In today’s competitive landscape, sourcing reliable and efficient tire inflators is crucial for businesses looking to enhance their service offerings and maintain customer satisfaction. The ETENWOLF Vortex S6 tire inflator stands out as a versatile solution designed to meet the demands of various sectors, from automotive services to outdoor recreation. This guide aims to equip international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, with comprehensive insights into the Vortex S6.

We will explore its key features, applications, and the extensive benefits it offers to businesses that require high-performance inflators. Additionally, we’ll delve into supplier vetting processes, pricing structures, and the overall market dynamics that influence purchasing decisions. By the end of this guide, buyers will be empowered to make informed choices, ensuring they select a product that aligns with their operational needs and budgetary constraints.

Understanding the global market for tire inflators like the ETENWOLF Vortex S6 is essential for businesses aiming to optimize their fleet management, roadside assistance, or recreational vehicle services. This guide provides actionable insights that will help you navigate the complexities of sourcing and integrating this essential equipment into your operations, ultimately leading to improved efficiency and customer satisfaction.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| ETENWOLF Vortex S6 | 19,200 mAh battery, 160 PSI max pressure, dual-cylinder motor | Off-road vehicles, SUVs, trucks, bicycles | Prós: High capacity, fast inflation, versatile. Contras: Higher price point. |

| ETENWOLF Vortex S6 SE | 15,600 mAh battery, compact design | Light-duty vehicles, bicycles, sports equipment | Prós: Cost-effective, portable. Contras: Lower battery capacity. |

| ETENWOLF Vortex S7 | 38,400 mAh battery, advanced cooling system | Heavy-duty applications, RVs, off-road vehicles | Prós: Long-lasting, powerful. Contras: Bulkier design. |

| ETENWOLF AIR 3 | 2,600 mAh battery, lightweight, designed for inflatables | Air mattresses, pool toys, sports balls | Prós: Extremely portable, budget-friendly. Contras: Limited to small inflatables. |

| ETENWOLF P300 PLUS | Electric ball pump, compact, easy to use | Sports teams, recreational facilities | Prós: Specialized for balls, affordable. Contras: Not suitable for vehicle tires. |

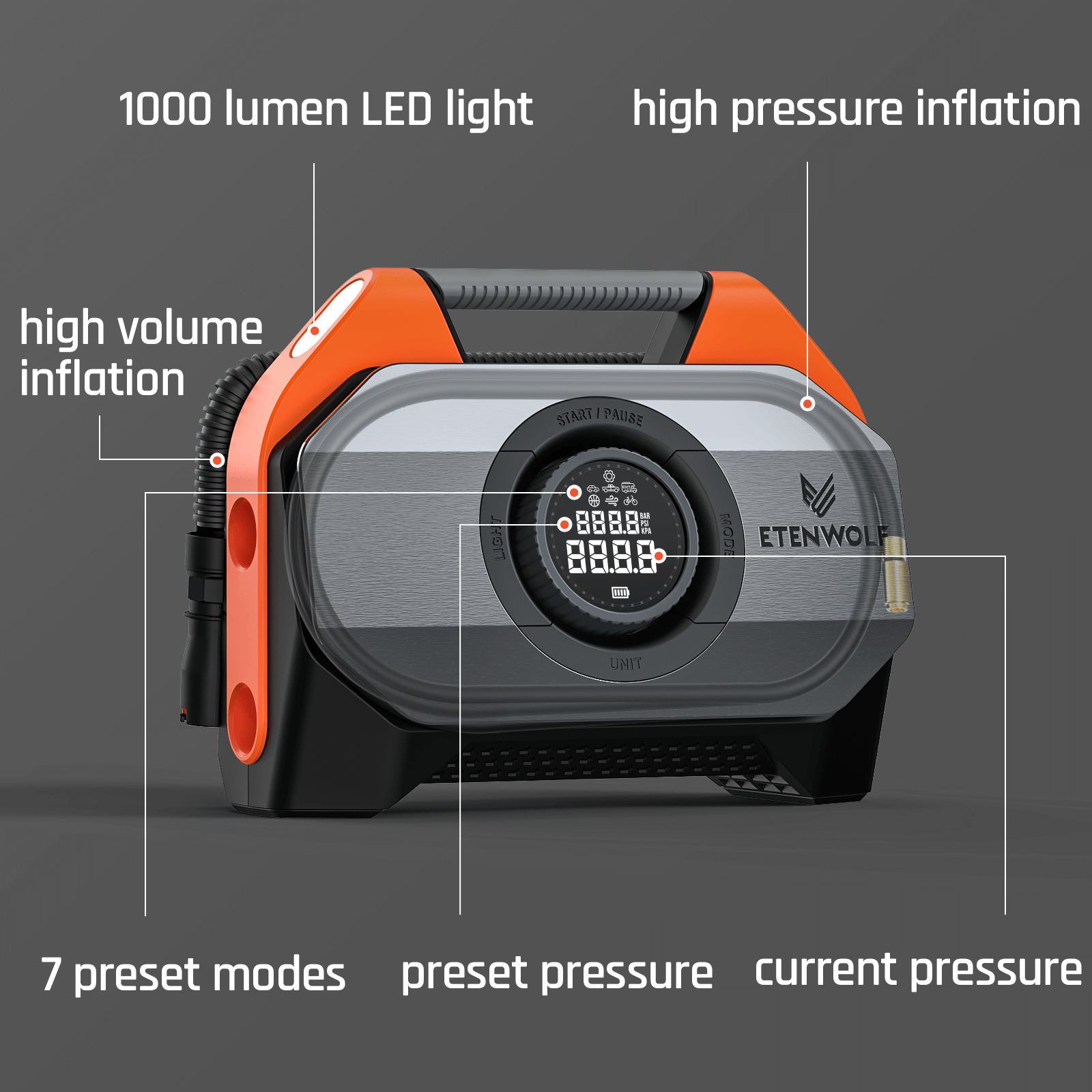

The ETENWOLF Vortex S6 is designed for heavy-duty applications, featuring a robust 19,200 mAh battery and a maximum pressure of 160 PSI. This model is ideal for off-road vehicles, SUVs, and trucks, making it a valuable asset for businesses in the automotive sector or any industry relying on large vehicles. Its dual-cylinder motor allows for rapid inflation, significantly reducing downtime during tire maintenance. However, its premium pricing may deter budget-conscious buyers.

The ETENWOLF Vortex S6 SE is a more compact version, equipped with a 15,600 mAh battery. This model is suitable for light-duty vehicles, bicycles, and sports equipment, making it a great choice for businesses in recreational sectors. Its lower price point makes it attractive for B2B buyers looking to equip their teams with efficient inflators without overspending. However, its reduced battery capacity may limit its use in more demanding scenarios.

For businesses requiring an even more powerful solution, the ETENWOLF Vortex S7 features an impressive 38,400 mAh battery and an advanced cooling system. This model is tailored for heavy-duty applications, such as RVs and off-road vehicles, where reliability and performance are crucial. While it offers longer-lasting power, its bulkier design might be a consideration for companies prioritizing portability.

The ETENWOLF AIR 3 is specifically designed for inflating smaller items like air mattresses and pool toys. With a lightweight 2,600 mAh battery, it is highly portable and budget-friendly, making it suitable for businesses in the hospitality or leisure sectors. However, its limited functionality means it is not suitable for vehicle tires, which could restrict its appeal for companies needing a versatile inflator.

The ETENWOLF P300 PLUS is an electric ball pump tailored for sports teams and recreational facilities. Its compact design and ease of use make it a favorite for quickly inflating sports balls, ensuring teams are always ready for action. While it is affordable and specialized, it lacks the capability to handle larger inflatables or tires, which may limit its usefulness for broader applications.

| Indústria/Setor | Specific Application of etenwolf vortex s6 tire inflator | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Transportation and Logistics | Fleet maintenance for trucks and heavy vehicles | Ensures optimal tire pressure, enhancing fuel efficiency and safety | Consider battery life, charging time, and pressure accuracy |

| Construção | Inflation of heavy-duty machinery tires | Reduces downtime by enabling quick tire inflation on-site | Evaluate the inflator’s max pressure and airflow capabilities |

| Automotive Services | Tire inflation and maintenance for various vehicle types | Improves customer service speed and vehicle safety | Look for portability, ease of use, and multi-vehicle compatibility |

| Event Management | Quick inflation of inflatable structures for events | Saves time and labor costs during event setup | Assess the inflator’s power capacity and included accessories |

| Agricultura | Tire inflation for farm machinery and vehicles | Enhances productivity and reduces the risk of tire-related incidents | Consider durability and performance in remote locations |

In the transportation and logistics industry, maintaining a fleet of trucks and heavy vehicles is crucial for operational efficiency. The ETENWOLF Vortex S6 tire inflator provides a reliable solution for ensuring that all vehicles are equipped with properly inflated tires. By maintaining optimal tire pressure, businesses can achieve better fuel efficiency and reduce the risk of tire blowouts, which can lead to costly downtime. For international buyers, especially in regions like Africa and the Middle East, sourcing a durable and efficient tire inflator that can withstand varying climates and terrains is essential.

In construction, heavy-duty machinery often requires frequent tire inflation to maintain performance on rugged terrains. The ETENWOLF Vortex S6 tire inflator allows construction teams to quickly inflate tires on-site, reducing downtime and keeping projects on schedule. Its robust design and high-pressure capabilities ensure it can handle the demands of construction equipment. Buyers in South America and Europe should consider the inflator’s reliability and power output, especially in remote areas where access to maintenance services may be limited.

Illustrative image related to etenwolf vortex s6 tire inflator

Automotive service providers benefit significantly from the ETENWOLF Vortex S6 tire inflator by enhancing their tire maintenance offerings. The inflator’s precision and ease of use allow technicians to quickly inflate tires for various vehicle types, improving service speed and customer satisfaction. Additionally, the built-in digital display ensures accurate pressure readings, reducing the likelihood of human error. B2B buyers in the automotive sector should prioritize features like portability and multi-vehicle compatibility to cater to diverse customer needs.

Event management companies often require quick solutions for setting up inflatable structures, such as tents and obstacle courses. The ETENWOLF Vortex S6 tire inflator can rapidly inflate these structures, saving valuable time and labor costs during setup. Its compact design also allows for easy transportation to various event locations. Buyers should assess the inflator’s power capacity and included accessories to ensure it meets the demands of different event sizes and types.

In the agricultural sector, the ETENWOLF Vortex S6 tire inflator is essential for maintaining the tire pressure of farm machinery and vehicles. Properly inflated tires enhance productivity by reducing the risk of tire-related incidents that can disrupt operations. Farmers in remote locations, particularly in Africa and South America, require a durable and efficient tire inflator that can perform reliably in challenging conditions. Key considerations for sourcing include the inflator’s durability and performance capabilities, ensuring it can withstand the rigors of agricultural use.

O problema: B2B buyers in sectors such as logistics or automotive services often require tire inflators for prolonged use, especially during busy seasons or on remote job sites. The ETENWOLF Vortex S6 features a robust 19,200mAh battery, but users may worry about its performance during extensive operations. If the inflator is used to fill multiple tires or inflatables back-to-back, there’s a concern about the battery depleting before the job is finished, leading to downtime and potential delays in service.

Illustrative image related to etenwolf vortex s6 tire inflator

A solução: To maximize the battery life of the ETENWOLF Vortex S6 during extended use, B2B buyers should strategically plan their inflation tasks. Consider using the inflator to fill larger tires first, as these typically require more air and may take longer to inflate. Additionally, utilizing the inflator’s onboard storage for accessories can streamline the process and reduce time spent switching tools. Implementing a routine maintenance schedule—such as checking battery health and performing periodic performance tests—will also ensure that the inflator operates at peak efficiency. Lastly, consider investing in additional units for high-demand scenarios, thereby ensuring that there is always a backup ready to go.

O problema: In diverse markets such as those in Africa or South America, B2B buyers often deal with a wide range of vehicles, from standard cars to larger SUVs and trucks. Some may face challenges when trying to use the ETENWOLF Vortex S6 with different tire types and valve systems, leading to inefficiencies and user frustration. The necessity to have a versatile tool that can handle a variety of inflatables is paramount for businesses in these regions.

A solução: The ETENWOLF Vortex S6 comes equipped with a variety of adapters, including a Presta valve adapter, enabling compatibility with multiple tire types. B2B buyers should ensure their staff are well-trained on how to use these adapters effectively. Creating a user manual or training session can greatly enhance team confidence and efficiency in utilizing the inflator across various vehicles. Additionally, buyers can stock up on common valve adapters to ensure they are always prepared for unexpected needs. Regularly updating inventory based on the types of vehicles serviced will also help in managing compatibility issues effectively.

O problema: In industries where precision is crucial, such as transportation or manufacturing, maintaining the correct tire pressure is vital for safety and efficiency. B2B buyers may be apprehensive about the accuracy of the ETENWOLF Vortex S6’s pressure gauge, particularly if they have experienced discrepancies with other inflators in the past. This concern can lead to hesitancy in adopting new equipment, as inaccuracies can cause operational disruptions.

A solução: The ETENWOLF Vortex S6 boasts a precision accuracy of ±1 PSI, which is essential for ensuring that tires are inflated to the correct levels. To build confidence in this feature, B2B buyers should perform routine calibration checks of the inflator against a trusted pressure gauge. Establishing a systematic approach for regularly verifying the device’s accuracy can alleviate concerns and promote trust in the equipment. Additionally, encourage staff to familiarize themselves with the digital display, which shows both current and target pressures, ensuring they understand how to use the preset modes effectively. By promoting a culture of safety and precision, businesses can leverage the Vortex S6 as a reliable tool in their operations.

In the manufacturing of the ETENWOLF Vortex S6 Tire Inflator, several materials play a crucial role in ensuring performance, durability, and user satisfaction. Understanding these materials from a B2B perspective can aid international buyers in making informed purchasing decisions.

Plastic is often used for the casing and certain internal components of the Vortex S6. Key properties include lightweight, corrosion resistance, and good thermal stability. Plastics such as ABS (Acrylonitrile Butadiene Styrene) are commonly employed due to their impact resistance and ability to withstand varying temperatures.

Illustrative image related to etenwolf vortex s6 tire inflator

Metals, particularly aluminum and steel, are used in components that require strength and durability, such as the motor housing and high-pressure hoses. Aluminum offers a favorable strength-to-weight ratio, while steel provides superior strength and resistance to deformation.

Rubber is primarily used for seals and hoses in the Vortex S6. Its key properties include excellent elasticity, chemical resistance, and the ability to maintain integrity under pressure.

The electronic components of the Vortex S6, including the digital display and battery management system, are typically made from various materials such as silicon and copper. These materials are essential for ensuring accurate pressure readings and efficient battery performance.

| Material | Typical Use Case for ETENWOLF Vortex S6 Tire Inflator | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Plástico | Casing and internal components | Leve e econômico | Less durable than metals under extreme conditions | Baixa |

| Metal (Aluminum/Steel) | Motor housing and high-pressure hoses | High durability and pressure resistance | Higher cost and added weight | Med |

| Borracha | Seals and hoses | Excellent sealing properties | Degradation over time due to environmental exposure | Baixa |

| Electronic Components | Digital display and battery management system | Enhanced user experience with precision | Sensitive to environmental conditions | Alta |

This strategic material selection guide provides valuable insights for B2B buyers considering the ETENWOLF Vortex S6 Tire Inflator, particularly in international markets. Understanding the properties, advantages, and limitations of these materials can help buyers make informed decisions that align with their operational needs and compliance requirements.

The manufacturing process of the ETENWOLF Vortex S6 Tire Inflator involves several critical stages, each designed to ensure that the final product meets high-quality standards. The main stages include material preparation, forming, assembly, and finishing.

Material preparation is the first step, where high-quality raw materials are sourced, including plastics, metals, and electronic components. ETENWOLF prioritizes the use of durable materials that can withstand various environmental conditions, making the inflator suitable for heavy-duty tasks. Suppliers are selected based on their ability to meet material specifications, and incoming materials undergo rigorous inspection to ensure compliance with industry standards.

In the forming stage, advanced techniques such as injection molding and CNC machining are employed to create the inflator’s components. Injection molding ensures precision in the production of plastic parts, while CNC machining provides accuracy for metal components, crucial for the inflator’s durability and functionality.

During the assembly stage, skilled technicians integrate the components using automated systems and manual assembly techniques. This hybrid approach allows for both speed and quality control, ensuring that each unit is assembled according to ETENWOLF’s strict specifications. Moreover, the assembly process includes the installation of the dual-cylinder motor and the powerful 19,200 mAh battery, which are pivotal for the inflator’s performance.

Illustrative image related to etenwolf vortex s6 tire inflator

The finishing stage involves surface treatments and quality checks to enhance the aesthetic and functional properties of the inflator. This may include painting, coating, or applying protective finishes to increase resistance to wear and corrosion. Each unit undergoes a final inspection to ensure it meets ETENWOLF’s quality standards before packaging.

Quality assurance is paramount in the manufacturing of the ETENWOLF Vortex S6 Tire Inflator. The company adheres to several international standards, including ISO 9001, which emphasizes a quality management system that ensures consistent product quality and customer satisfaction.

For international markets, compliance with industry-specific standards such as CE marking for the European market and API standards for performance and safety is critical. These certifications not only enhance product credibility but also facilitate smoother entry into various markets, ensuring that the inflator meets local regulations and safety requirements.

Illustrative image related to etenwolf vortex s6 tire inflator

Quality control (QC) is embedded at multiple checkpoints throughout the manufacturing process. The main QC stages include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

During IQC, raw materials and components are inspected upon arrival. This includes checking for defects, verifying specifications, and ensuring that materials meet the required quality standards. Any materials that do not pass inspection are rejected and returned to the supplier.

IPQC is conducted during the manufacturing process to monitor production consistency and quality. This involves regular checks at various assembly stages to ensure that components are being assembled correctly and that machinery is functioning properly. Real-time adjustments are made as necessary to mitigate any potential quality issues.

FQC is the last line of defense before products are packaged and shipped. Each Vortex S6 unit undergoes comprehensive testing to verify its performance, including pressure tests, battery life assessments, and functionality checks. This ensures that every inflator meets the high standards set by ETENWOLF.

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify supplier quality control practices.

Conducting supplier audits is an effective way to assess a manufacturer’s quality control processes. Buyers should request audits that examine the manufacturing facilities, quality management systems, and adherence to international standards. This can provide valuable insights into the supplier’s operational efficiency and commitment to quality.

Buyers should also ask for quality assurance reports, which document the results of various quality tests conducted during the manufacturing process. These reports should detail compliance with relevant standards, including any certifications obtained. Regular updates on quality metrics can further enhance transparency and trust.

Illustrative image related to etenwolf vortex s6 tire inflator

Engaging third-party inspection agencies can add an extra layer of verification. These agencies conduct independent assessments of the manufacturing process and product quality, providing impartial evaluations that can reassure buyers of the product’s reliability and compliance with international standards.

International buyers should be aware of the nuances in quality control that may vary by region. For example, regulations and standards differ significantly across markets, which can affect product compliance and certification processes. Understanding local requirements can help buyers avoid potential pitfalls when importing products like the ETENWOLF Vortex S6 Tire Inflator.

Cultural differences in business practices can also impact quality assurance. Buyers should familiarize themselves with local customs and regulations in the countries they are sourcing from. This knowledge can aid in building strong relationships with suppliers and ensuring that quality standards are consistently met.

In conclusion, the ETENWOLF Vortex S6 Tire Inflator is manufactured through a meticulous process that emphasizes quality at every stage. By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions and ensure they are sourcing high-quality products that meet their operational needs.

Illustrative image related to etenwolf vortex s6 tire inflator

This practical sourcing guide is designed to assist international B2B buyers in the procurement of the ETENWOLF Vortex S6 Tire Inflator. By following this step-by-step checklist, buyers can ensure they make informed decisions that align with their operational needs and budget constraints.

Identifying the technical requirements for the Vortex S6 is crucial before initiating any procurement process. Consider the inflator’s specifications such as maximum pressure (160 PSI), battery capacity (19,200mAh), and airflow rate (11 Gallon/MIN). This step ensures that the selected model meets the performance needs of your fleet or operations.

Conduct thorough research on potential suppliers to validate their credibility. Look for suppliers with certifications such as ISO or other relevant industry standards that demonstrate product quality and reliability. Additionally, check for reviews and testimonials from previous B2B clients, particularly in your target regions like Africa, South America, the Middle East, and Europe.

Understanding the pricing model of the Vortex S6 is essential for budget management. Compare prices across different suppliers and take into account factors like shipping costs, bulk order discounts, and any available promotional offers. This evaluation helps in identifying the best value for your investment while ensuring that quality is not compromised.

Examine the warranty options and return policies provided by the supplier. The Vortex S6 typically comes with a 90-day money-back guarantee and an optional two-year extended warranty. Knowing the terms of these policies can protect your investment and provide peace of mind, especially for high-volume orders.

Illustrative image related to etenwolf vortex s6 tire inflator

Confirm the shipping options and estimated delivery times from your chosen supplier. Efficient logistics are critical for operational continuity, especially in industries where tire inflators are needed urgently. Inquire about tracking systems and the ability to ship to your specific region, as this can vary widely.

Before finalizing your order, request demonstrations or samples of the Vortex S6. This step allows you to assess the product’s performance and suitability for your specific applications, such as inflating tires for SUVs or trucks. Engaging with the product firsthand can also facilitate better negotiations based on your observations.

Once all prior steps are satisfactorily completed, prepare to finalize your purchase agreement. Ensure all terms are clearly outlined, including payment methods, delivery schedules, and any after-sales support. A well-documented agreement minimizes misunderstandings and establishes a clear framework for the transaction.

By following this checklist, B2B buyers can confidently navigate the procurement process for the ETENWOLF Vortex S6 Tire Inflator, ensuring that they secure a reliable and efficient product tailored to their operational needs.

Analyzing the cost structure and pricing for the ETENWOLF Vortex S6 tire inflator provides valuable insights for international B2B buyers. Understanding the various cost components and price influencers can help businesses make informed purchasing decisions.

Illustrative image related to etenwolf vortex s6 tire inflator

Materiais: The primary materials include high-quality plastic for the casing, metal components for the motor, and electronic parts for the digital display. The robust construction of the Vortex S6 contributes to its durability and performance, with the cost of materials impacting the overall pricing structure.

Trabalho: Labor costs encompass the wages for skilled workers involved in the assembly and quality control processes. The complexity of the design, which includes features like a dual-cylinder motor and precision pressure gauge, necessitates skilled labor, thereby influencing the final cost.

Custos indiretos de fabricação: This includes expenses related to factory operations, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help keep these overheads in check, but any inefficiencies can drive up costs.

Ferramentas: The initial investment in tooling and molds for the production of the inflator is significant, especially for customized or specialized components. Amortizing these costs over larger production runs can lower the per-unit cost.

Controle de qualidade (QC): Rigorous quality control measures ensure that each unit meets safety and performance standards. The costs associated with QC can vary based on the certifications required for different markets, particularly for international buyers who may need compliance with specific regulations.

Logística: Shipping and handling costs are crucial, especially for international transactions. Factors such as distance, shipping method, and destination impact the logistics expenses significantly.

Margem: Finally, the manufacturer’s margin is added to cover profits and reinvestment. This can vary widely based on market positioning and competitive strategies.

Volume/MOQ: Bulk purchasing can lead to lower per-unit costs. Buyers should inquire about minimum order quantities (MOQs) that could unlock better pricing tiers.

Especificações e personalização: Custom features or branding can increase costs. Buyers should weigh the benefits of customizations against their budget constraints.

Materiais e certificações de qualidade: Higher-quality materials and certifications (such as CE or ISO) can elevate costs but also enhance product reliability, a critical factor for B2B buyers in safety-sensitive industries.

Fatores do fornecedor: The reputation and reliability of the supplier can influence pricing. Established suppliers may command higher prices due to perceived quality and service levels.

Incoterms: Understanding the agreed-upon Incoterms is vital for pricing clarity. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the costs and risks at various stages of the shipping process.

Negociação: Engage suppliers in discussions about pricing flexibility, especially if purchasing in bulk. Highlighting long-term partnerships can also lead to better terms.

Eficiência de custo: Consider the Total Cost of Ownership (TCO), which includes purchase price, shipping, potential tariffs, and maintenance costs over the product’s lifespan. A higher initial investment may lead to lower operational costs if the product is more durable.

Nuances de preços para compradores internacionais: International buyers should be aware of currency fluctuations, import duties, and taxes that may affect the total cost. Establishing a clear understanding of these factors can aid in budgeting effectively.

In summary, a comprehensive analysis of the cost structure and pricing factors for the ETENWOLF Vortex S6 tire inflator can guide international B2B buyers in making strategic sourcing decisions. It is crucial to consider all components and influencers to optimize procurement strategies effectively.

When it comes to tire inflation solutions, businesses have several options to consider beyond the ETENWOLF Vortex S6 Tire Inflator. Understanding alternative products can help B2B buyers make informed decisions based on their specific operational needs, budget constraints, and performance expectations. This analysis compares the Vortex S6 with two viable alternatives: a traditional electric tire inflator and a manual pump, highlighting their strengths and weaknesses.

| Aspecto de comparação | Etenwolf Vortex S6 Tire Inflator | Traditional Electric Tire Inflator | Manual Tire Pump |

|---|---|---|---|

| Desempenho | 160 PSI max, 11 GPM air flow | Up to 150 PSI, variable air flow | 35-40 PSI (manual effort) |

| Custo | $159.99 | $50 – $100 | $15 – $30 |

| Facilidade de implementação | User-friendly, quick setup | Simple plug-and-play | Requires physical effort |

| Manutenção | Low maintenance, durable design | Moderate (occasional checks) | Very low, minimal upkeep |

| Melhor caso de uso | Heavy-duty vehicles, emergencies | General vehicle maintenance | Recreational use, bicycles |

Traditional electric tire inflators are widely used for their affordability and ease of use. Typically priced between $50 and $100, these inflators can handle various vehicle types, including cars and light trucks. They usually connect to a standard power outlet or vehicle’s 12V outlet, making them convenient for most users. However, their performance may be limited compared to the Vortex S6, with a maximum pressure of around 150 PSI and a slower air flow rate.

Prós:

– Cost-effective for basic tire inflation needs.

– Easy to operate with minimal setup required.

Contras:

– Lower maximum pressure and air flow compared to the Vortex S6.

– Potentially less durable, requiring more maintenance over time.

Illustrative image related to etenwolf vortex s6 tire inflator

Manual tire pumps are a budget-friendly alternative, generally costing between $15 and $30. These pumps require physical effort to inflate tires and are particularly useful for smaller tires, such as those on bicycles or sports equipment. While they are simple and require virtually no maintenance, the labor-intensive nature of manual pumping can be a drawback, especially for larger vehicles or in emergency situations.

Prós:

– Extremely low cost and maintenance.

– Portable and lightweight, making them easy to transport.

Contras:

– Significant physical effort required, which may not be feasible for all users.

– Limited effectiveness for larger tires or high-pressure applications.

Choosing the right tire inflator depends heavily on your specific operational requirements and budget. The ETENWOLF Vortex S6 Tire Inflator stands out for its high performance, robust design, and suitability for heavy-duty applications, making it ideal for businesses that prioritize reliability and efficiency. In contrast, traditional electric inflators serve well for general maintenance needs at a lower cost, while manual pumps can be a practical choice for occasional, lightweight tasks. B2B buyers should assess their unique circumstances, including vehicle types and inflation frequency, to select the most appropriate solution for their operations.

Illustrative image related to etenwolf vortex s6 tire inflator

Understanding the technical specifications of the ETENWOLF Vortex S6 Tire Inflator is essential for B2B buyers to ensure that the product meets their operational needs. Here are some critical specifications:

Max Pressure (160 PSI)

– The maximum pressure indicates the highest level of inflation the unit can achieve. A higher PSI allows for versatility in inflating various vehicle tires, including heavy-duty trucks and SUVs. This capability is crucial for businesses that require reliable and efficient tire inflation solutions, particularly in industries like logistics and transportation.

Battery Capacity (19,200 mAh)

– This specification reflects the inflator’s power storage capability. A robust battery capacity allows for multiple inflations on a single charge, making the Vortex S6 ideal for on-the-go applications. For B2B buyers, a high-capacity battery translates to reduced downtime and increased operational efficiency.

Air Flow Rate (42L/min)

– The airflow rate measures how quickly the inflator can pump air into a tire. A higher flow rate means faster inflation times, which is beneficial for businesses that need to manage time effectively. This is particularly important in sectors such as automotive services and emergency response where time is of the essence.

Digital Pressure Gauge Accuracy (±1 PSI)

– Precision in tire inflation is vital for safety and performance. The Vortex S6 features a digital pressure gauge with an accuracy of ±1 PSI, ensuring that tires are inflated to the correct pressure. For B2B customers, accurate inflation is essential to maintain vehicle performance and prevent premature tire wear, thus reducing costs over time.

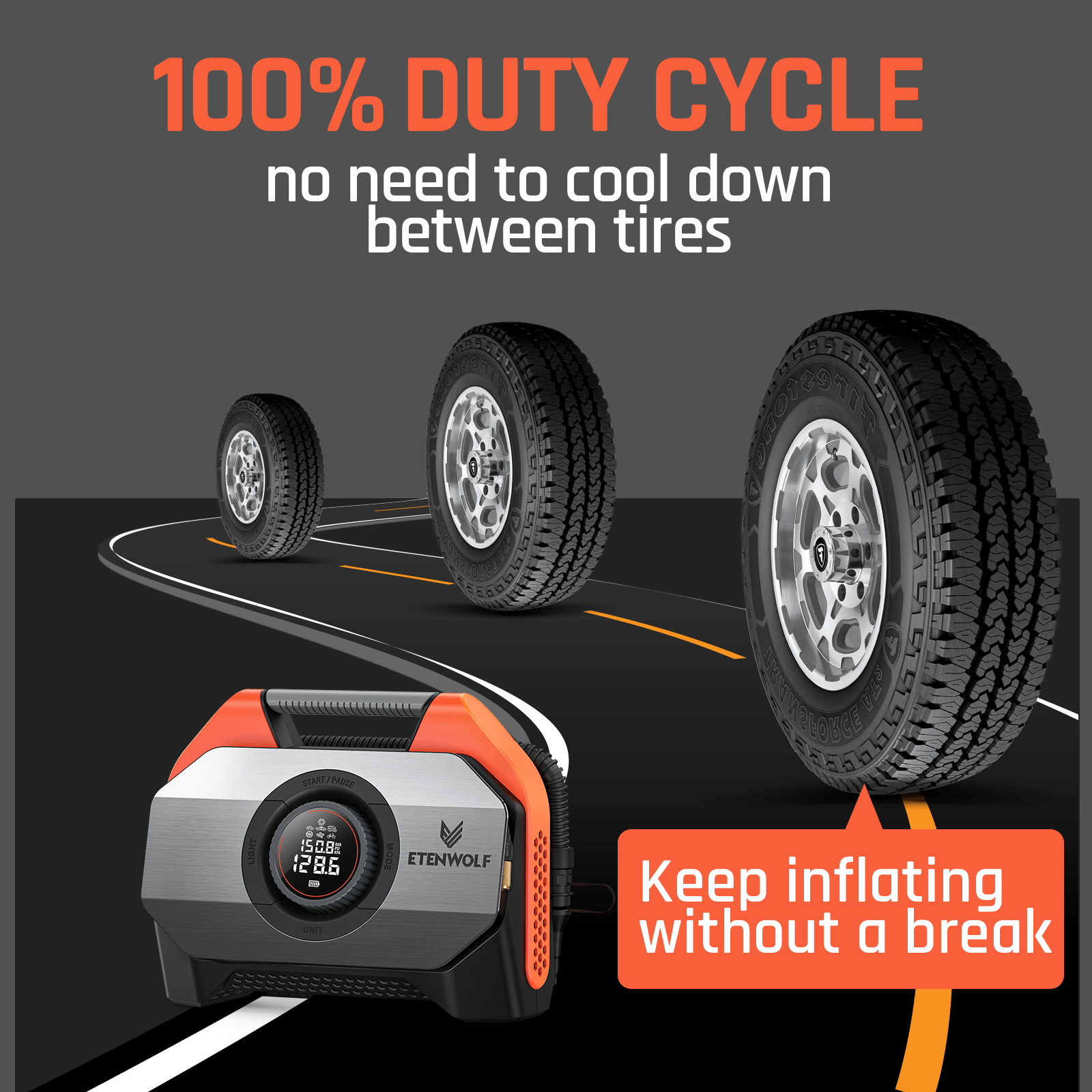

Durability and Duty Cycle (100% Duty Cycle)

– The duty cycle indicates how long the inflator can operate continuously without overheating. The Vortex S6 is designed for a 100% duty cycle, meaning it can run continuously without risk of damage. This feature is crucial for businesses that require heavy use of tire inflators, as it minimizes the need for replacements and repairs.

LED Lighting (1000 LUMENS)

– The built-in LED lighting enhances usability in low-light conditions, making it easier to operate the inflator during nighttime or in poorly lit environments. For B2B operations, such as roadside assistance services, this feature can significantly improve safety and efficiency.

Familiarity with industry terminology is vital for effective communication and negotiation in B2B transactions. Here are some key terms to know:

OEM (fabricante original do equipamento)

– Refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify the quality and reliability of the tire inflator components.

MOQ (Quantidade mínima de pedido)

– This term denotes the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, especially for businesses looking to stock the Vortex S6 for resale or operational use.

RFQ (Request for Quotation, solicitação de cotação)

– An RFQ is a standard business process used to invite suppliers to bid on specific products or services. B2B buyers should utilize RFQs when seeking competitive pricing and terms for the ETENWOLF Vortex S6, ensuring they receive the best deal.

Incoterms (Termos Comerciais Internacionais)

– These are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to manage shipping costs and responsibilities effectively.

Garantia e suporte pós-venda

– Terms related to the manufacturer’s commitment to repair or replace faulty products within a specified period. The Vortex S6 offers a 2-year warranty, which is a critical consideration for B2B buyers assessing long-term reliability and support.

Prazo de entrega

– This refers to the time taken from placing an order to delivery. For businesses, understanding lead times for the ETENWOLF Vortex S6 is crucial for planning and operational efficiency, ensuring that they have the inflators when needed.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational requirements and market strategies.

The global tire inflator market, particularly for products like the ETENWOLF Vortex S6, is experiencing significant growth driven by increasing vehicle ownership and the rise in outdoor recreational activities. In regions such as Africa, South America, the Middle East, and Europe, factors like a burgeoning middle class, urbanization, and improved infrastructure are propelling demand for portable and efficient tire inflation solutions. B2B buyers in these markets are increasingly looking for products that offer durability, efficiency, and multifunctionality—traits exemplified by the Vortex S6, which caters to various vehicles, including SUVs and trucks.

Emerging trends in B2B sourcing include the integration of smart technology into tire inflators, enhancing user experience and operational efficiency. The Vortex S6, for instance, features a digital display for precise pressure settings and an auto-stop function that ensures optimal inflation without user intervention. Additionally, as consumers become more environmentally conscious, there is a growing preference for energy-efficient products, leading suppliers to innovate and adopt sustainable practices. The Vortex S6’s substantial 19,200mAh battery and quick inflation capabilities cater to this trend, appealing to both individual consumers and businesses that require reliable performance in remote or outdoor settings.

Sustainability is becoming a critical consideration for B2B buyers in the tire inflator market, particularly as global awareness of environmental issues rises. Buyers are increasingly favoring suppliers that demonstrate commitment to reducing their environmental impact through sustainable practices. The ETENWOLF Vortex S6 addresses this concern by utilizing a durable design that promises longevity, which in turn reduces waste and the need for frequent replacements.

Illustrative image related to etenwolf vortex s6 tire inflator

Moreover, ethical sourcing of materials is gaining traction. Buyers are looking for products made from eco-friendly materials and those that carry certifications indicating responsible manufacturing processes. The Vortex S6’s components, designed for longevity and performance, help in minimizing the overall carbon footprint associated with production and logistics. Companies that can provide transparency in their supply chains and demonstrate adherence to sustainability standards are likely to gain a competitive edge in this evolving marketplace.

The evolution of tire inflators has shifted dramatically from manual pumps to sophisticated battery-operated models like the ETENWOLF Vortex S6. Initially, tire inflators were basic tools requiring significant manual effort and time, limiting their usability in urgent situations. With the advent of technology, inflators have transformed into portable, efficient, and user-friendly devices that cater to a diverse range of inflation needs, from vehicle tires to sporting equipment.

The introduction of smart features, such as digital displays and automatic shut-off functions, reflects the industry’s response to the growing demand for convenience and efficiency. As B2B buyers increasingly prioritize these features, manufacturers are expected to continue innovating, ensuring that products like the Vortex S6 remain relevant in an ever-evolving market landscape. This trajectory highlights the importance of adapting to consumer needs while maintaining a focus on quality and sustainability.

How do I solve issues with tire inflators not reaching the desired pressure?

To ensure that your ETENWOLF Vortex S6 tire inflator reaches the desired pressure, first check that the unit is calibrated correctly. The Vortex S6 has a precision accuracy of ±1 PSI, so make sure the tire pressure settings are accurately inputted. If the inflator struggles to reach the target pressure, inspect the hoses and connectors for any blockages or leaks. Additionally, ensure that the battery is fully charged, as a low battery can hinder performance. Regular maintenance and proper usage will enhance the inflator’s efficiency.

What is the best tire inflator for heavy-duty vehicles?

The ETENWOLF Vortex S6 is an excellent choice for heavy-duty vehicles such as SUVs, trucks, and off-road vehicles. With a maximum pressure of 160 PSI and a powerful 19,200 mAh battery, it efficiently inflates larger tires quickly. Its digital display ensures accurate pressure readings, and the onboard storage for accessories makes it convenient for various inflation tasks. This all-in-one solution is designed for durability and reliability, making it a top pick for businesses in need of a robust tire inflator.

What are the payment terms for purchasing the Vortex S6 in bulk?

When sourcing the ETENWOLF Vortex S6 tire inflator in bulk, payment terms may vary depending on the supplier agreement. Typically, B2B transactions allow for various options such as upfront payment, net 30/60 days, or even letter of credit arrangements. It’s advisable to discuss these terms directly with the supplier to ensure they meet your financial capabilities and cash flow requirements. Establishing clear payment terms upfront can help mitigate risks and enhance the purchasing experience.

What is the minimum order quantity (MOQ) for the ETENWOLF Vortex S6?

The minimum order quantity (MOQ) for the ETENWOLF Vortex S6 tire inflator may vary based on the supplier’s policies and your location. Generally, for international B2B buyers, MOQs can range from 10 to 100 units. It’s important to communicate with the supplier to determine the MOQ that fits your business needs, as well as potential discounts for larger orders. Understanding the MOQ can help you plan your inventory and manage costs effectively.

How can I ensure quality assurance (QA) for my order of tire inflators?

To ensure quality assurance (QA) for your order of ETENWOLF Vortex S6 tire inflators, request documentation regarding the product’s compliance with international quality standards. It’s beneficial to inquire about the manufacturing processes, certifications, and testing procedures the inflators undergo. Establishing a QA checklist before shipment can help in assessing the products upon arrival. Additionally, consider requesting samples prior to bulk orders to evaluate the product quality firsthand.

What logistics considerations should I keep in mind when importing tire inflators?

When importing ETENWOLF Vortex S6 tire inflators, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Choose between air freight for faster delivery or sea freight for cost-effectiveness, depending on your urgency and budget. Ensure that you have a reliable freight forwarder who can handle customs documentation and duties. Additionally, be aware of regional regulations regarding the import of electronic devices, which may require specific certifications or compliance checks.

Can the ETENWOLF Vortex S6 be customized for my business needs?

Yes, the ETENWOLF Vortex S6 tire inflator can be customized to meet your business requirements. Customization options may include branding with your company’s logo, color variations, or specific packaging needs. It’s advisable to discuss these customization options with the supplier during the negotiation process. Understanding the lead times and costs associated with customization can help you effectively plan your marketing strategy and product launch.

What should I consider when vetting a supplier for tire inflators?

When vetting a supplier for the ETENWOLF Vortex S6 tire inflator, assess their reputation, reliability, and experience in the industry. Look for reviews and testimonials from other B2B buyers to gauge their satisfaction. Verify that the supplier has the necessary certifications and adheres to quality standards. It’s also beneficial to check their customer service responsiveness and support capabilities, as these factors can significantly impact your purchasing experience and ongoing relationship.

Domínio: carbuzz.com

Registrado: 2003 (22 anos)

Introdução: Product Name: ETENWOLF Vortex S6 Heavy Duty Tire Inflator

Principais recursos:

– Air Output: 15 cubic feet per minute

– Inflation Time: Fills a 31-inch tire up to 35 psi in under one minute

– Suitable for: Large vehicles (pickup trucks, RVs), crossovers, classic cars

– Built-in LED screen for current pressure display

– Automatic shut-off when target pressure is reached

– Includes several attachments (not…

In conclusion, the ETENWOLF Vortex S6 Tire Inflator presents a compelling case for strategic sourcing in the tire inflator market. With its robust 19,200 mAh battery, precision capabilities, and multi-functionality, this heavy-duty compressor is tailored to meet the diverse needs of international buyers across various sectors. Its competitive pricing combined with a 90-day money-back guarantee and a two-year extended warranty enhances its appeal, ensuring a risk-free investment.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, the Vortex S6 stands out as an essential tool for maintaining vehicle efficiency and safety. Its ability to quickly inflate tires of larger vehicles, along with its emergency LED lighting features, makes it an invaluable asset for any fleet or service provider.

Illustrative image related to etenwolf vortex s6 tire inflator

As you consider your procurement strategies, prioritize solutions that offer durability, efficiency, and versatility. The ETENWOLF Vortex S6 Tire Inflator is not just a purchase; it’s a strategic investment in quality and performance that can enhance your operational capabilities. Explore partnership opportunities today to leverage this innovative product and optimize your service offerings in the competitive global market.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.

Illustrative image related to etenwolf vortex s6 tire inflator