In the fast-paced world of logistics and transportation, ensuring optimal tire performance is a critical challenge faced by businesses across diverse markets. Understanding nitrogen tire inflation is essential for B2B buyers seeking to enhance vehicle safety, improve fuel efficiency, and reduce overall maintenance costs. This comprehensive guide delves into the intricacies of nitrogen tire inflation, exploring various types, applications, and the potential advantages over traditional air filling.

We will also examine the best practices for supplier vetting, ensuring that you partner with reputable providers who can meet your specific needs. Additionally, we will provide insights into the cost considerations associated with nitrogen inflation, empowering you to make informed purchasing decisions that align with your operational goals.

This guide is tailored for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia. By equipping you with detailed knowledge and actionable insights, we aim to facilitate smarter procurement strategies that can lead to enhanced performance and cost savings in your fleet operations. Whether you are looking to reduce tire degradation, improve handling, or simply ensure compliance with industry standards, this resource will serve as your go-to reference for navigating the global market of nitrogen tire inflation.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Standard Nitrogen Inflation | Utilizes 95% pure nitrogen; common in passenger vehicles | Passenger vehicles, light trucks | Prós: Reduces pressure loss; enhances safety. Contras: Limited benefits for everyday use; requires maintenance. |

| High-Pressure Nitrogen Inflation | Designed for heavy-duty applications; higher nitrogen purity | Commercial trucks, aviation, motorsports | Prós: Maintains pressure under extreme conditions; reduces tire wear. Contras: Higher initial cost; specialized service required. |

| Nitrogen Generation Systems | On-site nitrogen generation for continuous supply | Fleet management, large-scale operations | Prós: Cost-effective for large fleets; minimizes downtime. Contras: Initial investment; maintenance of equipment. |

| Hybrid Inflation | Combination of nitrogen and regular air | Mixed fleet operations | Prós: Flexibility in filling; cost savings. Contras: Reduced effectiveness of nitrogen benefits. |

| Specialty Nitrogen Inflation | Tailored for specific industries (e.g., aviation, racing) | Aviation, motorsports, industrial vehicles | Prós: Optimized for performance; enhances safety in critical applications. Contras: Specialized training required; potentially higher costs. |

Standard nitrogen inflation is characterized by the use of nitrogen gas with a purity of around 95%. This method is primarily employed in passenger vehicles and light trucks. B2B buyers in the automotive sector may find this option appealing due to its potential to reduce tire pressure loss, thereby enhancing safety and performance. However, the benefits may not be as pronounced for standard usage, and regular maintenance is necessary to realize the advantages fully.

High-pressure nitrogen inflation is specifically designed for heavy-duty applications, such as commercial trucks and aviation. This variation features a higher nitrogen purity level, which helps maintain tire pressure under extreme conditions. Businesses in logistics and transportation will benefit from reduced tire wear and improved fuel efficiency. While the initial investment may be higher, the long-term savings in tire replacement costs can justify the expense.

Nitrogen generation systems provide an on-site solution for businesses with large fleets or operations requiring continuous nitrogen supply. These systems can significantly reduce costs over time, especially for companies managing extensive vehicle fleets. The primary B2B consideration here is the upfront investment in equipment, which can be offset by reduced downtime and service costs. Regular maintenance of the nitrogen generation equipment is essential for optimal performance.

Illustrative image related to what is nitrogen tire inflation

Hybrid inflation combines nitrogen and regular air, offering flexibility in tire filling for mixed fleet operations. This option is particularly suitable for businesses that operate a variety of vehicle types, allowing for cost savings while still leveraging some benefits of nitrogen. However, B2B buyers should be aware that mixing gases may reduce the effectiveness of the nitrogen’s advantages, requiring regular monitoring of tire pressure.

Specialty nitrogen inflation is tailored for specific industries, such as aviation, motorsports, and industrial vehicles. This variation is optimized for performance and safety in critical applications. Companies operating in these sectors will find this option valuable, as it enhances tire performance and longevity. However, the need for specialized training and potentially higher costs can be a barrier for some businesses, necessitating careful consideration of the overall return on investment.

| Indústria/Setor | Specific Application of what is nitrogen tire inflation | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Aviation | Tire inflation for commercial and private aircraft | Enhanced safety and reduced maintenance costs | Ensure nitrogen purity and availability of inflation equipment |

| Transportation & Logistics | Fleet maintenance for trucks and delivery vehicles | Improved fuel efficiency and reduced tire wear | Reliable nitrogen supply and regular pressure monitoring systems |

| Mining & Construction | Heavy machinery tire inflation | Increased tire lifespan and reduced downtime | Access to high-purity nitrogen and specialized inflation tools |

| Automotive Racing | Tire inflation for racing vehicles | Optimal performance and safety during high-speed operations | Consistent nitrogen supply and precise pressure management |

| Industrial Equipment | Tire inflation for forklifts and material handling equipment | Enhanced operational efficiency and reduced maintenance costs | Availability of nitrogen inflation systems and service support |

In the aviation industry, nitrogen tire inflation is crucial for both commercial and private aircraft. Tires filled with nitrogen maintain pressure more effectively, reducing the risk of blowouts during takeoff and landing. This application is particularly important given the high safety standards in aviation. International buyers must ensure that they source nitrogen with high purity levels and have access to specialized inflation equipment to meet regulatory requirements.

Illustrative image related to what is nitrogen tire inflation

For transportation and logistics companies, nitrogen tire inflation is implemented in the maintenance of fleets, including trucks and delivery vehicles. Using nitrogen helps maintain tire pressure, leading to improved fuel efficiency and reduced tire wear. This is essential for companies looking to minimize operating costs. Buyers in this sector should consider reliable nitrogen supply chains and invest in regular tire pressure monitoring systems to maximize the benefits.

In the mining and construction industries, heavy machinery relies on nitrogen tire inflation to enhance tire longevity and reduce downtime. The use of nitrogen minimizes pressure loss, which is critical for equipment that operates in rugged environments. Buyers in these sectors need to ensure they have access to high-purity nitrogen and specialized inflation tools to cater to the demanding conditions of their operations.

In automotive racing, nitrogen tire inflation is used to optimize vehicle performance and safety at high speeds. Nitrogen helps maintain consistent tire pressure, which is vital for handling and traction during races. Teams must have a consistent nitrogen supply and precise pressure management systems to ensure optimal tire performance. This application is particularly valuable for buyers looking to enhance competitive performance on the racetrack.

For industrial equipment such as forklifts and material handling machinery, nitrogen tire inflation offers enhanced operational efficiency and reduced maintenance costs. By preventing tire pressure loss, businesses can ensure that their equipment operates smoothly and reliably. Buyers should prioritize the availability of nitrogen inflation systems and service support to maintain optimal equipment performance and minimize potential disruptions in operations.

Illustrative image related to what is nitrogen tire inflation

O problema:

B2B buyers managing large fleets, such as logistics or transportation companies, often grapple with the decision to implement nitrogen tire inflation due to the associated costs. While nitrogen can offer benefits like reduced tire pressure loss and potential fuel savings, the initial investment of around $5 per tire can quickly add up, especially when servicing hundreds of vehicles. Additionally, the perceived complexity of maintaining nitrogen levels can deter decision-makers from making the switch, fearing that it may complicate routine maintenance and inflate operational costs.

A solução:

To address this pain point, fleet managers should conduct a thorough cost-benefit analysis that factors in both short-term and long-term savings. Start by monitoring tire pressure and fuel efficiency before and after implementing nitrogen inflation on a select number of vehicles. This empirical data will provide concrete evidence of any improvements in fuel economy and tire longevity. Furthermore, establishing a partnership with a reliable nitrogen supplier can help streamline costs and ensure proper maintenance. Training staff to understand the advantages and proper handling of nitrogen inflation will reduce the perceived complexity and improve compliance. Investing in nitrogen inflation for the entire fleet may yield substantial savings over time, justifying the initial costs.

O problema:

Many B2B buyers in industries like automotive service or fleet maintenance encounter skepticism from clients or internal stakeholders regarding the benefits of nitrogen tire inflation compared to traditional air. Common misconceptions revolve around the belief that nitrogen inflation is merely a marketing gimmick or that air is just as effective. This skepticism can lead to reluctance in adopting nitrogen inflation, causing businesses to miss out on potential advantages such as reduced tire degradation and longer tire life.

A solução:

To counteract these misconceptions, B2B buyers should invest in educational initiatives that clearly outline the scientific benefits of nitrogen inflation. Hosting workshops or webinars featuring industry experts can provide valuable insights into how nitrogen reduces oxidation and pressure loss in tires. Providing clients with data from reputable studies, such as those conducted by Consumer Reports, can also reinforce the advantages of nitrogen inflation. Additionally, offering a trial period where clients can experience the benefits firsthand may alleviate concerns and encourage adoption. By building a foundation of knowledge and trust, businesses can effectively promote the advantages of nitrogen tire inflation.

O problema:

For companies that decide to implement nitrogen tire inflation, maintaining the correct nitrogen levels can pose a significant challenge. B2B buyers often face difficulties in ensuring that all service personnel are adequately trained and equipped to monitor and refill tires with nitrogen. This lack of proper maintenance can lead to diminished benefits, such as increased pressure loss or even safety risks from under-inflated tires, ultimately negating the advantages of switching to nitrogen.

A solução:

To effectively manage nitrogen tire maintenance, B2B buyers should develop a comprehensive training program for their service teams. This program should cover the importance of regular tire pressure checks, the correct procedures for nitrogen inflation, and how to handle mixed inflation (when air is added). Investing in specialized nitrogen inflation equipment can also streamline the process and ensure that tires are filled correctly. Additionally, establishing a routine schedule for tire inspections and nitrogen top-offs will help maintain optimal tire performance. Utilizing tire pressure monitoring systems (TPMS) can provide real-time data, alerting teams when nitrogen levels drop and allowing for proactive maintenance. By prioritizing proper training and monitoring, businesses can fully capitalize on the benefits of nitrogen tire inflation.

When considering nitrogen tire inflation systems, several materials are integral to their performance and effectiveness. Understanding the properties, advantages, and limitations of these materials is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Aluminum is widely used in the construction of nitrogen inflation equipment due to its favorable properties. It has excellent corrosion resistance, particularly when anodized, and can withstand a wide range of temperatures and pressures. Its lightweight nature makes it ideal for portable nitrogen generation systems.

Prós: Aluminum is durable, lightweight, and resistant to corrosion, making it suitable for outdoor environments. It is also relatively easy to manufacture and can be machined into complex shapes.

Contras: While generally cost-effective, aluminum can be more expensive than some alternatives, especially in high-purity applications. It may also require protective coatings to enhance its longevity in harsh environments.

Impacto no aplicativo: Aluminum’s compatibility with nitrogen makes it a preferred choice for components like valves and tanks. However, it is essential to ensure that the aluminum used meets international standards such as ASTM or DIN.

Illustrative image related to what is nitrogen tire inflation

Stainless steel is another popular material in nitrogen tire inflation systems, particularly for high-pressure applications. It boasts excellent strength, corrosion resistance, and durability, making it suitable for long-term use.

Prós: Stainless steel can withstand extreme conditions and is less likely to degrade over time compared to other materials. Its strength allows for the construction of robust and safe storage tanks and piping systems.

Contras: The primary drawback of stainless steel is its higher cost compared to aluminum. Additionally, it can be heavier, which may affect the portability of nitrogen inflation equipment.

Impacto no aplicativo: Stainless steel is often used in high-pressure storage tanks and piping systems. Compliance with standards such as ASTM A312 for stainless steel pipes is crucial for international buyers.

Composite materials, particularly carbon fiber reinforced polymers, are gaining traction in nitrogen tire inflation systems due to their lightweight and high-strength characteristics. They are particularly beneficial in applications where weight savings are critical.

Illustrative image related to what is nitrogen tire inflation

Prós: Composites offer high strength-to-weight ratios and excellent resistance to corrosion and environmental degradation. They can be tailored for specific applications, enhancing performance.

Contras: The manufacturing process for composites can be complex and expensive, making them less accessible for some applications. Additionally, they may not be as readily available as metals in certain regions.

Impacto no aplicativo: Composites are ideal for specialized applications, such as in aviation or high-performance automotive sectors. Buyers should ensure that the composites used meet relevant international standards.

Rubber is primarily used in the seals and gaskets of nitrogen tire inflation systems. Its elasticity and ability to form tight seals are crucial for maintaining pressure and preventing leaks.

Prós: Rubber is cost-effective and provides excellent sealing capabilities. It is also flexible, allowing for easy installation and maintenance.

Contras: Rubber can degrade over time, especially when exposed to extreme temperatures or chemicals. Its lifespan may be shorter compared to metals or composites.

Impacto no aplicativo: The choice of rubber should consider temperature ratings and compatibility with nitrogen. International buyers should ensure compliance with standards such as ASTM D2000 for rubber materials.

| Material | Typical Use Case for what is nitrogen tire inflation | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Valves and tanks in nitrogen generation systems | Leve e resistente à corrosão | Higher cost than some alternatives | Médio |

| Aço inoxidável | High-pressure storage tanks and piping | Excellent strength and durability | Heavier and more expensive than aluminum | Alta |

| Composto | Specialized applications in aviation and automotive | Alta relação resistência/peso | Complex manufacturing process | Alta |

| Borracha | Seals and gaskets in inflation systems | Cost-effective and excellent sealing capability | Degrades over time under extreme conditions | Baixa |

This comprehensive analysis provides valuable insights for B2B buyers considering materials for nitrogen tire inflation systems, helping them make informed decisions based on performance, cost, and application suitability.

Illustrative image related to what is nitrogen tire inflation

The manufacturing process for nitrogen tire inflation systems involves several key stages, each crucial for ensuring quality and performance. Understanding these stages helps B2B buyers assess the reliability of their suppliers.

The process begins with the selection of high-purity nitrogen gas, which is typically derived from air through methods such as cryogenic distillation or pressure swing adsorption. The equipment used to produce nitrogen includes compressors, filters, and dryers designed to eliminate impurities and moisture. B2B buyers should ensure that suppliers use high-quality materials that meet international standards, as the purity of nitrogen directly impacts tire performance.

In this stage, the nitrogen is compressed and stored in specialized tanks. The tanks must be constructed from durable materials that can withstand high pressures. Advanced technologies are employed to ensure that the gas is maintained at a constant temperature and pressure, which is essential for consistent tire inflation. Buyers should look for suppliers that utilize automated systems for precision in gas handling, minimizing human error during this critical phase.

The assembly of nitrogen tire inflation systems involves integrating various components such as valves, gauges, and hoses. Each component must be carefully assembled to ensure a leak-proof system. B2B buyers should inquire about the assembly techniques used by suppliers, such as automated assembly lines that enhance precision and reduce assembly time. Additionally, the use of standardized parts can facilitate easier maintenance and replacement.

Illustrative image related to what is nitrogen tire inflation

Once assembled, the systems undergo a finishing process that includes rigorous testing for leaks and performance. This stage often incorporates advanced diagnostic tools to simulate real-world conditions. Buyers should confirm that their suppliers conduct thorough testing procedures to ensure the reliability of the systems. Any system that fails to meet specified criteria is either repaired or discarded, ensuring that only high-quality products reach the market.

Quality assurance is vital in the manufacturing of nitrogen tire inflation systems, particularly for B2B buyers who require reliable products. Various international and industry-specific standards guide quality assurance processes.

ISO 9001 is the most recognized standard for quality management systems, emphasizing customer satisfaction and continuous improvement. Suppliers should be certified to this standard, ensuring that they have established processes for quality control at every manufacturing stage. B2B buyers can request certification documentation to verify compliance.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for oil and gas applications may also be relevant. These certifications ensure that products meet specific safety and performance requirements. Buyers should verify that suppliers maintain these certifications to mitigate risks associated with product failures.

Illustrative image related to what is nitrogen tire inflation

Quality control (QC) checkpoints are essential for ensuring the integrity of nitrogen tire inflation systems. These checkpoints help identify defects early in the manufacturing process, reducing waste and enhancing product reliability.

Controle de qualidade de entrada (IQC): This initial stage involves inspecting raw materials and components before they enter the production process. Suppliers should conduct tests to ensure that materials meet specified standards for purity and performance.

Controle de qualidade durante o processo (IPQC): During manufacturing, ongoing inspections are conducted to monitor production processes. This includes checks for dimensional accuracy, assembly integrity, and system performance. Automated systems can enhance the efficiency of this stage.

Controle de qualidade final (FQC): After assembly, systems undergo comprehensive testing to ensure they function correctly and meet performance specifications. This stage may involve pressure testing and functionality assessments under simulated conditions.

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. This includes conducting audits, reviewing quality reports, and utilizing third-party inspections.

Buyers should request detailed audit reports that outline the supplier’s quality management processes, including compliance with ISO and industry-specific standards. Audits should also assess the effectiveness of the supplier’s quality control measures, including how they handle non-conformities.

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control practices. These agencies can perform independent evaluations of the manufacturing processes and final products, offering B2B buyers additional assurance of product quality.

For international B2B buyers, understanding the nuances of quality control across different regions is crucial. Variations in regulations and market expectations can impact product quality and safety.

Different regions may have specific regulations governing the manufacturing and testing of nitrogen tire inflation systems. For instance, the European Union has stringent CE marking requirements, while buyers in the Middle East may need to comply with local regulations that differ from those in Europe or North America. It is essential for buyers to understand these regional standards to ensure compliance and product safety.

Building strong relationships with suppliers can enhance quality control outcomes. B2B buyers should communicate their quality expectations clearly and engage in regular discussions regarding quality improvements. This collaborative approach can foster mutual understanding and commitment to maintaining high standards.

In conclusion, understanding the manufacturing processes and quality assurance protocols for nitrogen tire inflation systems is essential for B2B buyers. By focusing on the main stages of manufacturing, relevant quality standards, control checkpoints, and verification methods, buyers can make informed decisions and ensure they partner with reliable suppliers.

This guide provides a comprehensive checklist for B2B buyers interested in procuring nitrogen tire inflation solutions. Understanding the nuances of nitrogen inflation can lead to enhanced tire performance, reduced maintenance costs, and improved safety for commercial fleets. Follow these steps to ensure a successful procurement process.

Establish clear technical requirements for nitrogen tire inflation systems tailored to your operational needs. Consider factors such as tire types, vehicle specifications, and the volume of nitrogen required. Accurate specifications will help you communicate effectively with suppliers and ensure they can meet your unique demands.

Conduct thorough research to identify potential suppliers who specialize in nitrogen tire inflation systems. Look for companies with a proven track record in your region, especially those familiar with the specific needs of industries in Africa, South America, the Middle East, and Europe. Utilize online directories, industry forums, and trade shows to compile a list of viable candidates.

Before engaging with suppliers, verify their certifications and compliance with international standards. Look for ISO certifications and adherence to local regulations related to tire maintenance and safety. This step is crucial to ensure that the supplier meets quality standards and minimizes risks associated with non-compliance.

Whenever possible, request demonstrations or samples of the nitrogen inflation systems being offered. This allows you to assess the functionality, ease of use, and reliability of the equipment firsthand. Ensure that the demonstrations cover key features such as inflation speed, purity levels, and maintenance requirements.

Evaluate the level of after-sales support and training provided by potential suppliers. Comprehensive support can significantly reduce downtime and enhance the efficiency of your nitrogen inflation processes. Look for suppliers that offer training programs, maintenance services, and readily available customer support.

Illustrative image related to what is nitrogen tire inflation

Obtain detailed quotations from multiple suppliers and compare them based on pricing and contract terms. Consider not just the initial costs but also the long-term value, including maintenance, warranty, and service agreements. This analysis will help you make an informed decision that aligns with your budget and operational goals.

Before finalizing your procurement, consider negotiating a trial period with the selected supplier. This allows you to evaluate the nitrogen tire inflation system’s performance within your operational environment without a long-term commitment. Monitor key metrics such as tire pressure retention, fuel efficiency, and overall fleet safety during this period.

By following these steps, you can ensure a well-informed procurement process that aligns with your business objectives and enhances your tire maintenance strategy through nitrogen inflation.

When considering the sourcing of nitrogen tire inflation systems, several cost components come into play, impacting the overall pricing structure. Understanding these elements can guide international B2B buyers in making informed purchasing decisions.

Materiais: The primary material cost involves the nitrogen generation system, which typically includes nitrogen compressors and filtration units. Additionally, the gas itself, although primarily derived from ambient air, may include costs associated with its purification process to achieve the desired purity levels (often 95% or higher). The quality of these materials significantly affects pricing.

Trabalho: Labor costs can vary depending on the complexity of the nitrogen generation system and the region of sourcing. Skilled labor may be required for the installation and maintenance of these systems, which should be factored into the total cost.

Custos indiretos de fabricação: This includes costs related to facility operations, utilities, and equipment depreciation. Depending on the manufacturer’s location, these overhead costs may fluctuate significantly, impacting the final price of the nitrogen inflation systems.

Ferramentas: Specialized tooling may be necessary for the production of nitrogen generation systems, particularly if customization is required. This can increase initial setup costs, which are often amortized over the volume of units produced.

Controle de qualidade (QC): Ensuring the reliability and efficiency of nitrogen tire inflation systems involves rigorous quality control measures. The costs associated with QC processes, including testing and certification, contribute to the overall pricing.

Logística: Transportation and shipping costs, especially for international buyers, can significantly impact pricing. Factors such as shipping distance, method, and compliance with local regulations should be considered when sourcing nitrogen systems.

Margem: Suppliers typically build in a profit margin that reflects their operational costs and market positioning. Understanding the margin expectations of suppliers can help buyers negotiate better terms.

Several price influencers can affect the final cost of nitrogen tire inflation systems. B2B buyers should consider the following:

Illustrative image related to what is nitrogen tire inflation

Volume/MOQ: Purchasing in larger quantities often results in lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) to optimize pricing.

Especificações e personalização: Customized systems designed to meet specific operational needs may incur additional costs. Buyers should clearly outline their requirements to avoid unexpected expenses.

Qualidade e certificações: Systems that meet international quality standards or possess specific certifications may come at a premium. However, investing in higher-quality systems can lead to long-term cost savings through improved efficiency and reduced maintenance.

Fatores do fornecedor: Supplier reputation, reliability, and service quality can also impact pricing. Established suppliers may charge more but offer better support and warranty options.

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is crucial for cost management. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect the total cost.

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to cost-efficient sourcing:

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and product specifications. This knowledge empowers buyers during negotiations.

Custo total de propriedade (TCO): Evaluate not only the upfront costs but also the long-term operational costs associated with nitrogen tire inflation systems. This includes maintenance, efficiency, and potential savings on fuel and tire longevity.

Leverage Relationships: Establishing strong relationships with suppliers can lead to better pricing, terms, and support. Engaging in long-term partnerships can yield mutual benefits.

Esteja ciente das nuances dos preços: Different regions may have unique pricing structures based on local market conditions, tariffs, and supply chain logistics. Understanding these nuances can provide leverage in negotiations.

Isenção de responsabilidade sobre preços indicativos: Always be cautious of indicative pricing that may not account for fluctuations in materials, labor, and logistics. Request detailed quotes that reflect current market conditions to ensure accuracy.

By considering these cost components and pricing influencers, B2B buyers can make strategic decisions regarding nitrogen tire inflation systems that align with their operational needs and budget constraints.

When it comes to tire inflation, the choice between nitrogen and other alternatives can significantly impact performance, cost, and maintenance. Understanding these alternatives helps B2B buyers make informed decisions tailored to their operational needs, especially in sectors such as transportation, logistics, and automotive services.

| Aspecto de comparação | What Is Nitrogen Tire Inflation | Compressed Air | Tire Sealant Solutions |

|---|---|---|---|

| Desempenho | Reduces pressure loss; maintains tire integrity longer than air. | Standard performance; pressure loss over time. | Provides temporary fix; not a long-term solution. |

| Custo | Higher initial cost ($5+ per tire); ongoing nitrogen refills needed. | Generally low-cost; air is often free at service stations. | Initial cost for sealant, but can save on tire replacement. |

| Facilidade de implementação | Requires specialized equipment for nitrogen filling. | Widely available; easy to use. | Simple to apply; can be done by the user. |

| Manutenção | Requires regular checks; topping off with nitrogen needed. | Frequent checks necessary to maintain pressure. | Minimal maintenance; seals punctures automatically. |

| Melhor caso de uso | Ideal for high-performance vehicles and heavy-duty applications. | Suitable for everyday passenger vehicles. | Best for emergency repairs and temporary solutions. |

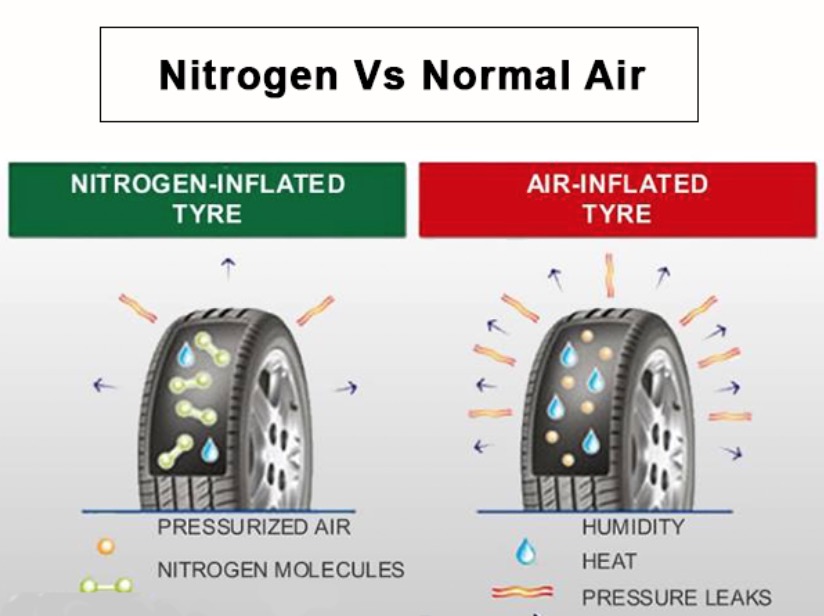

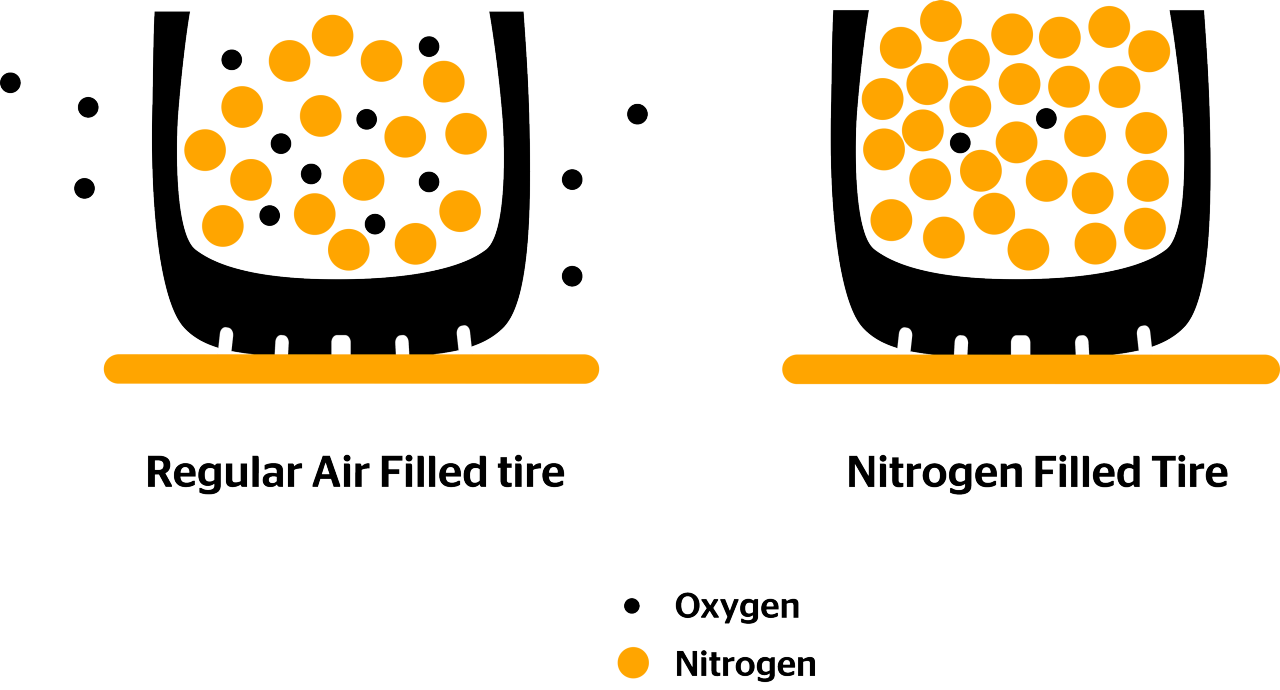

Compressed air is the traditional method for inflating tires and is widely accessible. The primary advantage of using compressed air is its cost-effectiveness; many service stations provide it for free. However, compressed air has its drawbacks, such as a higher rate of pressure loss compared to nitrogen and the potential for moisture buildup, which can lead to tire degradation over time. Regular monitoring of tire pressure is essential, making it less convenient for users who may forget to check frequently.

Tire sealants are an innovative alternative that offers a quick solution to punctures. When a tire punctures, the sealant fills the hole, creating an airtight seal. The benefits of tire sealants include minimal maintenance and ease of use, as they can often be applied by the user without specialized equipment. However, sealants are not a long-term solution; they provide temporary fixes and do not address the need for regular tire pressure checks. Additionally, sealants can sometimes interfere with proper tire repairs, complicating future maintenance.

Choosing the right tire inflation solution depends on your specific business requirements and operational conditions. For companies operating heavy-duty vehicles or requiring optimal tire performance, nitrogen inflation can offer advantages that justify the higher cost. Conversely, businesses looking for a straightforward, cost-effective approach may prefer traditional compressed air. Tire sealants can serve as a convenient option for emergency situations, but they should not replace routine tire maintenance. Ultimately, B2B buyers should evaluate their unique circumstances, budget constraints, and maintenance capabilities to determine the most suitable tire inflation method for their operations.

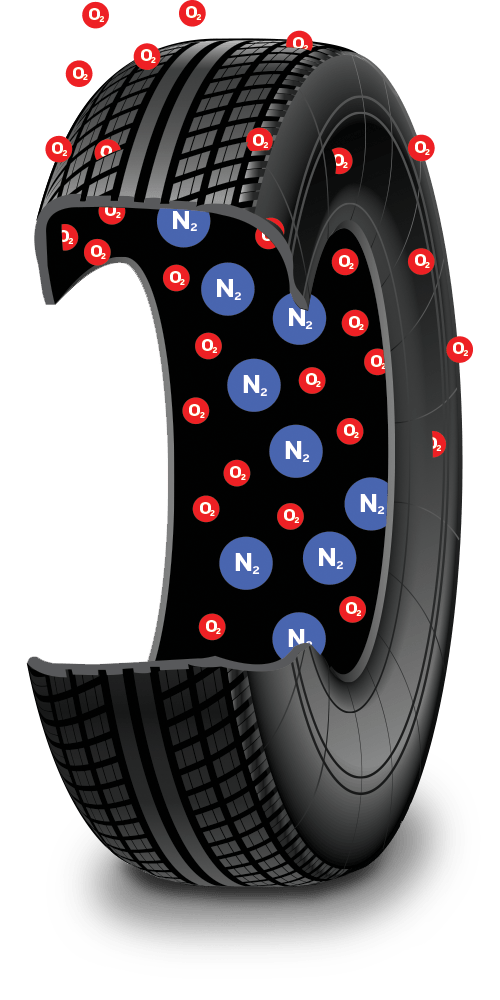

When evaluating nitrogen tire inflation, understanding its technical properties is crucial for making informed B2B purchasing decisions. Here are some critical specifications:

Nitrogen Purity Level

– Definição: The percentage of nitrogen in the gas used to inflate tires. High-quality nitrogen inflation systems typically achieve a purity level of 95% or higher.

– Importância: Higher purity levels reduce the presence of moisture and oxygen, which can degrade tire materials over time. For businesses in automotive services, ensuring high nitrogen purity can enhance tire longevity and performance, leading to increased customer satisfaction and retention.

Pressure Retention Rate

– Definição: The rate at which tires maintain their inflation pressure over time. Studies have shown that nitrogen-filled tires lose pressure at a slower rate compared to those filled with regular air.

– Importância: For fleet operators and commercial vehicle managers, better pressure retention translates to reduced maintenance costs and improved fuel efficiency, as well as enhanced safety due to optimal tire performance.

Temperature Stability

– Definição: The ability of nitrogen to maintain consistent tire pressure across varying temperature conditions.

– Importância: Nitrogen is less affected by temperature fluctuations than regular air, which can expand and contract more significantly. This stability is especially important for operations in regions with extreme weather conditions, ensuring that tire performance remains consistent and predictable.

Oxidation Resistance

– Definição: The degree to which nitrogen inflation minimizes the oxidation of tire materials.

– Importância: Reducing oxidation extends tire life and enhances safety. B2B buyers should consider this property when assessing the total cost of ownership, as longer-lasting tires can lead to significant savings over time.

Moisture Content

– Definição: The amount of water vapor present in the gas used for tire inflation.

– Importância: Lower moisture content in nitrogen reduces the risk of tire degradation and improves performance. Businesses focused on fleet management should prioritize nitrogen inflation to mitigate the risks associated with moisture in traditional air, enhancing overall fleet reliability.

Understanding industry jargon is essential for effective communication and decision-making in B2B contexts. Here are some key terms related to nitrogen tire inflation:

Illustrative image related to what is nitrogen tire inflation

OEM (fabricante original do equipamento)

– Definição: Uma empresa que produz peças ou equipamentos que podem ser comercializados por outro fabricante.

– Relevância: When sourcing nitrogen inflation systems, knowing whether a supplier is an OEM can indicate the quality and reliability of the equipment being offered.

MOQ (Quantidade mínima de pedido)

– Definição: A menor quantidade de um produto que um fornecedor está disposto a vender.

– Relevância: Understanding MOQ is critical for B2B buyers when planning inventory and budgeting. Suppliers with high MOQs may affect cash flow and inventory management strategies.

RFQ (Request for Quotation, solicitação de cotação)

– Definição: A standard business process where a buyer requests price quotes from suppliers for specific products or services.

– Relevância: When considering nitrogen inflation systems, issuing an RFQ can help buyers compare prices and terms from multiple vendors, ensuring they make cost-effective purchasing decisions.

Incoterms (Termos Comerciais Internacionais)

– Definição: Um conjunto de termos comerciais internacionais predefinidos que esclarecem as responsabilidades de compradores e vendedores.

– Relevância: Familiarity with Incoterms is essential for B2B buyers involved in international procurement of nitrogen inflation equipment, as it defines cost responsibilities and risks during shipping and delivery.

Tire Pressure Monitoring System (TPMS)

– Definição: An electronic system that monitors the air pressure inside the tires and alerts the driver when it falls below a certain threshold.

– Relevância: For businesses implementing nitrogen tire inflation, integrating TPMS can enhance tire safety and performance, making it an important consideration for fleet operations.

By understanding these technical properties and industry terms, B2B buyers can make more informed decisions regarding nitrogen tire inflation, ultimately enhancing operational efficiency and safety in their vehicle fleets.

The nitrogen tire inflation market is experiencing significant growth due to increasing awareness of its benefits over traditional air inflation. As global vehicle ownership rises, particularly in emerging economies in Africa and South America, the demand for enhanced tire performance and safety is becoming paramount. Key drivers include the need for improved fuel efficiency, reduced tire wear, and enhanced safety, particularly in heavy-duty and commercial vehicles.

Current technology trends emphasize automated tire inflation systems that utilize nitrogen, which streamline the process and ensure optimal tire pressure. Innovations such as mobile nitrogen generation units are gaining traction, allowing businesses to provide on-site services that cater to the growing demand, especially in remote areas. Additionally, the introduction of smart tire monitoring systems that integrate IoT technology is shaping sourcing strategies. These systems can alert users when tire pressure drops, regardless of whether they are filled with air or nitrogen, reinforcing the importance of regular maintenance.

Moreover, international buyers are increasingly considering sourcing nitrogen from local suppliers to mitigate transportation costs and enhance supply chain efficiency. In regions like the Middle East and Europe, where regulatory standards for vehicle emissions are becoming stricter, the adoption of nitrogen inflation is seen as a proactive measure to comply with these regulations while promoting sustainability.

Illustrative image related to what is nitrogen tire inflation

Sustainability is becoming a critical consideration for B2B buyers in the nitrogen tire inflation sector. The environmental impact of tire production and disposal is significant, with concerns over waste and pollution prompting businesses to seek more sustainable practices. Using nitrogen can contribute to longer tire life and better fuel efficiency, which indirectly reduces carbon emissions from vehicles.

Ethical sourcing is also gaining prominence, with companies increasingly expected to demonstrate responsible practices throughout their supply chains. This includes ensuring that nitrogen generation processes are energy-efficient and that suppliers adhere to environmental regulations. Certifications such as ISO 14001 for environmental management systems can serve as benchmarks for suppliers, providing assurance to buyers about their commitment to sustainability.

Furthermore, as businesses seek to enhance their brand reputation, investing in ‘green’ certifications for their nitrogen supply chains can yield competitive advantages. By prioritizing environmentally friendly practices, companies can appeal to a growing segment of eco-conscious consumers and businesses, especially in regions with stringent environmental policies like Germany and Saudi Arabia.

The use of nitrogen in tire inflation has evolved significantly since its inception. Initially adopted in aviation and motorsports, where performance and safety are critical, nitrogen inflation has gradually penetrated the consumer market. The primary advantage recognized was nitrogen’s lower permeability compared to air, which results in reduced pressure loss over time.

Illustrative image related to what is nitrogen tire inflation

As the automotive industry began to focus on fuel efficiency and environmental impact in the early 2000s, nitrogen tire inflation gained attention. The marketing of nitrogen inflation services to everyday consumers often highlighted benefits like improved fuel economy and tire longevity, although studies have shown mixed results. Today, nitrogen inflation is more commonly used in commercial and heavy-duty applications, where the benefits are more pronounced.

This evolution reflects a broader trend toward performance optimization in the automotive sector, driven by technological advancements and changing consumer expectations. As B2B buyers consider their sourcing strategies, understanding the historical context of nitrogen tire inflation can provide valuable insights into its role in the modern automotive landscape.

1. How does nitrogen tire inflation compare to regular air in terms of performance?

Nitrogen tire inflation is often marketed as superior to regular air due to its reduced permeability, which can lead to slower pressure loss over time. In practical tests, nitrogen-filled tires lost an average of 2.2 psi over a year, compared to 3.5 psi for air-filled tires. While this difference is minimal, nitrogen can help maintain tire pressure, which is crucial for safety and efficiency. However, it’s essential to regularly check tire pressure regardless of the inflation method, as all tires will eventually lose pressure.

2. What are the cost implications of using nitrogen for tire inflation?

The initial cost for nitrogen tire inflation can range from $5 to $10 per tire, which might seem higher than filling tires with regular air. However, for businesses operating fleets or heavy-duty vehicles, the potential savings from improved fuel efficiency and tire longevity can offset these costs. Companies should consider the long-term benefits of reduced tire wear and maintenance, as well as the potential for enhanced safety and performance.

3. How can I verify the quality of nitrogen tire inflation services from suppliers?

To ensure you are sourcing high-quality nitrogen tire inflation services, ask potential suppliers about their nitrogen purity levels and the equipment used for inflation. Ideally, the nitrogen should be at least 95% pure. Additionally, inquire about their quality assurance processes and whether they perform routine maintenance on their inflation systems. Requesting references or case studies from other businesses can also provide insight into their reliability and service quality.

4. What should I consider regarding minimum order quantities (MOQ) for nitrogen inflation services?

When sourcing nitrogen tire inflation services, it’s important to discuss MOQs with suppliers. Some may have flexible options for businesses with varying needs, while others may require a minimum commitment, especially for bulk orders or ongoing service contracts. Consider your tire maintenance schedule and fleet size to determine if the MOQ aligns with your operational requirements. Negotiating terms that fit your business model can help optimize costs and service efficiency.

5. What payment terms are typically offered for nitrogen tire inflation services?

Payment terms for nitrogen tire inflation services can vary widely among suppliers. Common options include upfront payments, net 30 or net 60 terms, and discounts for early payments. For international transactions, consider currency exchange rates and potential tariffs that may affect overall costs. Establish clear agreements in advance to avoid any misunderstandings, and consider using escrow services for larger contracts to ensure both parties fulfill their obligations.

6. How can I ensure the logistics of nitrogen tire inflation are efficiently managed?

Efficient logistics for nitrogen tire inflation services involve clear communication with your supplier regarding delivery schedules and service frequency. Ensure that the supplier can accommodate your operational hours and locations, especially if your business operates in multiple regions. Additionally, consider implementing a tracking system to monitor tire pressure and maintenance schedules, which can help streamline logistics and enhance overall service delivery.

7. Are there customization options available for nitrogen tire inflation services?

Many suppliers offer customization options for nitrogen tire inflation services to meet specific business needs. This can include tailored service packages, frequency of tire checks, and specialized equipment for different vehicle types. Discuss your requirements with potential suppliers to understand their flexibility and how they can adapt their services to better align with your operational demands. Customization can lead to improved efficiency and cost savings.

8. What quality assurance measures should I expect from nitrogen tire inflation suppliers?

Quality assurance in nitrogen tire inflation services is crucial for maintaining tire performance and safety. Expect suppliers to have standard operating procedures for inflation, including regular equipment maintenance and staff training. Additionally, inquire about their testing protocols for nitrogen purity and tire pressure management. A reputable supplier will be transparent about their QA processes and willing to share performance metrics or testimonials from previous clients, ensuring that you receive reliable service.

Domínio: reddit.com

Registrado: 2005 (20 anos)

Introdução: Nitrogen is used in tires of commercial and military aircraft and racing cars due to extreme forces and temperatures. For passenger cars, nitrogen serves no significant purpose as it is chemically inert and dry, potentially leading to a slight decrease in oxidation of the tire’s inner lining, but this is negligible since tires wear out before this matters. Tires filled with air are already about 7…

Domínio: robertson-tire.com

Registrado: 1999 (26 anos)

Introdução: Nitrogen-filled tires lose pressure about 40% slower than regular air. They can contain up to 98% pure nitrogen, which helps maintain air pressure longer compared to conventional air (which is about 78% nitrogen and 21% oxygen). Benefits of nitrogen-filled tires include: increased tread life, better tire pressure retention, cooler-running tire temperatures, improved handling and performance, exten…

Domínio: cars.usnews.com

Registrado: 1995 (30 anos)

Introdução: Nitrogen in Tires: Pros and Cons

– Nitrogen is used instead of air in tires for various reasons, including performance, safety, and comfort.

– Nitrogen escapes from tires more slowly than regular air due to the larger atomic radius of nitrogen atoms.

– A study by the National Highway Traffic Safety Administration (NHTSA) found that while nitrogen does slow pressure loss, the difference is not sign…

Domínio: sunsationall.com

Registrado: 2012 (13 anos)

Introdução: Nitrogen Tire Inflation service offered at SUNSATIONall for $20.00. Benefits include: 1) Uses high purity nitrogen, purging 95-99% of oxygen through a 3 purge cycle. 2) Quick inflate system that fills all 4 tires simultaneously in about 5 minutes. 3) Prevents oxidation, rust, and corrosion in tires and wheels. 4) Reduces moisture and water-related issues. 5) Better pressure retention, with nitroge…

Domínio: continentaltire.com

Registrado: 1996 (29 anos)

Introdução: Nitrogen is offered as an alternative to air for tire inflation. It is an inert (non-flammable) gas that does not support moisture or combustion, making it suitable for specialized tire service applications such as aircraft, mining, and professional auto racing. Nitrogen can help reduce tire pressure variations, but for everyday consumer tire service, it is not required. Regular tire inflation pre…

Domínio: continental-tires.com

Registrado: 2000 (25 anos)

Introdução: Nitrogen in tires provides benefits such as improved tire pressure retention, reduced oxidation, and enhanced fuel efficiency. It is becoming popular among driving enthusiasts and is offered by many tire dealers and garages. Maintaining proper tire pressure is crucial for long-term tire care.

As international B2B buyers explore nitrogen tire inflation, the strategic sourcing of this service offers notable benefits, particularly for industries reliant on vehicle fleets. The marginal reduction in pressure loss and potential for enhanced tire longevity can translate into significant cost savings over time. Additionally, nitrogen’s role in reducing oxidation may be particularly advantageous for heavy-duty applications found in sectors such as logistics and construction.

However, it’s crucial to weigh these benefits against the logistical considerations involved in sourcing nitrogen. Buyers should ensure that their suppliers are equipped to provide high-purity nitrogen and maintain consistent service quality. As the market continues to evolve, fostering partnerships with reliable suppliers will be key to maximizing the value of nitrogen tire inflation.

Looking ahead, the global shift towards more sustainable and efficient transport solutions will likely position nitrogen tire inflation as a viable option for various industries. We encourage buyers from Africa, South America, the Middle East, and Europe to engage with suppliers who can deliver tailored nitrogen solutions that meet their unique operational needs. Embracing this technology now can pave the way for enhanced efficiency and competitiveness in the future.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.