In an increasingly competitive global market, sourcing reliable car compressors that meet specific operational needs can be a daunting task for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, the challenge lies not just in identifying quality suppliers but also in navigating the complexities of varying standards, regulations, and costs. This guide serves as your comprehensive resource for understanding the diverse landscape of car compressors, including types, applications, and essential supplier vetting processes.

We delve into the intricacies of the market, offering insights into the latest technological advancements and cost considerations that can significantly impact your purchasing decisions. Additionally, we provide practical tips for assessing suppliers, ensuring that you can confidently choose partners who align with your business goals and standards.

By equipping you with actionable information, this guide empowers you to make informed decisions that enhance operational efficiency and drive profitability. From understanding the nuances of compressor types tailored for different vehicles to evaluating the best practices in supplier engagement, this resource is designed to streamline your sourcing process and elevate your purchasing strategy.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

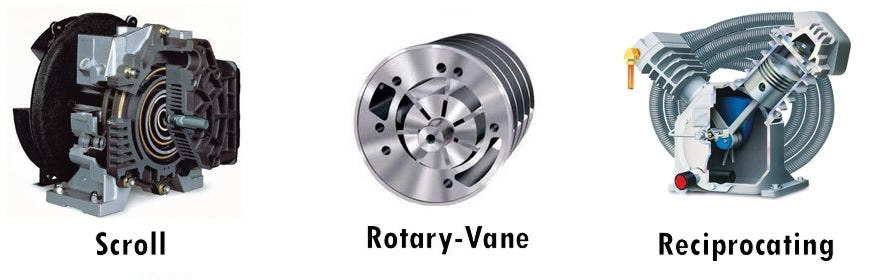

| Reciprocating Compressors | Uses pistons to compress air; typically high-pressure | Automotive repair shops, manufacturing | Prós: High efficiency and pressure; Contras: Noisy, requires maintenance. |

| Rotary Screw Compressors | Continuous operation with two rotors; low noise level | Large automotive facilities, industrial use | Prós: Reliable for continuous use; Contras: Higher initial cost. |

| Scroll Compressors | Uses spiral scrolls for compression; compact design | HVAC applications, small auto shops | Prós: Quiet operation, low maintenance; Contras: Limited output capacity. |

| Centrifugal Compressors | Utilizes high-speed rotating impellers; high flow rate | Heavy-duty vehicles, large fleets | Prós: Efficient for large volumes; Contras: Complex design, higher cost. |

| Portable Compressors | Compact and easy to transport; often battery-operated | Field service, emergency repairs | Prós: Versatile and convenient; Contras: Limited power and capacity. |

Reciprocating compressors are widely used in various automotive and industrial applications. They operate using pistons to compress air, making them suitable for high-pressure requirements. B2B buyers should consider their efficiency and ability to deliver high pressure, which is essential for tasks like tire inflation and air tool operation. However, they can be noisy and require regular maintenance, which may increase operational costs.

Rotary screw compressors are favored in large automotive facilities due to their continuous operation capabilities. They utilize two rotors to compress air, resulting in lower noise levels and consistent airflow. For B2B buyers, the reliability and efficiency of rotary screw compressors make them ideal for demanding environments. However, the higher initial investment might be a consideration for budget-conscious buyers.

Scroll compressors are compact and utilize spiral scrolls for air compression. They are particularly suitable for HVAC applications and small auto shops where space is limited. The quiet operation and low maintenance requirements are significant advantages for businesses seeking efficiency. However, their limited output capacity may not meet the needs of larger operations, making them more suitable for specific niches.

Centrifugal compressors leverage high-speed rotating impellers to achieve a high flow rate, making them ideal for heavy-duty vehicles and large fleets. Their efficiency in handling large volumes of air is a critical factor for B2B buyers in industries requiring substantial compressed air supply. Despite their advantages, the complex design and higher costs can be barriers for smaller businesses or those with limited budgets.

Portable compressors are designed for convenience, often battery-operated or lightweight, making them easy to transport. They are particularly useful for field service and emergency repairs, providing versatility in various environments. B2B buyers appreciate their convenience and adaptability; however, they should be aware of the limitations in power and capacity compared to larger stationary models.

| Indústria/Setor | Specific Application of Car Compressors | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Automotive Repair | Enchimento e manutenção de pneus | Ensures vehicle safety and performance | Reliability, compact size, and ease of use are crucial. |

| Transportation | Air supply for pneumatic tools | Increases efficiency in repair and maintenance tasks | High durability and compatibility with various tools are key. |

| Fabricação | Powering air-operated machinery | Enhances productivity and operational efficiency | Must meet specific pressure and volume requirements. |

| Construção | Providing compressed air for construction equipment | Facilitates heavy-duty operations and project timelines | Consider power source compatibility and portability. |

| Agricultura | Running irrigation systems and pneumatic devices | Improves efficiency in resource management | Need for ruggedness and adaptability to various environments. |

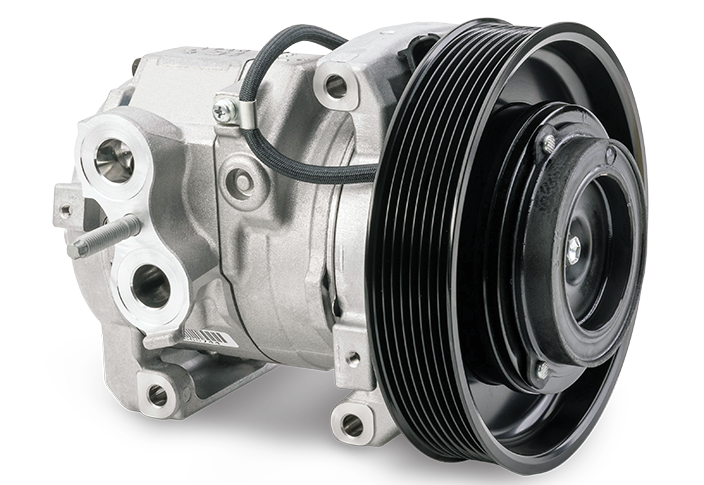

In the automotive repair sector, car compressors are essential for tire inflation and maintenance. They ensure that vehicles operate safely and efficiently by maintaining optimal tire pressure. This is particularly critical in regions with varying climates, such as Africa and South America, where tire pressure can fluctuate dramatically. Buyers in this industry must prioritize reliability and ease of use, as downtime can lead to significant losses in service revenue.

Car compressors are crucial in the transportation industry, particularly for powering pneumatic tools used in vehicle maintenance and repairs. Efficient air supply can streamline operations, reducing the time required for tire changes or brake repairs. International buyers, especially from Europe and the Middle East, should focus on compressors that offer high durability and compatibility with a wide range of pneumatic tools to maximize productivity.

In manufacturing, car compressors are employed to power air-operated machinery, which is vital for various production processes. Their use can significantly enhance operational efficiency by providing a consistent air supply for tools and equipment. Businesses in this sector must ensure that the compressors they source meet specific pressure and volume requirements to align with their production needs, especially in high-demand markets like Germany.

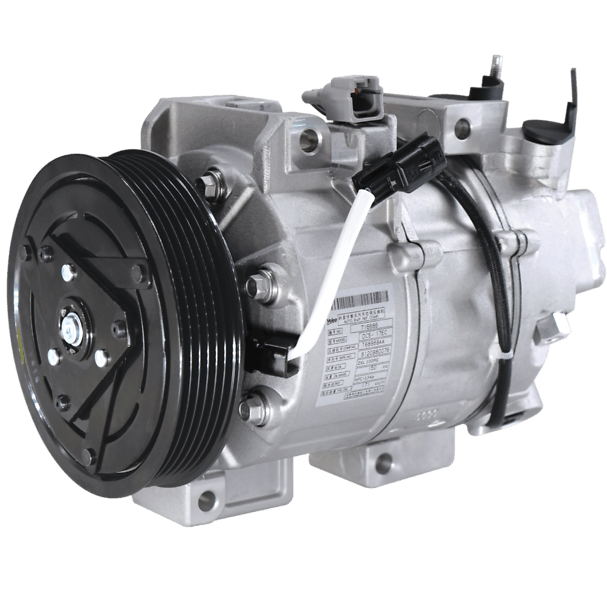

Illustrative image related to car compressors

In the construction industry, car compressors provide the compressed air needed for various equipment, such as jackhammers and nail guns. This functionality is essential for facilitating heavy-duty operations and adhering to project timelines. Buyers should consider the portability and power source compatibility of compressors, ensuring they can be easily transported and used on diverse job sites, particularly in remote areas of Africa and South America.

Car compressors find application in agriculture by powering irrigation systems and various pneumatic devices. This capability significantly improves resource management and operational efficiency, which is critical in regions facing water scarcity. Buyers in the agricultural sector should look for compressors that are rugged and adaptable to different environmental conditions, ensuring reliability even in challenging terrains commonly found in parts of Africa and South America.

O problema: A common challenge B2B buyers face when selecting car compressors is the insufficient air pressure for varied tasks. For instance, in automotive repair shops or tire service centers, the demand for different air pressure levels can be high. A compressor that operates at a maximum of 90 PSI may not be suitable for powering pneumatic tools, inflating large tires, or conducting paint jobs that require higher pressure. This limitation can lead to operational delays and increased labor costs, as technicians may have to switch tools or compressors frequently.

A solução: To address this issue, buyers should prioritize compressors with adjustable pressure settings and higher maximum PSI ratings. Before making a purchase, consider the specific applications and tools that will be used. A versatile compressor, such as those offering 150 PSI or more, can cater to a broader range of tasks. Additionally, investing in a two-stage compressor, which compresses air twice for improved efficiency, can provide the necessary power for demanding applications. Always verify that the compressor’s specifications align with your operational needs and consider models with built-in regulators for precise pressure control.

O problema: Portability and space constraints are significant pain points for many B2B buyers, especially those operating in urban environments or smaller workshops. Compressors are often heavy and bulky, making them difficult to move or store. This can hinder productivity, as workers may waste time relocating equipment or struggle to find adequate storage solutions. Furthermore, inadequate storage can lead to damage and maintenance issues, increasing long-term costs.

Illustrative image related to car compressors

A solução: To overcome portability and storage issues, buyers should look for compact, lightweight car compressors designed for easy transport. Models equipped with wheels and ergonomic handles can facilitate movement across job sites. Additionally, consider tankless or portable designs that minimize space usage without sacrificing performance. When planning for storage, ensure that the compressor fits well within the designated area and consider vertical storage options if floor space is limited. Investing in a protective cover can also help prevent dust and moisture damage during periods of inactivity.

O problema: Reliability issues can plague businesses that rely heavily on car compressors, particularly in regions with extreme weather conditions. For example, compressors may struggle to start in cold temperatures or overheat during prolonged use in high heat. This inconsistency can lead to downtime, affecting service delivery and overall business reputation. Buyers often find themselves dealing with frequent breakdowns, resulting in costly repairs or replacements.

A solução: To ensure consistent performance, B2B buyers should select compressors specifically designed for their environmental conditions. Look for units that offer robust construction and weather-resistant features. For colder climates, compressors with low-temperature start capabilities are essential, while those in hotter regions should consider models with effective cooling systems. Additionally, regular maintenance schedules should be established, including checks on oil levels, filters, and air intake systems, to ensure optimal performance. Implementing a routine inspection protocol can significantly enhance reliability and extend the lifespan of the equipment.

By addressing these pain points with tailored solutions, B2B buyers can enhance their operations, reduce costs, and improve overall service quality in their businesses.

Illustrative image related to car compressors

In the manufacturing of car compressors, the choice of materials significantly influences performance, durability, and cost-effectiveness. Understanding the properties, advantages, and limitations of common materials is crucial for international B2B buyers, especially those navigating diverse market conditions in Africa, South America, the Middle East, and Europe.

Aluminum is a popular choice for car compressor components due to its lightweight nature and excellent thermal conductivity. It typically withstands moderate pressure and temperature variations, making it suitable for various automotive applications.

Prós: Aluminum offers good corrosion resistance, which is particularly beneficial in humid or saline environments. Its lightweight nature contributes to overall vehicle efficiency, enhancing fuel economy.

Contras: While aluminum is durable, it may not withstand extreme pressures as effectively as other metals, potentially limiting its use in high-performance applications. Additionally, the cost of high-grade aluminum can be significant.

Impacto no aplicativo: Aluminum is compatible with air and various automotive fluids, making it a versatile choice. However, careful consideration must be given to its pressure ratings to ensure safety and reliability.

Illustrative image related to car compressors

International Considerations: Buyers should ensure compliance with relevant standards such as ASTM and DIN, particularly in regions with stringent automotive regulations. In Europe, for example, adherence to EU directives on material safety is crucial.

Steel, known for its exceptional strength and durability, is often used in high-pressure components of car compressors. Its ability to withstand significant temperature and pressure fluctuations makes it ideal for heavy-duty applications.

Prós: Steel’s high tensile strength allows for the construction of robust compressor housings and components that can endure harsh operating conditions. It also offers excellent wear resistance.

Contras: The primary drawback of steel is its susceptibility to corrosion unless adequately treated. This can lead to increased maintenance costs and reduced lifespan in corrosive environments.

Impacto no aplicativo: Steel is suitable for applications involving high-pressure air and gas, but its weight can negatively impact vehicle efficiency.

International Considerations: Buyers in regions like Africa and South America should consider local environmental conditions when selecting steel grades, as corrosion resistance may be a priority. Compliance with international standards ensures that the materials meet safety and performance benchmarks.

Illustrative image related to car compressors

Plastics, particularly engineering plastics like polyamide (nylon) and polycarbonate, are increasingly used in car compressors for non-structural components. They offer unique advantages in terms of weight reduction and cost savings.

Prós: Plastics are lightweight and can be molded into complex shapes, reducing manufacturing complexity. They also provide good chemical resistance and can be engineered to meet specific thermal and mechanical properties.

Contras: The primary limitation of plastics is their lower strength compared to metals, which may restrict their use in high-pressure applications. Additionally, they may have lower temperature ratings, affecting performance in extreme conditions.

Illustrative image related to car compressors

Impacto no aplicativo: Plastics are particularly suitable for components that do not experience extreme pressure, such as covers and non-load-bearing parts. Their compatibility with various automotive fluids must be verified to prevent degradation.

International Considerations: B2B buyers should be aware of regional regulations regarding plastic materials, especially in Europe, where there are strict guidelines on the use of certain plastics in automotive applications.

Cast iron is often used in the construction of compressor cylinders and housings due to its excellent wear resistance and ability to dampen vibrations.

Prós: Cast iron’s durability and strength make it ideal for heavy-duty applications, and it can withstand high pressures and temperatures. Its inherent vibration-damping properties also contribute to quieter operation.

Contras: The weight of cast iron can be a disadvantage in applications where reducing vehicle weight is essential. Additionally, cast iron is more prone to corrosion than other materials unless treated.

Impacto no aplicativo: Cast iron is best suited for high-performance compressors that require robust construction. Its compatibility with air and oil makes it a reliable choice for various automotive applications.

International Considerations: Buyers should ensure compliance with industry standards and consider the specific environmental conditions in their region, as corrosion resistance may be a significant factor.

| Material | Typical Use Case for car compressors | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Lightweight components | Excellent corrosion resistance | Limited pressure tolerance | Médio |

| Aço | High-pressure components | Alta resistência à tração | Susceptible to corrosion | Médio |

| Plástico | Non-structural components | Leve e econômico | Lower strength and temperature ratings | Baixa |

| Cast Iron | Compressor cylinders and housings | Exceptional durability and wear resistance | Heavy and prone to corrosion | Médio |

This guide provides a comprehensive overview of material selection for car compressors, equipping international B2B buyers with the insights necessary to make informed purchasing decisions.

The manufacturing process of car compressors involves several critical stages that ensure the final product meets industry standards and customer expectations. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to car compressors

Preparação de materiais: This initial stage involves selecting high-quality raw materials such as aluminum, steel, and various alloys. Suppliers typically conduct thorough inspections to ensure the materials meet the required specifications. The materials are then cut, shaped, and treated to enhance durability and performance.

Formação: In this stage, manufacturers employ techniques like machining, casting, and forging to create the essential components of the compressor. Advanced CNC (Computer Numerical Control) machines are often utilized for precision and consistency. Techniques such as die casting are common for producing complex shapes efficiently.

Montagem: Once the components are formed, they are meticulously assembled. This process often requires automated systems to ensure precision and minimize human error. Components such as pistons, valves, and motors are integrated carefully, often utilizing robotics for tasks that require high accuracy.

Acabamento: The final stage involves surface treatment and finishing processes such as anodizing or powder coating to enhance corrosion resistance and aesthetics. The compressors are also tested for leaks and functionality during this stage to ensure they operate as intended.

Quality assurance (QA) is a fundamental aspect of the manufacturing process for car compressors, ensuring that products meet international standards and customer specifications. The QA process typically includes adherence to various international standards and industry-specific certifications.

Relevant International Standards: One of the most recognized standards in quality management is ISO 9001, which focuses on consistent quality and customer satisfaction. Compliance with ISO 9001 assures B2B buyers that the manufacturing processes are standardized and continuously improved. Other important certifications may include CE marking for products sold in Europe and API (American Petroleum Institute) standards for specific applications.

Pontos de verificação de controle de qualidade:

– Controle de qualidade de entrada (IQC): This checkpoint verifies that incoming materials meet specified standards before they enter production. Any non-conforming materials are rejected at this stage.

– Controle de qualidade durante o processo (IPQC): During manufacturing, IPQC monitors the production process to ensure that each step adheres to quality standards. This includes regular checks on machinery calibration and operator adherence to protocols.

– Controle de qualidade final (FQC): Once assembly is complete, FQC involves rigorous testing of the finished compressors. This may include performance testing, leak detection, and durability assessments to ensure the product functions correctly under various conditions.

To ensure the quality and reliability of car compressors, manufacturers employ various testing methods throughout the production process. Common methods include:

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is critical. Here are several effective strategies:

Auditorias de fornecedores: Conducting regular audits of suppliers can provide firsthand insight into their manufacturing and quality control practices. This may include evaluating their production facilities, quality management systems, and adherence to international standards.

Quality Assurance Reports: Requesting detailed quality assurance reports can help buyers understand the testing methods used, the results of those tests, and how the supplier addresses any identified issues.

Inspeções de terceiros: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can be scheduled at various stages of production to ensure compliance with agreed standards.

International B2B buyers must be aware of specific nuances related to quality control and certification when sourcing car compressors. Differences in regulatory environments, standards, and certifications can impact product quality and market acceptance.

Regional Standards Compliance: Different regions may have unique standards that products must meet. For example, while CE marking is crucial for the European market, UL certification may be necessary for North America. Buyers should ensure that their suppliers comply with the relevant certifications for their target markets.

Documentation and Traceability: Maintaining proper documentation and traceability of materials and processes is essential for compliance with international standards. Buyers should verify that suppliers can provide complete documentation for all components, including material certifications and quality control records.

Cultural and Language Barriers: When dealing with suppliers in diverse regions, cultural and language differences can impact communication regarding quality expectations. Establishing clear communication channels and understanding local practices can mitigate these challenges.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions, ensuring they source high-quality car compressors that meet their operational needs and comply with international standards.

In this practical sourcing guide, we provide a comprehensive checklist tailored for B2B buyers aiming to procure car compressors. This guide will help streamline the sourcing process, ensuring you make informed decisions that align with your operational needs.

Before initiating your search for suppliers, it’s essential to outline the specific technical requirements for the car compressors you need. Consider factors such as pressure ratings, tank size, and power source (e.g., 12V or 24V). Clear specifications will help you narrow down options and communicate effectively with potential suppliers.

Understanding current market trends and price ranges for car compressors is vital for making a competitive purchase. Investigate recent developments in compressor technology, such as energy efficiency or advanced features. This knowledge will not only aid in negotiating prices but also ensure you are investing in products that meet industry standards.

Thoroughly vetting suppliers is crucial to ensure reliability and quality. Request detailed company profiles, including their manufacturing capabilities, experience, and customer reviews. Pay special attention to their expertise in your specific market region, as this can influence product availability and after-sales support.

Ensuring that your potential suppliers hold relevant certifications is key to guaranteeing product quality and compliance with international standards. Look for certifications such as ISO 9001 for quality management and CE marking for compliance with European regulations. This step mitigates risks associated with defective products and enhances your reputation in the market.

Once you’ve identified potential suppliers, engage in negotiations to establish favorable terms. Discuss pricing, payment options, delivery schedules, and warranty conditions. Be clear about your expectations to avoid misunderstandings later on.

After confirming your order, ensure that the supplier offers robust after-sales support. This includes warranty terms, repair services, and availability of spare parts. Reliable after-sales service is crucial for minimizing downtime and maintaining operational efficiency.

Before finalizing your purchase, review the agreement in detail. Ensure that all negotiated terms are documented clearly, including delivery timelines and payment schedules. A well-structured agreement protects both parties and sets the foundation for a successful business relationship.

Illustrative image related to car compressors

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing car compressors, ensuring they make informed and strategic purchasing decisions.

Understanding the cost structure of car compressors is critical for B2B buyers looking to optimize their procurement strategies. The primary cost components include:

Materiais: The quality and type of materials used in manufacturing car compressors significantly influence the cost. High-grade metals and advanced polymers can increase durability but also elevate the price.

Trabalho: Labor costs vary by region and can impact the overall pricing. Countries with higher labor costs may produce compressors at a premium, while regions with lower labor expenses can offer more competitive pricing.

Custos indiretos de fabricação: This includes expenses related to factory operations, utilities, and maintenance. Efficient manufacturing processes can help minimize overhead, thus lowering overall costs.

Ferramentas: The initial investment in tooling for compressor production can be substantial. Custom designs may require specialized tooling, which can increase upfront costs but may lead to better long-term returns if they fulfill specific market needs.

Controle de qualidade (QC): Rigorous QC processes ensure that compressors meet safety and performance standards, which can add to production costs. However, investing in QC can reduce the risk of defects and improve customer satisfaction.

Logística: Shipping and handling costs are significant, especially for international buyers. Factors such as distance, shipping method, and customs can add complexity and expense.

Margem: Supplier margins vary based on their market positioning and business model. Understanding the typical margin within your target market can aid in negotiations.

Several factors can influence the pricing of car compressors:

Volume e quantidade mínima de pedidos (MOQ): Purchasing in larger volumes often leads to discounted rates. Establishing a long-term partnership with suppliers can also yield better pricing.

Especificações e personalização: Custom features may increase costs. However, tailored solutions can provide competitive advantages in specific markets.

Materiais e certificações de qualidade: Compressors made from premium materials or those that meet international quality standards (e.g., ISO certifications) typically command higher prices but may offer better performance and reliability.

Fatores do fornecedor: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge more but can offer peace of mind regarding product reliability.

Incoterms: Understanding delivery terms is crucial for cost calculations. Incoterms dictate who is responsible for shipping, insurance, and tariffs, impacting the total cost of ownership.

For B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant savings. Here are actionable tips:

Illustrative image related to car compressors

Research and Benchmarking: Conduct thorough market research to understand prevailing prices for similar compressors. Benchmarking against competitors can provide leverage in negotiations.

Foco no custo total de propriedade (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, energy efficiency, and replacement parts. Highlighting TCO can justify higher initial investments if they lead to lower operational costs.

Establish Long-Term Relationships: Building a strong relationship with suppliers can lead to better pricing and terms. Suppliers may be more willing to negotiate with buyers who demonstrate commitment.

Leverage Volume Discounts: If possible, consolidate purchases to meet MOQs and secure volume discounts. This strategy can significantly reduce per-unit costs.

Be Cautious with Price Fluctuations: Be aware of pricing trends in the market. Prices can fluctuate based on material availability, demand, or geopolitical factors. Timing your purchase can lead to cost savings.

In summary, understanding the comprehensive cost structure and pricing influencers is essential for B2B buyers in the car compressor market. By leveraging negotiation strategies and focusing on TCO, international buyers can optimize their sourcing decisions and enhance their procurement processes. Be aware that prices can vary significantly based on numerous factors, and it’s advisable to treat indicative prices as a starting point for negotiations.

When considering the best solution for air compression needs in the automotive sector, it is essential to evaluate car compressors alongside viable alternatives. Various technologies and methods can achieve similar outcomes, each with unique advantages and potential drawbacks. This analysis will compare car compressors to portable tire inflators and electric air pumps to help B2B buyers make informed decisions.

| Aspecto de comparação | Car Compressors | Portable Tire Inflators | Bombas de ar elétricas |

|---|---|---|---|

| Desempenho | High PSI output, suitable for heavy-duty tasks | Moderate PSI, ideal for light tasks | Variable PSI, versatile for different applications |

| Custo | Typically ranges from $250 to $3,500 | Affordable, usually under $100 | Mid-range, generally $50 to $300 |

| Facilidade de implementação | Requires installation; some models are portable | Plug-and-play, very user-friendly | Easy to use; may require a power source |

| Manutenção | Regular upkeep needed, especially for heavy-use models | Minimal maintenance required | Manutenção geralmente baixa |

| Melhor caso de uso | Commercial garages, heavy-duty applications | Personal use, occasional tire inflation | Home use, versatile tasks beyond tires |

Portable tire inflators are compact and user-friendly, making them ideal for personal use and occasional tire inflation. Their affordability is a significant advantage, often costing less than $100, which is appealing for budget-conscious buyers. However, their performance is limited compared to car compressors, as they typically provide lower PSI output and are not suitable for heavy-duty applications. Additionally, they may not withstand continuous use, making them less reliable for commercial settings.

Electric air pumps offer versatility and convenience, functioning well for various applications, such as inflating sports equipment, pool toys, and even car tires. Their price range is generally moderate, making them accessible for many users. While electric air pumps are easy to use and often lightweight, they may not provide the high PSI necessary for heavy-duty automotive tasks. Moreover, their performance can vary significantly based on the model, leading to inconsistent results.

Selecting the right air compression solution involves evaluating specific operational needs, budget constraints, and performance requirements. For businesses requiring heavy-duty air compression for automotive repairs or tire services, investing in a car compressor may be the best choice due to its durability and high output. Conversely, companies focusing on light-duty tasks or personal use may find portable tire inflators or electric air pumps to be more cost-effective and easier to manage. Conducting a thorough analysis of the intended use cases, along with a careful assessment of total cost of ownership, will enable B2B buyers to make an informed decision that aligns with their operational goals.

When evaluating car compressors, several technical properties are crucial for ensuring optimal performance and reliability. Understanding these specifications can greatly influence purchasing decisions and operational efficiency.

The pressure rating, measured in pounds per square inch (PSI), indicates the maximum pressure the compressor can generate. A higher PSI rating means the compressor can deliver more power, making it essential for tasks requiring high-pressure air, such as inflating tires or powering pneumatic tools. For B2B buyers, understanding PSI is critical when matching compressor capabilities to specific applications, ensuring that the equipment meets operational demands.

Illustrative image related to car compressors

The flow rate, typically measured in cubic feet per minute (CFM), represents the volume of air the compressor can deliver in a given time frame. A higher CFM is necessary for applications that require a continuous air supply, such as spray painting or running multiple pneumatic tools. For businesses, knowing the CFM helps in selecting compressors that can keep up with workload demands, thereby minimizing downtime.

The duty cycle indicates the ratio of time a compressor can operate versus its downtime. Expressed as a percentage, a duty cycle of 50% means the compressor can run for 5 minutes and must rest for 5 minutes. Understanding the duty cycle is vital for businesses that rely on compressors for extended periods, ensuring they select a model that can sustain their operational needs without overheating or failing.

The tank size, measured in gallons, determines the amount of compressed air stored for immediate use. A larger tank provides a buffer, allowing for a more consistent air supply during high-demand periods. For B2B buyers, selecting the right tank size is essential to maintain efficiency and avoid interruptions in operations.

The material grade of the compressor components, such as the tank, motor, and fittings, affects durability and performance. High-grade materials can withstand higher pressures and resist corrosion, which is particularly important in harsh environments. Buyers should consider the material specifications to ensure longevity and reliability, reducing the need for frequent replacements.

Illustrative image related to car compressors

Noise level, measured in decibels (dB), indicates how loud the compressor operates. For businesses in urban areas or confined spaces, selecting a quieter model can prevent disturbances and ensure compliance with local regulations. Understanding noise levels is crucial for maintaining a conducive work environment.

Navigating the car compressor market requires familiarity with specific trade terminology that can impact procurement and operational efficiency.

OEM refers to companies that produce parts or equipment that are marketed by another company. In the context of car compressors, OEM parts are often preferred for their reliability and compatibility. B2B buyers should prioritize OEM products to ensure they receive high-quality, standardized components that fit seamlessly into their existing systems.

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for businesses to manage inventory effectively and maintain cash flow. Buyers must consider their operational needs and budget constraints when negotiating MOQs with suppliers.

An RFQ is a formal request sent to suppliers to obtain price quotes for specific products. This process allows buyers to compare prices, terms, and conditions from multiple vendors. For B2B buyers, issuing RFQs can facilitate better purchasing decisions and foster competitive pricing.

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and responsibilities, ensuring smoother transactions and reducing the likelihood of disputes.

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is crucial for B2B buyers to ensure timely delivery and project scheduling. Buyers should communicate with suppliers about lead times to align their operational timelines accordingly.

The warranty period is the duration during which a manufacturer guarantees the performance and quality of the compressor. Knowing the warranty terms can protect businesses from unexpected repair costs and provide peace of mind regarding product reliability.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when purchasing car compressors, ultimately enhancing their operational efficiency and cost-effectiveness.

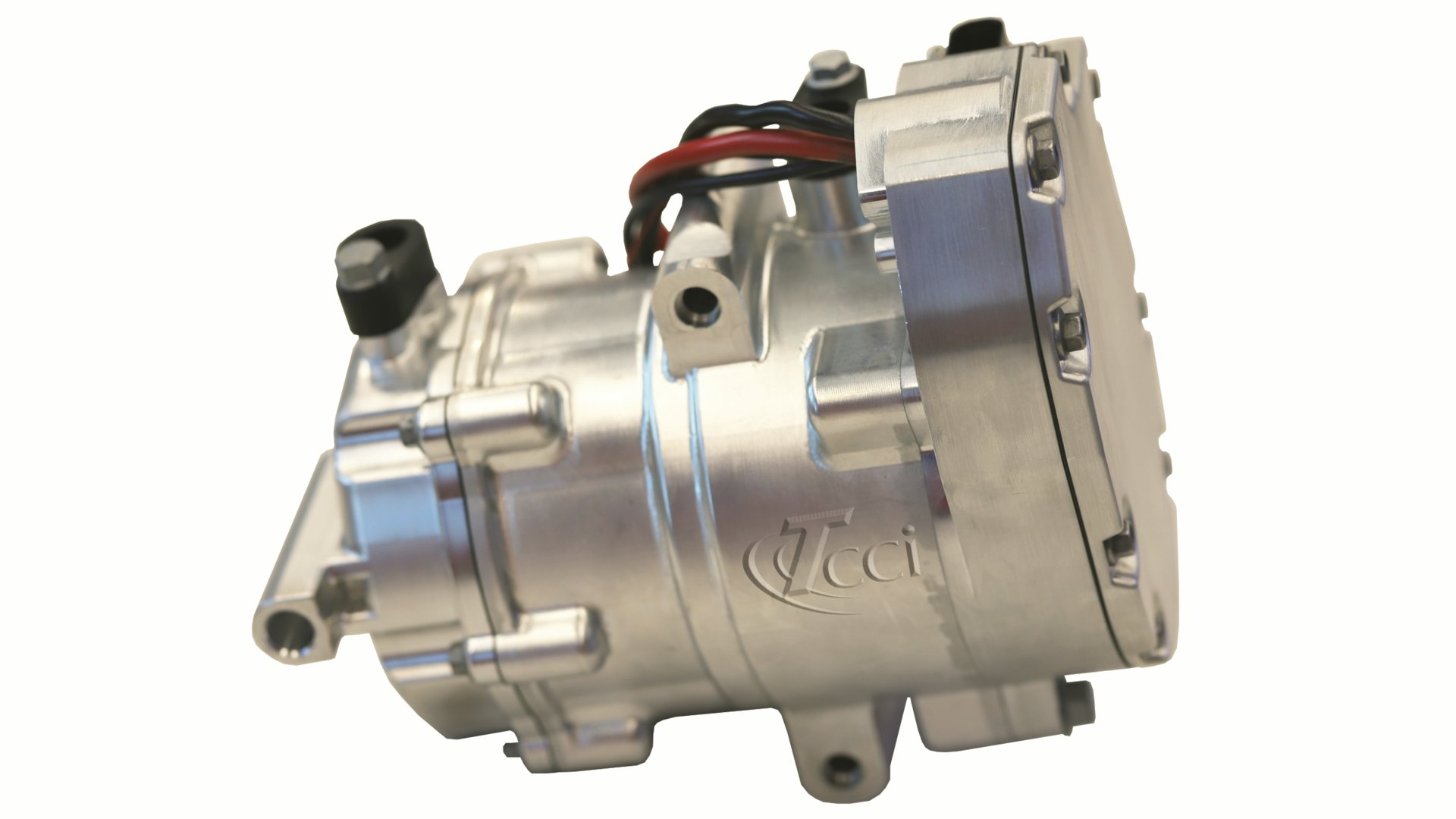

The global car compressors market is experiencing significant growth driven by several key factors. Firstly, the increasing demand for automotive air conditioning systems, particularly in regions with hot climates like Africa and the Middle East, is propelling the need for efficient compressors. Additionally, the rise of electric vehicles (EVs) is introducing new technologies and requirements for compressors, as manufacturers seek to enhance energy efficiency and performance. Emerging trends in digitalization and Industry 4.0 are transforming sourcing strategies, with international B2B buyers increasingly leveraging data analytics and IoT to optimize supply chains and monitor compressor performance.

Furthermore, sustainability is becoming a prominent theme within the industry. Buyers are now prioritizing suppliers who adopt eco-friendly practices and materials. This shift is particularly evident in Europe, where regulatory frameworks are evolving to encourage greener technologies. The integration of smart technologies in compressors, such as variable speed drives and advanced control systems, is also gaining traction, offering buyers enhanced operational efficiency and reduced energy consumption.

In summary, international B2B buyers should focus on suppliers who not only meet traditional performance criteria but also align with modern expectations regarding sustainability and technological innovation. Understanding these market dynamics will empower buyers to make informed sourcing decisions that align with future trends.

Sustainability and ethical sourcing have become critical factors for B2B buyers in the car compressors sector. The environmental impact of manufacturing processes, particularly concerning carbon emissions and resource consumption, has led many companies to seek suppliers committed to reducing their ecological footprint. Buyers are increasingly looking for manufacturers who utilize eco-friendly materials and processes, reflecting a broader commitment to sustainability in their operations.

Ethical supply chains are also gaining importance, with buyers demanding transparency in sourcing practices. This includes ensuring that raw materials are obtained responsibly and that labor practices comply with international standards. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential benchmarks for suppliers.

Moreover, the push for ‘green’ materials and technologies is reshaping product offerings. For instance, compressors designed with recyclable components or those that utilize refrigerants with low global warming potential are becoming more sought after. By prioritizing suppliers who embrace these principles, B2B buyers can enhance their brand reputation and align with consumer preferences increasingly favoring sustainability.

Illustrative image related to car compressors

The car compressors market has evolved significantly over the decades. Initially, compressors were primarily mechanical devices focused on delivering basic air conditioning functions in vehicles. However, with advancements in technology and an increasing focus on vehicle performance, the design and functionality of compressors have undergone substantial improvements.

In the late 20th century, the introduction of variable displacement compressors allowed for better efficiency and control over air conditioning systems, marking a significant shift in the market. As automotive technology continued to advance, the integration of electronic components and digital controls became prevalent, paving the way for modern compressors that are more efficient and adaptable to varying vehicle requirements.

Today, the market is not only influenced by technological advancements but also by growing consumer awareness around environmental issues, driving the need for sustainable solutions and ethical sourcing practices. This historical context is crucial for B2B buyers as it underscores the importance of selecting suppliers who are not just responsive to current demands but also proactive in addressing future challenges in the automotive landscape.

How do I choose the right car compressor for my business needs?

Selecting the appropriate car compressor involves understanding your specific requirements, such as the type of vehicles you service and the intended applications. Evaluate the compressor’s PSI (pounds per square inch) rating, airflow capacity (CFM), and tank size based on your operational demands. Additionally, consider whether a portable or stationary model suits your business better. Conducting a thorough needs assessment will help you choose a compressor that enhances efficiency and productivity.

What factors should I consider when sourcing car compressors internationally?

When sourcing car compressors internationally, consider the manufacturer’s reputation, product quality, and compliance with local regulations. Investigate the supplier’s certifications, such as ISO standards, to ensure adherence to international quality norms. Additionally, assess their shipping capabilities, lead times, and after-sales support to avoid potential disruptions. Building a relationship with trustworthy suppliers can also facilitate smoother transactions and better terms.

What are the typical minimum order quantities (MOQs) for car compressors?

Minimum order quantities (MOQs) for car compressors can vary significantly based on the supplier and product type. Generally, MOQs may range from a few units for smaller suppliers to several dozen for larger manufacturers. It’s essential to discuss your specific needs with potential suppliers, as many are willing to negotiate MOQs, especially for long-term partnerships or repeat orders. Understanding your inventory needs will help you make informed purchasing decisions.

What payment terms should I expect when buying car compressors?

Payment terms for purchasing car compressors can vary widely among suppliers. Common terms include a percentage upfront (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or financing options, especially for larger orders. It’s crucial to clarify payment methods, currency preferences, and any potential discounts for early payment to ensure a smooth transaction process.

How can I ensure the quality of car compressors I purchase?

To guarantee the quality of car compressors, request product samples or prototypes before placing a bulk order. Additionally, conduct a factory audit or quality assurance checks to verify manufacturing processes. Look for certifications that demonstrate compliance with international standards, such as CE or UL. Establishing clear quality expectations and maintaining open communication with your supplier can help address any quality concerns promptly.

What logistics considerations should I keep in mind when importing car compressors?

When importing car compressors, consider shipping methods, customs clearance, and delivery timelines. Evaluate whether air freight or sea freight is more suitable for your needs, keeping in mind cost and urgency. Additionally, familiarize yourself with import duties and taxes in your country to avoid unexpected expenses. Partnering with a logistics provider experienced in international trade can streamline the shipping process and mitigate potential delays.

Can I customize car compressors to meet specific business needs?

Many manufacturers offer customization options for car compressors, allowing you to tailor specifications such as size, power, and features to suit your business requirements. Discuss your needs with the supplier, including any branding or design elements you wish to incorporate. Customization may involve additional costs and longer lead times, so it’s essential to clarify these factors upfront during negotiations.

What are the common issues to watch for when sourcing car compressors?

When sourcing car compressors, be vigilant about potential issues such as hidden costs, unclear warranties, and inadequate after-sales support. Ensure that the supplier provides clear documentation regarding product specifications and warranties. Additionally, watch for potential language barriers that could lead to misunderstandings. Establishing a strong communication channel and setting clear expectations can help mitigate these risks and foster a successful partnership.

Domínio: rycompressors.com

Registrado: 2014 (11 anos)

Introdução: 2021 Lincoln Navigator Reserve Sport Utility 4-Door 3.5L A/C Compressor and Clutch (AFH386) $284.99; 2021 Lincoln Navigator L Reserve Sport Utility 4-Door 3.5L A/C Compressor and Clutch (AFH386) $284.99; 2021 Lincoln Navigator L Livery Sport Utility 4-Door 3.5L A/C Compressor and Clutch (AFH386) $284.99; 2021 Lincoln Navigator L Black Label Sport Utility 4-Door 3.5L A/C Compressor and Clutch (AFH3…

Domínio: store.arbusa.com

Registrado: 1998 (27 anos)

Introdução: Portable & Vehicle Mounted Air Compressor Systems from ARB 4×4 USA. Key features include: durable, high-performance compressors for tires, tools, and Air Lockers. New Brushless Compressors offer 50% more output, smart cooling, and quick-release mounts for unmatched airflow in a compact design. Product categories include: Twin Motor Onboard 12V Air Compressor (CKMTA12) – $659.95, Single Motor Onboa…

Domínio: reddit.com

Registrado: 2005 (20 anos)

Introdução: Looking for a good air compressor primarily to use for car tires. Recommendations include: 1. Viair 88p – noted for its value and utility. 2. Milwaukee M18 – praised for quality, especially if using existing Milwaukee batteries. 3. California Air Tools – recommended for being oil-free and quiet, with a specific mention of an 8-gallon model that is portable.

Domínio: ebay.com

Registrado: 1995 (30 anos)

Introdução: This company, eBay – Automotive Air Compressors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domínio: bestbuy.com

Registrado: 1994 (31 anos)

Introdução: Auto Air Compressors & Inflators available at Best Buy include 29 items sorted by best selling. Key brands include AstroAI, NOCO, Fanttik, AGPtek, CAROSS, Giantpower, and HOTO. Features include portable design, plug-in on/off switch, rechargeable options, and no assembly required. Power sources vary with battery-powered and plug-in options. Customer ratings range from top-rated to 4 stars and up. …

In the evolving landscape of the automotive industry, strategic sourcing of car compressors plays a pivotal role in ensuring operational efficiency and cost-effectiveness. Buyers are encouraged to focus on reliable suppliers who offer quality products, flexible shipping options, and competitive pricing. Understanding local market demands across regions such as Africa, South America, the Middle East, and Europe will enable businesses to make informed decisions that align with their operational goals.

Illustrative image related to car compressors

Investing in advanced compressor technologies can lead to significant long-term benefits, including enhanced performance and reduced maintenance costs. As manufacturers continue to innovate, staying abreast of these advancements will provide a competitive edge. Moreover, leveraging local pickup options can streamline logistics and reduce overhead costs, which is particularly beneficial for businesses operating in remote areas.

Looking ahead, international B2B buyers are urged to forge strong partnerships with suppliers who are committed to sustainability and technological advancements. By doing so, they can position themselves favorably in a rapidly changing market. Now is the time to assess your sourcing strategies and embrace the opportunities that await in the global marketplace for car compressors. Engage with trusted suppliers today to secure your supply chain for tomorrow.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.