Navigating the complexities of sourcing a near air pump can be a daunting task for B2B buyers in today’s global market. With varying regulations, supply chain issues, and the diverse needs of industries, finding a reliable supplier that meets quality standards while remaining cost-effective is crucial. This guide is designed to equip international buyers—especially those from Africa, South America, the Middle East, and Europe, including regions like Saudi Arabia and Germany—with the knowledge necessary to make informed purchasing decisions.

In this comprehensive resource, we will explore the different types of near air pumps available in the market, their specific applications across various sectors, and the essential criteria for vetting suppliers. Additionally, we will provide insights into pricing strategies, helping buyers identify cost-effective solutions without compromising on quality.

By understanding the landscape of the near air pump market, buyers can streamline their procurement processes, mitigate risks, and ultimately enhance operational efficiency. This guide empowers businesses to navigate the complexities of international sourcing with confidence, ensuring they select the right near air pump to meet their unique operational needs. Whether you are looking to enhance your product offerings or improve service delivery, this guide serves as a valuable tool in making strategic purchasing decisions.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Portable Air Compressors | Compact, battery-operated, or AC-powered devices | Automotive repair shops, mobile service providers | Prós: Convenient, versatile, easy to store. Contras: Limited air capacity compared to larger units. |

| Stand-alone Tire Pumps | Fixed installations, often found at gas stations | Tire shops, automotive service centers | Prós: High capacity, accessible for public use. Contras: Requires maintenance and space. |

| Bicycle Repair Stations | Designed specifically for inflating bike tires | Cycling shops, public parks, urban areas | Prós: Eco-friendly, promotes cycling. Contras: Limited to bicycle use only. |

| Industrial Air Pumps | Heavy-duty, designed for high-volume inflation needs | Manufacturing, construction industries | Prós: High efficiency, durable for industrial settings. Contras: Higher cost, requires dedicated space. |

| Smart Air Pumps | Connected devices with digital displays and apps | Fleet management, logistics companies | Prós: Data tracking, user-friendly. Contras: Higher upfront investment, dependency on technology. |

Portable air compressors are versatile devices that can be powered by batteries or AC outlets, making them suitable for various environments. They are compact and easy to transport, allowing businesses to offer mobile tire inflation services or roadside assistance. When purchasing, B2B buyers should consider the compressor’s air capacity, recharge time, and whether it meets the specific needs of their operations, such as inflating heavy-duty tires or smaller vehicle tires.

Stand-alone tire pumps are typically found at gas stations and automotive service centers. These fixed installations are designed for high-volume use, providing easy access to customers looking to inflate their tires. For B2B buyers, the main considerations include the pump’s reliability, maintenance requirements, and the cost of installation. While they offer convenience and efficiency, they also require adequate space and regular upkeep to ensure they remain operational.

Bicycle repair stations cater specifically to cyclists, offering convenient access to air pumps for tire inflation. These stations are usually installed in public spaces like parks or urban areas, promoting cycling as an eco-friendly transportation option. B2B buyers, such as municipalities or cycling shops, should evaluate the placement and accessibility of these stations to maximize usage. While they foster community engagement and support sustainable transport, their functionality is limited to bicycles.

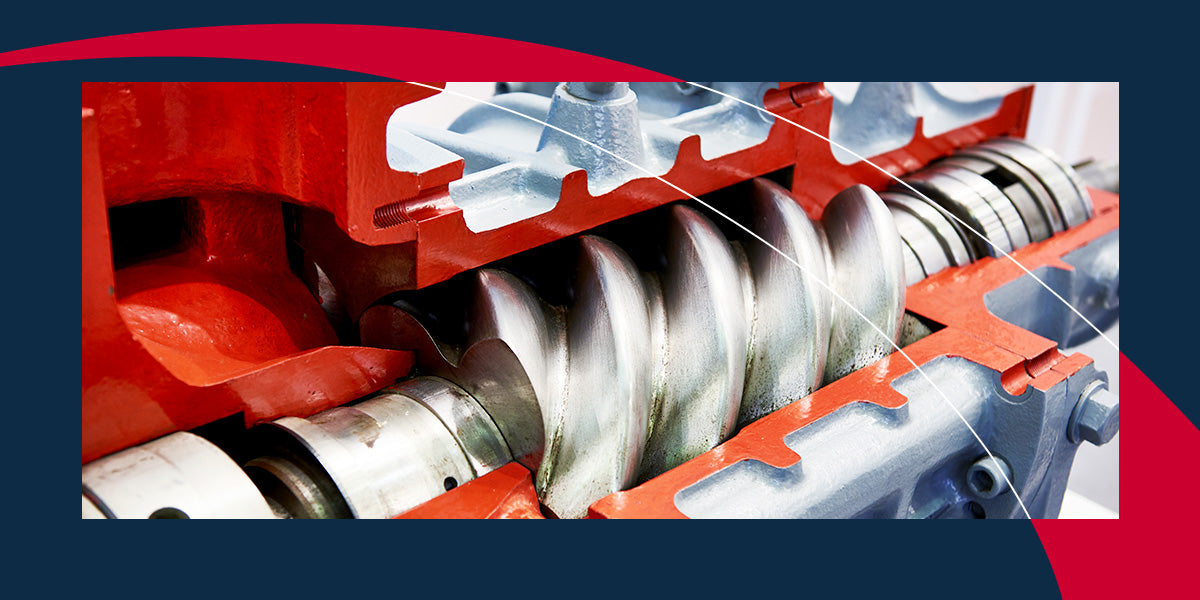

Industrial air pumps are designed for high-volume inflation tasks, making them ideal for manufacturing and construction environments. These heavy-duty machines can handle demanding workloads and are built for durability. B2B buyers in industries requiring frequent tire inflation or pneumatic tools should assess the pump’s efficiency, power requirements, and maintenance needs. Although they come with a higher price tag, their long-term reliability can justify the investment.

Smart air pumps integrate technology with tire inflation, offering features such as digital displays and app connectivity for tracking air pressure and maintenance schedules. This innovation is particularly beneficial for fleet management and logistics companies, helping to optimize vehicle performance and reduce downtime. When considering a smart air pump, B2B buyers should focus on compatibility with existing systems, ease of use, and the potential for data analytics. While they may require a higher initial investment, the long-term savings on fuel and maintenance can be significant.

| Indústria/Setor | Specific Application of near air pump | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Automotivo | Tire inflation at service stations | Enhances customer satisfaction by providing free air | Reliability, ease of use, maintenance support |

| Fabricação | Air supply for pneumatic tools | Increases operational efficiency and reduces downtime | Energy efficiency, compatibility with existing systems |

| Transportation & Logistics | Inflating tires on delivery vehicles | Reduces costs associated with tire wear and fuel consumption | Durability, portability, and ease of operation |

| Cycling & Recreation | Public bike pump stations | Encourages cycling, promoting sustainability and health | Accessibility, weather resistance, and maintenance needs |

| Construção | Air supply for construction equipment | Ensures equipment operates efficiently and safely | Power requirements, durability, and service availability |

In the automotive industry, near air pumps are commonly used at service stations to provide tire inflation services. This application enhances customer satisfaction by offering a convenient and often free solution for maintaining tire pressure. For businesses, ensuring that customers can easily access air contributes to repeat visits and loyalty. Buyers in this sector should prioritize reliability and ease of use to minimize downtime and maintenance costs.

In manufacturing environments, near air pumps are essential for supplying air to pneumatic tools and machinery. This application is crucial for increasing operational efficiency and reducing potential downtime caused by equipment failure. International buyers, particularly from regions with fluctuating power supplies, should consider energy-efficient models that can integrate seamlessly with their existing systems to maximize productivity.

In the transportation and logistics sector, near air pumps are vital for inflating tires on delivery vehicles. Proper tire inflation is critical for reducing wear and tear, which in turn minimizes fuel consumption and operational costs. When sourcing near air pumps, businesses should focus on durability and portability, ensuring that the pumps can withstand the rigors of daily use in various environments.

Near air pumps are increasingly found in public bike pump stations, facilitating tire inflation for cyclists. This initiative not only supports cycling as a sustainable mode of transportation but also promotes public health by encouraging more people to cycle. Buyers in this sector should consider accessibility features, weather resistance, and low maintenance requirements to ensure these stations serve their communities effectively.

In the construction industry, near air pumps are used to provide air to various construction equipment, ensuring that tools operate efficiently and safely. This application is critical to maintaining productivity on job sites. Buyers should pay attention to the power requirements and durability of the pumps, as construction environments can be demanding, requiring robust solutions that can withstand heavy use and adverse conditions.

O problema: Many B2B buyers, particularly those managing fleets or logistics in regions like Africa or South America, face challenges in locating air pumps during long journeys. This issue can lead to increased downtime and costs, particularly if they need to stop at multiple locations to find a service station with a functional air pump. In many areas, the availability of air pumps is inconsistent, and they often encounter outdated or malfunctioning equipment. This not only frustrates drivers but also affects overall operational efficiency.

A solução: To mitigate this issue, businesses should invest in a portable air compressor that can be stored in vehicles. This compact solution ensures that drivers can inflate tires regardless of their location. Additionally, companies can create partnerships with local gas stations or tire shops to establish a reliable network of air pump locations. Utilizing mobile applications or GPS mapping services can help drivers identify nearby air pumps quickly. Encouraging drivers to keep a log of reliable air pump locations can also enhance operational efficiency, reducing downtime in the field.

O problema: Inconsistent air pressure in tires can significantly impact vehicle safety and performance, particularly for companies operating in regions with varying climates and road conditions. B2B buyers may struggle with ensuring that air pumps provide accurate pressure readings, leading to under-inflation or over-inflation. This inconsistency can cause tire blowouts, increased fuel consumption, and ultimately, higher operational costs.

A solução: To address this challenge, companies should consider investing in high-quality, calibrated air pumps that meet international standards for accuracy. Regular maintenance and calibration of air pumps are essential to ensure that they function correctly. Additionally, implementing a routine check for tire pressure as part of the vehicle maintenance schedule can help maintain optimal performance and safety. Educating drivers on the importance of tire pressure and how to use air pumps effectively can also minimize risks associated with improper inflation.

Illustrative image related to near air pump

O problema: B2B buyers operating in remote or rural regions often find that access to air pumps is severely limited. This lack of availability can be a critical issue for businesses relying on vehicles for transportation or delivery services. When drivers cannot find an air pump nearby, it can lead to delays, increased costs, and even lost business opportunities.

A solução: Companies should explore establishing mobile air services that can operate in remote areas. This could involve equipping service vehicles with portable air compressors to provide on-the-go inflation services. Additionally, businesses can collaborate with local mechanics or tire repair shops to offer air services in under-served areas, ensuring that drivers have access to necessary resources. Furthermore, developing a strategic route planning system that includes known air pump locations can help minimize the chances of running into this issue. Engaging with local communities to identify potential partners for air services can also enhance resource availability and operational reliability.

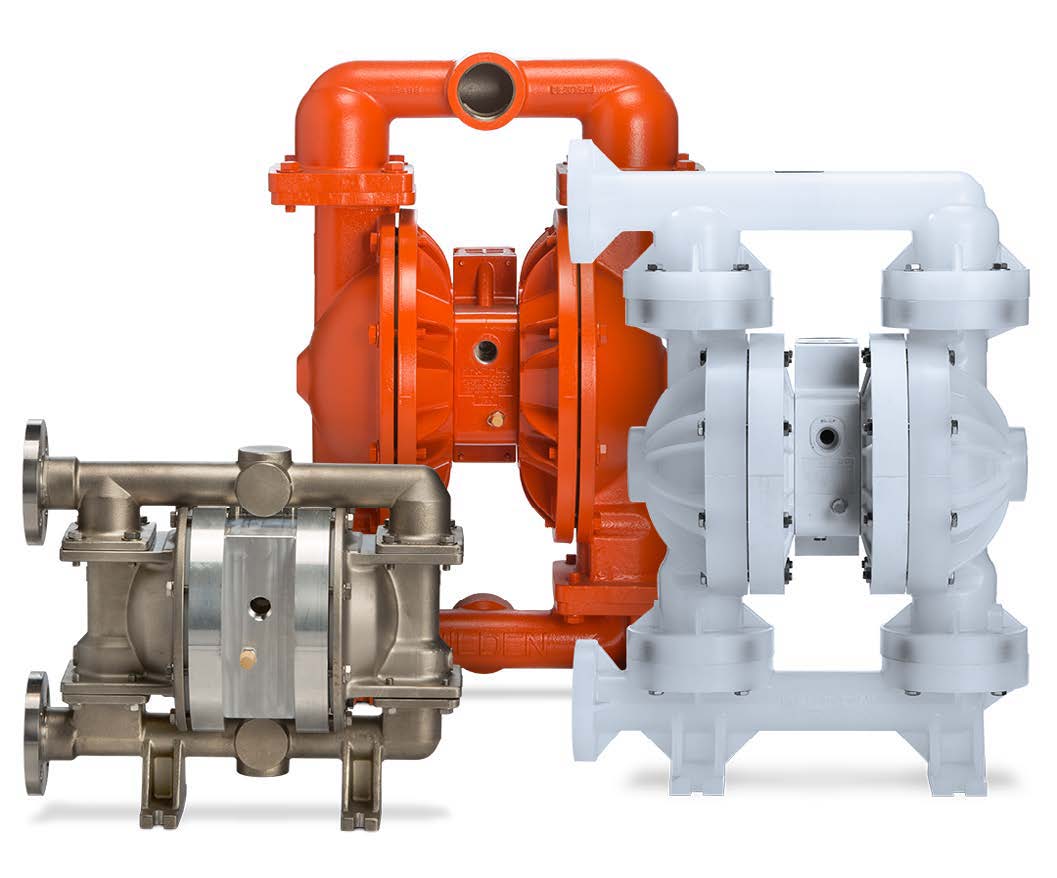

When selecting materials for near air pumps, it is crucial to consider various factors that impact performance, durability, and cost. Below is an analysis of four common materials used in the construction of near air pumps, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

Aluminum is a widely used material in the manufacturing of near air pumps due to its favorable properties. It has a good strength-to-weight ratio, making it lightweight yet durable. Aluminum can withstand moderate temperatures and pressures, typically rated up to 300°F and 150 psi, depending on the alloy. Its natural corrosion resistance is enhanced with anodization, making it suitable for various environments.

Prós: Aluminum is relatively inexpensive and easy to machine, which simplifies manufacturing processes. Its lightweight nature aids in portability, making it ideal for portable air pumps.

Contras: While aluminum has decent corrosion resistance, it may not be suitable for harsh chemical environments. It can also be prone to denting and scratching, which may affect aesthetics and performance over time.

Illustrative image related to near air pump

Impacto no aplicativo: Aluminum is compatible with air and non-corrosive gases, making it suitable for general-purpose near air pumps.

Considerações para compradores internacionais: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Europe may prefer aluminum alloys that meet specific performance criteria for durability and corrosion resistance.

Stainless steel is another popular choice for near air pump construction, known for its exceptional corrosion resistance and durability. It can withstand higher temperatures (up to 1500°F) and pressures (up to 300 psi), making it suitable for more demanding applications.

Prós: Stainless steel is highly durable and can handle a wide range of environmental conditions. Its corrosion resistance ensures longevity, reducing maintenance costs over time.

Contras: The higher cost of stainless steel compared to aluminum can be a drawback for budget-conscious buyers. Additionally, its heavier weight may limit portability.

Illustrative image related to near air pump

Impacto no aplicativo: Stainless steel is compatible with a broader range of media, including corrosive gases and liquids, making it ideal for specialized applications.

Considerações para compradores internacionais: Buyers should ensure that the stainless steel grade selected complies with local standards, such as JIS in Japan or ASTM in the U.S. This is particularly important in regions like Saudi Arabia, where environmental conditions can be harsh.

Plastic materials, such as polycarbonate and polypropylene, are increasingly used in near air pump applications due to their lightweight and corrosion-resistant properties. These materials can typically handle temperatures up to 200°F and pressures around 100 psi.

Illustrative image related to near air pump

Prós: Plastics are cost-effective and can be molded into complex shapes, allowing for innovative designs. They are also resistant to many chemicals, making them suitable for specific applications.

Contras: While plastics are lightweight, they may not provide the same durability as metals. They can be more susceptible to wear and tear, especially in high-stress applications.

Impacto no aplicativo: Plastic is suitable for applications involving air and non-corrosive gases, but caution should be exercised in environments with extreme temperatures or pressures.

Considerações para compradores internacionais: Buyers should verify that the selected plastic meets relevant safety and performance standards, particularly in regions with stringent regulations.

Illustrative image related to near air pump

Brass is often used in fittings and connectors for near air pumps due to its excellent machinability and corrosion resistance. It can typically handle temperatures up to 400°F and pressures around 200 psi.

Prós: Brass provides a good balance of strength and corrosion resistance, making it suitable for various applications. Its attractive appearance can also enhance the overall aesthetics of the product.

Contras: Brass can be more expensive than aluminum and may not be suitable for all environments, particularly those involving aggressive chemicals.

Impacto no aplicativo: Brass is ideal for applications involving air and non-corrosive gases, particularly in fittings and connectors.

Illustrative image related to near air pump

Considerações para compradores internacionais: Compliance with international standards is crucial, especially in regions like Germany, where quality assurance is paramount.

| Material | Typical Use Case for near air pump | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | General-purpose air pumps | Leve e econômico | Prone to denting and scratching | Baixa |

| Aço inoxidável | High-performance applications | Excellent corrosion resistance | Higher cost and weight | Alta |

| Plástico | Lightweight, portable air pumps | Cost-effective and moldable | Less durable under stress | Baixa |

| Brass | Fittings and connectors | Good strength and aesthetics | Higher cost and chemical sensitivity | Med |

This analysis provides a comprehensive overview of material options for near air pumps, allowing international B2B buyers to make informed decisions based on their specific needs and regional considerations.

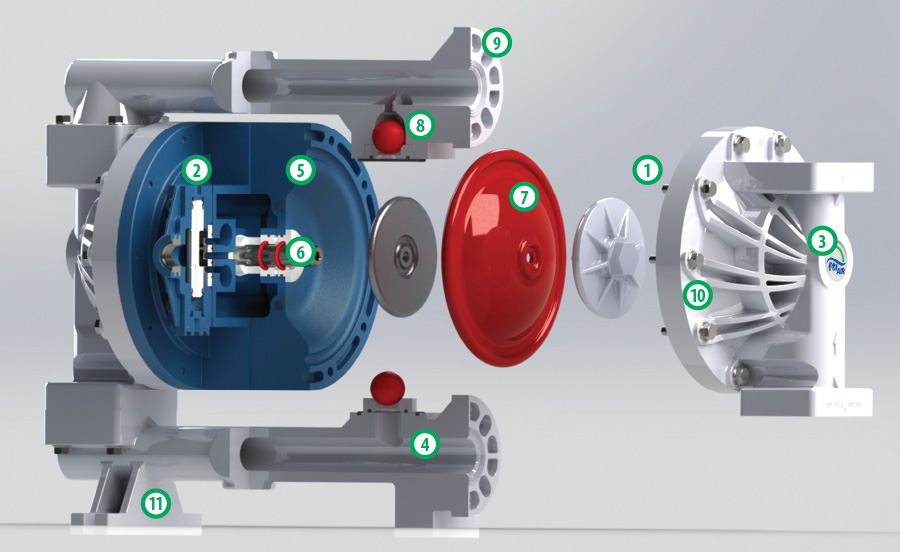

Manufacturing near air pumps involves several critical stages to ensure both functionality and durability. Understanding these stages can help B2B buyers evaluate potential suppliers effectively.

The manufacturing process begins with material preparation, which typically involves sourcing high-quality components. Common materials for near air pumps include:

Suppliers should ensure that materials meet international standards and are sourced from reputable suppliers to avoid quality issues.

Illustrative image related to near air pump

The forming stage involves shaping the raw materials into the required components. This can be achieved through various techniques:

Each method has its pros and cons, and the choice often depends on the desired specifications, volume of production, and cost considerations.

Once the components are formed, the next step is assembly. This stage includes:

Effective assembly processes often use jigs and fixtures to maintain precision and reduce human error.

Finishing is the final stage in the manufacturing process, which enhances the pump’s aesthetics and protects against environmental factors. Common finishing techniques include:

Quality assurance (QA) is essential in ensuring that near air pumps meet international and industry-specific standards. Here are the key aspects of QA in this sector.

Manufacturers should adhere to various international standards to ensure product quality and safety. Relevant standards include:

B2B buyers should verify that their suppliers are compliant with these standards, as this can significantly impact product quality and regulatory compliance.

Quality control (QC) checkpoints are critical in the manufacturing process. Common QC checkpoints include:

Illustrative image related to near air pump

Implementing these checkpoints helps identify issues early, reducing waste and enhancing overall quality.

Manufacturers use various testing methods to ensure the functionality and durability of near air pumps. Some common testing methods include:

These testing methods help ensure that products meet or exceed the expectations of B2B buyers.

Verifying a supplier’s quality control processes is crucial for B2B buyers, especially when sourcing from international markets. Here are effective strategies:

Buyers should request and review supplier audits and quality assurance reports. Key aspects to examine include:

Illustrative image related to near air pump

Engaging third-party inspection services can provide additional assurance of product quality. These inspections can include:

Third-party inspectors can offer unbiased assessments, giving B2B buyers confidence in their purchasing decisions.

International buyers should be aware of specific nuances related to QC and certification, especially when sourcing from regions like Africa, South America, the Middle East, and Europe. Key considerations include:

By addressing these aspects, B2B buyers can navigate the complexities of sourcing near air pumps while ensuring high-quality products that meet their operational needs.

This guide is designed to assist B2B buyers in effectively sourcing near air pumps, which are essential for various applications, from automotive maintenance to cycling. By following this step-by-step checklist, you can ensure that you make informed purchasing decisions that align with your operational needs.

Illustrative image related to near air pump

Understanding your specific requirements is crucial. Determine the type of near air pump needed—whether for automotive, cycling, or industrial use. Consider factors such as air pressure, volume, and portability. This clarity will help you narrow down potential suppliers and models.

Stay updated on the latest trends in air pump technology. Innovations like eco-friendly models or digital pressure gauges can enhance efficiency and user experience. Researching these trends will help you identify products that offer greater value and align with your sustainability goals.

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, case studies, and references from buyers in similar industries. Look for suppliers with a proven track record of reliability and quality. Additionally, assess their customer service and support capabilities, as these can significantly impact your purchasing experience.

Whenever possible, request samples of the near air pumps you are considering. Testing the product firsthand allows you to evaluate its performance, build quality, and usability. Pay attention to ease of operation and maintenance requirements. This step is essential in ensuring the product meets your operational standards.

Ensure that the products meet relevant industry standards and regulations. Check for certifications such as ISO, CE, or UL, which can indicate product quality and safety. Understanding compliance requirements in your region, particularly in international markets like Africa or Europe, is vital for avoiding legal issues and ensuring product reliability.

Illustrative image related to near air pump

Once you have shortlisted potential suppliers, compare their pricing structures, including shipping and handling fees. Look for value-added services such as warranties, return policies, and after-sales support. A lower price might be tempting, but consider the total cost of ownership, including maintenance and operational efficiency.

After selecting the right supplier and product, draft a clear purchase agreement. This should outline all terms, including delivery timelines, payment terms, and service agreements. Ensure that both parties understand their responsibilities to avoid misunderstandings later on. A well-structured agreement can facilitate smoother transactions and long-term relationships.

By following this checklist, B2B buyers can approach the procurement of near air pumps with confidence, ensuring that they select products that meet their needs and contribute positively to their operations.

When evaluating the cost structure for sourcing near air pumps, several critical components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to near air pump

Materials: The choice of materials is foundational in determining the cost. High-quality materials often lead to better performance and durability, but they come at a premium. Common materials used in air pumps include metals, plastics, and rubber, each with varying costs based on market conditions.

Labor: Labor costs can fluctuate based on geographic location, skill level, and prevailing wage rates. In regions like Europe, where labor laws may dictate higher wages and benefits, costs may be significantly higher than in developing regions.

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Understanding the overhead structure of potential suppliers is crucial, as it can vary widely based on operational efficiency.

Tooling: The initial investment in tooling can be substantial, especially for customized air pumps. Buyers should consider whether the supplier has the capability to manage these costs effectively, as it can impact pricing in the long term.

Quality Control (QC): Implementing rigorous QC processes can add to the upfront costs but is essential for ensuring product reliability. Certifications (e.g., ISO standards) can also influence the cost structure, as they often require additional testing and documentation.

Logistics: Shipping costs can vary greatly depending on the distance between the supplier and buyer, as well as the chosen mode of transport (air, sea, or land). Incoterms, which define the responsibilities of buyers and sellers in international trade, also play a significant role in logistics costs.

Margin: Finally, suppliers will include a profit margin in their pricing, which can vary based on market conditions and competition. Understanding the typical margins in the near air pump market can help buyers gauge whether they are receiving a fair price.

Price influencers can significantly affect the final cost of near air pumps. Factors such as volume or minimum order quantities (MOQ), specifications and customization, material choices, quality certifications, supplier reliability, and Incoterms all play a role.

Volume/MOQ: Generally, purchasing in larger quantities can lead to lower unit costs due to economies of scale. However, buyers must ensure they have the capacity to store and manage larger orders.

Specifications/Customization: Custom-designed air pumps often come at a higher price due to the additional engineering and production time required. Buyers should weigh the benefits of customization against the associated costs.

Materials: The choice of materials directly impacts both the cost and quality of the final product. Premium materials may increase costs but can lead to better performance and longevity.

Quality/Certifications: Products with certifications indicating higher quality or environmental sustainability may command higher prices. Buyers should assess whether these certifications are necessary for their market.

Supplier Factors: The reliability and reputation of suppliers can influence pricing. Well-established suppliers may charge more due to their proven track record, while newer suppliers may offer lower prices to gain market share.

Incoterms: Understanding Incoterms is crucial for managing logistics costs. They define who is responsible for shipping, insurance, and tariffs, which can significantly affect the total cost.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, effective negotiation and understanding of cost structures can lead to better pricing outcomes.

Negotiation Strategies: Establish clear negotiation parameters before discussions begin. Consider leveraging volume purchases or long-term contracts to secure more favorable terms.

Cost-Efficiency: Evaluate the total cost of ownership, which includes not just the purchase price but also maintenance, operational costs, and potential downtime. This holistic view can reveal the true value of a supplier’s offering.

Pricing Nuances for International Buyers: Be aware of additional costs that may arise from currency exchange rates, tariffs, and import duties. Understanding these factors can help in budgeting and negotiation.

Conduct Market Research: Familiarize yourself with industry benchmarks and typical pricing structures for near air pumps. This knowledge will empower you during negotiations and help identify reasonable price expectations.

In conclusion, a comprehensive understanding of the cost structure and pricing dynamics associated with near air pumps can significantly enhance sourcing decisions. By considering the outlined cost components, price influencers, and negotiation tips, buyers can achieve better value and optimize their procurement strategies.

In the quest for efficient inflation solutions, businesses often seek alternatives to traditional near air pumps. These alternatives can vary widely in terms of technology, cost, and ease of use. Understanding the strengths and weaknesses of each option is crucial for B2B buyers looking to optimize their operations, particularly in regions like Africa, South America, the Middle East, and Europe.

| Aspecto de comparação | Near Air Pump | Portable Air Compressor | Bicycle Repair Stations |

|---|---|---|---|

| Desempenho | Reliable for various vehicle types | High pressure output, portable | Limited to bikes, manual effort |

| Custo | Typically low to moderate | Moderate, one-time purchase | Usually free, community-driven |

| Facilidade de implementação | Simple to use at designated spots | Easy to operate, requires charging | Accessible in urban areas |

| Manutenção | Minimal upkeep required | Regular checks for battery life | Very low, depends on community |

| Melhor caso de uso | Urban centers, fleet maintenance | Road trips, personal vehicles | Cycling communities, urban cyclists |

A portable air compressor offers a flexible solution for tire inflation. These devices are designed for high-pressure output and can be used for various vehicle types, making them a versatile choice for businesses with diverse fleets. They are relatively easy to operate, requiring only a power source, and can be taken on road trips or used at home.

Illustrative image related to near air pump

Prós: The primary advantages of portable air compressors include their ability to deliver high-pressure inflation quickly and their portability. They can be used in various settings and are especially handy in remote locations where traditional air sources may be unavailable.

Contras: However, the initial investment can be moderate, and users must ensure the device is charged or plugged in, which may not always be convenient. Regular maintenance checks are also necessary to ensure optimal performance.

Bicycle repair stations are becoming increasingly popular in urban areas, providing accessible air pumps for cyclists. These stations are typically set up in community spaces and are free to use, encouraging cycling as an eco-friendly transportation option.

Prós: The most significant advantage of bicycle repair stations is their cost-effectiveness, as they are usually free to the public. They promote community engagement and environmental sustainability, catering specifically to cycling enthusiasts.

Contras: On the downside, these stations are limited to bicycles, making them unsuitable for businesses that operate vehicles with larger tires. The reliance on manual operation may also deter some users who prefer automated solutions.

When selecting the right inflation solution, B2B buyers should consider factors such as the specific needs of their fleet, the locations they operate in, and budget constraints. Near air pumps are ideal for businesses with a central urban focus, while portable air compressors offer versatility for varied environments. Bicycle repair stations serve a niche market but can be an excellent community resource. Ultimately, the decision should align with the operational demands and the strategic goals of the business, ensuring efficiency and cost-effectiveness in tire maintenance.

When considering a near air pump for industrial or commercial use, several technical properties are critical to ensure optimal performance and reliability. Understanding these specifications can significantly influence purchasing decisions.

1. Grau do material

The material grade of a near air pump typically refers to the quality and type of materials used in its construction, such as aluminum, stainless steel, or high-grade plastics. Higher material grades can enhance durability, resistance to corrosion, and overall lifespan of the pump. For B2B buyers, selecting a pump made from superior materials can reduce maintenance costs and downtime, leading to improved operational efficiency.

2. Pressure Rating

The pressure rating indicates the maximum pressure the pump can safely handle, usually measured in PSI (pounds per square inch). This specification is vital for ensuring the pump meets the specific requirements of the application, such as inflating tires or powering pneumatic tools. B2B buyers must ensure that the pressure rating aligns with their operational needs to avoid equipment failure and ensure safety.

Illustrative image related to near air pump

3. Flow Rate

Measured in cubic feet per minute (CFM), the flow rate reflects how quickly the pump can deliver air. A higher flow rate is essential for applications requiring rapid inflation or air supply, such as in automotive service stations or manufacturing plants. For B2B buyers, understanding the flow rate helps in selecting a pump that meets productivity requirements without compromising on performance.

4. Tolerance and Precision

Tolerance refers to the allowable deviation from a specified dimension or pressure in the pump’s performance. High precision in manufacturing tolerances ensures that the pump operates effectively within its intended parameters. This is crucial for businesses that rely on exact specifications for their operations, as it impacts efficiency and product quality.

5. Noise Level

Noise level, often measured in decibels (dB), indicates how loud the pump operates during use. For workplaces where noise regulations are strict or where a quieter environment is preferred, selecting a pump with a lower noise level can enhance employee comfort and satisfaction. B2B buyers must consider this aspect, especially for pumps used in urban or populated areas.

Understanding trade terminology is essential for effective communication and negotiation in the procurement process. Here are some commonly used terms in the near air pump market:

1. OEM (fabricante original do equipamento)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the near air pump industry, OEMs are crucial as they provide essential components that meet specific quality standards. B2B buyers should consider OEM partnerships for reliable sourcing of high-quality pumps.

Illustrative image related to near air pump

2. MOQ (Quantidade mínima de pedido)

MOQ represents the minimum number of units a supplier is willing to sell in a single order. This term is significant for B2B buyers as it affects inventory management and purchasing strategies. Understanding MOQ can help businesses optimize their supply chain and reduce costs associated with overstocking or underordering.

3. RFQ (Request for Quotation, solicitação de cotação)

An RFQ is a formal document sent by a buyer to suppliers to solicit price quotes for specific products or services. In the near air pump sector, an RFQ allows businesses to compare pricing and terms from multiple suppliers, facilitating informed decision-making and budget management.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They cover aspects such as shipping, insurance, and tariffs. For B2B buyers, understanding Incoterms is essential for navigating international procurement and ensuring compliance with shipping regulations.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. In the context of near air pumps, shorter lead times can be critical for businesses needing quick replacements or additional units. B2B buyers should inquire about lead times when negotiating contracts to align their inventory needs with supplier capabilities.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing near air pumps, ultimately enhancing operational efficiency and reducing costs.

Illustrative image related to near air pump

The near air pump sector is witnessing significant growth driven by a surge in demand for convenient and efficient tire inflation solutions. Key global drivers include the increasing vehicle ownership rates, particularly in emerging markets across Africa and South America, where automotive growth is outpacing infrastructure development. In the Middle East and Europe, the emphasis on road safety and vehicle maintenance is prompting consumers and businesses alike to invest in quality air pumps, leading to a robust market expansion.

Emerging B2B tech trends are reshaping sourcing strategies in this sector. Companies are increasingly leveraging data analytics and IoT technologies to enhance product efficiency and user experience. For instance, smart air pumps equipped with sensors can provide real-time tire pressure data, allowing businesses to offer added value to customers. Additionally, e-commerce platforms are becoming critical for international buyers, enabling easy access to a diverse range of products and competitive pricing from suppliers across the globe.

As international buyers navigate these dynamics, they must consider the implications of varying regulatory standards, especially in regions like the European Union where environmental regulations are strict. Understanding local market needs and preferences is crucial for successful sourcing strategies, particularly in diverse markets such as Saudi Arabia and Germany.

Sustainability is becoming increasingly vital in the near air pump sector, as environmental concerns shape consumer preferences and regulatory frameworks. The production and disposal of air pumps can have significant environmental impacts, necessitating a focus on sustainable practices. B2B buyers are prioritizing suppliers that incorporate eco-friendly materials and processes into their manufacturing practices. This includes utilizing recyclable materials and reducing carbon footprints throughout the supply chain.

Ethical sourcing has emerged as a critical factor in supplier selection. Companies are expected to demonstrate transparency and responsibility in their sourcing practices, which can include fair labor practices and compliance with local and international regulations. Buyers should look for suppliers with recognized ‘green’ certifications, such as ISO 14001, which signal a commitment to environmental management, or those that use sustainable materials like bioplastics.

Additionally, as consumers become more environmentally conscious, they are likely to favor brands that align with their values. This trend presents an opportunity for B2B buyers to differentiate themselves in the marketplace by choosing suppliers who prioritize sustainability, thereby enhancing brand reputation and customer loyalty.

The near air pump industry has evolved significantly over the last few decades, transitioning from manual and mechanical devices to sophisticated electronic models. Initially, air pumps were primarily used in automotive workshops, but the rise of consumerism and the growing number of personal vehicles have shifted demand toward portable and easily accessible solutions.

With technological advancements, modern air pumps now include features such as digital displays, automatic shut-off functions, and built-in LED lights, making them user-friendly and efficient. The growth of e-commerce has further revolutionized the sector, enabling suppliers to reach a broader audience and streamline the purchasing process. Today, the near air pump market is characterized by innovation, sustainability, and an increasing focus on meeting consumer demands for convenience and efficiency.

This evolution reflects broader trends in consumer behavior and technological advancement, positioning the near air pump sector as a dynamic and integral part of the automotive aftermarket industry.

How do I select the right near air pump for my business needs?

Choosing the right near air pump involves assessing your specific application requirements, such as the volume of air needed, portability, and power source. Consider factors like the pump’s pressure range, flow rate, and durability based on your operational environment. Engage with suppliers to understand their product offerings, and if possible, request samples or demonstrations to evaluate performance. Also, check for certifications that meet your industry standards to ensure reliability and safety.

What is the best air pump for commercial tire inflation?

For commercial tire inflation, a high-capacity, heavy-duty air pump is ideal. Look for models that offer a high CFM (cubic feet per minute) rating for faster inflation times and a pressure range suitable for various tire sizes. Brands renowned for commercial use, like Ingersoll Rand or Senco, typically provide robust options. Additionally, consider features such as automatic shut-off, which enhances safety and efficiency, and ensure the pump meets local regulations for commercial use.

What factors should I consider when vetting suppliers for air pumps?

When vetting suppliers, prioritize their industry experience, product quality, and customer reviews. Request references and check their financial stability through credit reports or trade references. Assess their manufacturing capabilities and compliance with international standards, as this can affect product quality. Additionally, ensure they have a responsive customer service team for post-purchase support, and inquire about warranty and return policies to protect your investment.

What is the minimum order quantity (MOQ) for near air pumps?

Minimum order quantities (MOQ) for near air pumps can vary widely depending on the manufacturer and product type. Typically, MOQs range from 50 to 500 units for bulk orders. It’s crucial to negotiate these terms during your discussions with suppliers, especially if you’re a smaller business. Some suppliers may offer flexibility in MOQs for new customers or through trial orders, enabling you to test the market before committing to larger quantities.

What payment terms are common for international B2B purchases of air pumps?

Common payment terms in international B2B transactions include a deposit (often 30% to 50%) upfront with the balance due upon shipment or delivery. Letters of credit are also popular for larger orders, providing security for both parties. It’s essential to negotiate terms that align with your cash flow and risk tolerance. Always clarify payment methods accepted (such as wire transfers, PayPal, or credit terms) and ensure they comply with your country’s regulations.

How can I ensure quality assurance (QA) for air pumps sourced internationally?

To ensure quality assurance for internationally sourced air pumps, request certifications and compliance documentation from the supplier, such as ISO 9001. Conduct factory audits if feasible, or use third-party inspection services to assess product quality before shipment. Establish clear specifications and acceptance criteria in your purchase agreement. Additionally, consider implementing a quality control process upon receipt, including testing pumps for functionality and safety.

What logistics considerations should I keep in mind when importing air pumps?

When importing air pumps, consider shipping methods (air, sea, or land) based on cost, speed, and volume. Understand customs regulations in your country to ensure compliance and avoid delays. Work with a reliable freight forwarder who can navigate the complexities of international shipping, including tariffs and documentation. Also, factor in lead times for production and shipping to align with your inventory needs.

Can I customize the air pumps to meet specific operational requirements?

Many manufacturers offer customization options for air pumps, such as branding, specifications, and features tailored to your business needs. Discuss your requirements with suppliers, including any unique functionalities like pressure settings or color schemes. Be prepared to meet minimum order quantities for custom products, and clarify any additional costs associated with modifications. Customization can enhance your brand identity and ensure the product aligns perfectly with your operational requirements.

Domínio: freeairpump.com

Registrado: 2012 (13 anos)

Introdução: FreeAirPump.com provides a crowdsourced map of locations offering free air for tires, including gas stations and bike repair stations. Users can add locations and report errors. The site also offers guidance on portable air compressors for those unable to find free air. In Connecticut, free air is available at gas stations, while California mandates free air for paying customers. The site encourag…

Domínio: yelp.com

Registrado: 2003 (22 anos)

Introdução: This company, Yelp – Best Reviewed Gas Stations, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domínio: smart.dhgate.com

Registrado: 2004 (21 anos)

Introdução: Electric Portable Compressor Vehicle Tools 150PSI Handheld Inflatable Pump: Ideal for busy drivers who want quick, accurate inflation anywhere. Key benefit: Rapid inflation with a rechargeable battery and cordless convenience.

Domínio: freetireair.com

Registered: 2023 (2 years)

Introdução: Free Tire Air Pumps in Philadelphia, Pennsylvania. 43 verified locations including gas stations and convenience stores. Unlimited free air available with personal tire air pump. Locations include multiple Wawa stores across Philadelphia.

In summary, strategic sourcing of near air pumps presents a significant opportunity for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The growing demand for efficient and cost-effective air solutions highlights the importance of identifying reliable suppliers who can provide high-quality pumps tailored to specific operational needs. By leveraging strategic sourcing, businesses can not only reduce costs but also enhance their service offerings, driving customer satisfaction and loyalty.

Moreover, the rise of eco-friendly practices in sourcing and manufacturing near air pumps aligns with global sustainability trends, making it essential for companies to consider environmentally responsible suppliers. As markets evolve, staying ahead of industry innovations will enable businesses to maintain a competitive edge.

Looking ahead, international buyers are encouraged to explore partnerships that focus on innovation, quality, and sustainability in the near air pump sector. Engaging with local suppliers and utilizing comprehensive sourcing platforms can facilitate access to the best products and services available. By taking proactive steps now, businesses can secure a robust supply chain that meets future demands effectively.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.