In the ever-evolving global market, effectively managing tire inflation pressure stands as a critical challenge for B2B buyers, particularly those in sectors reliant on transportation and logistics. Sourcing the right tire inflation solutions can directly impact vehicle safety, operational efficiency, and overall cost-effectiveness. This comprehensive guide delves into the multifaceted aspects of tire inflation pressure, encompassing recommended pressure levels, the implications of both under- and over-inflation, and the role of tire pressure monitoring systems (TPMS).

International buyers from diverse regions, including Africa, South America, the Middle East, and Europe, will find valuable insights into selecting appropriate tire pressure solutions tailored to their specific needs. The guide covers essential topics such as identifying optimal tire pressure for various vehicle types, understanding the applications across different terrains, and vetting suppliers to ensure quality and reliability. Additionally, it addresses cost considerations and the long-term benefits of maintaining proper tire inflation, such as improved fuel efficiency and reduced tire wear.

Empowering informed purchasing decisions, this guide serves as a vital resource for B2B buyers seeking to navigate the complexities of tire inflation pressure in an increasingly competitive marketplace. By understanding these key dynamics, businesses can enhance their operational performance and safety standards, ultimately driving greater success in their respective industries.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Recommended Pressure | Manufacturer-specified optimal pressure for safety | Fleet management, automotive service providers | Prós: Enhances safety, improves fuel efficiency. Contras: Requires regular monitoring. |

| Maximum Pressure | Maximum safe pressure limit specified on tire sidewall | Heavy-duty vehicle operations, transport logistics | Prós: Supports heavy loads temporarily. Contras: Risk of blowouts if used regularly. |

| Minimum Pressure | Pressure below which safety and performance are compromised | Commercial vehicle maintenance, tire retailers | Prós: Avoids under-inflation risks. Contras: No explicit minimum stated, can lead to confusion. |

| Cold Pressure | Pressure measurement taken when tires are cold | Tire manufacturers, automotive OEMs | Prós: Accurate performance assessment. Contras: Requires timing and conditions for measurement. |

| Tire Pressure Monitoring Systems (TPMS) | Real-time monitoring of tire pressure levels | Fleet management, automotive technology firms | Prós: Alerts for pressure changes, enhances safety. Contras: Can malfunction or require calibration. |

Recommended tire pressure is the optimal air pressure specified by vehicle manufacturers, crucial for ensuring safety, enhancing fuel efficiency, and prolonging tire life. For B2B buyers in sectors such as fleet management and automotive services, adhering to these specifications is essential. Regular monitoring ensures that vehicles operate smoothly, reducing the risk of accidents and minimizing operational costs. Buyers should prioritize tools and systems that facilitate easy access to this information, such as tire pressure gauges and monitoring systems.

Maximum pressure, indicated on the tire’s sidewall, represents the upper limit of air pressure that a tire can safely handle. This type of inflation is particularly relevant for businesses engaged in heavy-duty operations, such as transport logistics. While it allows for carrying heavier loads, using maximum pressure as a routine practice can lead to dangerous blowouts and compromised handling. B2B buyers should consider the operational context and ensure that maximum pressure is only utilized when necessary, such as during towing or transporting heavy goods.

Minimum tire pressure is a critical concept, although manufacturers do not typically specify a minimum value. Instead, any pressure below the recommended level can lead to under-inflation, risking safety and performance. For commercial vehicle maintenance providers, understanding the implications of low tire pressure is vital. They should educate clients about the importance of maintaining at least the recommended pressure to avoid increased fuel consumption and tire wear. Buyers must also consider the implications of the lack of a clear minimum pressure guideline when selecting tire maintenance solutions.

Cold pressure refers to the tire pressure measurement taken when the tire is not heated from driving. This is crucial for accurate assessments of tire performance, as temperature fluctuations can significantly alter pressure readings. For B2B buyers, particularly in the tire manufacturing and automotive sectors, understanding the importance of cold pressure ensures that vehicles are maintained under optimal conditions. Buyers should invest in systems that remind users to check tire pressure in appropriate conditions, enhancing overall vehicle safety and performance.

TPMS provides real-time monitoring of tire pressures, alerting drivers when levels drop below safe thresholds. This technology is increasingly critical for fleet management and automotive technology firms, as it enhances safety and operational efficiency. By investing in TPMS, B2B buyers can prevent the risks associated with under-inflation, such as blowouts and reduced fuel efficiency. However, buyers should also be aware of potential malfunctions and the need for regular calibration to ensure accurate performance.

| Indústria/Setor | Specific Application of Tire Inflation Pressure | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Transportation & Logistics | Fleet Management Systems | Enhances safety, reduces fuel costs, and prolongs tire lifespan. | Need for reliable tire pressure monitoring systems (TPMS) and gauges. |

| Agricultura | Agricultural Vehicle Maintenance | Ensures optimal performance of tractors and other farm equipment, reducing downtime. | Sourcing high-capacity tire pressure gauges suitable for rugged environments. |

| Mining & Construction | Heavy Machinery Operations | Prevents tire blowouts and improves operational efficiency in harsh conditions. | Durable, accurate pressure monitoring tools designed for extreme conditions. |

| Automotive Service | Tire Maintenance Services | Provides essential service for customer safety and satisfaction, enhancing business reputation. | Access to comprehensive tire pressure data and calibration tools for various tire types. |

| Public Transport | Bus and Taxi Fleet Operations | Ensures passenger safety and lowers operational costs through efficient fuel consumption. | Need for scalable tire pressure monitoring solutions across diverse vehicle types. |

In the transportation and logistics sector, tire inflation pressure is critical for fleet management systems. Properly inflated tires enhance vehicle safety, optimize fuel efficiency, and extend tire lifespan, which translates to significant cost savings. International buyers, particularly in regions like Africa and South America, must consider sourcing reliable tire pressure monitoring systems (TPMS) that can withstand varying climatic conditions and provide accurate readings to prevent under-inflation or over-inflation.

In agriculture, maintaining the correct tire inflation pressure in tractors and other heavy machinery is essential for optimal performance. Proper tire inflation reduces the risk of tire damage, ensures better traction, and minimizes soil compaction, which can affect crop yields. Buyers in this sector should prioritize high-capacity tire pressure gauges that are durable and can operate effectively in rugged environments, ensuring consistent performance throughout the farming season.

In the mining and construction industries, tire inflation pressure is vital for heavy machinery operations. Proper inflation helps prevent blowouts and enhances the operational efficiency of vehicles working in harsh conditions. Businesses in these sectors should focus on sourcing durable and accurate tire pressure monitoring tools that can withstand extreme environments, providing reliable data to maintain safety and reduce costly downtime.

For automotive service providers, maintaining tire inflation pressure is a key aspect of tire maintenance services. Accurate inflation is crucial for ensuring customer safety and enhancing overall satisfaction, which can significantly improve a service provider’s reputation. B2B buyers in this field should seek comprehensive tire pressure data solutions and calibration tools that accommodate various tire types, ensuring they can deliver reliable services to their clientele.

In public transport, such as bus and taxi fleets, proper tire inflation pressure is essential for passenger safety and operational efficiency. Correctly inflated tires lead to better fuel consumption and lower operational costs, benefiting both service providers and passengers. Buyers in this industry should invest in scalable tire pressure monitoring solutions that can be effectively implemented across diverse vehicle types, ensuring consistent safety and performance standards.

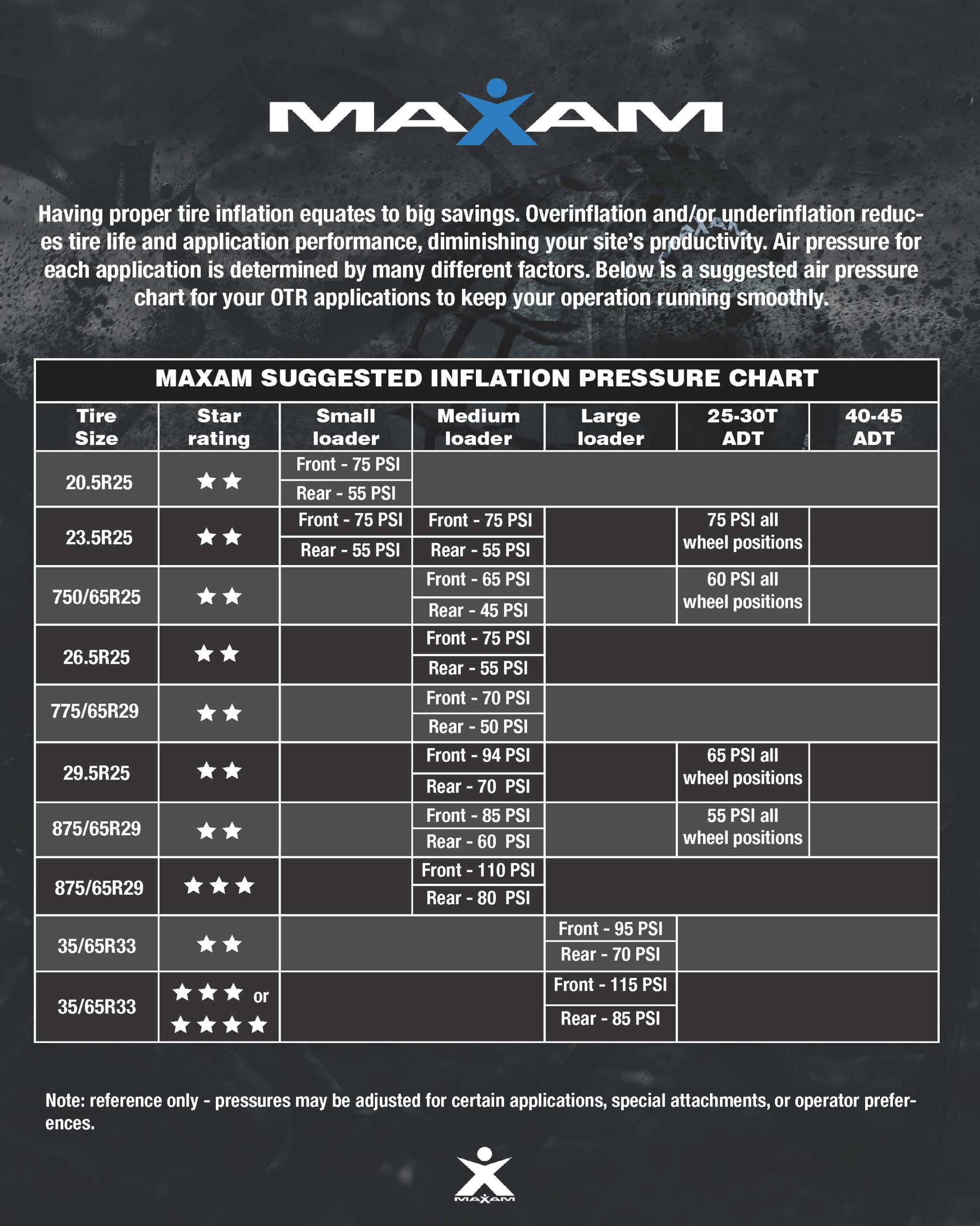

Illustrative image related to tire inflation pressure

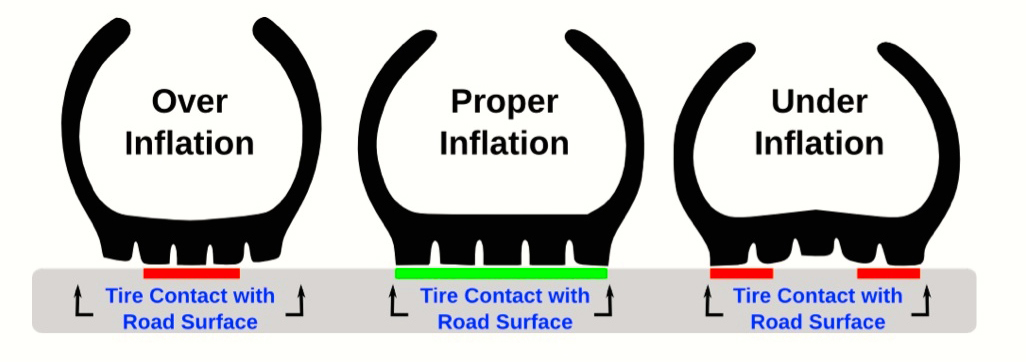

O problema: For businesses operating a fleet of vehicles, maintaining the correct tire pressure is crucial for safety, operational efficiency, and cost management. However, many fleet managers struggle with inconsistent tire pressure due to varied usage patterns, different vehicle models, and environmental factors. In regions like Africa or South America, where road conditions can vary significantly, the risk of under-inflation or over-inflation increases. This not only leads to increased fuel consumption but can also result in tire blowouts, which pose safety risks and lead to costly downtime.

A solução: To address these challenges, fleet managers should implement a proactive tire maintenance program that includes regular tire pressure checks and the use of Tire Pressure Monitoring Systems (TPMS). Investing in a centralized tire pressure management system can help monitor and adjust tire pressure automatically, providing real-time data on each vehicle. Additionally, creating a standard operating procedure for checking tire pressure—ideally once a month and before long trips—can instill a culture of safety and maintenance within the fleet. Training drivers to recognize the importance of maintaining optimal tire pressure and equipping them with digital gauges can further enhance safety and efficiency.

O problema: B2B buyers often face confusion regarding tire pressure specifications, especially when dealing with multiple tire brands and vehicle models. Misunderstanding the difference between recommended tire pressure and maximum tire pressure can lead to improper inflation practices. This issue can be particularly pronounced in regions like the Middle East, where high temperatures can affect tire performance and pressure readings, leading to over-inflation risks.

A solução: To mitigate this issue, businesses should establish clear guidelines for tire inflation based on the manufacturer’s specifications, which can be found in the vehicle’s manual or on the tire information placard. Conducting training sessions for maintenance staff to educate them on interpreting these specifications correctly can significantly reduce the risk of errors. Additionally, implementing a routine review of tire pressure before any long journeys or heavy loads can help ensure that tires are inflated to the recommended level, taking into account the temperature and load conditions.

Illustrative image related to tire inflation pressure

O problema: Many B2B buyers are not fully aware of how tire pressure directly impacts fuel efficiency. Under-inflated tires increase rolling resistance, causing vehicles to consume more fuel. In regions like Brazil, where fuel prices can be volatile, this can lead to significant operational costs. Furthermore, companies may not have a clear strategy for addressing tire pressure issues, resulting in wasted resources and decreased profitability.

A solução: To tackle this issue, organizations should conduct regular fuel consumption analysis and correlate it with tire pressure data. By using telematics systems that track tire pressure alongside fuel efficiency metrics, businesses can identify trends and make informed decisions about maintenance schedules. Additionally, implementing a rewards program for drivers who consistently maintain optimal tire pressure can foster accountability and drive behavior change. Regular workshops on the cost-saving benefits of proper tire maintenance can also help reinforce the importance of this practice in reducing fuel expenses, ultimately benefiting the bottom line.

When selecting materials for tire inflation pressure systems, several factors come into play, including temperature and pressure ratings, corrosion resistance, and overall durability. Below, we analyze four common materials used in these systems, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Principais propriedades: Rubber is known for its elasticity and ability to withstand a wide range of temperatures. It can handle pressures typically between 28 to 36 PSI, which is standard for most vehicles. Additionally, rubber exhibits good resistance to wear and tear.

Prós e contras: The primary advantage of rubber is its flexibility and ability to create airtight seals, essential for maintaining tire pressure. However, rubber can degrade over time due to UV exposure and extreme temperatures, leading to potential leaks or failures. Cost-wise, rubber is relatively low, making it an economical choice for many applications.

Impacto no aplicativo: Rubber is compatible with air and nitrogen, which are common gases used in tire inflation. However, it may not perform well under extreme temperatures, which can be a concern in regions with harsh climates, such as parts of Africa and the Middle East.

Illustrative image related to tire inflation pressure

Considerações para compradores internacionais: Buyers should ensure that the rubber used complies with regional standards such as ASTM or DIN. In markets like Brazil, where humidity can be high, selecting high-quality rubber that resists moisture is crucial.

Principais propriedades: Metals, particularly aluminum and steel, are often used in valves and fittings due to their high strength and resistance to deformation under pressure. They can withstand high temperatures and pressures, making them suitable for heavy-duty applications.

Prós e contras: The main advantage of metal components is their durability and resistance to wear. However, metals can corrode if not treated properly, especially in humid or saline environments. The cost of metal components can be higher than rubber, which may impact budget considerations.

Impacto no aplicativo: Metals are generally compatible with various gases used for tire inflation. However, corrosion resistance is a significant factor, particularly in coastal regions of South America or the Middle East, where salt exposure can lead to rapid degradation.

Illustrative image related to tire inflation pressure

Considerações para compradores internacionais: Buyers should look for metals that meet international corrosion resistance standards. In Europe, for example, compliance with EN standards is essential for ensuring product reliability.

Principais propriedades: Plastics, such as polyamide and polycarbonate, are lightweight and can be molded into complex shapes. They offer good chemical resistance and can handle moderate pressures.

Prós e contras: The primary advantage of plastics is their versatility and low weight, which can contribute to overall vehicle efficiency. However, plastics may not withstand high temperatures and pressures as effectively as metals or rubber. They are generally more affordable than metals but can be more expensive than rubber.

Impacto no aplicativo: Plastics are suitable for components that require intricate designs, such as valve caps. Their chemical resistance makes them compatible with various gases, but their performance can be limited in extreme conditions.

Considerações para compradores internacionais: Buyers should ensure that the plastics meet relevant safety and performance standards, especially in regions with stringent regulations like Europe. Additionally, understanding the local climate’s impact on plastic durability is crucial.

Principais propriedades: Composite materials combine the strengths of different materials, often incorporating fibers with resins. They can be engineered for specific performance characteristics, such as high strength-to-weight ratios and excellent corrosion resistance.

Prós e contras: The advantage of composites is their ability to be tailored for specific applications, providing high performance while being lightweight. However, they can be more complex to manufacture and may come at a higher cost compared to traditional materials.

Impacto no aplicativo: Composites can be used in high-performance tire inflation systems, especially in racing or heavy-duty applications. Their resistance to environmental factors makes them suitable for diverse climates.

Considerações para compradores internacionais: Buyers should consider the manufacturing complexity and ensure that the composite materials used comply with local regulations. In regions like Africa, where infrastructure may vary, understanding the supply chain for composite materials is essential.

| Material | Typical Use Case for tire inflation pressure | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Borracha | Tire seals and inner linings | Flexibility and airtight sealing | Degrades under UV and extreme temps | Baixa |

| Metal | Valves and fittings | Alta resistência e durabilidade | Prone to corrosion | Med |

| Plástico | Valve caps and lightweight components | Lightweight and versatile | Limited high-temperature performance | Med |

| Composto | High-performance applications | Tailored performance characteristics | Maior complexidade de fabricação | Alta |

This comprehensive analysis provides valuable insights for B2B buyers in the tire inflation pressure market, enabling informed material selection based on specific needs and regional considerations.

The manufacturing process of tires is intricate, involving several critical stages that ensure safety, performance, and adherence to inflation pressure specifications. The primary stages include material preparation, forming, assembly, and finishing.

1. Material Preparation:

The first step involves sourcing high-quality raw materials, including natural and synthetic rubber, fabric, and steel. These materials are formulated with specific additives to enhance durability, flexibility, and resistance to heat. For tire inflation, the rubber compounds are particularly engineered to maintain air retention and withstand temperature fluctuations, crucial for maintaining optimal tire pressure.

Illustrative image related to tire inflation pressure

2. Forming:

In this stage, the prepared materials are shaped into tire components. The tire’s inner liner, which is essential for air retention, is produced and then combined with other components like belts and tread. Advanced techniques such as calendering are employed to ensure uniform thickness and consistency, which directly affects the tire’s ability to hold pressure.

3. Assembly:

During assembly, the various components are put together. This involves layering the inner liner, body plies, belts, and tread in a precise order. The use of automated machinery ensures that each tire is constructed to exact specifications, reducing variability that could impact performance.

4. Finishing:

The final stage includes curing the assembled tire in a mold under heat and pressure, a process that solidifies the tire’s shape and enhances its structural integrity. This step is crucial as it influences the tire’s elasticity and strength, both of which play a role in maintaining proper inflation levels.

Quality control (QC) is vital throughout the tire manufacturing process to ensure that the end product meets international standards and customer expectations. Various checkpoints are established, guided by both international standards like ISO 9001 and industry-specific certifications such as CE and API.

Illustrative image related to tire inflation pressure

Key QC Checkpoints:

Controle de qualidade de entrada (IQC): This initial inspection involves verifying the quality of raw materials before they enter the production line. Suppliers are often required to provide certification that their materials meet specific standards, and testing may include checking for material composition and integrity.

Controle de qualidade durante o processo (IPQC): Continuous monitoring occurs throughout the manufacturing stages. Techniques such as statistical process control (SPC) are employed to track variations and ensure that every component is produced within specified tolerances. This helps in identifying defects early, minimizing waste and rework.

Controle de qualidade final (FQC): After the tires are cured, a comprehensive inspection is conducted. This includes visual inspections for defects, dimensional checks, and pressure tests to confirm that the tires can maintain the required inflation levels under various conditions.

Tire manufacturers employ a variety of testing methods to ensure that tires meet safety and performance standards related to inflation pressure:

Inflation Pressure Testing: Tires are subjected to pressure tests to ensure they can withstand the specified PSI without failure. This testing simulates real-world conditions, ensuring that the tires perform safely under load.

Teste de durabilidade: This involves running tires through extensive wear simulations to assess how they maintain pressure over time and under various driving conditions.

Temperature Testing: Given that tire pressure can be affected by temperature changes, manufacturers conduct tests to evaluate how well tires retain pressure in extreme conditions.

Dynamic Testing: This method assesses the tire’s performance while in motion, including handling characteristics, stability, and braking efficiency under varying inflation levels.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, ensuring the integrity of supplier QC practices is critical. Here are actionable steps to verify QC processes:

Auditorias de fornecedores: Conducting regular audits of suppliers helps assess their adherence to quality standards. This includes reviewing their manufacturing processes, QC protocols, and compliance with international certifications.

Solicitação de relatórios de qualidade: Suppliers should provide detailed reports of their QC processes, including results from testing methods and any certifications obtained. This transparency allows buyers to evaluate the supplier’s commitment to quality.

Inspeções de terceiros: Engaging independent third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can cover everything from raw material quality to final product testing.

Certification Verification: Buyers should verify that suppliers hold relevant certifications such as ISO 9001, CE, or other industry-specific standards. This verification can often be done through the certifying bodies or directly with the supplier.

International B2B buyers must be aware of specific nuances when it comes to QC and certification:

Regulamentos regionais: Different regions may have varying regulations regarding tire safety and performance. Buyers should familiarize themselves with local standards and ensure that suppliers comply with them.

Considerações culturais: Understanding cultural differences in business practices can aid in more effective communication and collaboration with suppliers. This can influence how quality assurance processes are implemented and adhered to.

Logistical Challenges: Transportation and environmental factors can affect tire quality during shipping. Buyers should ensure that suppliers have measures in place to protect tires from damage and pressure loss during transit.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices related to tire inflation pressure is essential for B2B buyers. By focusing on these aspects, companies can ensure they procure high-quality tires that not only meet safety standards but also enhance operational efficiency and reduce costs.

Illustrative image related to tire inflation pressure

To ensure the efficient procurement of tire inflation pressure solutions, this practical sourcing guide will help B2B buyers navigate essential steps. Proper tire inflation is crucial not only for vehicle safety but also for operational efficiency and cost-effectiveness. Here’s a step-by-step checklist to guide your sourcing process.

Understanding the specific requirements for your fleet or vehicle types is the foundation of effective sourcing. Determine the types of vehicles you operate, as different vehicles have varying tire pressure specifications. Additionally, assess whether you need manual gauges, digital monitors, or automated tire inflation systems, considering factors like usage frequency and environmental conditions.

Establish clear technical specifications for the tire inflation equipment you require. This includes acceptable pressure ranges, compatibility with different tire types, and features like portability or integration with existing systems. Articulating these specifications will streamline the supplier selection process and ensure you receive suitable products for your needs.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with proven track records of reliability and customer service. Additionally, assess their ability to provide support, maintenance, and training for the products they offer.

Ensure that potential suppliers comply with international and local safety standards relevant to tire inflation systems. Look for certifications from recognized bodies that demonstrate adherence to quality and safety regulations. This is particularly important in regions with stringent regulations, such as Europe and the Middle East, where compliance can affect your overall operational legality.

Request detailed quotations from shortlisted suppliers, ensuring clarity on pricing models. Consider whether prices are fixed or variable, and inquire about bulk purchase discounts or financing options. Understanding payment terms is crucial for budgeting and cash flow management, especially for larger fleets.

Whenever possible, ask suppliers for demonstrations or trial periods for their tire inflation solutions. This allows you to evaluate the equipment’s performance, ease of use, and integration capabilities firsthand. A trial period can also help identify any potential issues or shortcomings before making a full commitment.

Investigate the after-sales support offered by suppliers, including warranty terms, availability of spare parts, and technical assistance. Reliable after-sales service can significantly reduce downtime and maintenance costs. Ensure that the warranty covers critical components and that support channels are easily accessible.

By following this structured checklist, B2B buyers can make informed decisions regarding tire inflation pressure solutions, ultimately enhancing safety, efficiency, and cost-effectiveness in their operations.

When analyzing the cost structure for tire inflation pressure sourcing, several components play a critical role. The primary cost elements include:

Materiais: The quality and type of materials used in tire manufacturing, such as rubber compounds and reinforcement materials, significantly influence overall costs. High-performance tires may require specialized materials, increasing the price.

Trabalho: Labor costs encompass the wages of skilled workers involved in tire production and assembly. In regions with higher labor costs, such as Europe, this can impact the overall pricing strategy.

Custos indiretos de fabricação: This includes expenses related to factory operations, utilities, and maintenance. Efficient production processes can help mitigate these costs, making it essential for manufacturers to optimize their operational workflows.

Ferramentas: The initial investment in molds and manufacturing equipment is crucial, particularly for custom tire specifications. Manufacturers must balance tooling costs against expected production volumes to ensure profitability.

Controle de qualidade (QC): Implementing rigorous QC measures is essential for ensuring tire safety and performance. However, these measures add to the overall cost structure. Certifications, such as ISO or regional safety standards, may also contribute to higher costs.

Logística: Transportation and distribution costs, including shipping and handling, affect pricing, especially for international transactions. Variations in logistics costs can arise based on the distance from manufacturing hubs to target markets.

Margem: Manufacturers typically set a profit margin based on the cost structure outlined above. This margin can vary depending on market dynamics, competition, and the perceived value of the product.

Several factors influence pricing in the tire inflation pressure market:

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Bulk purchases often lead to discounts, making it beneficial for buyers to negotiate favorable terms based on volume commitments.

Specifications/Customization: Custom tire specifications, such as unique sizes or specialized features, can increase costs. Buyers should be prepared for additional expenses when requesting tailored solutions.

Materials Quality/Certifications: The choice of materials directly impacts pricing. Tires made with advanced compounds or those certified for specific performance standards will generally command a higher price.

Fatores do fornecedor: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge premium prices, while newer entrants might offer competitive rates to gain market share.

Incoterms: Understanding Incoterms is crucial for international buyers, as they define the responsibilities of buyers and sellers in shipping. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect total costs and should be negotiated wisely.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can yield significant savings:

Aproveite o custo total de propriedade (TCO): Consider not just the purchase price but the overall costs associated with the tires, including maintenance, fuel efficiency, and lifespan. A lower initial price may not always result in long-term savings.

Research and Benchmarking: Understanding market trends and pricing benchmarks can provide leverage during negotiations. Buyers should gather data on competitor pricing and industry standards.

Criar relacionamentos: Establishing strong relationships with suppliers can lead to better pricing and terms. Frequent communication and reliability can foster trust, resulting in more favorable negotiation outcomes.

Flexibility in Terms: Be open to negotiating terms beyond price, such as payment terms, warranties, or service agreements. These factors can enhance the overall value of the deal.

Considerações culturais: When dealing with suppliers from different regions, being aware of cultural nuances in negotiation styles can facilitate smoother discussions and lead to better outcomes.

Navigating the costs and pricing dynamics of tire inflation pressure sourcing requires a thorough understanding of the various cost components and influencers. By employing effective negotiation strategies and considering the total cost of ownership, B2B buyers can secure favorable deals while ensuring the safety and performance of their tire investments. It’s essential to stay informed and proactive in discussions to maximize value in this competitive marketplace.

Isenção de responsabilidade: Pricing and cost structures are indicative and can vary significantly based on market conditions, supplier agreements, and regional factors. Always conduct thorough market research before finalizing any purchasing decisions.

Illustrative image related to tire inflation pressure

In the realm of tire management, maintaining optimal tire inflation pressure is crucial for safety, fuel efficiency, and tire longevity. However, there are alternative solutions and technologies that can also enhance tire performance and safety. This section compares traditional tire inflation management against other viable methods, providing B2B buyers with insights into their options.

| Aspecto de comparação | Tire Inflation Pressure | Tire Pressure Monitoring System (TPMS) | Nitrogen Tire Inflation |

|---|---|---|---|

| Desempenho | Maintains optimal tire performance when correctly monitored. | Provides real-time alerts for tire pressure deviations, enhancing safety. | Reduces pressure loss and maintains stable inflation over time. |

| Custo | Minimal costs for gauges and air compressors. | Moderate upfront costs for installation; low maintenance. | Higher initial investment; nitrogen refills can be costlier than air. |

| Facilidade de implementação | Simple to check and adjust; requires manual effort. | Requires installation and integration with vehicle systems. | Requires specialized equipment for filling and monitoring. |

| Manutenção | Regular checks needed (monthly recommended). | Low maintenance; alerts automate pressure checks. | Requires occasional refills but less frequent than air. |

| Melhor caso de uso | Everyday vehicles and light-duty applications. | Fleet management and vehicles in high-pressure environments. | High-performance vehicles, racing, and commercial fleets. |

Tire Pressure Monitoring Systems (TPMS) offer a modern alternative to manual tire inflation management. They utilize sensors to monitor tire pressure in real time and alert drivers when pressure falls outside the recommended range. This proactive approach enhances safety by reducing the risk of blowouts and improving fuel efficiency through timely interventions. However, TPMS systems can involve moderate initial installation costs and may require specialized knowledge for maintenance.

Nitrogen tire inflation is increasingly popular, particularly in high-performance and commercial applications. Nitrogen molecules are larger than oxygen molecules, leading to reduced pressure loss over time and more stable tire inflation. This method can improve tire longevity and fuel efficiency. However, the initial setup costs can be higher due to the need for specialized filling equipment, and refilling nitrogen can be more expensive compared to standard air.

Illustrative image related to tire inflation pressure

When deciding on the best tire management solution, B2B buyers should consider their specific operational needs and budget constraints. For standard applications, maintaining proper tire inflation pressure may suffice. However, for fleets or high-performance vehicles, investing in TPMS or nitrogen tire inflation can lead to improved safety, efficiency, and tire life. Assessing the performance requirements, cost implications, and ease of implementation will ensure that businesses select the most suitable option for their unique circumstances.

Understanding tire inflation pressure is crucial for businesses involved in automotive sales, fleet management, or tire manufacturing. The following outlines essential technical properties and terminology that international B2B buyers should be familiar with.

RTP is the optimal air pressure specified by the vehicle manufacturer, typically found on a label inside the driver’s door or in the vehicle’s owner manual. It varies by vehicle model and tire size, usually ranging from 28 to 36 PSI (pounds per square inch). Maintaining the RTP is vital for safety, fuel efficiency, and tire longevity. For B2B buyers, ensuring compliance with RTP can reduce operational costs and enhance customer satisfaction.

Cold pressure refers to the tire pressure measured when the tires are at ambient temperature, not having been driven for at least three hours. This measurement is critical for accurate readings and helps prevent over-inflation or under-inflation, which can lead to tire failure. For businesses, understanding cold pressure ensures that service personnel can accurately advise customers, enhancing service quality and safety.

This is the highest pressure that a tire can safely handle, indicated on the tire sidewall. While it may exceed the RTP, inflating tires to this level during regular driving is inadvisable due to safety risks such as blowouts and impaired vehicle handling. Businesses should educate their clients about the distinction between maximum and recommended pressures to prevent misuse.

TPMS is an electronic system that monitors tire pressure and alerts the driver when it falls below a specified threshold, typically 25% under the recommended pressure. This technology is essential for maintaining safety and efficiency in fleet operations. B2B buyers should consider the integration of TPMS in their vehicle offerings to enhance safety features and customer appeal.

The load index indicates the maximum load a tire can support at the recommended inflation pressure. This specification is crucial for businesses that deal with heavy-duty vehicles or specialized applications. Understanding load index helps buyers select appropriate tires for their needs, ensuring safety and compliance with regulations.

OEM refers to the company that manufactures the original parts of a vehicle, including tires. In tire procurement, buyers often seek OEM specifications to ensure compatibility and performance. Understanding OEM standards is critical for businesses looking to maintain quality in their offerings.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps businesses manage inventory and supply chain logistics effectively. For tire suppliers, understanding MOQ can facilitate better negotiation terms and optimize stock levels.

An RFQ is a document that buyers send to suppliers requesting price quotes for specific products or services. In the tire industry, issuing RFQs allows businesses to compare prices and terms from multiple suppliers, ensuring competitive purchasing decisions.

International Commercial Terms (Incoterms) are a set of rules that define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers in the tire market to mitigate risks and ensure smooth transactions.

Tread depth measures the depth of the grooves in a tire’s tread, directly impacting traction and safety. For B2B buyers, understanding the implications of tread depth on tire performance can influence purchasing decisions, particularly in sectors requiring high safety standards.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions regarding tire inflation pressure, ultimately enhancing operational efficiency and safety in their fleets.

The tire inflation pressure sector is experiencing significant transformation driven by several global factors. Increased awareness of road safety and fuel efficiency is propelling demand for accurate tire pressure management systems. These systems not only enhance vehicle safety but also contribute to fuel savings—an important consideration for businesses operating fleets in regions like Africa, South America, and the Middle East, where fuel costs can be substantial. Additionally, the growing adoption of advanced technologies such as IoT-enabled tire pressure monitoring systems (TPMS) is reshaping sourcing trends. These technologies provide real-time data analytics, enabling proactive maintenance and reducing downtime for vehicles, which is critical for logistics and transportation businesses.

Illustrative image related to tire inflation pressure

Emerging markets, particularly in regions like Saudi Arabia and Brazil, are witnessing a surge in the adoption of smart tire technology. This trend is coupled with the increasing emphasis on digital platforms for B2B transactions, where buyers can easily source products and services online. Moreover, sustainability is becoming a pivotal consideration, with buyers seeking suppliers who prioritize eco-friendly practices and products. Consequently, manufacturers are innovating to produce tires that maintain optimal pressure longer, reducing the frequency of replacements and lowering the environmental impact.

Sustainability and ethical sourcing are increasingly critical in the tire inflation pressure sector. The environmental impact of tire production and disposal is significant, with traditional manufacturing processes contributing to pollution and waste. B2B buyers, especially in Europe and regions with stringent environmental regulations, are now more inclined to partner with suppliers who demonstrate a commitment to sustainability. This includes sourcing materials that are recycled or derived from renewable resources, as well as adopting production methods that minimize waste and carbon emissions.

The demand for ‘green’ certifications is on the rise, with buyers seeking assurance that their suppliers adhere to recognized environmental standards. This trend not only enhances the brand reputation of businesses but also aligns with consumer preferences for sustainable products. Furthermore, ethical supply chains are becoming non-negotiable, with businesses increasingly scrutinizing the practices of their suppliers to ensure fair labor practices and responsible sourcing. By prioritizing sustainable and ethical sourcing, B2B buyers can mitigate risks associated with supply chain disruptions and enhance their corporate social responsibility initiatives.

The tire inflation pressure sector has evolved significantly over the past few decades, transitioning from basic mechanical gauges to sophisticated electronic monitoring systems. Initially, tire pressure was managed manually, relying on simple pressure gauges and driver awareness. However, with the advent of technology, tire pressure monitoring systems (TPMS) became standard in many vehicles, significantly enhancing safety and performance.

The sector’s evolution reflects broader trends in automotive technology, including the integration of sensors and data analytics. Today, businesses are not only focused on tire performance but also on the implications of tire maintenance for operational efficiency and safety. As the industry continues to innovate, the emphasis on sustainable practices and ethical sourcing is shaping the future of tire inflation pressure management, ensuring that it meets the demands of a more environmentally conscious market.

How do I solve issues with inaccurate tire pressure readings?

Inaccurate tire pressure readings can stem from a faulty gauge or environmental factors affecting tire temperature. To resolve this, first ensure that you are using a reliable, calibrated tire pressure gauge. Check the tire pressure when the tires are cold, ideally in the morning or after the vehicle has been parked for at least two hours. If discrepancies persist, consider investing in a digital tire pressure monitoring system (TPMS) that provides real-time data, which can help in maintaining optimal tire pressure and enhancing safety.

What is the best tire pressure for heavy-duty vehicles?

The optimal tire pressure for heavy-duty vehicles, such as trucks and buses, typically ranges from 80 to 120 PSI, depending on the manufacturer’s specifications and the load carried. It’s crucial to refer to the tire information placard or the owner’s manual for precise recommendations. Maintaining the correct pressure helps in maximizing load capacity, improving fuel efficiency, and ensuring safety. Regularly checking tire pressure, especially before long hauls, is vital for operational efficiency.

How can I ensure compliance with international tire pressure standards?

To ensure compliance with international tire pressure standards, familiarize yourself with regulations set by organizations such as the International Organization for Standardization (ISO) and local authorities in your target markets. Additionally, work with suppliers who are knowledgeable about regional requirements and can provide documentation proving adherence to safety standards. Regular audits and inspections of your supply chain can help maintain compliance and mitigate risks associated with non-conformance.

What factors should I consider when vetting tire inflation pressure suppliers?

When vetting suppliers for tire inflation pressure solutions, consider their industry experience, certifications, and reputation in the market. Review their product range to ensure they offer solutions suitable for your specific needs, such as heavy-duty tires or TPMS. Additionally, assess their customer service, lead times, and ability to provide technical support. Request references or testimonials from existing customers to gauge their reliability and service quality.

What are the minimum order quantities (MOQ) for tire pressure products?

Minimum order quantities (MOQ) can vary significantly among suppliers. Typically, MOQs for tire pressure gauges or monitoring systems may range from 100 to 1,000 units, depending on the supplier’s production capabilities and your specific requirements. It’s advisable to discuss your purchasing needs directly with potential suppliers to negotiate favorable terms, especially if you are a new buyer or exploring trial orders.

What payment terms are common in international tire pressure procurement?

Common payment terms for international procurement of tire pressure products may include letters of credit, advance payments, or net 30-60 days after delivery. It’s crucial to establish clear payment terms upfront to avoid misunderstandings. Consider using secure payment methods such as escrow services for large transactions to ensure both parties meet their obligations. Additionally, assess the currency risks involved and discuss potential hedging strategies with your financial advisor.

How do I manage logistics for tire pressure product shipments?

Managing logistics for tire pressure product shipments involves selecting reliable freight carriers that specialize in international shipping. Assess factors such as shipping costs, delivery times, and customs clearance processes when planning your logistics. Utilize tracking systems to monitor shipments and ensure timely delivery. Collaborating with a logistics partner experienced in your target regions can help navigate local regulations and improve overall supply chain efficiency.

What quality assurance measures should I implement for tire pressure products?

Implementing robust quality assurance measures for tire pressure products involves regular inspections and testing of incoming goods. Establish criteria for evaluating product quality based on safety standards, durability, and accuracy. Develop a comprehensive quality control checklist that includes compliance with international regulations. Additionally, consider adopting ISO quality management systems to formalize your QA processes and ensure continuous improvement in product quality and performance.

Domínio: pirelli.com

Registrado: 1995 (30 anos)

Introdução: Recommended tire pressure is the optimal air pressure established by the vehicle manufacturer, typically between 28 and 36 PSI. It can be found in the car’s operator manual or on a sticker inside the driver’s door. The pressure should be checked when the tire is cold. Maximum pressure is indicated on the tire’s sidewall and should not be used for everyday driving. Under-inflation can lead to safet…

Domínio: toyotires.com

Registrado: 1997 (28 anos)

Introdução: Load and Inflation Tables provide assistance for replacing tires with optional sizes, including plus sizes not listed on the vehicle’s tire information placard (T.I.P) or in the owner’s manual. For original equipment (OE) size inflation pressure, refer to the T.I.P. found on the vehicle door jam, glove compartment, or near the gas cap. Important: Consult the vehicle’s owner’s manual for specific s…

Domínio: mastercrafttires.com

Registrado: 1997 (28 anos)

Introdução: Recommended inflation pressures for tires are specified in pounds per square inch (psi) or kilopascals (kPa) as indicated on the vehicle’s tire placard, certification label, or in the owner’s manual. Underinflation causes excessive heat buildup and internal structural damage, leading to tire failure. Overinflated tires are more likely to be damaged by impacts. Proper inflation is critical for tire…

Domínio: tirerack.com

Registrado: 1996 (29 anos)

Introdução: This company, Tire Rack – Maximum Inflation Pressure, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domínio: tiresize.com

Registrado: 2000 (25 anos)

Introdução: Tire Pressure Calculator: A tool to calculate new tire pressure when changing tire sizes to match the vehicle’s original tire load capacity. It references general load inflation charts to adjust the new tire’s pressure for correct load capacity and tire wear specifications. Recommended tire pressure is found on the vehicle’s door jamb. The calculator requires OEM tire size, load rating, and pressu…

Understanding tire inflation pressure is crucial for B2B buyers in the automotive and transportation sectors. Proper tire maintenance not only enhances vehicle safety and performance but also significantly reduces operational costs through improved fuel efficiency and tire longevity. By prioritizing the recommended tire pressure—typically between 28 and 36 PSI—buyers can minimize risks associated with under- or over-inflation, such as blowouts and uneven tire wear.

Strategic sourcing plays a vital role in ensuring access to high-quality tires and inflation monitoring systems, such as Tire Pressure Monitoring Systems (TPMS). Implementing regular tire pressure checks and adhering to manufacturer recommendations helps businesses optimize their fleets’ performance. Furthermore, sourcing from reputable suppliers guarantees that the products meet international standards, particularly important for buyers in diverse regions like Africa, South America, the Middle East, and Europe.

As the automotive landscape evolves, staying informed about tire inflation technologies and best practices is essential. Buyers should actively engage with suppliers to explore innovative solutions that enhance safety and efficiency. By making informed purchasing decisions today, businesses can pave the way for a more sustainable and cost-effective future. Embrace this opportunity to optimize your tire management strategy and drive success across your operations.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.