In today’s fast-paced global market, sourcing the right tools for maintaining vehicle performance is paramount, especially when considering how to use a tire inflator effectively. Whether you’re a fleet manager in Nigeria, a logistics provider in Vietnam, or an automotive retailer in Europe, understanding the nuances of tire inflators can significantly impact operational efficiency and safety. This comprehensive guide delves into various types of tire inflators, their specific applications, and essential factors to consider when selecting a supplier.

Throughout this guide, B2B buyers will gain insights into the vital role of proper tire maintenance, including the implications of tire pressure on fuel efficiency and vehicle safety. We’ll also explore how to vet suppliers, evaluate costs, and identify high-quality products that meet international standards. By empowering you with actionable knowledge, this guide aims to facilitate informed purchasing decisions that cater to the unique challenges faced by businesses across Africa, South America, the Middle East, and Europe. Ultimately, equipping your operations with the right tire inflators not only enhances vehicle performance but also contributes to a safer and more efficient transportation environment.

| Название типа | Ключевые отличительные особенности | Основные приложения B2B | Краткие плюсы и минусы для покупателей |

|---|---|---|---|

| Portable Electric Inflator | Compact, battery-operated, often includes built-in pressure gauge | Automotive repair shops, fleet maintenance | Плюсы: Easy to store, quick inflation; Конс: Limited battery life may require recharging. |

| AC/DC Tire Inflator | Dual power options (AC for home use, DC for vehicles) | Car rental companies, roadside assistance | Плюсы: Versatile; works at home or on the road; Конс: May require adapters for some vehicles. |

| Heavy-Duty Air Compressor | High PSI capacity, suitable for larger tires or multiple tires at once | Transportation companies, heavy machinery | Плюсы: Fast inflation, durable; Конс: Bulky and less portable. |

| Smart Tire Inflator | Digital interface with preset PSI settings and auto shut-off | Automotive manufacturers, tire retailers | Плюсы: User-friendly, precise inflation; Конс: Более высокая первоначальная стоимость. |

| Manual Tire Pump | Hand-operated, no electricity required | Emergency kits, remote areas | Плюсы: No power source needed, lightweight; Конс: Labor-intensive and time-consuming. |

Portable electric inflators are compact devices powered by rechargeable batteries, making them ideal for quick tire inflation on the go. They often come equipped with built-in pressure gauges and automatic shut-off features to prevent over-inflation. These inflators are particularly suitable for automotive repair shops and fleet maintenance operations where efficiency and ease of use are paramount. When purchasing, buyers should consider battery life, inflation speed, and whether the unit is compatible with various tire types.

AC/DC tire inflators offer the flexibility of dual power sources, allowing them to be used both at home and on the road. This versatility is beneficial for car rental companies and roadside assistance services that need reliable inflation solutions in varying environments. Buyers should evaluate the power cord length, ease of switching between AC and DC, and any necessary adapters. The ability to use the inflator in multiple settings enhances its utility, making it a valuable addition to any automotive service fleet.

Heavy-duty air compressors are designed for high-capacity tire inflation, making them suitable for larger vehicles and equipment. These compressors are commonly used by transportation companies and those maintaining heavy machinery, where rapid inflation of multiple tires is necessary. While they offer fast inflation rates and durability, buyers should consider their size and weight, which may limit portability. Evaluating the PSI capacity and the compressor’s compatibility with different tire sizes is crucial for B2B buyers.

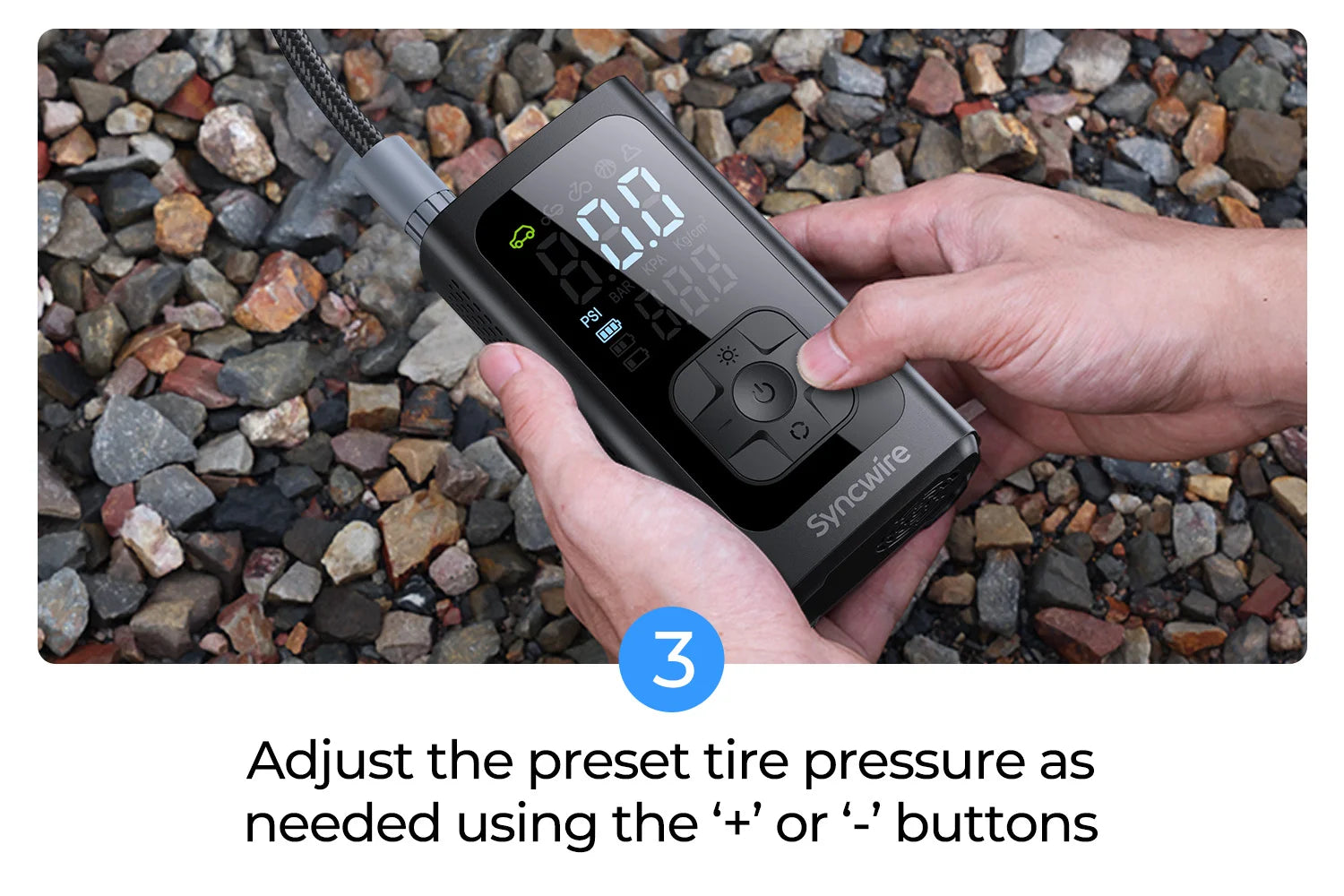

Smart tire inflators feature digital interfaces that allow users to set desired PSI levels easily. They are designed for precision and often include automatic shut-off features, making them popular among automotive manufacturers and tire retailers. While these units are user-friendly and enhance accuracy, they typically come at a higher price point. B2B buyers should assess the reliability of the digital display, preset modes for different tire types, and overall build quality to ensure they meet operational needs.

Manual tire pumps are hand-operated devices that require no electricity, making them useful in remote areas or as part of emergency kits. While they are lightweight and easy to store, they demand more physical effort and time to inflate tires. This type of inflator is best suited for businesses focused on self-sufficiency or those operating in regions with limited access to power. Buyers should consider the pump’s construction quality and ease of use when selecting a manual option for their operations.

| Промышленность/сектор | Specific Application of how to use a tire inflator | Ценность/выгода для бизнеса | Ключевые соображения по поиску источников для данного приложения |

|---|---|---|---|

| Automotive Repair Shops | Regular tire maintenance and inflation for customer vehicles | Improved customer satisfaction and safety through proper tire care | Reliability, ease of use, and support for various tire types |

| Transportation & Logistics | Quick tire inflation for fleet vehicles during transit | Minimized downtime and enhanced operational efficiency | Portability, durability, and compatibility with different vehicles |

| Construction & Heavy Equipment | Inflation of tires for machinery and vehicles on job sites | Reduced risk of accidents and improved productivity on-site | Robust design, high-pressure capabilities, and ease of transport |

| Sports & Recreation | Maintaining pressure in sports equipment like bicycles and balls | Enhanced performance and safety in recreational activities | Versatility, ease of use, and ability to handle various inflatables |

| Retail & Service Stations | Offering tire inflation services to customers at fuel stations | Increased foot traffic and additional revenue streams | User-friendly design, speed of inflation, and durability for frequent use |

In automotive repair shops, tire inflators are essential tools for performing routine maintenance on customer vehicles. Technicians use them to ensure tires are inflated to the correct PSI, which enhances vehicle safety and performance. By maintaining proper tire pressure, shops can significantly reduce the risk of blowouts and improve fuel efficiency for their clients. For international buyers, especially in regions with varying vehicle types, the inflator must accommodate different tire sizes and have reliable pressure settings to ensure consistent service quality.

In the transportation and logistics industry, tire inflators are vital for maintaining fleet vehicles. Quick access to tire inflation can prevent delays caused by flat or under-inflated tires, thereby enhancing operational efficiency. Companies benefit from reduced downtime and increased safety for drivers. When sourcing inflators, businesses should consider the portability of the device, its durability for frequent use, and compatibility with a range of vehicle types, particularly in diverse markets like Africa and South America.

Construction sites often utilize various machinery that requires proper tire inflation for optimal performance. Tire inflators ensure that equipment such as excavators and forklifts operate safely and effectively. By preventing tire-related accidents, businesses can enhance productivity and maintain project timelines. Buyers in this sector should prioritize inflators that can handle high pressure and are robust enough for rugged environments, ensuring reliability even in challenging conditions.

In the sports and recreation industry, tire inflators are used to maintain the correct pressure in bicycles, sports balls, and other inflatables. Proper inflation is crucial for performance and safety, particularly in competitive environments. Buyers should seek versatile inflators that can easily switch between different pressure settings and types of equipment. The ability to quickly inflate tires or balls can enhance customer satisfaction and encourage repeat business in retail or service settings.

Retail and service stations can attract more customers by offering tire inflation services. A tire inflator provides a quick and convenient solution for motorists, enhancing their overall experience. This added service can lead to increased foot traffic and additional revenue streams for the business. When sourcing tire inflators, stations should focus on user-friendly designs that allow quick inflation, durability for high-frequency use, and reliability to ensure customer satisfaction.

Проблема: Many B2B buyers, especially those in regions with varying vehicle models and tire specifications, struggle to identify the correct tire pressure for different vehicles. This challenge is compounded by the lack of standardized pressure recommendations and the language barriers that may exist in manuals and labels. Misunderstanding the required PSI can lead to over-inflation or under-inflation, which not only affects vehicle performance but also poses safety risks. In industries where vehicle uptime is critical, such as logistics and transportation, this can translate into costly delays and accidents.

Решение: To address this issue, B2B buyers should prioritize sourcing tire inflators that feature built-in pressure gauges and preset pressure settings for common vehicle types. When selecting an inflator, ensure it includes a comprehensive guide or app that provides pressure specifications for various vehicles based on make and model. Additionally, buyers can create a centralized database of tire pressure specifications for the fleet they manage, ensuring that all users have access to accurate information. Training sessions can also be conducted to familiarize personnel with checking and setting tire pressures correctly, emphasizing the importance of adhering to manufacturer recommendations to maintain safety and efficiency.

Проблема: Over-inflation is a prevalent concern among B2B buyers who regularly use tire inflators. This is particularly relevant for those managing a fleet of vehicles, where each vehicle may have different tire pressure needs. The fear of causing tire damage or blowouts due to incorrect inflation can lead to hesitation in using tire inflators, resulting in tires being inadequately inflated and increasing the risk of tire failure on the road. This not only jeopardizes safety but can also lead to significant operational disruptions.

Решение: Investing in advanced tire inflators that feature an automatic shut-off function is essential for mitigating over-inflation concerns. These inflators can be programmed to stop once the desired PSI is reached, eliminating the guesswork and ensuring accurate inflation. Additionally, buyers should establish a routine maintenance schedule that includes regular tire pressure checks and the use of reliable digital pressure gauges for confirmation. Training staff to understand the risks of both under-inflation and over-inflation will foster a culture of safety and adherence to proper tire care practices.

Illustrative image related to how to use a tire inflator

Проблема: In high-volume operations, such as fleet management or logistics, the process of inflating tires can become inefficient and time-consuming if not managed correctly. Buyers may find that some tire inflators are slow, cumbersome, or difficult to use, leading to operational delays and frustration among staff. This inefficiency can impact overall productivity, especially when inflating multiple vehicles in a short time frame, resulting in lost revenue and increased labor costs.

Решение: To enhance efficiency, B2B buyers should look for portable tire inflators with high flow rates and quick inflation capabilities. Features such as a user-friendly interface, automatic pressure detection, and rapid-connect systems can drastically reduce the time spent on each inflation task. Additionally, implementing a standard operating procedure (SOP) that outlines the steps for using the tire inflator can help streamline the process. Regular training sessions to improve staff proficiency with the inflator will ensure that they are equipped to handle the equipment quickly and effectively. Furthermore, considering the purchase of multiple units can facilitate simultaneous use across the fleet, minimizing downtime and maximizing productivity.

When selecting materials for tire inflators, it’s essential to consider their properties, durability, and compatibility with various applications. Here, we analyze four common materials used in tire inflators: plastic, aluminum, rubber, and stainless steel. Each material has unique advantages and limitations that can significantly impact performance and user experience.

Illustrative image related to how to use a tire inflator

Plastic is often used in the housing and components of tire inflators due to its lightweight nature and versatility. Key properties include good impact resistance and moderate temperature tolerance, typically rated between -20°C to 60°C.

Плюсы:

– Lightweight and cost-effective, making it ideal for portable designs.

– Resistant to corrosion, which is beneficial in humid or wet environments.

Cons:

– Lower durability compared to metals; it can become brittle over time, especially under extreme temperatures.

– Limited pressure resistance, which may not be suitable for high-performance inflators.

For international buyers, particularly in regions like Africa and South America, the cost-effectiveness of plastic can be appealing. However, they should be aware of the potential for reduced longevity in harsher climates.

Aluminum is frequently utilized for the body and internal components of tire inflators due to its excellent strength-to-weight ratio and resistance to corrosion. It typically withstands temperatures from -40°C to 100°C and pressures up to 150 PSI.

Плюсы:

– High durability and lightweight, making it suitable for both portable and stationary applications.

– Excellent heat dissipation properties, which can prevent overheating during extended use.

Cons:

– Higher manufacturing costs than plastic, which may impact the overall pricing of the inflator.

– Susceptible to scratching and denting, which can affect aesthetics and performance over time.

For B2B buyers in Europe and the Middle East, aluminum’s balance of performance and weight makes it a popular choice. Compliance with standards such as ASTM and DIN can also be easily met with aluminum components.

Illustrative image related to how to use a tire inflator

Rubber is primarily used in seals and hoses within tire inflators, providing flexibility and ensuring airtight connections. Its temperature rating typically ranges from -30°C to 80°C, making it suitable for various environments.

Плюсы:

– Excellent elasticity and resilience, allowing for effective sealing.

– Good resistance to wear and tear, prolonging the lifespan of components.

Cons:

– Limited resistance to certain chemicals, which can degrade rubber over time.

– Can be affected by UV exposure, leading to cracking and loss of effectiveness.

For buyers in regions like Nigeria and Vietnam, where environmental conditions can vary, selecting high-quality rubber components is crucial for ensuring reliability and performance.

Illustrative image related to how to use a tire inflator

Stainless steel is often used for high-pressure components and fittings due to its exceptional strength and corrosion resistance. It can handle extreme temperatures and pressures, typically rated from -40°C to 150°C.

Плюсы:

– Very durable and resistant to corrosion, making it ideal for long-term use.

– High pressure and temperature ratings, suitable for heavy-duty applications.

Cons:

– Higher cost compared to other materials, which can affect the overall price of the inflator.

– Heavier than aluminum or plastic, which may not be ideal for portable units.

For international B2B buyers, particularly in the Middle East where durability is paramount, stainless steel offers a reliable option, although the cost may be a consideration.

| Материал | Typical Use Case for how to use a tire inflator | Ключевое преимущество | Основные недостатки/ограничения | Относительная стоимость (низкая/средняя/высокая) |

|---|---|---|---|---|

| Пластик | Корпус и неструктурные элементы | Легкий и экономичный | Lower durability and pressure resistance | Низкий |

| Алюминий | Кузов и структурные элементы | Высокая прочность и легкость | Более высокие производственные затраты | Средний |

| Резина | Seals and hoses | Excellent sealing and flexibility | Limited chemical resistance | Средний |

| Нержавеющая сталь | High-pressure fittings and components | Исключительная прочность и коррозионная стойкость | Higher cost and weight | Высокий |

This analysis provides a comprehensive overview of material considerations for tire inflators, helping international B2B buyers make informed decisions based on performance, cost, and application suitability.

Manufacturing a tire inflator involves several key stages, each crucial to ensuring the final product is reliable, efficient, and safe for consumers. Understanding these stages helps B2B buyers make informed decisions when sourcing products.

The manufacturing process begins with the preparation of raw materials. Common materials include:

These materials must meet specific quality standards to ensure that the tire inflator performs effectively under varying conditions.

Once materials are prepared, the next step is forming. This involves various techniques such as:

Each technique is selected based on the component’s requirements, ensuring that the final product meets performance standards.

The assembly stage involves bringing together all the formed components. Key steps include:

Attention to detail during this stage is critical, as improper assembly can lead to performance issues.

Illustrative image related to how to use a tire inflator

The finishing stage focuses on enhancing both the performance and appearance of the tire inflator. This may include:

Quality assurance at this stage is vital to ensure that each tire inflator meets consumer expectations.

Quality assurance (QA) is a critical aspect of tire inflator manufacturing. Adhering to international standards and implementing effective QA practices can significantly affect product reliability and safety.

B2B buyers should be aware of relevant international standards that ensure product quality:

These certifications serve as indicators of a manufacturer’s commitment to quality.

Quality control involves several checkpoints throughout the manufacturing process:

These checkpoints help maintain consistency and quality across all units produced.

To ensure that tire inflators meet performance and safety standards, manufacturers employ various testing methods, including:

These tests help ensure that the inflator can perform reliably in real-world conditions.

When sourcing tire inflators, B2B buyers should take steps to verify the quality control practices of potential suppliers:

These steps are crucial for mitigating risks and ensuring that the sourced products meet the necessary standards.

Illustrative image related to how to use a tire inflator

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

By being aware of these nuances, international buyers can navigate the complexities of sourcing tire inflators effectively.

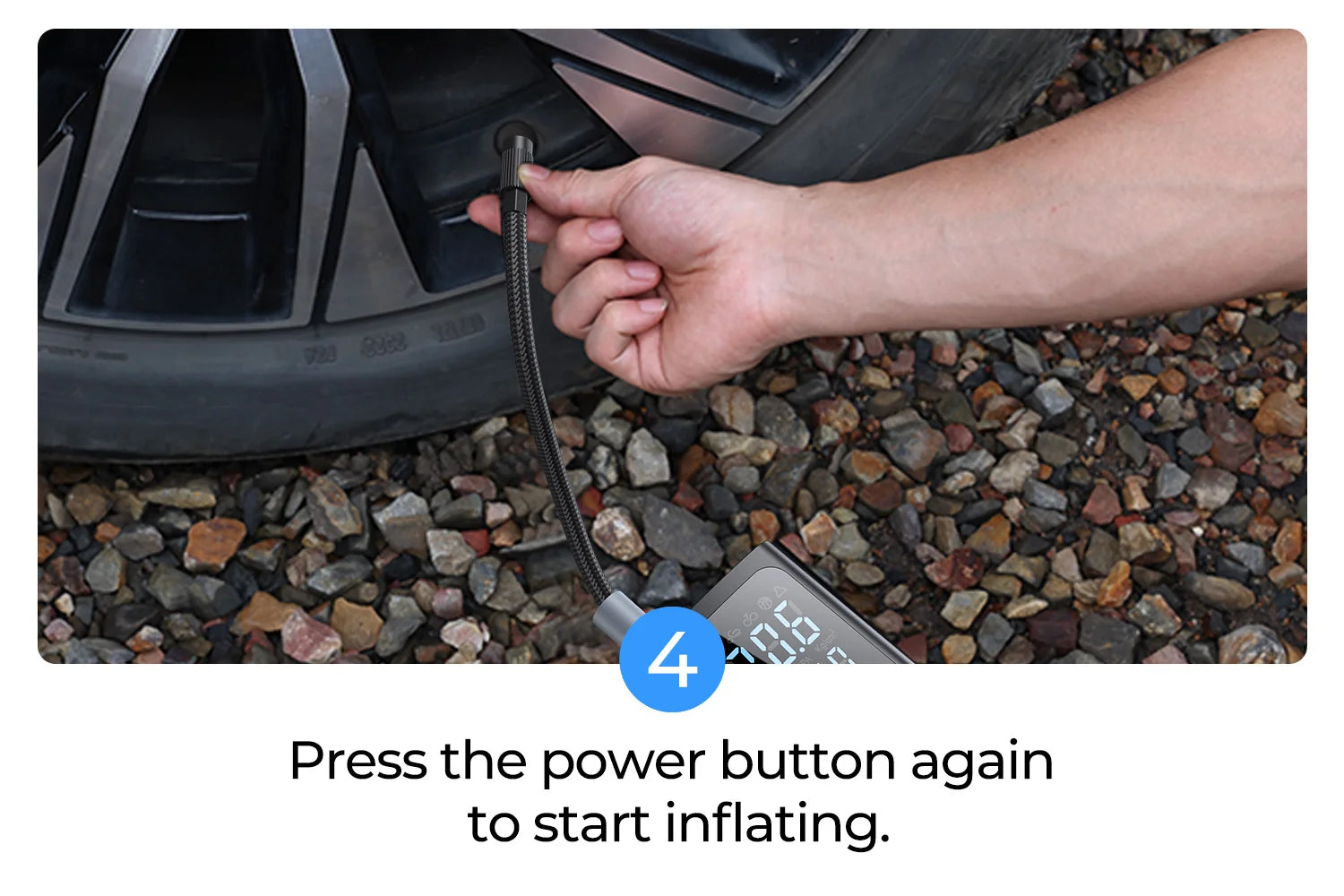

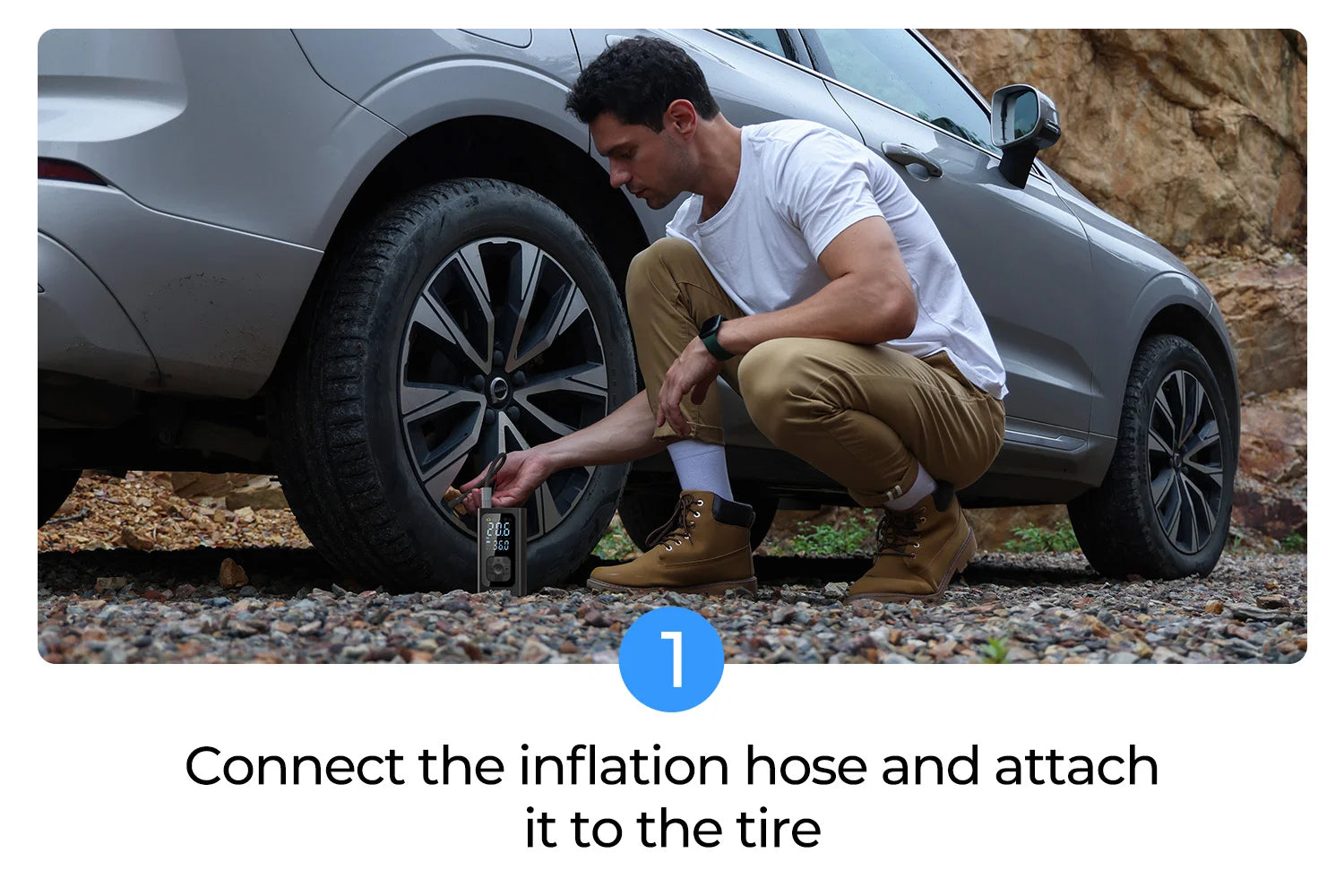

To effectively utilize a tire inflator, especially for B2B buyers looking to enhance their fleet management or maintenance operations, a structured approach is essential. This guide provides a comprehensive checklist to ensure that the process of using a tire inflator is efficient, safe, and effective.

Before using a tire inflator, familiarize yourself with the recommended tire pressure specifications for your vehicles. This information is typically found in the vehicle owner’s manual, on the driver’s side door jamb, or sometimes on the fuel filler cap. Correct tire pressure is vital for optimal vehicle performance, fuel efficiency, and safety on the road.

When procuring a tire inflator, consider the specific needs of your operations. Look for features such as automatic shut-off, built-in pressure gauges, and portability. A high-quality inflator will not only save time but also prevent potential safety hazards associated with incorrect tire pressure.

Illustrative image related to how to use a tire inflator

Before committing to a supplier, conduct thorough evaluations. Request company profiles, case studies, and references from other businesses in similar sectors. Understanding a supplier’s reliability and product quality can prevent future issues and ensure you receive the best equipment for your needs.

Verify that the tire inflator complies with international safety and quality standards. Look for certifications such as ISO or CE, which indicate that the product meets established safety and performance criteria. Compliance is crucial not only for safety but also for maintaining your company’s reputation.

Ensure that all personnel who will be using the tire inflator are adequately trained. Proper training on how to connect the inflator, set the correct pressure, and monitor the inflation process minimizes the risk of accidents and ensures efficient operation.

Establish a routine for inspecting and maintaining the tire inflator. Regular checks can help identify any wear and tear that might affect performance. A well-maintained inflator is less likely to fail when you need it most, thus ensuring your fleet remains roadworthy.

After implementation, keep track of how often the inflator is used and its performance over time. Analyzing usage data can help you assess whether your current inflator meets operational demands or if adjustments are needed.

Illustrative image related to how to use a tire inflator

By following this structured checklist, B2B buyers can ensure they are well-equipped to implement tire inflators effectively, enhancing both operational efficiency and safety across their fleet.

When considering the sourcing of tire inflators, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Материалы: The quality and type of materials used in the construction of the tire inflator significantly influence costs. High-quality plastics, metals, and electronic components can increase the price but enhance durability and performance.

Труд: Labor costs vary by region and can be influenced by the local wage standards. In countries with higher labor costs, manufacturers might pass these expenses onto buyers, while more cost-effective labor markets can yield lower prices.

Производственные накладные расходы: This includes indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturing processes and facilities can help minimize overhead costs, ultimately affecting the pricing structure.

Инструментальная оснастка: Initial tooling costs for production molds and machinery can be substantial, especially for customized inflators. These costs are often amortized over the production volume, impacting the unit price.

Контроль качества (QC): Ensuring that tire inflators meet safety and performance standards requires investment in quality control measures. Robust QC processes can increase costs but are essential for maintaining product reliability.

Логистика: Transportation and handling costs are critical, particularly for international shipments. Factors such as shipping distances, freight methods, and customs duties can significantly affect total expenses.

Маржа: The manufacturer’s profit margin will vary based on market positioning and competition. Understanding the margin can help buyers negotiate better prices.

Several price influencers play a crucial role in determining the final cost of tire inflators:

Объем/MOQ (минимальное количество заказа): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs and consider bulk purchasing to maximize savings.

Технические характеристики/настройка: Custom features or specifications can increase production costs. Buyers should weigh the need for customization against potential price hikes.

Материалы: The choice of materials can greatly influence price. For instance, premium components may enhance functionality but also raise costs.

Качество/сертификация: Products with certifications (e.g., ISO, CE) may carry higher prices due to the added assurance of quality. Buyers should consider the value of certifications in relation to their market.

Факторы поставщика: Supplier reputation, reliability, and service can affect pricing. Established suppliers may charge more but offer better support and product assurance.

Инкотермс: Understanding Incoterms is vital for international buyers. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can impact overall costs, including logistics and risk management.

To maximize value and minimize costs when sourcing tire inflators, consider the following tips:

Negotiation Strategies: Engage in discussions with suppliers to explore potential discounts based on order volume or long-term commitments. Establishing a good relationship can lead to better terms.

Общая стоимость владения (TCO): Evaluate the TCO, which includes initial purchase price, maintenance, and operational costs over the product’s lifespan. This broader perspective can reveal better value options.

Нюансы ценообразования для международных покупателей: Understand regional pricing dynamics, including tariffs and local market conditions. Buyers from Africa, South America, the Middle East, and Europe should factor in currency fluctuations and import duties that may impact overall costs.

Research and Benchmarking: Conduct thorough market research to compare prices and features across different suppliers. Benchmarking against industry standards can help identify competitive pricing.

Prices for tire inflators can vary widely based on the factors mentioned above. The information provided is indicative and should be considered as part of a broader analysis when making purchasing decisions. Always consult suppliers for the most accurate pricing tailored to specific requirements.

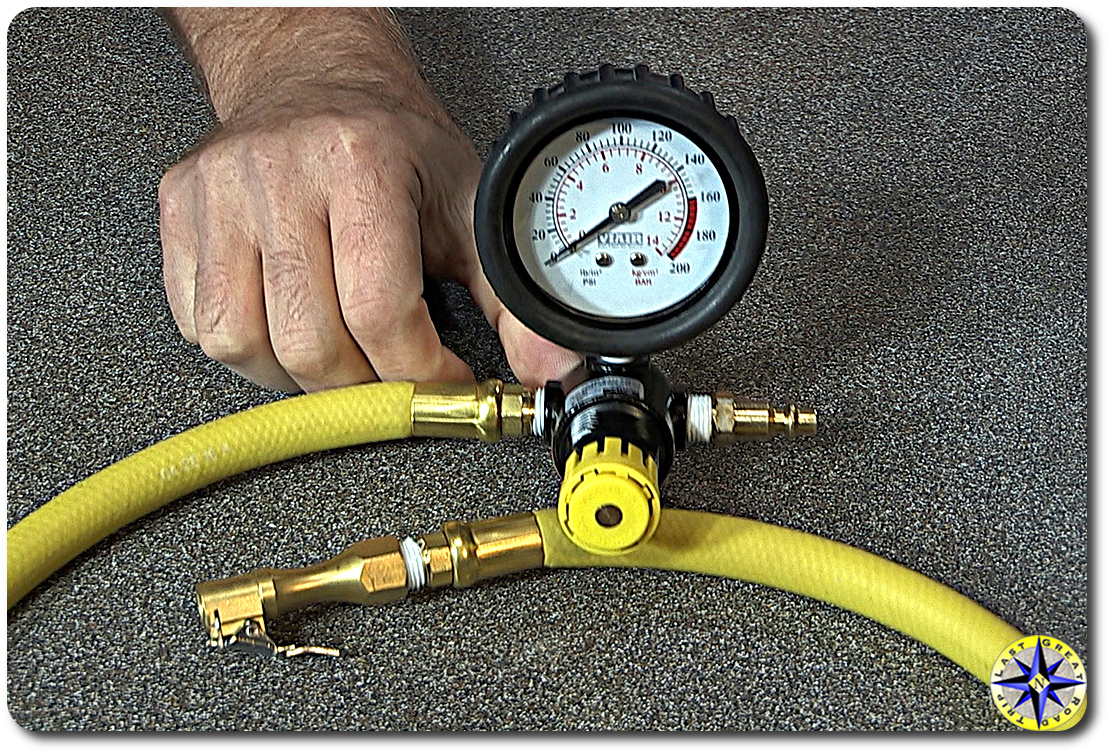

When it comes to maintaining optimal tire pressure, a tire inflator is a popular choice for many vehicle owners. However, there are other methods and technologies available that can also achieve this goal. Understanding these alternatives can help B2B buyers make informed decisions based on their specific needs, whether for fleet management, commercial transportation, or personal use.

Illustrative image related to how to use a tire inflator

| Сравнительный аспект | How To Use A Tire Inflator | Manual Pump | Nitrogen Tire Inflation |

|---|---|---|---|

| Производительность | Quick and efficient inflation | Time-consuming, labor-intensive | Consistent pressure retention |

| Стоимость | Moderate initial investment | Low-cost, but labor-intensive | Higher initial investment, but savings on maintenance |

| Простота реализации | User-friendly, minimal skill required | Requires physical effort and technique | Requires special equipment and training |

| Техническое обслуживание | Low maintenance, portable | Requires regular maintenance | Requires system checks and potential refills |

| Лучший пример использования | General use for personal and commercial vehicles | Emergency situations or remote areas | High-performance applications, long-term cost savings |

Manual pumps, also known as hand pumps, provide a basic alternative for tire inflation. They are cost-effective and can be easily transported. However, the performance of manual pumps is significantly lower compared to tire inflators, as they require physical effort and time to achieve desired tire pressure. This method is best suited for situations where power sources are unavailable, such as remote locations or during emergencies. The main drawback is the labor-intensive nature of manual inflation, which may not be feasible for businesses with high-volume tire maintenance needs.

Nitrogen tire inflation involves filling tires with nitrogen gas instead of regular air. This method is known for its ability to maintain tire pressure over extended periods, reducing the frequency of inflation. While the initial investment in nitrogen inflation systems can be higher, the long-term benefits include improved fuel efficiency and tire longevity, making it an attractive option for fleet operations or high-performance vehicles. However, this method requires specialized equipment and training, which may not be practical for all businesses.

Selecting the appropriate tire inflation method depends on various factors, including cost, ease of use, and specific business requirements. For most B2B buyers, a tire inflator represents a balance of performance, affordability, and convenience, making it suitable for both personal and commercial applications. Manual pumps may suffice for occasional use or emergencies, while nitrogen inflation is ideal for businesses focused on long-term efficiency and performance. Ultimately, understanding the advantages and limitations of each alternative can guide buyers in making the best choice for their tire maintenance strategy.

Illustrative image related to how to use a tire inflator

Understanding the technical specifications of tire inflators is crucial for B2B buyers to make informed purchasing decisions. Here are essential properties that should be considered:

Flow Rate (CFM or L/min)

The flow rate indicates how quickly the inflator can pump air into a tire, usually measured in cubic feet per minute (CFM) or liters per minute (L/min). A higher flow rate means faster inflation, which is beneficial for commercial applications where time efficiency is critical. For instance, a flow rate of 1.25 CFM can inflate a standard tire significantly quicker than a lower-rated inflator.

Максимальное давление (PSI)

The maximum pressure rating, measured in pounds per square inch (PSI), defines the upper limit of pressure the inflator can safely deliver. This specification is vital for ensuring compatibility with various tire types, especially in industries that deal with heavy vehicles or specialized machinery. An inflator with a maximum pressure of 150 PSI would be suitable for both passenger vehicles and light trucks.

Power Source (AC/DC)

Tire inflators can be powered by alternating current (AC) or direct current (DC). Understanding the power source is essential for buyers who need portability and flexibility. DC inflators, often powered by vehicle batteries, are ideal for roadside assistance, while AC inflators may be better suited for workshops where a power outlet is readily available.

Weight and Portability

The weight of the inflator impacts its portability, which is a significant consideration for mobile applications. Lightweight models are easier to transport and store, making them preferable for businesses that require frequent tire servicing on-site. A compact design can also enhance user convenience, particularly in regions with limited storage space.

Durability and Material Grade

The durability of a tire inflator is often determined by the materials used in its construction. High-grade materials can withstand wear and tear, making them suitable for industrial use. Buyers should look for inflators made from robust plastics or metals that offer longevity, especially in harsh environments.

Особенности безопасности

Safety features such as automatic shut-off, built-in pressure gauges, and overheat protection are critical for preventing accidents. An inflator that automatically stops when the desired pressure is reached minimizes the risk of over-inflation, which can lead to tire damage or failure. This is particularly important in commercial settings where safety standards must be strictly adhered to.

Familiarity with industry terminology can facilitate smoother transactions and enhance communication between buyers and suppliers. Here are several key terms:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the tire inflator market, an OEM might supply components for various brands, ensuring compatibility and quality. Understanding OEM relationships can help buyers identify reputable suppliers.

MOQ (минимальное количество заказа)

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it directly affects inventory management and cash flow. Buyers should negotiate MOQs to align with their business needs and avoid excess inventory costs.

RFQ (запрос котировок)

An RFQ is a document issued by a buyer requesting pricing and other details from suppliers. This process allows businesses to compare different options based on specifications and pricing, ensuring they receive the best value for their investment.

Инкотермс (международные коммерческие термины)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping agreements. Understanding these terms helps buyers clarify shipping costs, risks, and delivery obligations, which is essential for effective logistics management.

Соглашения о гарантии и обслуживании

Warranty and service agreements outline the terms under which a supplier will repair or replace faulty products. Knowledge of these agreements is vital for buyers to ensure they have support post-purchase, particularly for high-value inflators used in commercial applications.

Tire Pressure Monitoring System (TPMS)

TPMS refers to technology that monitors the air pressure inside the tires and alerts the driver when pressure is too low. Understanding this term is beneficial for businesses integrating tire inflators with modern vehicle systems, enhancing overall safety and efficiency.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding tire inflators, ensuring they select the right products for their operational needs.

Illustrative image related to how to use a tire inflator

The tire inflator market is experiencing significant growth driven by several global factors. Increased vehicle ownership in emerging markets, particularly in Africa and South America, is propelling demand for portable tire inflators. Urbanization and the expansion of transportation networks are further contributing to this trend. International B2B buyers are increasingly focusing on sourcing tire inflators that offer advanced features such as automatic shut-off, built-in pressure gauges, and multi-functionality for diverse applications, including cars, bicycles, and sports equipment.

Emerging technologies, such as app integration and smart sensors, are influencing purchasing decisions. Buyers are seeking inflators that can connect to smartphones for monitoring tire pressure and offering maintenance reminders. Additionally, the rise of e-commerce platforms has made it easier for businesses to source high-quality tire inflators globally, with competitive pricing and access to a wider range of product specifications. The focus on user-friendly designs, compactness, and efficiency is paramount for B2B buyers looking for reliable solutions.

Sustainability is becoming increasingly crucial in the tire inflator sector, influencing how international buyers approach sourcing. Companies are now expected to consider the environmental impact of their products, including the materials used in tire inflators and their energy consumption. Buyers are actively seeking suppliers who prioritize eco-friendly manufacturing processes and materials, such as recyclable plastics and energy-efficient motors.

Ethical sourcing practices are also gaining traction, with businesses looking to partner with manufacturers that adhere to fair labor practices and transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and other green certifications can serve as indicators of a supplier’s commitment to sustainability. For B2B buyers, aligning their sourcing strategies with sustainability goals not only enhances their brand reputation but also meets the growing consumer demand for environmentally responsible products.

Illustrative image related to how to use a tire inflator

The tire inflator market has evolved significantly over the past few decades. Initially, tire inflators were bulky, manual devices that required considerable effort and time to operate. However, advancements in technology have led to the development of portable, electric inflators that are user-friendly and efficient. The introduction of features such as automatic pressure settings and digital displays has revolutionized how consumers and businesses approach tire maintenance.

As the automotive industry continues to innovate, the tire inflator market is expected to adapt, incorporating smart technologies and connectivity features that enhance usability. This evolution reflects broader trends in consumer electronics and automotive technology, making tire inflators an essential tool for vehicle maintenance across diverse markets.

How do I solve issues with tire inflator compatibility?

To resolve compatibility issues with tire inflators, first verify the inflator’s specifications against the tire type you intend to inflate. Most inflators come with multiple attachments for various valve types. Ensure that your inflator supports the valve configuration of your tires (Schrader vs. Presta, for example). If you encounter persistent issues, consider sourcing inflators from suppliers that offer a range of compatible accessories or customizable features to cater to diverse tire needs.

What is the best tire inflator for commercial vehicles?

When selecting a tire inflator for commercial vehicles, prioritize models with higher flow rates and durable construction. Look for features such as automatic shut-off, built-in pressure gauges, and multi-functional capabilities (e.g., inflating different types of tires and sports equipment). Brands that offer robust warranties and customer support are also preferable. Researching user reviews and seeking recommendations from industry peers can help identify the best options for your specific commercial applications.

How can I ensure the quality of tire inflators from suppliers?

To ensure the quality of tire inflators, conduct thorough supplier vetting by checking certifications, quality assurance processes, and customer testimonials. Request samples for testing to assess the inflator’s performance and durability firsthand. Additionally, inquire about the materials used and any relevant safety standards compliance. Establishing a strong communication channel with suppliers will also facilitate better quality control and responsiveness to your needs.

What are the minimum order quantities (MOQ) for tire inflators?

Minimum order quantities (MOQ) for tire inflators can vary significantly among suppliers. Typically, MOQs may range from 50 to several hundred units, depending on the manufacturer and the product specifications. When negotiating with suppliers, consider your inventory management strategy and demand forecasts. If you require smaller quantities, look for suppliers who cater to smaller businesses or those willing to negotiate flexible terms.

What payment terms should I expect when sourcing tire inflators?

Payment terms for tire inflators can vary widely based on supplier policies and your negotiation power. Common terms include partial payment upfront (30-50%) with the balance due upon delivery or after inspection. Some suppliers may offer net 30 or net 60 payment terms for established business relationships. It’s crucial to clarify these terms upfront and understand any potential impacts on cash flow, especially when operating in international markets.

What logistics considerations should I take into account for tire inflators?

When sourcing tire inflators internationally, logistics considerations include shipping methods, lead times, and customs regulations. Evaluate whether air freight or sea freight is more cost-effective based on your urgency and budget. Additionally, familiarize yourself with import duties and taxes that may apply. Partnering with a logistics provider experienced in handling international shipments can streamline the process and ensure compliance with local regulations.

How can I customize tire inflators for my business needs?

Customization options for tire inflators often include branding, color choices, and specific features tailored to your market. Engage directly with manufacturers to discuss your requirements, such as the inclusion of unique pressure settings or additional attachments for different tire types. Many suppliers are willing to accommodate custom orders, especially for larger quantities, which can enhance your product’s appeal and differentiation in the market.

What are the common safety precautions when using a tire inflator?

When using a tire inflator, prioritize safety by wearing protective gear, such as gloves and safety glasses. Always check the tire pressure before inflation to avoid over-inflation, which can lead to tire blowouts. Ensure the inflator is in good working condition, and follow the manufacturer’s instructions meticulously. Additionally, be mindful of the inflator’s heat generation during use and allow it to cool down as needed to prevent overheating or damage.

Домен: reddit.com

Зарегистрирован: 2005 (20 лет)

Введение: Automatic air station for vehicle tires, typically found at locations like Wawa or Sheets. Steps to use: 1. Set the desired tire pressure on the station (default is usually 32 PSI) using up and down arrows. 2. Attach the nozzle to the tire valve. 3. Squeeze the lever to start pumping air. The machine will check the tire pressure multiple times during the process. 4. After finishing, the machine wi…

Домен: team-bhp.com

Зарегистрирован: 2004 (21 год)

Введение: Tyre inflator powered by car’s 12V socket, includes a connector for easy attachment to tyre valve, features a pressure gauge, takes approximately 7-8 minutes to inflate a completely deflated tyre to 30 psi, becomes hot during use, priced around Rs.2000 on Amazon, useful for emergency situations, especially in cars without a spare tyre.

Домен: wikihow.com

Зарегистрирован: 2004 (21 год)

Введение: This company, WikiHow – Tire Inflation Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Домен: lincoln.com

Зарегистрирован: 1997 (28 лет)

Введение: The Tire Inflator and Sealant Kit is designed for temporary tire repair in case of a flat tire. It allows users to inflate and seal a tire to reach a Lincoln Retailer for service. The kit is suitable for punctures smaller than 0.24 inches and should not be used for sidewall punctures. Users must follow specific instructions found in the Owner’s Manual, including safety precautions and operational …

In conclusion, leveraging a tire inflator is essential for maintaining optimal vehicle performance and safety. Understanding the correct tire pressure is paramount, as it directly impacts fuel efficiency, tire longevity, and overall driving safety. By implementing the step-by-step process outlined in this guide, international B2B buyers can ensure their operations remain efficient and reliable, particularly in regions where road conditions may vary significantly.

Illustrative image related to how to use a tire inflator

Strategic sourcing of high-quality tire inflators, such as the ETENWOLF Zephyr S3, can offer companies a competitive edge by enhancing their service offerings and minimizing downtime due to tire issues. The features of modern inflators—like automatic shut-off functions, integrated pressure gauges, and portability—provide added value that can streamline maintenance processes across fleets.

As the automotive market continues to evolve, staying informed about innovative tire maintenance solutions will be crucial for businesses in Africa, South America, the Middle East, and Europe. Embrace the opportunity to enhance your operations by investing in reliable tire inflators, ensuring that your fleet is always road-ready and efficient.

Информация, представленная в данном руководстве, включая сведения о производителях, технические характеристики и анализ рынка, предназначена исключительно для информационных и образовательных целей. Она не является профессиональной консультацией по закупкам, финансовой или юридической консультацией.

Несмотря на то, что мы приложили все усилия для обеспечения точности и своевременности информации, мы не несем ответственности за любые ошибки, упущения или устаревшую информацию. Условия рынка, сведения о компании и технические стандарты могут быть изменены.

Illustrative image related to how to use a tire inflator

Покупатели B2B должны проводить независимую и тщательную юридическую экспертизу перед принятием решения о покупке. Это включает в себя прямые контакты с поставщиками, проверку сертификатов, запрос образцов и обращение за профессиональной консультацией. Риск, связанный с использованием любой информации, содержащейся в данном руководстве, несет исключительно читатель.