In the fast-evolving landscape of industrial tools, sourcing a reliable air pressure gauge hose can pose significant challenges for international B2B buyers. Whether you are operating in Nigeria, Germany, or Brazil, the quest for quality and compatibility in air pressure gauge hoses is critical for ensuring efficient operations across various applications, from automotive maintenance to heavy machinery servicing. This guide aims to demystify the complexities of the global market by providing comprehensive insights into the types of air pressure gauge hoses available, their specific applications, and essential supplier vetting criteria.

Buyers will find valuable information on cost considerations, quality standards, and innovative features that can enhance functionality. Understanding these elements is crucial in making informed purchasing decisions that align with operational needs and budget constraints.

Moreover, this guide emphasizes the importance of selecting the right suppliers who can not only meet your quality expectations but also navigate the regulatory and logistical challenges unique to your region. By equipping B2B buyers with actionable insights, we aim to empower organizations to optimize their procurement processes, ensuring they secure the best products for their specific operational demands in diverse markets.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Standard Rubber Hose | Flexible, durable, withstands high pressure | Automotive, industrial machinery | Плюсы: Cost-effective, good flexibility. Конс: May degrade faster under extreme conditions. |

| Reinforced PVC Hose | Lightweight, resistant to abrasion and chemicals | Construction, manufacturing | Плюсы: Lightweight, good chemical resistance. Конс: Less flexible in colder temperatures. |

| Digital Gauge Hose | Integrated digital pressure display | Automotive service, tire shops | Плюсы: Accurate readings, easy to read. Конс: More expensive, requires batteries. |

| Extension Hose | Longer reach, often with self-locking connectors | Tire inflation, automotive maintenance | Плюсы: Increased reach, convenient. Конс: Bulkier, may require additional storage space. |

| Copper Hose | Rigid, excellent thermal conductivity | Mechanical applications, HVAC systems | Плюсы: Durable, resistant to high temperatures. Конс: Less flexible, can be heavier. |

Standard rubber hoses are a popular choice for many B2B applications due to their flexibility and durability. They can withstand high pressure and are often used in automotive and industrial machinery settings. Buyers should consider the operational environment, as these hoses may degrade faster under extreme temperatures or chemical exposure. Their cost-effectiveness makes them an attractive option for businesses looking to manage expenses without sacrificing quality.

Reinforced PVC hoses are designed to be lightweight and resistant to abrasion and chemicals, making them suitable for construction and manufacturing applications. These hoses are particularly advantageous in environments where chemical exposure is a concern. However, they may become less flexible in colder temperatures, which is an important consideration for businesses operating in diverse climates. Their ease of handling and storage is a plus for many B2B buyers.

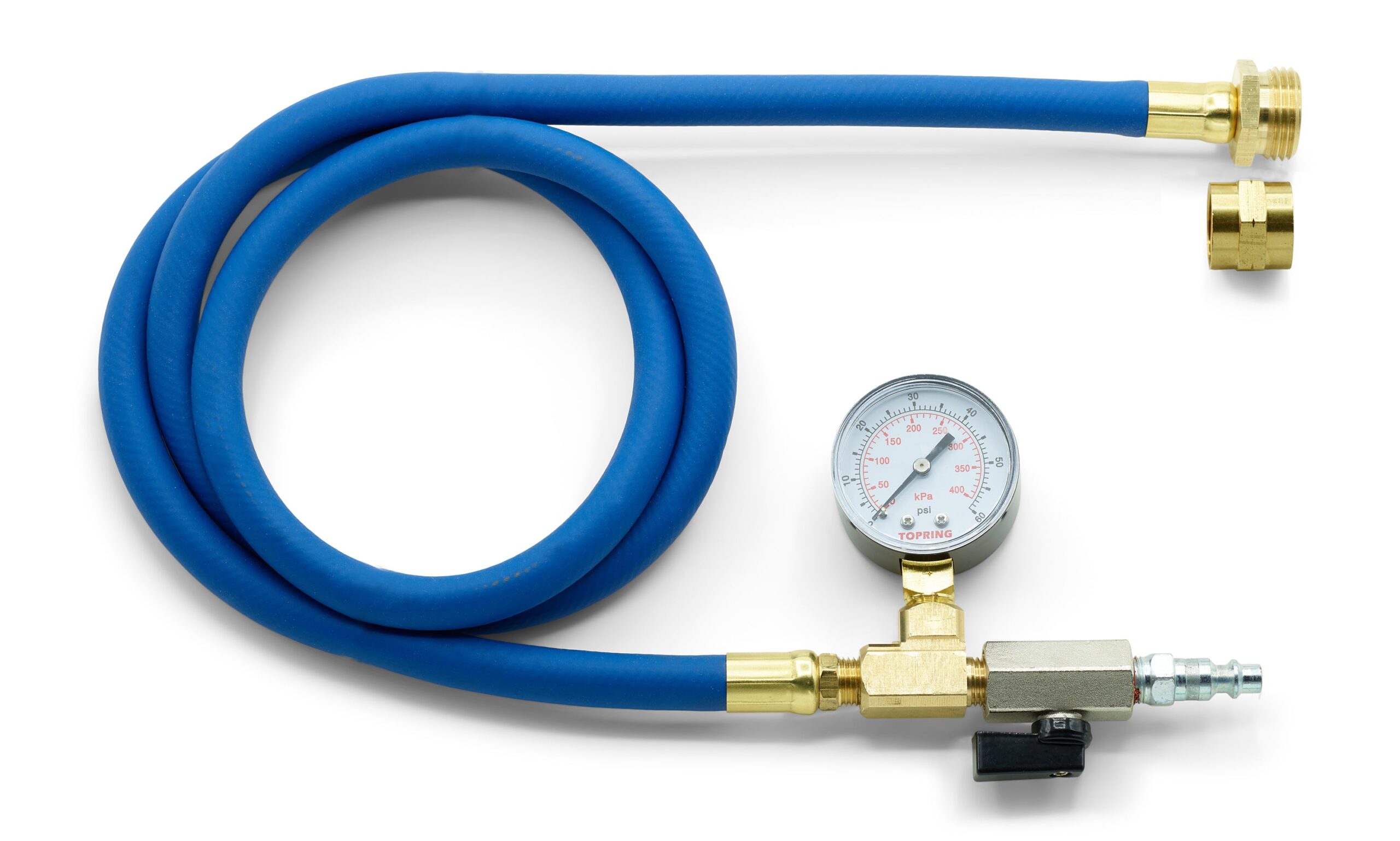

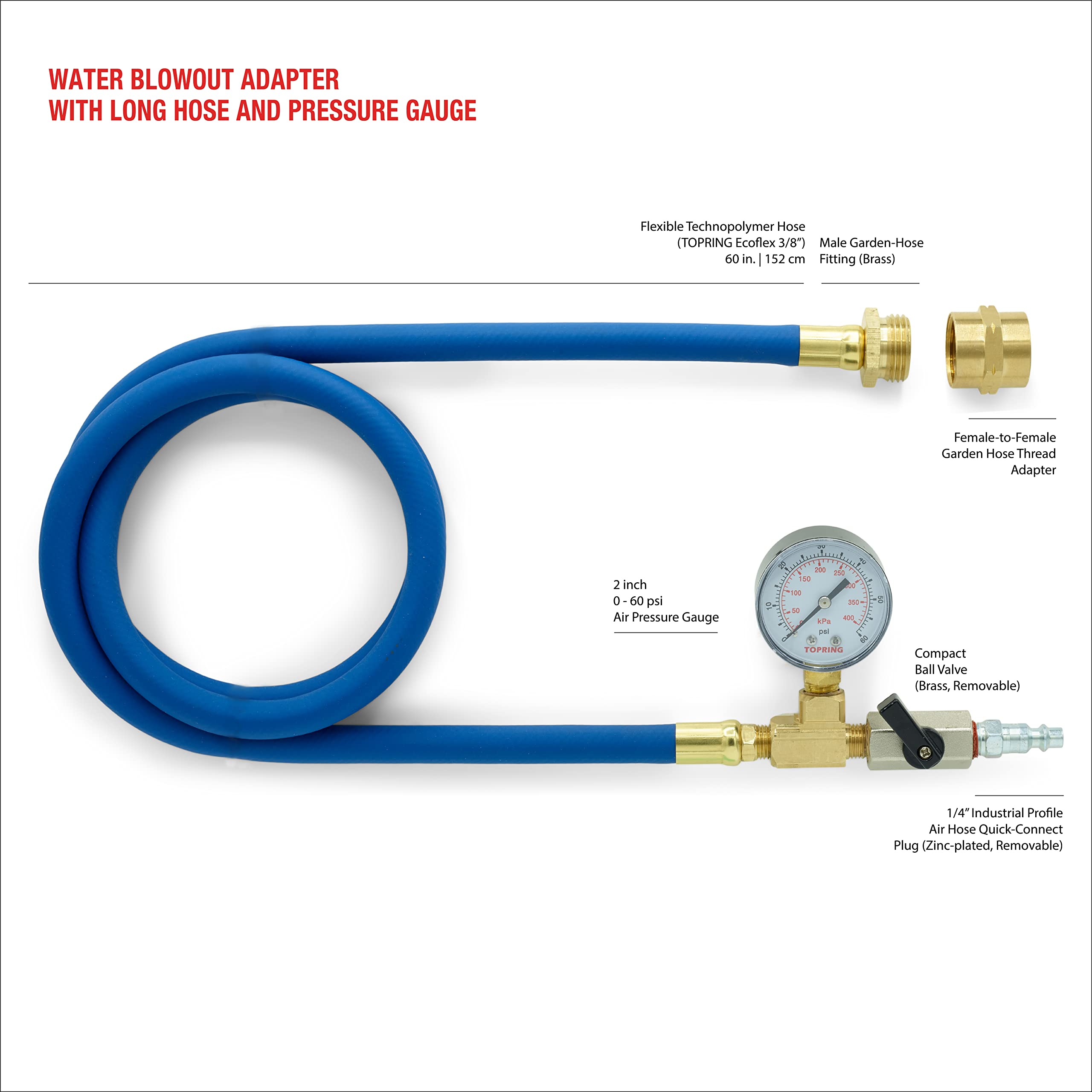

Illustrative image related to air pressure gauge hose

Digital gauge hoses come equipped with integrated digital pressure displays that provide precise readings. This feature is particularly beneficial in automotive service and tire shops where accuracy is paramount. While they tend to be more expensive than traditional hoses, the convenience of easy-to-read digital displays can justify the investment for businesses that prioritize efficiency and accuracy in their operations. Buyers should also consider the need for battery replacements when evaluating these hoses.

Extension hoses are designed to offer longer reach, often featuring self-locking connectors for added convenience. These hoses are particularly useful in tire inflation and automotive maintenance, allowing technicians to operate from a distance without compromising on performance. Although they can be bulkier and require additional storage space, the increased reach can enhance productivity and efficiency in various applications. Businesses should weigh the trade-offs of size versus functionality when selecting these hoses.

Copper hoses are known for their rigidity and excellent thermal conductivity, making them ideal for mechanical applications and HVAC systems. Their durability and resistance to high temperatures make them suitable for demanding environments. However, their lack of flexibility and heavier weight compared to other hose types may limit their use in certain applications. B2B buyers should assess the specific needs of their operations to determine if the benefits of copper hoses align with their requirements.

| Промышленность/сектор | Specific Application of air pressure gauge hose | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Automotive | Tire pressure monitoring and inflation | Ensures optimal tire performance and safety | Durability, compatibility with various tire valves |

| Manufacturing & Industrial | Pneumatic tool operation and maintenance | Enhances operational efficiency and reduces downtime | Pressure rating, material compatibility, length options |

| Сельское хозяйство | Equipment calibration for irrigation systems | Improves water conservation and crop yield | Weather resistance, flexibility, and length requirements |

| Строительство | Pressure testing of concrete and other materials | Validates material integrity and safety standards | Resistance to abrasion, pressure ratings, and certifications |

| Нефть и газ | Monitoring pressure in pipelines and drilling equipment | Prevents leaks and ensures operational safety | High pressure tolerance, chemical resistance, and certifications |

In the automotive industry, air pressure gauge hoses are essential for tire pressure monitoring and inflation. Accurate tire pressure is crucial for vehicle safety, fuel efficiency, and tire longevity. These hoses allow for easy connection to tire inflators and gauges, providing real-time pressure readings. Buyers in this sector must consider the durability of the hose, its compatibility with various tire valve types, and the hose length to ensure effective use across different vehicles.

Illustrative image related to air pressure gauge hose

In manufacturing and industrial settings, air pressure gauge hoses are vital for the operation and maintenance of pneumatic tools. These hoses facilitate the transfer of compressed air, ensuring tools operate efficiently and effectively. A well-maintained air pressure gauge hose can significantly reduce downtime caused by equipment failures. Buyers should prioritize sourcing hoses with appropriate pressure ratings, material compatibility with specific industrial environments, and various length options to meet diverse operational needs.

In agriculture, air pressure gauge hoses are used for calibrating equipment in irrigation systems. Proper calibration ensures that water is distributed evenly, optimizing water conservation and enhancing crop yields. These hoses must be weather-resistant and flexible to withstand outdoor conditions. Buyers should focus on sourcing hoses that meet specific length requirements and are designed to endure exposure to various environmental elements, ensuring reliability in agricultural applications.

In the construction industry, air pressure gauge hoses are used for pressure testing materials like concrete. This testing is critical to validate the integrity and safety of construction materials before use. By ensuring that materials meet required safety standards, businesses can avoid costly failures and ensure worker safety. Buyers must consider hoses that are resistant to abrasion and have high-pressure ratings, along with necessary certifications to comply with industry regulations.

In the oil and gas sector, air pressure gauge hoses are crucial for monitoring pressure in pipelines and drilling equipment. Accurate pressure readings help prevent leaks and ensure operational safety, which is vital in this high-stakes industry. Buyers should look for hoses that can tolerate high pressures, offer chemical resistance, and possess relevant certifications to guarantee safety and compliance with industry standards. This ensures that equipment operates efficiently and safely under extreme conditions.

Проблема: B2B buyers often face challenges with air pressure gauge hoses that deliver inaccurate readings, leading to potential operational inefficiencies and safety concerns. In industries such as automotive or manufacturing, even minor discrepancies in pressure can result in equipment malfunction or product defects. Buyers may find themselves stuck with low-quality hoses that do not maintain calibration, which ultimately affects the reliability of their tire inflators or pneumatic tools.

Illustrative image related to air pressure gauge hose

Решение: To combat this issue, it is crucial to invest in high-quality air pressure gauge hoses that are designed for durability and accuracy. When sourcing hoses, look for products that come with a calibration certification, ensuring they meet industry standards. Additionally, consider hoses made from reinforced materials that resist wear and tear over time. Regular maintenance, including periodic recalibration and inspection, will also help maintain accuracy. Suppliers like Steelman Tools and JACO provide hoses with built-in gauges that simplify the monitoring process, ensuring that your operations run smoothly without the risk of inaccurate readings.

Проблема: Frequent damage to air pressure gauge hoses can be a significant pain point for B2B buyers, particularly in rugged work environments. Hoses can suffer from abrasions, kinks, or cuts, leading to air leaks that compromise pressure readings and inflate tires inaccurately. This can result in wasted resources and increased downtime, which is particularly costly in high-volume operations.

Решение: To minimize hose damage, it is essential to select hoses that are specifically designed for heavy-duty use. Look for air pressure gauge hoses made from high-quality rubber or thermoplastic materials that offer superior resistance to wear and environmental factors. Additionally, consider investing in protective accessories such as hose reels or guards that can shield the hoses from physical damage while in use. Implementing a regular inspection routine to check for signs of wear can also preemptively identify issues before they lead to significant operational challenges. Suppliers like Pegasus Robotics offer durable hoses that withstand harsh conditions, ensuring longevity and reliability.

Illustrative image related to air pressure gauge hose

Проблема: Compatibility between air pressure gauge hoses and existing equipment can be a major hurdle for B2B buyers. Many businesses may find that their current hoses do not fit their tire inflators or pneumatic tools, leading to inefficient setups and the need for additional adapters or fittings. This not only adds to operational costs but can also lead to frustration among staff who rely on efficient workflows.

Решение: To avoid compatibility issues, it is advisable to conduct a thorough assessment of your existing equipment before purchasing air pressure gauge hoses. Check the specifications of your inflators and tools, particularly the required connection types and sizes. When sourcing hoses, opt for those that come with multiple fitting options or are customizable, allowing for greater flexibility in usage. Suppliers like Glowshift Direct offer comprehensive installation kits that include all necessary fittings, ensuring seamless integration with your equipment. This proactive approach will not only streamline your operations but also enhance the overall efficiency of your processes.

When selecting materials for air pressure gauge hoses, it is essential to consider properties such as temperature and pressure ratings, corrosion resistance, and overall durability. Below, we analyze four common materials used in the manufacturing of these hoses, focusing on their suitability for various applications and the specific needs of international B2B buyers.

Ключевые свойства:

Rubber hoses typically offer a good balance of flexibility and durability, with temperature ratings ranging from -40°F to 212°F (-40°C to 100°C). They are generally resistant to abrasion but can be susceptible to ozone degradation.

Плюсы и минусы:

Rubber is cost-effective and easy to manufacture, making it a popular choice for many applications. However, its susceptibility to environmental factors like UV light and ozone can limit its lifespan, particularly in harsh climates.

Влияние на применение:

Rubber hoses are suitable for air and water applications but may not be ideal for corrosive media. They are commonly used in automotive and industrial settings.

Соображения для международных покупателей:

Buyers in regions like Africa and South America should ensure compliance with local environmental standards, as rubber may not perform well in extreme conditions. In contrast, European buyers might prefer hoses that meet DIN standards for durability and safety.

Ключевые свойства:

PVC hoses are lightweight and have a temperature rating of approximately -10°F to 150°F (-23°C to 65°C). They offer good chemical resistance and are less prone to UV degradation compared to rubber.

Плюсы и минусы:

While PVC is affordable and easy to produce, it is less flexible than rubber and can become brittle over time, especially in cold temperatures. This limits its effectiveness in applications requiring high flexibility.

Illustrative image related to air pressure gauge hose

Влияние на применение:

PVC hoses are suitable for air and some chemical applications but are not recommended for high-pressure situations. They are often used in light-duty applications.

Соображения для международных покупателей:

Buyers from the Middle East may benefit from PVC hoses’ resistance to UV light, while European buyers should ensure compliance with EU regulations regarding material safety and environmental impact.

Ключевые свойства:

Stainless steel hoses can withstand high temperatures (up to 1,200°F or 650°C) and high pressures, making them ideal for demanding applications. They are highly resistant to corrosion and wear.

Плюсы и минусы:

Stainless steel offers exceptional durability and longevity but comes at a higher cost. Manufacturing stainless steel hoses is more complex, requiring specialized techniques.

Illustrative image related to air pressure gauge hose

Влияние на применение:

These hoses are suitable for high-pressure air applications and corrosive environments, making them ideal for industrial and automotive uses.

Соображения для международных покупателей:

Buyers in Europe may require hoses that meet stringent standards like ASTM or DIN for material quality. Buyers in regions with harsh environmental conditions, such as Africa, should consider stainless steel for its corrosion resistance.

Ключевые свойства:

Nylon hoses typically have a temperature range of -40°F to 200°F (-40°C to 93°C) and offer good chemical resistance. They are lightweight and flexible, making them easy to handle.

Плюсы и минусы:

Nylon is durable and resistant to abrasion, but it can be more expensive than rubber and PVC. Its flexibility makes it suitable for various applications, but it may not be ideal for high-pressure situations.

Влияние на применение:

Nylon hoses are often used in pneumatic applications and can handle various gases and liquids, but they may not be suitable for high-pressure air systems.

Illustrative image related to air pressure gauge hose

Соображения для международных покупателей:

Buyers from South America should ensure that nylon hoses meet local safety standards, while those in Europe may look for compliance with EU regulations regarding material quality.

| Материал | Typical Use Case for air pressure gauge hose | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Резина | Automotive and industrial applications | Cost-effective and flexible | Susceptible to UV and ozone degradation | Низкий |

| ПВХ | Light-duty applications | Lightweight and good chemical resistance | Less flexible and can become brittle | Низкий |

| Нержавеющая сталь | High-pressure and corrosive environments | Exceptional durability and corrosion resistance | Более высокая стоимость и сложность производства | Высокий |

| Нейлон | Pneumatic applications | Прочный и гибкий | More expensive and limited high-pressure use | Средний |

This analysis provides a comprehensive overview of the materials used in air pressure gauge hoses, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

The manufacturing process of air pressure gauge hoses involves several critical stages, each designed to ensure that the final product meets stringent quality and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

Подготовка материалов

The first step in manufacturing air pressure gauge hoses is the selection and preparation of raw materials. Typically, high-quality rubber or thermoplastic materials are used for their durability and flexibility. These materials are sourced from reputable suppliers who comply with international standards. Before production begins, materials undergo rigorous inspection to confirm their quality, which includes checking for defects, ensuring appropriate hardness, and verifying compliance with industry regulations.

Illustrative image related to air pressure gauge hose

Техника формовки

Once the materials are prepared, they undergo forming techniques, which may involve extrusion or molding. In extrusion, raw materials are melted and forced through a die to create a continuous hose shape. This method allows for precise control over the hose dimensions and wall thickness. Alternatively, molding techniques may be used for more complex shapes or fittings, ensuring that each component of the hose is designed for optimal performance.

Assembly Processes

After the hoses are formed, the next stage is assembly. This involves attaching fittings, connectors, and any other components necessary for the hose’s functionality. Automated machinery is often employed to ensure consistent assembly quality, while manual checks are performed to address any potential issues. The integration of technology, such as robotic assembly, can further enhance precision and efficiency in this stage.

Завершающие штрихи

The final stage in the manufacturing process is finishing. This includes applying surface treatments, conducting quality checks, and packaging the hoses for shipment. Surface treatments may involve adding protective coatings or markings that comply with industry standards. It is during this phase that the hoses are thoroughly tested for leaks, durability, and performance under various pressure conditions.

Illustrative image related to air pressure gauge hose

Quality assurance (QA) is a cornerstone of the manufacturing process for air pressure gauge hoses, ensuring that each product meets both customer expectations and regulatory requirements.

What International Standards Guide Quality Assurance?

Manufacturers of air pressure gauge hoses typically adhere to several international standards, the most prominent being ISO 9001. This standard outlines a framework for a quality management system (QMS), emphasizing continuous improvement and customer satisfaction. Other relevant certifications may include CE marking, indicating compliance with European health, safety, and environmental protection standards, and API standards for hoses used in the oil and gas industry.

Каковы ключевые контрольные точки контроля качества?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Illustrative image related to air pressure gauge hose

Which Testing Methods Are Commonly Used?

Testing methods for air pressure gauge hoses include hydrostatic testing, which assesses the hose’s ability to withstand high pressures, and burst testing, which determines the maximum pressure the hose can handle before failure. Additionally, visual inspections are crucial for detecting surface defects, while dimensional checks ensure that the hoses meet specified measurements.

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to mitigate risks associated with product quality.

Каковы лучшие практики проведения аудита поставщиков?

Conducting regular audits of suppliers can provide insights into their quality control practices. Buyers should assess suppliers’ adherence to international standards like ISO 9001 and their ability to produce consistent quality products. It’s advisable to request documentation of previous audits, quality reports, and certifications to understand the supplier’s commitment to quality.

How Can Buyers Use Third-Party Inspection Services?

Engaging third-party inspection services can further enhance confidence in supplier quality. These independent entities can conduct inspections at various stages of the manufacturing process, providing an unbiased evaluation of the product quality. This is particularly beneficial for buyers unfamiliar with local manufacturing practices or those sourcing from regions with varying quality standards.

What Are the Unique QC Considerations for Different Regions?

International buyers must also consider regional variations in quality control and standards compliance. For instance, European buyers may prioritize CE certification, while buyers in Africa or South America might focus on local compliance standards. Understanding these nuances is crucial for ensuring that the products meet the specific requirements of the target market.

The manufacturing processes and quality assurance practices for air pressure gauge hoses are vital for ensuring that the final products meet high standards of performance and reliability. By understanding the stages of manufacturing, the role of quality assurance, and how to verify supplier practices, B2B buyers can make informed decisions when sourcing these critical components. Adhering to international standards and implementing robust quality control measures not only enhances product integrity but also builds trust in the supplier relationship, fostering long-term business success.

When sourcing air pressure gauge hoses, it’s essential to follow a structured approach to ensure that you select the right products for your business needs. This guide provides a step-by-step checklist to help international B2B buyers navigate the procurement process effectively.

Before beginning the sourcing process, outline the technical requirements for the air pressure gauge hoses you need. This includes determining the appropriate pressure ratings, hose lengths, materials (such as rubber or PVC), and compatibility with existing equipment. Having clear specifications helps to streamline your search and ensures you only consider products that meet your operational needs.

Understanding current market trends and pricing is crucial for making informed purchasing decisions. Research the average costs of air pressure gauge hoses within your target markets, such as Africa, Europe, and South America. Look for fluctuations in pricing based on materials and technological advancements, which can affect your budget and sourcing strategy.

Illustrative image related to air pressure gauge hose

Thoroughly vet potential suppliers to ensure they can meet your specifications and reliability requirements. Request company profiles, product catalogs, and references from existing clients, particularly those in similar industries or regions. It’s also important to consider their reputation in the market, which can often be assessed through online reviews and industry forums.

Ensure that the suppliers you are considering hold relevant certifications and comply with international standards. Look for certifications such as ISO 9001 for quality management or specific certifications that pertain to air pressure gauge products. Compliance not only ensures product quality but also mitigates risks associated with international trade.

Before placing a bulk order, request samples of the air pressure gauge hoses to evaluate their quality and performance. Conduct tests to check for durability, flexibility, and resistance to pressure. This step is vital as it allows you to assess whether the hoses meet your operational standards before making a significant financial commitment.

After confirming the quality of the hoses, consider the after-sales support and warranty options provided by the supplier. A good supplier should offer comprehensive support, including troubleshooting, maintenance guidance, and warranty terms. This ensures that you have the necessary support in case of defects or issues, protecting your investment in the long run.

Once you have selected a supplier, finalize the terms and conditions of the purchase. This includes negotiating pricing, payment terms, delivery schedules, and return policies. Clear communication and documentation of these terms are crucial to avoid misunderstandings and ensure a smooth transaction.

Illustrative image related to air pressure gauge hose

Following this checklist will help you navigate the procurement process for air pressure gauge hoses efficiently, ensuring that you make informed decisions that align with your business requirements.

When sourcing air pressure gauge hoses, it’s essential to understand the various cost components that contribute to the final price. The primary cost elements include:

Материалы: The choice of materials significantly impacts the cost. High-quality rubber, metal fittings, and specialized polymers can elevate prices, while lower-grade materials reduce costs but may compromise performance and durability.

Труд: Labor costs involve the expenses associated with skilled workers involved in manufacturing, assembling, and testing the hoses. Regions with lower labor costs can offer more competitive pricing, making it essential for international buyers to consider the supplier’s geographical location.

Производственные накладные расходы: This encompasses all indirect costs associated with production, including utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help minimize these overheads, allowing suppliers to offer more competitive prices.

Инструментальная оснастка: Custom tooling for specialized hoses can be a significant upfront cost. For mass production, however, this cost can be amortized over larger order volumes, reducing the per-unit cost.

Контроль качества (QC): Implementing stringent QC measures ensures that the hoses meet industry standards and buyer specifications, which can add to the cost. However, investing in QC can lead to lower defect rates and increased customer satisfaction.

Логистика: Shipping and handling costs vary significantly based on the distance, shipping method, and volume of the order. Buyers should consider these costs as part of the total sourcing expenses.

Маржа: Suppliers typically incorporate a profit margin into their pricing. Understanding the competitive landscape and negotiating effectively can help buyers secure better deals.

Several factors influence the pricing of air pressure gauge hoses:

Объем/MOQ (минимальное количество заказа): Larger orders often lead to reduced per-unit costs due to economies of scale. Negotiating favorable terms for higher volumes can significantly lower costs.

Технические характеристики и персонализация: Custom specifications, such as length, diameter, or specific fittings, can increase costs. Buyers should weigh the need for customization against the potential price increase.

Сертификация материалов и качества: Hoses made from higher-grade materials or those with specific quality certifications (e.g., ISO standards) typically command higher prices. Buyers must assess whether the added quality justifies the cost.

Факторы поставщика: Supplier reliability, reputation, and production capabilities can also impact pricing. Suppliers with a proven track record may charge a premium for their products, while new entrants might offer lower prices to gain market share.

Инкотермс: The chosen Incoterms (International Commercial Terms) affect logistics costs and responsibilities. Understanding these terms can help buyers make informed decisions regarding shipping and associated costs.

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, several strategies can optimize sourcing costs:

Обсудите условия: Always negotiate pricing, payment terms, and delivery schedules. Suppliers may have flexibility, especially for larger orders or long-term contracts.

Учитывайте общую стоимость владения (TCO): Evaluate the long-term costs associated with the hoses, including maintenance, replacement, and potential downtime due to quality issues. A lower upfront cost may not always equate to a better deal in the long run.

Research and Compare Suppliers: Conduct thorough market research to identify multiple suppliers. Comparing prices, quality, and service can help secure the best deal.

Leverage Local Knowledge: Engage local representatives or consultants who understand regional dynamics, pricing trends, and supplier capabilities. This can provide valuable insights and enhance negotiation leverage.

Будьте внимательны к нюансам ценообразования: Different regions may have varying pricing structures influenced by local demand, import tariffs, and shipping costs. Understanding these nuances can help buyers make more informed decisions.

Prices for air pressure gauge hoses can fluctuate based on market conditions, supplier agreements, and other external factors. The prices mentioned in this analysis are indicative and may vary. Buyers are encouraged to obtain quotes from multiple suppliers to ensure the best pricing for their specific needs.

When assessing options for measuring air pressure, particularly in tire inflation and pneumatic systems, understanding the available alternatives to air pressure gauge hoses is critical for B2B buyers. Various technologies and methods can achieve similar results, but they vary in performance, cost, ease of implementation, maintenance, and best use cases. Below, we present a comparison of air pressure gauge hoses against two viable alternatives: digital tire inflators and mechanical air pressure gauge kits.

| Сравнительный аспект | Air Pressure Gauge Hose | Digital Tire Inflator | Mechanical Air Pressure Gauge Kit |

|---|---|---|---|

| Производительность | Reliable for accurate readings; requires manual operation | Provides quick inflation and pressure reading; digital display for precision | Offers accurate readings; requires manual inflation |

| Стоимость | Generally low-cost ($5 – $15) | Moderate cost ($20 – $150) | Low to moderate cost ($10 – $40) |

| Простота реализации | Simple to attach and use | Requires basic knowledge of digital devices | Easy to use; minimal setup required |

| Техническое обслуживание | Low maintenance; check for wear | Requires battery replacement; needs care to avoid damage | Low maintenance; durability varies by model |

| Лучший пример использования | Ideal for regular tire checks and automotive applications | Best for quick inflation in emergencies or frequent use | Suitable for mechanical systems and automotive applications |

Digital tire inflators are an innovative alternative that combines pressure measurement with inflation capabilities. They typically feature a built-in gauge that provides instant readings on a digital display. The main advantage is the speed and efficiency they offer, making them ideal for emergency situations or high-volume applications where time is of the essence. However, they come at a higher cost and may require occasional battery replacements, which can be a drawback in resource-limited environments.

Mechanical air pressure gauge kits are another alternative that provides reliable pressure readings. These kits typically include a gauge, hose, and fittings, allowing users to measure pressure accurately. They are known for their durability and simplicity, making them a great choice for users who prefer a straightforward, no-frills approach. However, they may lack the speed and convenience of digital models and require manual inflation, which can be a disadvantage in fast-paced settings.

When deciding between an air pressure gauge hose and its alternatives, B2B buyers should consider their specific needs and operational context. If quick inflation and precision are paramount, a digital tire inflator may be the best choice, despite the higher cost and maintenance requirements. For regular use with a focus on durability and low cost, an air pressure gauge hose or mechanical gauge kit could be more suitable. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that align with their operational demands and budgetary constraints.

Understanding the essential technical properties of air pressure gauge hoses is crucial for B2B buyers to ensure compatibility, durability, and performance in various applications. Here are several critical specifications:

Класс материала

Air pressure gauge hoses are commonly constructed from materials such as rubber, PVC, or reinforced thermoplastic. The choice of material affects flexibility, temperature resistance, and durability. For instance, rubber hoses are often preferred for their resilience and ability to withstand high pressures, while PVC hoses are lightweight and more cost-effective. Selecting the appropriate material is vital for ensuring the hose can handle specific environmental conditions and pressures, reducing the risk of failure.

Номинальное давление

The pressure rating indicates the maximum pressure the hose can safely handle, typically expressed in PSI (pounds per square inch). For air pressure gauge hoses, ratings can range from 100 PSI to over 300 PSI. Buyers must ensure that the hose’s pressure rating aligns with the intended application, as using a hose rated below the required pressure can lead to catastrophic failure and safety hazards.

Temperature Range

This specification defines the operational temperature limits of the hose, which can affect its performance and longevity. For example, a hose that operates effectively between -40°F to 200°F may be suitable for various environments, including automotive and industrial applications. Understanding the temperature range ensures that the hose will maintain its integrity under varying conditions.

Diameter and Length

The inner diameter of the hose affects airflow and pressure drop, while the length can influence the ease of use and installation. Standard diameters for air pressure gauge hoses usually range from 1/4 inch to 1/2 inch. Buyers must consider the specific requirements of their equipment and the intended application when selecting diameter and length to optimize performance.

Connector Type

Different hoses come with various connector types, such as threaded or quick-release fittings. The compatibility of these connectors with existing equipment is crucial for ensuring a seamless connection and preventing leaks. Selecting the right connector type can enhance usability and efficiency in operations.

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end products. In the context of air pressure gauge hoses, OEM suppliers typically provide hoses designed specifically for certain gauges or equipment, ensuring compatibility and performance.

MOQ (минимальное количество заказа)

MOQ defines the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is crucial for buyers to manage inventory effectively and to negotiate better pricing based on order volume.

RFQ (запрос котировок)

An RFQ is a formal request sent to suppliers to obtain price quotes for specific quantities of products. For air pressure gauge hoses, an RFQ helps buyers compare pricing, delivery times, and terms from multiple suppliers, enabling informed purchasing decisions.

Инкотермс (международные коммерческие термины)

Incoterms are a set of pre-defined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Knowing the relevant Incoterms helps buyers understand shipping costs, risks, and responsibilities associated with the delivery of air pressure gauge hoses.

Время выполнения

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is critical for planning and ensuring that businesses have the necessary hoses on hand when needed.

By grasping these technical properties and trade terminology, B2B buyers can make informed decisions when sourcing air pressure gauge hoses, optimizing their supply chain, and ensuring operational efficiency.

The air pressure gauge hose market is experiencing significant growth, driven by the increasing demand for precision in tire inflation and other pneumatic applications. As industries expand globally, particularly in emerging markets in Africa, South America, and the Middle East, the need for reliable and efficient air pressure solutions has never been more critical. In Europe, particularly Germany, the focus is on high-quality standards and technological innovations that enhance the performance and longevity of air pressure gauge hoses.

Key trends influencing the market include the integration of smart technology in air pressure gauges, which allows for real-time monitoring and data analytics. This shift towards digitalization enhances operational efficiency and reduces human error. Moreover, manufacturers are increasingly adopting modular designs for hoses, enabling easier replacement and maintenance, which is particularly appealing to B2B buyers looking for cost-effective solutions.

Another emerging trend is the rise of e-commerce platforms that facilitate the sourcing of air pressure gauge hoses. International buyers can now access a wider array of suppliers, compare prices, and evaluate product specifications more efficiently. This trend is especially beneficial for buyers in regions like Nigeria and Brazil, where traditional sourcing methods may have been limited.

Sustainability is becoming a pivotal consideration in the air pressure gauge hose sector, as environmental awareness among consumers and businesses rises. The production and disposal of hoses can have significant environmental impacts, prompting buyers to seek out suppliers who prioritize eco-friendly practices. This includes using sustainable materials in the manufacturing process and implementing waste reduction strategies.

Ethical sourcing is equally important, as businesses aim to ensure that their supply chains are free from exploitation and harmful labor practices. B2B buyers are increasingly looking for suppliers with ‘green’ certifications, which indicate compliance with environmental standards and ethical labor practices. For instance, hoses made from recycled materials or those that are designed for longevity can appeal to environmentally conscious buyers.

Investing in sustainable and ethically sourced products not only enhances brand reputation but also aligns with the growing consumer preference for responsible business practices. Suppliers that can demonstrate their commitment to sustainability will likely gain a competitive edge in the market.

The air pressure gauge hose industry has evolved considerably over the past few decades, transitioning from rudimentary designs to advanced, high-performance solutions. Initially, hoses were primarily made from rubber, which was prone to wear and tear. The introduction of synthetic materials has significantly improved durability and resistance to environmental factors.

The evolution of technology has also played a crucial role, with innovations such as digital gauges and smart inflators enhancing accuracy and user experience. Today, air pressure gauge hoses are integral to various industries, including automotive, manufacturing, and construction, underscoring their relevance in maintaining safety and efficiency.

As the market continues to adapt to new technologies and sustainability demands, international B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their operational needs and corporate values.

How do I ensure the quality of air pressure gauge hoses from suppliers?

To ensure quality, it’s essential to conduct thorough supplier vetting. Look for suppliers with certifications such as ISO 9001, which indicates adherence to quality management standards. Request samples to evaluate the hose’s durability, flexibility, and pressure rating before placing bulk orders. Additionally, consider visiting the supplier’s manufacturing facility if feasible, or use third-party inspection services to verify product quality before shipment.

What specifications should I consider when sourcing air pressure gauge hoses?

When sourcing air pressure gauge hoses, consider factors such as the hose material (e.g., rubber or PVC), pressure rating, length, and compatibility with your existing equipment. Additionally, check for features like temperature resistance and flexibility, which can affect performance in different environments. Understanding these specifications will help you choose a hose that meets your operational needs and ensures reliability in use.

What are the common payment terms for international purchases of air pressure gauge hoses?

Payment terms can vary significantly among suppliers, but common practices include letters of credit, advance payments, or payment upon delivery. For larger orders, consider negotiating favorable terms, such as partial upfront payments and the remainder upon shipment. Ensure that you clarify the payment method and currency beforehand to avoid misunderstandings and facilitate smoother transactions.

What is the typical minimum order quantity (MOQ) for air pressure gauge hoses?

MOQs can vary based on the supplier and the type of hose you are ordering. Generally, MOQs for air pressure gauge hoses range from 100 to 500 units. However, some suppliers may offer flexibility, especially for first-time buyers or smaller businesses. Discuss your specific needs with potential suppliers to explore options and negotiate MOQs that align with your purchasing capabilities.

How can I customize air pressure gauge hoses to suit my business needs?

Customization options often include varying lengths, colors, and fittings to match your equipment. Many suppliers offer bespoke solutions to accommodate specific requirements. When discussing customization, provide detailed specifications, including the intended application, pressure ratings, and any other relevant information. It’s also beneficial to request prototypes or samples to evaluate the customizations before finalizing your order.

What should I know about logistics when importing air pressure gauge hoses?

Logistics play a critical role in the timely delivery of your air pressure gauge hoses. Consider factors such as shipping methods, lead times, and customs regulations in your country. Partner with a reliable freight forwarder who understands the complexities of international trade, including import duties and taxes. Ensure that your supplier provides all necessary documentation to facilitate smooth customs clearance.

What are the best practices for maintaining air pressure gauge hoses?

To ensure longevity and optimal performance, regularly inspect hoses for signs of wear or damage, such as cracks or leaks. Store hoses in a cool, dry place away from direct sunlight to prevent degradation of materials. Additionally, clean hoses after use and avoid exposing them to harsh chemicals. Following these practices can help maintain the integrity of the hoses and extend their service life.

How do I handle disputes with suppliers regarding air pressure gauge hoses?

In the event of a dispute, start by reviewing the contract terms and conditions to understand your rights and obligations. Communicate directly with the supplier to address the issue, providing evidence and documentation to support your claims. If the matter cannot be resolved amicably, consider mediation or arbitration as alternative dispute resolution methods. Engaging a legal expert familiar with international trade can also provide guidance on the best course of action.

Домен: jacosuperiorproducts.com

Зарегистрирован: 2014 (11 лет)

Введение: Lightning S2X Tire Inflator Hose Extension Self-Locking Nozzle | Patented Air Hose Adapter for Tire Pumps (Open Flow) – Price: $27.99 (originally $39.99)\nLightning L2X Tire Inflator Hose Extension Self-Locking Nozzle | Patented Lock-on Air Hose Adapter for Tire Pumps (Open Flow) – Price: $29.99 (originally $39.99)\nFeatures: Designed to replace standard screw-on, clip-on, or thumb-lock tire valve…

Домен: autometer.com

Зарегистрирован: 1996 (29 лет)

Введение: Air Hose Assembly for Tire Pressure Replacement, 24 inches in length, includes strain reliefs, bleed valve, and bullet foot air chuck.

Домен: glowshiftdirect.com

Зарегистрирован: 2005 (20 лет)

Введение: GlowShift Mechanical Air Pressure Gauge Install Kit, Extended holiday returns through January 31st, Free shipping on all orders over $50, Customer service available Mon-Fri: 9:00 AM – 5:00 PM EST, Various gauge types including boost gauges, oil pressure gauges, fuel pressure gauges, and more, Multiple gauge series available including 7 Color Series, Elite 10 Color Series, MaxTow Series, and Classi…

In the competitive landscape of air pressure gauge hoses, strategic sourcing emerges as a crucial element for international B2B buyers. By focusing on quality, compatibility, and supplier reliability, businesses can significantly enhance operational efficiency and customer satisfaction. The diverse range of products available—from self-locking nozzle extensions to complete hose kits—provides numerous options tailored to specific industry needs.

As buyers in Africa, South America, the Middle East, and Europe navigate their sourcing decisions, understanding local market dynamics and supplier capabilities becomes vital. This approach not only mitigates risks associated with supply chain disruptions but also fosters long-term partnerships that can lead to innovation and improved product offerings.

Looking ahead, the demand for high-quality air pressure gauge hoses is expected to grow, driven by advancements in automotive and industrial applications. B2B buyers are encouraged to actively engage with suppliers, assess their product lines, and explore customization options to stay ahead in the market. By prioritizing strategic sourcing, businesses can ensure they are equipped with the best tools to meet evolving industry standards and customer expectations.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.