baixa |

| Borracha | Seals and hoses in pumps | Excellent sealing and air retention | Degrada-se ao longo do tempo com a exposição | Baixa |

| Aço | Heavy-duty track pumps | High durability and pressure tolerance | Heavier and prone to rust | Alta |

This analysis provides B2B buyers with actionable insights into the materials used in bike tire inflation pumps, aiding in informed decision-making based on performance, cost, and compliance with international standards.

The manufacturing process of bike pumps involves several critical stages that ensure the final product is both functional and reliable. Understanding these stages is crucial for B2B buyers seeking quality assurance in their procurement processes.

The first stage in manufacturing bike pumps is material preparation. This typically involves sourcing high-quality materials such as aluminum or steel for the pump body and durable plastics for the pump head. The choice of materials directly impacts the pump’s durability, weight, and performance.

Suppliers often conduct initial inspections of raw materials to ensure compliance with international standards. This is where the integrity of the manufacturing process begins, as subpar materials can lead to product failures and increased warranty claims.

Once materials are prepared, the forming process begins. Techniques such as extrusion for aluminum or steel and injection molding for plastic components are commonly employed. Extrusion allows for the creation of long, continuous shapes, which are then cut to size for various pump components.

For plastic parts, injection molding provides precision and allows for complex shapes, ensuring an airtight seal at the valve connection. This stage is critical as it determines the pump’s efficiency and user experience.

The assembly stage involves bringing together all individual components, including the cylinder, piston, and valve mechanism. Automated assembly lines are often used to ensure consistency and speed. However, manual assembly is also vital for components that require careful handling, such as the pump head, especially for Presta valves that are more delicate.

Illustrative image related to how to inflate a bike tire with a pump

Quality control during assembly includes checking for proper alignment and fit of components, ensuring that each pump can withstand the pressures required during operation.

The finishing stage may involve surface treatments such as anodizing aluminum components to enhance corrosion resistance or applying finishes that improve grip and aesthetics. This stage is essential for ensuring that pumps not only perform well but also meet the aesthetic expectations of end consumers.

Additionally, final inspection and testing occur during this stage to verify that all components function as intended.

Illustrative image related to how to inflate a bike tire with a pump

Quality assurance in the manufacturing of bike pumps is vital for establishing trust and reliability in the product. B2B buyers should be familiar with both international and industry-specific standards that govern quality assurance.

One of the most recognized international standards for quality management is ISO 9001. Compliance with ISO 9001 indicates that a manufacturer has implemented effective quality management systems, which can significantly reduce the risk of defects.

For pumps specifically, CE marking may be relevant, particularly for buyers in Europe. This certification assures that the product meets EU safety, health, and environmental protection standards.

In addition to ISO and CE, other industry-specific certifications might be relevant, such as those from the American Petroleum Institute (API) for pumps used in industrial applications. Understanding these certifications helps B2B buyers assess product quality and compliance with market regulations.

Quality control is a multi-faceted process that involves several checkpoints throughout the manufacturing stages. Each checkpoint serves a specific purpose in ensuring that the final product meets established standards.

Illustrative image related to how to inflate a bike tire with a pump

Controle de qualidade de entrada (IQC): This is the first line of defense against defects, where raw materials and components are inspected upon arrival. This stage ensures that only materials meeting specified standards are used in production.

Controle de qualidade durante o processo (IPQC): During manufacturing, IPQC involves monitoring processes and inspecting components as they are formed and assembled. This allows for immediate corrective actions if deviations from standards are detected.

Controle de qualidade final (FQC): After assembly, FQC checks the completed bike pumps for functionality, safety, and compliance with specifications. This includes pressure testing to ensure that pumps can withstand the required air pressure without leaks.

For B2B buyers, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are some actionable steps to consider:

Conducting supplier audits is an effective way to assess a manufacturer’s adherence to quality standards. These audits can be scheduled or random, providing insights into the supplier’s processes and compliance with ISO or other relevant standards.

Requesting quality control reports and certifications from suppliers can provide additional assurance. These documents should detail the outcomes of inspections and tests conducted throughout the manufacturing process.

Illustrative image related to how to inflate a bike tire with a pump

Engaging third-party inspection agencies can offer an unbiased evaluation of a supplier’s quality control systems. This step is particularly important for international buyers who may not have the resources to conduct on-site audits.

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific challenges that may arise in quality control.

Understanding the regulatory environment in different regions is crucial. For example, compliance with EU standards may differ significantly from those in South America. Buyers should ensure that their suppliers are familiar with the specific regulations applicable to their target markets.

Standard testing methods include pressure testing, durability testing, and performance evaluation. These tests help ensure that bike pumps can withstand the rigors of use while meeting safety and performance standards.

By focusing on these manufacturing and quality assurance processes, B2B buyers can make informed decisions when sourcing bike pumps, ensuring they procure high-quality products that meet market demands and regulatory requirements.

This guide serves as a practical checklist for B2B buyers looking to procure the necessary tools and equipment for inflating bike tires using a pump. Understanding how to effectively source and utilize these tools is crucial for ensuring optimal performance and safety in cycling operations, whether for retail, rental, or maintenance services.

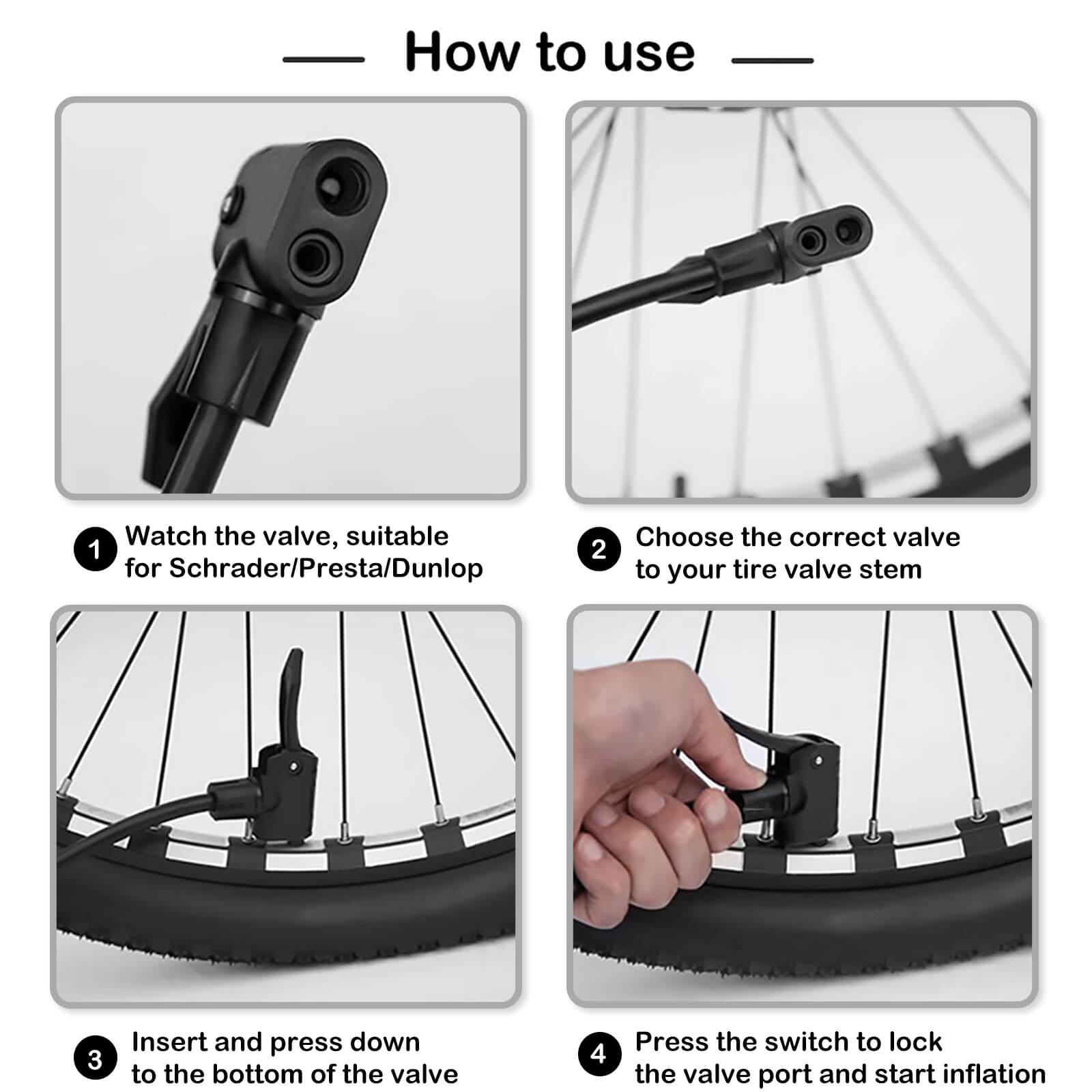

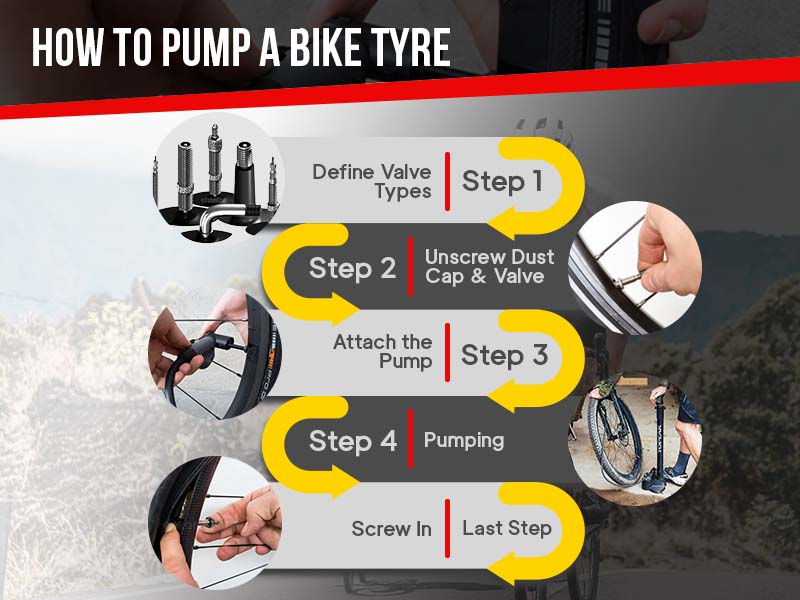

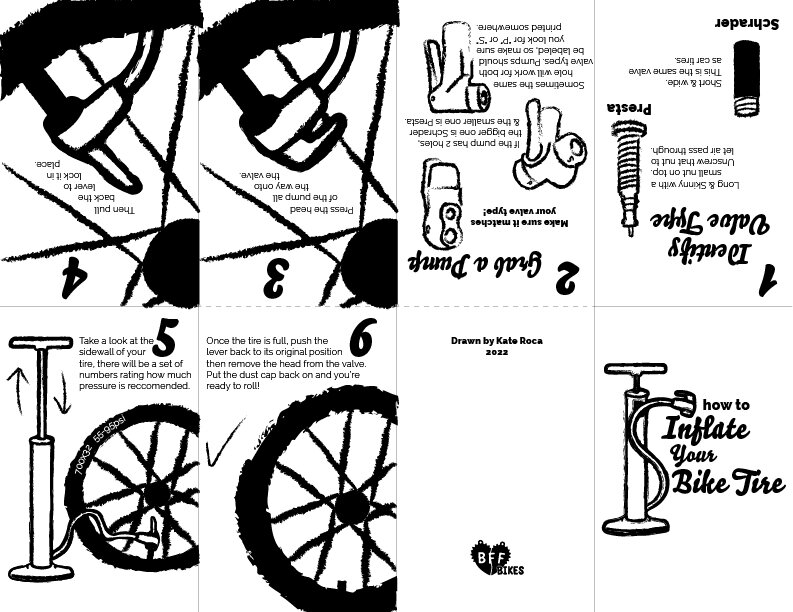

Understanding the different types of valves—Schrader, Presta, and Dunlop—is essential. Each valve type requires specific pump compatibility, which directly affects the inflating process. Ensure that your pump can accommodate both Schrader and Presta valves to maximize versatility.

Select a pump that meets your operational needs. Options include track pumps for stationary use and mini pumps for portability.

– Track Pumps: Ideal for workshops or retail settings, offering quick inflation and pressure gauges.

– Mini Pumps: Best for mobile applications, fitting conveniently into bike frames or pockets.

Illustrative image related to how to inflate a bike tire with a pump

Before finalizing a purchase, confirm that potential suppliers hold relevant certifications and adhere to industry standards. This ensures the reliability and safety of the equipment. Request documentation that demonstrates compliance with international quality and safety regulations.

Evaluate the durability of pumps and accessories. Robust construction is crucial for frequent use, especially in commercial settings. Look for products that come with warranties, as this reflects the manufacturer’s confidence in their quality and provides peace of mind for your investment.

If possible, request product demonstrations or samples to assess usability and effectiveness. This step allows you to gauge the performance of different pumps in real-world scenarios, helping you make informed decisions based on hands-on experience.

Explore supplementary products that enhance the inflation process. Accessories such as pressure gauges, valve adapters, and CO2 inflators can offer additional convenience and efficiency. Ensure compatibility with your chosen pump to streamline operations.

Prioritize suppliers who offer robust customer support and after-sales service. This is crucial for troubleshooting and maintenance, especially in a B2B context where downtime can lead to significant losses. Check for reviews or testimonials that highlight a supplier’s responsiveness and service quality.

By following this checklist, B2B buyers can make informed decisions when sourcing the tools necessary for inflating bike tires, ultimately enhancing operational efficiency and customer satisfaction.

When sourcing solutions for inflating bike tires, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materiais: The type and quality of materials used in pumps, such as plastics and metals, directly influence costs. High-quality materials that offer durability and performance may lead to higher initial costs but can reduce long-term expenses due to longevity.

Trabalho: Labor costs vary based on the production location. Countries with lower wage standards can reduce overall costs, but this may come at the expense of quality. Skilled labor is essential for ensuring that pumps are manufactured to specifications and can handle the rigors of regular use.

Custos indiretos de fabricação: This includes all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help mitigate these costs.

Ferramentas: The cost of tools and equipment required for production can be significant, especially for custom or specialized pump designs. Investing in high-quality tooling can improve production efficiency and product quality.

Controle de qualidade: Implementing strict QC measures is crucial for maintaining product reliability. However, this adds to costs. Buyers should evaluate suppliers based on their QC practices to ensure they meet industry standards.

Logística: Transportation and shipping costs can vary greatly depending on the origin and destination. Understanding Incoterms is vital for managing these costs effectively.

Margem: Suppliers typically add a profit margin to cover their operational costs and risks. Understanding industry norms for margins can help buyers negotiate better deals.

Several factors influence the pricing of bike tire inflation solutions, particularly for international B2B buyers.

Volume/MOQ: Suppliers often provide discounts for bulk purchases. Buyers should consider their inventory needs and negotiate minimum order quantities (MOQs) to maximize cost efficiency.

Especificações e personalização: Customized pumps or those with specialized features may incur additional costs. Buyers should assess whether the added features justify the price increase.

Materiais e certificações de qualidade: Products made from premium materials or those with specific certifications (e.g., ISO) often come at a premium. Buyers should weigh the benefits of quality against the budget.

Fatores do fornecedor: The reputation and reliability of suppliers can also affect pricing. Established suppliers may charge more due to their proven track record but may offer better service and support.

Incoterms: Understanding the terms of shipping and delivery can significantly impact the total cost. Buyers should negotiate Incoterms that minimize their liability and costs.

To optimize sourcing strategies, buyers should consider several actionable tips:

Negociação: Don’t hesitate to negotiate prices and terms with suppliers. Leverage bulk purchasing power and long-term relationships to secure better deals.

Eficiência de custo: Assess the total cost of ownership rather than just the purchase price. Consider factors like durability, warranty, and maintenance costs.

Nuances de preços para compradores internacionais: Be aware of currency fluctuations, tariffs, and taxes that may affect pricing when sourcing from international suppliers. Establishing clear payment terms can help mitigate risks.

Local Supplier Options: Explore local suppliers, especially in regions like Africa and South America, to reduce shipping costs and support local economies.

Auditorias de fornecedores: Conduct regular audits of suppliers to ensure they meet quality and performance standards. This can prevent costly issues down the line.

The prices associated with bike tire inflation solutions can fluctuate based on market conditions, supplier negotiations, and individual buyer specifications. It is advisable to request quotes from multiple suppliers to ensure competitive pricing while considering the quality and service levels offered.

Inflating a bike tire is a fundamental task for cyclists, and while using a pump is the most common method, there are several alternative solutions available. This analysis compares the traditional pump method against other viable options, helping B2B buyers evaluate the best approach for their specific needs.

| Aspecto de comparação | How To Inflate A Bike Tire With A Pump | Inflador de CO2 | Electric Air Compressor |

|---|---|---|---|

| Desempenho | Highly effective for regular use | Quick inflation, but temporary | Consistent pressure, efficient |

| Custo | Affordable, typically $20-$50 | Moderate, $10-$30 per cartridge | Higher initial cost, $50-$150 |

| Facilidade de implementação | Requires manual effort, but straightforward | Simple, requires no training | Easy to use, plug-and-play |

| Manutenção | Minimal, clean and check periodically | Requires cartridge replacement | Regular checks needed for functionality |

| Melhor caso de uso | Ideal for home use and maintenance | Best for emergencies or races | Suitable for frequent use, especially in workshops |

CO2 inflators offer a rapid inflation solution, utilizing compressed carbon dioxide cartridges to fill a tire quickly. Their compact size makes them ideal for cyclists on the go, especially in emergency situations. However, the primary downside is that the inflation is temporary; tires may deflate overnight as the gas escapes. Additionally, while the initial cost is low, ongoing expenses for cartridges can add up, making it a less sustainable option for regular use.

Electric air compressors provide a reliable and consistent method for inflating bike tires. They are particularly advantageous for users who have multiple bikes or require frequent inflation, such as in a workshop setting. The ease of use—simply plug in and press a button—adds to their appeal. However, the upfront cost can be significantly higher than traditional pumps, and they require access to a power source, which may not always be available in outdoor scenarios.

When selecting the right solution for inflating bike tires, B2B buyers should consider several factors, including frequency of use, budget constraints, and the specific environment where the inflation will take place. For regular maintenance in a controlled environment, a traditional pump or electric compressor may be the best choice. However, for those needing quick fixes on the go, a CO2 inflator could be more practical. Ultimately, understanding the unique requirements of their operations will guide buyers to make the most informed decision.

Illustrative image related to how to inflate a bike tire with a pump

When selecting pumps for bike tire inflation, understanding critical specifications can significantly influence purchasing decisions. Here are some essential properties to consider:

Grau do material

The construction material of the pump impacts durability and performance. Most high-quality pumps are made from aluminum or reinforced plastic. Aluminum pumps offer superior strength and longevity, making them ideal for heavy use in commercial settings. Reinforced plastics can be lighter and more portable, suitable for retail environments where ease of transport is essential.

Pressure Tolerance

This specification refers to the maximum air pressure a pump can deliver, typically measured in psi (pounds per square inch). Pumps designed for high-pressure applications (up to 160 psi) are essential for road bikes, while those with lower tolerances (up to 60 psi) suffice for mountain bikes. Understanding pressure tolerance helps businesses select the right pump for their target market, ensuring customer satisfaction and safety.

Valve Compatibility

Pumps must be compatible with different valve types: Presta, Schrader, and Dunlop. A versatile pump can cater to a broader range of bicycles, appealing to a diverse customer base. Ensuring compatibility is crucial for retailers and distributors to minimize returns and maximize customer convenience.

Pump Head Design

The design of the pump head, or chuck, can significantly affect usability. Options include push-on heads and threaded heads with locking mechanisms. A well-designed head ensures an airtight seal, reducing air loss during inflation. Understanding the nuances of pump head design allows B2B buyers to choose products that enhance user experience, thereby increasing sales.

Pressure Gauge Accuracy

An integrated pressure gauge is vital for monitoring inflation levels. Accuracy ratings can vary, with some gauges offering ±1 psi tolerance. Accurate gauges enable users to achieve optimal tire pressure, enhancing bike performance and safety. For manufacturers, offering pumps with reliable gauges can differentiate their products in a competitive market.

Weight and Portability

The weight of the pump is a critical factor, especially for mini-pumps intended for on-the-go repairs. Lightweight designs facilitate ease of transport, appealing to cyclists who prioritize convenience. For B2B buyers, selecting products that balance weight and functionality can enhance their offerings, meeting diverse customer needs.

Understanding industry jargon is essential for effective communication and negotiation in the B2B environment. Here are some common terms relevant to bike tire pumps:

OEM (fabricante original do equipamento)

An OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the bike pump industry, OEM relationships can lead to increased efficiency and reduced costs for businesses looking to offer branded products without the overhead of manufacturing.

MOQ (Quantidade mínima de pedido)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cash flow. Understanding MOQs helps businesses plan their purchases efficiently and avoid excess inventory.

RFQ (Request for Quotation, solicitação de cotação)

An RFQ is a document that solicits price quotations from suppliers for specific products. In the context of bike tire pumps, submitting an RFQ enables buyers to compare pricing, delivery times, and terms across multiple suppliers, fostering informed decision-making.

Incoterms (Termos Comerciais Internacionais)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers involved in international trade, ensuring clarity in agreements and minimizing disputes.

SKU (Unidade de Manutenção de Estoque)

An SKU is a unique identifier for each distinct product and service that can be purchased. In the context of bike pumps, using SKUs helps retailers track inventory efficiently, manage stock levels, and streamline order fulfillment processes.

Prazo de entrega

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is critical for B2B buyers as it affects inventory management and customer satisfaction. Shorter lead times can be a competitive advantage in the fast-paced bike retail market.

These technical properties and trade terms are crucial for B2B buyers in the bike tire pump industry. A solid grasp of these concepts can enhance decision-making, improve supplier relationships, and ultimately drive business success.

The bike tire inflation market is experiencing significant growth driven by increasing cycling popularity and a rising awareness of the health and environmental benefits of cycling. In regions like Africa, South America, the Middle East, and Europe, there is a noticeable trend toward urban cycling as cities invest in infrastructure to support bike-friendly transportation. This shift is also fueled by government initiatives promoting eco-friendly commuting options, especially in Europe and parts of South America.

Illustrative image related to how to inflate a bike tire with a pump

Additionally, technological advancements in pump designs, such as portable CO2 inflators and smart pumps equipped with pressure gauges, are reshaping the market. These innovations cater to the growing demand for convenience among cyclists who seek efficient and user-friendly solutions. B2B buyers are increasingly looking for suppliers that offer versatile products compatible with various valve types, including Presta and Schrader, to meet the diverse needs of consumers.

Supply chain dynamics are also evolving, with a focus on direct sourcing from manufacturers to mitigate costs and enhance supply chain transparency. International buyers are advised to establish relationships with manufacturers in key regions, such as Southeast Asia and Eastern Europe, where production costs are lower, yet quality remains high. Embracing e-commerce platforms for bulk purchasing is another trend that streamlines sourcing processes, allowing buyers to access a wider range of products quickly.

Sustainability has become a pivotal factor in sourcing strategies within the bike tire inflation sector. As consumers increasingly demand environmentally friendly products, B2B buyers must consider the environmental impact of the pumps they source. This includes evaluating the materials used in pump production, such as recycled plastics and metals, which can significantly reduce the carbon footprint of the manufacturing process.

Ethical sourcing practices are also gaining traction, with buyers prioritizing suppliers that adhere to fair labor practices and environmentally responsible production methods. Certifications such as ISO 14001 for environmental management and Fair Trade status can enhance a supplier’s credibility and appeal to eco-conscious consumers.

Furthermore, the market is seeing a rise in the adoption of ‘green’ certifications for products, which not only reflect a commitment to sustainability but also serve as a marketing tool. B2B buyers are encouraged to seek out manufacturers that offer products with these certifications, as they can provide a competitive edge in markets increasingly driven by consumer preferences for sustainability.

The evolution of bike tire inflation technologies can be traced back to the late 19th century with the advent of pneumatic tires, which revolutionized cycling by significantly improving ride comfort and performance. Early pumps were rudimentary, primarily using leather and wood. However, as cycling gained popularity, the demand for more efficient and reliable inflation methods led to innovations in pump design.

By the mid-20th century, the introduction of the Schrader and Presta valves standardized tire inflation across various bike types, simplifying the pumping process for cyclists. The development of portable mini pumps in the 1980s catered to the needs of cyclists on the go, allowing for quick fixes during rides. Today, advancements such as CO2 inflators and smart pumps with digital pressure gauges reflect a growing emphasis on convenience and precision, aligning with contemporary consumer expectations.

Understanding this historical context helps B2B buyers appreciate the technological advancements that have shaped the current market, informing their sourcing decisions for the future.

How do I solve a problem with my bike tire not inflating?

If your bike tire is not inflating, first check the compatibility between the pump and the valve type (Presta or Schrader). Ensure that the pump head is securely attached to the valve to create an airtight seal. If the tire remains deflated, inspect for punctures in the inner tube. If the tube is damaged, it will need to be replaced. Regular checks and maintenance can prevent these issues and ensure smooth operation.

What is the best pump type for inflating bike tires?

For general use, a track pump (or floor pump) is ideal as it provides efficiency and ease of use, particularly with a pressure gauge for accuracy. For on-the-go repairs, a mini pump is recommended for its portability, though it may require more effort. CO2 inflators can also be a quick solution for emergencies but are not a substitute for regular pumping needs. Consider the valve type compatibility when selecting a pump.

How often should I check and inflate my bike tires?

It is advisable to check your bike tire pressure before each ride. Regular checks can help maintain optimal performance and prevent issues like punctures or decreased ride quality. If storing a bike for an extended period, periodically check and inflate the tires to prevent damage to the inner tube. A quick squeeze can help gauge if they need air, or a dedicated tire pressure gauge can provide more accuracy.

What payment terms should I expect when purchasing bike pumps in bulk?

Payment terms can vary significantly among suppliers. Common arrangements include upfront payments, partial deposits followed by balance payments upon delivery, or net terms that allow for payment within a specified period post-delivery. Always clarify terms before finalizing orders, and consider using secure payment methods to protect your investment. Understanding local banking practices can also facilitate smoother transactions.

How can I vet suppliers for bike pumps and accessories?

To vet suppliers, check their industry reputation, customer reviews, and certifications. Request samples to assess product quality and compatibility with your needs. Additionally, inquire about their manufacturing processes and quality assurance measures. Engage in direct communication to gauge their responsiveness and willingness to accommodate your specific requirements, such as customization options or minimum order quantities (MOQ).

What customization options are available for bike pumps?

Many manufacturers offer customization options, including branding with your logo, color variations, and specific valve compatibility. Discuss your requirements with suppliers to see what options are available. Customization can enhance your brand visibility and cater to specific market preferences, particularly in diverse regions like Africa and South America, where local trends may influence design choices.

What are the logistics considerations for importing bike pumps?

Logistics considerations include shipping methods, customs regulations, and lead times. Choose a reliable shipping partner familiar with international trade and customs procedures to avoid delays. Be aware of import duties and taxes that may apply in your country. Establishing a clear communication line with your supplier can help streamline the logistics process, ensuring timely delivery of your products.

How do I ensure quality assurance when sourcing bike pumps internationally?

Quality assurance can be ensured by establishing clear specifications before ordering and requesting samples. Many suppliers provide quality certifications, which can be verified through third-party audits. Consider implementing a quality control inspection during production or before shipment to address any issues. Building a long-term relationship with your supplier can also foster better quality management practices.

Domínio: bikeradar.com

Registrado: 2006 (19 anos)

Introdução: Track pump: A home essential, offers a long flexible hose, a large camber for quick air transfer, and a base for weight support. Most feature a pressure gauge. Mini pump: Should ideally have a hose for easier use.

Domínio: reddit.com

Registrado: 2005 (20 anos)

Introdução: The user mentions having a “shitty pump” without a gauge, indicating a need for a better quality pump. A suggestion is made to get a decent pump with a gauge, specifically mentioning the Topeak Joe Blow as an example.

Domínio: wikihow.com

Registrado: 2004 (21 anos)

Introdução: Inflating bike tires requires identifying the valve type (Schrader or Presta), knowing the recommended PSI (printed on the tire’s side), and using the appropriate pump. For Schrader valves, a gas station pump can be used without an adapter, while Presta valves may require a Presta adapter for gas station pumps. The process involves unscrewing the valve cap, attaching the pump, monitoring the PSI, …

Domínio: dedhambike.com

Registrado: 2000 (25 anos)

Introdução: Bicycle tire pump (price range: $50 to $300); CO2 cartridge for on-the-go tire inflation; compatible with both Schrader and Presta valves; built-in gauge recommended for accurate pressure measurement; recommended tire pressure for road bikes: 80-100 PSI; mountain bikes: 30-50 PSI; gravel bikes: 25-40 PSI; tubeless setups allow lower pressures (low 20s to upper teens PSI).

In conclusion, effectively inflating a bike tire with a pump is a fundamental skill that significantly enhances cycling performance and safety. By understanding the different valve types and selecting the appropriate pump, businesses can ensure their products meet the diverse needs of cyclists across various regions. Strategic sourcing of high-quality pumps not only improves customer satisfaction but also reduces the risk of product returns due to compatibility issues or inefficiencies.

As international B2B buyers from Africa, South America, the Middle East, and Europe continue to expand their cycling markets, investing in reliable and versatile pumping solutions becomes paramount. This not only supports the growing demand for cycling as a mode of transportation and recreation but also fosters a culture of safety and reliability among users.

Looking forward, businesses should prioritize building partnerships with manufacturers that offer innovative pumping technologies and adaptable solutions to meet evolving consumer preferences. By doing so, you can position your company as a leader in the cycling supply chain, ready to cater to the needs of a global market. Embrace the opportunity to enhance your product offerings and drive growth in the cycling industry today.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.

Illustrative image related to how to inflate a bike tire with a pump