In today’s dynamic global market, sourcing the right tire inflation tools is crucial for businesses aiming to maintain operational efficiency and safety. With a diverse range of options available, international B2B buyers face the challenge of identifying high-quality products that meet specific industry standards while also ensuring cost-effectiveness. This guide serves as a comprehensive resource, exploring various types of tire inflation tools—including gauges, inflators, and accessories—along with their applications in different sectors such as automotive, agriculture, and logistics.

Buyers will gain insights into the critical factors for supplier vetting, including certifications, reliability, and customer support. Moreover, we delve into pricing structures and the potential for bulk purchasing discounts, empowering decision-makers to optimize their procurement strategies. For businesses in regions like Africa, South America, the Middle East, and Europe, including Brazil and Vietnam, this guide offers tailored advice on navigating local market nuances and logistics considerations.

By equipping B2B buyers with the knowledge needed to make informed purchasing decisions, this guide aims to enhance operational readiness and sustainability. Understanding the significance of quality tire inflation tools not only contributes to the longevity of vehicles but also bolsters overall safety standards in the workplace.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Manual Tire Pressure Gauges | Simple, mechanical devices; often pocket-sized; require manual reading | Automotive shops, fleet maintenance | Prós: Low cost, portable. Contras: Less accurate, time-consuming. |

| Digital Tire Inflators | Electronic display for pressure; automatic shut-off; various PSI ranges | Trucking, heavy equipment maintenance | Prós: High accuracy, easy to read. Contras: Higher initial cost. |

| Bead Seat Inflators | Designed to seat tire beads; high-pressure capabilities | Tire shops, commercial vehicle servicing | Prós: Efficient for large tires, quick inflation. Contras: Bulky, requires training. |

| Automatic Tire Inflation Systems | Wall-mounted or portable; preset PSI; multi-hose configurations | Large fleets, tire service centers | Prós: Saves time, reduces human error. Contras: Higher investment, complex setup. |

| Air Chucks and Accessories | Various styles (e.g., dual foot, angled); used with compressors | General automotive repair, tire shops | Prós: Versatile and affordable. Contras: May wear out over time. |

Manual tire pressure gauges are traditional tools that provide a mechanical reading of tire pressure. They are typically compact and easy to use, making them suitable for various automotive applications, especially in smaller workshops or for personal use. B2B buyers should consider their affordability and portability; however, they may lack the precision and efficiency of digital alternatives. These gauges require manual monitoring, which can be time-consuming in high-volume settings.

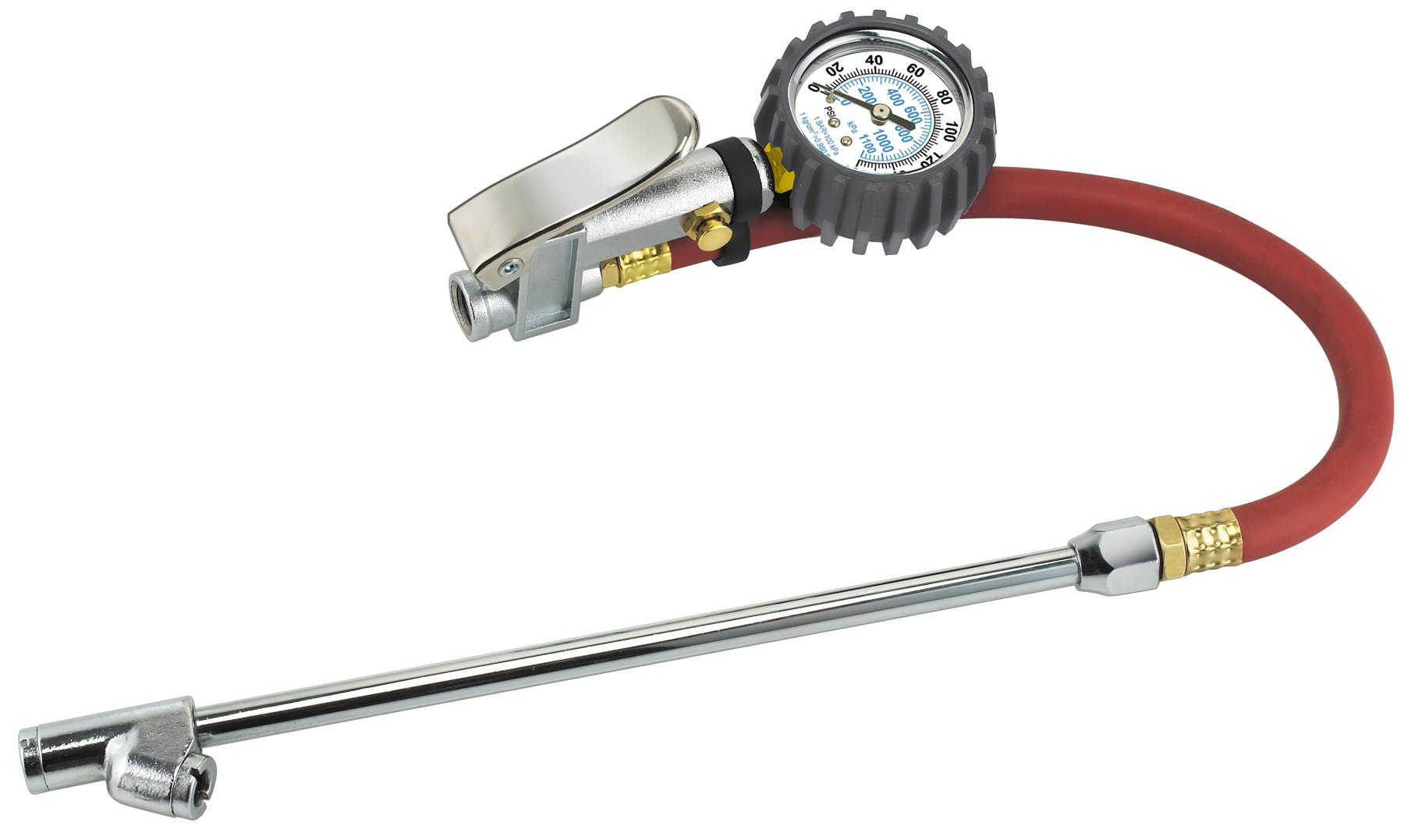

Digital tire inflators are equipped with electronic displays that provide precise tire pressure readings. They often feature automatic shut-off functions, which enhance safety and prevent over-inflation. These inflators are particularly beneficial in settings such as trucking and heavy equipment maintenance, where accuracy is paramount. While they come at a higher initial investment, their efficiency and ease of use can lead to significant time savings in tire maintenance.

Illustrative image related to tire inflation tools

Bead seat inflators are specialized tools designed for quickly seating tire beads during installation. They operate at high pressures, making them ideal for larger tires used in commercial vehicles. Tire shops and service centers benefit from their efficiency, as they can significantly reduce the time required for tire changes. However, these inflators can be bulky and may require additional training for safe operation.

Automatic tire inflation systems are designed for high-traffic environments, allowing for preset tire pressures and multi-hose configurations. They are particularly useful for large fleets and tire service centers, where speed and accuracy are critical. While the upfront costs and installation complexity can be higher, the long-term benefits include reduced labor costs and minimized human error in tire maintenance.

Air chucks and accessories, such as dual foot and angled chucks, are essential components for connecting inflators to tires. They are versatile and affordable, making them a staple in automotive repair shops and tire service locations. Buyers should keep in mind that while these tools are generally durable, they may wear out over time and require periodic replacement to ensure reliable performance.

| Indústria/Setor | Specific Application of tire inflation tools | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Automotive Repair | Routine tire maintenance for passenger and commercial vehicles | Enhances safety, reduces tire wear, and improves fuel efficiency | Reliability, accuracy, and ease of use of inflation tools |

| Logistics and Transportation | Maintenance of fleet vehicles, including trucks and buses | Minimizes downtime and enhances vehicle performance | Durability under heavy use, compatibility with various tire sizes |

| Agricultura | Inflation of tires on agricultural equipment and vehicles | Ensures optimal traction and productivity in the field | Robustness for rough terrain, adaptability to varying pressures |

| Construção | Tire inflation for heavy machinery and equipment | Increases operational efficiency and reduces equipment failure | High-pressure capabilities, easy portability |

| Mining | Inflation of tires on mining trucks and equipment | Enhances safety and reduces operational risks | Resistance to extreme conditions and puncture resistance |

In the automotive repair industry, tire inflation tools are essential for maintaining the safety and efficiency of both passenger and commercial vehicles. Regular tire pressure checks and adjustments help prevent blowouts, improve fuel efficiency, and extend tire lifespan. For international buyers, particularly in regions like Africa and South America, sourcing durable and accurate inflation tools is critical, as they may encounter varied tire specifications and environmental conditions.

In logistics and transportation, tire inflation tools are vital for fleet maintenance, ensuring that trucks and buses operate at optimal performance. Properly inflated tires reduce fuel consumption and minimize the risk of tire-related accidents, directly impacting operational costs. Buyers in the Middle East and Europe should prioritize tools that offer reliability and compatibility with a range of tire sizes, as fleet compositions can vary significantly.

Agricultural equipment requires specialized tire inflation tools to ensure proper tire pressure, which is crucial for maintaining traction and efficiency in the field. Under-inflated tires can lead to soil compaction and reduced crop yields. For agricultural businesses in regions like Brazil and Vietnam, sourcing robust tools that can withstand rough terrains and varying pressure requirements is essential for maximizing productivity.

In the construction industry, tire inflation tools are used to maintain heavy machinery and equipment, which is vital for operational efficiency. Proper tire inflation helps prevent equipment failure and reduces the risk of accidents on job sites. Buyers in this sector should look for tools with high-pressure capabilities and portability, as construction environments often require quick adjustments and easy transport.

In mining operations, tire inflation tools are critical for the safety and efficiency of heavy-duty vehicles. These tools ensure that tires are maintained at the appropriate pressure, which is essential for handling the extreme conditions often found in mining environments. Buyers in this sector must consider sourcing tools that offer resistance to punctures and can operate under high-pressure conditions, ensuring the safety and reliability of their equipment.

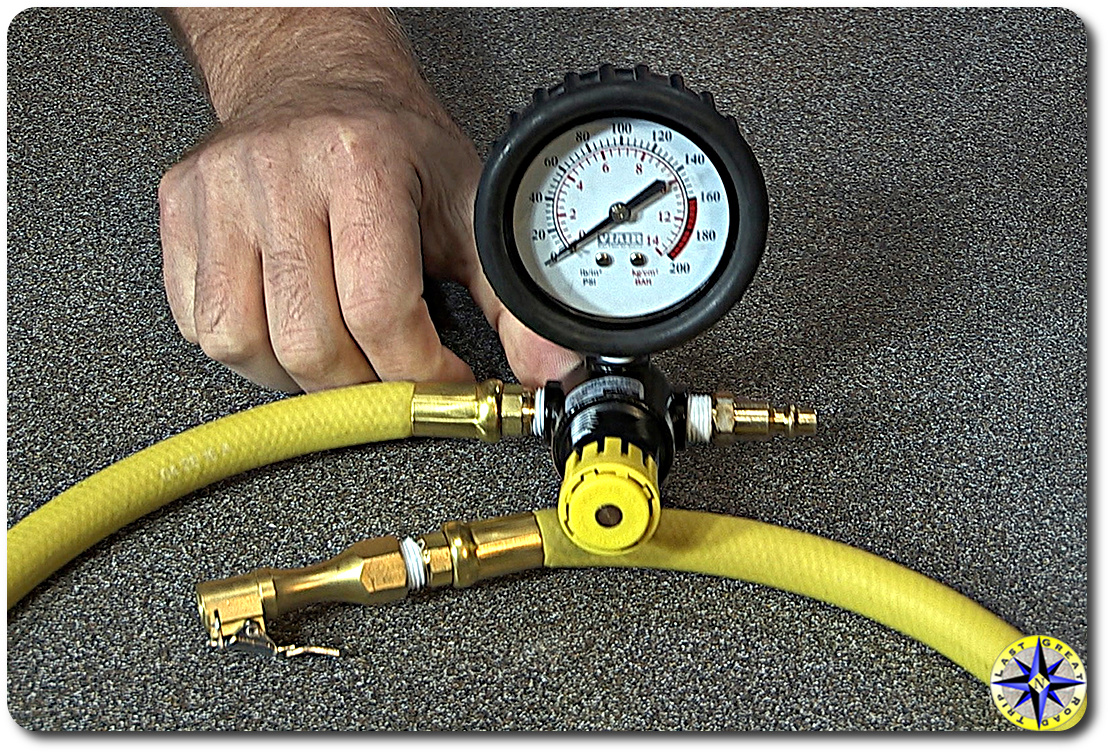

O problema: For B2B buyers in sectors such as transportation and logistics, maintaining consistent tire pressure is vital for operational efficiency. However, many businesses face challenges with traditional tire inflation tools that provide inaccurate readings or inconsistent inflation. This inconsistency can lead to frequent tire blowouts, reduced fuel efficiency, and increased maintenance costs, ultimately affecting the bottom line. Buyers may find themselves frustrated when their current tools fail to deliver reliable performance, leading to costly downtime.

Illustrative image related to tire inflation tools

A solução: To address this issue, businesses should invest in high-quality digital tire inflators with built-in pressure gauges that offer precise readings and automatic shut-off features. Tools like those from Steelman or Branick provide accuracy and help eliminate guesswork. Additionally, implementing a regular maintenance schedule for tire pressure checks can help ensure that all vehicles are operating at optimal pressure levels. Training staff on the correct usage of these tools will also ensure that they can quickly and efficiently inflate tires, reducing the risk of human error.

O problema: Many companies operate diverse vehicle fleets, which can create challenges when sourcing tire inflation tools. Different vehicles often require specific types of tire inflators and accessories, leading to confusion and inefficiency when trying to keep various tools on hand. This situation can frustrate maintenance teams who may struggle to find the right equipment quickly, especially during peak operational times.

A solução: To streamline operations, B2B buyers should look for versatile tire inflation tools that can accommodate a wide range of vehicles. Investing in universal air chucks and adapters can significantly reduce compatibility issues. Suppliers like Gemplers offer a variety of inflation tools designed for heavy-duty applications, which can be useful across different vehicle types. Furthermore, establishing a standardized inflation toolkit for the fleet can help ensure that all maintenance personnel are trained to use the same equipment effectively, reducing confusion and saving time during tire maintenance.

O problema: Companies operating in remote regions often face logistical challenges when it comes to sourcing reliable tire inflation tools. Limited access to quality equipment can lead to delays in operations, as teams may struggle to find the necessary tools to maintain tire pressure. This can be particularly problematic for businesses in sectors like agriculture or mining, where vehicle downtime can result in significant financial losses.

A solução: To overcome this hurdle, B2B buyers should consider sourcing portable tire inflation solutions that are both robust and easy to transport. Tools like portable air compressors or battery-operated inflators can be invaluable for teams working in remote locations. Additionally, establishing partnerships with local suppliers or distributors can help ensure that replacement parts and additional tools are readily available when needed. It’s also advisable to conduct regular training sessions on the usage of portable inflation tools to empower field teams to handle tire issues efficiently, minimizing downtime and keeping operations running smoothly.

When selecting tire inflation tools, the choice of materials significantly impacts their performance, durability, and suitability for various applications. Here, we analyze four common materials used in the manufacturing of these tools: steel, aluminum, rubber, and plastic. Each material has unique properties that influence their effectiveness in different environments and applications.

Steel is a widely used material in tire inflation tools due to its strength and durability. It typically has a high-temperature and pressure rating, making it suitable for heavy-duty applications. Steel tools can withstand harsh conditions, including extreme temperatures and high-pressure environments, which are common in tire servicing.

Illustrative image related to tire inflation tools

Prós: Steel is highly durable and resistant to deformation under stress. It also has good corrosion resistance when treated or coated, which is essential for tools exposed to moisture and other corrosive elements.

Contras: The primary drawback of steel is its weight, which can make tools cumbersome to handle. Additionally, steel tools can be more expensive to manufacture due to the costs associated with processing and finishing.

Impacto no aplicativo: Steel is compatible with various media, including air and nitrogen, making it versatile for different tire inflation needs. However, international buyers should ensure compliance with standards such as ASTM for quality assurance.

Aluminum is another popular material, particularly for lighter tools. It has a lower density than steel, making it easier to handle while still offering good strength and corrosion resistance.

Illustrative image related to tire inflation tools

Prós: The lightweight nature of aluminum tools enhances usability, especially in mobile applications where portability is key. Aluminum also resists corrosion effectively, making it suitable for humid or saline environments.

Contras: While aluminum is strong, it is not as durable as steel and can be prone to deformation under excessive pressure. Additionally, the cost of high-quality aluminum can be higher than steel, depending on market fluctuations.

Impacto no aplicativo: Aluminum tools are ideal for applications requiring frequent transport or use in challenging environments. Buyers from regions with high humidity, such as parts of South America and the Middle East, may prefer aluminum for its corrosion resistance.

Rubber is primarily used in seals and hoses within tire inflation systems. Its elasticity and flexibility make it an excellent choice for components that require a tight seal to prevent air leaks.

Prós: Rubber provides excellent sealing capabilities and can withstand a range of temperatures. It is also relatively inexpensive to produce and can be molded into various shapes.

Contras: Rubber can degrade over time, especially when exposed to UV light or extreme temperatures. This degradation can lead to reduced performance and the need for frequent replacements.

Impacto no aplicativo: In tire inflation tools, rubber components must be compatible with the gases used (air or nitrogen) and resistant to the conditions they will face. International buyers should consider local climate conditions when selecting rubber-based components.

Plastic is often used for gauges and some components of tire inflators due to its lightweight and cost-effective nature. It can be molded into complex shapes, allowing for innovative designs.

Prós: Plastic is lightweight, inexpensive, and resistant to corrosion. It can also be produced in various colors and styles, appealing to aesthetic preferences.

Illustrative image related to tire inflation tools

Contras: Plastic is generally less durable than metal materials and can become brittle over time, especially under UV exposure. It may not withstand high-pressure applications as effectively as metal.

Impacto no aplicativo: Plastic components are suitable for low-pressure applications and less demanding environments. Buyers should ensure that any plastic parts meet relevant safety and performance standards, particularly in regions with strict regulations.

| Material | Typical Use Case for tire inflation tools | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Aço | Heavy-duty inflators and gauges | Alta durabilidade e resistência | Heavy and costly to manufacture | Alta |

| Alumínio | Lightweight inflators and portable tools | Leve e resistente à corrosão | Less durable than steel | Médio |

| Borracha | Seals and hoses in inflation systems | Excellent sealing capability | Degrada-se com o tempo | Baixa |

| Plástico | Gauges and low-pressure components | Leve e econômico | Less durable and brittle over time | Baixa |

This guide provides B2B buyers with essential insights into material selection for tire inflation tools, helping them make informed purchasing decisions that align with their operational needs and regional considerations.

Illustrative image related to tire inflation tools

The manufacturing process of tire inflation tools involves several critical stages, including material preparation, forming, assembly, and finishing. Each stage is designed to ensure that the final product meets the required specifications for accuracy, durability, and safety.

The initial phase involves selecting high-quality materials such as steel, aluminum, and rubber. These materials are chosen for their strength and resilience, which are essential for the reliable performance of tire inflation tools. Once selected, materials undergo a series of treatments to enhance their properties. For instance, metals may be treated with coatings to prevent corrosion, while rubber components are processed to ensure flexibility and durability.

After material preparation, the forming process begins. This typically involves various techniques such as stamping, machining, and molding. Stamping is often used for producing metal parts, where sheets of metal are cut and shaped into specific forms. Machining may be applied to achieve precise dimensions and surface finishes on components like air chucks and gauges. For rubber parts, molding techniques ensure that the components fit seamlessly with the metal parts, enhancing the overall functionality of the inflation tools.

Illustrative image related to tire inflation tools

The assembly stage is critical as it combines all the manufactured components into a complete tire inflation tool. During this phase, parts are carefully fitted together, and any necessary adjustments are made to ensure proper alignment and operation. Automated assembly lines may be utilized to enhance efficiency, but manual assembly is also common, especially for more intricate tools. Quality checks are often integrated into the assembly process to catch any defects before the final product moves to finishing.

Finishing processes are essential for aesthetics and functionality. This may include surface treatments like polishing, painting, or anodizing, which not only improve the appearance but also enhance corrosion resistance and durability. Additionally, any calibration required for gauges is performed during this stage to ensure accuracy in tire pressure readings. Each finished product undergoes a final inspection to ensure it meets all specifications before packaging and shipping.

Quality assurance (QA) is vital in ensuring that tire inflation tools are safe, reliable, and effective. Various international and industry-specific standards guide the QA processes, enabling manufacturers to maintain high-quality outputs.

Many manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems, ensuring consistent quality in production. Additionally, CE marking is essential for products sold within the European market, indicating compliance with health, safety, and environmental protection standards. In regions like the Middle East, specific certifications may be required, which can vary by country.

Quality control (QC) checkpoints are integrated throughout the manufacturing process. These include:

Testing methods for tire inflation tools often include pressure tests, durability tests, and accuracy checks. For instance, gauges are calibrated against known standards to verify their precision, while inflators may be subjected to pressure cycling to assess their performance under varying conditions. Manufacturers may also employ non-destructive testing techniques to identify any hidden defects without damaging the product.

B2B buyers seeking reliable suppliers should take proactive steps to verify the quality control processes of potential partners. Here are effective strategies:

Conducting audits of prospective suppliers is crucial. Buyers should request documentation of their quality management systems, including ISO certifications and internal audit reports. This allows buyers to assess the supplier’s commitment to quality and adherence to industry standards.

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes. These inspections typically occur at various stages—pre-production, during production, and pre-shipment—offering comprehensive insights into the quality of the products.

Illustrative image related to tire inflation tools

International buyers, especially from regions like Africa, South America, and the Middle East, should be aware of specific local regulations and standards that may affect product quality. Understanding these nuances can help buyers avoid compliance issues and ensure that the products meet local market requirements. Additionally, establishing clear communication channels with suppliers about quality expectations can facilitate smoother transactions and build trust.

The manufacturing processes and quality assurance protocols for tire inflation tools are complex but essential for ensuring product reliability and safety. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ensuring that they receive high-quality tools that meet their operational needs. Whether sourcing from local manufacturers or international suppliers, a keen focus on quality control will ultimately lead to better performance and customer satisfaction in the field.

This sourcing guide provides a systematic checklist for B2B buyers looking to procure tire inflation tools. By following these actionable steps, businesses can ensure they select the right tools for their operational needs while maximizing efficiency and cost-effectiveness.

Establishing clear technical specifications is crucial for effective procurement. Determine the types of vehicles or equipment you will be servicing, as different applications may require varying tire inflation tools. Key specifications to consider include:

– Pressure Range: Ensure the tools can handle the PSI requirements for your vehicles.

– Type of Tools: Decide between manual gauges, digital inflators, or automatic inflation systems based on your operational needs.

Understanding the latest market trends and innovations in tire inflation tools can help you make informed decisions. Investigate new technologies that enhance accuracy, speed, and safety in tire inflation. Look for:

– Digital vs. Analog: Digital tools often provide more precise measurements and additional features, like temperature compensation.

– Heavy-Duty Options: For larger fleets, consider tools designed for commercial use that can withstand rigorous demands.

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess suppliers based on:

– Certificações: Verify industry-standard certifications to ensure quality and safety compliance.

– Reputation: Look for reviews or testimonials from other B2B customers to gauge reliability and service.

The quality and durability of tire inflation tools directly impact their performance and lifespan. Examine product specifications and materials used in construction. Key points to evaluate include:

– Material Quality: Look for tools made from high-grade materials that resist wear and tear.

– Warranty Terms: A robust warranty can be an indicator of a manufacturer’s confidence in their product’s durability.

Illustrative image related to tire inflation tools

After-sales support is an essential factor in the overall value of your purchase. Ensure the supplier offers comprehensive support, including:

– Technical Assistance: Access to customer service for troubleshooting and technical questions.

– Maintenance Services: Inquire if the supplier provides maintenance or repair services for their tools.

Conduct a thorough comparison of pricing among different suppliers while considering the value offered. Look beyond the initial cost and evaluate:

– Descontos em massa: Many suppliers offer discounts for larger orders, which can significantly reduce costs.

– Total Cost of Ownership: Factor in potential savings from durability, efficiency, and after-sales support in your overall assessment.

Once you have gathered all necessary information, develop a procurement strategy that aligns with your business objectives. This strategy should encompass:

– Budget Allocation: Ensure your budget accommodates both initial purchase and ongoing maintenance costs.

– Supplier Relationships: Establishing strong relationships with suppliers can lead to better negotiation outcomes and priority support in the future.

By following this checklist, B2B buyers can confidently navigate the procurement process for tire inflation tools, ensuring they select the best products and suppliers to meet their operational needs.

When evaluating the cost structure of tire inflation tools, several critical components come into play. Materiais make up a significant portion of the cost, including metals for gauges, rubber for hoses, and various plastics. The quality of these materials can greatly influence durability and performance, affecting the long-term value of the tool. Trabalho costs encompass the wages paid to workers involved in manufacturing and assembly, which can vary depending on the region.

Custos indiretos de fabricação includes costs related to utilities, facilities, and equipment maintenance. This overhead can be higher in regions with stricter regulations or higher energy costs. Ferramentas costs, which involve the creation and maintenance of molds and other tools used in production, can also add to the overall expense. Quality control (QC) processes ensure that the products meet safety and performance standards, which can add additional costs but are critical for maintaining product integrity. Lastly, logistics costs, including transportation and warehousing, play a crucial role in the total cost, especially for international buyers who may face additional tariffs and shipping fees.

Several factors influence the pricing of tire inflation tools, making it essential for buyers to understand their implications. Volume e quantidades mínimas de pedidos (MOQ) are critical; larger orders typically yield lower per-unit costs. Customization options, such as specific gauge readings or unique hose lengths, can increase the price, as they may require additional tooling or production processes.

Illustrative image related to tire inflation tools

The choice of materials significantly impacts pricing. For example, premium materials may enhance durability but come at a higher cost. Additionally, the quality certifications of the tools, such as ISO or CE markings, can influence prices. Fatores do fornecedor, such as reputation, reliability, and geographical location, also play a role, as reputable suppliers may charge a premium for their products.

Finally, the Incoterms selected for shipping can drastically affect costs. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will dictate who bears the cost and risk at various points in the supply chain, influencing the final price paid by the buyer.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, negotiating prices effectively can lead to significant savings. First, understanding the Custo total de propriedade (TCO) is crucial. This includes not only the purchase price but also maintenance, replacement, and operational costs over the tool’s lifespan.

Leverage volume purchasing to negotiate better terms. Suppliers are often willing to offer discounts for larger orders, which can reduce the overall cost. Consider discussing payment terms; extending payment periods can improve cash flow without increasing costs.

Illustrative image related to tire inflation tools

Another strategy is to request quotes from multiple suppliers to create competitive pressure. This can help secure more favorable pricing and terms. Additionally, be open to long-term partnerships with suppliers, which can lead to better pricing and service as trust is built over time.

International buyers must navigate various nuances when purchasing tire inflation tools. Currency fluctuations can significantly affect pricing, so it’s wise to lock in rates when possible. Be aware of local import duties and taxes, which can add to the final cost.

Understanding local market conditions is essential; prices may vary significantly based on regional supply and demand dynamics. Additionally, consider the impact of local regulations on tool specifications, as compliance may require additional investment in certain markets.

Lastly, be cautious about discrepancies in quality. Lower-priced tools may not meet the same standards as those from reputable suppliers, leading to potential safety and reliability issues. Always prioritize quality over price to ensure a good return on investment.

Prices for tire inflation tools can vary widely based on specifications, supplier relationships, and geographic location. The examples provided are indicative and should be verified with suppliers for the most accurate and current pricing.

Illustrative image related to tire inflation tools

In the world of tire maintenance, tire inflation tools serve a crucial role in ensuring optimal performance and safety. However, various alternative solutions exist that can also meet the needs of businesses dealing with tire management. Understanding these alternatives is vital for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, where tire-related operational efficiencies can significantly impact productivity and costs.

| Aspecto de comparação | Tire Inflation Tools | Automated Tire Inflation Systems | Manual Hand Pumps |

|---|---|---|---|

| Desempenho | High accuracy; quick inflation | Automated, consistent inflation | Variable accuracy; slower inflation |

| Custo | Moderate cost (from $8 to $150) | High initial investment (from $500+) | Low cost (typically under $50) |

| Facilidade de implementação | Simple to use; minimal training required | Requires installation and training | Requires manual effort; easy to use |

| Manutenção | Low maintenance; periodic checks needed | Moderate maintenance; system checks needed | Low maintenance; occasional repairs needed |

| Melhor caso de uso | Regular vehicle maintenance | Fleet operations and high-volume usage | Personal or low-volume applications |

Automated tire inflation systems provide a highly efficient solution for businesses that manage large fleets or have high tire maintenance demands. These systems automatically inflate tires to the optimal pressure, ensuring consistency and reducing the risk of human error. The primary advantage is the labor savings and enhanced safety from maintaining correct tire pressure. However, the initial investment can be significant, which may be a barrier for smaller operations. Additionally, installation and regular maintenance are required to ensure optimal performance.

Manual hand pumps are a cost-effective alternative for small businesses or individual users who require occasional tire inflation. They are portable, easy to use, and do not require electricity or complex setups. While they are inexpensive and low-maintenance, their performance is less reliable than automated systems, with inflation speed and accuracy varying based on user skill. Manual pumps are best suited for low-volume applications, such as personal vehicles or small fleets, where the demand for tire inflation is infrequent.

When selecting the appropriate tire inflation solution, B2B buyers should consider their specific operational needs. Factors such as the size of the fleet, the frequency of tire maintenance, and budget constraints play a critical role in this decision. For businesses managing large fleets, investing in automated tire inflation systems can lead to long-term cost savings and increased safety. Conversely, smaller operations may find that traditional tire inflation tools or manual hand pumps meet their needs without a significant financial burden. Ultimately, the right choice balances performance, cost, and ease of use to achieve the best outcomes for tire management.

When selecting tire inflation tools for your business, understanding the essential technical specifications is critical for ensuring reliability, efficiency, and safety. Here are several key properties that B2B buyers should consider:

Illustrative image related to tire inflation tools

Grau do material

The material used in tire inflation tools, such as brass, steel, or high-density plastic, affects durability and corrosion resistance. Brass is commonly preferred for air chucks due to its resistance to rust, while high-density plastics may be used in lighter, portable inflators. Selecting tools made from high-quality materials can reduce maintenance costs and extend the lifespan of the equipment.

Faixa de pressão

Tire inflation tools typically operate within specific pressure ranges, often expressed in PSI (pounds per square inch). For example, a digital tire inflator might operate within a range of 0-150 PSI. Understanding the pressure requirements for different vehicles or machinery is vital for ensuring safety and optimal performance. Inaccurate pressure can lead to tire wear or failure, impacting operational efficiency.

Accuracy Tolerance

The accuracy of tire pressure gauges is measured in terms of tolerance, often expressed as a percentage or in PSI. High-quality gauges generally have a tolerance of ±1% or better. This precision is crucial in industries where tire performance can affect safety and fuel efficiency. Investing in tools with higher accuracy can minimize discrepancies and improve overall vehicle management.

Hose Length and Flexibility

The length and flexibility of the hose attached to tire inflation tools can impact usability. Longer hoses, such as those measuring 15 feet or more, allow for easier access to hard-to-reach tires, while flexible hoses can withstand bending without kinking. This feature is particularly important in commercial settings where multiple vehicles may need servicing simultaneously.

Connection Type

Tire inflation tools come with various connection types, including clip-on, lock-on, and push-on fittings. The choice of connection affects ease of use and the ability to maintain a secure seal during inflation. Tools with quick-release fittings can enhance efficiency, particularly in high-volume tire service environments.

Digital vs. Analog Display

The display type of tire gauges can influence user experience. Digital displays offer clearer readings and often include additional features such as backlighting and auto shut-off. Analog gauges, while simpler, can be less prone to battery failure. Businesses should evaluate their operational needs to determine which display type offers the best utility.

Familiarity with industry jargon can enhance communication and streamline procurement processes. Here are some common terms relevant to tire inflation tools:

OEM (fabricante original do equipamento)

This term refers to companies that produce parts and equipment that may be sold under another company’s brand name. In tire inflation, understanding OEM specifications ensures that replacement parts are compatible with existing tools, which can be crucial for maintaining operational efficiency.

MOQ (Quantidade mínima de pedido)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for businesses to manage inventory effectively and avoid overstocking or stockouts, especially in international markets where shipping costs can escalate.

RFQ (Request for Quotation, solicitação de cotação)

An RFQ is a document used to invite suppliers to submit pricing and other details for a specific product or service. Issuing an RFQ allows businesses to compare options and negotiate better terms, leading to cost savings and improved supplier relationships.

Incoterms (Termos Comerciais Internacionais)

These are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps businesses mitigate risks related to shipping and delivery, ensuring clarity in logistics and cost allocation.

Warranty Terms

Warranty terms outline the conditions under which a supplier will repair or replace defective products. Understanding warranty coverage is vital for risk management and can influence purchasing decisions, particularly for high-value tools.

Calibration

Calibration refers to the process of adjusting the accuracy of a measuring instrument. For tire inflation tools, regular calibration ensures that pressure readings remain accurate, which is essential for safety and performance. Knowing the calibration requirements can help businesses maintain compliance and operational standards.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they invest in the right tire inflation tools for their specific needs.

The tire inflation tools sector is witnessing significant transformation driven by technological advancements and changing consumer demands. In recent years, the adoption of digital inflators and tire pressure monitoring systems (TPMS) has surged, particularly among automotive businesses aiming for precision and efficiency in tire maintenance. This trend is particularly relevant for B2B buyers in emerging markets like Africa and South America, where the need for reliable and efficient tire management solutions is critical to optimizing fleet operations.

Moreover, the integration of IoT technology is revolutionizing how tire inflation tools are utilized. Businesses are increasingly investing in smart inflators that provide real-time data, enhancing operational efficiency and safety. This trend is also observed in Europe and the Middle East, where stricter regulatory frameworks are pushing companies to adopt high-tech solutions for compliance and performance monitoring.

Illustrative image related to tire inflation tools

Another notable trend is the growing demand for portable and compact tire inflation tools. This shift is primarily driven by the rise in consumer preferences for DIY maintenance and the expansion of e-commerce platforms that facilitate easy access to these products. International buyers, especially from regions with diverse terrains like Brazil and Vietnam, are particularly inclined towards versatile tools that can cater to various vehicle types.

The importance of sustainability and ethical sourcing in the tire inflation tools sector cannot be overstated. As global awareness of environmental issues increases, businesses are under pressure to adopt sustainable practices. This includes sourcing materials that are eco-friendly and ensuring that the manufacturing processes comply with environmental standards. For B2B buyers, aligning procurement strategies with sustainability goals can enhance brand reputation and customer loyalty.

Moreover, certifications such as ISO 14001 for environmental management and the use of recyclable materials in production processes are becoming crucial factors in supplier selection. Companies that prioritize green certifications not only contribute to reducing their carbon footprint but also stand out in a competitive marketplace. Buyers in Africa, South America, and Europe should actively seek suppliers who demonstrate a commitment to sustainable practices, as this can lead to long-term partnerships and improved supply chain resilience.

In addition, the focus on ethical supply chains is gaining traction. Buyers are increasingly scrutinizing suppliers for fair labor practices and transparency in sourcing. This is particularly important for international buyers who must navigate diverse regulatory environments and cultural expectations. Establishing relationships with suppliers that prioritize ethical practices can mitigate risks and foster trust in the supply chain.

Illustrative image related to tire inflation tools

The evolution of tire inflation tools can be traced back to basic manual pumps, which have significantly transformed with technological advancements. Initially, these tools were simple and labor-intensive, relying on manual effort to inflate tires. However, as the automotive industry expanded in the 20th century, the demand for more efficient and reliable tire inflation solutions surged.

The introduction of electric and digital inflators marked a significant milestone, offering faster and more accurate inflation processes. With the rise of automation and IoT, modern tire inflation tools now come equipped with features such as digital gauges, automatic shut-off capabilities, and connectivity options for real-time monitoring. This evolution not only enhances user experience but also aligns with the growing emphasis on safety and efficiency in vehicle maintenance. For B2B buyers, understanding this historical context can provide valuable insights into product development and market opportunities, especially when considering investments in cutting-edge tire inflation technologies.

How do I solve issues with inaccurate tire pressure readings?

Inaccurate tire pressure readings can stem from faulty gauges or improper calibration. To resolve this, invest in high-quality digital or analog gauges from reputable suppliers known for precision engineering. Regularly calibrate your gauges according to manufacturer instructions to ensure consistent accuracy. Additionally, consider purchasing calibration tools that allow you to verify gauge accuracy on-site, which is particularly useful when operating in diverse environments, such as those found in Africa or South America.

What is the best tire inflation tool for heavy-duty vehicles?

For heavy-duty vehicles, a high-capacity inflator with a robust construction is essential. Look for tools designed to handle high PSI ratings, typically above 100 PSI, and consider models with features such as automatic shut-off and built-in pressure gauges for added convenience. Brands that specialize in commercial-grade tools, like Branick or Steelman, offer models specifically tailored for trucks and industrial applications, ensuring durability and reliability.

How can I vet suppliers of tire inflation tools for international trade?

To effectively vet suppliers, start by checking their industry reputation through online reviews and testimonials from previous clients. Request references and evaluate their responsiveness to inquiries. It’s also prudent to ask for certifications and compliance with international quality standards. Utilizing platforms like Alibaba or trade-specific directories can provide insights into supplier reliability and product quality, helping you make informed sourcing decisions.

What are the typical minimum order quantities (MOQs) for tire inflation tools?

MOQs can vary significantly based on the supplier and the specific product. Generally, for B2B buyers, MOQs range from 50 to 500 units. However, some suppliers may offer lower MOQs for custom or specialized tools. It’s advisable to discuss your needs directly with suppliers to negotiate MOQs that align with your purchasing plans, especially if you’re entering new markets in regions like Europe or the Middle East.

What payment terms are common when sourcing tire inflation tools internationally?

Common payment terms include advance payment, letter of credit, or net 30/60 days, depending on the supplier’s policies and your negotiation strength. For first-time purchases, suppliers may require partial upfront payment. As you establish a relationship, you may be able to negotiate more favorable terms. Always ensure that payment methods are secure and that contracts clearly outline terms to avoid potential disputes.

How can I customize tire inflation tools to meet my specific needs?

Customization options often depend on the supplier’s capabilities. Many manufacturers offer bespoke solutions, such as branding, specific PSI ranges, or additional features like integrated lighting or digital displays. When discussing customization, provide detailed specifications and inquire about the lead times and costs associated with such modifications. Engaging directly with manufacturers can also yield more flexible options tailored to your operational requirements.

What quality assurance measures should I consider when sourcing tire inflation tools?

Quality assurance is crucial for ensuring the reliability of tire inflation tools. Look for suppliers that adhere to international quality standards such as ISO 9001. Request information about their testing procedures and warranty policies. Conducting a factory audit can also provide insights into their manufacturing processes and quality control systems. Additionally, consider requesting samples before placing large orders to assess product quality firsthand.

What logistics considerations should I keep in mind when importing tire inflation tools?

When importing, evaluate shipping options, lead times, and customs regulations specific to your destination country. Choose a logistics partner experienced in handling industrial equipment to streamline the process. Be mindful of import duties and taxes that may apply. Additionally, ensure that your supplier can provide all necessary documentation, such as certificates of origin and compliance, to facilitate smooth customs clearance and avoid delays.

Domínio: steelmantools.com

Registrado: 2005 (20 anos)

Introdução: [{‘name’: ‘STEELMAN # 75052 Straight Chuck Tire Inflator with Built-In Gauge and Green 12-Inch Hose’, ‘price’: ‘$29.99’, ‘availability’: ‘In stock’}, {‘name’: ‘STEELMAN # 75051 Straight Chuck Tire Inflator with Built-In Gauge and 12-Inch Hose’, ‘price’: ‘$21.99’, ‘availability’: ‘In stock’}, {‘name’: ‘STEELMAN # 97977 High Accuracy Digital Gauge Tire Inflator with Temperature Compensation and 15-I…

Domínio: gemplers.com

Registrado: 1996 (29 anos)

Introdução: This company, Gemplers – Tire Inflation Tools, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domínio: jacosuperiorproducts.com

Registrado: 2014 (11 anos)

Introdução: FlowPro® Digital Tire Inflator with Pressure Gauge – 200 PSI: $39.95 (originally $89.99) – Rated “Best Inline Tire Pressure Gauge” by Car and Driver Magazine. FlowPro® Tire Inflator with Pressure Gauge – 100 PSI: $35.95 (originally $79.99). FlowPro® 2.0 Digital Tire Inflator with Pressure Gauge – 200 PSI: $39.95 (originally $89.99) – Features patented Lightning® Air Chuck. FlowPro® Digital Tire In…

Domínio: morrflate.com

Registrado: 2019 (6 anos)

Introdução: This company, Morrflate – 60-Day Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

As the demand for efficient and reliable tire inflation tools continues to rise, strategic sourcing emerges as a pivotal factor for international B2B buyers. By understanding the nuances of the tire inflation tools market, including product variety—from digital gauges to heavy-duty inflators—buyers can make informed decisions that enhance operational efficiency and safety.

Illustrative image related to tire inflation tools

Moreover, leveraging partnerships with reputable suppliers ensures access to high-quality products that meet specific industry standards. It is crucial to consider not only the initial purchase price but also the long-term value, including durability and ease of use. This strategic approach can significantly reduce maintenance costs and downtime, ultimately driving profitability.

Looking ahead, the tire inflation tools market is poised for innovation, with advancements in technology promising enhanced precision and automation. International buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, should seize this opportunity to upgrade their equipment. Engaging with suppliers who offer cutting-edge solutions can provide a competitive edge in today’s fast-paced market. Embrace the future of tire maintenance and elevate your operations by sourcing the best tire inflation tools available.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Illustrative image related to tire inflation tools

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.