As the demand for portable auto air compressors continues to rise globally, B2B buyers face the challenge of sourcing reliable, high-performance units that meet diverse operational needs. Whether you are in Africa, South America, the Middle East, or Europe, understanding the nuances of portable auto air compressors is essential for making informed purchasing decisions. This comprehensive guide addresses critical aspects such as types of compressors, their various applications, supplier vetting processes, and cost considerations, all tailored to the international market landscape.

In today’s fast-paced automotive industry, the ability to quickly inflate tires or maintain optimal pressure is crucial for vehicle performance and safety. This guide empowers international buyers by providing actionable insights into the features and specifications that matter most, including pressure capacity, portability, and battery options. Furthermore, we delve into the importance of selecting reputable suppliers who adhere to quality standards, ensuring that your investment yields long-term value.

By navigating through this guide, you will be equipped with the knowledge to identify the right portable auto air compressor for your business needs, enhancing your operational efficiency while minimizing costs. Join us as we explore the dynamic world of portable auto air compressors and enable your organization to thrive in a competitive marketplace.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Cordless Tire Inflator | Battery-powered, compact, often with digital gauges | Automotive repair shops, roadside assistance | Prós: Portability, ease of use; Contras: Limited battery life, may require recharging. |

| 12V Plug-In Compressor | Connects to vehicle’s 12V outlet, usually larger | Fleet maintenance, service vehicles | Prós: Continuous power supply; Contras: Less portable, dependent on vehicle power. |

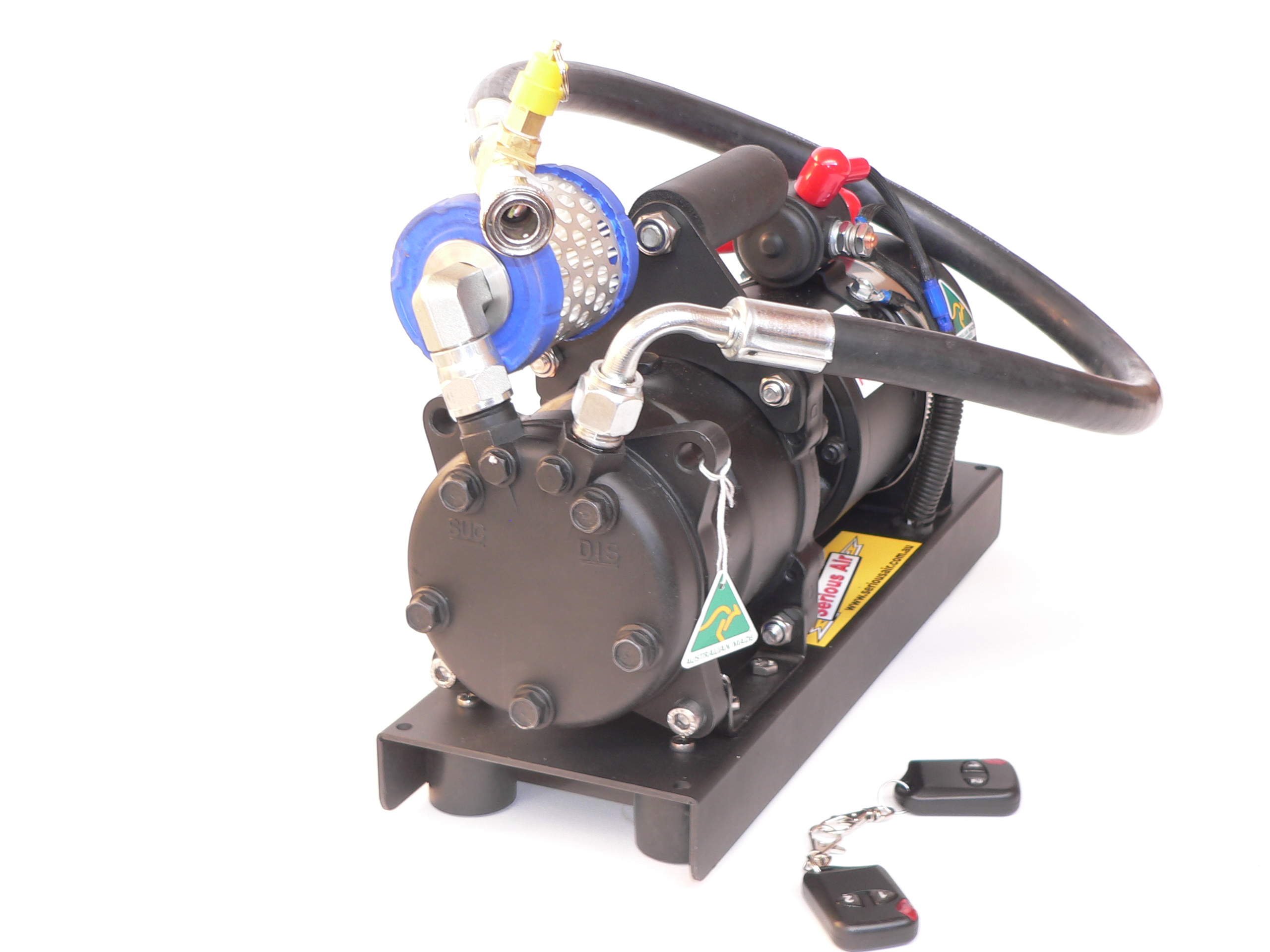

| Heavy-Duty Air Compressor | High PSI capacity, often bulky, connects to battery | Construction, agriculture, off-road vehicles | Prós: Fast inflation, suitable for larger tires; Contras: Less portable, requires battery access. |

| Mini Air Pump | Ultra-compact, often USB rechargeable | Personal use, small vehicle maintenance | Prós: Extremely portable; Contras: Limited power, may not inflate larger tires effectively. |

| Multi-Function Inflator | Includes additional features like lights and adapters | Recreational vehicle maintenance, home use | Prós: Versatile for various inflation needs; Contras: Can be bulkier, more expensive. |

Cordless tire inflators are battery-operated devices that offer significant portability and ease of use, making them ideal for automotive repair shops and roadside assistance services. They typically feature digital gauges for accurate pressure readings and can inflate tires quickly. B2B buyers should consider battery life and charging times, as these factors can affect operational efficiency during service calls.

Illustrative image related to portable auto air compressor

12V plug-in compressors connect directly to a vehicle’s power outlet, providing a continuous power supply for tire inflation. These compressors are commonly used in fleet maintenance and service vehicles, where consistent performance is critical. Buyers should evaluate the compressor’s hose length and ease of access to tires to ensure effective operation in various settings.

Heavy-duty air compressors are designed for high-pressure applications, making them suitable for construction and agricultural sectors. They can inflate larger tires quickly, which is essential for vehicles used in rugged environments. However, their bulkiness and need for direct battery connections may limit their portability. Buyers should assess the compressor’s PSI capacity and durability based on the intended use.

Mini air pumps are ultra-compact devices that can easily fit into glove compartments or backpacks, making them perfect for personal use or small vehicle maintenance. While they are highly portable, their power is limited, and they may not be capable of inflating larger tires effectively. B2B buyers should weigh the convenience of size against performance needs.

Multi-function inflators offer additional features like built-in lights, USB charging ports, and various adapters for different inflation needs. They are popular in recreational vehicle maintenance and home use due to their versatility. However, buyers should consider the potential trade-off between added features and overall portability, as these inflators can be bulkier and more expensive than simpler models.

| Indústria/Setor | Specific Application of Portable Auto Air Compressor | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Automotive Repair | Tire Inflation and Maintenance | Enhances vehicle safety and performance | Durability, ease of use, and power source compatibility |

| Transportation & Logistics | Fleet Maintenance | Reduces downtime and ensures operational efficiency | Size, weight, and power options for mobile use |

| Construção | Equipment and Tool Maintenance | Increases productivity by minimizing delays | Portability, PSI capacity, and battery life |

| Agricultura | Agricultural Equipment Maintenance | Ensures optimal performance of farming machinery | Robustness, multi-application capability, and price |

| Outdoor Recreation | Inflating Recreational Equipment | Enhances customer satisfaction and convenience | Compact design, ease of storage, and versatility |

In the automotive repair industry, portable auto air compressors are essential for tire inflation and maintenance. They allow technicians to quickly check and adjust tire pressure, which is crucial for vehicle safety and performance. Properly inflated tires improve fuel efficiency and extend tire life, reducing overall operating costs. Buyers in this sector should prioritize compressors that are durable, easy to operate, and compatible with various power sources, especially in regions with inconsistent electricity supply.

For businesses in transportation and logistics, maintaining a fleet of vehicles is critical for operational efficiency. Portable auto air compressors enable quick tire inflation and pressure checks, minimizing vehicle downtime. This is particularly important for long-haul trucking where delays can lead to significant financial losses. When sourcing compressors, logistics companies should consider the size and weight of the unit for easy transport, as well as its power options to ensure versatility across different vehicle types.

In the construction industry, portable auto air compressors are used for maintaining various equipment and tools, such as pneumatic nailers and impact wrenches. They help ensure that tools operate at peak performance, thereby increasing productivity and minimizing project delays. Buyers should look for compressors with robust construction to withstand harsh job site conditions, adequate PSI capacity for heavy-duty applications, and long battery life for extended use without frequent recharging.

Agricultural operations rely on portable auto air compressors for maintaining farm machinery, including tractors and irrigation systems. Regular inflation of tires and equipment ensures that machinery operates efficiently, which is vital for maximizing crop yields. Buyers in the agricultural sector should focus on compressors that are robust enough for outdoor use, capable of multi-application functionality, and reasonably priced to fit within budget constraints, especially in developing regions.

For businesses in the outdoor recreation sector, such as those renting out bicycles, boats, or inflatable equipment, portable auto air compressors are invaluable for quick inflation. They enhance customer satisfaction by ensuring that equipment is ready for use without delays. When sourcing these compressors, companies should prioritize compact designs that are easy to store and transport, as well as versatile units that can handle various inflatables to cater to diverse customer needs.

O problema: For B2B buyers operating in sectors like construction or agriculture, having a reliable means to inflate heavy-duty tires is crucial. Often, these tires are not only larger but also require higher pressure levels, typically around 80 psi. When working in remote locations, the lack of access to traditional air compressors can pose a significant challenge. A flat tire can lead to costly downtime, affecting project timelines and budgets. Moreover, many portable air compressors on the market may not have the capacity or power to handle such demands, leaving users frustrated and in a bind.

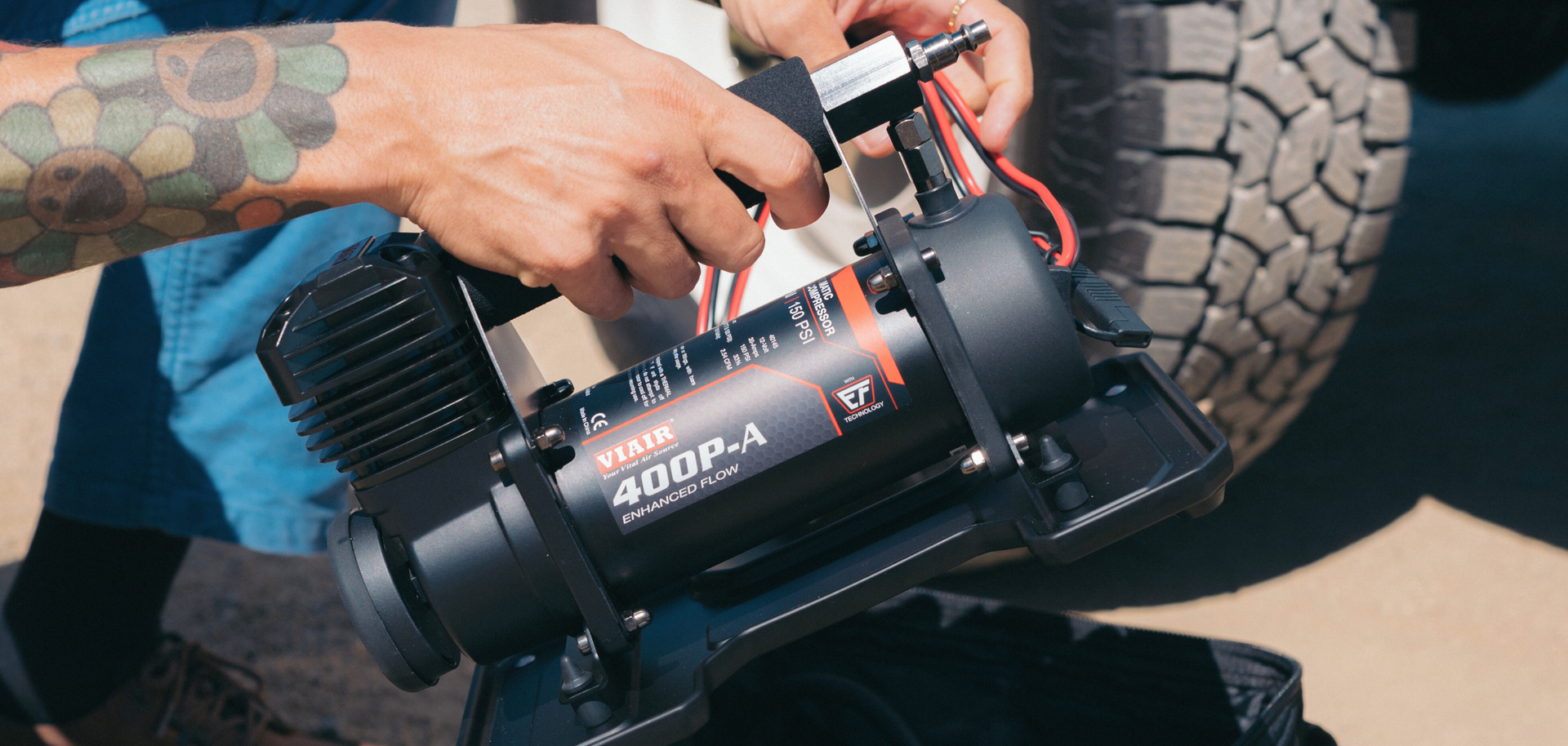

A solução: To effectively address this pain point, B2B buyers should prioritize sourcing portable air compressors specifically designed for heavy-duty applications. Look for models with a high PSI rating and robust construction that can withstand rugged environments. For example, compressors like the Viair 88P are built for larger tires and can quickly inflate them, making them ideal for off-road or remote work sites. Additionally, ensure that the compressor comes with battery clamps or a reliable power source that can handle extended use without overheating. It’s advisable to conduct thorough testing in your operating conditions before purchasing, ensuring that the chosen compressor can meet your inflation needs reliably.

O problema: Many portable air compressors come equipped with built-in pressure gauges, but not all of them are accurate. This can lead to over-inflation or under-inflation of tires, both of which can cause premature tire wear, blowouts, or even accidents. B2B buyers may find themselves facing increased operational costs due to damaged tires and additional maintenance needs. The risk of relying on a faulty gauge is particularly heightened in industries where safety is paramount, such as logistics and transportation.

A solução: To mitigate the risk of inaccurate pressure readings, B2B buyers should invest in portable air compressors with high-quality digital pressure gauges known for their precision. It’s also wise to complement the compressor with an independent, calibrated pressure gauge for double-checking tire pressure. When sourcing compressors, look for user reviews that specifically mention gauge accuracy and reliability. Training staff on the importance of checking tire pressure with both the compressor gauge and a backup gauge can further enhance safety and prevent costly mistakes. Additionally, consider implementing a regular maintenance schedule for both the compressor and tires to ensure optimal performance.

O problema: While cordless portable air compressors offer great convenience, their battery life can be a significant limitation, especially in B2B settings that require frequent use or inflation of multiple tires. Users may find that a single charge is insufficient to inflate all four tires, particularly if they have larger vehicles or are dealing with heavy-duty applications. This limitation can lead to interruptions in workflow and increased frustration among operators.

A solução: To overcome battery life limitations, B2B buyers should look for cordless models that have proven battery longevity or the ability to be powered by multiple sources. For instance, the AstroAI Cordless Tire Inflator is noted for its ability to inflate multiple tires on a single charge. When considering a purchase, inquire about the estimated number of tires that can be inflated per charge and how long the compressor takes to recharge. Additionally, having a backup power solution, such as a 12-volt adapter for vehicle use, can ensure continuity in operations. Establishing a routine for charging and maintaining the battery can also extend its life and reliability, making the compressor a dependable tool in your fleet.

When selecting materials for portable auto air compressors, it’s crucial to consider their properties, advantages, and limitations. This analysis focuses on four common materials: aluminum, steel, plastic, and rubber. Each material has unique characteristics that can significantly impact the performance and suitability of the compressor for various applications.

Aluminum is widely used in the construction of portable auto air compressors due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C (302°F) and a pressure rating that can accommodate typical automotive applications.

Illustrative image related to portable auto air compressor

Prós: Aluminum is durable yet lightweight, making it easier to transport. Its resistance to rust and corrosion enhances the longevity of the compressor, especially in humid or coastal environments.

Contras: The primary drawback is its higher cost compared to steel, which can affect the overall pricing of the compressor. Additionally, while aluminum is strong, it may not withstand impacts as well as steel.

Impacto no aplicativo: Aluminum is suitable for compressors intended for use in various climates, particularly in regions with high humidity, such as parts of Africa and South America.

Illustrative image related to portable auto air compressor

Considerações para compradores internacionais: Compliance with international standards like ASTM B221 for aluminum extrusions is essential. Buyers should also consider the availability of aluminum components in their region to avoid supply chain issues.

Steel is another common material used in portable auto air compressors, particularly for structural components. It offers high strength and can withstand higher pressure ratings, making it suitable for heavy-duty applications.

Prós: Steel’s durability makes it ideal for rugged use, and it is generally more cost-effective than aluminum. It can also be treated for corrosion resistance, extending its lifespan.

Contras: The primary limitation is its weight, which can hinder portability. Steel components may also require additional protective coatings to prevent rust, especially in humid environments.

Impacto no aplicativo: Steel is particularly beneficial for compressors designed for heavy-duty tasks, such as those used in the construction or agricultural sectors.

Considerações para compradores internacionais: Compliance with standards such as ASTM A36 for structural steel is crucial. Buyers in regions like the Middle East and Europe may also prefer galvanized steel for additional corrosion protection.

Plastic is often used for non-structural components of portable air compressors, such as housing and fittings. It offers a good balance of durability and weight, with temperature ratings typically around 70°C (158°F).

Prós: Plastic is lightweight and can be molded into complex shapes, allowing for innovative designs. It is also resistant to corrosion and can be produced at a lower cost.

Contras: The primary disadvantage of plastic is its lower strength compared to metals, which may limit its use in high-pressure applications. It can also degrade over time under exposure to UV light.

Illustrative image related to portable auto air compressor

Impacto no aplicativo: Plastic components are ideal for compressors designed for light-duty tasks, such as inflating sports equipment or small tires.

Considerações para compradores internacionais: Buyers should ensure compliance with standards like ISO 9001 for quality management systems. Additionally, they should verify the compatibility of plastic materials with local environmental regulations.

Rubber is primarily used for seals and hoses in portable air compressors. It has excellent flexibility and can handle a wide range of temperatures, typically from -40°C to 100°C (-40°F to 212°F).

Illustrative image related to portable auto air compressor

Prós: Rubber provides an excellent seal, preventing air leaks and ensuring efficient operation. It is also resistant to wear and tear, making it suitable for moving parts.

Contras: The main limitation of rubber is its susceptibility to degradation from ozone and UV exposure, which can affect its longevity.

Impacto no aplicativo: Rubber is crucial in applications where flexibility and sealing are paramount, such as in compressors used in varying climates.

Illustrative image related to portable auto air compressor

Considerações para compradores internacionais: Buyers should look for compliance with standards like ASTM D2000 for rubber products. In regions with extreme weather, such as parts of Africa and the Middle East, selecting high-quality rubber compounds is essential.

| Material | Typical Use Case for portable auto air compressor | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Lightweight portable compressors | Corrosion resistance and lightweight | Higher cost than steel | Médio |

| Aço | Heavy-duty compressors for construction | Alta resistência e durabilidade | Heavier and may require rust protection | Baixa |

| Plástico | Housing and fittings for light-duty compressors | Econômico e leve | Lower strength and UV degradation | Baixa |

| Borracha | Seals and hoses in compressors | Excellent sealing and flexibility | Susceptible to ozone and UV degradation | Médio |

This material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on application needs and regional considerations.

The manufacturing of portable auto air compressors involves several critical stages, each designed to ensure the production of high-quality, reliable products. These stages typically include material preparation, forming, assembly, and finishing.

Illustrative image related to portable auto air compressor

Preparação de materiais

The first step involves sourcing high-quality raw materials. Manufacturers often use durable metals and plastics, which are essential for the compressor’s longevity and performance. Materials are selected based on their resistance to corrosion and pressure, with aluminum and high-grade steel being popular choices. Once sourced, materials undergo inspection for quality assurance, ensuring they meet specified standards before moving to the next stage.

Formação

The forming stage encompasses various techniques, including casting, machining, and molding. For metal components, processes like die casting or CNC machining are common. These methods allow precise shaping of parts such as the compressor housing, cylinder, and other critical components. Plastics may be injection molded to create lightweight components that reduce the overall weight of the compressor, enhancing portability.

Montagem

After forming, components are brought together in an assembly line. This stage may involve both manual and automated processes, where parts are fitted together with attention to detail. Manufacturers may use robotic systems for tasks requiring high precision, such as the installation of valves and pressure gauges. Quality checks are often integrated into the assembly line to catch defects early.

Acabamento

The final stage involves surface treatments and final inspections. This may include painting, powder coating, or anodizing to enhance aesthetics and protect against environmental factors. Finishing processes also ensure that the compressor meets aesthetic standards, which can be an important selling point in B2B markets. Post-finishing, compressors undergo a final inspection before packaging, ensuring they are ready for distribution.

Quality control (QC) is critical in ensuring that portable auto air compressors meet safety, reliability, and performance standards. Manufacturers typically adhere to international standards such as ISO 9001, which emphasizes a systematic approach to managing quality.

International Standards and Certifications

ISO 9001 is a widely recognized standard that outlines the criteria for a quality management system. Compliance signifies that a manufacturer consistently provides products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for oil and gas applications may be relevant, depending on the product’s intended use.

Pontos de verificação de controle de qualidade

Quality control involves multiple checkpoints throughout the manufacturing process:

B2B buyers must ensure that their suppliers adhere to stringent quality control practices. Here are several strategies to verify QC processes:

Auditorias de fornecedores

Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. An audit typically involves reviewing documentation, inspecting facilities, and assessing compliance with international standards.

Relatórios de qualidade

Requesting quality reports from suppliers can offer transparency into their QC processes. These reports may include information on defect rates, testing results, and certifications obtained. Regularly reviewing these reports can help buyers identify any quality trends or issues.

Inspeções de terceiros

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These services can conduct inspections at various stages of production, ensuring adherence to agreed-upon specifications and standards.

When sourcing portable auto air compressors from international suppliers, especially in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of several QC nuances:

Regional Compliance Requirements

Different regions may have specific compliance and certification requirements. For example, products sold in Europe must meet CE certification standards, which may not be necessary in other markets. Understanding these requirements is crucial to avoid potential legal issues and ensure market acceptance.

Cultural and Economic Factors

Cultural differences can influence manufacturing practices and quality expectations. B2B buyers should consider the economic stability of the supplier’s country, as this can affect the consistency of quality and adherence to international standards.

Language Barriers

Language differences can pose challenges in communication regarding quality specifications and standards. Ensuring that all parties have a clear understanding of quality requirements is essential for successful collaboration.

By understanding the manufacturing processes and quality assurance measures for portable auto air compressors, B2B buyers can make informed decisions, ensuring they source reliable and high-quality products for their markets. These insights not only enhance product reliability but also contribute to building long-term supplier relationships based on trust and quality assurance.

This guide provides a comprehensive checklist for B2B buyers looking to procure portable auto air compressors. With the rising demand for efficient, reliable, and user-friendly inflators in various markets, understanding the essential features and supplier considerations is critical for making informed purchasing decisions.

Establishing clear technical specifications is fundamental to ensure the portable auto air compressor meets your business needs. Consider factors such as maximum pressure (psi), inflation speed, power source (cordless or corded), and size/weight for portability. These specifications will help you narrow down options that are suitable for your intended use, whether for personal vehicles, commercial fleets, or heavy-duty applications.

Understanding current market trends and demand patterns is crucial for effective sourcing. Analyze market data to identify which features are most sought after in different regions, such as Africa, South America, and Europe. For instance, compact designs may be more popular in urban areas, while heavy-duty models might be preferred for rural or off-road applications.

Before committing to a purchase, thoroughly vet potential suppliers. Review company profiles, certifications, and customer testimonials to gauge their reliability and product quality. Additionally, ask for case studies or references from businesses in similar sectors to gain insights into their performance and service reliability.

Requesting product samples is a vital step in the procurement process. This allows you to evaluate the compressor’s performance, usability, and durability firsthand. Testing the product under real-world conditions will help you determine if it meets your defined specifications and operational needs.

Illustrative image related to portable auto air compressor

Pricing is a crucial factor in the procurement process. Gather quotes from multiple suppliers to compare pricing models, including bulk purchase discounts or payment terms. Evaluate the total cost of ownership, which includes maintenance and potential replacement costs over time.

After-sales support is critical for ensuring long-term satisfaction and operational efficiency. Confirm the availability of customer service and technical support from the supplier. A solid warranty can provide peace of mind and protection against defects or performance issues.

Once all evaluations are complete, finalize your purchase agreement with the selected supplier. Ensure all terms discussed are documented, including pricing, delivery schedules, and after-sales support commitments. A well-defined contract will help prevent misunderstandings and ensure a smooth procurement process.

By following this checklist, B2B buyers can navigate the complexities of sourcing portable auto air compressors, ensuring they select products that meet their operational requirements while fostering reliable supplier relationships.

When sourcing portable auto air compressors, understanding the cost structure is critical for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

Illustrative image related to portable auto air compressor

Materiais: The cost of raw materials like plastic, metal, and electronic components can vary significantly based on quality and availability. High-quality materials not only enhance durability but also impact the final product’s price.

Trabalho: Labor costs differ by region, influenced by local wage standards and skill levels. In emerging markets like Africa and South America, lower labor costs may reduce overall expenses, but this could also affect product quality.

Custos indiretos de fabricação: This includes fixed and variable costs associated with production, such as utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can help mitigate these costs.

Ferramentas: Initial tooling costs for molds and dies can be substantial, especially for customized products. Buyers should consider these costs in relation to their projected order volumes.

Controle de qualidade (QC): Investment in QC processes is essential to ensure product reliability. Companies that prioritize QC may incur higher costs upfront, but this often results in reduced warranty claims and increased customer satisfaction.

Logística: Transportation and warehousing costs can fluctuate based on geographical location and shipping methods. International shipping, particularly to regions like the Middle East or Europe, necessitates careful planning to manage costs effectively.

Margem: Supplier margins will vary based on market demand, competition, and the supplier’s operational efficiency. Understanding these margins can provide insight into potential negotiation points.

Several factors can influence the pricing of portable auto air compressors, particularly for B2B buyers looking to optimize their sourcing strategy.

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact unit costs. Higher volume orders typically yield lower prices per unit due to economies of scale.

Especificações e personalização: Customized products or unique specifications may incur additional costs. Buyers should clearly outline their requirements to receive accurate pricing.

Materiais e certificações de qualidade: Premium materials and certifications (e.g., ISO, CE) can elevate costs but may be necessary for compliance and market competitiveness.

Fatores do fornecedor: The supplier’s reputation, experience, and reliability can influence pricing. Established suppliers may charge more for their perceived value, while new entrants might offer lower prices to capture market share.

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is crucial for calculating total landed costs. Incoterms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect overall expenses.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiation and cost-efficiency strategies are essential.

Leverage Volume Discounts: Negotiate based on potential order volumes. Suppliers are often willing to offer better pricing for larger commitments.

Considere o custo total de propriedade (TCO): Evaluate not just the purchase price but also maintenance, operational costs, and potential downtime. A higher initial investment may yield lower long-term costs.

Explorar vários fornecedores: Diversifying suppliers can create competitive pressure, potentially leading to better pricing and terms. Always assess suppliers based on quality, not just cost.

Esteja ciente das nuances dos preços: International buyers should understand local market conditions, currency fluctuations, and import duties that may affect pricing. This awareness can lead to more informed purchasing decisions.

Request Samples and Prototypes: Before committing to large orders, ask for samples to evaluate quality and performance. This step can prevent costly mistakes later on.

Sourcing portable auto air compressors requires careful consideration of cost components and pricing influences. By understanding these factors and employing strategic negotiation tactics, B2B buyers can optimize their sourcing decisions and achieve better value for their investments. Keep in mind that prices can vary widely based on the aforementioned elements, and it is advisable to request detailed quotations from suppliers to gauge the market accurately.

Illustrative image related to portable auto air compressor

When considering the best solutions for tire inflation, businesses must evaluate not just the portable auto air compressor, but also several alternative technologies that serve similar purposes. Understanding these alternatives helps buyers make informed decisions based on performance, cost, and usability.

| Aspecto de comparação | Portable Auto Air Compressor | Electric Tire Inflator | Manual Foot Pump |

|---|---|---|---|

| Desempenho | High PSI capability; quick inflation for multiple tires | Moderate PSI; slower inflation speed | Low PSI; manual effort required |

| Custo | $40 – $90 | $30 – $70 | $10 – $30 |

| Facilidade de implementação | Plug-and-play; often battery-powered | Simple plug-in; limited by power source | Requires physical effort; portable |

| Manutenção | Baixa; é necessária uma limpeza ocasional | Low; check for electrical issues | Minimal; clean and store properly |

| Melhor caso de uso | Ideal for emergencies and regular maintenance | Suitable for light vehicles and occasional use | Perfect for bicycles and low-pressure needs |

Electric tire inflators are compact devices that plug into a vehicle’s power outlet or are battery-operated. They provide a moderate level of PSI and are particularly useful for light vehicles. The pros of electric inflators include ease of use and portability. However, they may lack the power required for larger tires and can be slower than portable auto air compressors. Their reliance on a power source can limit their utility in remote areas or during power outages.

Manual foot pumps are the most basic and cost-effective option for tire inflation. They require no power source and are lightweight, making them easy to carry. However, they demand physical effort, which may not be feasible for all users. Their inflation capability is generally lower than that of portable auto air compressors, making them less suitable for emergency situations or when quick inflation is necessary. While their maintenance is minimal, the manual effort required can be a significant drawback for users looking for convenience.

Selecting the right tire inflation solution depends on your specific requirements. If your business operates in environments where rapid inflation and high PSI capabilities are crucial—such as automotive repair shops or logistics companies—a portable auto air compressor is likely the best choice. For lighter vehicles or occasional use, an electric tire inflator may suffice, offering a balance of convenience and performance. Conversely, if cost is a primary concern and the application is limited to lower-pressure needs, a manual foot pump could be adequate. Ultimately, understanding the unique demands of your operations will guide you in choosing the most effective tire inflation solution.

When considering portable auto air compressors, understanding their technical specifications is essential for informed purchasing decisions. Here are some critical properties that B2B buyers should evaluate:

Illustrative image related to portable auto air compressor

Maximum pressure, measured in pounds per square inch (PSI), indicates the highest air pressure the compressor can achieve. This is crucial for applications requiring high tire pressures, such as those found in trucks or SUVs. A compressor with a higher PSI rating can accommodate a wider range of vehicles and applications, making it versatile for different markets.

The duty cycle refers to the amount of time a compressor can operate before needing a rest. It is typically expressed as a percentage (e.g., 50% duty cycle means it can run for 5 minutes and must rest for 5 minutes). A higher duty cycle is beneficial for commercial applications where prolonged use is necessary, ensuring efficiency and reducing downtime.

Portable air compressors can be powered by batteries, 12-volt outlets, or standard electrical outlets. The choice of power source affects portability and usability in various environments. For example, battery-powered models are ideal for remote areas, while those that plug into a vehicle’s outlet may offer higher performance but require proximity to the vehicle.

The airflow rate, measured in cubic feet per minute (CFM), indicates how quickly the compressor can inflate a tire or other objects. A higher CFM rating allows for faster inflation, which is particularly valuable in commercial settings where time is critical. Understanding the airflow rate helps businesses match compressors to their specific needs.

The weight and dimensions of a portable air compressor impact its portability and ease of storage. Lighter, more compact models are preferable for consumers who require mobility, such as roadside assistance providers. For B2B buyers, evaluating these dimensions can help determine the best fit for their logistics and storage constraints.

The materials used in the construction of the compressor influence its durability and reliability. High-quality materials, such as reinforced plastics and metal alloys, can withstand harsh environments and prolong the lifespan of the equipment. For B2B buyers, investing in robust compressors reduces long-term replacement costs and enhances service reliability.

Familiarity with industry terminology can streamline communication and negotiations in the B2B space. Here are some key terms to know:

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for buyers looking to source high-quality components or complete systems.

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is crucial for B2B buyers as it affects purchasing decisions, inventory management, and pricing strategies. Knowing the MOQ helps businesses plan their budgets and stock levels accordingly.

An RFQ is a document issued by a buyer to solicit pricing information from suppliers. This process is essential for comparing prices and terms from multiple vendors, ensuring that businesses receive competitive offers and can make informed purchasing decisions.

Illustrative image related to portable auto air compressor

Incoterms are a set of international trade rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms helps buyers navigate international transactions, ensuring clarity on delivery responsibilities and costs.

The warranty period is the time frame during which a manufacturer guarantees the product against defects. For B2B buyers, a longer warranty period often indicates confidence in product quality and can reduce the risk associated with purchasing decisions.

By grasping these technical properties and trade terms, B2B buyers can make informed choices when sourcing portable auto air compressors, ultimately enhancing their operational efficiency and profitability.

The portable auto air compressor market is experiencing robust growth, driven by increasing vehicle ownership, a rise in outdoor recreational activities, and growing awareness of vehicle maintenance. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are keenly observing these trends. The demand for compact and efficient inflators is rising, particularly for those designed for diverse applications, from passenger vehicles to larger trucks and SUVs.

Emerging technologies in the sector include advancements in battery efficiency, allowing for longer operational times and faster inflation rates. Cordless models are gaining traction, appealing to users looking for convenience and portability. Additionally, the integration of smart features such as digital pressure gauges and automatic shut-off mechanisms enhances user experience, making these tools more reliable and user-friendly.

Illustrative image related to portable auto air compressor

Sourcing trends indicate a shift towards suppliers who can provide high-quality products at competitive prices, emphasizing the importance of robust supply chain management. B2B buyers are increasingly looking for manufacturers who can adapt to fluctuating market demands and offer customization options. As the market evolves, understanding these dynamics will be crucial for international buyers seeking to make informed purchasing decisions.

Sustainability has become a pivotal concern in the portable auto air compressor sector, influencing both sourcing practices and product development. Environmental impacts associated with manufacturing and disposing of air compressors are prompting buyers to prioritize ethical sourcing. B2B buyers are increasingly evaluating suppliers based on their environmental practices, such as waste management, energy consumption, and carbon footprint.

The demand for “green” certifications and materials is on the rise, with buyers seeking products that minimize environmental impact. This includes the use of recyclable materials and energy-efficient components in air compressor manufacturing. Suppliers who can demonstrate compliance with international environmental standards and offer sustainable product options are likely to gain a competitive edge.

Additionally, transparency in the supply chain is becoming essential. Buyers are looking for suppliers who can provide detailed information about their sourcing processes and the sustainability of their materials. This focus not only supports environmental goals but also aligns with the growing consumer preference for ethically sourced products, ultimately benefiting brands that prioritize sustainability in their operations.

The evolution of portable auto air compressors dates back several decades, transitioning from bulky, stationary units to compact, versatile models designed for ease of use. Initially, these devices were primarily used in commercial settings, but advancements in technology have made them accessible and essential for everyday consumers and businesses alike.

In recent years, the market has shifted towards lightweight, battery-operated models that cater to the growing demand for convenience. Features such as built-in LED lights, multiple nozzle attachments, and digital displays have also become standard, enhancing functionality and user experience.

For B2B buyers, understanding this evolution is crucial, as it provides insights into product reliability and advancements in technology that can influence purchasing decisions. As manufacturers continue to innovate, buyers must stay informed about the latest developments to ensure they are sourcing the most efficient and effective products available. This knowledge not only aids in selecting the right products but also fosters strategic partnerships with suppliers who are aligned with the latest industry trends.

How do I choose the right portable auto air compressor for my business needs?

Choosing the right portable auto air compressor involves assessing your specific requirements. Consider factors such as the maximum PSI needed for your applications, the size and weight for portability, and the power source (battery or plug-in). Evaluate the inflator’s speed and efficiency, particularly if you handle multiple vehicles or flat tires frequently. Additionally, look for features like built-in pressure gauges, automatic shutoff, and adaptability for various inflation tasks. Reading reviews and testing different models can also help determine the best fit for your operations.

What are the key features to look for in a portable auto air compressor?

When sourcing a portable auto air compressor, prioritize features such as maximum PSI capacity, battery life, and charging options. A digital pressure gauge for accuracy and an automatic shutoff function can enhance user experience. Compact design is essential for easy storage and transport. Additional functionalities like built-in lights, USB charging ports, and various nozzle adapters for different inflation tasks can also be beneficial. Ensure the compressor is durable and has a warranty to safeguard your investment.

How do I ensure the quality of the portable auto air compressors I am sourcing?

To ensure quality, vet suppliers thoroughly by checking their certifications, production processes, and quality control measures. Request samples for testing and assess their performance against your requirements. Look for manufacturers that adhere to international standards such as ISO and CE certifications. Additionally, inquire about their warranty policies and after-sales support to address any potential issues. Regular communication and visits to the manufacturing site can further enhance trust in the supplier’s quality assurance.

What are the typical minimum order quantities (MOQ) for portable auto air compressors?

Minimum order quantities (MOQ) can vary significantly based on the supplier and the specific model of the compressor. Generally, MOQs range from 50 to 500 units for bulk purchases. When negotiating with suppliers, clarify if MOQs can be adjusted based on your business needs or if they offer tiered pricing for larger orders. Understanding the supplier’s production capacity and flexibility can help you secure a favorable arrangement that aligns with your inventory management.

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary, but common practices include a 30% deposit before production and the remaining 70% before shipping. Some suppliers may offer letter of credit or payment through platforms like PayPal or Alibaba for added security. Discussing payment methods early in negotiations is crucial to avoid misunderstandings. Ensure that you understand any additional costs such as shipping, customs duties, and taxes that may apply when importing goods to your country.

How can I handle logistics when importing portable auto air compressors?

Handling logistics involves coordinating shipping, customs clearance, and delivery. Choose reliable freight forwarders with experience in handling similar products. They can assist with documentation, customs regulations, and transportation options. Consider shipping methods (air vs. sea) based on urgency and budget. Ensure that your suppliers provide the necessary paperwork, including commercial invoices and packing lists. Familiarize yourself with local import regulations to avoid delays and additional costs upon arrival.

What customization options are available for portable auto air compressors?

Many manufacturers offer customization options, including branding, color, and features tailored to your market. Discuss your specific requirements with suppliers to explore possibilities such as adding logos, modifying design specifications, or including additional accessories. Customization may affect lead times and pricing, so it’s essential to clarify these aspects early in the negotiation process. Ensure that any agreed-upon modifications are documented in the contract to prevent misunderstandings.

What should I consider regarding warranties and after-sales service for compressors?

Warranties and after-sales service are critical when sourcing portable auto air compressors. Review the warranty period offered by the manufacturer, typically ranging from one to three years, and understand what it covers (parts, labor, etc.). Inquire about the process for addressing defects or issues post-purchase, including return policies and repair services. A responsive customer service team can significantly enhance your experience, so ensure the supplier has established support channels for international buyers.

Domínio: automoblog.com

Registrado: 2004 (21 anos)

Introdução: Best Portable Tire Inflators for 2025: 1. Slime Cordless Tire Inflator – Easy to use and stow. 2. 20V Avid Power Cordless Tire Inflator – Drill-style design and carrying case. 3. Fanttik X8 Apex – Overall good quality and functionality, features a flashlight and USB outlet. 4. DeWalt 20V MAX Tire Inflator – Robust and powerful with four memory settings. 5. Milwaukee M18 Cordless Tire Inflator – Du…

Domínio: avidpowertool.com

Registrado: 2018 (7 anos)

Introdução: [{‘name’: ‘Avid Power Tire Inflator’, ‘type’: ‘Portable Air Compressor’, ‘features’: ‘Triple Power Source, Inflation & Deflation Modes, Dual Powerful Motors’, ‘color’: ‘Orange’, ‘price’: ‘$79.99’}, {‘name’: ‘AVID POWER 12V Tire Inflator’, ‘type’: ‘Portable Air Compressor’, ‘features’: ’60 PSI Display Gauge, LED Light, Compact, Lightweight’, ‘color’: ‘Red’, ‘price’: ‘$21.99’}, {‘name’: ‘AVID POWER …

As the demand for portable auto air compressors continues to rise, strategic sourcing becomes a vital process for B2B buyers, especially in dynamic markets like Africa, South America, the Middle East, and Europe. Key takeaways highlight the importance of selecting high-quality, reliable products that meet diverse regional needs, from compact inflators suitable for urban environments to robust models designed for heavy-duty use. Understanding the nuances of product specifications, such as PSI ratings and portability, empowers buyers to make informed decisions that enhance customer satisfaction and operational efficiency.

Moreover, investing in portable air compressors can lead to significant cost savings by improving vehicle maintenance and extending tire lifespan. As international markets evolve, suppliers that prioritize innovation and sustainability will likely gain a competitive edge.

In this context, B2B buyers are encouraged to leverage strategic sourcing practices to align with reputable manufacturers and adapt to emerging trends. As we move forward, the potential for growth in this sector is substantial, making it an opportune time to explore partnerships that can drive mutual success. Prioritize quality, efficiency, and adaptability in your sourcing strategy to capitalize on the burgeoning demand for portable auto air compressors.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.