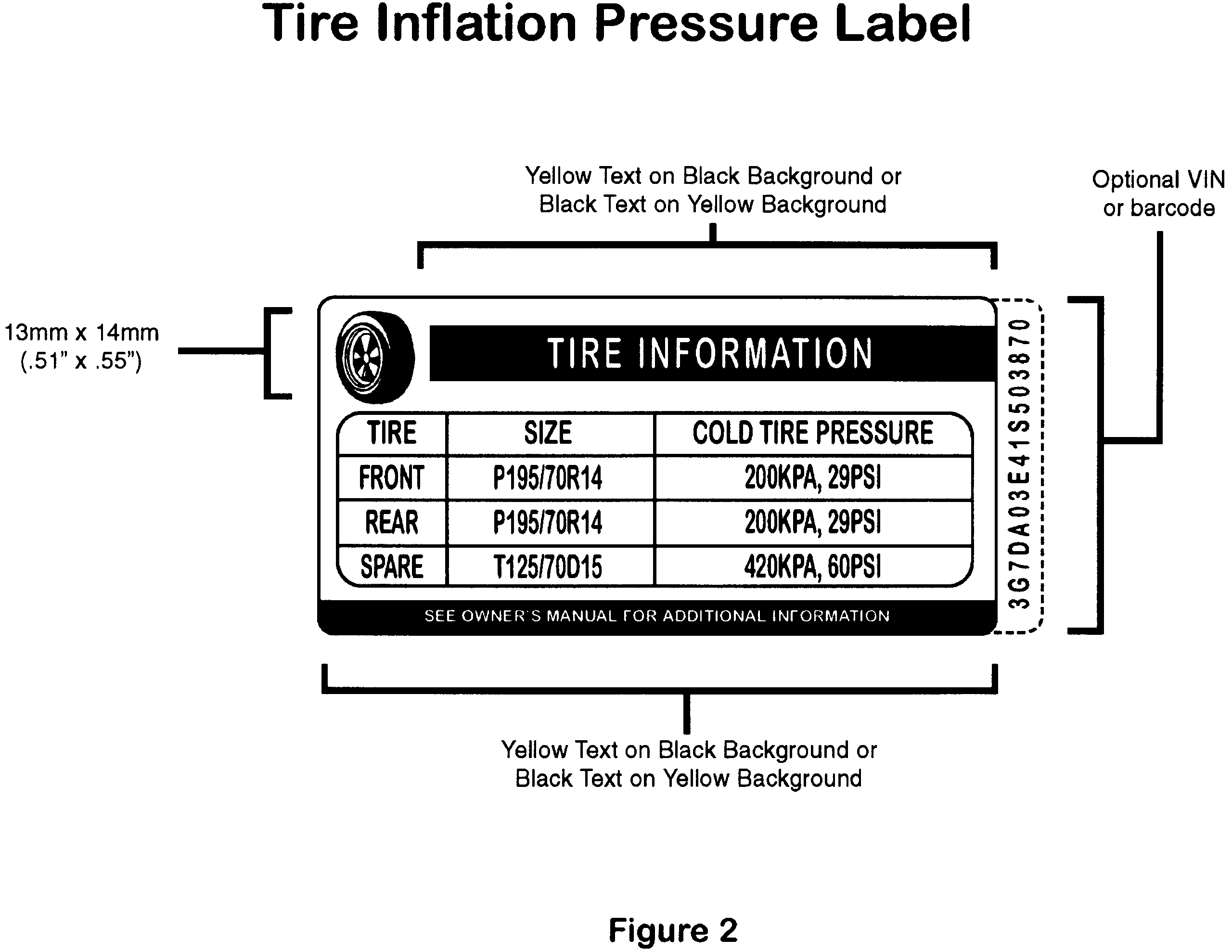

In today’s competitive landscape, international B2B buyers must navigate numerous challenges, including the critical issue of incorrect tire inflation. This often-overlooked factor can lead to a cascade of operational inefficiencies such as increased tire wear, compromised vehicle handling, and diminished fuel efficiency. As companies strive to optimize their fleets, understanding the ramifications of improper tire inflation is essential for making informed purchasing decisions.

This comprehensive guide delves into the various types of tire inflation issues, their applications across different vehicle categories, and the best practices for supplier vetting. It also addresses the costs associated with tire maintenance and replacement, providing actionable insights that can help mitigate risks. Buyers from diverse regions—including Africa, South America, the Middle East, and Europe—will find tailored strategies to enhance fleet performance while reducing operational costs.

By leveraging the insights presented in this guide, you can empower your organization to make strategic decisions that not only enhance safety but also improve overall efficiency. Whether you are sourcing tires, evaluating suppliers, or implementing maintenance protocols, our expert recommendations will facilitate a deeper understanding of how correct tire inflation impacts your bottom line. Equip your business with the knowledge necessary to thrive in the global marketplace and ensure the longevity of your fleet.

| Nome do tipo | Principais características distintivas | Aplicativos B2B primários | Prós e contras resumidos para compradores |

|---|---|---|---|

| Under-inflation | Tires have lower pressure than recommended. | Logistics, transportation, fleet management | Pros: Lower initial costs; Cons: Increased fuel consumption, reduced tire life. |

| Over-inflation | Tires are inflated beyond recommended levels. | Automotive manufacturing, rental services | Pros: Improved handling; Cons: Increased risk of blowouts, uneven tire wear. |

| Uneven inflation | Variance in tire pressure across different tires. | Vehicle maintenance, automotive repair services | Pros: Potential for specialized diagnostics; Cons: Complicated to manage, inconsistent handling. |

| Seasonal inflation adjustments | Variation in tire pressure based on temperature changes. | Fleet operations, agricultural vehicles | Pros: Enhanced safety in varying climates; Cons: Requires regular monitoring and adjustments. |

| Monitoring system failures | Ineffective tire pressure monitoring systems (TPMS). | Automotive technology, fleet management | Pros: Alerts for maintenance; Cons: Reliance on technology can lead to negligence. |

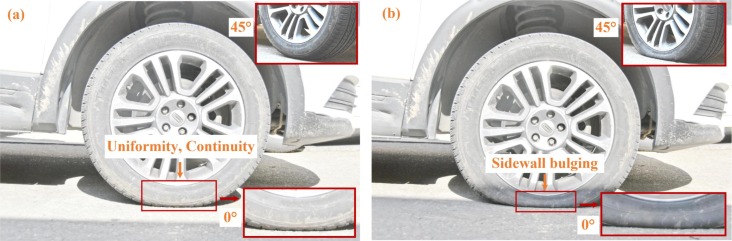

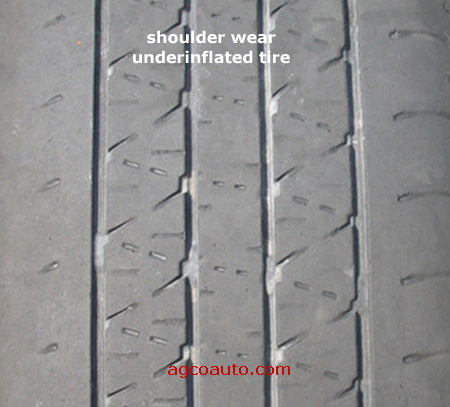

Under-inflation occurs when tires are not filled to the recommended pressure, leading to increased rolling resistance and decreased fuel efficiency. This type of inflation issue is particularly relevant for businesses with fleets, as it can significantly impact operational costs. Buyers should consider investing in regular tire pressure checks and maintenance schedules to mitigate the risks associated with under-inflation, such as uneven tire wear and increased fuel expenses.

Over-inflation involves filling tires beyond their specified pressure limits, which can enhance handling but also poses a risk of blowouts and uneven tire wear. This variation is critical for industries reliant on vehicle performance and safety, such as automotive manufacturing and rental services. Buyers must weigh the benefits of improved handling against the potential risks, ensuring that tire pressure is monitored regularly to maintain safety standards.

Uneven inflation refers to discrepancies in tire pressure among different tires, leading to compromised vehicle handling and increased wear on certain tires. This issue is particularly pertinent for vehicle maintenance and automotive repair services, where diagnosing tire pressure imbalances can be crucial. For B2B buyers, investing in tire monitoring systems or comprehensive maintenance services can help avoid the complications of uneven inflation, ensuring consistent vehicle performance.

Seasonal inflation adjustments account for changes in tire pressure due to temperature variations, which can significantly affect tire performance. For businesses operating in diverse climates, such as agricultural sectors, understanding and managing seasonal inflation is vital for safety and efficiency. Buyers should consider implementing a proactive tire management strategy that includes seasonal checks to optimize tire performance throughout the year.

Monitoring system failures occur when tire pressure monitoring systems (TPMS) do not accurately reflect tire conditions, leading to potential safety hazards. This issue is critical for automotive technology and fleet management sectors, as reliance on faulty systems can result in negligence regarding tire maintenance. B2B buyers should prioritize investing in reliable monitoring technologies and regular manual checks to ensure that tire conditions are accurately assessed, minimizing risks associated with incorrect inflation.

| Indústria/Setor | Specific Application of incorrect tire inflation can adversely affect | Valor/benefício para a empresa | Principais considerações de fornecimento para este aplicativo |

|---|---|---|---|

| Logistics & Transport | Fleet management and vehicle safety | Reduces operational costs by minimizing tire wear and fuel consumption | Quality tire monitoring systems and maintenance services |

| Agricultura | Agricultural machinery performance | Enhances efficiency and productivity, leading to better crop yields | Reliable tire inflation equipment suited for rugged terrain |

| Construção | Heavy machinery operation | Ensures safety and reduces downtime, preventing costly accidents | Durable tires designed for construction environments |

| Automotivo | Passenger and commercial vehicle servicing | Improves customer satisfaction and reduces warranty claims | High-quality tire pressure monitoring systems |

| Mining | Mining equipment reliability | Maximizes equipment lifespan and minimizes operational disruptions | Specialized tires for extreme conditions and environments |

In the logistics and transport sector, incorrect tire inflation can significantly impact fleet management and vehicle safety. Under-inflated tires lead to uneven wear, increased fuel consumption, and reduced handling capabilities, which can result in accidents. For international B2B buyers, particularly those operating in regions with diverse road conditions, investing in quality tire monitoring systems and regular maintenance services is essential. These measures not only enhance safety but also decrease operational costs, making logistics operations more efficient.

In agriculture, incorrect tire inflation can adversely affect the performance of tractors and other machinery. Proper tire pressure is crucial for optimal traction and load distribution, impacting the efficiency of farming operations. For buyers in regions like South America and Africa, where agricultural productivity is vital, investing in reliable tire inflation equipment is necessary. This ensures that machinery operates effectively, leading to improved crop yields and reduced fuel costs, ultimately benefiting the agricultural business.

In the construction industry, the performance of heavy machinery is heavily reliant on correct tire inflation. Incorrect tire pressure can lead to safety hazards and increased downtime due to equipment failure. For B2B buyers in the construction sector, especially in the Middle East and Europe, sourcing durable tires designed for construction environments is critical. Such investments ensure safety, enhance equipment reliability, and minimize operational disruptions, ultimately leading to cost savings and improved project timelines.

For automotive businesses, both passenger and commercial vehicle servicing require a keen focus on tire inflation. Incorrectly inflated tires can lead to customer dissatisfaction due to poor vehicle performance and increased wear, which can result in warranty claims. International buyers, particularly in regions like Germany and Nigeria, should prioritize high-quality tire pressure monitoring systems to ensure customer vehicles are maintained at optimal performance levels. This not only enhances customer satisfaction but also protects the business from potential financial losses.

In the mining sector, the reliability of equipment is paramount, and incorrect tire inflation can lead to significant operational disruptions. Mining environments often pose extreme challenges, and improperly inflated tires can increase the risk of accidents and equipment failure. B2B buyers in this industry should consider sourcing specialized tires designed for extreme conditions. Ensuring proper tire inflation can maximize equipment lifespan and minimize operational downtime, which is crucial for maintaining productivity in mining operations.

O problema: B2B buyers managing a fleet of vehicles often face significant challenges due to incorrect tire inflation. For instance, a logistics company may notice a spike in fuel costs and an increase in tire replacements. This is frequently linked to under-inflated tires, which create higher rolling resistance, leading to reduced fuel efficiency and increased operational costs. Additionally, uneven tire wear can compromise vehicle safety and lead to costly downtime, affecting overall fleet efficiency.

A solução: To combat these issues, fleet managers should implement a proactive tire maintenance program that includes regular tire pressure checks. Investing in advanced tire pressure monitoring systems (TPMS) can help ensure that all vehicles maintain optimal tire pressure. Additionally, establishing a routine schedule for tire inspections, ideally every time a vehicle is serviced, can catch inflation issues before they escalate. Training drivers on the importance of tire maintenance and encouraging them to report any anomalies can further enhance fleet safety and efficiency. By prioritizing tire health, companies can significantly reduce fuel costs and extend the lifespan of their tires.

O problema: Businesses that rely on delivery vehicles may encounter serious problems with vehicle handling due to incorrect tire inflation. For example, a courier service may find that their vehicles are harder to control, especially under adverse weather conditions. This not only increases the risk of accidents but also affects delivery timelines and customer satisfaction. Poor handling can lead to driver frustration and increased liability for the company.

A solução: To mitigate the risks associated with poor vehicle handling, B2B buyers should focus on establishing stringent tire maintenance protocols. Regularly scheduled tire pressure checks, ideally bi-weekly or before long trips, can be instituted to prevent inflation-related handling issues. Additionally, educating drivers about the signs of improper tire inflation—such as pulling to one side or unusual vibrations—can enable quicker responses to potential problems. Companies might also consider partnering with a tire service provider to facilitate on-site tire inspections and maintenance, ensuring that all vehicles are road-ready and safe for operation.

O problema: B2B buyers in industries reliant on transportation, such as construction or agriculture, often struggle with the hidden costs associated with increased fuel consumption from incorrect tire inflation. For instance, a construction company may not realize that under-inflated tires are causing their heavy machinery to consume more fuel, leading to budget overruns. This not only affects profit margins but can also hinder project timelines due to unexpected operational costs.

A solução: To address fuel inefficiencies, businesses should adopt a holistic approach to tire management. This includes not only regular tire pressure checks but also analyzing fuel consumption data against tire performance metrics. By integrating fuel management software that tracks fuel usage alongside tire condition, companies can identify patterns and correlations that reveal the impact of tire inflation on fuel efficiency. Furthermore, investing in training sessions that emphasize the financial benefits of proper tire inflation can motivate employees to prioritize tire maintenance. By fostering a culture of proactive tire management, businesses can significantly reduce fuel costs and improve their bottom line.

When addressing the issue of incorrect tire inflation, various materials play a critical role in ensuring optimal tire performance and longevity. Below, we analyze three common materials used in tire manufacturing and maintenance, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Principais propriedades: Rubber is known for its excellent elasticity, providing the necessary flexibility and grip on various surfaces. It can withstand a wide range of temperatures and pressures, making it suitable for different driving conditions.

Prós e contras: The primary advantage of rubber is its durability and ability to absorb shocks, which enhances ride comfort. However, it can degrade over time due to exposure to UV light and ozone, leading to cracking and loss of performance. Additionally, while rubber is relatively inexpensive, high-performance rubber compounds can be costly.

Impacto no aplicativo: Rubber tires are compatible with various vehicles, from passenger cars to heavy-duty trucks. However, improper inflation can lead to uneven wear, which may necessitate more frequent replacements.

Considerações para compradores internacionais: Buyers in regions like Africa and South America should consider local climate conditions that may affect rubber durability. Compliance with local standards, such as ASTM or DIN, is essential for ensuring safety and performance.

Principais propriedades: Steel belts are commonly used in tire construction to enhance strength and stability. They offer high tensile strength and resistance to deformation under pressure, which is crucial for maintaining tire shape.

Prós e contras: The key advantage of steel is its ability to improve handling and load capacity, especially in high-performance tires. However, steel can add weight to the tire, potentially affecting fuel efficiency. Additionally, the manufacturing process for steel belts can be complex and costly.

Impacto no aplicativo: Steel-reinforced tires are particularly beneficial for commercial vehicles that require durability and load-bearing capacity. However, improper inflation can lead to increased stress on the steel belts, resulting in premature failure.

Considerações para compradores internacionais: Buyers in Europe, particularly Germany, should ensure that steel components meet stringent EU regulations for safety and performance. Understanding local manufacturing capabilities is also crucial for sourcing high-quality steel.

Principais propriedades: Nylon is often used in tire construction for its lightweight and flexible properties. It provides excellent resistance to wear and tear, making it suitable for various driving conditions.

Illustrative image related to incorrect tire inflation can adversely affect

Prós e contras: The primary advantage of nylon is its ability to reduce overall tire weight, which can improve fuel efficiency and handling. However, nylon may not offer the same level of heat resistance as other materials, which can be a concern in high-temperature environments.

Impacto no aplicativo: Nylon tires are particularly suitable for passenger vehicles and light trucks. However, incorrect inflation can lead to increased rolling resistance, negatively impacting fuel economy.

Considerações para compradores internacionais: In regions like the Middle East, where temperatures can soar, it is vital for buyers to ensure that nylon tires are designed to withstand high heat. Compliance with international standards is essential to guarantee product reliability.

| Material | Typical Use Case for incorrect tire inflation can adversely affect | Principais vantagens | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Borracha | Standard tire manufacturing for passenger and commercial vehicles | Excellent elasticity and shock absorption | Degrades over time due to UV exposure | Médio |

| Aço | Reinforcement for high-performance and commercial tires | High tensile strength improves handling | Adds weight, affecting fuel efficiency | Alta |

| Nylon | Lightweight tires for passenger vehicles | Reduces overall tire weight, improving fuel efficiency | Limited heat resistance | Médio |

In conclusion, selecting the right materials for tire manufacturing and maintenance is crucial for optimizing performance and safety. International B2B buyers must consider local conditions, compliance with standards, and the specific needs of their markets when making material choices.

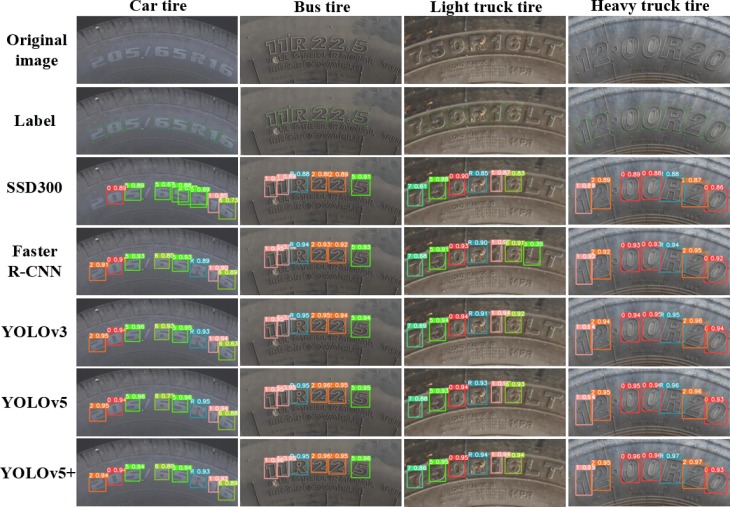

The manufacturing of tires involves several critical stages that ensure the final product meets the necessary performance and safety standards.

The first stage in tire manufacturing is material preparation, which includes the selection of high-quality raw materials such as natural rubber, synthetic rubber, carbon black, silica, and various chemicals. Each component plays a specific role in enhancing the durability and performance of the tire. For instance, carbon black reinforces the rubber, while silica improves fuel efficiency and wet traction.

Once the materials are prepared, they are mixed and processed into compounds. This process often involves sophisticated machinery that ensures consistency and quality. The compounds are then shaped into tire components, including the tread, sidewalls, and inner linings. Advanced techniques such as extrusion and calendering are used to form these components accurately, ensuring they meet precise specifications.

In the assembly stage, the various tire components are brought together. This process often employs automated systems to enhance efficiency and reduce human error. Key elements such as the steel belts, tread, and sidewalls are assembled in a specific sequence to ensure the tire’s structural integrity. This stage is crucial, as improper assembly can lead to issues like incorrect tire inflation.

The final stage, finishing, involves curing the assembled tire in a mold under heat and pressure. This step solidifies the tire’s shape and enhances its durability. Quality control checks are integrated at this stage to ensure that the tire meets all specifications before it is released into the market.

Illustrative image related to incorrect tire inflation can adversely affect

Quality assurance (QA) is integral to tire manufacturing, focusing on preventing defects and ensuring the safety and performance of the final product.

Manufacturers must adhere to various international standards, such as ISO 9001, which outlines quality management principles. Compliance with these standards demonstrates a commitment to quality and reliability, essential for B2B buyers.

In addition to ISO standards, industry-specific certifications such as the European Conformity (CE) mark and the American Petroleum Institute (API) standards may apply, depending on the tire’s intended use. These certifications ensure that the tires meet specific safety and performance criteria.

Quality control checkpoints are strategically placed throughout the manufacturing process. These include:

Controle de qualidade de entrada (IQC): This stage involves inspecting raw materials and components before they enter production. Ensuring that only high-quality materials are used is crucial for the final product’s performance.

Controle de qualidade durante o processo (IPQC): During the manufacturing stages, continuous monitoring occurs to identify and rectify any issues early. This stage employs various testing methods to assess the quality of the tire components.

Controle de qualidade final (FQC): After the tires are finished, they undergo rigorous testing, including visual inspections and performance tests. This stage ensures that each tire meets the required standards before leaving the factory.

Testing methods play a vital role in assessing tire quality. Common methods include:

Tire Pressure Testing: Ensures that the tire can withstand the pressure levels it will encounter during use.

Uniformity Testing: Assesses the tire’s roundness and balance, which are critical for safe driving and handling.

Teste de durabilidade: Simulates long-term use to evaluate how the tire performs under various conditions, including extreme temperatures and loads.

Rolling Resistance Testing: Measures how efficiently a tire rolls, which directly impacts fuel consumption and overall vehicle performance.

B2B buyers must take proactive steps to ensure their suppliers adhere to high-quality standards. Here are several strategies:

Auditorias de fornecedores: Conducting regular audits of suppliers can provide valuable insights into their manufacturing processes and quality control measures. This practice helps identify any potential issues before they become significant problems.

Relatórios de qualidade: Requesting detailed quality reports from suppliers can help buyers understand how often tires are tested and the outcomes of those tests. This transparency is vital for assessing the reliability of the supplier.

Inspeções de terceiros: Engaging third-party inspection services can provide an objective evaluation of the supplier’s quality control practices. These inspections often focus on compliance with international standards and industry-specific regulations.

International B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, must navigate various quality control nuances.

Diferenças culturais: Understanding cultural approaches to quality assurance can be crucial. For example, some regions may prioritize cost over quality, while others may have stringent regulations that must be adhered to.

Conformidade regulatória: Different regions have varying regulatory requirements that can affect tire manufacturing. Buyers must ensure that their suppliers comply with local regulations in addition to international standards.

Logistics and Supply Chain Considerations: The complexities of international logistics can impact the quality of tires. Buyers should consider the entire supply chain, from raw material sourcing to transportation, to ensure that quality is maintained throughout the process.

Understanding the manufacturing processes and quality assurance measures in tire production is crucial for B2B buyers. By focusing on key manufacturing stages, adhering to international standards, employing rigorous testing methods, and verifying supplier practices, buyers can ensure they procure high-quality tires that meet safety and performance expectations. This knowledge is particularly vital for international buyers operating across diverse markets, where quality assurance practices may differ significantly.

To assist B2B buyers in navigating the critical issue of incorrect tire inflation, this practical sourcing guide outlines essential steps to ensure procurement processes are effective and aligned with safety and operational efficiency. Proper tire inflation is not merely a matter of maintenance; it significantly impacts tire wear, vehicle handling, and fuel efficiency. Following this checklist will help buyers make informed decisions when sourcing tire-related products and services.

Illustrative image related to incorrect tire inflation can adversely affect

Understanding your specific requirements is crucial before sourcing. Consider the types of vehicles in your fleet, their operating conditions, and the average load they carry. This will help determine the appropriate tire specifications, including size, tread pattern, and pressure ratings.

Identify suppliers with a proven track record in tire products and services. Evaluate their experience in your industry and their understanding of regional conditions, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

Ensure that the tires and inflation systems you consider meet international quality and safety standards. Look for certifications such as ISO, DOT, or ECE, which indicate compliance with stringent manufacturing processes.

Incorporate advanced tire pressure monitoring systems (TPMS) that can alert drivers to inflation issues in real-time. This technology can significantly reduce the risks associated with incorrect tire inflation.

When sourcing tires, consider the total cost of ownership, which includes initial purchase price, maintenance costs, fuel efficiency, and potential safety liabilities. A cheaper tire may lead to higher overall costs due to frequent replacements and fuel inefficiencies.

Ensure that your supplier provides robust service agreements that cover installation, maintenance, and emergency services. This will help mitigate risks associated with tire inflation and ensure ongoing support.

Finally, implement a routine maintenance schedule for tire inspections and inflation checks. Regular monitoring can prevent issues related to incorrect tire inflation, ultimately improving safety and efficiency.

Illustrative image related to incorrect tire inflation can adversely affect

By following these steps, B2B buyers can effectively source tire solutions that minimize the risks associated with incorrect tire inflation, ultimately enhancing safety and operational efficiency across their fleets.

When assessing the impact of incorrect tire inflation on sourcing, several cost components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materiais: The primary materials affected by incorrect tire inflation are the tires themselves. Poorly inflated tires can lead to uneven wear and premature replacement, increasing the frequency of purchases. Businesses should consider the quality and longevity of tires, as investing in higher-quality materials may reduce overall costs in the long run.

Trabalho: Labor costs are incurred not only during the installation of tires but also in the maintenance and checks required to ensure proper inflation. Regular inspections and maintenance can mitigate the risk of inflation-related issues, thus impacting labor costs positively if managed efficiently.

Custos indiretos de fabricação: Overhead costs can increase if improper tire inflation leads to increased tire production due to higher replacement rates. This includes costs associated with facility maintenance and equipment used for tire manufacturing.

Ferramentas: Specialized equipment may be needed for both tire manufacturing and maintenance (such as tire pressure monitoring systems). If these tools are not adequately maintained or calibrated, they can lead to incorrect tire inflation, resulting in additional costs.

Controle de qualidade (QC): Implementing rigorous QC processes can prevent the fallout from incorrect tire inflation. Investing in quality assurance measures may seem costly upfront but can save businesses from the repercussions of tire-related accidents and inefficiencies.

Logística: Incorrect tire inflation can lead to increased fuel consumption, which not only raises operational costs but also affects logistics efficiency. Businesses should factor in how inflated tires can impact fuel costs and overall logistics performance.

Margem: The profit margin can be adversely affected by increased operational costs due to the consequences of incorrect tire inflation. This necessitates a careful pricing strategy to maintain profitability while ensuring safety and efficiency.

Several price influencers come into play when sourcing tires, particularly in regions like Africa, South America, the Middle East, and Europe.

Volume/MOQ: Minimum order quantities (MOQ) can significantly influence pricing. Buyers should negotiate bulk purchasing agreements to achieve lower per-unit costs.

Specifications/Customization: Custom tire specifications can lead to higher costs. However, investing in tires tailored to specific vehicle types or operating conditions can improve performance and reduce long-term costs.

Materiais: The choice of materials directly impacts the price. Premium materials may have a higher upfront cost but can lead to reduced maintenance and replacement costs.

Quality/Certifications: Tires with higher quality ratings or certifications may command a higher price but can also offer better performance and safety, leading to lower total costs over time.

Fatores do fornecedor: The reliability and reputation of suppliers can affect pricing. Established suppliers may offer better warranties and support, justifying higher prices.

Incoterms: Understanding the implications of Incoterms is crucial for international buyers. Different terms can affect shipping costs and responsibilities, influencing the overall pricing structure.

For international B2B buyers, particularly those from emerging markets, here are some actionable tips to ensure cost-efficiency:

Negotiate Prices: Always negotiate pricing, especially when purchasing in bulk. Suppliers may offer discounts for larger orders or long-term contracts.

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the TCO, including maintenance, fuel efficiency, and replacement costs. This perspective helps in making informed decisions.

Considere as regulamentações locais: Be aware of regional regulations regarding tire specifications and safety standards, which can affect sourcing decisions and costs.

Criar relacionamentos com fornecedores: Establishing strong relationships with suppliers can lead to better pricing, terms, and support.

Leverage Technology: Utilize technology for tire monitoring and maintenance to reduce risks associated with incorrect tire inflation, ultimately lowering costs.

The pricing discussed is indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. It is essential to conduct thorough market research and supplier evaluations to obtain precise and tailored pricing for your sourcing needs.

Illustrative image related to incorrect tire inflation can adversely affect

When managing a fleet or operating heavy machinery, ensuring optimal tire performance is critical. Incorrect tire inflation can lead to various issues such as increased fuel consumption, uneven tire wear, and compromised vehicle handling. However, there are alternative solutions and methods that can mitigate these risks and enhance overall vehicle safety and efficiency.

| Aspecto de comparação | Incorrect Tire Inflation Can Adversely Affect | Tire Pressure Monitoring Systems (TPMS) | Regular Tire Maintenance Services |

|---|---|---|---|

| Desempenho | Can cause uneven wear and increased fuel costs | Provides real-time tire pressure data | Regular checks ensure optimal performance |

| Custo | Leads to premature tire replacement and higher fuel expenses | Moderate initial investment, potential savings on fuel | Ongoing maintenance costs but prolongs tire life |

| Facilidade de implementação | Common issue; requires regular checks | Easy installation; requires monitoring | Requires scheduling and service appointments |

| Manutenção | Neglect leads to safety risks | Low maintenance; occasional recalibration | Requires routine checks and balancing |

| Melhor caso de uso | General awareness for all vehicle operators | Ideal for fleets and long-distance transport | Best for businesses prioritizing safety and cost-efficiency |

Tire Pressure Monitoring Systems are designed to provide real-time data on tire pressure, alerting drivers when levels fall below recommended thresholds. This proactive approach helps prevent the adverse effects associated with incorrect tire inflation.

Prós:

– Enhances safety by alerting drivers to potential issues.

– Can lead to fuel savings by maintaining optimal tire pressure.

– Reduces the risk of blowouts and accidents.

Illustrative image related to incorrect tire inflation can adversely affect

Contras:

– Initial costs can be significant for installation.

– Reliance on technology can lead to complacency in manual checks.

Engaging professional tire maintenance services ensures that tires are regularly checked and maintained, which includes balancing, alignment, and inflation checks. This comprehensive approach not only addresses tire pressure but also enhances overall vehicle performance.

Prós:

– Comprehensive service that addresses multiple aspects of tire health.

– Can extend the lifespan of tires and improve fuel efficiency.

– Professional assessment can identify underlying issues.

Contras:

– Ongoing costs associated with regular maintenance.

– Scheduling and service availability can be a logistical challenge.

When evaluating options for managing tire inflation and maintenance, B2B buyers should consider the specific needs of their operations. For businesses focused on immediate safety and real-time data, investing in a TPMS may be beneficial. Conversely, organizations that prioritize comprehensive vehicle care may find regular maintenance services to be the most effective solution. Ultimately, the choice should align with operational goals, budget constraints, and the critical need for safety and efficiency in vehicle management.

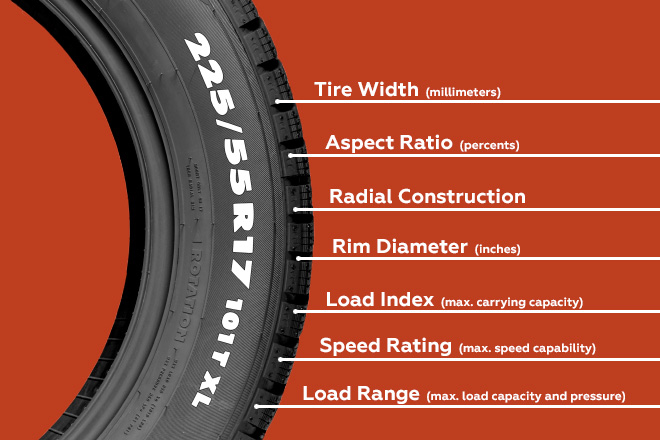

Understanding the technical properties associated with tire inflation is crucial for B2B buyers, particularly those in automotive manufacturing, fleet management, and logistics sectors. Here are several critical specifications that play a significant role:

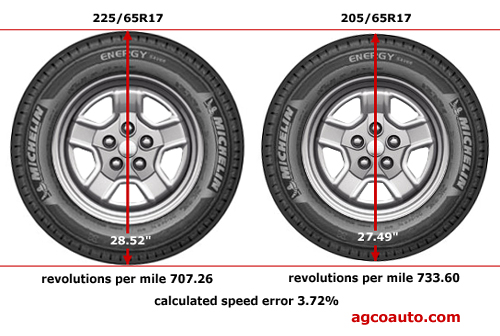

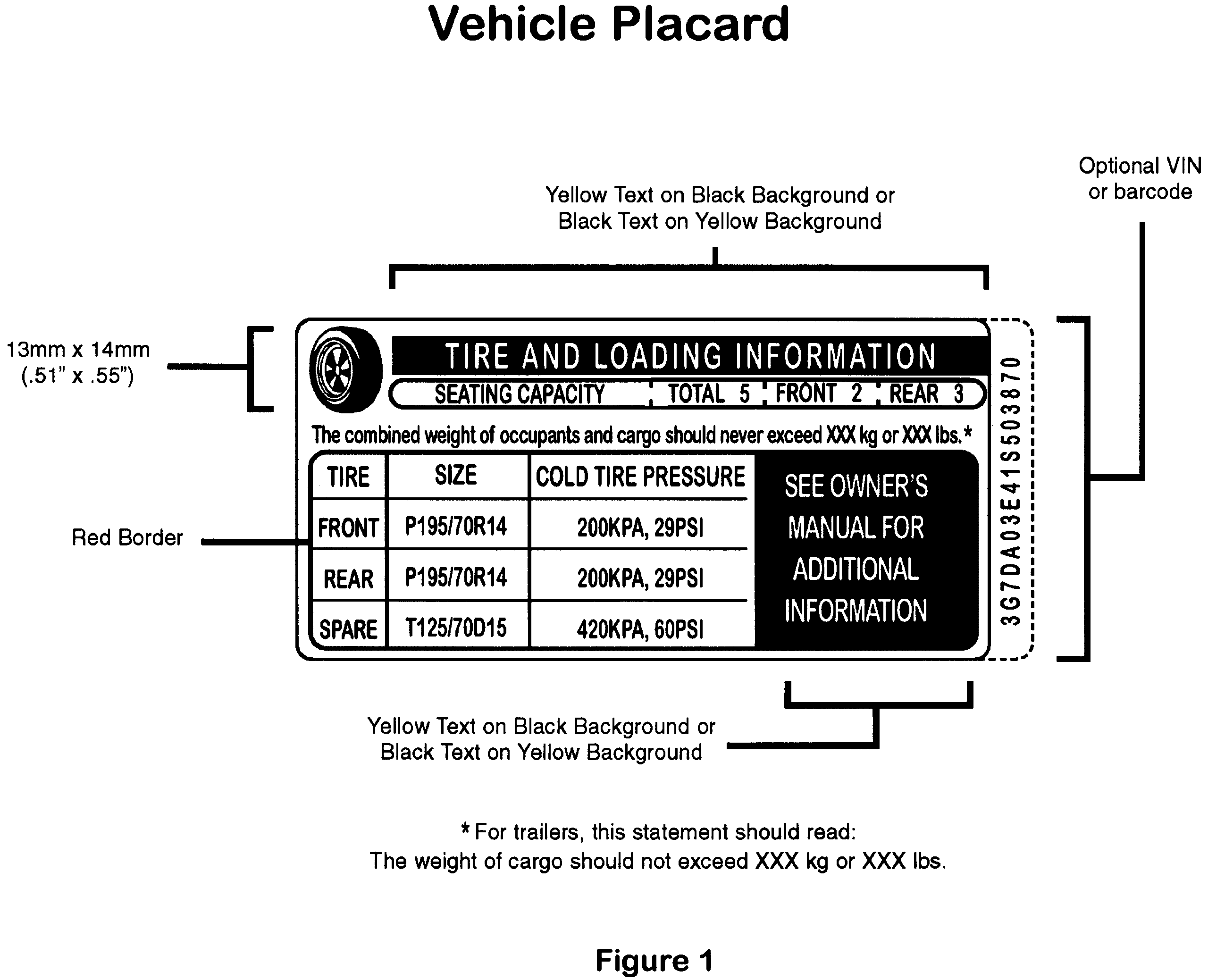

Tires are designed to operate optimally within specific pressure ranges, usually measured in pounds per square inch (PSI). Maintaining the correct PSI is essential for ensuring tire longevity, safety, and fuel efficiency. Incorrect inflation can lead to uneven tire wear, which increases replacement costs and operational downtime.

The load index indicates the maximum weight each tire can support when properly inflated. This specification is critical for fleet managers and transportation companies, as overloading tires can lead to blowouts and accidents. Understanding load index ratings helps businesses choose the right tires for their specific vehicle types and load requirements.

Tires are manufactured to perform within specific temperature ranges. Extreme temperatures can affect tire pressure and material integrity. For B2B buyers in regions with extreme weather conditions, selecting tires that can withstand local temperature variations is essential to ensure safety and performance.

Tread depth is vital for traction and handling, especially in adverse weather conditions. Insufficient tread depth due to incorrect tire inflation can significantly compromise vehicle safety. Regularly checking and maintaining appropriate tread depth helps prevent accidents and enhances the overall efficiency of a fleet.

Rolling resistance refers to the energy required to keep a tire rolling at a constant speed. Tires that are under-inflated have higher rolling resistance, leading to increased fuel consumption. For businesses focused on sustainability and cost-efficiency, selecting tires with low rolling resistance can lead to significant savings in fuel costs over time.

Familiarity with industry jargon can empower decision-makers to make informed choices. Here are several essential terms related to tire inflation:

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the tire industry, working with OEMs ensures that the tires meet the specific standards and requirements set by vehicle manufacturers, which is crucial for safety and performance.

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory effectively and negotiate better pricing with suppliers, especially when sourcing tires for large fleets.

An RFQ is a document sent to suppliers to solicit price bids for specific products or services. In the context of tire procurement, an RFQ can help businesses compare prices and specifications from multiple suppliers, ensuring they receive the best value.

Illustrative image related to incorrect tire inflation can adversely affect

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping agreements. Understanding these terms is essential for B2B transactions involving tire shipments across borders, as they clarify shipping costs, risks, and responsibilities.

TPMS is a technology designed to monitor the air pressure inside pneumatic tires. Having a reliable TPMS can significantly reduce the risk of driving with incorrectly inflated tires, thus enhancing safety and reducing operational costs for businesses with vehicle fleets.

For B2B buyers, especially those involved in automotive and logistics sectors, a clear understanding of tire inflation properties and trade terminology is essential. It helps in making informed procurement decisions, enhancing safety, and improving operational efficiency. By prioritizing these technical specifications and familiarizing themselves with industry jargon, businesses can better navigate the complexities of tire management and maintenance.

The global tire market is experiencing significant dynamics influenced by factors such as increasing vehicle ownership, rising fuel prices, and heightened awareness of vehicle safety and performance. Incorrect tire inflation has emerged as a critical concern, particularly for international B2B buyers in regions like Africa, South America, the Middle East, and Europe. For instance, in Germany, strict regulations surrounding vehicle safety are driving demand for tire pressure monitoring systems (TPMS), while in Nigeria, the focus is on cost-effective solutions to improve vehicle longevity and efficiency.

Current trends indicate a growing integration of technology in tire management. B2B buyers are increasingly sourcing advanced tire pressure monitoring systems that provide real-time data on tire health, enabling proactive maintenance. This technology not only enhances safety by mitigating risks associated with incorrect inflation but also optimizes fuel efficiency—a crucial consideration given the rising fuel costs globally. Furthermore, the push for electric vehicles (EVs) is amplifying the need for specialized tires that cater to different inflation needs, emphasizing the necessity for buyers to stay updated on product innovations.

Illustrative image related to incorrect tire inflation can adversely affect

Emerging sustainability trends also affect sourcing practices. As companies face mounting pressure to reduce their environmental footprint, demand for tires made from sustainable materials is on the rise. International buyers must navigate these evolving market dynamics to ensure they are sourcing products that meet both regulatory requirements and consumer expectations.

The environmental impact of incorrect tire inflation extends beyond safety; it significantly affects fuel consumption and greenhouse gas emissions. Under-inflated tires can increase rolling resistance, leading to higher fuel usage and, consequently, greater emissions. This reality emphasizes the need for B2B buyers to prioritize sustainability in their sourcing strategies.

Ethical supply chains are becoming increasingly important as consumers and businesses alike demand transparency. Buyers in the tire sector should consider suppliers who adhere to sustainable practices, such as using eco-friendly materials and processes that minimize waste. Certifications like the Global Recycled Standard (GRS) or the ISO 14001 for environmental management can be beneficial indicators of a supplier’s commitment to sustainability.

Moreover, integrating sustainable practices in sourcing not only enhances a company’s reputation but also aligns with global sustainability goals, which can be a decisive factor in competitive markets. By focusing on ethical sourcing, businesses can contribute to reducing the overall environmental impact associated with tire inflation issues while also responding to consumer demand for environmentally responsible products.

Illustrative image related to incorrect tire inflation can adversely affect

The understanding of tire inflation and its implications has evolved significantly over the decades. Historically, tire inflation was often overlooked, with many drivers unaware of its critical role in vehicle safety and performance. However, as vehicle technology advanced and safety regulations tightened, the awareness surrounding tire maintenance grew.

The introduction of tire pressure monitoring systems in the early 2000s marked a pivotal moment, allowing drivers to receive real-time information about tire pressure. This technology has since become a standard feature in many vehicles, underscoring the importance of proper tire inflation.

Moreover, as the automotive industry shifts towards sustainability and energy efficiency, the focus on correct tire inflation is more relevant than ever. B2B buyers are now not only looking for products that enhance safety but also those that support broader environmental goals. Understanding the historical context of tire inflation issues helps buyers recognize the trends and technologies shaping the current market, enabling informed sourcing decisions.

How do I solve issues related to incorrect tire inflation?

To address problems stemming from incorrect tire inflation, first, regularly monitor and maintain tire pressure according to the manufacturer’s specifications. Invest in a reliable tire pressure gauge and establish a routine check, especially before long journeys or seasonal changes. Additionally, ensure that your tire pressure monitoring system (TPMS) is functioning properly. Educate your drivers about the importance of tire maintenance, and consider implementing a preventive maintenance program that includes regular tire inspections to identify and correct inflation issues before they escalate.

What is the best method for checking tire pressure?

The most effective method for checking tire pressure involves using a digital or analog tire pressure gauge. Ensure the tires are cold (not driven for at least three hours) for an accurate reading. Remove the valve cap and press the gauge onto the valve stem to get a measurement. Compare the reading against the vehicle manufacturer’s recommended tire pressure found in the owner’s manual or on the door jamb. Regular checks should be part of your fleet maintenance routine to prevent issues related to incorrect inflation.

How can incorrect tire inflation impact fuel costs?

Incorrect tire inflation can lead to increased fuel consumption due to higher rolling resistance. Under-inflated tires require more energy to move, which forces the engine to work harder, thus consuming more fuel. Studies indicate that maintaining proper tire pressure can improve fuel efficiency by up to 3%. For businesses managing fleets, this translates to significant cost savings over time, making tire inflation management a crucial component of overall operational efficiency.

What are the consequences of neglecting tire inflation?

Neglecting tire inflation can result in several adverse outcomes, including uneven tire wear, compromised vehicle handling, and increased risk of blowouts. These issues not only jeopardize driver safety but can also lead to higher operational costs due to frequent tire replacements and potential accidents. For B2B buyers, ensuring that suppliers provide quality tires and maintenance services is essential to mitigate these risks and maintain fleet reliability.

How can I vet suppliers for tire products and services?

When vetting suppliers for tire products, consider their reputation, years in business, and customer reviews. Request references from other B2B clients and check their compliance with international standards. Evaluate their capacity to offer customization options based on your specific needs, such as tire type or size. Additionally, inquire about their quality assurance processes and whether they provide after-sales support to ensure that you can maintain proper tire inflation.

What customization options should I look for in tire suppliers?

Look for suppliers who can provide customization options tailored to your fleet’s operational needs. This may include specific tire types suited for different terrains or climates, such as all-season or off-road tires. Consider suppliers that offer branding options for fleet vehicles and those who can accommodate unique specifications like load ratings. Customization not only enhances the performance of your fleet but also aligns with your brand identity.

What minimum order quantities (MOQ) should I expect from tire suppliers?

Minimum order quantities can vary significantly among tire suppliers, often depending on the type of tires and the supplier’s production capabilities. For bulk orders, MOQs can range from a few dozen to several hundred units. It’s important to discuss your specific requirements upfront to negotiate favorable terms. Some suppliers may offer flexibility in MOQs for long-term contracts or loyalty agreements, allowing you to manage inventory effectively.

What payment terms are standard in tire procurement?

Payment terms in tire procurement typically vary by supplier and can range from upfront payments to net 30 or net 60 days. It is advisable to negotiate terms that align with your cash flow needs. Some suppliers may offer discounts for early payments or bulk orders. Additionally, consider the reliability of the supplier and their credit terms, as this can impact your financial planning and overall procurement strategy. Always ensure that contracts clearly outline payment terms to avoid disputes.

Domínio: brainly.com

Registrado: 2004 (21 anos)

Introdução: Incorrect tire inflation can adversely affect tire wear, vehicle handling, and gas mileage. Proper tire inflation is crucial for maintaining even tire wear, ensuring good vehicle handling, and optimizing fuel efficiency. Under-inflated tires can lead to uneven wear, reduced grip on the road, and increased fuel consumption.

Domínio: jacosuperiorproducts.com

Registrado: 2014 (11 anos)

Introdução: JACO Superior Products offers a top-rated collection of certified accurate air pressure monitoring tools engineered with precision to keep you and your family safe on the road. Their product range includes tire pressure gauges, tire inflators, tire air chucks, tire repair kits, and various accessories. They emphasize the importance of using high-quality, certified accurate tire pressure gauges to …

Domínio: cliffsnotes.com

Registrado: 1995 (30 anos)

Introdução: This company, CliffsNotes – Tire Inflation Impact, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Domínio: answers.com

Registrado: 1996 (29 anos)

Introdução: Incorrect tire inflation can adversely affect tire wear, vehicle handling, and gas mileage. Proper tire pressure information can typically be found on a decal located on the door jam of the car.

Improper tire inflation is a critical issue that can lead to increased operational costs and safety risks for businesses across various sectors. Key takeaways emphasize that incorrect tire pressure can significantly impact tire wear, vehicle handling, and fuel efficiency, ultimately resulting in higher maintenance expenses and potential liability issues. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these implications is vital for enhancing fleet performance and ensuring safety.

Strategic sourcing plays an essential role in mitigating these risks. By sourcing high-quality tires and tire management solutions, businesses can ensure optimal performance, reduce fuel consumption, and extend the lifespan of their vehicles. Collaborating with reputable suppliers who prioritize quality and reliability can lead to long-term savings and operational efficiency.

As you consider your procurement strategies, prioritize tire management solutions that address these challenges. Investing in regular tire maintenance and accurate inflation monitoring systems will not only enhance your fleet’s safety but also contribute to overall operational excellence. Take proactive steps today to safeguard your investments and drive sustainable growth in your business.

As informações fornecidas neste guia, inclusive o conteúdo referente a fabricantes, especificações técnicas e análise de mercado, são apenas para fins informativos e educacionais. Elas não constituem aconselhamento profissional sobre compras, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos feito todos os esforços para garantir a precisão e a atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Illustrative image related to incorrect tire inflation can adversely affect

Os compradores B2B devem realizar sua própria due diligence independente e completa antes de tomar qualquer decisão de compra. Isso inclui entrar em contato diretamente com os fornecedores, verificar as certificações, solicitar amostras e buscar consultoria profissional. O risco de confiar em qualquer informação contida neste guia é de responsabilidade exclusiva do leitor.