In today’s competitive global market, sourcing reliable solutions for inflating tires presents a significant challenge for B2B buyers, especially in diverse regions such as Africa, South America, the Middle East, and Europe. Proper tire inflation is not just a matter of safety; it directly impacts fuel efficiency, tire longevity, and overall vehicle performance. This comprehensive guide offers a deep dive into the essential aspects of tire inflation, including various types of inflation technologies, applications across different vehicle categories, and the critical process of vetting suppliers.

As you navigate this complex landscape, you will gain insights into cost considerations, the importance of tire pressure maintenance, and the latest innovations in tire inflation methods. With a focus on empowering international buyers, this guide equips you with the knowledge needed to make informed purchasing decisions that enhance operational efficiency and safety. By understanding the nuances of tire inflation, you can better evaluate supplier offerings and ensure compliance with local and international standards.

Whether you are based in bustling urban centers or remote regions, this guide aims to support your quest for high-quality tire inflation solutions that meet your specific business needs. Unlock the potential of your fleet and improve your bottom line by mastering the art of tire inflation with the insights provided in this essential resource.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Compressed Air Inflation | Utilizes standard air compressors for inflation. | Automotive service stations, fleet management. | Плюсы: Widely available, cost-effective. Конс: Higher air loss rate, requires regular monitoring. |

| Nitrogen Inflation | Uses nitrogen gas, reducing air loss and pressure fluctuations. | Premium vehicle maintenance, racing teams. | Плюсы: Longer tire life, improved fuel efficiency. Конс: Higher initial cost, limited availability. |

| Portable Air Compressors | Compact devices for on-the-go tire inflation. | Personal use, small fleet operations. | Плюсы: Convenient, easy to use. Конс: Limited power, may require frequent charging. |

| Tire Pressure Monitoring Systems (TPMS) | Automated systems that monitor tire pressure continuously. | Fleet management, automotive manufacturing. | Плюсы: Enhances safety, reduces maintenance costs. Конс: Initial installation cost, potential for sensor failure. |

| Manual Inflation | Traditional method using handheld pumps and gauges. | Small businesses, DIY mechanics. | Плюсы: Low cost, no power source needed. Конс: Time-consuming, requires manual checks for accuracy. |

Compressed air inflation is the most common method for inflating tires, utilizing air compressors found at service stations. This method is cost-effective and easily accessible for businesses managing fleets or automotive service stations. However, compressed air can lead to quicker air loss, requiring regular pressure checks to maintain optimal tire performance. B2B buyers should consider the availability of air compressors and the need for consistent tire pressure monitoring in their operations.

Nitrogen inflation is a premium option that offers several advantages, particularly for high-performance vehicles and fleets requiring enhanced tire longevity. Nitrogen’s larger molecules reduce air seepage, maintaining pressure longer than compressed air. This method is especially beneficial for businesses focused on fuel efficiency and tire lifespan, such as racing teams or luxury vehicle service providers. However, the higher cost and limited access to nitrogen inflation services may deter some buyers.

Portable air compressors are ideal for businesses that require flexibility in tire maintenance. These compact devices allow for quick inflation at any location, making them suitable for small fleet operations or personal use. While they offer convenience, buyers should be aware of their limited power and potential need for frequent recharging. Assessing the volume of tires needing inflation can help determine if a portable compressor meets operational needs.

TPMS provides a modern solution for businesses looking to enhance safety and efficiency in tire management. By continuously monitoring tire pressure, these systems can alert users to issues before they become significant problems, reducing maintenance costs and improving vehicle safety. While the initial installation may be costly, the long-term benefits of reduced tire wear and improved fuel economy make TPMS a valuable investment for fleet managers and automotive manufacturers.

Manual inflation, using handheld pumps and gauges, remains a practical option for small businesses or DIY mechanics. This method is low-cost and does not require electrical power, making it accessible in various situations. However, it can be time-consuming and relies heavily on the user’s ability to accurately gauge tire pressure. For businesses with limited budgets or those operating in remote areas, manual inflation may still be a suitable choice.

| Промышленность/сектор | Specific Application of inflating tires | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Transportation and Logistics | Fleet Management for Cargo Vehicles | Enhanced fuel efficiency and reduced tire wear | Reliable tire pressure monitoring systems; bulk tire supplies |

| Сельское хозяйство | Inflation for Agricultural Machinery Tires | Improved traction and reduced soil compaction | Durable tires suitable for various terrains; inflation equipment availability |

| Строительство | Heavy Equipment Tire Inflation | Increased safety and productivity on job sites | High-capacity inflators; maintenance contracts for tire services |

| Automotive Services | Tire Service Stations for Passenger Vehicles | Customer satisfaction through reliable service | Calibration of pressure gauges; partnerships with tire manufacturers |

| Mining and Quarrying | Tire Inflation for Off-Road Vehicles | Extended tire life and reduced operational costs | Specialized tires for rugged terrains; nitrogen inflation options |

In the transportation and logistics sector, proper tire inflation is critical for fleet management. Under-inflated tires can lead to increased fuel consumption and uneven wear, resulting in higher operational costs. Businesses must ensure that their fleet operates with reliable tire pressure monitoring systems to maintain optimal performance. International buyers should consider sourcing high-quality inflators and calibration tools to ensure accurate tire pressure management across diverse climates and terrains.

Agricultural machinery relies heavily on properly inflated tires to enhance traction and minimize soil compaction. In regions like Africa and South America, where agricultural practices are vital, ensuring that tires are inflated to the correct pressure can significantly impact crop yields. Buyers in this sector should focus on sourcing durable tires that can withstand various field conditions, alongside reliable inflation equipment that can be used in remote areas.

In the construction industry, tire inflation for heavy equipment is essential for maintaining safety and productivity. Properly inflated tires provide better stability and handling, reducing the risk of accidents on job sites. Companies should look for high-capacity inflators that can accommodate the specific needs of their heavy machinery. Additionally, establishing maintenance contracts for regular tire inspections and inflation can further enhance operational efficiency.

Illustrative image related to inflating tires

For automotive service stations, offering tire inflation services is a key value proposition that enhances customer satisfaction. Ensuring that passenger vehicles are equipped with properly inflated tires improves safety and fuel efficiency. Service providers must invest in reliable tire pressure gauges and inflators, ensuring they are calibrated accurately to avoid customer complaints. Building partnerships with tire manufacturers can also provide access to the latest tire technologies and training for service staff.

In mining and quarrying, tire inflation for off-road vehicles is crucial for extending tire life and reducing operational costs. These vehicles often operate in harsh conditions, making it essential to maintain optimal tire pressure for safety and performance. Businesses should consider sourcing specialized tires designed for rugged terrains and explore nitrogen inflation options to minimize air loss. This approach not only enhances tire longevity but also improves overall productivity in challenging environments.

Проблема: For businesses managing a fleet of vehicles, maintaining optimal tire pressure is a persistent challenge. Many fleet managers struggle with the inconsistency of tire pressure monitoring across various vehicles, leading to increased operational costs. Under-inflated tires can cause premature wear, reduce fuel efficiency, and compromise safety, particularly in regions with variable climates, such as Africa and South America. Additionally, the manual checking of tire pressure is time-consuming and prone to human error, exacerbating the issue of reliability.

Решение: Implementing a centralized tire pressure monitoring system (TPMS) can streamline this process significantly. These systems provide real-time data on tire pressure for all vehicles in the fleet, allowing managers to address issues proactively. When sourcing TPMS, look for solutions that integrate easily with existing fleet management software to facilitate seamless data reporting and alerts. Regular training for drivers on the importance of monitoring tire pressure and the use of TPMS can further enhance tire maintenance practices. This proactive approach not only extends tire lifespan but also contributes to fuel savings, making it a cost-effective strategy for fleet operations.

Проблема: Overinflation of tires is a common issue faced by B2B buyers in industries reliant on heavy machinery or transportation. In many cases, operators either misread pressure gauges or fail to adjust for temperature changes, leading to overinflated tires. This situation can severely affect vehicle handling and safety, particularly on wet or uneven surfaces, which is critical in construction or agricultural sectors where such equipment is frequently used. The result is not just increased tire wear, but also a higher risk of accidents, which can lead to significant liability issues.

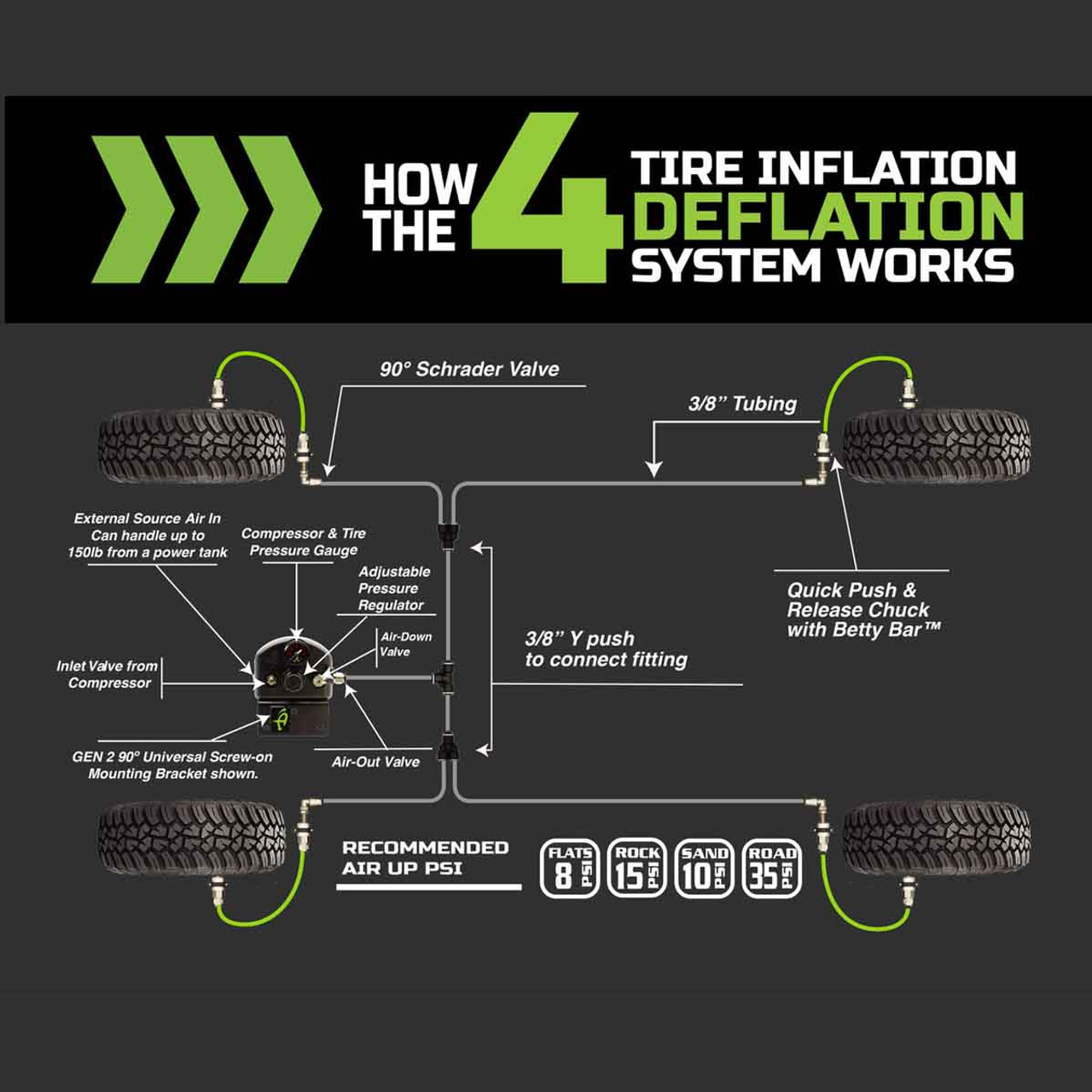

Illustrative image related to inflating tires

Решение: To combat the risks associated with overinflation, businesses should invest in high-quality, calibrated tire inflation gauges and ensure their employees are trained on their use. Establish a routine for checking tire pressure, especially before starting operations, to account for changes in temperature and load conditions. It’s also advisable to set up a standard operating procedure that includes regular maintenance checks and the use of portable air compressors to adjust tire pressure as needed. Additionally, engaging a tire service provider for periodic inspections can help ensure compliance with safety standards and reduce the risk of overinflation.

Проблема: Companies operating in remote areas often face the challenge of limited access to tire inflation services. This can be particularly problematic in regions with underdeveloped infrastructure, where reaching a service station may require significant travel. Delays in addressing tire pressure issues can lead to reduced vehicle performance, increased fuel consumption, and even operational downtime, all of which can impact profitability.

Решение: Investing in portable tire inflation equipment can be a game-changer for businesses in these settings. Portable air compressors allow companies to maintain tire pressure on-site, reducing reliance on external services. When selecting equipment, consider the compressor’s PSI capabilities, ease of transport, and compatibility with various tire types. Additionally, establishing a routine for checking tire pressure before heading to remote locations can help mitigate risks. Training staff on how to use the equipment effectively ensures that tire maintenance can be handled promptly, contributing to operational efficiency and safety.

When it comes to inflating tires, the choice of materials can significantly impact performance, safety, and cost-effectiveness. Here, we analyze four common materials used in tire inflation systems: rubber, metal, plastic, and composite materials. Each material has its own set of properties, advantages, and disadvantages that international B2B buyers should consider.

Rubber is the most widely used material for tire valves and seals due to its excellent elasticity and ability to maintain a tight seal under varying pressures. Key properties include a high-temperature rating (up to 100°C), good pressure resistance, and decent corrosion resistance against moisture and air.

Illustrative image related to inflating tires

Плюсы: Rubber is durable, cost-effective, and easy to manufacture. It provides excellent sealing capabilities, which is crucial for maintaining tire pressure.

Cons: Over time, rubber can degrade due to UV exposure and temperature fluctuations, leading to potential leaks. Additionally, it may not be suitable for extreme temperature environments.

Влияние на применение: Rubber valves are compatible with various media, including air and nitrogen, making them versatile for different tire inflation systems.

Соображения для международных покупателей: Buyers in regions like Africa and South America should ensure compliance with local standards, such as ASTM or JIS, to guarantee safety and performance.

Metal, particularly aluminum and brass, is commonly used for tire valve stems and connectors. These materials offer high strength and corrosion resistance, especially when treated with protective coatings.

Плюсы: Metal components are robust and can withstand high pressures, making them suitable for heavy-duty applications. They also provide longevity and reliability in various environmental conditions.

Cons: The manufacturing process for metal parts can be complex and costly. Additionally, metal can corrode if not properly treated, especially in humid or saline environments.

Влияние на применение: Metal components are essential for high-pressure tire systems, ensuring that they can handle the demands of larger vehicles like trucks and buses.

Соображения для международных покупателей: Buyers should be aware of corrosion standards and ensure that metal components meet local regulations, especially in coastal regions where salt exposure is a concern.

Plastic materials, such as polypropylene and nylon, are increasingly being used for tire inflation components due to their lightweight nature and resistance to corrosion.

Illustrative image related to inflating tires

Плюсы: Plastics are generally less expensive and easier to mold into complex shapes, making them suitable for various designs. They also resist chemical exposure, which is beneficial in diverse environments.

Cons: While plastics are durable, they may not withstand high temperatures and pressures as effectively as rubber or metal. This can limit their use in high-performance applications.

Влияние на применение: Plastic components can be used in low to moderate pressure applications, making them ideal for passenger vehicles and light trucks.

Соображения для международных покупателей: Compliance with environmental regulations is crucial, particularly in Europe, where there are stringent standards for plastic materials in automotive applications.

Composite materials, which combine fibers (like carbon or glass) with resins, offer a unique blend of properties. They are lightweight, strong, and resistant to temperature fluctuations.

Illustrative image related to inflating tires

Плюсы: Composites provide excellent performance in extreme conditions, making them suitable for specialized tire applications. Their lightweight nature can improve fuel efficiency in vehicles.

Cons: The manufacturing process for composites can be expensive and complex, which may deter some manufacturers. Additionally, they may not be as widely available as traditional materials.

Влияние на применение: Composites can be used in high-performance tires, especially in racing or specialized vehicles where weight and strength are critical.

Соображения для международных покупателей: Buyers should consider the availability and cost of composite materials in their region, as well as any specific compliance standards that may apply.

| Материал | Typical Use Case for inflating tires | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Резина | Tire valves and seals | Excellent sealing capabilities | Разрушается со временем | Низкий |

| Металл | Valve stems and connectors | High strength and corrosion resistance | Complex manufacturing process | Средний |

| Пластик | Low to moderate pressure applications | Легкий и экономичный | Limited high-pressure application | Низкий |

| Композит | High-performance tire applications | Lightweight and strong | Дорогие и сложные в производстве | Высокий |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on the specific needs and conditions of their markets.

The manufacturing of tires involves a series of meticulously orchestrated processes that ensure high performance and safety. The main stages include material preparation, forming, assembly, and finishing.

Material preparation is the foundational step in tire manufacturing. It involves sourcing high-quality raw materials such as rubber compounds, steel belts, textile fabrics, and chemical additives. The quality of these materials is crucial as they directly influence the tire’s durability, traction, and performance. Suppliers often conduct rigorous tests to evaluate the physical and chemical properties of the materials. B2B buyers should ensure that their suppliers adhere to international standards for material quality, such as ISO 9001, to guarantee the integrity of the tires produced.

The forming stage is where the prepared materials are shaped into the tire’s design. This process typically involves several techniques, including extrusion, calendering, and molding.

The precision in these techniques is vital for ensuring uniformity and performance across batches. B2B buyers should look for manufacturers that employ advanced technology and automation in these processes to reduce variability and enhance product quality.

The assembly process integrates various components, including the inner liner, body plies, belts, and tread. Each component must be positioned accurately to maintain balance and performance.

Quality assurance during assembly is crucial. Manufacturers should implement real-time monitoring systems to detect anomalies and ensure that components meet specified tolerances. B2B buyers should inquire about the assembly line processes used by suppliers to ensure they meet industry standards.

Quality control (QC) is an integral part of the tire manufacturing process, ensuring that each tire meets safety and performance standards. There are several checkpoints and international standards that manufacturers should adhere to.

International standards such as ISO 9001 provide a framework for quality management systems. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for tires intended for specific markets or applications.

Various testing methods are employed to evaluate tire performance, including:

B2B buyers should request detailed reports on testing methodologies from suppliers to ensure that the tires meet performance expectations.

To ensure that a supplier’s quality control processes are robust, B2B buyers can take several steps:

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding regional compliance requirements and certifications is vital. Different markets may have specific standards that must be met, and buyers should ensure that their suppliers are compliant with these regulations.

By understanding the intricacies of tire manufacturing processes and quality assurance, B2B buyers can make informed decisions, ensuring that they procure high-quality products that meet their operational needs.

To ensure the effective procurement of tire inflation solutions, this guide provides a comprehensive checklist for B2B buyers. Proper tire inflation is crucial for vehicle safety, fuel efficiency, and overall tire longevity. As such, understanding the procurement process is essential for any business that relies on transportation.

Begin by defining the specific needs of your organization regarding tire inflation. Consider factors such as the type of vehicles in your fleet, the typical operating conditions, and whether you require additional features like digital gauges or portable compressors. Understanding these requirements will help you narrow down potential suppliers.

Conduct thorough research to identify potential suppliers that specialize in tire inflation equipment. Look for companies with a strong reputation in the market, particularly those that have experience serving businesses similar to yours. Pay attention to online reviews and industry publications to gauge supplier reliability.

Before proceeding with any supplier, verify their certifications and compliance with international standards. This is crucial for ensuring product quality and safety. Look for certifications such as ISO (International Organization for Standardization) and any relevant local standards that apply to your region.

Once you have shortlisted potential suppliers, request product samples to assess their tire inflation solutions firsthand. This allows you to evaluate the quality, ease of use, and functionality of their products. Testing samples can also help identify any potential issues before making a bulk purchase.

Analyze the pricing structures of your selected suppliers. Ensure that you understand not only the cost of the equipment but also any additional fees such as shipping, handling, and warranty services. It’s also important to discuss payment terms, including any discounts for bulk orders or early payments.

After-sales support is vital for maintaining tire inflation equipment. Inquire about the supplier’s warranty, return policy, and availability of customer service. A responsive support team can help resolve issues quickly, minimizing downtime for your operations.

Illustrative image related to inflating tires

Once you have gathered all necessary information and evaluated potential suppliers, it’s time to finalize the procurement agreement. Ensure that all terms discussed are documented clearly, including delivery timelines, payment schedules, and service agreements. A well-defined contract protects both parties and establishes clear expectations.

By following these steps, B2B buyers can make informed decisions when sourcing tire inflation solutions, ensuring they meet their operational needs effectively while fostering long-term supplier relationships.

When sourcing tire inflation solutions, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

Материалы: The costs associated with raw materials, including rubber compounds, steel belts, and other components used in tire construction, can vary significantly. High-quality materials typically lead to enhanced performance and longevity but also increase costs.

Труд: Labor costs encompass the wages of workers involved in tire manufacturing and inflation equipment production. Regions with lower labor costs may provide a competitive advantage, but this can also influence the quality of the end product.

Производственные накладные расходы: This includes expenses related to factory operations, maintenance, and utilities. Efficient manufacturing processes can help reduce these costs, impacting the final pricing of tire inflation products.

Инструментальная оснастка: Investments in tooling and machinery are essential for producing tires and inflation systems. The initial setup costs can be high, but economies of scale can lower per-unit costs as production increases.

Контроль качества (QC): Rigorous QC processes ensure that products meet safety and performance standards. While implementing comprehensive QC can increase costs, it ultimately protects brand reputation and reduces warranty claims.

Логистика: Shipping costs, which include freight and handling, can significantly affect overall pricing, especially for international transactions. Understanding Incoterms is vital for anticipating these costs.

Маржа: Manufacturers typically add a profit margin to cover their expenses and earn a profit. This margin can vary based on market conditions and competition.

Several factors influence pricing in the tire inflation market, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

Объем/МОК: Purchasing in bulk often leads to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to maximize savings.

Технические характеристики и персонализация: Customizing tire inflation equipment or tire specifications can increase costs. Buyers should balance the need for specific features with budget constraints.

Материалы: The choice of materials can dramatically affect pricing. High-performance tires or inflation systems made from advanced materials may come at a premium but can offer long-term savings through durability.

Качество и сертификация: Products that meet international quality standards and certifications (e.g., ISO, DOT) may have higher upfront costs but can ensure safety and reliability, reducing the total cost of ownership (TCO).

Факторы поставщика: The reputation, reliability, and service level of suppliers can influence pricing. Establishing long-term relationships with reputable suppliers can lead to better pricing and service.

Инкотермс: Understanding the terms of shipment (Incoterms) is crucial for international buyers. These terms dictate responsibilities for shipping costs, insurance, and risk, impacting overall pricing.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, there are several strategies to ensure cost-effective sourcing of tire inflation products:

Переговоры: Engage in thorough negotiations with suppliers to secure favorable pricing. Leverage bulk purchasing and long-term contracts to negotiate better terms.

Ориентируйтесь на общую стоимость владения (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, performance, and warranty claims. A higher initial investment in quality products may yield savings over time.

Evaluate Pricing Nuances: Be aware of regional pricing differences and currency fluctuations that may affect costs. Understanding local market conditions can help in making informed purchasing decisions.

Диверсификация поставщиков: Consider sourcing from multiple suppliers to mitigate risks related to price fluctuations and supply chain disruptions.

Stay Informed on Market Trends: Regularly review industry reports and market trends to understand pricing dynamics and anticipate changes that may impact sourcing strategies.

By carefully analyzing these components, B2B buyers can make informed decisions that optimize their sourcing strategies for tire inflation solutions, ensuring both cost-effectiveness and quality in their procurement processes.

As the demand for efficient and effective tire management solutions grows, it is essential for B2B buyers to consider various alternatives to traditional tire inflation. While inflating tires with air remains a common practice, other technologies and methods offer unique advantages and disadvantages. This section will compare traditional tire inflation against two viable alternatives: nitrogen inflation and the use of tire sealants.

| Сравнительный аспект | Inflating Tires | Nitrogen Inflation | Tire Sealants |

|---|---|---|---|

| Производительность | Reliable for standard use; maintains pressure for shorter periods. | Provides more stable pressure over time; reduces air loss. | Seals punctures quickly; reduces the risk of flats. |

| Стоимость | Low initial cost; requires regular visits to gas stations. | Higher initial cost; often requires specialized service. | Moderate cost; typically one-time application. |

| Простота реализации | Simple to perform at gas stations; requires basic tools. | Requires access to nitrogen filling stations; less common. | Easy to apply; can be done during tire installation. |

| Техническое обслуживание | Regular monitoring needed; tires lose air over time. | Less frequent checks needed; nitrogen retains pressure longer. | Minimal maintenance; effective for the life of the tire. |

| Лучший пример использования | General consumer vehicles; cost-effective for regular use. | Performance vehicles, long-haul trucks; enhances fuel efficiency. | Off-road and fleet vehicles; ideal for puncture-prone environments. |

Nitrogen inflation is increasingly popular in various sectors, particularly for performance vehicles and commercial fleets. The primary advantage is that nitrogen molecules are larger than oxygen molecules, which reduces the rate of air loss, maintaining optimal tire pressure longer. This leads to enhanced fuel efficiency, improved handling, and extended tire life. However, nitrogen inflation typically requires specialized equipment and may not be readily available in all regions, making it less accessible for some users. Additionally, the initial cost of nitrogen inflation can be higher than traditional air inflation, which may deter some buyers.

Tire sealants offer a unique solution by creating a protective layer inside the tire that seals small punctures automatically. This method is particularly beneficial for vehicles operating in rugged environments where flat tires are common. The primary advantage is the immediate response to punctures, allowing vehicles to remain operational without the need for immediate tire changes. However, tire sealants do not replace the need for proper tire inflation; they must be used in conjunction with regular pressure checks. Additionally, some sealants can be messy and may require professional removal during tire replacement.

Selecting the most appropriate tire management solution requires a thorough understanding of specific operational needs and conditions. B2B buyers should consider factors such as vehicle type, operating environment, and cost implications. For businesses that prioritize performance and fuel efficiency, nitrogen inflation may be the superior choice. Conversely, for those operating in rugged terrains or with high flat tire rates, tire sealants could offer significant benefits. Ultimately, the decision should align with the overall maintenance strategy and operational goals of the business, ensuring optimal tire performance and safety.

Illustrative image related to inflating tires

Tire Pressure (PSI/BAR)

Tire pressure is measured in pounds per square inch (PSI) or bar. Maintaining the correct tire pressure is crucial for optimizing fuel efficiency, ensuring safety, and prolonging tire life. Under-inflated tires can lead to increased fuel consumption and faster wear, while over-inflated tires can cause poor handling and reduced traction. For B2B buyers, understanding the optimal pressure specifications helps in selecting appropriate tires for different vehicles and applications.

Tread Depth

Tread depth refers to the height of the rubber on the tire that makes contact with the road. It plays a vital role in traction, particularly in adverse weather conditions. A minimum tread depth is necessary for safety, and knowing the specifications can help businesses avoid liability issues and ensure compliance with local regulations. Monitoring tread depth is also essential for planning timely tire replacements.

Load Index

The load index indicates the maximum weight a tire can safely carry at a specified pressure. This specification is critical for fleet managers and logistics companies, as it helps them choose tires that can handle the weight of their vehicles under varying load conditions. Understanding load index ratings is key to ensuring operational efficiency and safety in transportation.

Speed Rating

Speed rating signifies the maximum speed a tire can sustain under its rated load. This property is essential for businesses operating vehicles in high-speed environments, such as delivery services or logistics. Selecting the appropriate speed rating helps in maintaining safety and performance standards, reducing the risk of tire failure.

Temperature Resistance

Temperature resistance refers to a tire’s ability to withstand heat generated during operation. This property is particularly important in regions with extreme temperatures or for vehicles that operate under heavy loads. B2B buyers should consider temperature ratings when selecting tires to ensure they perform optimally and safely in specific climates.

OEM (Original Equipment Manufacturer)

OEM refers to the company that manufactures the original parts used in a vehicle. For tire buyers, understanding OEM specifications ensures compatibility and quality assurance. When sourcing tires, businesses often seek OEM products to maintain warranty coverage and operational reliability.

MOQ (минимальное количество заказа)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the tire industry, understanding MOQ can help businesses effectively manage inventory and costs. Negotiating MOQs with suppliers is crucial for optimizing procurement strategies, especially for large fleets.

RFQ (запрос котировок)

An RFQ is a formal document requesting pricing and terms from suppliers for specific products or services. In the tire industry, issuing an RFQ allows businesses to compare offers from multiple suppliers, ensuring they receive competitive pricing and favorable terms. This process is vital for budgeting and strategic sourcing.

Инкотермс (международные коммерческие термины)

Incoterms define the responsibilities of buyers and sellers in international trade. They specify who is responsible for shipping, insurance, and tariffs. For B2B tire buyers, understanding Incoterms is essential for managing logistics and ensuring compliance with international shipping regulations.

Calibration

Calibration refers to the process of ensuring that tire inflation gauges and other measuring tools provide accurate readings. Accurate calibration is crucial for maintaining proper tire pressure, which directly impacts safety and efficiency. Businesses should prioritize regular calibration checks to uphold operational standards.

Nitrogen Inflation

Nitrogen inflation involves filling tires with nitrogen gas instead of regular air. Nitrogen molecules are larger, allowing for slower pressure loss, which can enhance tire performance and longevity. B2B buyers should consider nitrogen inflation options as part of their tire maintenance strategies to improve efficiency and reduce downtime.

Understanding these technical properties and trade terms equips businesses to make informed decisions regarding tire inflation, enhancing safety, efficiency, and cost-effectiveness in their operations.

The global inflating tires market is experiencing significant growth, driven by several factors including increasing vehicle production, rising awareness of road safety, and growing fuel efficiency standards. As urbanization accelerates in regions like Africa and South America, the demand for reliable transportation solutions is leading to a surge in vehicle ownership, thereby boosting the tire market. Moreover, the integration of advanced technologies such as smart tire monitoring systems is emerging as a key trend. These systems not only monitor tire pressure but also provide data analytics for optimizing tire performance, which is particularly appealing to B2B buyers looking to enhance fleet efficiency.

In terms of sourcing trends, international buyers are increasingly seeking partnerships with manufacturers that offer innovative solutions, such as eco-friendly tire materials and advanced manufacturing techniques. The rise of e-commerce platforms is also transforming the sourcing landscape, making it easier for buyers in remote regions to access a wider range of products. Furthermore, emerging markets are witnessing a shift towards local sourcing to reduce costs and improve supply chain resilience. B2B buyers are advised to focus on suppliers who can provide transparency in their manufacturing processes and demonstrate compliance with international quality standards.

Illustrative image related to inflating tires

Sustainability is becoming a critical consideration for B2B buyers in the inflating tires sector. The environmental impact of tire production and disposal is significant, with conventional tires contributing to landfill waste and carbon emissions. Consequently, there is a growing demand for ‘green’ certifications and eco-friendly materials, such as natural rubber and recycled materials, which can mitigate these effects. Buyers are increasingly prioritizing suppliers who have adopted sustainable practices in their manufacturing processes, as this not only aligns with global sustainability goals but also enhances brand reputation.

Ethical sourcing is another vital aspect of the supply chain, particularly in regions like Africa and South America, where labor practices can vary widely. B2B buyers should ensure that their suppliers adhere to fair labor practices and provide safe working conditions. Engaging with manufacturers that have established ethical supply chains can lead to long-term partnerships and reduce risks associated with reputational damage. By focusing on sustainability and ethical sourcing, businesses can not only meet regulatory requirements but also cater to the growing consumer demand for responsible products.

The inflating tires sector has evolved significantly since the introduction of the first pneumatic tire in the late 19th century. Initially, tires were made from solid rubber, which limited their performance and comfort. The invention of air-filled tires revolutionized the industry, offering improved handling and ride quality. Over the decades, technological advancements have led to the development of radial tires, which provide better fuel efficiency and durability.

In recent years, the sector has seen a shift towards smart tire technologies, incorporating sensors that monitor tire pressure and performance in real time. This evolution is particularly relevant for B2B buyers who manage fleets, as it allows for proactive maintenance and cost savings. The focus on sustainability and ethical sourcing is also a relatively recent development, reflecting broader societal trends towards responsible consumption and environmental stewardship. As the market continues to evolve, B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their business objectives.

Illustrative image related to inflating tires

How do I solve tire inflation issues in my fleet?

To address tire inflation issues in your fleet, first implement a regular tire pressure monitoring system. This can include using tire pressure gauges or installing TPMS (Tire Pressure Monitoring Systems) for real-time updates. Train your staff on the importance of maintaining proper tire pressure, emphasizing the impact on fuel efficiency and safety. Establish a routine for checking tire pressures at least once a month and before long trips. Additionally, consider investing in a portable air compressor for immediate adjustments, ensuring your fleet operates efficiently and safely.

What is the best method for inflating tires in a commercial setting?

For commercial settings, the best method for inflating tires involves using a calibrated tire inflation gauge and an air compressor. Ensure that tire pressure is checked when the tires are cold for the most accurate readings. Regularly calibrate your equipment to maintain accuracy. Additionally, consider using nitrogen instead of regular air, as it retains pressure longer and reduces the frequency of inflation, which can be beneficial for high-use vehicles. Establishing a systematic approach will enhance operational efficiency and tire longevity.

What are the key factors to consider when sourcing tire inflation equipment?

When sourcing tire inflation equipment, consider quality, reliability, and supplier reputation. Verify that equipment meets international safety and performance standards. Look for suppliers that provide comprehensive warranties and customer support. Additionally, assess the availability of spare parts and service options, especially in your region. Evaluate pricing and payment terms, ensuring they align with your budget and cash flow. Lastly, consider the logistical aspects of shipping and delivery times to ensure timely availability of the equipment.

How can I vet suppliers for tire inflation products?

To vet suppliers for tire inflation products, start by checking their certifications and industry compliance. Research their business history, customer reviews, and case studies to gauge reliability. Request samples of products to assess quality firsthand. Evaluate their manufacturing processes and quality assurance protocols to ensure they meet your specifications. Additionally, establish communication to discuss terms, conditions, and after-sales support. A strong supplier relationship is crucial for long-term success, so prioritize those who demonstrate transparency and responsiveness.

What are typical minimum order quantities (MOQs) for tire inflation equipment?

Minimum order quantities (MOQs) for tire inflation equipment can vary significantly based on the supplier and product type. Generally, MOQs may range from a few units to several dozen, especially for specialized equipment. When negotiating with suppliers, express your interest in establishing a long-term partnership, which may allow for lower MOQs. Always confirm the MOQ before placing an order to ensure it aligns with your inventory needs and budget constraints, and consider the potential for bulk purchasing discounts.

What payment terms should I negotiate with tire inflation suppliers?

When negotiating payment terms with tire inflation suppliers, aim for conditions that support your cash flow. Common terms include net 30 or net 60 days, allowing you time to generate revenue from sales before payment is due. Consider discussing options for upfront deposits in exchange for favorable pricing or credit terms. Ensure that the payment method is secure, and consider using letters of credit for larger transactions to mitigate risk. Clear communication about payment expectations is essential to maintaining a healthy supplier relationship.

How can I ensure quality assurance (QA) in tire inflation equipment?

To ensure quality assurance (QA) in tire inflation equipment, request detailed product specifications and compliance certificates from suppliers. Implement a quality control process that includes regular inspections of incoming products. Consider setting up a trial period where you can test the equipment under real conditions. Establish clear criteria for performance and durability. Additionally, maintain open lines of communication with your suppliers for feedback and support, fostering a collaborative approach to quality management.

What logistics considerations should I keep in mind when importing tire inflation products?

When importing tire inflation products, consider shipping methods, costs, and delivery times. Select a reliable freight forwarder with experience in your specific region to navigate customs regulations efficiently. Ensure that all necessary documentation, such as invoices and certificates of origin, is prepared to avoid delays. Additionally, factor in potential tariffs and taxes that may apply to your imports. Establish a clear communication plan with your supplier regarding shipment tracking and updates to manage expectations and ensure timely receipt of your products.

Домен: michelinman.com

Зарегистрирован: 2001 (24 года)

Введение: Michelin offers a complete range of tires for various mobility needs, including passenger cars, SUVs, light commercial vehicles, and electric/hybrid vehicles. Their tire families include CrossClimate, Defender, Pilot Sport, Primacy, LTX, X Ice, Energy™, Latitude Sport, Pilot Alpin, and Premier. Michelin also provides tires for motorcycles and bicycles, with specific categories for different riding…

Домен: courtesychryslerdodgeramsuperstitionsprings.com

Зарегистрирован: 2019 (6 лет)

Введение: The guide provides step-by-step instructions on how to properly inflate tires, including checking tire pressure with a gauge, recommended tire pressure for new CDJR vehicles (32 to 35 psi when cold), and tips on avoiding overinflation. It also explains how to reset the tire pressure light, including methods such as driving at high speed, using the TPMS reset button, and disconnecting the battery. …

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: This company, Reddit – Tire Pressure Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Домен: auto.howstuffworks.com

Зарегистрирован: 1998 (27 лет)

Введение: Self-inflating tires allow vehicles to adjust to current terrain for optimal performance and safety. They are primarily available for commercial and military applications, with the exception of the CTIS system on Hummers. Underinflated tires, which affect 80% of cars on the road, can lead to reduced gas mileage, poor handling, and increased tire wear. Tires can lose air through normal driving, per…

Домен: acg.aaa.com

Registered: 1990 (35 years)

Введение: AAA Auto Club Group provides services in Colorado, Florida, Georgia, Illinois, Indiana, Iowa, Michigan, Minnesota, Nebraska, North Carolina, North Dakota, Puerto Rico, South Carolina, Tennessee, and Wisconsin. Tools needed for inflating a car tire include a tire pressure gauge, vehicle’s air pressure specifications, and access to an air compressor. The guide emphasizes the importance of maintainin…

In the evolving landscape of tire inflation, strategic sourcing plays a pivotal role in ensuring safety, efficiency, and sustainability for businesses across Africa, South America, the Middle East, and Europe. The proper inflation of tires not only enhances fuel efficiency and extends tire lifespan but also mitigates risks associated with under- and over-inflation, such as increased emissions and hazardous road handling. By aligning with reliable suppliers who provide high-quality tire inflation equipment and services, B2B buyers can reduce operational costs and improve overall fleet performance.

As tire technology continues to advance, including innovations such as nitrogen inflation and portable compressors, businesses have the opportunity to optimize their tire maintenance strategies. Staying informed about these developments will empower international buyers to make educated purchasing decisions that align with their operational goals.

Looking ahead, it is crucial for businesses to invest in effective tire inflation practices to foster safety and sustainability. By prioritizing strategic sourcing and leveraging the latest advancements in tire technology, companies can drive efficiency and contribute to a greener future. Engage with trusted suppliers today to ensure your tire management practices meet the demands of tomorrow’s market.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Illustrative image related to inflating tires

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.