In the dynamic landscape of automotive maintenance, sourcing a reliable manual air pump for cars presents a unique challenge for international B2B buyers. As vehicle ownership continues to rise in regions such as Africa, South America, the Middle East, and Europe, the demand for efficient and dependable inflation solutions has never been greater. Manual air pumps not only serve as a cost-effective alternative to electric inflators but also provide essential support in remote areas where power sources may be limited.

This comprehensive guide delves into the various types of manual air pumps available, their specific applications across different automotive needs, and critical insights into supplier vetting processes. We will explore essential factors such as pricing structures, quality standards, and the latest technological advancements in pump design, equipping buyers with the knowledge needed to make informed purchasing decisions.

By addressing the unique challenges faced by B2B buyers—such as fluctuating market demands and regional supply chain issues—this guide empowers businesses to navigate the global market effectively. Whether you are a distributor looking to expand your product offerings or a retailer aiming to meet the needs of your customers, understanding the nuances of manual air pumps is crucial for success in today’s competitive environment.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Bomba manual | Manual operation, lightweight, portable | Emergency kits, small vehicle fleets | Prós: Cost-effective, easy to use. Contras: Trabalho intensivo, inflação mais lenta. |

| Foot Pump | Operated by foot, higher PSI capacity | Workshops, garages | Prós: Faster inflation, hands-free operation. Contras: Bulkier, requires more space. |

| Dual Action Pump | Inflates on both push and pull strokes | Sports equipment, bicycles | Prós: Efficient air delivery, versatile. Contras: May require more maintenance. |

| Mini Compressor | Compact design, manual or electric options available | Automotive service, roadside assistance | Prós: Quick inflation, portable. Contras: Limited pressure for larger tires. |

| Pressure Gauge Pump | Integrated pressure gauge for precise inflation | Tire maintenance, automotive repair | Prós: Accurate readings, prevents over-inflation. Contras: Slightly higher cost. |

Hand pumps are a staple in manual air pump options, favored for their simplicity and portability. Typically made from durable materials, they require no electricity, making them ideal for remote locations or emergency situations. B2B buyers should consider the hand pump’s inflation rate and ease of use, especially for teams that may need to operate them frequently. While they are cost-effective, the manual effort required can be a drawback in high-demand scenarios.

Foot pumps utilize a foot pedal to generate air pressure, allowing for hands-free operation. They can achieve higher PSI levels compared to hand pumps, making them suitable for inflating larger tires quickly. This type of pump is commonly used in workshops and garages where efficiency is key. For B2B buyers, the space requirement and weight of foot pumps should be evaluated, especially in mobile service units.

Dual action pumps are designed to inflate tires on both the push and pull strokes, significantly enhancing efficiency. These pumps are versatile and can be used for a variety of applications, including sports equipment and bicycle tires. B2B buyers should assess the durability and maintenance requirements of dual action pumps, as their complexity may lead to higher upkeep. Their efficiency makes them a valuable addition to any toolkit.

Mini compressors are compact and can be manual or electric, offering quick inflation capabilities. They are particularly useful in automotive services and roadside assistance, where time is of the essence. B2B buyers should consider the power source and pressure capabilities when selecting mini compressors, as some may not be suitable for larger tires. Their portability is a significant advantage for businesses that operate in various locations.

Pressure gauge pumps come equipped with built-in pressure gauges, allowing users to monitor tire pressure accurately during inflation. This feature is crucial for tire maintenance and automotive repair, as it helps prevent over-inflation and ensures optimal tire performance. For B2B buyers, the investment in a pressure gauge pump can lead to better customer satisfaction and reduced tire wear. However, the initial cost may be higher than standard pumps, making it essential to weigh the long-term benefits.

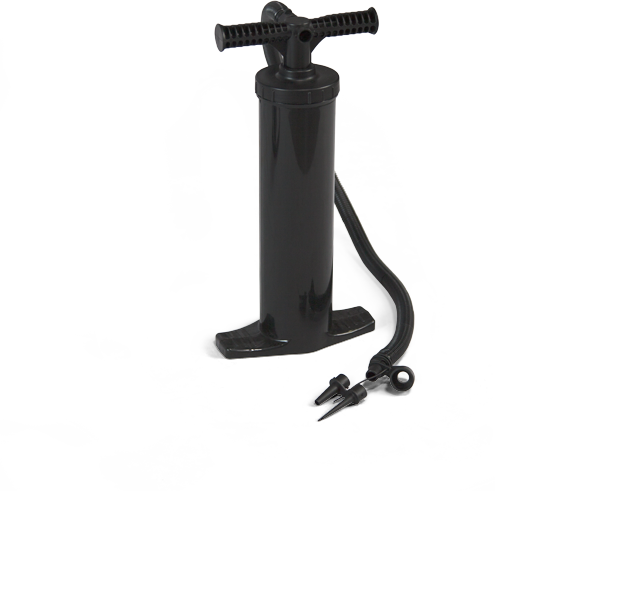

Illustrative image related to manual air pump for car

| Indústria/Setor | Specific Application of manual air pump for car | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Automotive Repair Shops | Enchimento e manutenção de pneus | Ensures vehicle safety and performance, reduces downtime | Quality, durability, and ease of use; consider local climate conditions |

| Transportation & Logistics | Fleet maintenance and emergency roadside service | Enhances operational efficiency and reduces repair costs | Compact design for easy storage; compatibility with various tire sizes |

| Recreational Vehicle Rentals | Inflating tires and recreational equipment | Improves customer satisfaction and vehicle readiness | Lightweight and portable models; quick inflation capability |

| Construction & Heavy Machinery | Tire inflation for construction vehicles | Minimizes equipment downtime and maximizes productivity | High-pressure capabilities; rugged construction for durability |

| Sports & Leisure | Inflating sports equipment and recreational items | Expands service offerings and enhances customer experience | Versatile nozzles for different uses; easy transportability |

In automotive repair shops, manual air pumps are essential for tire inflation and maintenance. They are used to ensure that tires are at the correct pressure, which is crucial for vehicle safety and performance. Manual pumps can also be employed for inflating various automotive components, such as air springs or suspension systems. For international B2B buyers, sourcing pumps that are durable and easy to operate is vital, especially in regions with varied climatic conditions that may affect pump performance.

In the transportation and logistics sector, manual air pumps are invaluable for fleet maintenance and emergency roadside service. They allow drivers to quickly inflate tires, reducing the risk of accidents caused by under-inflated tires and minimizing downtime for fleet vehicles. Buyers should consider compact designs that are easy to store in vehicles, as well as compatibility with a range of tire sizes to accommodate different fleet vehicles.

For recreational vehicle rental companies, manual air pumps are crucial for inflating both vehicle tires and recreational equipment such as inflatable kayaks or camping gear. Having a reliable manual pump ensures that vehicles are ready for customer use, enhancing satisfaction and safety. B2B buyers in this sector should prioritize lightweight and portable models that can deliver quick inflation, as well as versatility in nozzle attachments for various inflatable items.

Illustrative image related to manual air pump for car

In construction and heavy machinery applications, manual air pumps are used for tire inflation on construction vehicles, which is vital for maintaining equipment performance and minimizing downtime. Properly inflated tires improve traction and fuel efficiency, which are critical in construction environments. Buyers should focus on pumps with high-pressure capabilities and rugged construction, as these features ensure reliability in demanding work conditions.

In the sports and leisure industry, manual air pumps serve to inflate sports equipment, such as balls and inflatable games. They enable businesses to expand their service offerings and improve customer experiences by providing quick and efficient inflation solutions. When sourcing these pumps, businesses should look for versatile nozzles that can accommodate various types of equipment and prioritize easy transportability for on-the-go use.

O problema: Many B2B buyers, especially those operating fleets or rental services, often face challenges in ensuring that tires are inflated to the correct pressure. Manual air pumps, while useful, can sometimes lead to inaccurate inflation due to the lack of built-in pressure gauges. This can result in under-inflated or over-inflated tires, which not only affects vehicle safety but can also lead to increased fuel consumption and tire wear, resulting in higher operational costs.

A solução: To effectively address this issue, B2B buyers should consider sourcing manual air pumps that feature integrated pressure gauges. These gauges allow users to monitor tire pressure in real-time, ensuring the correct inflation level is achieved. When selecting a manual air pump, prioritize models that are ergonomically designed for ease of use, allowing operators to inflate tires efficiently without excessive effort. Additionally, investing in a separate, high-quality tire pressure gauge can provide an extra layer of assurance. Regular training sessions for staff on the importance of maintaining proper tire pressure and the correct use of the pumps can further enhance safety and efficiency.

Illustrative image related to manual air pump for car

O problema: For companies that manage multiple vehicles, using manual air pumps can be labor-intensive and time-consuming. Each inflation process requires physical effort and can take longer than expected, especially if the pump is not designed for high-pressure applications. This inefficiency can lead to downtime, affecting productivity and delaying service delivery.

A solução: B2B buyers should look for high-efficiency manual air pumps that are designed to minimize effort while maximizing output. Pumps with dual-action functionality—where air is pushed into the tire on both the upstroke and downstroke—can significantly reduce the time required for inflation. Additionally, investing in a portable and compact design can facilitate easier handling and storage. Buyers should also consider standardizing their fleet with a specific model of manual air pump to streamline training and maintenance processes, thereby enhancing operational efficiency across the board.

O problema: Another common challenge faced by B2B buyers is the versatility of manual air pumps. Many businesses deal with a range of vehicles, from passenger cars to larger commercial vehicles, each requiring different tire pressures and valve types. A single manual air pump may not be suitable for all applications, leading to frustration and inefficiency during tire maintenance.

A solução: To overcome this limitation, it is crucial to source a manual air pump that comes with multiple nozzle attachments to accommodate various valve types, such as Schrader and Presta valves. This adaptability ensures that the pump can be used across different vehicle types without the need for multiple devices. Additionally, consider pumps with adjustable pressure settings, allowing users to customize inflation based on specific vehicle requirements. Providing employees with comprehensive training on the various applications of the pump will ensure they are well-equipped to handle diverse tire maintenance needs, enhancing both safety and operational efficiency.

When selecting materials for manual air pumps designed for automotive applications, it is crucial to consider properties that directly impact performance, durability, and cost-effectiveness. The following analysis covers four common materials: plastic, aluminum, steel, and rubber. Each material’s characteristics and implications for B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, are discussed.

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is often used in the construction of manual air pumps due to its lightweight and corrosion-resistant properties. These plastics can withstand moderate pressure and temperature variations, making them suitable for various climates.

Prós e contras: The primary advantage of plastic is its low cost and ease of manufacturing, which allows for mass production. However, plastic may not be as durable as metal counterparts, leading to potential wear and tear over time. Additionally, its performance under extreme temperature or pressure conditions can be limited.

Impacto no aplicativo: Plastic pumps are generally compatible with air and non-corrosive gases. However, they may not be suitable for applications requiring high durability or exposure to harsh chemicals.

Considerações para compradores internacionais: Compliance with international standards such as ASTM and ISO is essential. Buyers should also consider the local availability of materials and the environmental impact of plastic waste.

Aluminum is a popular choice for manual air pumps due to its excellent strength-to-weight ratio and resistance to corrosion. It can handle higher pressures than plastic, making it suitable for more demanding applications.

Prós e contras: The key advantage of aluminum is its durability and lightweight nature, which enhances portability. However, aluminum is generally more expensive than plastic and may require more complex manufacturing processes, potentially increasing lead times.

Impacto no aplicativo: Aluminum pumps are compatible with air and a variety of gases, making them versatile for different uses. They perform well in both hot and cold climates, making them suitable for international markets.

Considerações para compradores internacionais: Buyers should ensure that aluminum products meet relevant standards, such as DIN or JIS, particularly in regions with strict quality controls.

Steel, particularly stainless steel, is known for its exceptional strength and durability. It can withstand high pressures and is highly resistant to corrosion, making it ideal for heavy-duty applications.

Prós e contras: The primary advantage of steel is its longevity and robustness, which can justify a higher initial investment. However, steel pumps are heavier than their plastic or aluminum counterparts, which may affect portability. The manufacturing process can also be more complex and costly.

Impacto no aplicativo: Steel pumps are suitable for high-pressure applications and can handle a wide range of gases. Their durability makes them ideal for use in harsh environments.

Considerações para compradores internacionais: Buyers need to be aware of compliance with international standards, especially in regions with stringent regulations. The weight of steel pumps may also impact shipping costs and logistics.

Illustrative image related to manual air pump for car

Rubber is often used in seals and gaskets within manual air pumps, providing excellent flexibility and sealing capabilities. It can withstand a range of temperatures and pressures, making it essential for maintaining pump integrity.

Prós e contras: The key advantage of rubber is its ability to create airtight seals, which is crucial for pump efficiency. However, rubber can degrade over time, especially when exposed to UV light or ozone, requiring regular maintenance or replacement.

Impacto no aplicativo: Rubber is compatible with air and many gases, but its longevity can be affected by environmental factors.

Considerações para compradores internacionais: Buyers should consider the quality of rubber used, as different grades can significantly impact performance. Compliance with relevant standards is also essential, especially in regions with specific material regulations.

Illustrative image related to manual air pump for car

| Material | Typical Use Case for manual air pump for car | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Plástico | General-purpose air pumps | Leve e econômico | Less durable under high stress | Baixa |

| Alumínio | Portable air pumps for varied applications | Durável e resistente à corrosão | Custo mais alto e fabricação complexa | Med |

| Aço | Heavy-duty air pumps | Exceptional strength and longevity | Heavier and costlier to manufacture | Alta |

| Borracha | Seals and gaskets in pumps | Excelente capacidade de vedação | Degrada-se com o tempo | Med |

This strategic material selection guide provides valuable insights for B2B buyers looking to invest in manual air pumps for cars, ensuring they make informed decisions that align with their operational needs and market demands.

Manufacturing manual air pumps for cars involves several key stages, each crucial for ensuring product quality and functionality. The primary stages include material preparation, forming, assembly, and finishing.

The first step in the manufacturing process is the selection and preparation of raw materials. Common materials for manual air pumps include high-density polyethylene (HDPE) for the body, rubber for seals, and metal components for the pump mechanism. Suppliers should source materials that comply with international safety and quality standards to ensure durability and performance.

Before manufacturing, materials undergo quality checks to verify their specifications. This includes testing for tensile strength, flexibility, and resistance to environmental factors. Using high-quality materials is essential, as it directly impacts the pump’s longevity and effectiveness.

Forming is the next crucial stage, where raw materials are shaped into components. Common techniques include injection molding for plastic parts, stamping for metal components, and extrusion for hoses.

Injection molding allows for precise shaping of the pump body and ensures uniformity across products. Stamping is used to create metal parts, which are often required for the pump mechanism. During this stage, manufacturers must adhere to strict dimensional tolerances to ensure all components fit together seamlessly.

Assembly is where individual components come together to create the final product. This process typically involves several sub-steps, including:

Using skilled labor during assembly is critical, especially when dealing with intricate mechanisms that require precision. Furthermore, manufacturers often implement lean manufacturing principles to minimize waste and optimize productivity.

Finishing involves the application of coatings, labels, and packaging. For manual air pumps, this may include:

Quality assurance (QA) is vital in ensuring that the final product meets both manufacturer and customer expectations. The QA process typically follows international standards, such as ISO 9001, which outlines the requirements for a quality management system.

B2B buyers should look for compliance with various international and industry-specific standards. Some relevant standards include:

Compliance with these standards not only guarantees quality but also facilitates market entry in different regions, including Africa, South America, the Middle East, and Europe.

Quality control (QC) involves several checkpoints throughout the manufacturing process:

Each of these checkpoints helps to minimize defects and ensure that only high-quality products reach the market.

Illustrative image related to manual air pump for car

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Here are some effective methods:

International B2B buyers must consider various nuances when it comes to quality control:

In conclusion, thorough knowledge of the manufacturing processes and quality assurance practices for manual air pumps is essential for B2B buyers. By understanding these aspects, buyers can make informed decisions and select suppliers that meet their quality expectations, ultimately leading to successful partnerships.

This guide aims to assist B2B buyers in efficiently sourcing manual air pumps for cars, ensuring they make informed decisions that align with their business needs.

Begin by determining the specific requirements for the manual air pump. Consider factors such as the intended use (e.g., for cars, bicycles, or recreational vehicles) and the expected pressure range. Understanding these needs will help narrow down options and prevent overspending on unnecessary features.

Conduct thorough market research to identify reputable suppliers. Look for companies that specialize in automotive tools and have a proven track record in the industry. Examine market trends to understand the demand for manual air pumps and the competitive landscape, which can inform your negotiation strategy.

Assess the quality of the manual air pumps offered by potential suppliers. Focus on materials used, durability, and ease of use. Key features to consider include:

– Pressure Capacity: Ensure the pump meets the necessary PSI for car tires.

– Portability: Look for lightweight and compact designs that facilitate easy transport.

Ensure that the suppliers you are considering comply with international safety and quality standards. Request documentation that verifies certifications, such as ISO or CE markings. This step is essential to ensure product reliability and to mitigate risks associated with substandard products.

Before making a bulk purchase, request samples from shortlisted suppliers. Testing the products allows you to assess their performance in real-world scenarios. Check for:

– Ease of Operation: Ensure that the pump is user-friendly and efficient.

– Pressure Gauge Accuracy: Verify that the gauge provides accurate readings, as this is crucial for safe tire inflation.

Illustrative image related to manual air pump for car

Once you are satisfied with the quality of the products, initiate negotiations regarding pricing, payment terms, and delivery schedules. Be prepared to discuss bulk order discounts and any potential for future orders. Establishing favorable terms can significantly impact your overall costs.

After agreeing on terms, finalize your order and ensure that logistics are in place for timely delivery. Confirm shipping methods, estimated delivery times, and any customs considerations if sourcing internationally. Having a clear logistics plan will prevent delays and ensure a smooth procurement process.

By following these steps, B2B buyers can confidently navigate the sourcing process for manual air pumps, ensuring they select the right products to meet their business requirements.

When sourcing manual air pumps for cars, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

Materials: The cost of raw materials such as durable plastics, metals, and rubber significantly impacts the overall pricing. High-quality materials ensure longevity and reliability, which are crucial for automotive applications.

Labor: Labor costs vary by region and depend on the manufacturing process. Skilled labor is often required for assembly and quality assurance, which can increase costs, particularly in countries with higher wage standards.

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and equipment maintenance. Factories with advanced technology may have lower long-term overhead costs but might require higher initial investments.

Tooling: Initial tooling costs can be substantial, especially if the pump design requires unique molds or machinery. These costs are typically amortized over the production volume, affecting the price per unit.

Quality Control (QC): Implementing rigorous QC processes ensures that each pump meets safety and performance standards. While this adds to the cost, it also protects buyers from future liabilities.

Logistics: Shipping costs can vary significantly based on the origin, destination, and volume of the shipment. Consideration of Incoterms is crucial to understand who bears the risk and costs at different stages of transport.

Margin: Suppliers will include a margin in their pricing to cover business expenses and profit. Understanding market rates can help buyers negotiate better deals.

Several factors influence the pricing of manual air pumps for cars, which can vary widely based on buyer needs:

Volume/MOQ: Larger orders typically lead to lower per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can also affect overall pricing strategies.

Specifications and Customization: Custom features, such as specific pressure ratings or branding, can increase costs. Standard models are usually more cost-effective.

Material Quality and Certifications: Pumps made from higher-grade materials or those that meet specific certifications (e.g., ISO standards) may command higher prices. Buyers should weigh the benefits of quality against budget constraints.

Supplier Factors: The reputation, reliability, and geographic location of suppliers can influence pricing. Suppliers with established quality standards may charge more but offer better consistency and service.

Incoterms: Understanding Incoterms is vital for managing costs. For instance, choosing FOB (Free on Board) versus CIF (Cost, Insurance, and Freight) can shift the financial responsibility and risk during shipping.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, optimizing sourcing costs requires strategic approaches:

Negotiate Wisely: Use market knowledge to negotiate prices. Leverage competitive quotes from multiple suppliers to encourage better offers.

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, warranty, and operational costs over the product’s lifespan. A cheaper initial price may lead to higher long-term costs if quality is compromised.

Understand Pricing Nuances: Different regions may have varying pricing strategies due to local market conditions, tariffs, and trade agreements. Being informed can help buyers make better purchasing decisions.

Utilize Technology for Sourcing: Employ digital platforms and tools to compare prices and supplier capabilities efficiently. Online marketplaces can offer insights into current market trends and pricing.

In summary, a comprehensive understanding of the cost structure and pricing dynamics of manual air pumps for cars can empower B2B buyers to make informed decisions. Keep in mind that prices can fluctuate based on various factors, and it’s prudent to seek multiple quotations for a well-rounded view of the market.

In the automotive sector, selecting the right tire inflation solution is crucial for efficiency and operational effectiveness. While manual air pumps are a popular choice due to their simplicity and cost-effectiveness, there are various alternative technologies that can also meet the needs of B2B buyers. Understanding the differences in performance, cost, ease of implementation, maintenance requirements, and best use cases will help businesses make informed decisions when procuring tire inflation solutions.

Illustrative image related to manual air pump for car

| Aspecto de comparação | Manual Air Pump For Car | Electric Tire Inflator | Inflador de CO2 |

|---|---|---|---|

| Desempenho | Moderate (up to 70 PSI) | High (up to 250 PSI) | High (quick bursts) |

| Custo | Low ($10-$30) | Moderate ($30-$150) | Moderate ($20-$100) |

| Facilidade de implementação | Simple and intuitive | Requires power source | Requires CO2 cartridges |

| Manutenção | Low (occasional cleaning) | Moderate (check cords) | Low (cartridge replacement) |

| Melhor caso de uso | Emergency tire inflation | Regular tire maintenance | Quick inflation for sports or recreational use |

Electric tire inflators are designed for speed and convenience, making them ideal for regular tire maintenance. They typically connect to a vehicle’s 12V outlet or a standard electrical outlet, offering a consistent air supply with high pressure capabilities (up to 250 PSI). This makes them suitable for larger tires and multiple inflation tasks. However, they can be more expensive than manual pumps and require access to a power source, limiting their portability in certain situations.

CO2 inflators provide a unique solution for quick tire inflation, often used in cycling and recreational activities. They utilize CO2 cartridges to deliver rapid bursts of air, making them highly effective for immediate needs. The primary advantages include their compact size and lightweight design, which enhances portability. However, the reliance on cartridges can lead to ongoing costs, and the inflation pressure is typically lower compared to electric inflators, making them less suitable for automotive applications that require sustained inflation.

When selecting the appropriate tire inflation solution, B2B buyers should assess their specific requirements, including the frequency of use, budget constraints, and the typical environments in which the equipment will be employed. Manual air pumps offer a low-cost, straightforward option for emergency situations, while electric inflators provide efficiency for routine maintenance. CO2 inflators, on the other hand, excel in portability and quick inflation for recreational applications. By carefully evaluating these factors, businesses can make a well-informed decision that aligns with their operational needs and enhances their tire maintenance strategy.

When selecting a manual air pump for cars, understanding its technical properties is essential for ensuring quality and performance. Here are several critical specifications that B2B buyers should consider:

Grau do material

– The construction material of a manual air pump significantly influences its durability and performance. Common materials include high-grade plastics and metals like aluminum or steel. Higher-grade materials typically offer better resistance to wear and tear, making them suitable for prolonged use in various environments.

Maximum Pressure Rating (PSI)

– This specification indicates the maximum pressure the pump can achieve, usually measured in pounds per square inch (PSI). A higher PSI rating allows the pump to inflate larger tires or inflatable products more efficiently. For automotive applications, pumps with a minimum rating of 60-100 PSI are recommended, ensuring they meet the demands of standard car tires.

Pump Efficiency

– This refers to the amount of air delivered per stroke. A more efficient pump will require fewer strokes to inflate a tire, making it more user-friendly, especially in emergency situations. Efficiency can be influenced by the design of the pump mechanism and the size of the cylinder.

Weight and Portability

– The weight of the manual air pump is critical for portability. Lighter pumps are easier to carry and store, which is particularly important for emergency kits. A compact design can enhance convenience, enabling users to transport the pump in their vehicles without hassle.

Ergonomic Design

– An ergonomic design facilitates ease of use, especially for individuals who may need to use the pump frequently or in challenging positions. Features like a comfortable grip and an intuitive pumping action can significantly enhance user experience and efficiency.

Pressure Gauge Accuracy

– An integrated pressure gauge allows users to monitor the inflation process accurately. The accuracy of this gauge is crucial for preventing over-inflation or under-inflation, both of which can lead to tire damage or safety hazards. A clear, easy-to-read gauge is preferred for quick assessments.

Understanding industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms related to manual air pumps for cars:

Illustrative image related to manual air pump for car

OEM (fabricante original do equipamento)

– This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM specifications can help ensure compatibility and quality when sourcing manual air pumps.

MOQ (Quantidade mínima de pedido)

– MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is critical for budgeting and inventory planning. B2B buyers should consider their demand and storage capabilities when negotiating MOQs with suppliers.

RFQ (Request for Quotation, solicitação de cotação)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products. This is a common practice in B2B transactions, allowing buyers to compare offers and make informed purchasing decisions.

Incoterms (Termos Comerciais Internacionais)

– Incoterms are a series of international trade terms that define the responsibilities of buyers and sellers in transactions. Familiarity with these terms can help buyers understand shipping costs, risk, and delivery responsibilities.

Prazo de entrega

– This term refers to the amount of time from placing an order until the goods are received. Understanding lead times is crucial for inventory management and ensuring that products are available when needed.

Certification Standards

– These are industry-specific benchmarks that products must meet to ensure quality and safety. For manual air pumps, certifications may include ISO standards or other regional quality marks, which can enhance buyer confidence in product reliability.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing manual air pumps for cars, ultimately enhancing their operational efficiency and product quality.

The manual air pump market for cars is experiencing a notable transformation driven by several global factors. Increased vehicle ownership in emerging markets, particularly in Africa and South America, is fueling demand for affordable and portable inflation solutions. The rise of electric vehicles (EVs) and hybrids is also creating a niche market for lightweight and compact manual air pumps, as many EV owners seek emergency inflation solutions without the dependency on electrical sources.

In addition, the COVID-19 pandemic has shifted consumer behavior towards DIY vehicle maintenance, increasing the interest in manual air pumps. This trend is complemented by a growing awareness of the importance of regular tire maintenance for safety and fuel efficiency. Moreover, technological advancements are making manual pumps more user-friendly, featuring ergonomic designs and improved pressure gauges that enhance usability for end consumers.

Illustrative image related to manual air pump for car

International B2B buyers should also consider the implications of e-commerce growth. Online platforms are becoming crucial for sourcing, enabling suppliers to reach broader markets, including regions like the Middle East and Europe. This shift provides opportunities for B2B buyers to compare products, review specifications, and negotiate prices more effectively.

Sustainability is becoming a pivotal factor in the sourcing decisions of B2B buyers in the manual air pump sector. As environmental concerns continue to rise globally, manufacturers are increasingly prioritizing eco-friendly materials and sustainable production practices. This includes the use of recycled plastics and natural rubber in the production of manual air pumps, which not only reduces waste but also appeals to environmentally conscious consumers.

Moreover, ethical sourcing practices are gaining traction. B2B buyers are now more inclined to partner with suppliers who can demonstrate a commitment to fair labor practices and transparency in their supply chains. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as critical differentiators in a competitive marketplace.

Additionally, buyers should look for products that are designed to be energy-efficient and durable, reducing the need for frequent replacements. The demand for ‘green’ certifications is growing, as businesses recognize the value of aligning their procurement strategies with sustainable development goals. By prioritizing sustainable and ethical sourcing, companies not only enhance their brand reputation but also meet the expectations of a more environmentally aware consumer base.

The history of manual air pumps dates back to the early days of automotive development, where hand pumps were essential for tire maintenance. Initially, these pumps were simple devices with limited functionality. However, as vehicles became more sophisticated, so did the technology behind air pumps.

Illustrative image related to manual air pump for car

In the late 20th century, manufacturers began incorporating features such as built-in pressure gauges and more ergonomic designs, making them easier to use. The shift towards lightweight materials in the 21st century further revolutionized the market, allowing for portable options that cater to the needs of modern drivers.

Today, manual air pumps not only serve as an essential tool for tire maintenance but also reflect broader trends in consumer preferences for convenience and sustainability. This evolution underscores the importance of innovation in meeting the diverse needs of B2B buyers across various regions, from Europe to the Middle East, paving the way for future advancements in the sector.

1. How do I choose the right manual air pump for my car?

Selecting the right manual air pump involves assessing your specific needs, including the types of vehicles you service and the inflation pressure required. Look for pumps that offer a pressure gauge for accuracy, sturdy construction for durability, and portability for ease of use. Additionally, consider the pump’s capacity to handle larger tires if you deal with SUVs or trucks. Supplier reviews and product specifications can also guide you in making an informed decision.

2. What are the advantages of using a manual air pump for cars?

Manual air pumps are cost-effective, require no electricity, and are portable, making them ideal for emergency situations or remote areas. They are often lighter and easier to store than electric pumps. Moreover, they offer greater control over inflation pressure, which can prevent over-inflation. For businesses in regions with unreliable power sources, manual pumps can provide a reliable solution for tire maintenance.

3. What is the typical MOQ (Minimum Order Quantity) for manual air pumps?

The MOQ for manual air pumps can vary significantly based on the supplier and the specific product. Generally, it ranges from 100 to 1,000 units. It’s advisable to negotiate with suppliers for lower MOQs, especially when starting a new partnership or testing a product line. Consider discussing terms that allow for a trial order before committing to larger quantities.

4. What payment terms should I expect when sourcing manual air pumps internationally?

Payment terms can differ widely among suppliers. Common arrangements include a 30% deposit upon order confirmation, with the balance due before shipping. Some suppliers may offer letters of credit or payment through platforms like PayPal for added security. Always clarify terms in advance and consider using escrow services to protect your transaction, especially when dealing with new suppliers.

5. How can I ensure the quality of manual air pumps from suppliers?

To guarantee quality, request product samples before placing a bulk order. Check for certifications that meet international standards, such as ISO or CE markings. Additionally, inquire about the supplier’s quality assurance processes, including testing protocols and warranty policies. Regularly conducting audits or inspections at the manufacturing site can also help maintain quality assurance.

6. What logistical considerations should I keep in mind when importing manual air pumps?

When importing manual air pumps, consider shipping costs, customs duties, and delivery timelines. Choose a reliable freight forwarder who can navigate customs regulations in your target market. Additionally, ensure your shipping method aligns with your timeline and budget—air freight is faster but more expensive than sea freight. Lastly, confirm that the supplier provides necessary documentation for customs clearance.

7. Are there customization options available for manual air pumps?

Many suppliers offer customization options, including branding, color, and packaging. Discuss your specific needs with potential suppliers to determine what can be accommodated. Customization can enhance your brand visibility and cater to local market preferences. However, keep in mind that custom orders may require higher MOQs and longer lead times.

8. How do I vet suppliers for manual air pumps effectively?

Begin by researching potential suppliers through trade directories and industry networks. Look for reviews and testimonials from other buyers to gauge reliability and service quality. Request references and verify them to ensure credibility. Additionally, consider visiting the supplier’s facility if possible, or conduct a virtual audit to assess their production capabilities and quality control measures.

Domínio: reddit.com

Registrado: 2005 (20 anos)

Introdução: Corded tire pump preferred, no batteries, under $100, suitable for keeping in the trunk.

Domínio: ebay.com

Registrado: 1995 (30 anos)

Introdução: Manual Car and Truck Air Compressors available for sale on eBay. Key features include:

– Power Source: Manual (624 listings), Battery (1,915), Cigarette Lighter (1,004), Wall Outlet (164), Hard-Wired (236), Gas (75).

– Types of Air Compressors: Air Compressor (77), Pressure Gauge (129), Air Tank (3), Air Hose (71), Coupler (42), Blow Gun (19), Air Pressure Regulator (5), Tire Filler (2).

– Brands…

Domínio: garagejournal.com

Registrado: 2006 (19 anos)

Introdução: Manual hand pumps that can inflate a car tire, specifically larger sizes that can achieve 30psi with less effort. Recommendations include: 1. A larger bicycle pump or ‘track pump’ designed for mountain bikes, which has a larger bore for more air per stroke. 2. Zefal DoubleShot, a high volume two-barrel hand pump (no longer made, but noted for efficiency). 3. Zefal Alaskan Graph, a replacement for …

The manual air pump for cars represents a vital tool for automotive maintenance across various markets, particularly in regions such as Africa, South America, the Middle East, and Europe. Strategic sourcing of these products enables businesses to capitalize on emerging trends in manual inflation solutions, meeting the growing demand for reliable and cost-effective tire maintenance equipment.

Illustrative image related to manual air pump for car

B2B buyers should focus on key factors such as product quality, supplier reliability, and market adaptability. Companies like Campbell Hausfeld and Milton exemplify the diverse range of options available, from basic hand pumps to more advanced models designed for heavy-duty use. Understanding local market needs and preferences can provide a competitive edge, ensuring that buyers select products that resonate with their customer base.

Looking ahead, the increasing emphasis on sustainability and self-sufficiency will drive the demand for manual air pumps. As such, international buyers are encouraged to forge partnerships with manufacturers who prioritize innovation and eco-friendly practices. By investing in strategic sourcing, businesses can not only enhance their product offerings but also contribute to a more sustainable automotive landscape. Now is the time to explore these opportunities and secure the best solutions for your market.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.

Illustrative image related to manual air pump for car