In the competitive landscape of global transportation, ensuring optimal vehicle performance is paramount. One of the key challenges faced by fleet operators and logistics companies is the impact of incorrectly inflated tires on surface rolling resistance. When tires are not maintained at the recommended pressure, they can significantly increase rolling resistance, leading to diminished fuel efficiency and accelerated tire wear. This guide provides essential insights into the implications of tire inflation on operational costs, helping international B2B buyers navigate the complexities of sourcing and maintaining tires that enhance vehicle performance.

Throughout this comprehensive guide, we will explore various aspects of tire inflation, including the types of tires available, their applications across different industries, and effective strategies for supplier vetting. We will also delve into cost considerations, providing actionable recommendations for maximizing ROI in tire procurement and maintenance.

By understanding the intricacies of tire inflation and its direct effects on rolling resistance, B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including markets like Saudi Arabia and Vietnam—will be empowered to make informed purchasing decisions. This guide aims to equip stakeholders with the knowledge necessary to enhance fleet efficiency, reduce operational costs, and contribute to more sustainable transportation practices.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Underinflated Tires | Larger contact area with the road; increased flexing. | Transportation, logistics fleets | Плюсы: Improved grip; Конс: Higher fuel costs, increased wear. |

| Overinflated Tires | Reduced contact area; stiffer ride; uneven wear patterns. | Automotive, delivery services | Плюсы: Better fuel efficiency; Конс: Reduced traction, harsher ride. |

| Seasonally Inflated Tires | Inflation adjusted for temperature changes; can vary by season. | Agriculture, construction | Плюсы: Optimized performance; Конс: Requires regular monitoring. |

| Incorrectly Sized Tires | Misalignment with manufacturer specifications; affects pressure. | Heavy machinery, construction | Плюсы: Availability in various sizes; Конс: Increased rolling resistance and potential safety hazards. |

| Worn Tires | Tread depth below safety standards; compromised structure. | Управление автопарком, услуги аренды | Плюсы: Lower initial cost; Конс: Increased risk of blowouts, reduced fuel efficiency. |

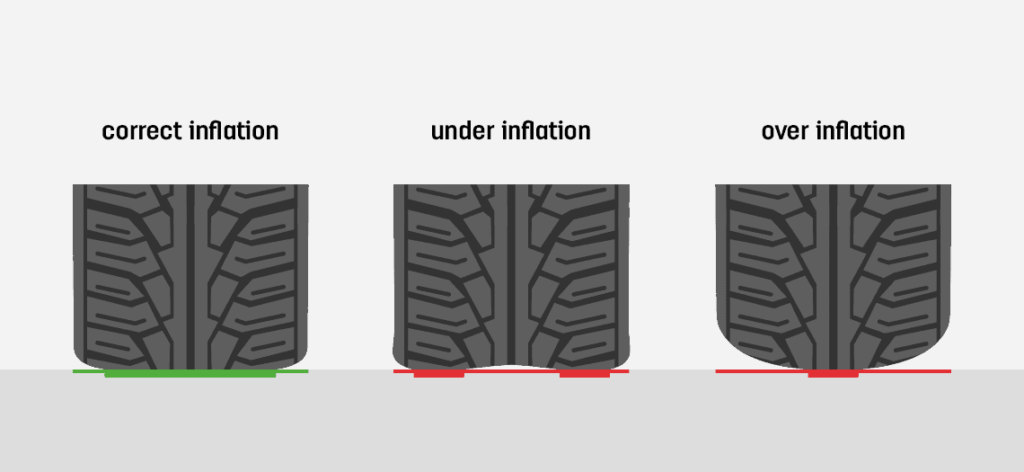

Underinflated tires are characterized by a larger contact area with the road, leading to increased flexing during motion. This results in higher rolling resistance, which can significantly decrease fuel efficiency and increase tire wear. For B2B buyers in transportation and logistics, the implications are clear: while underinflated tires may offer better grip in certain conditions, they lead to higher operational costs due to increased fuel consumption. Regular monitoring and maintenance of tire pressure are crucial to mitigate these effects and ensure optimal performance.

Overinflated tires feature a reduced contact area with the road, which can lead to a stiffer ride and uneven wear patterns. While they can improve fuel efficiency by reducing rolling resistance, the trade-off includes diminished traction and a harsher driving experience. For automotive and delivery service companies, this means that while they may save on fuel costs, they risk compromising safety and ride comfort. B2B buyers should weigh these factors against their operational needs and prioritize regular tire pressure checks to maintain optimal performance.

Seasonally inflated tires are adjusted for temperature changes, ensuring optimal pressure throughout the year. This is particularly relevant for industries such as agriculture and construction, where tire performance can significantly impact productivity. The benefits include enhanced traction and reduced rolling resistance tailored to specific conditions. However, these tires require diligent monitoring to ensure proper inflation, which can be a logistical challenge for some businesses. B2B buyers in these sectors should consider investing in tire pressure monitoring systems to streamline this process.

Incorrectly sized tires do not align with manufacturer specifications, affecting their ability to maintain the recommended pressure. This misalignment can lead to increased rolling resistance and potential safety hazards, particularly in heavy machinery applications. B2B buyers in construction must be vigilant in ensuring that the tires used on their equipment meet the necessary specifications to avoid costly downtime and repairs. While there may be a broader range of sizes available, the risks associated with incorrect sizing can outweigh the benefits.

Worn tires are identified by tread depths that fall below safety standards, compromising the tire’s structural integrity. This condition poses a heightened risk of blowouts and reduced fuel efficiency, making regular monitoring essential for fleet management and rental services. While worn tires may offer a lower initial cost, the long-term implications include increased maintenance costs and potential safety risks. B2B buyers should implement a robust tire management program to regularly assess tire conditions and ensure optimal performance across their fleets.

| Промышленность/сектор | Specific Application of incorrectly inflated tires increase surface rolling resistance | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Transportation & Logistics | Fleet management for delivery trucks | Improved fuel efficiency, reduced operational costs | Tire pressure monitoring systems, durable tire materials |

| Сельское хозяйство | Agricultural machinery operations (tractors, harvesters) | Extended tire lifespan, reduced downtime | Availability of specialized agricultural tires, local suppliers |

| Mining | Heavy machinery in mining operations (haul trucks, excavators) | Lower fuel consumption, enhanced equipment reliability | Sourcing from suppliers with heavy-duty tire options |

| Строительство | Construction vehicles (dump trucks, bulldozers) | Increased productivity, lower maintenance costs | Quality assurance of tires, local service agreements |

| Automotive Services | Tire maintenance and repair services | Enhanced customer satisfaction, repeat business | Access to tire inflation technology, training for staff |

In the transportation and logistics industry, incorrectly inflated tires can significantly hinder fleet efficiency. When delivery trucks operate with underinflated tires, they experience increased surface rolling resistance, leading to higher fuel consumption. This not only escalates operational costs but also affects delivery timelines. For international buyers, particularly in regions like Africa and South America, understanding the local terrain and climate conditions is crucial when sourcing durable tires and tire pressure monitoring systems that can withstand varying road conditions.

In agriculture, the performance of machinery such as tractors and harvesters is heavily influenced by tire inflation. Underinflated tires increase rolling resistance, which can lead to inefficient fuel use and reduced productivity during critical planting and harvesting periods. Buyers must consider sourcing specialized agricultural tires that cater to the unique demands of their operations, ensuring they can maintain optimal tire pressure through effective monitoring solutions. This is especially important in regions with diverse agricultural practices, such as the Middle East and Europe.

In mining, heavy machinery like haul trucks and excavators are essential for efficient operations. Incorrectly inflated tires can lead to increased rolling resistance, resulting in higher fuel costs and reduced equipment reliability. By investing in high-quality, heavy-duty tires that are properly inflated, mining companies can enhance productivity and minimize downtime. Buyers in regions rich in natural resources, such as South America and Africa, should prioritize suppliers that offer robust tire solutions and maintenance services tailored to the harsh mining environment.

Construction vehicles, including dump trucks and bulldozers, rely on optimal tire performance to complete projects on time and within budget. Incorrect tire inflation can lead to increased rolling resistance, which reduces fuel efficiency and accelerates tire wear. For construction firms, this translates into higher operational costs and potential project delays. Buyers in Europe and the Middle East should focus on sourcing high-quality tires that meet rigorous safety and performance standards, alongside establishing service agreements for regular tire maintenance.

In the automotive services sector, tire maintenance is vital for ensuring customer satisfaction and vehicle safety. Incorrectly inflated tires can lead to increased rolling resistance, negatively impacting fuel efficiency and tire longevity. Automotive service providers should invest in tire inflation technology and training for staff to effectively monitor and maintain tire pressure. Buyers in diverse markets such as Vietnam and Saudi Arabia should consider partnerships with suppliers that provide comprehensive tire solutions, including inflation systems and training programs to enhance service delivery.

Проблема: B2B buyers managing fleet operations often face the challenge of rising fuel costs, which can significantly impact profitability. When tires are incorrectly inflated, they create higher rolling resistance, requiring more energy to maintain vehicle speed. This inefficiency translates into increased fuel consumption, resulting in higher operational costs. For companies operating in regions like Africa and South America, where fuel prices can be volatile, this becomes a critical concern that can strain budgets and reduce competitiveness.

Решение: To combat this issue, fleet managers should implement a routine tire pressure monitoring system (TPMS). By investing in technology that allows for real-time monitoring of tire pressure across the fleet, companies can ensure that all vehicles maintain optimal tire inflation levels. Additionally, establishing a regular maintenance schedule that includes manual checks of tire pressure can help catch issues early. Providing training for drivers on the importance of tire maintenance can also promote proactive behavior. Implementing these strategies will not only enhance fuel efficiency but also reduce overall operational costs.

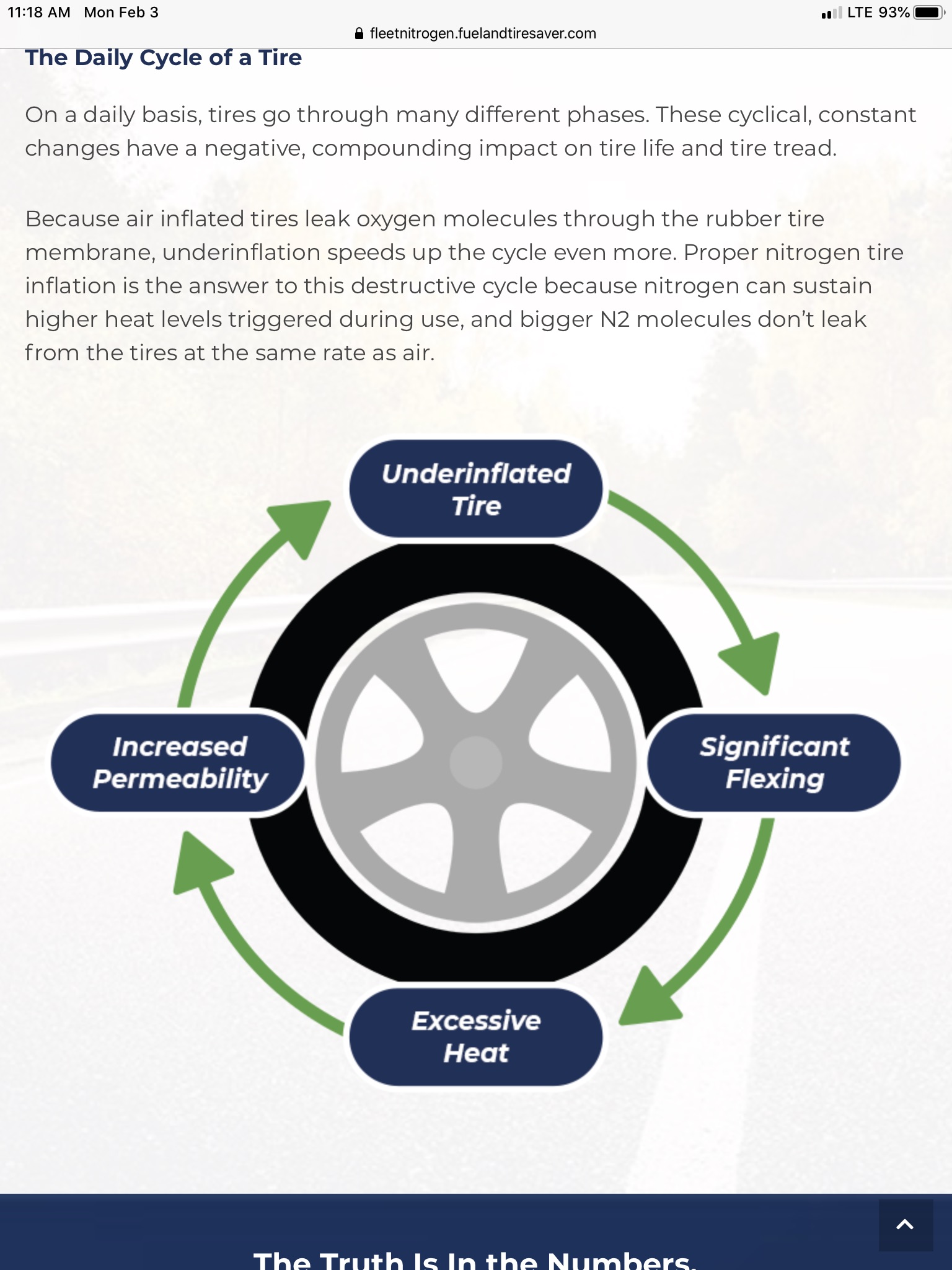

Проблема: Another significant pain point for B2B buyers is the accelerated wear on tires caused by incorrect inflation. Underinflated tires generate excessive heat due to increased flexing, leading to premature tire degradation. In regions with challenging road conditions, like the Middle East or parts of Europe, this can exacerbate the problem, leading to frequent tire replacements that disrupt operations and increase maintenance expenses.

Решение: To mitigate premature tire wear, businesses should adopt a comprehensive tire management program. This program should include regular inspections and data analysis of tire performance, focusing on tread depth and wear patterns. By utilizing tire management software, fleet operators can track tire history and performance, enabling them to identify underperforming tires before they lead to failures. Additionally, considering the use of high-quality, durable tires that are designed for specific conditions can improve longevity. A proactive approach to tire maintenance not only extends the life of each tire but also minimizes the total cost of ownership.

Проблема: Safety is paramount for any B2B buyer, especially those in industries such as logistics and transportation. Incorrectly inflated tires can lead to reduced traction and handling, increasing the risk of accidents. In regions with varying climates, like Europe and Vietnam, fluctuating temperatures can cause tire pressure to change, often without the driver’s knowledge. This poses a significant risk to both the driver and cargo, leading to liability issues and potential damage to the company’s reputation.

Решение: To enhance safety and mitigate risks associated with tire inflation, companies should invest in driver training programs that emphasize the importance of regular tire checks and maintenance. Additionally, implementing a policy that mandates pre-trip inspections for tire pressure can ensure that any discrepancies are caught before vehicles hit the road. Utilizing a combination of TPMS and education will empower drivers to take immediate action when tire pressures are not within the recommended range. This dual approach not only promotes a culture of safety but also protects the company from potential legal liabilities and enhances overall operational reliability.

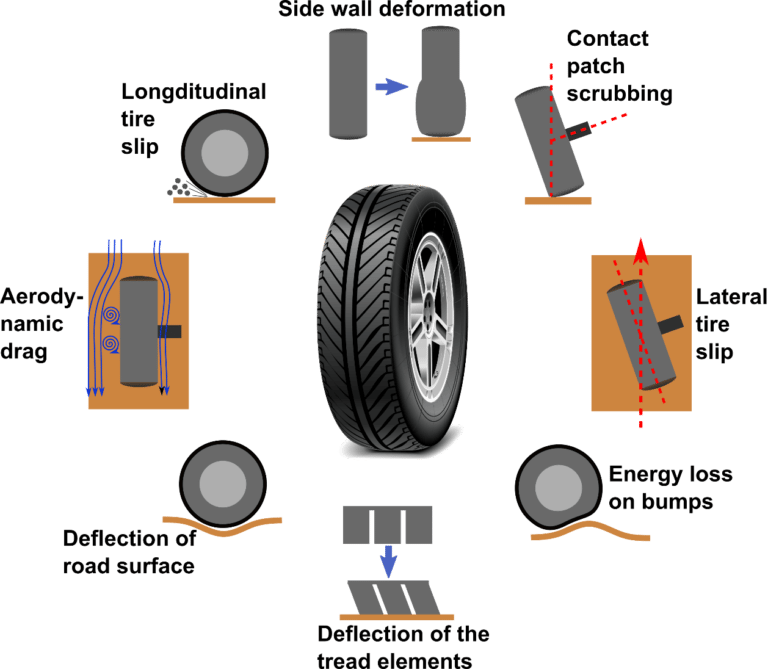

In the context of incorrectly inflated tires leading to increased surface rolling resistance, the choice of materials used in tire manufacturing plays a crucial role. Here, we analyze three common materials: rubber compounds, steel belts, and textile reinforcements. Each material has distinct properties that affect tire performance, durability, and overall efficiency.

Rubber compounds are the primary material used in tire manufacturing. They are engineered to provide optimal grip, flexibility, and durability under various conditions. Key properties include temperature resistance, wear resistance, and flexibility.

Плюсы: High-quality rubber compounds can enhance traction and reduce rolling resistance when properly inflated. They are also relatively cost-effective compared to other materials.

Конс: The durability of rubber can be compromised by environmental factors such as UV exposure and ozone degradation. Additionally, the manufacturing complexity can increase with the inclusion of specialized additives for performance enhancement.

Illustrative image related to incorrectly inflated tires increase surface rolling resistance

Влияние на применение: In regions with extreme temperatures, such as parts of Africa and the Middle East, selecting a rubber compound with a high-temperature rating is essential to maintain performance and minimize rolling resistance.

Steel belts are often incorporated into tires to provide structural integrity and enhance performance. They help maintain the tire’s shape under load, which is critical for minimizing rolling resistance.

Плюсы: Steel belts significantly improve the tire’s resistance to punctures and enhance overall durability. They also aid in maintaining proper tire shape, which is crucial for reducing rolling resistance.

Конс: The addition of steel can increase the weight of the tire, potentially leading to higher rolling resistance if the tire is not inflated correctly. Furthermore, the cost of steel belts can be higher than other materials.

Влияние на применение: For international buyers, especially in Europe where regulations on tire performance are stringent, selecting tires with high-quality steel belts can ensure compliance with safety standards.

Textile reinforcements, such as polyester or nylon, are used to provide flexibility and strength to the tire structure. These materials are essential for maintaining the tire’s shape and performance under varying loads.

Плюсы: Textile reinforcements allow for a lighter tire design, which can contribute to improved fuel efficiency. They also provide good resistance to flex fatigue, extending the tire’s lifespan.

Illustrative image related to incorrectly inflated tires increase surface rolling resistance

Конс: While textile reinforcements enhance flexibility, they may not provide the same level of puncture resistance as steel belts. Additionally, the manufacturing process can be complex and costly.

Влияние на применение: In regions like South America, where road conditions can vary significantly, selecting tires with appropriate textile reinforcements can help ensure durability and performance across different terrains.

| Материал | Typical Use Case for incorrectly inflated tires increase surface rolling resistance | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Rubber Compounds | Used in tire tread and sidewalls for grip and flexibility | High traction and cost-effective | Degrades under UV exposure and ozone | Средний |

| Steel Belts | Incorporated for structural integrity and shape maintenance | Enhanced durability and puncture resistance | Increases tire weight, potentially raising rolling resistance | Высокий |

| Textile Reinforcements | Provides flexibility and strength in tire structure | Lighter design improves fuel efficiency | Less puncture resistance than steel belts | Средний |

By understanding the properties and implications of these materials, international B2B buyers can make informed decisions that enhance tire performance, optimize fuel efficiency, and reduce operational costs.

Manufacturing tires involves several key stages, each playing a vital role in the final product’s performance, including its ability to maintain correct inflation. The process typically includes material preparation, forming, assembly, and finishing.

Подготовка материалов: The first step involves sourcing high-quality materials like rubber, fabric, and steel. Each component is selected based on specific performance criteria, such as durability and flexibility. For instance, the rubber compound must provide the right balance of traction and wear resistance. Ensuring the quality of these raw materials is essential, as substandard inputs can lead to tires that are more prone to deformation and, consequently, improper inflation.

Формирование: This stage includes the shaping of the tire components. The inner liner, body plies, and belts are formed into the appropriate shapes. Advanced techniques like extrusion and calendaring are used to create the rubber layers. Precision in this process is critical, as any inconsistencies can lead to uneven tire wear and inflation issues.

Сборка: During assembly, the formed components are combined. This involves stacking the inner liner, body plies, and belts before adding the tread. The assembly must be performed with precision to ensure that the tire maintains its shape under load and pressure. Improper assembly can lead to weak points that can exacerbate issues related to inflation.

Отделка: The final stage includes curing, where tires are heated in a mold to solidify their shape and enhance durability. This process also involves applying surface treatments that can affect rolling resistance. A well-finished tire will have uniform thickness and surface texture, which are crucial for maintaining proper inflation levels.

Quality control is integral to tire manufacturing, particularly for maintaining specifications that prevent issues like incorrect inflation. International standards like ISO 9001, along with industry-specific regulations such as CE marking for Europe, guide QC practices.

Контрольные точки контроля качества:

– Входящий контроль качества (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. Suppliers must meet specified criteria, as inferior materials can compromise tire performance.

– Внутрипроцессный контроль качества (IPQC): During manufacturing, ongoing inspections are conducted to ensure that each step adheres to quality standards. This involves measuring dimensions, checking material properties, and ensuring the correct assembly.

– Окончательный контроль качества (ОКК): At the end of the production line, tires undergo rigorous testing to validate their performance under various conditions. This may include pressure tests, rolling resistance measurements, and durability assessments.

Общие методы тестирования:

– Uniformity Testing: Ensures the tire is balanced and free of defects that could lead to uneven wear or poor inflation retention.

– Rolling Resistance Testing: Measures how much energy is lost as the tire rolls, which directly correlates with fuel efficiency and overall performance.

– Испытание на долговечность: Simulates real-world conditions to evaluate how well the tire can maintain its shape and integrity over time.

For international B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, ensuring the quality of tire suppliers is paramount. Here are actionable steps to verify supplier QC:

Аудиты поставщиков: Conducting thorough audits of potential suppliers can reveal their manufacturing processes and QC practices. Buyers should look for compliance with international standards and certifications, which indicate a commitment to quality.

Запрос отчетов о качестве: Buyers should ask for detailed quality reports that outline testing results, QC checkpoints, and any corrective actions taken during production. These reports provide insight into the supplier’s commitment to maintaining high standards.

Проверки третьих сторон: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices. These inspections can be particularly valuable for buyers unfamiliar with local manufacturing conditions.

Understanding the nuances of quality control and certification in various markets is crucial for B2B buyers. Here are some considerations:

Africa: Buyers should be aware of regional certifications and may need to consider local regulations that impact tire safety and performance. Engaging with suppliers who understand these regulations can streamline the procurement process.

South America: In this region, buyers should look for compliance with local standards such as INMETRO in Brazil, which governs product safety and quality. Suppliers with these certifications demonstrate their commitment to meeting local market needs.

Middle East: In countries like Saudi Arabia, adherence to GSO (Gulf Standards Organization) regulations is vital. Buyers should prioritize suppliers who have successfully navigated these certification processes.

Europe: The CE marking is a significant requirement for tires sold in Europe. Buyers should ensure that their suppliers not only have CE certification but also follow ISO standards to guarantee quality and safety.

In summary, the manufacturing processes and quality assurance practices surrounding tires play a crucial role in preventing issues related to incorrect inflation. By understanding these processes and implementing robust verification methods, B2B buyers can make informed purchasing decisions that enhance vehicle performance, improve fuel efficiency, and reduce operational costs. Ensuring that suppliers adhere to international standards and local regulations is essential for maintaining high-quality tire performance, ultimately benefiting both the buyer and the end consumer.

Illustrative image related to incorrectly inflated tires increase surface rolling resistance

This guide serves as a practical checklist for B2B buyers focused on understanding and addressing the implications of incorrectly inflated tires on surface rolling resistance. By following these steps, organizations can enhance fuel efficiency, prolong tire life, and ultimately reduce operational costs.

Recognizing how tire inflation affects rolling resistance is crucial. Underinflated tires increase the contact area with the road, leading to higher rolling resistance, which demands more energy from the vehicle’s engine. This not only reduces fuel efficiency but also accelerates tire wear, leading to increased replacement costs.

Before sourcing tires, clearly outline the specifications required for your fleet. This includes the type of vehicles, tire sizes, and recommended pressure levels. Understanding these factors will help you select the most appropriate tires and ensure they are suited for your operational needs.

Ensure that potential suppliers hold relevant certifications that attest to their quality and safety standards. Look for certifications such as ISO 9001 for quality management or any specific tire industry standards. These certifications provide assurance that the supplier adheres to rigorous quality controls, which is essential for maintaining performance and safety.

Gather comprehensive product information from suppliers, including tire composition, performance data, and recommended inflation pressures. This information is vital for assessing how different tires may perform under various conditions. Pay attention to fuel efficiency ratings and expected tire lifespan to make informed decisions.

Investigate the track record of potential suppliers in the tire industry. Look for case studies, testimonials, and references from other B2B clients, especially those in similar sectors or regions. A well-established supplier with a solid reputation is more likely to provide reliable products and support.

Perform a thorough cost-benefit analysis to compare the total cost of ownership for different tire options. This should include initial purchase costs, expected fuel savings from improved tire efficiency, and projected tire replacement costs. Understanding the long-term financial implications will guide you toward a more sustainable choice.

Once tires are procured, establish a regular maintenance program that includes routine checks of tire pressure and tread wear. Proper maintenance is essential to mitigate the effects of rolling resistance and maximize the lifespan of the tires. Training staff on the importance of tire care can further enhance operational efficiency.

Illustrative image related to incorrectly inflated tires increase surface rolling resistance

By following this checklist, B2B buyers can make informed decisions that significantly impact fuel efficiency, operational costs, and the overall performance of their fleet.

The cost structure associated with incorrectly inflated tires primarily involves several key components. Материалы play a significant role; tire composition, including rubber quality and additives, affects performance and longevity. Труд costs are incurred during manufacturing, installation, and maintenance, particularly when regular checks are necessary to ensure proper inflation levels. Manufacturing overhead includes expenses related to factory operations, utilities, and equipment maintenance, which can fluctuate based on production volumes.

Инструментальная оснастка costs, which are the expenses associated with the machinery and equipment used to produce tires, can also impact the overall pricing. High-quality tooling can lead to better manufacturing efficiency and product quality, ultimately reducing costs in the long run. Quality control (QC) measures are crucial, as they ensure that tires meet safety and performance standards. The costs associated with QC can vary depending on the certification requirements and the extent of testing conducted.

Логистика costs encompass shipping and handling, which can be particularly significant for international buyers. These costs vary based on the destination, shipping method, and any tariffs or import duties applicable to specific regions. Lastly, the margin that manufacturers and suppliers add to their pricing reflects their operational costs and desired profit levels.

Illustrative image related to incorrectly inflated tires increase surface rolling resistance

Several factors influence pricing in the sourcing of tires, particularly concerning rolling resistance. Объем и минимальное количество заказа (MOQ) can lead to significant cost savings. Bulk orders often result in lower per-unit pricing, which is critical for B2B buyers looking to optimize their procurement budgets.

Specifications and customization also play a pivotal role. Custom tires designed for specific applications or vehicles may incur additional costs, but they can lead to improved performance and reduced rolling resistance. The choice of materials is another influencer; premium materials may raise upfront costs but can enhance durability and fuel efficiency, ultimately affecting the Total Cost of Ownership (TCO).

Quality and certifications are vital considerations for international buyers. Tires that meet specific industry standards or possess certifications may be priced higher, but they offer assurance of reliability and safety. Supplier factors, such as reputation and reliability, can also influence pricing structures. Engaging with established suppliers often ensures better quality and service, albeit at a premium.

Lastly, Инкотермс define the responsibilities of buyers and sellers in international transactions, impacting the overall cost structure by clarifying who bears shipping costs, insurance, and risk during transit.

B2B buyers can implement several strategies to enhance cost efficiency in tire sourcing. Переговоры is a critical skill; engaging suppliers in discussions about pricing, especially for larger orders, can yield significant discounts. Additionally, understanding the Total Cost of Ownership is vital. While a lower purchase price may be attractive, it’s essential to consider long-term costs associated with fuel efficiency, maintenance, and tire lifespan.

Buyers should also be aware of pricing nuances specific to their regions. For instance, in Africa and South America, logistical challenges can increase costs, so sourcing from local suppliers may reduce shipping expenses. In contrast, European buyers might benefit from established supply chains and regulatory standards that ensure product quality.

Lastly, always keep in mind that indicative prices can vary based on market conditions, currency fluctuations, and geopolitical factors, making it essential to stay informed about global market trends and adjust sourcing strategies accordingly. By adopting these practices, buyers can make informed decisions that enhance their operational efficiency and contribute to overall cost savings.

Illustrative image related to incorrectly inflated tires increase surface rolling resistance

In the context of vehicle efficiency and operational costs, managing tire performance is critical. Incorrectly inflated tires lead to increased surface rolling resistance, which negatively impacts fuel consumption and tire lifespan. However, there are alternative solutions that can help mitigate these issues. This analysis compares the implications of incorrectly inflated tires with two viable alternatives: Tire Pressure Monitoring Systems (TPMS) и Inflatable Tire Technologies.

| Сравнительный аспект | Incorrectly Inflated Tires Increase Surface Rolling Resistance | Tire Pressure Monitoring Systems (TPMS) | Inflatable Tire Technologies |

|---|---|---|---|

| Производительность | High rolling resistance leads to decreased fuel efficiency and increased tire wear. | Maintains optimal tire pressure, improving fuel efficiency and reducing tire wear. | Adaptive inflation that adjusts pressure based on load, enhancing performance. |

| Стоимость | Increased operational costs due to fuel inefficiency and frequent tire replacements. | Initial installation costs, but long-term savings through improved efficiency. | Higher upfront costs; potential savings through reduced wear and improved efficiency. |

| Простота реализации | Requires regular manual checks and adjustments. | Easy integration with existing systems; alerts for low pressure. | Requires specialized installation and maintenance. |

| Техническое обслуживание | Regular checks and adjustments needed; can be overlooked. | Minimal maintenance; relies on technology for monitoring. | Requires periodic checks to ensure functionality and inflation adjustments. |

| Лучший пример использования | General use in fleets without advanced technology. | Ideal for commercial fleets focused on efficiency and safety. | Suitable for heavy-duty vehicles with varying load conditions. |

TPMS are electronic systems designed to monitor tire pressure in real-time. By providing alerts when pressure drops below optimal levels, TPMS enables proactive management of tire health. This technology enhances vehicle performance by ensuring tires are always inflated to manufacturer specifications, thus minimizing rolling resistance.

Плюсы: Improved fuel efficiency, reduced wear on tires, and enhanced safety through real-time monitoring.

Cons: Initial installation costs may be significant, and the system requires a power source, making it susceptible to battery failure.

Inflatable tire technologies, such as adjustable air pressure systems, allow for real-time tire pressure adjustments based on vehicle load and driving conditions. These systems can automatically inflate or deflate tires, optimizing performance and rolling resistance dynamically.

Плюсы: Provides enhanced performance and safety, particularly in varying load conditions. It can adapt to different driving scenarios, ensuring optimal tire contact with the road.

Illustrative image related to incorrectly inflated tires increase surface rolling resistance

Cons: Higher upfront investment and the complexity of installation may deter some businesses. Regular maintenance is also required to ensure system reliability.

When assessing solutions to combat the negative impacts of incorrectly inflated tires, B2B buyers must consider their specific operational needs, budget constraints, and the technological landscape of their fleet. While incorrectly inflated tires pose significant challenges, alternatives such as TPMS and inflatable tire technologies offer compelling benefits that can enhance fuel efficiency, reduce maintenance costs, and improve overall vehicle safety. A thorough evaluation of these factors will enable businesses to make informed decisions that align with their operational goals and sustainability initiatives.

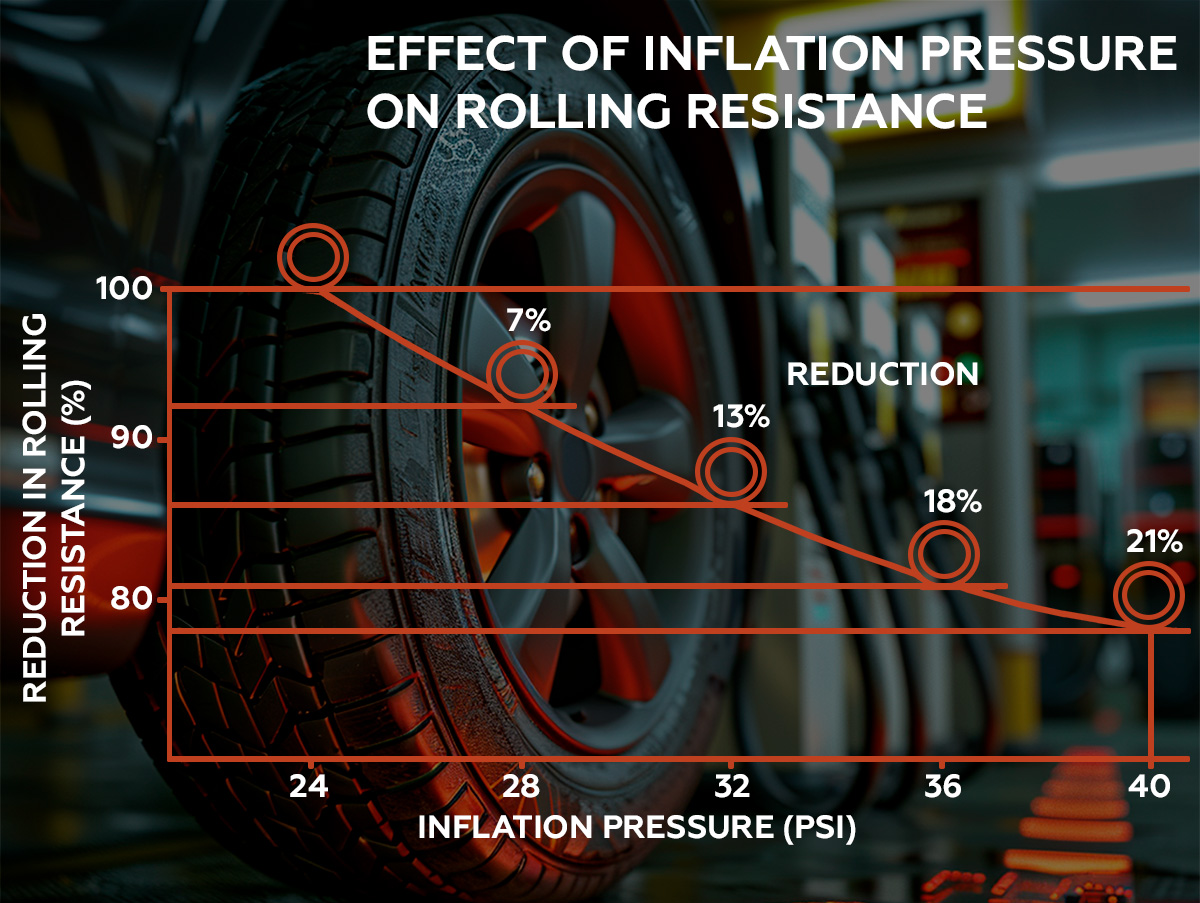

Maintaining the correct tire pressure is critical to minimizing rolling resistance. Tire pressure is typically measured in pounds per square inch (psi). Each vehicle comes with a recommended tire pressure specification, which balances safety, performance, and fuel efficiency. When tires are underinflated, they deform more significantly during operation, increasing the contact area with the road and, consequently, the rolling resistance. For B2B buyers, understanding the importance of adhering to these specifications can lead to reduced operational costs and enhanced vehicle performance.

Illustrative image related to incorrectly inflated tires increase surface rolling resistance

The material used in tire construction affects flexibility and heat resistance. Tires made from high-quality rubber compounds with appropriate additives can maintain better structural integrity under varying pressures. In contrast, lower-grade materials may lead to increased flexing and heat generation when tires are underinflated, resulting in higher rolling resistance and accelerated wear. B2B buyers should prioritize sourcing tires that utilize advanced materials to ensure longevity and efficiency.

Tires have specific load ratings that dictate the maximum weight they can safely carry. An underinflated tire cannot properly support its load, leading to excessive deformation and increased rolling resistance. Understanding load capacity is essential for fleet operators and logistics companies to ensure that their vehicles operate within safe parameters, thus enhancing fuel efficiency and reducing the risk of tire failure.

The tread pattern on a tire plays a significant role in rolling resistance. Tires designed with optimized tread patterns can reduce energy loss during rolling. For instance, tires with a shallower tread depth may offer lower rolling resistance than deeper tread designs when properly inflated. B2B buyers should consider tread design when selecting tires, as it directly impacts fuel economy and operational costs.

Tires operate under various temperature conditions, and their performance can significantly vary based on temperature changes. Underinflated tires generate excess heat, which can lead to blowouts and decreased efficiency. Understanding the temperature tolerance of different tire types helps businesses choose the right tires for their specific operational environments, ensuring safety and performance.

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the tire industry, OEM tires are those supplied by the vehicle manufacturer. Understanding OEM specifications helps B2B buyers ensure that they procure tires that meet the original performance standards set by vehicle manufacturers.

MOQ defines the smallest quantity of a product that a supplier is willing to sell. In the context of tire procurement, knowing the MOQ can aid businesses in planning their purchases effectively, especially when managing inventory for fleets. This understanding can prevent overstocking or underordering tires, thus optimizing operational costs.

An RFQ is a document that a buyer sends to suppliers requesting pricing and other relevant information for a specific quantity of tires. This process is crucial for B2B buyers to compare costs and terms across various suppliers, ensuring they secure the best deal for their operational needs.

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Understanding Incoterms is vital for B2B buyers, especially in international trade, as they outline who is responsible for costs, risks, and insurance during the shipping of tires. This knowledge helps in effective contract negotiation and risk management.

The Rolling Resistance Coefficient is a measure of the energy loss due to the deformation of tires as they roll. A lower RRC indicates better fuel efficiency and performance. B2B buyers should pay attention to this metric when selecting tires, as it directly affects operational costs and environmental impact.

By grasping these technical properties and industry terminology, B2B buyers can make informed decisions that enhance their operational efficiency and reduce costs associated with incorrectly inflated tires and increased rolling resistance.

Illustrative image related to incorrectly inflated tires increase surface rolling resistance

The market for incorrectly inflated tires and their impact on surface rolling resistance is influenced by several global drivers. A primary factor is the rising cost of fuel, which has heightened awareness among fleet managers and vehicle operators about the importance of tire maintenance. In emerging markets like Africa and South America, where fuel prices can significantly affect operational costs, businesses are increasingly adopting tire pressure monitoring systems (TPMS) and investing in training for regular tire checks. Additionally, the growing emphasis on vehicle safety regulations in Europe and the Middle East is pushing companies to prioritize tire maintenance as part of broader vehicle safety protocols.

Emerging technologies are also shaping the market dynamics. The integration of IoT in tire management allows for real-time monitoring of tire pressure, temperature, and wear, facilitating proactive maintenance strategies. Furthermore, the trend toward electrification of vehicles is driving the need for more efficient tire performance, as rolling resistance plays a critical role in extending the range of electric vehicles. As a result, international B2B buyers are increasingly seeking partnerships with suppliers who offer advanced tire technologies and sustainable solutions.

Sustainability and ethical sourcing are becoming paramount in the tire industry, especially given the environmental impact of incorrectly inflated tires. Underinflated tires not only lead to increased fuel consumption and higher greenhouse gas emissions but also contribute to more frequent tire replacements, exacerbating waste. For B2B buyers, understanding the environmental footprint of tire sourcing is crucial for compliance with regulations and corporate social responsibility (CSR) initiatives.

Suppliers are responding by adopting ‘green’ certifications and materials, such as sustainable rubber sourced from responsibly managed plantations. Companies are also focusing on developing tires that maintain optimal performance over longer periods, thereby reducing the frequency of replacements and the associated waste. Buyers should prioritize suppliers who demonstrate a commitment to sustainability through transparent supply chains and certifications like ISO 14001, which indicates a robust environmental management system. By aligning with sustainable partners, businesses can enhance their brand reputation and meet the growing consumer demand for eco-friendly practices.

Historically, the significance of tire inflation in relation to rolling resistance has been recognized since the early days of automotive engineering. In the 20th century, as vehicles became more prevalent, studies began to emerge that demonstrated how underinflated tires could negatively impact fuel efficiency and increase operational costs. The 1970s oil crisis further underscored the importance of fuel economy, leading to increased research into tire technology and inflation practices.

In recent decades, advancements in materials science and engineering have led to the development of tires that are more resistant to deformation and wear. Innovations such as run-flat tires and low rolling resistance designs have emerged, driven by both consumer demand for safety and regulatory pressures to improve fuel efficiency. Today, the dialogue around tire maintenance has evolved to include not only performance metrics but also sustainability considerations, shaping the future of the tire industry as it adapts to new market realities and consumer expectations.

In conclusion, international B2B buyers must navigate a complex landscape influenced by economic pressures, technological advancements, and sustainability imperatives. By focusing on proper tire inflation and understanding the broader implications of tire sourcing, businesses can optimize their operations while contributing to environmental stewardship.

How do I solve the issue of increased rolling resistance due to incorrectly inflated tires?

To address increased rolling resistance from incorrectly inflated tires, regularly check and maintain the tire pressure according to the manufacturer’s specifications. Implement a routine inspection schedule that includes measuring tire pressure and assessing tire condition. Utilizing tire pressure monitoring systems (TPMS) can aid in maintaining optimal inflation levels. Additionally, provide training for drivers and maintenance personnel on the importance of tire maintenance to ensure that vehicles operate efficiently, reducing fuel costs and enhancing safety.

What is the best practice for tire inflation in commercial fleets?

For commercial fleets, the best practice for tire inflation involves adhering to the manufacturer’s recommended pressure settings, which can usually be found in the vehicle’s manual or on the driver’s side door jamb. Regularly scheduled maintenance checks should be established, ideally bi-weekly or monthly, depending on fleet usage. Consider using nitrogen inflation, which can help maintain tire pressure longer than regular air. Implementing a centralized tire management system can also help streamline the process and ensure consistency across the fleet.

How can I evaluate suppliers for tires that minimize rolling resistance?

When evaluating suppliers for tires, consider their reputation in the market for providing high-quality, well-engineered products that focus on reducing rolling resistance. Request samples for testing and gather data on their tires’ performance under various conditions. Look for certifications or endorsements from recognized industry bodies that validate their claims. Additionally, assess their customer service, warranty offerings, and after-sales support, as these factors contribute to long-term satisfaction and operational efficiency.

What are the logistics considerations when sourcing tires internationally?

Sourcing tires internationally involves several logistics considerations, including shipping costs, import duties, and compliance with local regulations. Assess the total landed cost, which includes shipping, customs fees, and taxes, to determine the most cost-effective options. It’s crucial to understand the lead times for delivery and any potential delays due to customs clearance. Partnering with a logistics provider experienced in international trade can help streamline the process and mitigate risks associated with sourcing tires from abroad.

What customization options are available for tires to reduce rolling resistance?

Customization options for tires aimed at reducing rolling resistance may include modifications in tread design, rubber compounds, and tire dimensions. Many manufacturers offer the ability to tailor tires for specific vehicle types or operational conditions. Discuss your requirements with suppliers to explore options such as low rolling resistance designs, eco-friendly materials, or specialized tread patterns that enhance fuel efficiency. Ensure that any customizations align with the vehicle specifications and operational needs to maximize performance.

What are the minimum order quantities (MOQ) for purchasing tires?

Minimum order quantities (MOQ) for purchasing tires can vary significantly between suppliers and may depend on factors such as tire type, size, and customization options. Generally, bulk purchases lead to lower unit costs, so inquire about pricing structures based on order size. Suppliers may offer flexible MOQs for new customers or during promotional periods. Always negotiate terms that align with your purchasing strategy and ensure that you can meet your operational needs without excessive inventory.

What payment terms should I expect when sourcing tires internationally?

Payment terms for international tire sourcing can vary widely based on the supplier and the buyer’s relationship. Common terms include advance payment, letters of credit, or net 30/60/90 days. It’s advisable to negotiate favorable terms that balance cash flow considerations with supplier confidence. Consider using escrow services for large transactions to ensure security for both parties. Always review the terms carefully and ensure they are documented in the purchase agreement to avoid any misunderstandings.

How can I ensure quality assurance for tires sourced from international suppliers?

To ensure quality assurance for tires sourced internationally, establish clear specifications and standards that the tires must meet before procurement. Require suppliers to provide certifications and compliance documents that verify their adherence to industry standards. Implement a quality control process that includes pre-shipment inspections and testing of samples. Building a strong relationship with your suppliers and conducting regular audits can also help maintain high quality and consistency in the products received.

Домен: brainly.com

Зарегистрирован: 2004 (21 год)

Введение: Incorrectly inflated tires increase surface rolling resistance, leading to reduced fuel efficiency and increased tire wear. Maintaining proper tire inflation is crucial for optimal performance and safety. Regular checks of tire pressure are essential for vehicle maintenance. Underinflated tires have a larger contact area with the road, resulting in higher rolling resistance, which requires more en…

Домен: gauthmath.com

Зарегистрирован: 2020 (5 лет)

Введение: Gauthmath Extension Calculator, Gauth PLUS Math Resources, AI calculator, live tutors, initial amount 40 gm, half-life 5715 years, remaining amount after 1000 years 35.5432 gm.

Домен: climber.uml.edu.ni

Введение: This company, Climber – Enhanced Rolling Resistance, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Домен: jacosuperiorproducts.com

Зарегистрирован: 2014 (11 лет)

Введение: JACO Superior Products offers a top-rated collection of certified accurate air pressure monitoring tools engineered with precision to keep you and your family safe on the road. Their product range includes tire pressure gauges, digital gauges, low PSI gauges, Presta gauges, tire inflator gauges, tire air chucks, tire compressors, tire repair kits, tread depth gauges, and various bike tools and acc…

Домен: etenwolf.com

Зарегистрирован: 2021 (4 года)

Введение: Etenwolf Vortex S6 Tire Pressure Pump: Designed for quick and accurate inflation, ensuring optimal tire pressure. Features include a digital pressure gauge and automatic shut-off to prevent over-inflation. Portable and versatile, suitable for various types of tires from cars to heavy-duty vehicles.

Домен: app.pulsar.uba.ar

Зарегистрирован: 2014 (11 лет)

Введение: This company, Pulsar – Tire Inflation Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

In summary, the impact of incorrectly inflated tires on surface rolling resistance is a critical concern for businesses operating across diverse markets. Proper tire inflation is not merely a maintenance issue; it directly influences fuel efficiency and operational costs. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, ensuring that vehicles are equipped with correctly inflated tires can lead to significant savings in fuel consumption and extended tire life, ultimately enhancing overall fleet performance.

Strategic sourcing plays a vital role in addressing this challenge. By partnering with reliable suppliers who prioritize quality and compliance with tire specifications, businesses can mitigate the risks associated with underinflation. Regular maintenance checks and proactive sourcing strategies can ensure that fleets operate at optimal efficiency, reducing environmental impact and operational costs.

Looking ahead, it is essential for international buyers to adopt a forward-thinking approach to tire management. Investing in technology that monitors tire pressure in real-time can provide a competitive edge in today’s market. As the global demand for sustainable and cost-effective transportation solutions continues to grow, now is the time to prioritize tire maintenance and strategic sourcing to drive future success.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.